Improving Operational and Sustainability Performance in a Retail Fresh Food Market Using Lean: A Portuguese Case Study

Abstract

:1. Introduction

2. Literature Review

2.1. Retail Store Operations: Research Summary and Opportunities

- Demand side issues, including the study of consumer responses to stockouts [33,34,35,36,37,38]. These issues have been proven to affect store the image and brand loyalty [34]; and it has been concluded that more than 15% of customers usually decide to quit their purchase and go elsewhere to purchase a stockout product [39];

- Supply side issues, including the analyses of root-causes that explain the occurrence of OOS situations, as well as of countermeasures to improve the performance [35,40,41,42,43,44,45]. Reasons that contribute to OOS events include situations of a poor in-store operations performance [35], poor backroom inventory handling procedures [42], misplaced SKUs [43], late delivery by a supplier [44], large product variety [28], and promotional events that lead to more uncertainty on demand [45]; some authors also claim that higher levels of the inventory make in-store logistics more prone to execution errors [28,39].

2.2. Retail Food Waste, Lean and Sustainability

3. Case Study

3.1. Problem Statement

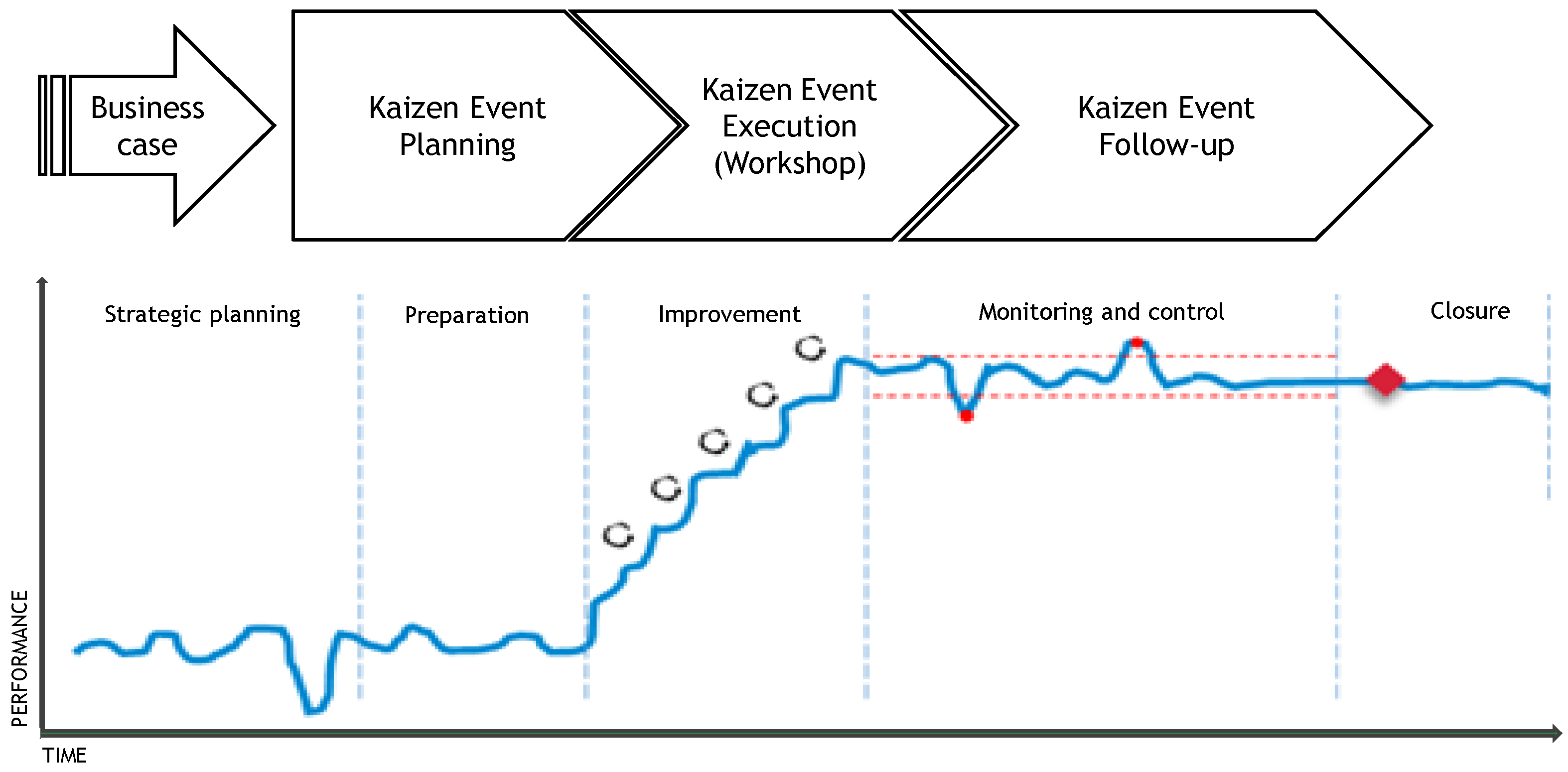

3.2. Methodology

- Kaizen Event Planning (duration: 2 weeks):

- Definition of the event scope;

- Selection of team members;

- Gathering of relevant data;

- Planning of the workshop;

- Kaizen Event Execution (duration: two-day workshop):

- Ground rules, agenda and methodology;

- Definition of the problem (step 1 of A3 Problem Solving);

- Characterization of the problem and determination of the baseline performance, or current condition (step 2 of A3 Problem Solving);

- Goal statement, or desired future state (step 3 of A3 Problem Solving);

- Root-causes analysis (step 4 of A3 Problem Solving);

- Definition and implementation of an action plan (step 5 of A3 Problem Solving);

- Definition of a control plan (step 6 of A3 Problem Solving);

- Kaizen Event Follow-up—stabilization (duration: 4 months):

- Monitoring of the actions’ effectiveness;

- Standardization, training and process stability.

3.3. Kaizen Event Planning

3.4. Kaizen Event Execution

3.4.1. Definition of the Problem

3.4.2. Characterization of the Problem and Estimation of the Baseline Performance

- Counter;

- Self-service.

3.4.3. Setting of Improvement Goals

3.4.4. Root-Causes Analysis

- The cutting process is not performed correctly, which tends to generate an excess of cold meat shavings. It was possible to verify that the way the ham cutting process was usually performed did not follow the best practices, thus producing an excess of trimmings;

- A lack of existing visual controls in the counter do not prevent the two pieces of the same product reference from being inadvertently opened;

- The range of products offered in the counter is not adequate. It was found that there is around a dozen products whose level of demand is quite low. The risk that these products, once opened, may have their quality degraded is significant. This means that such products should not have been available at the counter.

- Poor inventory management practices; in particular, two situations:

- ○

- Available inventory models are not used or not correctly utilized by the market manager;

- ○

- Very large order sizes when product promotions occur. It was found that, very often, the quantities of products ordered for promotion events were too high, resulting in too high inventory levels;

- The envisaged process to control the products’ expiry dates were not consistently performed, mainly due to a lack of an effective daily planning and management.

3.4.5. Definition of Planned Countermeasures (Action Plan)

3.4.6. Definition of a Control Plan and Planning for Follow-Up Actions

3.5. Kaizen Event Follow-Up

4. Discussion and Conclusions

5. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Buck, R.; Minvielle, A. A fresh take on food retailing. Perspect. Retail Consum. Goods 2014, 71–84. Available online: https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/retail/articles/perspectives%20-%20winter%202013/3_fresh_take_on_food_retailing_vf.ashx (accessed on 19 November 2021).

- Hirsch, S.; Lanter, D.; Finger, R. Profitability and Competition in EU Food Retailing. In Proceedings of the 2018 Agricultural & Applied Economics Association Annual Meeting, Washington, DC, USA, 5–7 August 2018. [Google Scholar]

- Ribeiro, R.; Sobral, P.; Peças, P.; Henriques, E. A sustainable business model to fight food waste. J. Clean. Prod. 2018, 177, 262–275. [Google Scholar] [CrossRef]

- Buisman, M.E.; Haijema, R.; Bloemhof-Ruwaard, J.M. Discounting and dynamic shelf life to reduce fresh food waste at retailers. Int. J. Prod. Econ. 2019, 209, 174–184. [Google Scholar] [CrossRef]

- Lohnes, J.D. Regulating surplus: Charity and the legal geographies of food waste enclosure. Agric. Hum. Values 2021, 38, 351–363. [Google Scholar] [CrossRef]

- Wilson, N.L.W.; Bradley, J.R.; Saputo, R.; Ho, S. Food waste: The role of date labels, package size, and product category. Food Qual. Prefer. 2017, 55, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Kavanaugh, M.; Quinlan, J.J. Consumer knowledge and behaviors regarding food date labels and food waste. Food Control 2020, 115, 107285. [Google Scholar] [CrossRef]

- Arcuri, S. Food poverty, food waste and the consensus frame on charitable food redistribution in Italy. Agric. Hum. Values 2019, 36, 263–275. [Google Scholar] [CrossRef]

- Massari, S.; Antonelli, M.; Principato, L.; Pratesi, C.A. Design Thinking to engage consumers in achieving zero waste food experiences: The CEASE framework. In Design Thinking for Food Well-Being; Batat, W., Ed.; Springer: Cham, Switzerland, 2021; pp. 247–260. [Google Scholar]

- Álvarez-Rodríguez, C.; Martín-Gamboa, M.; Iribarren, D. Sustainability-oriented efficiency of retail supply chains: A combination of life cycle assessment and dynamic network data envelopment analysis. Sci. Total Environ. 2020, 795, 135977. [Google Scholar] [CrossRef]

- Broekmeulen, R.A.C.M.; Van Donselaar, K.H. Quantifying the potential to improve on food waste, freshness and sales for perishables in supermarkets. Int. J. Prod. Econ. 2019, 209, 265–273. [Google Scholar] [CrossRef]

- Beck, A. Reconceptualising loss in retailing: Calling time on shrinkage. Int. Rev. Retail Distrib. Consum. Res. 2017, 27, 407–423. [Google Scholar] [CrossRef]

- Gomez-Conde, J.; Lunkes, R.J.; Rosa, F.S. Environmental innovation practices and operational performance: The joint effects of management accounting and control systems and environmental training. Account. Audit. Account. J. 2019, 32, 1325–1357. [Google Scholar] [CrossRef]

- Bertolini, M.; Romagnoli, G.; Weinhard, A. Proposing a value-added indicators framework for the apparel and fashion sector: Design and empirical evaluation. Int. J. RF Technol. 2017, 3, 143–164. [Google Scholar] [CrossRef]

- Saucède, F.; Fenneteau, H.; Codron, J.M. Department upkeep and shrinkage control: Two key variables in optimizing the performance of fruit and vegetables departments. Int. J. Retail Distrib. Manag. 2014, 42, 733–758. [Google Scholar] [CrossRef]

- Naidoo, M.; Gasparatos, A. Corporate environmental sustainability in the retail sector: Drivers, strategies and performance measurement. J. Clean. Prod. 2018, 203, 125–142. [Google Scholar] [CrossRef]

- Álvarez-Rodríguez, C.; Martín-Gamboa, M.; Iribarren, D. Sustainability-oriented management of retail stores through the combination of life cycle assessment and dynamic data envelopment analysis. Sci. Total Environ. 2019, 683, 49–60. [Google Scholar] [CrossRef]

- Mou, S.; Robb, D.J.; DeHoratius, N. Retail store operations: Literature review and research directions. Eur. J. Oper. Res. 2018, 265, 399–422. [Google Scholar] [CrossRef]

- EPS—European Physical Society. The Importance of Physics to the Economies of Europe—A Study by Cebr for the Period 2011–2016; European Physical Society: Mulhouse, France, 2019; pp. 5–13. [Google Scholar]

- PwC—Price Waterhouse Coopers. The Economic Impact of the US Retail Industry; National Retail Federation: Washington, DC, USA, 2020; pp. 1–19. [Google Scholar]

- Fredriksson, A.; Liljestrand, K. Capturing food logistics: A literature review and research agenda. Int. J. Logist. Res. Appl. 2015, 18, 16–34. [Google Scholar] [CrossRef]

- Fisher, M. Foreword: Special issue on retail operations. Prod. Oper. Manag. 2013, 22, 755–757. [Google Scholar] [CrossRef]

- Lagorio, A.; Pinto, R. Food and grocery retail logistics issues: A systematic literature review. Res. Transp. Econ. 2020, 87, 100841. [Google Scholar] [CrossRef]

- Teller, C.; Holweg, C.; Reiner, G.; Kotzab, H. Retail store operations and food waste. J. Clean. Prod. 2018, 185, 981–997. [Google Scholar] [CrossRef] [Green Version]

- Caro, F.; Kök, A.G.; Martínez-de-Albéniz, V. The future of retail operations. Manuf. Serv. Oper. Manag. 2020, 22, 47–58. [Google Scholar] [CrossRef]

- Bouzaabia, O.; Van Riel, A.C.R.; Semeijn, J. Managing in-store logistics: A fresh perspective on retail service. J. Serv. Manag. 2013, 24, 112–129. [Google Scholar] [CrossRef] [Green Version]

- Bertolini, M.; Ferreti, G.; Vignali, G.; Volpi, A. Reducing out of stock, shrinkage and overstock through RFID in the fresh food supply chain: Evidence from an Italian retail pilot. Int. J. RF Technol. 2013, 4, 107–125. [Google Scholar] [CrossRef]

- Chuang, H.; Oliva, R.; Liu, S. Examining the link between retailer inventory leanness and operational efficiency: Moderating roles of firm size and demand uncertainty. Prod. Oper. Manag. 2019, 28, 2338–2364. [Google Scholar] [CrossRef]

- Kirci, M.; Biçer, I.; Seifert, R.W. Optimal replenishment cycle for perishable items facing demand uncertainty in a two-echelon inventory system. Int. J. Prod. Res. 2019, 57, 1250–1264. [Google Scholar] [CrossRef]

- Calvo, E.; Cui, R.; Wagner, L. Disclosing product availability in online retail. Manuf. Serv. Oper. Manag. 2020. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management: Strategy, Planning and Operations, 3rd ed.; McGraw-Hill: New York, NY, USA, 2008. [Google Scholar]

- Aastrup, J.; Kotzab, H. Forty years of Out-of-Stock research—And shelves are still empty. Int. Rev. Retail Distrib. Consum. Res. 2010, 20, 147–164. [Google Scholar] [CrossRef]

- Sloot, L.M.; Verhoef, P.C.; Franses, P.H. The impact of brand equity and the hedonic level of products on consumer stock-out reactions. J. Retail. 2005, 81, 15–34. [Google Scholar] [CrossRef]

- Kucuk, S.U. Reducing out-of-stock costs in a developing retailer sector. J. Int. Consum. Mark. 2004, 16, 75–104. [Google Scholar] [CrossRef]

- Mckinnon, A.C.; Mendes, D.; Nababteh, M. In-store logistics: An analysis of on-shelf availability and stockout responses for three product groups. Int. J. Logist. Res. Appl. 2007, 10, 251–268. [Google Scholar] [CrossRef]

- Ku, H.; Kuo, C.; Fang, W.; Yu, Y. The impact of retail out-of-stock options on preferences: The role of consumers’ desire for assimilation versus differentiation. Mark. Lett. 2014, 25, 53–66. [Google Scholar] [CrossRef]

- Nguyen, D.H.; De Leeuw, S.; Dullaert, W.E.H. Consumer behaviour and order fulfilment in online retailing: A systematic review. Int. J. Manag. Rev. 2018, 20, 255–276. [Google Scholar] [CrossRef]

- Ali, D.H. Assessment of the effect of out-of-stock on customers purchasing behavior. Int. J. Transp. Eng. Technol. 2019, 5, 25–29. [Google Scholar]

- Benrqya, Y. An examination of the effects of cross-docking on retail out of stock. Int. J. Retail Distrib. Manag. 2021, 49, 636–651. [Google Scholar] [CrossRef]

- Fisher, M.; Raman, A. The New Science of Retailing: How Analytics are Transforming the Supply Chain and Improving Performance; Harvard Business Press: Boston, MA, USA, 2010; pp. 9–28. [Google Scholar]

- Ta, H.; Esper, T.L.; Tokar, T. Appealing to the crowd: Motivation message framing and crowdsourcing performance in retail operations. Prod. Oper. Manag. 2021, 30, 3192–3212. [Google Scholar] [CrossRef]

- Pires, M.; Pratas, J.; Liz, J.; Amorim, P. A framework for designing backroom areas in grocery stores. Int. J. Retail Distrib. Manag. 2017, 45, 230–252. [Google Scholar] [CrossRef]

- Rizwan, M.; Hensen, E.B. On the Shelf Availability in Food Based Discount Stores Molde Grocery Environment. Master’s Thesis, Molde University College, Molde, Sweden, 2009. [Google Scholar]

- Moorthy, R.; Behera, S.; Verma, S. On-shelf availability in retailing. Int. J. Comput. Appl. 2015, 116, 47–51. [Google Scholar] [CrossRef]

- Van Donselaar, K.H.; Peters, J.; De Jong, A.; Broekmeulen, R.A.C.M. Analysis and forecasting of demand during promotions for perishable items. Int. J. Prod. Econ. 2016, 172, 65–75. [Google Scholar] [CrossRef]

- De Moraes, C.C.; Costa, F.H.O.; Pereira, C.R.; Silva, A.L.; Delai, I. Retail food waste: Mapping causes and reduction practices. J. Clean. Prod. 2020, 256, 120124. [Google Scholar] [CrossRef]

- Mangla, S.K.; Govindan, K.; Luthra, S. Critical success factors for reverse logistics in Indian industries: A structural model. J. Clean. Prod. 2016, 129, 608–621. [Google Scholar] [CrossRef]

- Cho, Y.; Soster, R.L.; Burton, S. Enhancing environmentally conscious consumption through standardized sustainability information. J. Consum. Aff. 2018, 52, 393–414. [Google Scholar] [CrossRef]

- Upadhyaya, S.; Hughes, M.; Houston, H.R. Using sustainability as a framework for marketing curricula and pedagogy. J. Sustain. Educ. 2019, 20, 19. [Google Scholar]

- Huang, I.Y.; Manning, L.; James, K.L.; Grigoriadis, V.; Millington, A.; Wood, V.; Ward, S. Food waste management: A review of retailers’ business practices and their implications for sustainable value. J. Clean. Prod. 2021, 285, 125484. [Google Scholar] [CrossRef]

- Thompson, B. Green retail: Retailer strategies for surviving the sustainability storm. J. Retail Leis. Prop. 2007, 6, 281–286. [Google Scholar] [CrossRef] [Green Version]

- Sinha, R. Green retailing: An exploratory study examining the effects of sustainability on global retail landscape. In Proceedings of the Conference on Inclusive and Sustainable Growth Role of Industry, Government and Society, Nagpur, India, 15–16 July 2011. [Google Scholar]

- ElAlfy, A.; Palaschuk, N.; El-Bassiouny, D.; Wilson, J.; Weber, O. Scoping the evolution of corporate social responsibility (CSR) research in the sustainable development goals (SDGs) era. Sustainability 2020, 12, 5544. [Google Scholar] [CrossRef]

- Van Woensel, T.; Van Donselaar, K.; Broekmeulen, R.; Fransoo, J. Consumer responses to shelf out-of-stocks of perishable products. Int. J. Phys. Distrib. Logist. Manag. 2007, 37, 704–718. [Google Scholar] [CrossRef]

- Lukic, R. The effects of application of Lean concept in retail. Econ. Ser. Manag. 2012, 15, 88–98. [Google Scholar]

- Noda, T. Integration of Lean operation and pricing strategy in retail. J. Mark. Dev. Compet. 2015, 9, 50–60. [Google Scholar]

- Madhani, P.M. Performance optimisation of retail industry: Lean Six Sigma approach. ASBM J. Manag. 2020, 13, 74–91. [Google Scholar]

- Arnheiter, E.D.; Maleyeff, J. The integration of Lean management and Six Sigma. TQM Mag. 2005, 17, 5–18. [Google Scholar] [CrossRef] [Green Version]

- Bhamu, J.; Sangwan, K.S. Lean manufacturing: Literature review and research issues. Int. J. Oper. Prod. Manag. 2012, 34, 876–940. [Google Scholar] [CrossRef]

- Stone, K.B. Four decades of Lean: A systematic literature review. Int. J. Lean Six Sigma 2012, 3, 112–132. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large Scale Production; Productivity Press: New York, NY, USA, 1988; pp. 75–92. [Google Scholar]

- Gutpa, S.; Jain, S.K. A literature review on Lean manufacturing. Int. J. Manag. Sci. Eng. Manag. 2013, 8, 241–249. [Google Scholar]

- Alaskari, O.; Ahmad, M.M.; Pinedo-Cuenca, R. Development of a methodology to assist manufacturing SMEs in the selection of appropriate Lean tools. Int. J. Lean Six Sigma 2016, 7, 62–84. [Google Scholar] [CrossRef]

- Myerson, P. Lean retail. In The Routledge Companion to Lean Management; Netland, T.H., Powell, D.J., Eds.; Routledge: New York, NY, USA, 2017; pp. 413–421. [Google Scholar]

- Morcillo-Bellido, J.; Duran, A. Supply chain sustainability in Spanish major retailer through strategic alliances and Lean practices. In Closing the Gap between Practice and Research in Industrial Engineering; Viles, E., Ormazábal, M., Lleo, A., Eds.; Springer: Cham, Switzerland, 2018; pp. 11–18. [Google Scholar]

- Naruo, S.; Toma, S.G. From Toyota production system to Lean retailing: Lessons from Seven-Eleven Japan. In Advances in Production Management System; Olhager, J., Perrson, F., Eds.; Springer: New York, NY, USA, 2017; pp. 387–395. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Solutions: How Companies and Customers can Create Value and Wealth Together; Free Press: New York, NY, USA, 2005. [Google Scholar]

- Smith, L.; Sparks, L. Tesco’s supply chain management. In Logistics & Retail Management: Emerging Issues and New Challenges in the Retail Supply Chain, 3rd ed.; Fernie, J., Sparks, L., Eds.; Kogan Page: London, UK, 2009; pp. 143–171. [Google Scholar]

- Onetto, M. When Toyota met e-commerce. McKinsey Q. 2014, 2, 1–7. [Google Scholar]

- Domingo, T.M. The Adoption of Lean Techniques to Optimize the On-Shelf Availability of Products and Drive Business Performance in the Food Industry: A South African Manufacturing and Retail Case Study. Master’s Thesis, Cape Town University, Cape Town, South Africa, 2013. [Google Scholar]

- Sowards, D. How Lean improves shop productivity. Contractor Magazine, 15 August 2017; p. 36. [Google Scholar]

- Evans, J.R.; Lindsay, W.M. An Introduction to Six Sigma & Process Improvement, 2nd ed.; CENGAGE Learning: Stamford, CT, USA, 2015; pp. 199–221. [Google Scholar]

- Jaca, C.; Santos, J.; Errasti, A.; Viles, E. Lean thinking with improvement teams in retail distribution: A case study. Total Qual. Manag. 2012, 23, 449–465. [Google Scholar] [CrossRef]

- Kor, Y.Y.; Prabhu, J.; Esposito, M. How large food retailers can help solve the food waste crisis. Harv. Bus. Rev. 2017. Available online: https://hbr.org/2017/12/how-large-food-retailers-can-help-solve-the-food-waste-crisis (accessed on 19 November 2021).

- Buzby, J.C.; Bentley, J.T.; Padera, B.; Ammon, C.; Campuzano, J. Estimated fresh produce shrink and food loss in U.S. supermarkets. Agriculture 2015, 5, 626–648. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, S.K.; Chaudhuri, A.; Srivastava, R.K. Propagation of risks and their impact on performance in fresh food retail. Int. J. Logist. Manag. 2015, 26, 568–602. [Google Scholar] [CrossRef]

- Vadakkepatt, G.G.; Winterich, K.P.; Mittal, V.; Zinn, W.; Beitelspacher, L.; Aloysius, J.; Ginger, J.; Reilman, J. Sustainable retailing. J. Retail. 2021, 97, 62–80. [Google Scholar] [CrossRef]

- Cicatiello, C.; Franco, S.; Pancino, B.; Blasi, E. The value of food waste: An exploratory study on retailing. J. Retail. Consum. Serv. 2016, 30, 96–104. [Google Scholar] [CrossRef]

- Filimonau, V.; Gherbin, A. An exploratory study of food waste management practices in the UK grocery retail sector. J. Clean. Prod. 2017, 167, 1184–1194. [Google Scholar] [CrossRef] [Green Version]

- Kulikovskaja, V.; Aschemann-Witzel, J. Food waste avoidance actions in food retailing: The case of Denmark. J. Int. Food Agribus. Mark. 2017, 29, 328–345. [Google Scholar] [CrossRef]

- Hermsdorf, D.; Rombach, M.; Bitsch, V. Food waste reduction practices in German food retail. Br. Food J. 2017, 119, 2532–2546. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sanchez-Rodrigues, V.; Kumar, M. Synergies and misalignments in Lean and Green practices: A logistics industry perspective. Prod. Plan. Control 2019, 30, 369–384. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Zhu, Q.; Sarkis, J. Blockchain and the circular economy: Potential tensions and critical reflections from practice. Prod. Plan. Control 2020, 31, 950–966. [Google Scholar] [CrossRef]

- Bhasin, S. Lean Management beyond Manufacturing: A Holistic Approach; Springer: Cham, Coventry, UK, 2015; pp. 11–26. [Google Scholar]

- Bhuiyan, N.; Baghel, A. An overview of continuous improvement: From the past to the present. Manag. Decis. 2005, 43, 761–771. [Google Scholar] [CrossRef] [Green Version]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation—Expanded and Revised; Free Press: New York, NY, USA, 2003; pp. 29–36. [Google Scholar]

- Bicheno, J.; Holweg, M. The Lean Toolbox: A Handbook for Lean Transformation, 5th ed.; PICSIE Books: Buckingham, UK, 2016; pp. 18–31. [Google Scholar]

- Amani, P.; Lindbom, I.; Sundström, B.; Östergren, K. Green-Lean synergy-root-cause analysis in food waste prevention. Int. J. Food Syst. Dyn. 2015, 6, 99–109. [Google Scholar]

- Van der Goot, A.J.; Pelgrom, P.J.M.; Berghout, J.A.M.; Geerts, M.E.J.; Jankowiak, L.; Hardt, N.A.; Keijer, J.; Schutyser, M.A.I.; Nikiforidis, C.V.; Boom, R.M. Concepts for further sustainable production of foods. J. Food Eng. 2016, 168, 42–51. [Google Scholar] [CrossRef]

- Jagtap, S.; Bhatt, C.; Thik, J.; Rahimifard, S. Monitoring potato waste in food manufacturing using image processing and internet of things approach. Sustainability 2019, 11, 3173. [Google Scholar] [CrossRef] [Green Version]

- Lindberg, E.; Sohlin, T. Food Recalls in the Food Supply Chain: A Qualitative Study of Different Product Flows in a Retail Context, Degree Project; Umeå University: Umeå, Sweden, 2021. [Google Scholar]

- Pejić, V.; Lerher, T.; Jereb, B.; Lisec, A. Lean and Green paradigms in logistics: Review of published research. Promet Traffic Transp. 2016, 26, 593–603. [Google Scholar] [CrossRef] [Green Version]

- Jónsdóttir, S. Innovation Processes in Retailing: A Way to Green Food Retail? Master’s Thesis, Lund University, Lund, Sweden, 2012. [Google Scholar]

- Petljak, K.; Zulauf, K.; Štulec, I.; Seuring, S.; Wagner, R. Green supply chain management in food retailing: Survey-based evidence in Croatia. Supply Chain Manag. 2018, 23, 1–15. [Google Scholar] [CrossRef]

- Martin, K.; Osterling, M. The Kaizen Event Planner: Achieving Rapid Improvement in Office, Service, and Technical Environments; Productivity Press: New York, NY, USA, 2007; pp. 3–32. [Google Scholar]

- Hamel, M.R. Kaizen Event Fieldbook: Foundation, Framework, and Standard Work for Effective Events; Society of Manufacturing Engineers: Dearborn, MI, USA, 2010; pp. 85–196. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marques, P.A.; Carvalho, A.M.; Santos, J.O. Improving Operational and Sustainability Performance in a Retail Fresh Food Market Using Lean: A Portuguese Case Study. Sustainability 2022, 14, 403. https://doi.org/10.3390/su14010403

Marques PA, Carvalho AM, Santos JO. Improving Operational and Sustainability Performance in a Retail Fresh Food Market Using Lean: A Portuguese Case Study. Sustainability. 2022; 14(1):403. https://doi.org/10.3390/su14010403

Chicago/Turabian StyleMarques, Pedro Alexandre, André M. Carvalho, and José Oliveira Santos. 2022. "Improving Operational and Sustainability Performance in a Retail Fresh Food Market Using Lean: A Portuguese Case Study" Sustainability 14, no. 1: 403. https://doi.org/10.3390/su14010403

APA StyleMarques, P. A., Carvalho, A. M., & Santos, J. O. (2022). Improving Operational and Sustainability Performance in a Retail Fresh Food Market Using Lean: A Portuguese Case Study. Sustainability, 14(1), 403. https://doi.org/10.3390/su14010403