Field Study and Chemical Analysis of Plant Waste in the Fez-Meknes Region, Morocco

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling

2.1.1. Study Area

2.1.2. Respondents

- -

- Wood industries.

- -

- Olive oil mills.

- -

- Medicinal and aromatic plant cooperatives.

- -

- Regional Council Fez-Meknes.

- -

- Delegation of water and forests of the region Fez-Meknes.

2.1.3. Plant Material

- -

- The wastes of the most used medicinal plants in Moroccan traditions before and after their extraction (Thymus vulgaris, Rosmarinus officinalis, Origanum vulgare, Mentha pulegium Mentha spicata, Mentha piperita, Artemisia absinthium, Salvia Officinalis) [18],

- -

- Vegetable household wastes (vegetables and fruits),

- -

- Olive tree residues during the harvest (branches and leaves),

- -

- Olive pomace and forest residues (leaves, branches, cones, seeds, sawdust).

2.2. Fiber Dosage

- -

- Cellulose = (ADF − ADL)/initial dry mass.

- -

- Hemicelluloses = (NDF − ADF)/initial dry mass.

- -

- Lignin = ADL/initial dry mass.

2.3. Dosage of Sugars and Total Phenolic Compounds

2.4. Determination of Elemental, Proximate Compositions, and Caloric Value of Plants Wastes

- -

- The percentage of Moisture content was carried out using the ASTM E871 standard with the following equation:where A is the mass of the sample used and B is the mass of the sample after heating in 105 °C.Moisture% = (A − B)/A

- -

- The ash content percentage in biomass wastes was performed using the ASTM E830. standard with the following equation:where C is the weight of sample after heating 575 °C.Ash content%= C/A × 100

- -

- The percentage content of volatile matter contained in biomass wastes was conducted using the ASTM E872 standard with the following equation:where D is the weight of sample after heating.Volatile matter% = (B − D)/A

2.5. Statistical Analysis

3. Results

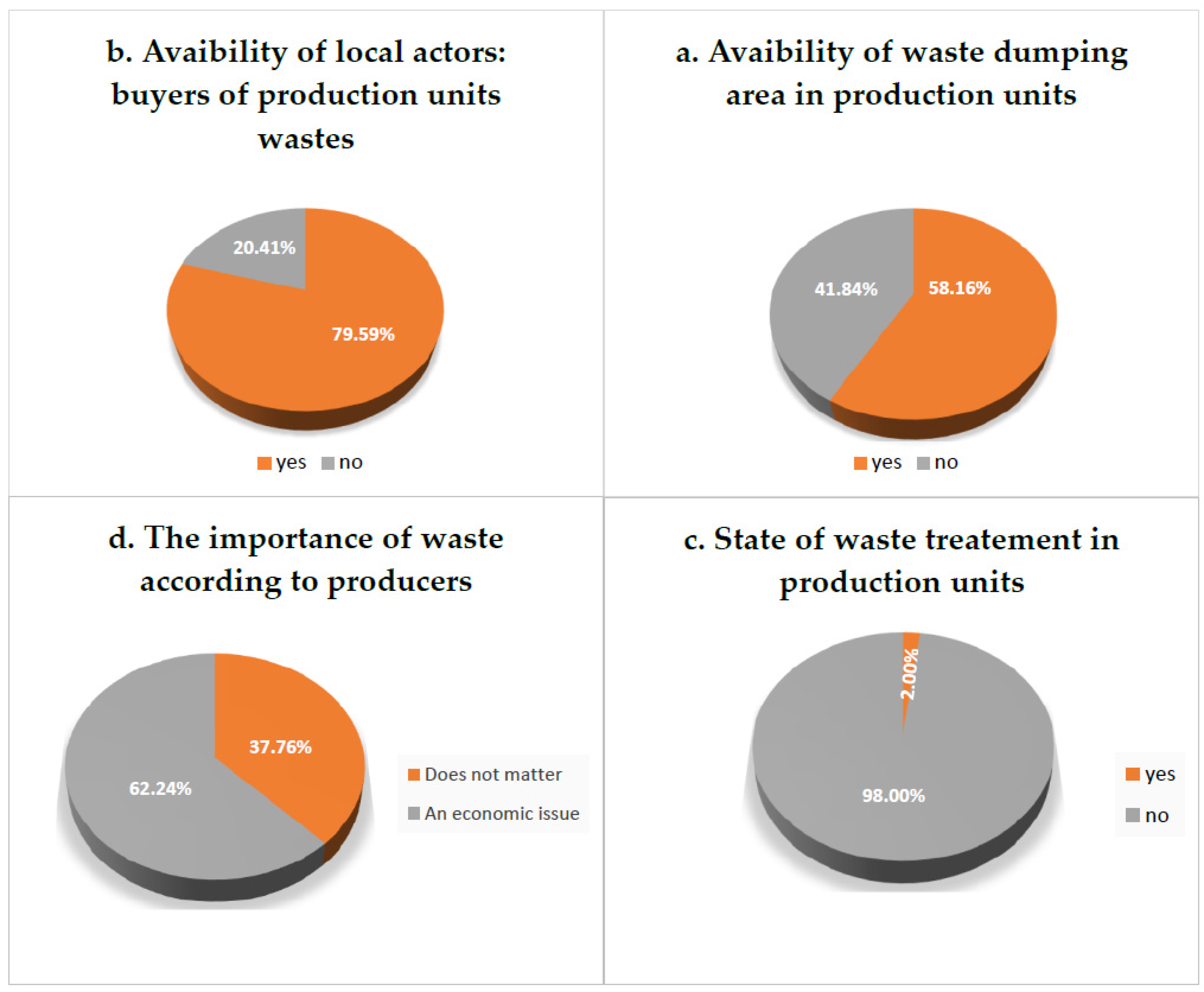

3.1. Survey Analysis

3.1.1. General Profile of the Respondents

3.1.2. Types of Solid Plant Waste

3.1.3. Treatment of Vegetable Waste

3.1.4. Obstacles to Plant Waste Treatment

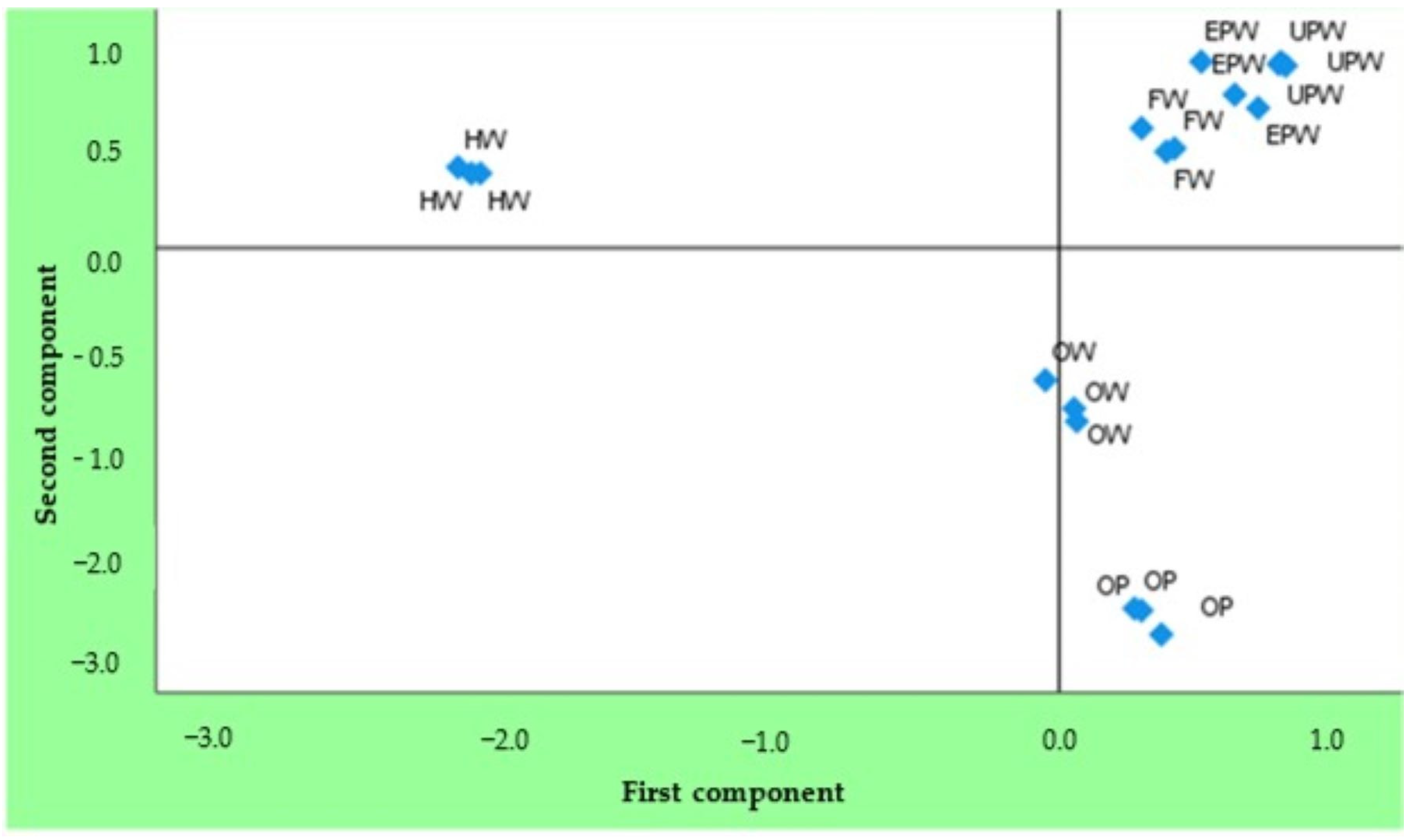

3.2. Fiber Content

- -

- The subsets: “HW”, “OW”, “FW, OP”, “EPW”, “UPW” have a significant difference at the level of cellulose contents.

- -

- The subsets: “HW”, “OW, FW, OP, EPW, UPW” contain significant difference at the level of lignin.

- -

- For each of the biomass’s OP, OW, and HW, their hemicellulose contents are significantly different, while the biomasses FW, UPW, and EPW do not show a significant difference between them.

- -

- The rate of the soluble fraction is quite dissimilar in all the samples studied, except between OP and OW where there is no significant difference.

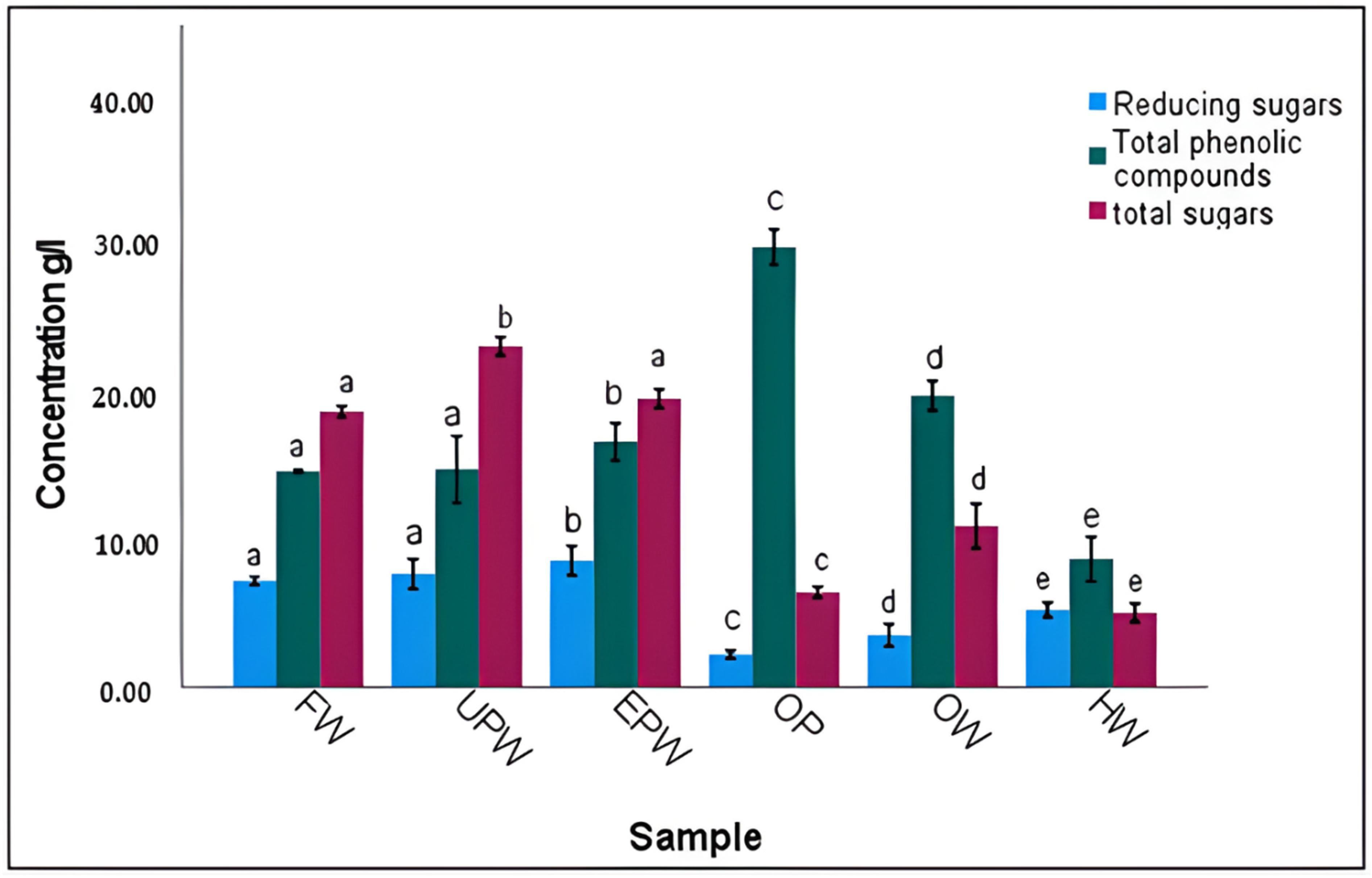

3.3. Content of Sugars and Phenolic Compounds

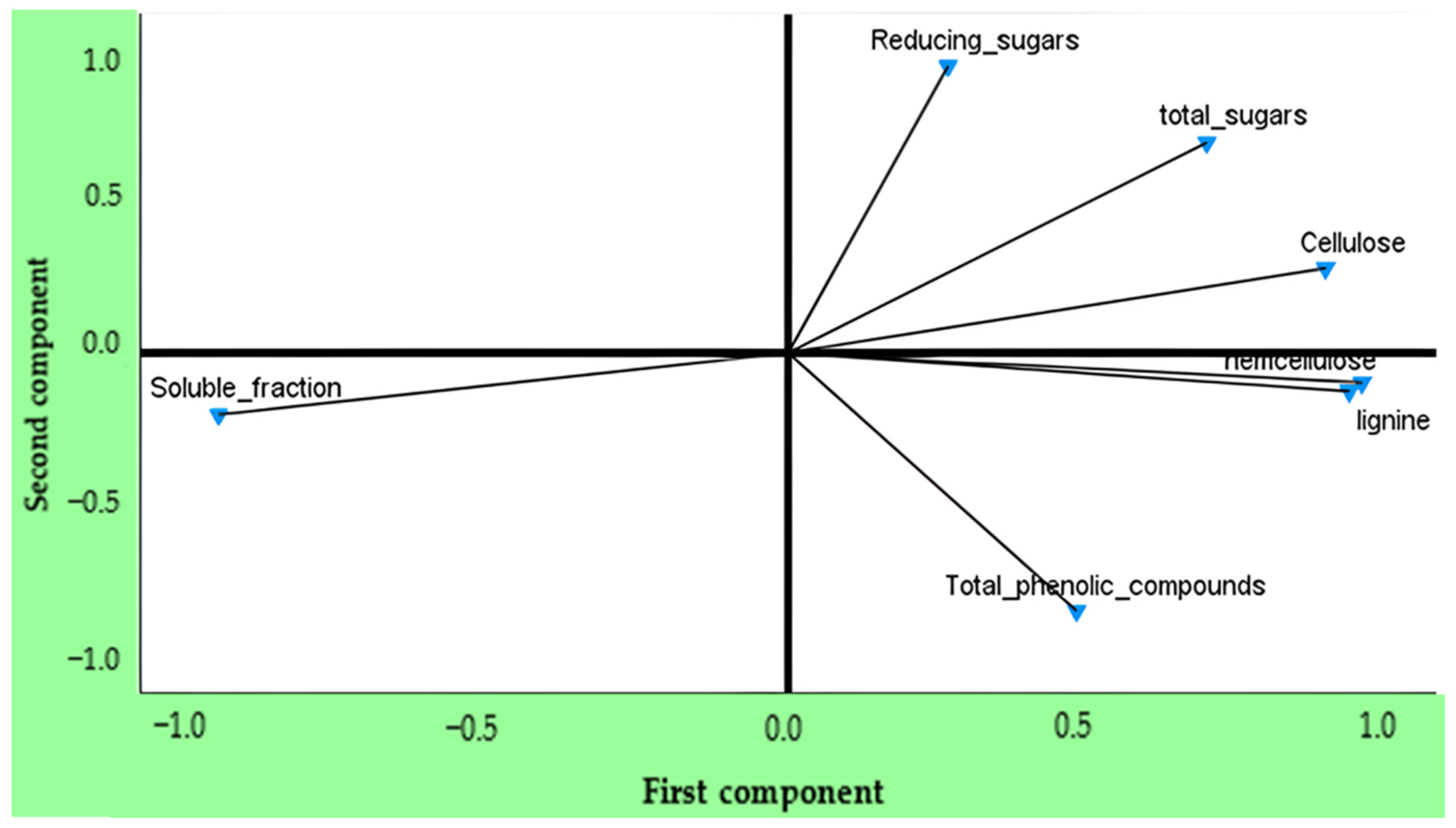

3.4. Correlation between the Different Parameters Measured

3.5. Elemental, Proximate Compositions and Caloric Value of Plant Waste

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IRENA. Renewable Capacity Statistics 2021 International Renewable Energy Agency (IRENA); IRENA: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Okolie, J.A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Chemistry and Specialty Industrial Applications of Lignocellulosic Biomass. Waste Biomass Valorization 2021, 12, 2145–2169. [Google Scholar] [CrossRef]

- Baruah, J.; Nath, B.K.; Sharma, R.; Kumar, S.; Deka, R.C.; Baruah, D.C.; Kalita, E. Recent Trends in the Pretreatment of Lignocellulosic Biomass for Value-Added Products. Front. Energy Res. 2018, 6, 141. [Google Scholar] [CrossRef]

- Haldar, D.; Purkait, M.K. Lignocellulosic Conversion into Value-Added Products: A Review. Process Biochem. 2020, 89, 110–133. [Google Scholar] [CrossRef]

- Sun, S.; Sun, S.; Cao, X.; Sun, R. The Role of Pretreatment in Improving the Enzymatic Hydrolysis of Lignocellulosic Materials. Bioresour. Technol. 2016, 199, 49–58. [Google Scholar] [CrossRef]

- Fahad, S.; Hasanuzzaman, M.; Alam, M.; Ullah, H.; Saeed, M.; Ali Khan, I.; Adnan, M. Environment, Climate, Plant and Vegetation Growth; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Fahad, S.; Sönmez, O.; Turan, V.; Adnan, M.; Saud, S.; Wu, C.; Wang, D. Sustainable Soil and Land Management and Climate Change, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar] [CrossRef]

- Kousksou, T.; Allouhi, A.; Belattar, M.; Jamil, A.; el Rhafiki, T.; Arid, A.; Zeraouli, Y. Renewable Energy Potential and National Policy Directions for Sustainable Development in Morocco. Renew. Sustain. Energy Rev. 2015, 47, 46–57. [Google Scholar] [CrossRef]

- Guedira, A.; Lamhamedi, M.S.; Satrani, B.; Boulmane, M.; Serrar, M.; Douira, A. Valorisation Des Matières Résiduelles et de La Biomasse Forestière Au Maroc: Compostage et Confection de Substrats Organiques Pour La Production de Plants Forestiers. Nat. Technol. 2012, 7, 87. [Google Scholar]

- Elachouri, M. Ethnobotany/Ethnopharmacology, and Bioprospecting: Issues on Knowledge and Uses of Medicinal Plants by Moroccan People. In Natural Products and Drug Discovery: An Integrated Approach; Elsevier: Amsterdam, The Netherlands, 2018; pp. 105–118. ISBN 9780081021040. [Google Scholar]

- Ministère de L’Agriculture Marocaine Ministère de L’Agriculture Marocaine. Available online: http://www.agriculture.gov.ma (accessed on 20 March 2022).

- Ministère de L’agriculture de la Pêche Maritime du Développement Rural et des Eaux et Forêts Marocaine. Haut Comissariat Aux Eaux et Foret et à la Lutte Contre la Désertification. In Stratégie Bois-Energie; Ministère de L’agriculture de la Pêche Maritime du Développement Rural et des Eaux et Forêts Marocaine: Rabat, Morocco, 2016. [Google Scholar]

- Mikou, K.; Rachiq, S.; Jarrar Oulidi, A. Étude Ethnobotanique Des Plantes Médicinales et Aromatiques Utilisées Dans La Ville de Fès Au Maroc. Phytotherapie 2016, 14, 35–43. [Google Scholar] [CrossRef]

- Bouyahya, A.; el Omari, N.; Elmenyiy, N.; Guaouguaou, F.E.; Balahbib, A.; Belmehdi, O.; Salhi, N.; Imtara, H.; Mrabti, H.N.; El-Shazly, M.; et al. Moroccan Antidiabetic Medicinal Plants: Ethnobotanical Studies, Phytochemical Bioactive Compounds, Preclinical Investigations, Toxicological Validations and Clinical Evidences; Challenges, Guidance and Perspectives for Future Management of Diabetes Worldwide. Trends Food Sci. Technol. 2021, 115, 147–254. [Google Scholar]

- Kharbouch, B.; Sandrine, D.A.; Lakhtar Hicham, N.M. Traitement et Valorisation Des Sous-Produits Oléicoles Par Compostage et Lombricompostage. Ph.D. Thesis, Aix-Marseille University, Marseille, France, 2018. [Google Scholar]

- IRENA International Renewable Energy Agency. Available online: https://www.Irena.Org/Bioenergy (accessed on 1 March 2022).

- Ministère de L’intérieur Marocaine. Monographie de La Région Fès-Meknès; Ministère de L’intérieur Marocaine: Rabat, Morocco, 2015.

- Benali, T.; Khabbach, A.; Ennabili, A.; Hammani, K. Ethnopharmacological Prospecting of Medicinal Plants from the Province of Guercif (NE of Morocco). Moroc. J. Biol. Number 2017, 14, 1–14. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Godin, B.; Ghysel, F.; Agneessens, R. Cellulose, Hemicelluloses, Lignin, and Ash Contents in Various Lignocellulosic Crops for Second Generation Bioethanol Production. Biotechnol. Agron. 2010, 14, 549–560. [Google Scholar]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Dubois, M.; Gilles, K.; Hamilton, J.K.; Rebers, P.A.; Smith, F. A New Paper Chromatography Solvent for Amino-Acids. Nature 1951, 168, 167–168. [Google Scholar] [CrossRef] [PubMed]

- Singleton, V.L.; Rossi, J.A. Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- Ministère de l’Enérgie des Mines et de L’environnement. Feuille de Route Nationale Pour La Valorisation Energétique de La Biomasse; Ministère de l’Enérgie des Mines et de L’environnement: Rabat, Morocco, 2021.

- Ministère de la Transition Energitique et du Développement Durable Valorisation Énergétique de Biomasse. Available online: Http://www.mem.gov.ma (accessed on 20 March 2022).

- Romaní, A.; Rocha, C.M.R.; Michelin, M.; Domingues, L.; Teixeira, J.A. Valorization of Lignocellulosic-Based Wastes. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 383–410. [Google Scholar] [CrossRef]

- Eloutassi, N.; Louaste, B.; Boudine, L.; Remmal, A. Hydrolyse Physico-Chimique et Biologique de La Biomasse Ligno-Cellulosique Pour La Production de Bio-Éthanol de Deuxième Génération. Nat. Technol. 2014, 10, 10. [Google Scholar]

- Prakash, O.; Naik, M.; Katiyar, R.; Naik, S.; Kumar, D.; Maji, D.; Shukla, A.; Deepak Nannaware, A.; Kalra, A.; Kumar Rout, P. Novel Process for Isolation of Major Bio-Polymers from Mentha Arvensis Distilled Biomass and Saccharification of the Isolated Cellulose to Glucose. Ind. Crops Prod. 2018, 119, 1–8. [Google Scholar] [CrossRef]

- Li, Y.; Feng, L.; Zhang, R.; He, Y.; Liu, X.; Xiao, X.; Ma, X.; Chen, C.; Liu, G. Influence of Inoculum Source and Pre-Incubation on Bio-Methane Potential of Chicken Manure and Corn Stover. Appl. Biochem. Biotechnol. 2013, 171, 117–127. [Google Scholar] [CrossRef]

- Sharma, H.K.; Xu, C.; Qin, W. Biological Pretreatment of Lignocellulosic Biomass for Biofuels and Bioproducts: An Overview. Waste Biomass Valorization 2019, 10, 235–251. [Google Scholar] [CrossRef]

- Stamogiannou, I.; van Camp, J.; Smagghe, G.; van de Walle, D.; Dewettinck, K.; Raes, K. Impact of Phenolic Compound as Activators or Inhibitors on the Enzymatic Hydrolysis of Cellulose. Int. J. Biol. Macromol. 2021, 186, 174–180. [Google Scholar] [CrossRef]

- Dayton, D.C.; Foust, T.D. Waste to Energy. In Analytical Methods for Biomass Characterization and Conversion; Elsevier: Amsterdam, The Netherlands, 2020; pp. 185–202. [Google Scholar]

- Shi, H.; Mahinpey, N.; Aqsha, A.; Silbermann, R. Characterization, Thermochemical Conversion Studies, and Heating Value Modeling of Municipal Solid Waste. Waste Manag. 2016, 48, 34–47. [Google Scholar] [CrossRef]

- Ozveren, U. An Artificial Intelligence Approach to Predict Gross Heating Value of Lignocellulosic Fuels. J. Energy Inst. 2017, 90, 397–407. [Google Scholar] [CrossRef]

- Nhuchhen, D.R.; Afzal, M.T. Supplementary Materials: HHV Predicting Correlations for Torrefied Biomass Using Proximate and Ultimate Analyses. Bioengineering 2017, 4, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trivedi, N.S.; Mandavgane, S.A.; Mehetre, S.; Kulkarni, B.D. Characterization and Valorization of Biomass Ashes. Environ. Sci. Pollut. Res. 2016, 23, 20243–20256. [Google Scholar] [CrossRef] [PubMed]

| Variable | Sub-Group | Number | Percentage% |

|---|---|---|---|

| 25–35 | 3 | 3.0 | |

| Age | 35–45 | 15 | 15.0 |

| 45–55 | 48 | 48.0 | |

| Over 55 | 34 | 34.0 | |

| Sex | Man | 72 | 72.0 |

| Woman | 28 | 28.0 | |

| Nonet | 27 | 27.6 | |

| Primary | 38 | 38.8 | |

| School level | College | 6 | 6.1 |

| Secondary | 5 | 5.1 | |

| University | 22 | 22.4 | |

| Private | 63 | 63.0 | |

| Sectors of production units | Public | 2 | 2.0 |

| Social economy | 35 | 35.0 | |

| Before 2000 | 29 | 29.6 | |

| Year of creation | 2000–2010 | 34 | 34.7 |

| After 2010 | 35 | 35.7 |

| Production Units | Number | Fraction Used | Solid Plant Waste | Quantity of Waste (Average in Ton/Year) |

|---|---|---|---|---|

| Wood industries | 39 | Wood | Sawdust, planing shavings | 13.59 |

| Medicinal and aromatic plant cooperatives | 21 | Leaves, Biomass Blend | Stems, roots, seeds | - |

| Olive oil mills | 31 | Seeds and fruits | Olive pomace | 2854.84 |

| Delegation of water and forests of the region Fez-Meknes | 1 | - | Leaves, branches, cones, seeds, sawdust | - |

| Regional Council Fez-Meknes | 1 | - | Household fruit and vegetable waste | - |

| Samples | ||||||

|---|---|---|---|---|---|---|

| FW | UPW | EPW | OP | OW | HW | |

| % Cellulose | 34.75 ± 1.2 a | 54.19 ± 0.50 b | 48.44 ± 0.60 c | 34.00 ± 0.50 a | 27.81 ± 1.5 d | 7.35 ± 0.70 e |

| % Hemicellulose | 28.44 ± 1.5 a | 28.50 ± 0.60 a | 27.19 ± 0.70 a,c | 17.13 ± 0.60 b | 24.69 ± 1.20 c | 4.29 ± 0.25 d |

| % lignin | 17.63 ± 1.3 a | 16.81 ± 0.40 a | 16.63 ± 1.5 a | 16.20 ± 1.7 a | 16.44 ± 0.50 a | 2.35 ± 0.40 b |

| % Soluble Fraction | 19.19 ± 0.50 a | 50 ± 0.25 b | 7.75 ± 0.80 c | 32.00 ± 1.1 d | 31.06 ± 0.50 d | 86.00 ± 1.50 e |

| Cellulose | Hemicellulose | Lignin | Soluble Fraction | Total Phenolic Compounds | Reducing Sugars | Total Sugars | |

|---|---|---|---|---|---|---|---|

| Cellulose | 1.000 | 0.846 | 0.792 | −0.964 | 0.258 | 0.516 | 0.844 |

| Hemicellulose | 1.000 | 0.978 | −0.937 | 0.551 | 0.175 | 0.643 | |

| Lignin | 1.000 | −0.907 | 0.546 | 0.137 | 0.611 | ||

| Soluble fraction | 1.000 | −0.311 | −0.451 | −0.842 | |||

| Total phenolic compounds | 1.000 | −0.623 | −0.242 | ||||

| Reducing sugars | 1.000 | 0.823 | |||||

| Total sugars | 1.000 |

| Samples | ||||||

|---|---|---|---|---|---|---|

| FW | UPW | EPW | OP | OW | HW | |

| Moisture (M) (wt.%) | 11.7 | 8.2 | 7.6 | 5.8 | 3.4 | 3.5 |

| Volatile matter (VM)% | 71 | 78.4 | 63.2 | 74 | 76.1 | 70.5 |

| Fixed carbon (FC)% | 15.5 | 9.6 | 24 | 16.5 | 18.2 | 15.4 |

| Ash (dry wt.%) | 1.5 | 2.7 | 5.1 | 4.5 | 2.2 | 10.4 |

| % Carbon (C) | 51 | 46.9 | 39.2 | 54 | 48.3 | 46.5 |

| % Oxygen(O) | 40.6 | 42.8 | 54.2 | 35.3 | 45 | 32 |

| % Hydrogen(H) | 7.5 | 6.7 | 5.3 | 7.6 | 5.9 | 6.8 |

| % Sulfur(S) | 0 | 0.3 | 0.09 | 0.08 | 0.1 | 0.4 |

| % Nitrogen(N) | 0.2 | 1.8 | 1.1 | 2.3 | 0.7 | 3.7 |

| Caloric value (MJ/Kg) | 19 | 19.8 | 14.5 | 21.6 | 18.5 | 12.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bendaoud, A.; Lahkimi, A.; Kara, M.; Moubchir, T.; Assouguem, A.; Belkhiri, A.; Allali, A.; Hmamou, A.; Almeer, R.; Sayed, A.A.; et al. Field Study and Chemical Analysis of Plant Waste in the Fez-Meknes Region, Morocco. Sustainability 2022, 14, 6029. https://doi.org/10.3390/su14106029

Bendaoud A, Lahkimi A, Kara M, Moubchir T, Assouguem A, Belkhiri A, Allali A, Hmamou A, Almeer R, Sayed AA, et al. Field Study and Chemical Analysis of Plant Waste in the Fez-Meknes Region, Morocco. Sustainability. 2022; 14(10):6029. https://doi.org/10.3390/su14106029

Chicago/Turabian StyleBendaoud, Ahmed, Amal Lahkimi, Mohammed Kara, Tarik Moubchir, Amine Assouguem, Abdelkhalek Belkhiri, Aimad Allali, Anouar Hmamou, Rafa Almeer, Amany A. Sayed, and et al. 2022. "Field Study and Chemical Analysis of Plant Waste in the Fez-Meknes Region, Morocco" Sustainability 14, no. 10: 6029. https://doi.org/10.3390/su14106029

APA StyleBendaoud, A., Lahkimi, A., Kara, M., Moubchir, T., Assouguem, A., Belkhiri, A., Allali, A., Hmamou, A., Almeer, R., Sayed, A. A., Peluso, I., & Eloutassi, N. (2022). Field Study and Chemical Analysis of Plant Waste in the Fez-Meknes Region, Morocco. Sustainability, 14(10), 6029. https://doi.org/10.3390/su14106029