A Novel Z Profile of Pultruded Glass-Fibre-Reinforced Polymer Beams for Purlins

Abstract

:1. Introduction

2. Materials and Methods

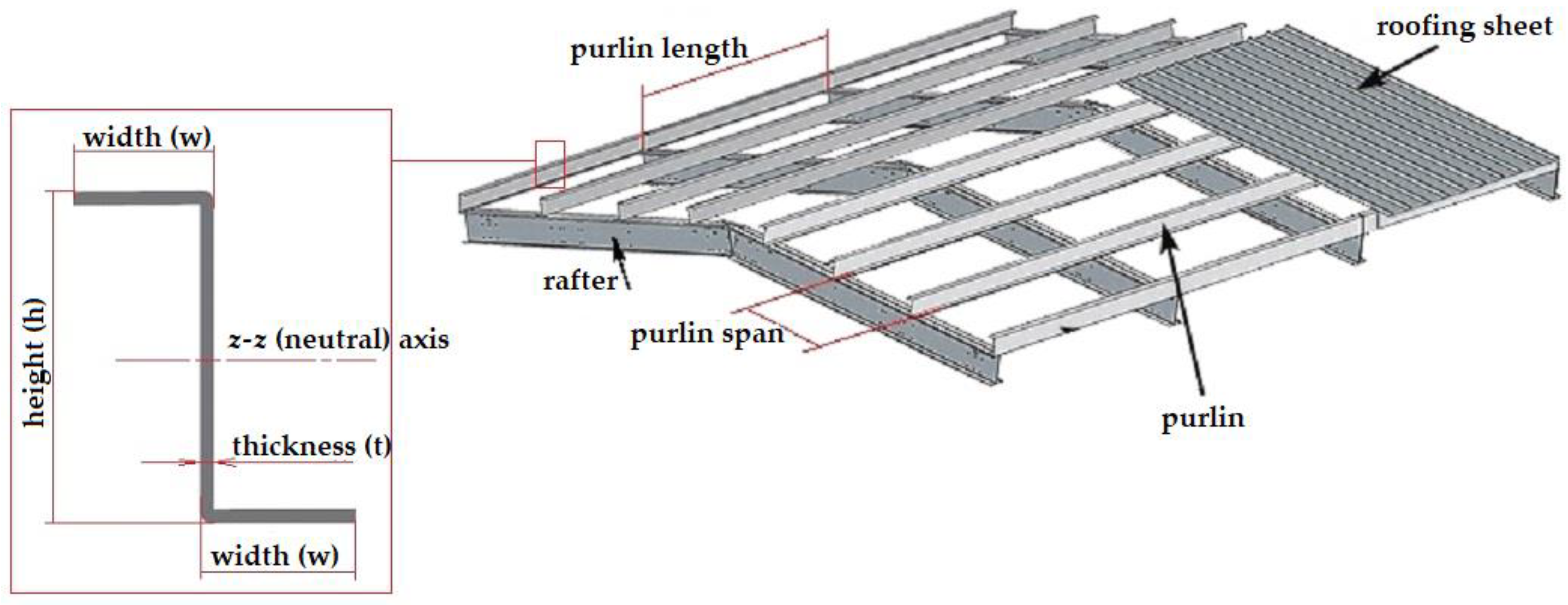

2.1. Optimum Profile of the Purlin

2.2. Purlin Prototypes and Structures

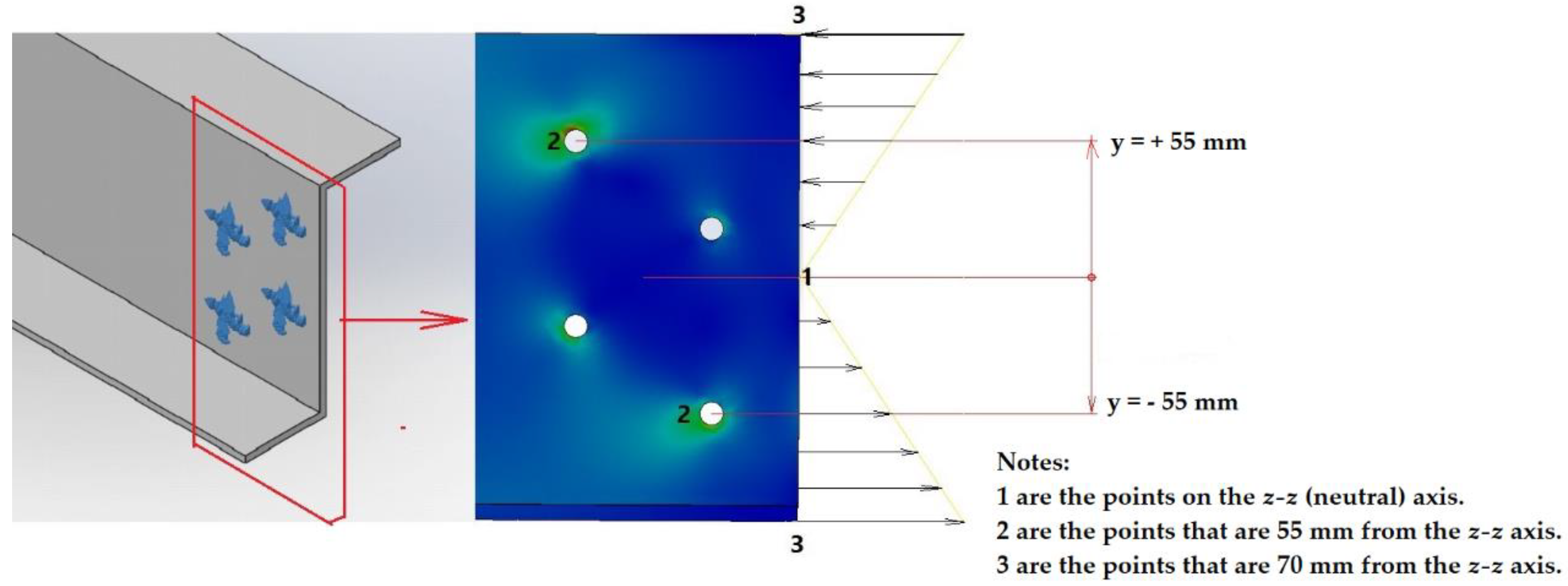

2.3. Finite Element Analysis of the Purlin Structure

3. Results

3.1. Purlin Profile

3.2. Purlin Prototypes and Structure

3.3. Finite Element Model of the Purlin Structure

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wojnar, A.; Sieńkowska, K. Comparison of strength and stiffness parameters of purlins with different cross-sections of profiles. Open Eng. 2020, 10, 604–611. [Google Scholar] [CrossRef]

- Sun, M.; Packer, J.A. Hot-dip galvanizing of cold-formed steel hollow sections: A state-of-the-art review. Front. Struct. Civ. Eng. 2019, 13, 49–651. [Google Scholar] [CrossRef]

- Ivan, S.C. Recent progress and required developments in atmospheric corrosion of galvanised steel and zinc. Materials 2017, 10, 1288. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Xu, S.; Li, R. Comparative investigation of the effect of corrosion on the mechanical properties of different parts of thin-walled steel. Thin-Walled Struct. 2020, 146, 106450. [Google Scholar] [CrossRef]

- Silva, R.S.; Meneguzzi, A. Passivation of carbon steel using intelligent epoxy paint. Coatings 2020, 10, 452. [Google Scholar] [CrossRef]

- Tiano, P.C.M.; Aoki, I.V. Corrosion protection of steel structures in industrial and marine atmospheres by waterborne acrylics DTM (direct to metal) paint system. In Proceedings of the European Corrosion Congress, EUROCORR 2015, Austria, Graz, 6–10 September 2015; p. 128475. [Google Scholar]

- Qureshi, J. A Review of Fibre Reinforced Polymer Structures. Fibers 2022, 10, 27. [Google Scholar] [CrossRef]

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2019, 24, 2419–2445. [Google Scholar] [CrossRef]

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Pultruded materials and structures: A review. J. Compos. Mater. 2020, 54, 4081–4117. [Google Scholar] [CrossRef]

- Shin, Y.H.; Yoong, Y.Y.; Hejazi, F.; Saifulnaz, M.R.R. Review on pultruded FRP structural design for building construction. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Sustainable Civil and Construction Engineering Conference, Kuala Lumpur, Malaysia, 25–27 August 2018; Volume 357, p. 012006. [Google Scholar] [CrossRef]

- Correia, J.R.; Fonseca, S.C.; Branco, F.A.; Ferreira, J.; Eusébio, M.I.; Rodrigues, M.P. Durability of glass fiber reinforced polyester (GFRP) pultruded profiles for construction applications. Mech. Compos. Mater. 2006, 42, 325–338. [Google Scholar] [CrossRef]

- Correia, J.R.; Branco, F.A.; Ferreira, J.; Fonseca, S.C.; Rodrigues, J.P.C. Lifetime performance of GFRP pultruded profiles for structural applications. In Proceedings of the IABSE Symposium Improving Infrastructure—Bringing People Closer Worldwide, Weimar, Germany, 19–21 September 2007. [Google Scholar] [CrossRef]

- Beura, S.; Thatoi, D.N.; Chakraverty, A.P.; Mohanty, U.K. Impact of the ambiance on GFRP composites and role of some inherent factors: A review report. J. Reinf. Plast. Compos. 2018, 37, 533–547. [Google Scholar] [CrossRef]

- Grmmatikos, S.A.; Jones, R.G.; Evernden, M.; Correia, J.R. Thermal cycling effects on the durability of a pultruded GFRP material for off-shore civil engineering structures. Compos. Struct. 2016, 153, 297–310. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Liu, W.; Wang, L.; Ling, Z. On-axis and off-axis compressive behavior of pultruded GFRP composites at elevated temperatures. Compos. Struct. 2020, 236, 111891. [Google Scholar] [CrossRef]

- Jafari, A.; Ashafi, H.; Bazli, M.; Ozbakkaloglu, T. Effect of thermal cycles on mechanical response of pultruded glass fiber reinforced polymer profiles of different geometries. Compos. Struct. 2019, 223, 110959. [Google Scholar] [CrossRef]

- Bazli, M.; Jafari, A.; Ashrafi, H.; Zhao, X.L.; Bai, Y.; Singh-Raman, R.K. Effects of UV radiation, moisture and elevated temperature on mechanical properties of GFRP pultruded profiles. Constr. Build. Mater. 2020, 231, 117137. [Google Scholar] [CrossRef]

- Setyanto, D. The possibility of E-glass woven roving as reinforcement of GFRP composite sheet roof. AIP Conf. Proc. 2016, 1717, 040007. [Google Scholar] [CrossRef]

- Fitzgerald, A.M.; Wong, N.; Fitzgerald, A.V.L.; Jesson, D.A.; Martin, F.; Murphy, R.J.; Young, T.; Hamerton, I.; Longana, M.L. Life Cycle Assessment of the High Performance Discontinuous Fibre (HiPerDiF) Technology and Its Operation in Various Countries. Sustainability 2022, 14, 1922. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Circular Design of Composite Products: A Framework Based on Insights from Literature and Industry. Sustainability 2021, 13, 7223. [Google Scholar] [CrossRef]

- Fitzgerald, A.; Proud, W.; Kandemir, A.; Murphy, R.J.; Jesson, D.A.; Trask, R.S.; Hamerton, I.; Longana, M.L. A Life Cycle Engineering Perspective on Biocomposites as a Solution for a Sustainable Recovery. Sustainability 2021, 13, 1160. [Google Scholar] [CrossRef]

- Chard, J.M.; Basson, L.; Creech, G.; Jesson, D.A.; Smith, P.A. Shades of Green: Life Cycle Assessment of a Urethane Methacrylate/Unsaturated Polyester Resin System for Composite Materials. Sustainability 2019, 11, 1001. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, M.C.S.; Fiúza, A.; Ferreira, A.; Dinis, M.D.L.; Castro, A.C.M.; Meixedo, J.P.M.; Alvim, M.R. Recycling Approach towards Sustainability Advance of Composite Materials’ Industry. Recycling 2016, 1, 178–193. [Google Scholar] [CrossRef] [Green Version]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef] [PubMed]

- Muc, A.; Stawiarski, A.; Chwal, M. Design of the hybrid FRP/concrete structures for bridge constructions. Compos. Struct. 2020, 2471, 112490. [Google Scholar] [CrossRef]

- Salakhutdinov, M.A.; Gimranov, L.R.; Kuznetsov, I.L.; Fakhrutdinov, A.E.; Nurgaleeva, L.M. PFRP structures under the predominately short-term load. Mag. Civ. Eng. 2020, 96, 3–14. Available online: https://engstroy.spbstu.ru/userfiles/files/2020/4(96)/01.pdf (accessed on 28 February 2022). [CrossRef]

- Russo, S. On failure modes and design of multi-bolted FRP plate in structural joints. Compos. Struct. 2019, 218, 325–334. [Google Scholar] [CrossRef]

- Cavaleri, L.; Di Paola, M.; Ferrotto, M.F.; Scalici, T.; Valenza, A. Structural performances of pultruded GFRP emergency structures—Part 1: Experimental characterization of materials and substructure. Compos. Struct. 2019, 214, 325–334. [Google Scholar] [CrossRef]

- Cavaleri, L.; Di Paola, M.; Ferrotto, M.F.; Scalici, T.; Valenza, A. Structural performances of pultruded GFRP emergency structures—Part 2: Full-scale experimental testing. Compos. Struct. 2019, 214, 304–315. Available online: https://pure.unipa.it/en/publications/structural-performances-of-pultruded-gfrp-emergency-structures-pa (accessed on 28 February 2022). [CrossRef]

- Hou, J.; Nie, X.; Zhang, L.; Huang, Y.; Bai, Y. Ultimate limit design of composite beams with modular GFRP deck and steel girder. Eng. Struct. 2018, 176, 337–348. [Google Scholar] [CrossRef]

- Yang, X.; Bai, Y.; Luo, F.J.; Zhao, X.L.; Ding, F. Dynamic and fatigue performances of a large-scale space frame assembled using pultruded GFRP composites. Compos. Struct. 2016, 138, 227–236. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design—A Systematic Approach, 3rd ed.; Springer: London, UK, 2007; pp. 63–124. [Google Scholar]

- Indonesian National Standard SNI 1727. 2000. Available online: http://sispk.bsn.go.id/sni/DetailSNI/12927 (accessed on 28 February 2022).

- Xin, H.; Liu, Y.; Mosallam, A.S.; He, J.; Du, A. Evaluation on material behaviors of pultruded glass fiber reinforced polymer (GFRP) laminates. Compos. Struct. 2017, 182, 283–300. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, L.; Su, B.; Lin, M.; Liao, Y.; Peng, Y.; Zhou, Y.; Luo, D. Influence of the property of hole on stress concentration factor for isotropic plates. In Proceedings of the 10th International Conference on Composite Science and Technology, Instituto Superior Tecnico, Lisboa, Portugal, 2–4 September 2015; Available online: http://www.dem.ist.utl.pt/iccst10/files/ICCST10_Proceedings/pdf/WEB_PAPERS/ICCST10_Upload_153.pdf (accessed on 28 February 2022).

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-19) an ACI Standard; American Concrete Institute: Farmington Hills, MI, USA, 2019; Available online: https://www.concrete.org/ (accessed on 28 February 2022).

- ASTM D2583 Standard. Available online: https://www.astm.org/d2583-13a.html (accessed on 28 February 2022).

- ASTM D638 Standard. Available online: https://www.astm.org/d0638-14.html (accessed on 28 February 2022).

- Li, C.; Xian, B. Mechanical property evolution and life prediction of carbon fiber and pultruded carbon fiber reinforced polymer plate exposed to elevated temperatures. Polym. Compos. 2020, 41, 5143–5155. [Google Scholar] [CrossRef]

- Priyanka, P.; Dixit, A.; Mali, H.S. High strength Kevlar fiber reinforced advanced textile composites (Review). Iran. Polym. J. 2019, 28, 621–638. [Google Scholar] [CrossRef]

- Alam, P.; Mamalis, D.; Robert, C.; Floreani, C.; Bradaigh, C.M.Ó. The fatigue of carbon fiber reinforced plastics—A review. Compos. Part B 2019, 166, 555–579. [Google Scholar] [CrossRef] [Green Version]

- Karatas, M.A.; Gokkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Zhang, S.; Caprani, C.C.; Heidarpour, A. Strain rate studies of pultruded glass fiber reinforced polymer material properties: A literature review. Constr. Build. Mater. 2018, 171, 984–1004. [Google Scholar] [CrossRef]

- Fernandes, L.A.; Silvestre, N.; Correia, J.R.; Arruda, M.R.T. Fracture toughness-based models for damage simulation of pultruded GFRP materials. Compos. Part B 2020, 186, 107818. [Google Scholar] [CrossRef]

- Saykin, V.V.; Nguyen, T.H.; Hajjar, J.F.; Deniz, D.; Song, J. Validation of a finite element approach to modeling of structural collapse of steel structures. In Proceedings of the Structures Congress, Boston, MA, USA, 3–5 April 2014; pp. 2162–2173. [Google Scholar] [CrossRef] [Green Version]

- Mantovani, D.P.; Rohen, L.A.; Neves, A.C.C.; Vieira, J.S.; Pontes, L.A.P.; Vieira, C.M.F.; Margem, F.M.; Monteiro, S.M. Comparative analysis of the tensile properties of polyester to epoxy matrixes composites reinforced with hemp fibers. In Proceedings of the 6th International workshop advances in cleaner production, Sao Paulo, Brasil, 24–26 May 2017; Available online: http://www.advancesincleanerproduction.net/sixth/files/sessoes/6B/5/mantovani_dp_et_al_academic.pdf (accessed on 28 February 2022).

- Ramadan, N.; Taha, M.; La Rosa, A.D.; Elsabbagh, A. Towards selection charts for epoxy resin, unsaturated polyester resin and their fibre fabric composites with flame retardants. Materials 2021, 14, 1181. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Q.; Li, W. Comparison of tensile and compressive properties of carbon/glass interlayer and intralayer hybrid composite. Materials 2021, 11, 1105. [Google Scholar] [CrossRef] [Green Version]

- Shakya, N.S.; Roux, J.A.; Jeswani, A.L. Effect of fiber volume fraction in fiber reinforcement compaction in resin injection pultrusion process. Polym. Polym. Compos. 2016, 24, 7–20. [Google Scholar] [CrossRef]

- Hashemi, F.; Tahir, P.M.; Madsen, B.; Jawaid, M.; Majid, D.L.; Branscheriau, L.; Juliana, A.H. Volumetric composition and shear strength evaluation of pultruded hybrid kenaf/glass fiber composites. J. Compos. Mater. 2016, 15, 2291–2303. [Google Scholar] [CrossRef]

| Technical Loads | Constant Distributed Forces |

|---|---|

| Purlin weight (“7.25 kg/m” or “71 N/m”) | QP = “71 N/m” |

| GFRP roofing sheet weight (“4 kg/m2” or “39 N/m2”) | QS = “63 N/m” |

| Live load (“20 psf” or “97.6 kg/m2” or “958 N/m2”) | QL = “1532 N/m” |

| Rain load (“20 kg/m2” or “196 N/m2”) | QR = “314 N/m” |

| Wind load (“90 mph” or “993 N/m2”) | QW = “1589 N/m” |

| Properties | Value |

|---|---|

| Tensile strength, σt | “400 × 106 N/m2” |

| Design tensile strength, σd | “320 × 106 N/m2” |

| Modulus of elasticity, E | “22 × 109 N/m2” |

| Longitudinal shear strength, τL | “40 × 106 N/m2” |

| Poisson ratio, ν | 0.32 |

| Sub-Functions | Alternative Solutions | |||

|---|---|---|---|---|

| 1st Solution | 2nd Solution | 3rd Solution | 4th Solution | |

| Withstands corrosive environment | GFRP | KFRP | CFRP | Hybrid of G/K/C-FRP |

| Withstands all technical loads | Pultruded beam with continuous roving and stitched mat reinforcement | |||

| Compact for handling and shipping | Z profile | C profile | Ω profile | - |

| Moment of Inertia (×106 mm4) | Thickness t (mm) | Height h (mm) | Width w (mm) | Cross-Section area A (mm2) | |

|---|---|---|---|---|---|

| (Iz-z)min | (Iz-z)actual | ||||

| 31.640 | 31.956 | 40 | 180 | 70 | 9912 |

| 31.640 | 32.251 | 21 | 200 | 75 | 6468 |

| 31.640 | 32.058 | 14 | 220 | 80 | 4928 |

| 31.640 | 32.693 | 10 | 240 | 90 | 4000 |

| 31.640 | 31.976 | 8 | 250 | 100 | 3472 |

| Tensile Properties | Samples Material | |

|---|---|---|

| Z55–45 | Z60–40 | |

| Longitudinal tensile strength | “396 ± 24.02 MPa” | “433 ± 21.24 MPa” |

| Longitudinal modulus of elasticity | “21,104 ± 198 MPa” | “22,440 ± 218 MPa” |

| Transversal tensile strength | “76 ± 7.23 MPa” | “70 ± 8.15 MPa” |

| Transversal modulus of elasticity | “6586 ± 82 MPa” | “6230 ± 69 MPa” |

| Longitudinal shear strength | “41.8 ± 2.1 MPa” | “45.5 ± 2.4 MPa” |

| Loads (kg) | Deflection at the Free End | ||

|---|---|---|---|

| Experimental Model (mm) | FE Model (mm) | Difference | |

| 0 | 0 | 0 | 0% |

| 46.39 | 4.4 | 4.53 | −2.96% |

| 69.59 | 7.0 | 6.80 | −2.86% |

| 92.78 | 9,0 | 9.07 | 0.78% |

| 115.98 | 110 | 11.35 | 3.18% |

| 139.18 | 13.0 | 13.61 | 4.69% |

| 162.37 | 16.5 | 15.88 | −3.76% |

| 185.57 | 19.0 | 18.15 | −4.47% |

| 208.76 | 22.0 | 20.42 | −7.18% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Setyanto, D.; Antonio, Y.A.; Darmawan, M.; Ubaidillah, U. A Novel Z Profile of Pultruded Glass-Fibre-Reinforced Polymer Beams for Purlins. Sustainability 2022, 14, 5862. https://doi.org/10.3390/su14105862

Setyanto D, Antonio YA, Darmawan M, Ubaidillah U. A Novel Z Profile of Pultruded Glass-Fibre-Reinforced Polymer Beams for Purlins. Sustainability. 2022; 14(10):5862. https://doi.org/10.3390/su14105862

Chicago/Turabian StyleSetyanto, Djoko, Yohanes Adeatma Antonio, Marten Darmawan, and Ubaidillah Ubaidillah. 2022. "A Novel Z Profile of Pultruded Glass-Fibre-Reinforced Polymer Beams for Purlins" Sustainability 14, no. 10: 5862. https://doi.org/10.3390/su14105862

APA StyleSetyanto, D., Antonio, Y. A., Darmawan, M., & Ubaidillah, U. (2022). A Novel Z Profile of Pultruded Glass-Fibre-Reinforced Polymer Beams for Purlins. Sustainability, 14(10), 5862. https://doi.org/10.3390/su14105862