Ubim Fiber (Geonoma baculífera): A Less Known Brazilian Amazon Natural Fiber for Engineering Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristic Density

2.1.1. Geometric Method

2.1.2. Archimedes’ Principle Method

2.1.3. Gas Pycnometry Density

2.2. XRD Analysis

2.2.1. Microfibrillar Angle (MFA)

2.2.2. Crystallinity Index (CI)

2.3. SEM Analysis

3. Results

3.1. Density Measurements

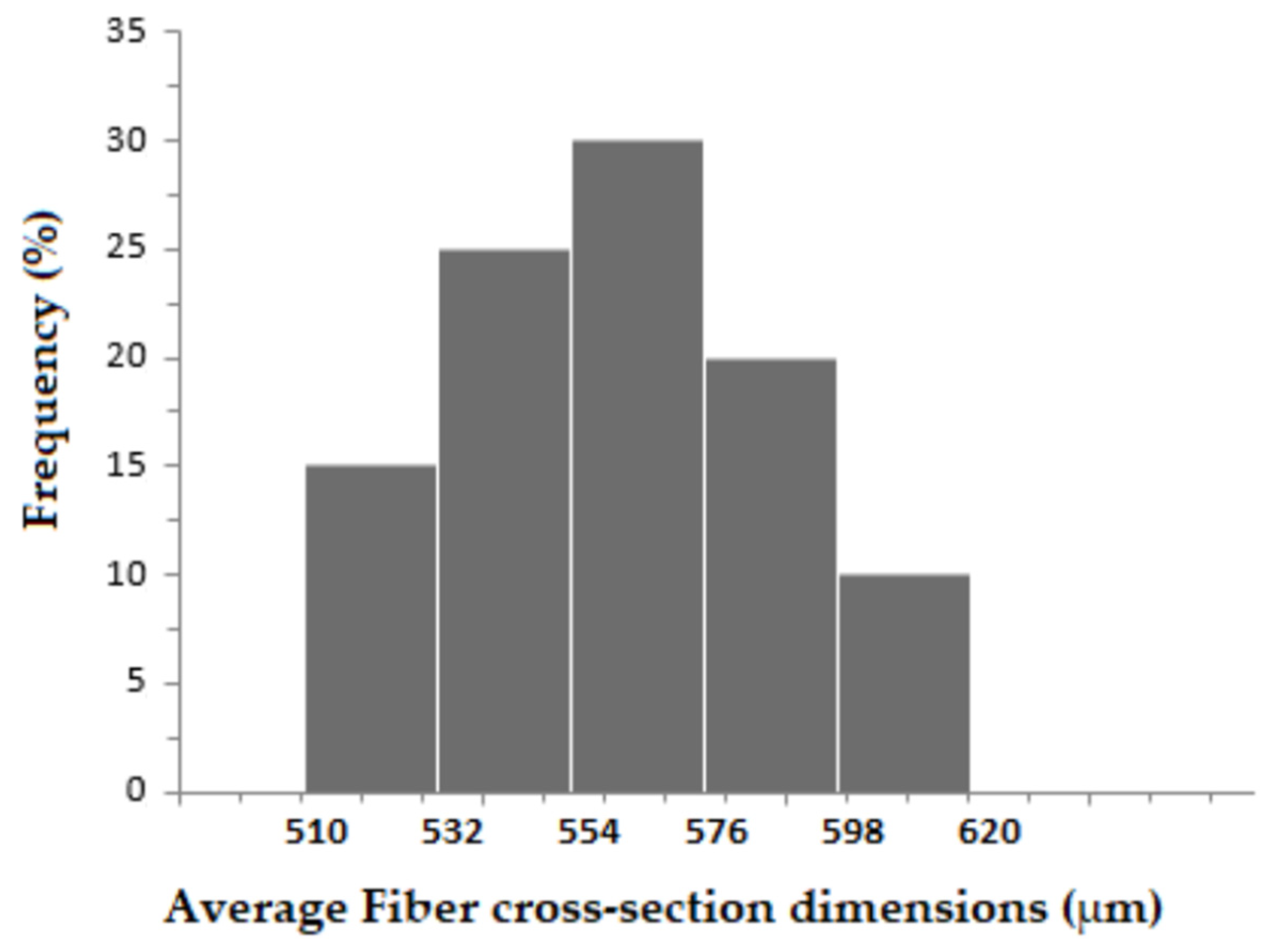

3.1.1. Geometric Method

3.1.2. Archimedes’ Technique

3.1.3. Gas Pycnometry Results

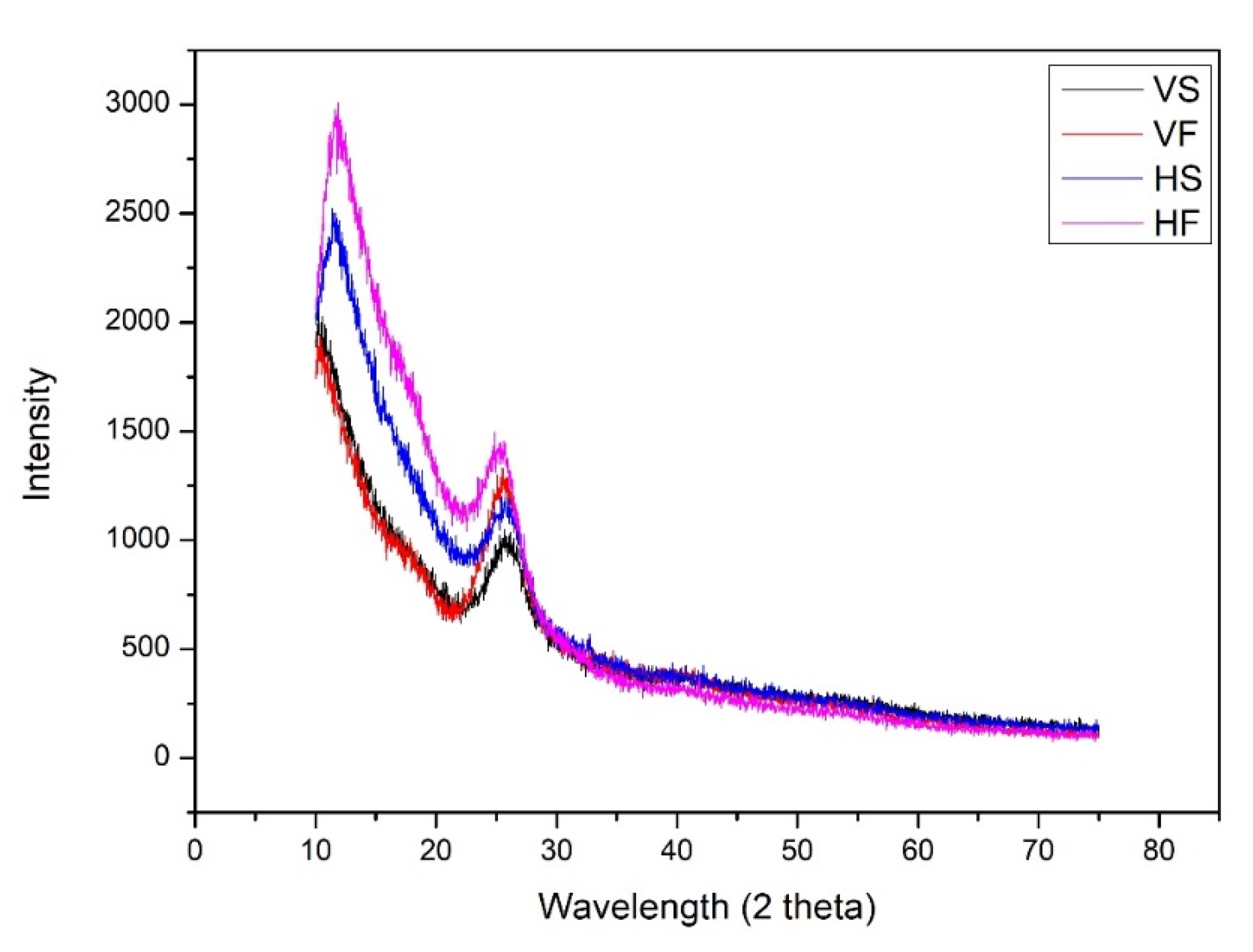

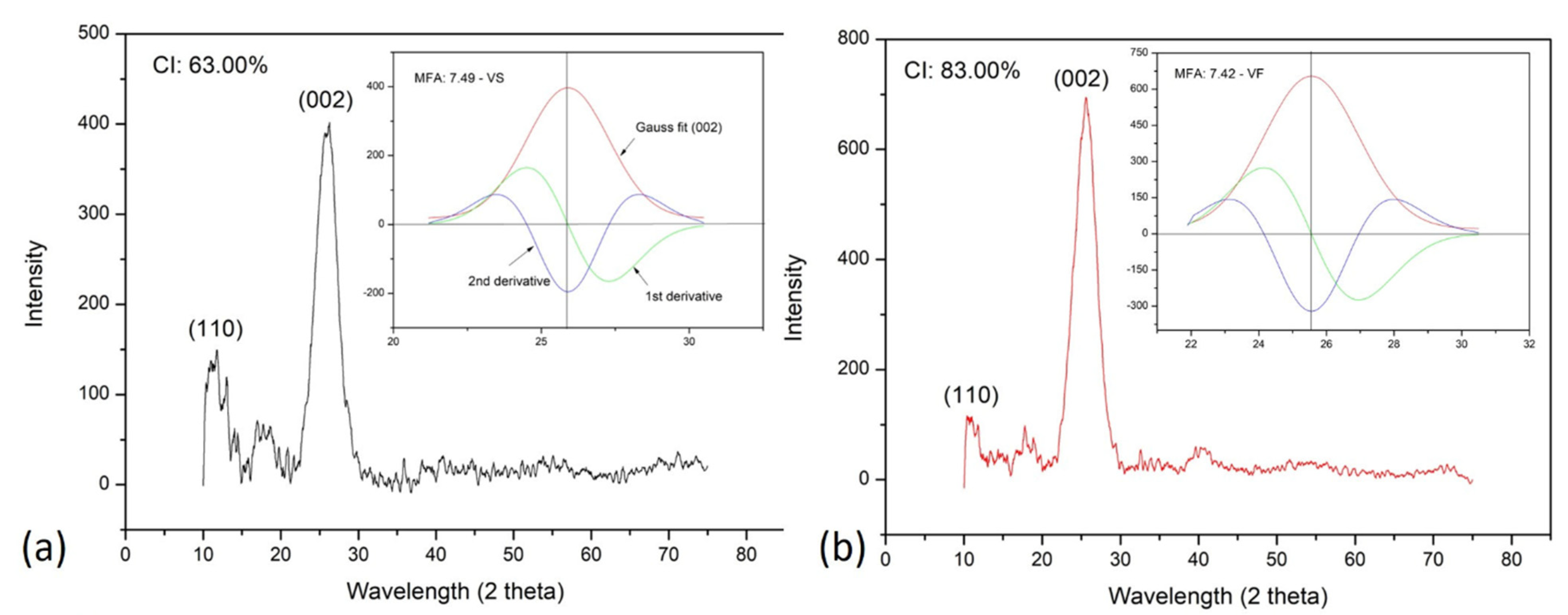

3.2. XRD Results

3.2.1. MFA Results

3.2.2. CI Results

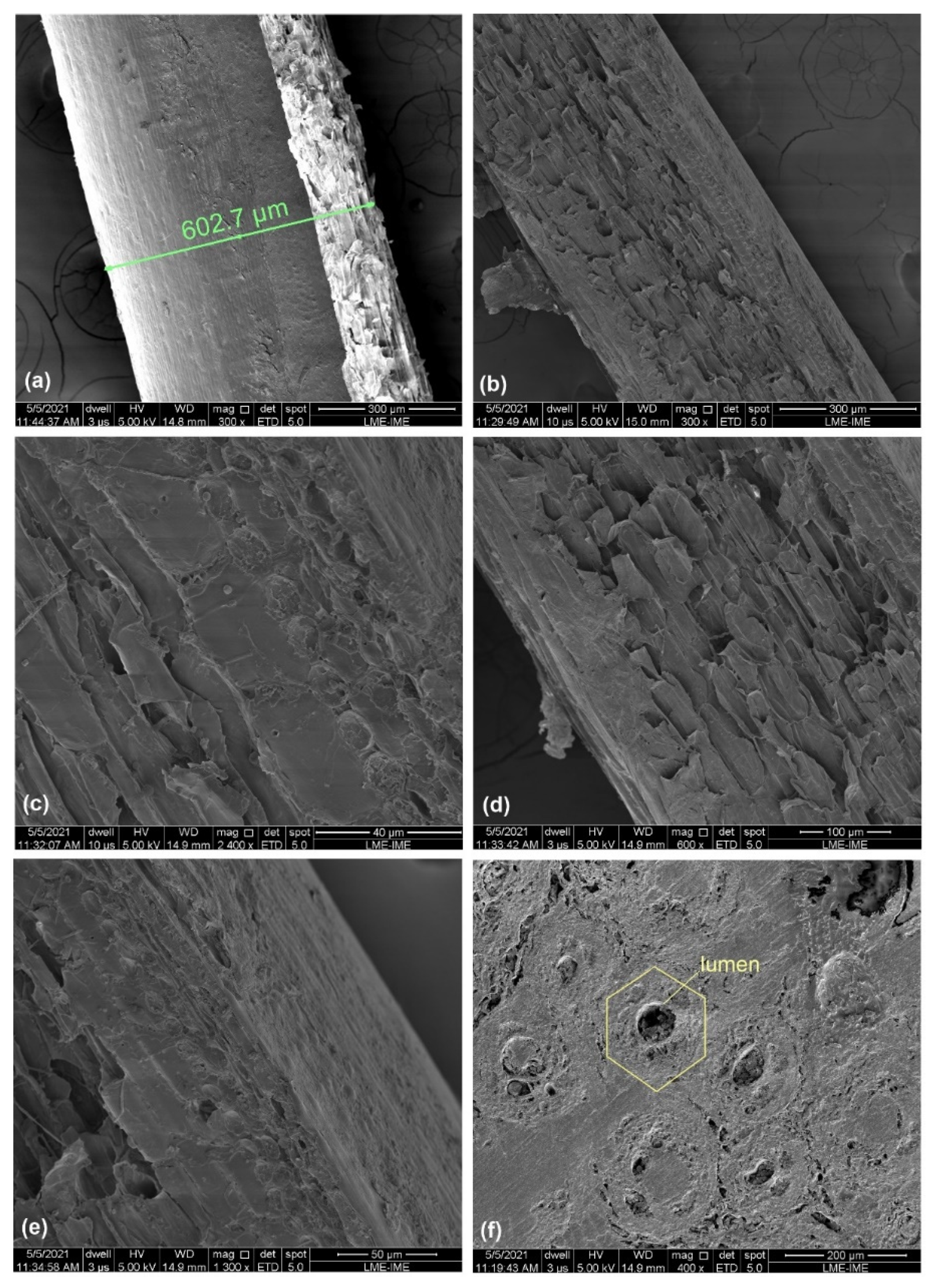

3.2.3. SEM Results

4. Summary and Conclusions

- Densities measured by the geometric method from 0.955 to 0.440 g/cm3 and analyzed by the Weibull statistical method revealed a tendency to decrease with increasing fiber cross-section dimensions, from 510 to 620 µm. After using the Archimedes’ technique, the density showed a mean value of 0.73 g/cm3, quite similar to the 0.70 g/cm3 that was found after using the geometric method, which are among the lowest reported so far for natural lignocellulosic fibers. By the gas pycnometry method the density was found as 1.86 ± 0.26 g/cm3 due to the exclusion of the porosity by the helium gas, but consistent with other NLF and pure cellulose with ~1.60 g/cm3.

- Microfibril angles from 7.42 to 7.49° were found by X-ray diffraction for different conditions of ubim stalk and fiber. A crystallinity index of 83% was evaluated by XRD in ubim fiber powder. This CI is within the range of reported values for several NLFs.

- These preliminary physical and microstructural characterizations performed for the ubim fiber, in association with a lower cost, indicate a promising application as reinforcement of polymer composites to be used as eco-friendly civil construction materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Chawla, K.K. Composite Materials: Science and Engineering, 3rd ed.; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar] [CrossRef]

- Amcor. Sustainability Review. 2018. Available online: https://www.amcor.com/sustainability/reports (accessed on 10 November 2021).

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos. Part B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on natural fiber reinforced polymer composite and its applications. Int. J. Polym. Sci. 2015, 15, 15. [Google Scholar] [CrossRef] [Green Version]

- Shah, D.U. Developing plant fibre composites for structural applications by optimising composite parameters: A critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Da Silva, I.L.A.; Da Costa, L.L. Natural lignocellulosic fibers as engineering materials: An overview. Met. Mater. Trans. A 2011, 42, 2963. [Google Scholar] [CrossRef] [Green Version]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. A comprehensive review on advanced sustainable woven natural fibre polymer composites. Polymers 2021, 13, 471. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A review on natural fibers for development of eco-friendly bio-composite: Characteristics, and utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Sundarakannan, R.; John, K.M.; Johnson, R.D.J.; Prasath, K.A.; Ajith, S.; Arumugaprabu, V.; Uthayakumar, M. Recent advancement in the natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2020, 277, 124109. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, S.; Li, Y.; Wang, Z.; Long, Y.; Yu, T.; Shen, Y. High performances of plant fiber reinforced composites—A new insight from hierarchical microstructures. Compos. Sci. Technol. 2020, 194, 108151. [Google Scholar] [CrossRef]

- da Luz, F.S.; Garcia Filho, F.D.C.; Del-Rio, M.T.G.; Nascimento, L.F.C.; Pinheiro, W.A.; Monteiro, S.N. Graphene-incorporated natural fiber polymer composites: A first overview. Polymers 2020, 12, 1601. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Sayed, S.M. Bionanocomposites materials for food packaging applications: Concepts and future outlook. Carbohydr. Polym. 2018, 193, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Singh, B.; Gupta, M.; Tarannum, H.; Randhawa, A. Natural fiber-based composite building materials. In Cellulose Fibers: Bio- and Nano-Polymer Composites: Green Chemistry Technology; Kalia, S., Kaith, B.S., Kaur, I., Eds.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Luz, F.S.D.; Lopera, H.A.C.; Nascimento, L.F.C.; Garcia Filho, F.D.C.; Monteiro, S.N. Energy absorption and limit velocity of epoxy composites incorporated with fique fabric as ballistic armor—A brief report. Polymers 2021, 13, 2727. [Google Scholar] [CrossRef] [PubMed]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Venugopal, A.; Boominathan, S.K. Physico-chemical, thermal and tensile properties of alkali-treated acacia concinna fiber. J. Nat. Fibers 2020, 1–16. [Google Scholar] [CrossRef]

- Jeyapragash, R.; Srinivasan, V.; Sathiyamurthy, S.J.M.T.P. Mechanical properties of natural fiber/particulate reinforced epoxy composites–A review of the literature. Mater. Today Proc. 2020, 22, 1223–1227. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Baillie, C.A.; Zafeiropoulos, N.; Mwaikambo, L.Y.; Ansell, M.P.; Dufresne, A.; Entwistle, K.M.; Herrera-Franco, P.J.; Escamilla, G.C.; Groom, L.; et al. Review: Current international research into cellulosic fibres and composites. J. Mater. Sci. 2001, 36, 2107–2131. [Google Scholar] [CrossRef]

- Ehrnrooth, E.M. Change in pulp fibre density with acid-chlorite delignification. J. Wood Chem. Technol. 2015, 4, 91–109. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. The determination of porosity and cellulose content of plant fibers by density methods. J. Mater. Sci. Lett. 2001, 20, 2095–2096. [Google Scholar] [CrossRef]

- Qiu, J.; Khalloufi, S.; Martynenko, A.; Van Dalen, G.; Schutyser, M.; Almeida-Rivera, C. Porosity, bulk density, and volume reduction during drying: Review of measurement methods and coefficient determinations. Dry. Technol. 2015, 33, 1681–1699. [Google Scholar] [CrossRef]

- Makarov, I.S.; Golova, L.K.; Kuznetsova, L.K.; Antonov, S.V.; Kotsyuk, A.V.; Ignatenko, V.Y.; Kulichikhin, V.G. Influence of Precipitation and Conditioning Baths on the Structure, Morphology, and Properties of Cellulose Films. Fibre Chem. 2016, 48, 298–305. [Google Scholar] [CrossRef]

- Donaldson, L. Microfibril angle: Measurement, variation and relationships—A review. Iawa J. 2008, 29, 345–386. [Google Scholar] [CrossRef]

- Meylan, B.A. The influence of microfibril angle on the longitudinal shrinkage-moisture content relationship. Wood Sci. Technol. 1972, 6, 293–301. [Google Scholar] [CrossRef]

- Marinelli, A.L.; Monteiro, M.R.; Ambrósio, J.D.; Branciforti, M.C.; Kobayashi, M.; Nobre, A.D. Development of poly-meric composites with natural plant fibers from biodiversity: A contribution to Amazon sustainability. Polimeros 2008, 18, 92–99. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Guimarães, J.L.; Wypych, F. Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos. Part A 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- Henderson, A.; Galeano, G.; Bernal, R. Field Guide to the Palms of the Americas; Princeton University Press: Princeton, NJ, USA, 1995; ISBN 978-0-6916-5612-0. [Google Scholar]

- Oliveira, J.; Potiguara, R.C.V.; Lobato, L.C.B. Vegetal fibers used in artisan fishing in the Salgado region, Pará (In Portu-Guese). Bulletin of the Museu Paraense Emílio Goeldi. Hum. Sci. 2006, 1, 113–127. [Google Scholar] [CrossRef] [Green Version]

- American Society for Testing and Materials—ASTM. Standard Test Method for Density of High Modulus Fiber. In D3800-99; ASTM International: West Conshohoken, PA, USA, 2010. [Google Scholar]

- American Society for Testing and Materials—ASTM. Standard Test Method for Density of Solid Pitch (Helium Pycnometer Method). In D4892-14; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Cave, I.D. X-ray measurement of microfibril angle. For. Prod. J. 1966, 16, 37–42. [Google Scholar]

- Segal, L.E.A. An empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Luz, F.S.d.; Teixeira Souza, A.; Demosthenes, L.C.d.C.; Pereira, A.C.; Filho, F.d.C.G.; Braga, F.d.O.; Figueiredo, A.B.-H.d.S.; Monteiro, S.N. Tucum fiber from amazon astrocaryum vulgare palm tree: Novel reinforcement for polymer composites. Polymers 2020, 12, 2259. [Google Scholar] [CrossRef] [PubMed]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Pereira, P.H.F.; Rosa, M.D.F.; Cioffi, M.O.H.; Benini, K.C.C.D.C.; Milanese, A.C.; Voorwald, H.J.C.; Mulinari, D.R. Vegetal fibers in polymeric composites: A review. Polimeros 2015, 25, 9–22. [Google Scholar] [CrossRef] [Green Version]

- Rekha, B.; Nagaraja Ganesh, B. X-ray Diffraction: An Efficient Method to Determine Microfibrillar Angle of Dry and Matured Cellulosic Fibers. J. Nat. Fibers 2020, 1–8. [Google Scholar] [CrossRef]

- Zhou, L.M.; Yeung, K.W.; Yuen, C.W.M.; Zhou, X. Characterization of ramie yarn treated with sodium hydroxide and crosslinked by 1,2,3,4-butanetetracarboxylic acid. J. Appl. Polym. Sci. 2004, 91, 1857–1864. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Gopi Krishna, M.; Kailasanathan, C.; Nagarajaganesh, B. Physico-chemical and morphological characterization of cellulose fibers extracted from Sansevieria roxburghiana schult. & Schult. F Leaves. J. Nat. Fibers 2020, 21, 1–17. [Google Scholar] [CrossRef]

- Raghavendra, G.; Ojha, S.; Acharya, S.K.; Pal, S.K. Jute fiber reinforced epoxy composites and comparison with the glass and neat epoxy composites. J. Compos. Mater. 2014, 48, 2537–2547. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. State of art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Eng. Sci. Technol. Int. J. 2015, 19, 717–736. [Google Scholar] [CrossRef] [Green Version]

- Baley, C.; Bourmaud, A. Average tensile properties of French elementary flax fibers. Mater. Lett. 2014, 122, 159–161. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; da Luz, F.S.; Pinheiro, W.A.; Monteiro, S.N. Mechanical properties of composites with graphene oxide functionalization of either epoxy matrix or curaua fiber reinforcement. J. Mater. Res. Technol. 2020, 9, 13390–13401. [Google Scholar] [CrossRef]

- Zhan, J.; Li, J.; Wang, G.; Guan, Y.; Zhao, G.; Lin, J.; Coutellier, D. Review on the performances, foaming and injection molding simulation of natural fiber composites. Polym. Compos. 2021, 42, 1305–1324. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibers and Biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Junior, H.L.O.; Moraes, A.G.O.; Poletto, M.; Zattera, A.J.; Amico, S.C. Chemical composition, tensile properties and struc-tural characterization of buriti fiber. Cellul. Chem. Technol. 2016, 50, 15–22. Available online: https://cellulosechemtechnol.ro/pdf/CCT1(2016)/p.15-22.pdf (accessed on 29 November 2021).

| Diameter Range (µm) | ρ (g/cm3) | Standard Deviation | Β | θ | R2 |

|---|---|---|---|---|---|

| 510–532 | 0.955 | 0.06 | 11.800 | 0.990 | 1.000 |

| 532–554 | 0.815 | 0.02 | 23.900 | 0.831 | 0.960 |

| 554–576 | 0.700 | 0.03 | 21.168 | 0.716 | 0.990 |

| 576–598 | 0.607 | 0.03 | 16.762 | 0.623 | 1.000 |

| 598–620 | 0.440 | 0.02 | 24.171 | 0.676 | 1.000 |

| ρmean | 0.703 |

| NLFs | Density (g/cm3) | Cellulose (%) | Crystallinity Index (%) | Microfibrillar Angle (◦) | Reference |

|---|---|---|---|---|---|

| Ubim | 0.70 | 66 | 83.0 | 7.46 | PW |

| Ramie | 1.50 | 85 | 75.0 | 7.50 | [17,28,39] |

| Hemp | 1.50 | 72 | 87.8 | 7.50 | [7,40] |

| Sisal | 1.50 | 75 | 72.2 | 20.0 | [7,17,28,41] |

| Coir (coconut) | 1.40 | 53 | 44.0 | 51.0 | [7,28] |

| Curaua | 0.92 | 71 | 75.6 | 18.8 | [43,45] |

| Jute | 1.45 | 60 | 71.3 | 8.00 | [7,40,42,43] |

| Flax | 1.38 | 71 | 63.1 | 10.0 | [7,44] |

| Banana | 1.50 | 65 | 39 | 11.0 | [7,37,46] |

| Pineapple | 1.60 | 83 | 38 | 14.0 | [7,37,38] |

| Bamboo | 1.21 | 45 | 60 | 6.0 | [7,37,38] |

| Sugarcane Bagasse | 0.49 | 69 | 45 | 14.5 | [7,37,38] |

| Kenaf | 1.50 | 72 | 72 | 4.1 | [37,46] |

| Cotton | 1.60 | 51 | 65 | 25 | [7,36,46] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marchi, B.Z.; Oliveira, M.S.; Bezerra, W.B.A.; de Sousa, T.G.; Candido, V.S.; da Silva, A.C.R.; Monteiro, S.N. Ubim Fiber (Geonoma baculífera): A Less Known Brazilian Amazon Natural Fiber for Engineering Applications. Sustainability 2022, 14, 421. https://doi.org/10.3390/su14010421

Marchi BZ, Oliveira MS, Bezerra WBA, de Sousa TG, Candido VS, da Silva ACR, Monteiro SN. Ubim Fiber (Geonoma baculífera): A Less Known Brazilian Amazon Natural Fiber for Engineering Applications. Sustainability. 2022; 14(1):421. https://doi.org/10.3390/su14010421

Chicago/Turabian StyleMarchi, Belayne Zanini, Michelle Souza Oliveira, Wendell Bruno Almeida Bezerra, Talita Gama de Sousa, Verônica Scarpini Candido, Alisson Clay Rios da Silva, and Sergio Neves Monteiro. 2022. "Ubim Fiber (Geonoma baculífera): A Less Known Brazilian Amazon Natural Fiber for Engineering Applications" Sustainability 14, no. 1: 421. https://doi.org/10.3390/su14010421

APA StyleMarchi, B. Z., Oliveira, M. S., Bezerra, W. B. A., de Sousa, T. G., Candido, V. S., da Silva, A. C. R., & Monteiro, S. N. (2022). Ubim Fiber (Geonoma baculífera): A Less Known Brazilian Amazon Natural Fiber for Engineering Applications. Sustainability, 14(1), 421. https://doi.org/10.3390/su14010421