1. Introduction

In the last decades, the topic of civil construction sustainability, considered from both environmental and economic points of view, has encouraged the development of innovative technological solutions that allow materials at the end of their service life to be recycled as secondary raw materials [

1,

2,

3], thus avoiding their direct disposal in landfills. In this regard, one of the most involved sectors is road construction, forced by the significant increase in the costs of pavement materials, particularly of bitumen, observed over the years [

4]. Therefore, the recycling of waste materials should be implemented in pavement management best practices in order to improve the sustainability of road construction.

There are several recycling approaches for asphalt pavements that differ in mixing temperature (cold recycling and hot recycling) and recycling location (in plant or in situ). Multiple studies confirm that cold recycling technologies are generally more environmentally friendly [

5,

6,

7,

8].

One of the most interesting solutions adopted by road agencies is represented by foamed bitumen (FB), since it allows waste materials to be stabilized, as well as low quantities of water or additives to be used, thus reducing the mixtures’ costs and environmental impact [

7]. The foaming bitumen process was first discussed by Csanyi in 1957 [

9], and since then FB technology has been investigated and discussed by many researchers in order to enhance pavement management and rehabilitation [

10,

11,

12,

13,

14].

He and Lu in 2004 [

15] discovered that adding a small percentage of cement (1 to 1.5%) to the mix composition does not provide appreciable improvements in terms of strength; however, it significantly increases its water resistance. Subsequently, He and Wong [

16] thoroughly investigated the decay properties of foamed bitumen, demonstrating that water content has a major impact on bitumen decay lines, in contrast to insufflated air pressure, which instead has a much smaller impact. Kowalska and Maciejewski [

17] in 2020 carried out an experiment on cold recycled mixtures with foamed bitumen and demonstrated how several bituminous binders are suitable for producing mixtures that can be used as road subgrades, using 50% reclaimed asphalt pavement and 30% recycled materials within the aggregate structure.

Given this framework, the main goal of the present research was to investigate the technical feasibility of cold recycled mixtures for road foundation layers, prepared with waste materials composing 100% of the aggregate structure, foamed bitumen, and cement. Different amounts of waste materials were combined [

18], namely electric arc furnace steel slag, ladle furnace slag, municipal solid waste incineration ash, coal fly ash, glass waste, and reclaimed asphalt pavement. This implements foamed bitumen technology in a context of sustainable road construction, management, and maintenance with reduced environmental impact.

2. Materials and Methods

The fundamental principle of the present research is to replace entirely the natural aggregate conventionally used in road foundations with industrial by-products and civil waste materials. The focus was on electric arc furnace (EAF) slags, ladle furnace (LF) slags, bottom ash from municipal solid waste incineration (MSWI), coal fly (CF) ash, glass waste (GW) and reclaimed asphalt pavement (RAP). Municipal waste produced in Italy in 2019 amounted to about 30 million tons [

19]. Since bottom ash from the incineration of municipal waste consists of 25% of the total initial waste [

20], around 7.5 million tons of MSWI bottom ash were produced. In Italy, around 1 million tons of CF ash are produced every year [

21], and, in 2014, 4.1 million tons of steel slags were produced [

22]. Regarding RAP, in 2014, only the Lombardy region roughly managed 1 million tons [

23]. As for GW, fewer references are available on its production; however, in 2008, 27 European countries (EU-27) produced about 4 million tons of glass waste [

24].

The re-use of wastes in pavement and civil engineering is clearly limited to those which are not characterized by a concentration of heavy metals above the legal thresholds. Therefore, the first step in the study was to evaluate the potential environmental hazard associated with the waste materials investigated. The toxicological properties were determined by means of the ICP-AES (Inductively Coupled Plasma–Atomic Emission Spectrometer) approach. In addition to the initial heavy metal concentration, the leaching process also needed to be investigated. In this case, the TCLP (Toxic Characteristic Leachability Procedure) was followed, according to the methods specified in EN 12457-2. Subsequently, physical and mechanical properties of the above-mentioned waste materials were determined, namely: shape, flakening, and plasticity indexes; equivalent in sand; Los Angeles coefficient; particle density; and size. For each of the foamed bitumen mixtures analyzed in the experimental study, the active filler used was the Portland cement CEM II/B LL 32.5R.

The binder used in the laboratory specimen’s production was a soft bitumen characterized by an 80/100 penetration grade, because, according to the literature [

25,

26], soft bitumens provide optimal properties in the foaming process. The water used for the subsequent foamed bitumen production was clear, and presented no dangerous chemical or organic agents.

Six different aggregate structures were prepared: five entirely composed of waste materials in different percentages (Mixes 1 to 5), and a control aggregate structure containing only limestone (LS). For each mix, 3 percentages of foamed bitumen were considered, namely 2%, 3%, and 4%. A fixed percentage of cement (2%) was included in all mixtures to provide proper moisture resistance.

It is worth noting that all waste materials were used in their original condition, as supplied by the production company, without selecting a specific aggregate size. The grain size curves were designed according to the reference envelope defined by the Italian national road agency (ANAS).

2.1. Optimum Moisture Content and Foaming Water Content Evaluation

To determine the values of maximum dry density and optimum moisture content (OMC), modified Proctor compaction tests were carried out on granular mixtures in accordance with EN 13286-2. Subsequently, the OMC value was implemented in the equation proposed by Wirtgen [

27] to estimate the mixing moisture content:

where

,

, and

represent the water content that should be added to the sample, the OMC, and the moisture content in the air-dried sample, respectively, expressed in percentage by mass.

The bitumen foaming phenomenon can be described by means of two main parameters, namely half-life (HL) and expansion ratio (ER) [

25,

26,

27,

28,

29,

30,

31,

32,

33], which are generally inversely proportional. According to Wirtgen Cold Recycling Manual [

27], and by means of Wirtgen WLS S10 foaming equipment, the foaming water content (FWC) that maximized the aforementioned bitumen’s foaming properties was determined by performing multiple tests repeated under various operating settings. Since a variation in FWC results in opposing effects on ER and HL (directly proportional to ER and inversely proportional to HL), the best FWC value was identified as the average between the FWC values that resulted in the lowest ER and HL.

2.2. Specimens Preparation and Mechanical Characterization

Wirtgen WLB S10 laboratory foaming equipment was used to inject both air and water into the hot bitumen. By means of a Hobart mixer, foamed bitumen was mixed with the aggregates for one minute, and the resulting mixtures were then compacted using 75 Marshall blows for each side of the cylindrical specimens [

27]. All foamed bitumen mixture specimens, after being cured for 24 h at room temperature, were aged at 40 °C in an oven for 3 days [

29,

30,

32,

33,

34]. With respect to the optimization of the foamed bitumen content (FBC), previous studies in the literature suggest different methodologies to carry out such an evaluation [

26,

28,

31,

35,

36,

37]. In this study, it was decided to estimate the optimum binder content following the indirect tensile strength (ITS) tests-based approach.

ITS values were evaluated at 25 °C, following the technical specifications reported in the standard EN 12697-23, on both dry and wet specimens. The latter were conditioned by soaking in water at 25 °C for 24 h before testing [

26,

28,

29,

32,

37]. The minimum FBC that provided the required minimum dry ITS value, according to ANAS acceptance requirements, was identified as optimal.

The stiffness properties of different mixtures were determined by performing indirect tensile stiffness modulus (ITSM) tests on Marshall specimens, following Annex C of EN 12697-26, at a temperature of 25 °C, with a rise time of 124 ms.

Finally, fatigue cracking resistance tests were performed at the reference temperature of 20 °C by means of repeated indirect tensile fatigue tests (ITFTs), following the British Standard Draft for development DD ABF. Similar to the ITSM protocol, the same cylindrical specimens, wave shape, and rise time were used. However, tests were carried out until sample failure or, alternatively, until a 10 mm deformation along the loading axis was reached. Furthermore, for the ITFT the stress-control procedure was used, instead of the strain-control approach typical of the ITSM test. The stress level adopted for the ITFTs was equal to 300 kPa, which has been verified as appropriate for a road foundation layer material [

38].

3. Results and Discussion

3.1. Bitumen and Aggregates Analysis

A penetration of 82 dmm at 25 °C was shown by the foamed bitumen under analysis. With respect to a foaming temperature equal to 180 °C and an optimal water content equal to 3%, HL and ER were found equal to 87 s and 18, respectively. These values are significantly higher than the recommended minimum thresholds of 16 s and 8 [

27], and suggest that an adequately large time is available for aggregate mixing operations. According to EN 12697-1, RAP material presents a bitumen content of 4.9% (by weight of the aggregate). Penetration (EN 1426) and Ring and Ball method (EN 1427) tests on such bitumen resulted in 9 dmm and 75 °C, respectively. These results highlight how aged and hard the bitumen of the RAP material was. In regard to the other waste materials investigated, they can be classified as non-harmful and non-hazardous according to Italian standards. The pH corresponding to the different industrial waste materials is shown in

Figure 1.

The results of the toxicological tests performed on the different industrial waste materials considered in this research are presented in

Table 1. The results show significantly different heavy metal concentrations. Specifically, EAF slags were characterized by the highest amount of thallium and total chromium; LF slags showed an intermediate content of all the heavy metals analyzed; MSWI ash was the richest in terms of lead; CF ash was characterized by the highest concentrations of cadmium, nickel, selenium, arsenic, and beryllium; whereas GW slags were characterized by the highest quantities of copper and zinc.

The findings of the leaching tests conducted on the industrial waste materials considered in the investigation are shown in

Table 2. It may be noted that all heavy metal concentrations are lower than the legal thresholds set by Italian law (Legislative Decree 152/2006). Since no toxicological issues were found for any of the waste materials, it was decided not to proceed further with chemical analysis on the foamed bitumen mixtures.

The aggregates’ physical and mechanical characterization, along with the reference technical standards, are reported in

Table 3. Based on the percentages of equivalent in sand, it can be observed that all waste materials are characterized by a cleanliness level well above the threshold level set by the ANAS specification, i.e., 30%. The EAF and LF slag particles, along with those of RAP and MSWI, present a cubic shape, confirmed by the low values of both shape and flakening indexes. Such a particle property is very advantageous since it provides a significant interlocking effect between the grains composing the aggregate structure of the foamed bitumen mixtures. This is not true for the GW particles, which presented high values of the flakening index, with particularly flat and elongated grain shapes. These properties potentially cause problems during the compaction operations, and, therefore, the maximum amount of such aggregates was fixed at 40%.

With respect to the Los Angeles test, a good result was achieved by the EAF slags, which, with a value of 19%, showed excellent abrasion and friction resistance. This value is fully satisfactory according to ANAS specification requirements, which are fixed at 30%. Conversely, RAP showed values still below the ANAS requirements, but with a far smaller margin. As expected and largely reported in the literature [

39,

40,

41,

42,

43,

44,

45], the particle density of the EAF slags was much higher than that of the other aggregates.

Figure 2 and

Figure 3 show the results of the particle size analysis conducted on the aggregates, whether recycled or virgin, in accordance with EN 933-1. A substantially continuous curve can be observed for recycled aggregate from LF slags, MSWI and RAP. Conversely, the aggregates deriving from EAF slags and GW are characterized by discontinuous curves. It can also be seen that CF ash presents very fine particles, to the point that it could be compared to an artificial filler from the point of view of grain size.

3.2. Grading and Composition of the Mixtures

The different compositions of the five mixtures entirely composed of waste materials, along with the composition of the LS control mixture, are described analytically and graphically in

Table 4 and

Figure 4, respectively. Values represent the percentage by weight of the aggregate.

Percentages of EAF and LF slags, as well as RAP and CF ash, were kept constant within the five different mixtures. Conversely, different percentages of MSWI ash and GW completed the aggregate structure and were used to evaluate their influence on the mechanical behavior of the foam bitumen-bound mixtures. EAF slags were used at a percentage of 20% to provide a relatively high amount of aggregate characterized by good physical and mechanical properties. According to

Table 3, both the morphological characteristics (shape and flakening index) and mechanical resistance (Los Angeles coefficient) of LF slags are lower than those of EAF slags; for this reason, the percentage of LF slags was fixed at 10%. RAP was included at 20% because of its useful particle size distribution. The percentage of CF ash was fixed at 10% for all mixtures, in order to meet the requirement for proper filler amount, and to ensure effective dispersion of the foamed bitumen, thus guaranteeing the good mechanical performance of the mixtures. The low cost of GW and MSWI ash makes mixtures containing such waste materials economically competitive. For this reason, their content was varied, while maintaining an overall percentage of both waste materials equal to 40%. Specifically, the percentage of MSWI started from 0% (Mix 1), and progressively increased by 10% up to Mix 5. Conversely, the GW content started from 40% (Mix 1) and progressively decreased by 10% up to Mix 5. It is worth underlining that, within the field of pavement engineering, the possibility of the combined utilization of different waste materials to prepare a mixture is a very positive technological aspect. In fact, it allows mixtures to be prepared even when there is a temporary low availability of glass waste, rather than MSWI ash.

3.3. Proctor Test Results

According to the methods described in EN 13286-2, the OMC was evaluated by means of a modified Proctor test; the results are presented in

Table 5. Since GW particles present higher density than MSWI ash ones, mixtures containing larger quantities of GW are characterized by higher values of dry density. The Proctor investigation involved 12 specimens (three replicates for four water contents) for each mix, resulting in a total of 72 specimens.

3.4. Indirect Tensile Strength Test Results

Table 6 shows the results of the indirect tensile strength tests for both dry and water soaked specimens. In addition, the tensile strength ratio (TSR), defined as the ratio between ITS soaked and ITS dry, is also presented for each mixture. ITS investigation involved nine specimens (three replicates for three foamed bitumen contents) for each mix, resulting in a total of 54 specimens for dry conditions and 54 specimens for soaked conditions.

ANAS technical specifications considered in the research require a minimum ITS dry value of 0.32 MPa; it can be observed that all the five mixtures fully composed of recycled aggregates presented ITS dry values above the acceptance threshold, for a foamed bitumen percentage of 2%. As a result, the optimum FBC value was found to be 2% by mass for all the mixtures. Such a percentage is also the lowest one used in the experimental investigation. Bowering and Martin [

46] proposed acceptance requisites in terms of dry ITS and TSR, fixed at 0.2 MPa and 50%, respectively; it can be appreciated that even these minimum thresholds have been overcome, therefore denoting an adequate moisture resistance of the foamed bitumen mixtures under investigation. Furthermore, all of them have shown ITS improvements in comparison with the LS control mixture, in a range of 43 to 121%, based on the specific composition analyzed. This is also verified in terms of ITS soaked, for which the difference is even greater (176% between Mix 3 and LS). These results are probably due to the high roughness of the metallurgical slags, which is an ideal condition to allow the development of a strong adhesion with the binder to allow the affinity of the RAP grains’ surface with the bitumen, and finally, for the benefits related to the use of a high amount of filler, namely coal ash, which provides a good dispersion of the foamed bitumen during the mixing phase. Focusing on the impact that GW and MSWI percentages have on ITS values, the best results are obtained for GW and MSWI percentages, both equal to 20%. Both Mix 1 (prepared with GW only) and Mix 5 (prepared with MSWI only) recorded lower ITS values than Mix 3. The smooth surface of the glass wastes (with respect to the other recycled aggregates considered) and the tendency of the MSWI ash to absorb bitumen [

47] represent critical characteristics that must be carefully balanced in the mix design, with the use of an intermediate amount of both the materials.

3.5. Stiffness Modulus and Fatigue Test Results

Table 7 summarizes the results of the ITSM tests performed on the mixtures prepared with the optimal FBC. Dry condition moduli ranged from 2468 MPa of the LS control mix to 6171 MPa of Mix 3, therefore showing satisfactory results given the alternative mix compositions. These moduli values are comparable to those of asphalt concretes analyzed by the authors under the same test conditions [

47]. ITSM tests were performed on 18 specimens, with three replicates for each mix prepared with the identified optimum binder content. Subsequently, ITFTs were performed on the same specimens.

The previous considerations about the influence of GW and MSWI percentages on the mixtures’ performance are also confirmed herewith regard to the ITSM values; the highest ITSM values are recorded for Mix 3. This mixture also reported the best results for the ITFT tests. Furthermore, for the mixtures containing the highest MSWI ash percentages (Mix 4 and Mix 5), the number of cycles to failure was significantly reduced by more than half. The fatigue investigation shows an even larger performance gap, and allows for a more detailed understanding of the analyzed mixtures’ mechanical behavior, even if only one stress level has been used.

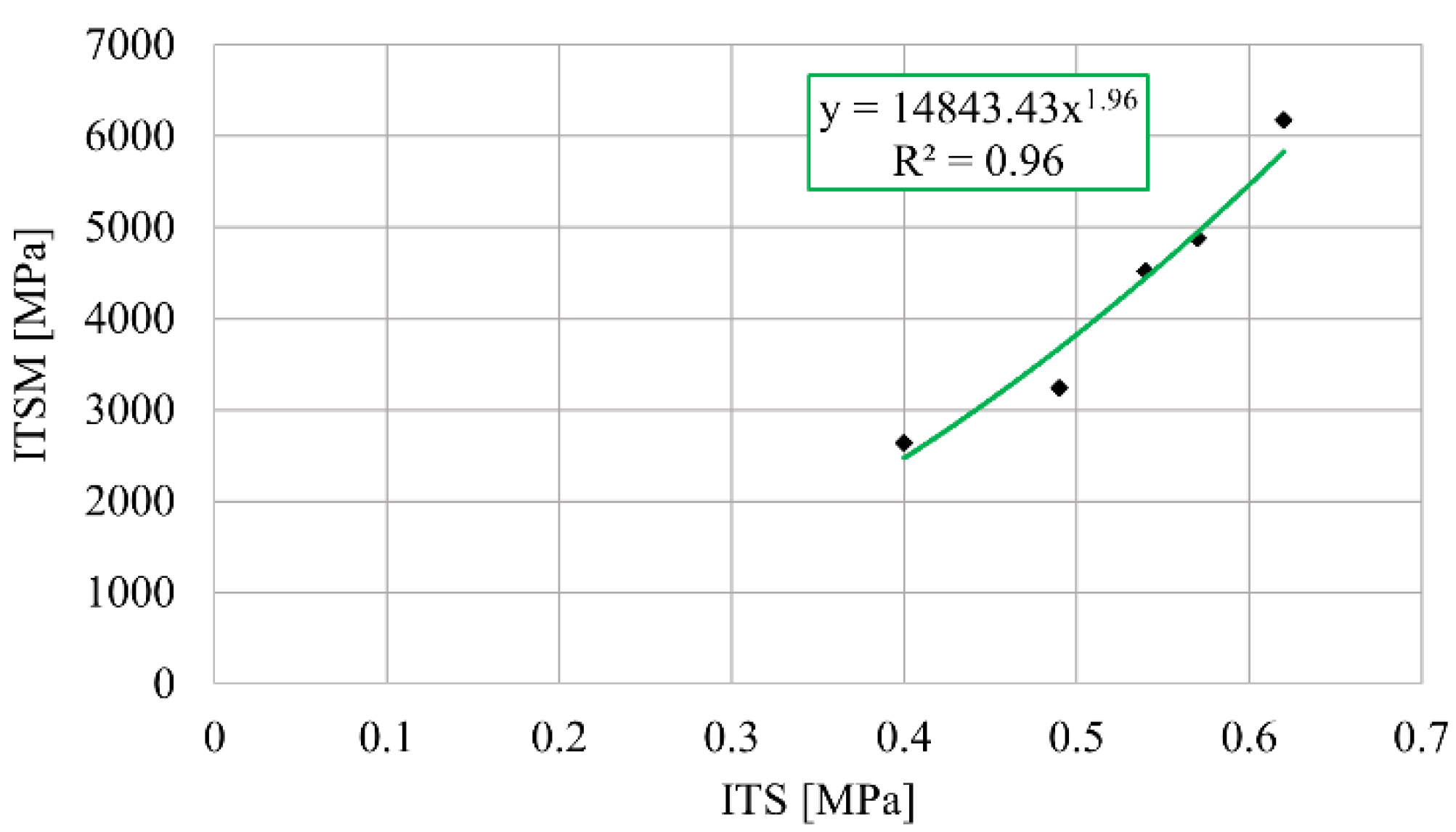

The correlation between the experimental values of ITSM and ITS recorded under dry conditions at a temperature of 25 °C was expressed by means of a power function, shown in

Figure 5. This resulted in an extremely good coefficient of determination equal to 0.96. Therefore, the possibility to establish a reliable relationship between the two key engineering parameters considered has been experimentally verified, confirming previous studies related to this aspect [

26,

38,

48].

4. Conclusions

The recycled aggregates analyzed, namely EAF slags, LF slags, MSWI ash, CF ash, GW, and RAP, resulted in physical and mechanical characteristics that can be compared to those of conventional virgin stone materials utilized in road constructions, without any hazard of heavy metals leaching.

The mix design was driven by the ITS test, and fully achieved all the technical requirements set by Italian reference standards for foamed bitumen mixtures prepared using only recycled aggregates, in different proportions, at 2% of both cement and foamed bitumen.

Laboratory test findings are fully satisfactory, especially for Mix 3 (20% of both GW and MSWI ash), which showed an ITS dry value equal to 0.62 MPa.

All the optimized foamed mixtures demonstrated adequate durability in terms of low moisture damage expressed by TSR.

Focusing on GW and MSWI ash, it can be concluded that the former leads to foamed bitumen mixtures characterized by better performance in terms of ITS, ITSM, and ITFTs. All these tests provided consistent results regarding the ranking of the investigated mixtures, with Mix 3 always achieving the best results.

Finally, fatigue investigations gave the possibility to observe, in terms of performance, significant variations between the behaviors of the investigated mixtures that were not easily detectable based on ITS and ITSM tests. For this reason, within the mix design process, it is recommended to combine the classical ITS procedures with fatigue tests in order to improve the mix optimization. The determination of the stiffness modulus alone, although it is very useful for the characterization of the mixtures’ mechanical behavior, does not provide the comprehensive evaluation expressed by fatigue tests.

Author Contributions

Conceptualization, N.B. and M.P.; methodology, N.B.; formal analysis, N.B., F.R. and M.P.; investigation, N.B. and M.P.; resources, M.P.; data curation, N.B.; writing—original draft preparation, N.B., F.R. and M.P.; writing—review and editing, N.B., F.R., F.D. and M.P.; visualization, F.R. and F.D.; supervision, N.B. and M.P.; project administration, N.B. and M.P.; funding acquisition, M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kibert, C.J. The next generation of sustainable construction. Build. Res. Inf. 2007, 35, 595–601. [Google Scholar] [CrossRef]

- Udomsap, A.; Hallinger, P. A bibliometric review of research on sustainable construction. J. Clean Prod. 2020, 254, 120073. [Google Scholar] [CrossRef]

- Mavi, R.K.; Gengatharen, D.; Mavi, N.K.; Hughes, R.; Campbell, A.; Yates, R. Sustainability in construction projects: A systematic literature review. Sustainability 2021, 13, 1932. [Google Scholar] [CrossRef]

- Zhang, Y.; Korkiala-Tanttu, L.K.; Gustavsson, H.; Miksic, A. Assessment for sustainable use of quarry fines as pavement construction materials: Part I-description of basic quarry fine properties. Materials 2019, 12, 1209. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muthen, K.M. Foamed Asphalt Mixes Mix Design Procedure. Transp. Res. Rec. 1998, 898, 290–296. [Google Scholar]

- Lesueur, D.; Clech, H.; Brosseaud, A.; Such, C.; Cazacliu, B.; Koenders, B.; Cérino, P.J.; Bonvallet, J. Foamed Bitumen: Foamability and Foam Stability. Road Mater. Pavement. Des. 2004, 5, 277–302. [Google Scholar] [CrossRef]

- Abreu, L.; Oliveira, J.R.M.; Silva, H.M.R.D.; Palha, D.; Fonseca, P.V. Suitability of different foamed bitumens for warm mix asphalts with increasing recycling rates. Constr. Build Mater. 2017, 142, 342–353. [Google Scholar] [CrossRef]

- Dinis-Almeida, M.; Afonso, M.L. Warm Mix Recycled Asphalt—A sustainable solution. J. Clean. Prod. 2015, 107, 310–316. [Google Scholar] [CrossRef]

- Csanyi, L.H. Foamed Asphalt in Bituminous Paving Mixtures. Highw. Res Board. Bull. 1957, 160, 108–122. [Google Scholar]

- Ramanujam, J.; Jones, J.; Janosevic, M. Design, Construction and Performance of Insitu Foamed Bitumen Stabilised Pavements. Queensl. Roads 2009, 7, 56–69. [Google Scholar]

- Ramanujam, J.M.; Jones, J.D. Characterization of foamed-bitumen stabilisation. Int. J. Pavement. Eng. 2007, 8, 111–122. [Google Scholar] [CrossRef]

- Theyse, H. First Level Analysis Report: HVS Testing of the Foamed-Bitumen-Treated Crushed Stone Base on the Slow Lane of the Southbound Carriageway of the N7 near Cape Town; Contract Report CR-2003/23; CSIR Transportek: Pretoria, South Africa, 2004. [Google Scholar]

- Loizos, A.; Papavasiliou, V. Evaluation of Foamed Asphalt Cold In-Place Pavement Recycling Using Nondestructive Techniques. J. Transp. Eng. 2006, 132, 970–978. [Google Scholar] [CrossRef]

- Romanoschi, S.A.; Hossain, M.; Heitzman, M.; Way, L. Foamed Asphalt Stabilized Reclaimed Asphalt Pavement: A Promising Technology for Mid-Western Roads. In Proceedings of the Mid-Continent Transportation Research Symposium, Ames, Iowa, 21–22 August 2003. [Google Scholar]

- He, Z.; Lu, W. Research on the Properties of Road Building Materials Treated with Foamed Bitumen in China. In Proceedings of the 8th Conference on Asphalt Pavements for Southern Africa, Sun City, South Africa, 12–16 October 2004; pp. 2–9. [Google Scholar]

- He, G.; Wong, W. Decay properties of the foamed bitumens. Constr. Build. Mater. 2006, 20, 866–877. [Google Scholar] [CrossRef]

- Kowalska, A.C.; Maciejewski, K. Performance and viscoelastic assessment of high-recycle rate cold foamed bitumen mixtures produced with different penetration binders for rehabilitation of deteriorated pavements. J. Clean. Prod. 2020, 258, 120517. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Comparative performance analysis of bituminous mixtures with EAF steel slags: A laboratory evaluation. In Proceedings of the 2008 Global Symposium on Recycling, Waste Treatment and Clean Technology, REWAS 2008, Cancun, Mexico, 12–15 October 2008; pp. 565–570. [Google Scholar]

- Istituto Superiore per la Protezione e la Ricerca Ambientale (ISPRA). Rapporto Rifiuti Urbani; ISPRA: Roma, Italy, 2020. [Google Scholar]

- Brunner, P.H.; Rechberger, H. Waste to energy—Key element for sustainable waste management. Waste Manag. 2015, 37, 3–12. [Google Scholar] [CrossRef]

- Nyale, S.M.; Babajide, O.O.; Birch, G.D.; Böke, N.; Petrik, L.F. Synthesis and characterization of coal fly ash-based foamed geopolymer. Procedia Environ. Sci. 2013, 18, 722–730. [Google Scholar] [CrossRef] [Green Version]

- Rondi, L.; Bregoli, G.; Sorlini, S.; Cominoli, L.; Collivignarelli, C.; Plizzari, G. Concrete with EAF steel slag as aggregate: A comprehensive technical and environmental characterisation. Compos. B Eng. 2016, 90, 195–202. [Google Scholar] [CrossRef]

- Pantini, S.; Borghi, G.; Rigamonti, L. Towards resource-efficient management of asphalt waste in Lombardy region (Italy): Identification of effective strategies based on the LCA methodology. Waste Manag. 2018, 80, 423–434. [Google Scholar] [CrossRef]

- ESTAT, Statistical Office of the European Communities. Environmental Statistics and Accounts in Europe; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Jenkins, K.; Molenaar, A.A.A.; De Groot, L.L.A.; Van de Ven, M.F.C. Developments in the uses of foamed bitumen in road pavements. Heron 2000, 45, 167–176. [Google Scholar]

- Wirtgen, G.M.B.H. Wirtgen Cold Recycling Manual, 2nd ed.; Wirtgen: Windhagen, Germany, 2004. [Google Scholar]

- Hodgkinson, A.; Visser, A.T. The role of fillers and cementitious binders when recycling with foamed bitumen or bitumen emulsion. In Proceedings of the 8th Conference on Asphalt Pavements for Southern Africa, Sun City, South Africa, 12–16 October 2004. [Google Scholar]

- Kim, Y.; Lee, H.D. Validation of new mix design procedure for cold in-place recycling with foamed asphalt. J. Mater. Civ. Eng. 2006, 18, 116–124. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, H.D. Development of mix design procedure for cold in-place recycling with foamed asphalt. J. Mater. Civ. Eng. 2007, 19, 1000–1010. [Google Scholar] [CrossRef]

- Ebels, L.J.; Jenkins, K. Mix design of bitumen stabilized materials: Best practice and considerations for classification. In Proceedings of the 9th Conference on Asphalt Pavements for Southern Africa, Gaborone, Botswana, 2–5 September 2007. [Google Scholar]

- He, G.P.; Wong, W.G. Laboratory study on permanent deformation of foamed asphalt mix incorporating reclaimed asphalt pavement materials. Constr. Build. Mater. 2007, 21, 1809–1819. [Google Scholar] [CrossRef]

- Sunarjono, S. Tensile strength and stiffness modulus of foamed asphalt applied to a grading representative of Indonesian road recycled pavement materials. Dinamika Teknik Sipil 2007, 7, 1–10. [Google Scholar]

- He, G.P.; Wong, W.G. Effects of moisture on strength and permanent deformation of foamed asphalt mix incorporating RAP materials. Constr Build Mater 2008, 22, 30–40. [Google Scholar] [CrossRef]

- Sunarjono, S.; Zoorob, S.E.; Thom, N.H. Influence of foaming water on the foaming process and resultant asphalt mix stiffness. In Proceedings of the 4th International SIIV Congress, Palermo, Italy, 12–14 September 2007. [Google Scholar]

- Ebels, L.J.; Jenkins, K. Characterization of bitumen stabilized granular pavement materials properties using tri-axial testing. In Proceedings of the Advanced Characterization of Pavement and Soil Engineering Materials, Athens, Greece, 20–22 June 2007. [Google Scholar]

- Jenkins, K.J.; Twagiraa, M.E.; Kelfkensa, R.W.; Mulusaa, W.K. New laboratory testing procedures for mix design and classification of bitumen-stabilised materials. Road Mater. Pavement Design 2012, 13, 618–641. [Google Scholar] [CrossRef]

- Mallick, R.B.; Hendrix, G. Use of foamed asphalt in recycling incinerator ash for construction of stabilized base course. Resour Conserv Recycl 2004, 42, 239–248. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Foamed bitumen bound mixtures made with marginal aggregates: An experimental study. In Sustainability, Eco-Efficiency and Conservation in Transportation Infrastructure Asset Management—Proceedings of the 3rd International Conference on Transportation Infrastructure, ICTI 2014, Pisa, Italy, 22–25 April 2014; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Recycling of steel slags in road foundations. Environ. Eng. Manag. J. 2010, 9, 773–777. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Electric Arc Furnace Steel Slags in “High Performance” Asphalt Mixes: A Laboratory Characterisation; MS Fall Extraction and Processing Division: Sohn International Symposium, San Diego, CA, USA, 2006. [Google Scholar]

- Hosseinzadeh, N.; Rezaei, M.J.; Hosseini, S.M. Investigation and Performance Improvement of Hot Mix Asphalt Concrete Containing EAF Slag. Int. J. Eng. Tech. 2016, 8, 260–264. [Google Scholar] [CrossRef] [Green Version]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Evaluation of asphalt mixtures incorporating electric arc furnace steel slag and copper mine tailings for road construction. Transp. Geotech. 2015, 2, 47–55. [Google Scholar] [CrossRef]

- Yonar, F.; Cokgor, E.U.; Dikbas, H.A.; Demir, B.; Ergun, M. Environmental Effects and Possible Highway Applications of Electric Arc Furnace Slag in Turkey. In Proceedings of the World Congress on New Technologies (NewTech 2015), Barcelona, Spain, 15–17 June 2015; pp. 1–10. [Google Scholar]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Characteristics and Utilization of Steel Slag in Road Construction. J. Teknologi. 2014, 70, 117–123. [Google Scholar] [CrossRef] [Green Version]

- Hainin, M.R.; Aziz, M.M.A.; Shokri, M.; Jaya, R.P.; Hassan, N.A.; Ahsan, A. Performance of Steel Slag in Highway Surface Course. J. Teknologi. 2014, 71, 99–102. [Google Scholar] [CrossRef] [Green Version]

- Bowering, R.H.; Martin, C.L. Foamed bitumen production & application of mixed evaluation & performance of pavements. J. Assoc. Asph. Paving Technol. 1976, 45, 453–477. [Google Scholar]

- Pasetto, M.; Baldo, N. Laboratory Evaluation of Bituminous Mixtures with Bottom Ash from Municipal Solid Waste Incineration (Mswi). In Proceedings of the 2008 Global Symposium on Recycling, Waste Treatment and Clean Technology, REWAS 2008, Cancun, Mexico, 12–15 October 2008; pp. 571–576. [Google Scholar]

- Pasetto, M.; Baldo, N. Laboratory investigation on foamed bitumen bound mixtures made with steel slag, foundry sand, bottom ash and reclaimed asphalt pavement. Road Mater. Pavement Design 2012, 13, 691–712. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).