Taguchi Loss Function in Intuitionistic Fuzzy Sets along with Personal Perceptions for the Sustainable Supplier Selection Problem

Abstract

:1. Introduction

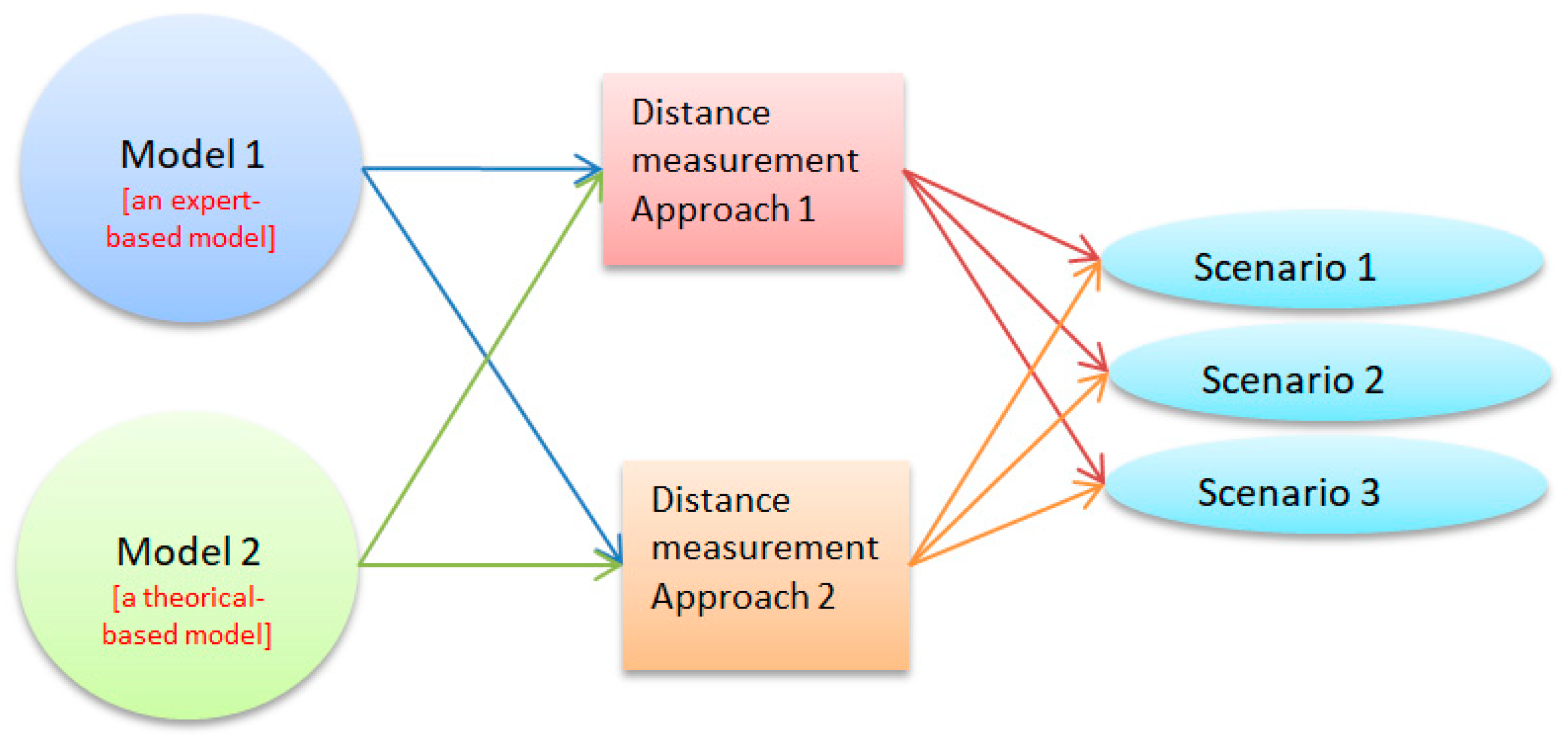

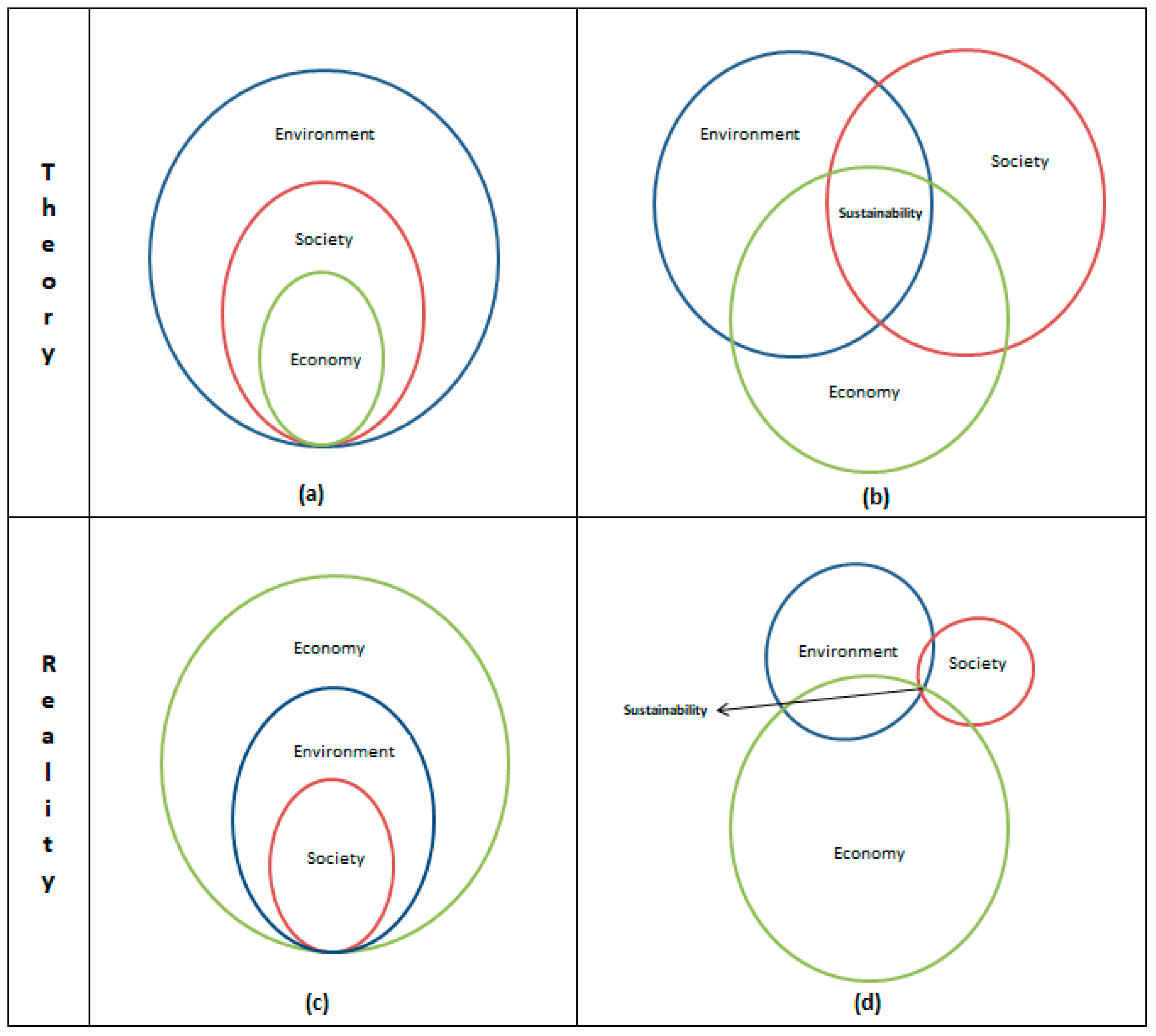

- Compare theory and reality of sustainability.

- Investigate personal perceptions of decision makers to tackle negative effects on evaluations of suppliers using eight criteria related to personal perception.

- Find the best sustainable supplier considering six main criteria and seventeen sub-criteria determined by three decision makers.

- Provide an alternative way to calculate the distance between ideal positive and negative of intuitionistic fuzzy sets using the Taguchi loss function.

- Validate the proposed distance measurement approach, comparing Taguchi loss function with the intuitionistic fuzzy normalised Euclidean distance.

2. Background

2.1. Applications on Sustainable Supplier Selection

2.2. Applications on Personal Perception

3. Material and Methods

3.1. Intuitionistic Fuzzy Sets

3.2. Definition of Criteria

3.3. Problem Statement

- For the second scenario, in order to assign the weight of each decision maker, eight criteria related to the personal perception are used. The linguistic terms and their corresponding intuitionistic fuzzy numbers shown in Table 5 are used to calculate their weights. It is assumed that the importance of each criterion is equal and Equation (11) is applied to calculate the decision makers ‘weights for each criterion to achieve the mean score for each decision maker. These scores are averaged and are assigned as the weights of the decision makers.

- For the third scenario, it is assumed that the weights of all decision makers are equal to each other, and the sum of their weight is equal to 1.

3.4. Notations

4. Preliminary Experiments and Results

4.1. Application of the Method Proposed

- For the first scenario, the linguistic evaluation of decision makers is performed assigning ‘Very important’ (VI) for the first decision maker (DM1), ‘Important’ (I) for the second decision maker (DM2) and ‘Medium’ (M) for the third decision maker (DM3). Equation (7) is used to calculate their weights, and they are found to be 0.38, 0.35 and 0.27, respectively.

- For the second scenario, decision makers are examined in terms of eight criteria, as shown in Table 7. Decision makers’ weights are calculated using Equation (7) for each decision maker, and the mean value is taken as a weight for each decision maker. It is found that the weight of DM1 is 0.32, the weight of DM2 is 0.40, and the weight of DM3 is 0.29.

- For the third scenario, their weights are defined equally as 0.33, 0.33 and 0.33 in the same sequence.

4.2. Results and Comparative Analysis

5. Discussion

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jamwal, A.; Agrawal, R.; Sharma, M.; Kumar, V.; Kumar, S. Developing a sustainability framework for industry 4.0. In Proceedings of the 28th CIRP Conference on Life Cycle Engineering, Jaipur, India, 10–12 March 2021; Volume 98, pp. 430–435. Available online: https://www.sciencedirect.com/science/article/pii/S2212827121001591 (accessed on 10 December 2021).

- Satyro, W.C.; de Mesquita Spinola, M.; de Almeida, C.M.B.; Giannetti, B.F.; Sacomano, J.B.; Contador, J.C.; Contador, J.L. Sustainable industries: Production planning and control as an ally to implement strategy. J. Clean. Prod. 2021, 281, 124781. [Google Scholar] [CrossRef]

- Dawe, N.K.; Ryan, K.L. The faulty three-legged-stool model of sustainable development. Conserv. Biol. 2003, 17, 1458–1460. [Google Scholar] [CrossRef]

- Patel, V.; Pauli, N.; Biggs, E.; Barbour, L.; Boruff, B.J. Why bees are critical for achieving sustainable development. Ambio 2020, 50, 49–59. [Google Scholar] [CrossRef] [Green Version]

- Dushenko, M.; Thærie Bjorbæk, C.; Steger-Jensen, K. Application of a sustainability model for assessing the relocation of a container terminal: A case study of kristiansand port. Sustainability 2019, 11, 87. [Google Scholar] [CrossRef] [Green Version]

- Turk, S.; Miller, S.; Ozcan, E.; John, R. A simulated annealing approach to supplier selection aware inventory planning. In Proceedings of the 2015 IEEE Congress on Evolutionary Computation (CEC), Sendai, Japan, 25–28 May 2015; pp. 1799–1806. [Google Scholar] [CrossRef] [Green Version]

- Schramm, V.B.; Cabral, L.P.B.; Schramm, F. Approaches for supporting sustainable supplier selection—A literature review. J. Clean. Prod. 2020, 273, 123089. [Google Scholar] [CrossRef]

- Zadeh, L. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef] [Green Version]

- Taguchi, G. System of Experimental Design: Engineering Methods to Optimize Quality and Minimize Costs, 1st ed.; UNIPUB/Kraus International Publications: Dearborn, MI, USA, 1987. [Google Scholar]

- Liao, C.-N.; Kao, H.-P. Supplier selection model using taguchi loss function, analytical hierarchy process and multichoice goal programming. Comput. Ind. Eng. 2010, 58, 571–577. [Google Scholar] [CrossRef]

- Sivakumar, R.; Kannan, D.; Murugesan, P. Green vendor evaluation and selection using ahp and taguchi loss functions in production outsourcing in mining industry. Resour. Policy 2015, 46, 64–75. [Google Scholar] [CrossRef]

- Kumar, R.; Padhi, S.S.; Sarkar, A. Supplier selection of an indian heavy locomotive manufacturer: An integrated approach using taguchi loss function, topsis, and ahp. IIMB Manag. Rev. 2019, 31, 78–90. [Google Scholar] [CrossRef]

- Shojaei, P.; Seyed Haeri, S.A.; Mohammadi, S. Airports evaluation and ranking model using taguchi loss function, best-worst method and vikor technique. J. Air Transp. Manag. 2018, 68, 4–13. [Google Scholar] [CrossRef]

- Blessley, M.; Mir, S.; Zacharia, Z.; Aloysius, J. Breaching relational obligations in a buyer-supplier relationship: Feelings of violation, fairness perceptions and supplier switching. Ind. Mark. Manag. 2018, 74, 215–226. [Google Scholar] [CrossRef]

- Roy, S.A.; Ali, S.M.; Kabir, G.; Enayet, R.; Suhi, S.A.; Haque, T.; & Hasan, R. A framework for sustainable supplier selection with transportation criteria. Int. J. Sustain. Eng. 2020, 13, 77–92. [Google Scholar] [CrossRef]

- Hsu, C.-W.; Hu, A.H. Applying hazardous substance management to supplier selection using analytic network process. J. Clean. Prod. 2009, 17, 255–264. [Google Scholar] [CrossRef]

- Amindoust, A.; Ahmed, S.; Saghafinia, A.; Bahreininejad, A. Sustainable supplier selection: A ranking model based on fuzzy inference system. Appl. Soft Comput. 2012, 12, 1668–1677. [Google Scholar] [CrossRef]

- Ahmadi, H.B.; Petrudi, S.H.H.; Wang, X. Integrating sustainability into supplier selection with analytical hierarchy process and improved grey relational analysis: A case of telecom industry. Int. J. Adv. Manuf. Technol. 2017, 90, 2413–2427. [Google Scholar] [CrossRef]

- Shalke, P.N.; Paydar, M.M.; Hajiaghaei-Keshteli, M. Sustainable supplier selection and order allocation through quantity discounts. Int. J. Manag. Sci. Eng. Manag. 2018, 13, 20–32. [Google Scholar]

- Abdel-Basset, M.; Mohamed, M.; Smarandache, F. A hybrid neutrosophic group anp-topsis framework for supplier selection problems. Symmetry 2018, 10, 226. [Google Scholar] [CrossRef] [Green Version]

- Memari, A.; Dargi, A.; Akbari Jokar, M.R.; Ahmad, R.; Abdul Rahim, A.R. Sustainable supplier selection: A multi-criteria intuitionistic fuzzy topsis method. J. Manuf. Syst. 2019, 50, 9–24. [Google Scholar] [CrossRef]

- Ecer, F.; Pamucar, D. Sustainable supplier selection: A novel integrated fuzzy best worst method (f-bwm) and fuzzy cocoso with bonferroni (cocoso’b) multi-criteria model. J. Clean. Prod. 2020, 266, 121981. [Google Scholar] [CrossRef]

- Chen, Z.; Ming, X.; Zhou, T.; Chang, Y. Sustainable supplier selection for smart supply chain considering internal and external uncertainty: An integrated rough-fuzzy approach. Appl. Soft Comput. 2020, 87, 106004. [Google Scholar] [CrossRef]

- Tayyab, M.; Sarkar, B. An interactive fuzzy programming approach for a sustainable supplier selection under textile supply chain management. Comput. Ind. Eng. 2021, 155, 107164. [Google Scholar] [CrossRef]

- Alavi, B.; Tavana, M.; Mina, H. A dynamic decision support system for sustainable supplier selection in circular economy. Sustain. Prod. Consum. 2021, 27, 905–920. [Google Scholar] [CrossRef]

- Joshi, R.; Kumar, S. A dissimilarity measure based on Jensen Shannon divergence measure. Int. J. Gen. Syst. 2019, 48, 280–301. [Google Scholar] [CrossRef]

- Hendiani, S.; Liao, H.; Ren, R.; Lev, B. A likelihood-based multi-criteria sustainable supplier selection approach with complex preference information. Inf. Sci. 2020, 536, 135–155. [Google Scholar] [CrossRef]

- Byrd, K.; Her, E.; Fan, A.; Almanza, B.; Liu, Y.; Leitch, S. Restaurants and COVID-19: What are consumers’ risk perceptions about restaurant food and its packaging during the pandemic? Int. J. Hosp. Manag. 2021, 94, 102821. [Google Scholar] [CrossRef]

- Truong, V.A.; Lang, B.; Conroy, D.M. Are trust and consumption values important for buyers of organic food? A comparison of regular buyers, occasional buyers, and non-buyers. Appetite 2021, 161, 105123. [Google Scholar] [CrossRef]

- Wang, X.-W.; Cao, Y.-M.; Zhang, N. The influences of incentive policy perceptions and consumer social attributes on battery electric vehicle purchase intentions. Energy Policy 2021, 151, 112163. [Google Scholar] [CrossRef]

- Long, Z.; Axsen, J.; Miller, I.; Kormos, C. What does tesla mean to car buyers? exploring the role of automotive brand in perceptions of battery electric vehicles. Transp. Res. Part A Policy Pract. 2019, 129, 185–204. [Google Scholar] [CrossRef]

- Nagel, D.M.; Giunipero, L.; Jung, H.; Salas, J.; Hochstein, B. Purchaser perceptions of early phase supplier relationships: The role of similarity and likeability. J. Bus. Res. 2021, 128, 174–186. [Google Scholar] [CrossRef]

- Aminoff, A.; Tanskanen, K. Exploration of congruence in perceptions of buyer–supplier attraction: A dyadic multiple case study. J. Purch. Supply Manag. 2013, 19, 165–184. [Google Scholar] [CrossRef]

- Oosterhuis, M.; Molleman, E.; van der Vaart, T. Differences in buyers’ and suppliers’ perceptions of supply chain attributes. Int. J. Prod. Econ. 2013, 142, 158–171. [Google Scholar] [CrossRef]

- Atanassov, K.T. Intuitionistic fuzzy sets. Fuzzy Sets Syst. 1986, 20, 87–96. [Google Scholar] [CrossRef]

- Szmidt, E.; Kacprzyk, J. Distances between intuitionistic fuzzy sets. Fuzzy Sets Syst. 2000, 114, 505–518. [Google Scholar] [CrossRef]

- Balan, S.; Sharma, S. An integrative supplier selection model using taguchi loss function, topsis and multi criteria goal programming. J. Intell. Manuf. 2013, 24, 1123–1130. [Google Scholar] [CrossRef]

- Kethley, R. Using taguchi loss functions to develop a single objective function in a multi-criteria context: A scheduling example. Int. J. Inf. Manag. Sci. 2008, 19, 589. [Google Scholar]

- Salminen, J.; Santos, J.M.; Kwak, H.; An, J.; Gyo Jung, S.; Jansen, B.J. Persona perception scale: Development and exploratory validation of an instrument for evaluating individuals’ perceptions of personas. Int. J. Hum. Comput. Stud. 2020, 141, 102437. [Google Scholar] [CrossRef]

- Abdolshah, M. A review of quality criteria supporting supplier selection. J. Qual. Reliab. Eng. 2013, 2013, 621073. [Google Scholar] [CrossRef] [Green Version]

- Taherdoost, H.; Brard, A. Analyzing the process of supplier selection criteria and methods. Procedia Manuf. 2019, 32, 1024–1034. [Google Scholar] [CrossRef]

- Karanth, R.; Karanth, Y.; Naranje, V.; Sankaram, M. Chapter five—Sustainable manufacturing of plastic packaging material: An innovative approach. In Sustainable Manufacturing and Design Woodhead Publishing Reviews: Mechanical Engineering Series; Kumar, K., Zindani, D., Davim, J.P., Eds.; Woodhead Publishing: Cambridge, UK, 2021; pp. 83–99. [Google Scholar]

- Mondal, K.; Pramanik, S. Intuitionistic fuzzy multicriteria group decision making approach to quality clay-brick selection problems based on grey relational analysis. J. Appl. Quant. Methods 2014, 9, 35–51. Available online: link.gale.com/apps/doc/A383330215/AONE?u=anon~f0a09bc3&sid=googleScholar&xid=aae5e425 (accessed on 1 May 2022).

- Türk, S.; Koç, A.; Şahin, G. Multi-criteria of PV solar site selection problem using GIS-intuitionistic fuzzy based approach in Erzurum province/Turkey. Sci. Rep. 2021, 11, 5034. [Google Scholar] [CrossRef]

- Pearson, K. Mathematical Contributions to the Theory of Evolution. III. Regression, Heredity, and Panmixia. Philos. Trans. R. Soc. Lond. Ser. A 1896, 187, 253–318. [Google Scholar] [CrossRef] [Green Version]

- Carter, C.; Easton, P. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Xiao, F. CaFtR: A Fuzzy Complex Event Processing Method. Int. J. Fuzzy Syst. 2022, 24, 1098–1111. [Google Scholar] [CrossRef]

- Joshi, R.; Kumar, S. A dissimilarity Jensen-Shannon divergence measure for intuitionistic fuzzy sets. Int. J. Intell. Syst. 2018, 33, 2216–2235. [Google Scholar] [CrossRef]

- Xiao, F. A Distance Measure for Intuitionistic Fuzzy Sets and Its Application to Pattern Classification Problems. IEEE Trans. Syst. Man Cybern. Syst. 2019, 51, 3980–3992. [Google Scholar] [CrossRef]

- Xie, D.; Xiao, F.; Pedrycz, W. Information Quality for Intuitionistic Fuzzy Values with Its Application in Decision Making. Eng. Appl. Artif. Intell. 2022, 109, 104568. [Google Scholar] [CrossRef]

| Sectors | Methods |

|---|---|

| Electronics industry [16] | Analytic Network Process (ANP) |

| Construction industry [17] | Fuzzy inference system |

| Telecommunication industry [18] | Combination of Grey Relational Analysis and AHP |

| Food packaging industry [19] | Multi-objective mathematical programming model along with TOPSIS |

| Dairy product manufacturer [20] | Integration of two methods: ANP and TOP-SIS |

| Auto side parts manufacturer [21] | Interval Type-2 Fuzzy set |

| Home appliance manufacturer [22] | Combined method of fuzzy best–worst method and fuzzy CoCoOn with Bonferroni |

| Vehicle transmission industry [23] | Integration of rough-fuzzy and TOP-SIS-DEMATEL |

| Textile industry [24] | Fuzzy multi-period multi-objective method |

| Petrochemical industry [25] | Fuzzy best–worst method with the fuzzy inference system |

| Producing transport vehicles [26] | Intuitionistic fuzzy dissimilarity measure |

| Authors | Enviromental Criteria | Social Criteria | Economic Criteria |

|---|---|---|---|

| [18] |

|

|

|

| [19] |

|

|

|

| [17] |

|

|

|

| [16] |

| NONE |

|

| [20] |

| NONE |

|

| [25] |

|

|

|

| [27] |

|

|

|

| [22] |

|

|

|

| [21] |

|

|

|

| Sectors | Authors | Methodology |

|---|---|---|

| Food safety | [28] | Survey to find out the risk perceptions of consumers during the COVID-19 pandemic. |

| Organic food | [29] | Interviews to analyze credibility effect on organic food consumption. |

| Battery-electric vehicle | [30] | Questionnaire to generate purchase intentions model under different hypotheses. |

| Battery-electric vehicle | [31] | Survey to assess consumer awareness of a particular car brand. |

| Buyer–supplier relationships | [32] | Survey to explore the role of similarity and likeability on buyer–supplier relationships. |

| Buyer–supplier interactions | [14] | Interviews to analyze supply chain professionals’ behaviors under different scenarios. |

| Buyer–supplier attraction | [33] | Interviews to explore how congruence in perceptions of attraction affects relationship success. |

| Supply chain attributes | [34] | Survey to explore dyadic buyer–supplier relationships and how attributes differ based on relations. |

| Criteria | Symbol | Sub-Criteria | Symbol |

|---|---|---|---|

| Quality | M1 | Quality control rejection rate; Customer rejection rate. | C1 C2 |

| Delivery | M2 | Delivery lead time; Delivery flexibility. | C3 C4 |

| Service Performance | M3 | Reliability; Empathy. | C5 C6 |

| Cost | M4 | Product price; Logistic cost. | C7 C8 |

| Environmental sustainability | M5 | Environmental efficiency; Green image; Pollution reduction; Green competencies. | C9 C10 C11 C12 |

| Social sustainability | M6 | Having OHSAS 18001 certification; Rate of health and safety incidents; Employee rights; Forced child labour; Staff training. | C13 C14 C15 C16 C17 |

| Linguistic Variables | IFNs (μ, ϑ, π) |

|---|---|

| Very important (VI) | (1, 0, 0) |

| Important (I) | (0.75, 0.20, 0.05) |

| Medium (M) | (0.50, 0.40, 0.10) |

| Unimportant (U) | (0.25, 0.60, 0.15) |

| Very unimportant (VU) | (0.10, 0.80, 0.10) |

| Notation | Meaning |

|---|---|

| Pi | The ith criterion to evaluate personal perception of decision makers where i = {1,…,8}. |

| Mj | The jth main criterion to evaluate suppliers where j = {1,…,6}. |

| Ck | The kth sub-criterion to evaluate suppliers where k = {1,…,16}. |

| The weight of the lth alternatives where where l = {1,2,3}. | |

| DMm | The mth decision maker |

| The global score of the kth sub-criterion where k = {1,…,17}. | |

| Importance of the kth sub-criterion where k = {1,…,17}. | |

| Performance of alternative m for the kth sub-criterion. | |

| Sn | The nth alternative (supplier). |

| The nth supplier for Scenario x. |

| Criterion | DM1 | DM2 | DM3 | Criterion | DM1 | DM2 | DM3 |

|---|---|---|---|---|---|---|---|

| P1 | VI | I | M | P5 | M | M | VI |

| P2 | VI | I | M | P6 | VI | I | VI |

| P3 | I | I | I | P7 | VI | M | M |

| P4 | VI | VI | VI | P8 | I | I | VI |

| Criterion | DM1 | DM2 | DM3 | Criterion | DM1 | DM2 | DM3 | Criterion | DM1 | DM2 | DM3 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | VI | VI | M | C3 | M | M | M | C11 | M | VI | I |

| M2 | VI | M | M | C4 | M | M | M | C12 | M | M | M |

| M3 | M | VI | M | C5 | VI | M | M | C13 | M | VI | U |

| M4 | VI | M | U | C6 | M | M | M | C14 | M | VI | VI |

| M5 | M | VI | M | C7 | VI | M | U | C15 | M | M | VI |

| M6 | M | M | M | C8 | VI | M | U | C16 | M | M | VI |

| C1 | M | VI | I | C9 | M | VI | M | C17 | M | M | VI |

| C2 | M | VI | I | C10 | M | M | M | - | - | - | - |

| Importance of Criteria | DM1 | DM2 | DM3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| μ | ϑ | π | μ | ϑ | π | μ | ϑ | π | |

| C1G | 0.50 | 0.40 | 0.10 | 1.00 | 0.00 | 0.00 | 0.38 | 0.52 | 0.11 |

| C2G | 0.50 | 0.40 | 0.10 | 1.00 | 0.00 | 0.00 | 0.38 | 0.52 | 0.11 |

| C3G | 0.50 | 0.40 | 0.10 | 0.25 | 0.64 | 0.11 | 0.25 | 0.64 | 0.11 |

| C4G | 0.50 | 0.40 | 0.10 | 0.25 | 0.64 | 0.11 | 0.25 | 0.64 | 0.11 |

| C5G | 0.50 | 0.40 | 0.10 | 0.50 | 0.40 | 0.10 | 0.25 | 0.64 | 0.11 |

| C6G | 0.25 | 0.64 | 0.11 | 0.50 | 0.40 | 0.10 | 0.25 | 0.64 | 0.11 |

| C7G | 1.00 | 0.00 | 0.00 | 0.25 | 0.64 | 0.11 | 0.06 | 0.84 | 0.10 |

| C8G | 1.00 | 0.00 | 0.00 | 0.25 | 0.64 | 0.11 | 0.06 | 0.84 | 0.10 |

| C9G | 0.25 | 0.64 | 0.11 | 1.00 | 0.00 | 0.00 | 0.25 | 0.64 | 0.11 |

| C10G | 0.25 | 0.64 | 0.11 | 0.50 | 0.40 | 0.10 | 0.25 | 0.64 | 0.11 |

| C11G | 0.25 | 0.64 | 0.11 | 1.00 | 0.00 | 0.00 | 0.38 | 0.52 | 0.11 |

| C12G | 0.25 | 0.64 | 0.11 | 0.50 | 0.40 | 0.10 | 0.25 | 0.64 | 0.11 |

| C13G | 0.75 | 0.20 | 0.05 | 0.50 | 0.40 | 0.10 | 0.13 | 0.76 | 0.12 |

| C14G | 0.25 | 0.64 | 0.11 | 0.50 | 0.40 | 0.10 | 0.50 | 0.40 | 0.10 |

| C15G | 0.25 | 0.64 | 0.11 | 0.25 | 0.64 | 0.11 | 0.50 | 0.40 | 0.10 |

| C16G | 0.25 | 0.64 | 0.11 | 0.25 | 0.64 | 0.11 | 0.50 | 0.40 | 0.10 |

| C17G | 0.25 | 0.64 | 0.11 | 0.25 | 0.64 | 0.11 | 0.50 | 0.40 | 0.10 |

| Criteria | DM1 | DM2 | DM3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| S1 | S2 | S3 | S1 | S2 | S3 | S1 | S2 | S3 | |

| M1 | VH | MH | MH | VH | MH | MH | VH | H | VH |

| M2 | H | H | MH | H | MH | VH | H | H | MH |

| M3 | VH | MH | VH | MH | MH | H | H | H | H |

| M4 | MH | MH | VH | MH | MH | VH | H | H | H |

| M5 | MH | H | H | MH | H | H | H | H | H |

| M6 | H | H | H | H | H | H | MH | H | H |

| C1 | H | VH | MH | MH | VH | VH | VH | VH | MH |

| C2 | VH | MH | MH | VH | VH | VH | VH | MH | MH |

| C3 | MH | H | VH | MH | H | VH | H | H | H |

| C4 | MH | H | VH | MH | H | VH | H | H | H |

| C5 | VH | VH | MH | MH | VH | H | H | H | H |

| C6 | MH | MH | MH | MH | MH | H | H | H | H |

| C7 | VH | MH | VH | MH | MH | VH | H | H | H |

| C8 | VH | MH | VH | MH | MH | VH | H | H | H |

| C9 | MH | H | H | MH | H | H | H | H | ML |

| C10 | H | H | H | H | H | H | MH | H | H |

| C11 | H | H | H | MH | H | H | MH | H | M |

| C12 | H | H | H | H | H | H | MH | H | M |

| C13 | VH | H | H | VH | H | MH | VH | H | H |

| C14 | H | H | H | H | H | H | H | MH | H |

| C15 | H | H | H | H | H | H | H | H | H |

| C16 | H | H | H | H | H | H | H | H | H |

| C17 | H | H | H | H | H | H | H | H | H |

| Decision Maker | S1 | S2 |

|---|---|---|

| DM1 | (0.64, 0.24, 0.13) | (0.55, 0.33, 0.12) |

| DM2 | (0.55, 0.33, 0.12) | (0.55, 0.33, 0.12) |

| DM3 | (0.72, 0.19, 0.09) | (0.64, 0.24, 0.13) |

| The Expert-Based Model | ||||||||

|---|---|---|---|---|---|---|---|---|

| Euclidean Distance | Taguchi Loss Function | |||||||

| Suppliers | Pos. Ideal | Neg. Ideal | Closeness Coefficent | Rank | Pos. İdeal | Neg. Ideal | Closeness Coefficent | Rank |

| S1Scenario1 | 0.73 | 0.29 | 0.2872 | 2 | 46.50 | 8.68 | 0.1573 | 2 |

| S2Scenario1 | 0.74 | 0.29 | 0.2849 | 3 | 45.97 | 8.57 | 0.1572 | 3 |

| S3Scenario1 | 0.72 | 0.31 | 0.2986 | 1 | 48.24 | 0.38 | 0.1628 | 1 |

| S1Scenario2 | 0.73 | 0.29 | 0.2864 | 3 | 46.40 | 8.63 | 0.1568 | 3 |

| S2Scenario2 | 0.73 | 0.30 | 0.2876 | 2 | 46.37 | 8.74 | 0.1586 | 2 |

| S3Scenario2 | 0.72 | 0.31 | 0.2992 | 1 | 48.32 | 9.42 | 0.1632 | 1 |

| S1Scenario3 | 0.74 | 0.29 | 0.2792 | 3 | 45.33 | 8.20 | 0.1532 | 3 |

| S2Scenario3 | 0.74 | 0.29 | 0.2803 | 2 | 45.25 | 8.30 | 0.1550 | 2 |

| S3Scenario3 | 0.73 | 0.30 | 0.2906 | 1 | 47.04 | 8.89 | 0.1589 | 1 |

| The Theorical-Based Model | ||||||||

| Euclidean Distance | Taguchi Loss Function | |||||||

| Suppliers | Pos. Ideal | Neg. Ideal | Closeness Coefficent | Rank | Pos. İdeal | Neg. Ideal | Closeness Coefficent | Rank |

| S1Scenario1 | 0.35 | 0.67 | 0.662 | 1 | 88.0 | 45.7 | 0.342 | 1 |

| S2Scenario1 | 0.45 | 0.58 | 0.568 | 2 | 80.2 | 34.1 | 0.298 | 2 |

| S3Scenario1 | 0.49 | 0.53 | 0.518 | 3 | 75.7 | 28.1 | 0.271 | 3 |

| S1Scenario2 | 0.34 | 0.67 | 0.665 | 1 | 88.40 | 46.0 | 0.342 | 1 |

| S2Scenario2 | 0.45 | 0.58 | 0.563 | 2 | 79.90 | 33. 4 | 0.295 | 2 |

| S3Scenario2 | 0.49 | 0.51 | 0.502 | 3 | 74.20 | 26. 2 | 0.261 | 3 |

| S1Scenario3 | 0.34 | 0.68 | 0.666 | 1 | 88.4 | 46.24 | 0.344 | 1 |

| S2Scenario3 | 0.45 | 0.58 | 0.564 | 2 | 79.9 | 33.73 | 0.297 | 2 |

| S3Scenario3 | 0.51 | 0.52 | 0.505 | 3 | 74. 4 | 26.66 | 0.264 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turk, S. Taguchi Loss Function in Intuitionistic Fuzzy Sets along with Personal Perceptions for the Sustainable Supplier Selection Problem. Sustainability 2022, 14, 6178. https://doi.org/10.3390/su14106178

Turk S. Taguchi Loss Function in Intuitionistic Fuzzy Sets along with Personal Perceptions for the Sustainable Supplier Selection Problem. Sustainability. 2022; 14(10):6178. https://doi.org/10.3390/su14106178

Chicago/Turabian StyleTurk, Seda. 2022. "Taguchi Loss Function in Intuitionistic Fuzzy Sets along with Personal Perceptions for the Sustainable Supplier Selection Problem" Sustainability 14, no. 10: 6178. https://doi.org/10.3390/su14106178

APA StyleTurk, S. (2022). Taguchi Loss Function in Intuitionistic Fuzzy Sets along with Personal Perceptions for the Sustainable Supplier Selection Problem. Sustainability, 14(10), 6178. https://doi.org/10.3390/su14106178