Long-Term Partnerships in Japanese Firms’ Logistics Outsourcing: From a Sustainable Perspective

Abstract

:1. Introduction

2. Literature Review

2.1. Logistics Outsourcing Practice by Country

2.2. Long-Term Partnership as a Traditional Japanese Business Practice

2.3. Supply Chain Collaboration, Resilience and Sustainability

3. Methodology

4. Case Analysis and Findings

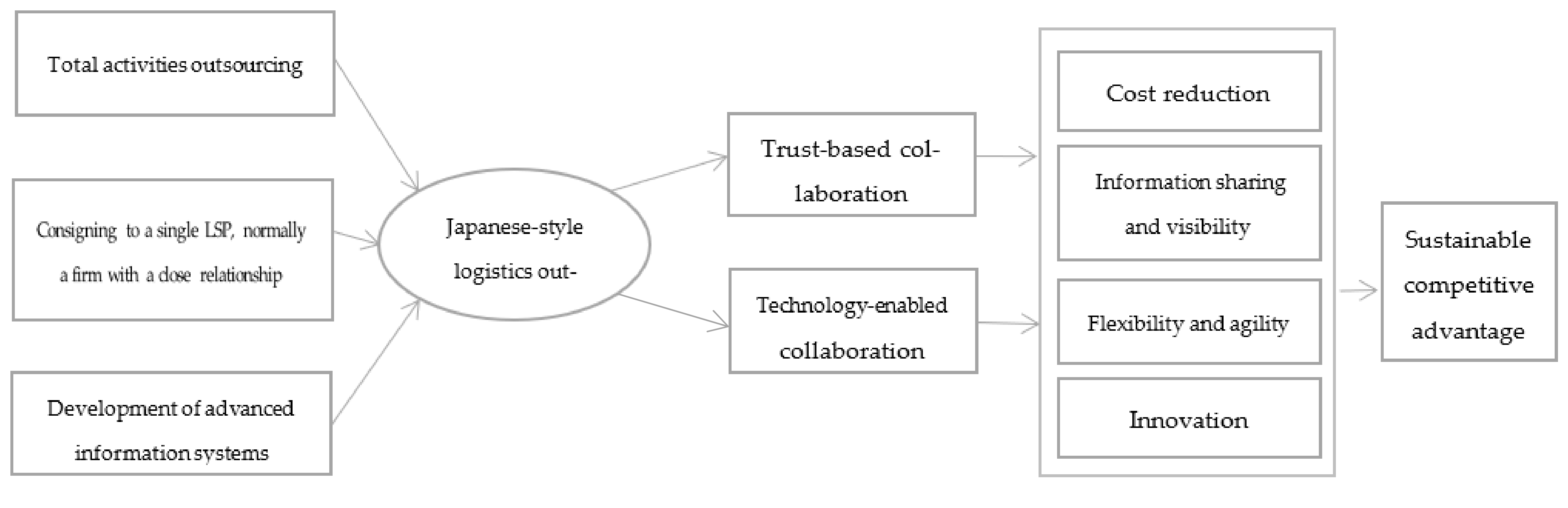

4.1. Japanese-Style Logistics Outsourcing

4.2. Mechanisms by Which Long-Term Transactions Create Sustainable Competitive Advantage

5. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abegglen, J.C.; Stalk, G. Kaisha, the Japanese Corporation; Basic Book: New York, NY, USA, 1985. [Google Scholar]

- Makino, S.; Lehmberg, D. The past and future contributions of research on Japanese management. Asian Bus. Manag. 2020, 19, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Tomeczek, A.F. The evolution of Japanese keiretsu networks: A review and text network analysis of their perceptions in economics. Jpn. World Econ. 2022, 62, 101132. Available online: https://www.sciencedirect.com/science/article/pii/S0922142522000184 (accessed on 28 March 2022). [CrossRef]

- Li, J.P. Long-term business relationships between Japanese companies. Sensyu-Keieigaku-Ronsyu 2007, 84, 163–183. (In Japanese) [Google Scholar]

- Umeki, M. Development and limits of long-term transactions in Japan. Ryutsukeizaidaigaku-Ronshu 2013, 47, 321–330. (In Japanese) [Google Scholar]

- Sheu, C.; Yen, H.J.R.; Chae, B. Determinants of supplier-retailer collaboration: Evidence from an international study. Int. J. Oper. Prod. Manag. 2006, 26, 24–49. [Google Scholar] [CrossRef]

- Christopher, M.; Peck, H. Building the Resilient. Supply Chain. Int. J. Logist. Manag. 2004, 15, 1–14. [Google Scholar]

- Jüttner, U.; Maklan, S. Supply chain resilience in the global financial crisis: An empirical study. Supply Chain Manag. Int. J. 2011, 16, 246–259. [Google Scholar] [CrossRef]

- Makukha, K.; Gray, R. Logistics partners between shippers and logistics service providers: The relevance of strategy. Int. J. Logist. Res. Appl. 2004, 7, 361–377. [Google Scholar] [CrossRef]

- Rahman, S. An exploratory study of outsourcing 3PL services: An Australian perspective. BIJ 2011, 18, 342–358. [Google Scholar] [CrossRef]

- Jaafar, H.S.; Rafiq, M. Logistics outsourcing practices in the UK: A survey. Int. J. Logist. Res. Appl. 2005, 8, 299–312. [Google Scholar] [CrossRef]

- Lieb, R.; Bentz, B.A. The use of third-party logistics services by large American manufacturers: The 2004 survey. Transp. J. 2005, 44, 5–15. [Google Scholar] [CrossRef]

- Dey, A.; LaGuardia, P.; Srinivasan, M. Building sustainability in logistics operations: A research agenda. Acad. Manage Rev. 2011, 34, 1237–1259. [Google Scholar] [CrossRef] [Green Version]

- Fantasia, J.J. Are you a candidate for third party logistics? Transp. Distr. 1993, 34, 30. [Google Scholar]

- Richardson, H.L. Outsourcing: The power work source. Transp. Distr. 1992, 33, 22–24. [Google Scholar]

- Gooley, T.B. The state of third-party logistics in Europe. Logist. Manag. 1997, 36, 80A–81A. [Google Scholar]

- Larson, P.D.; Gammelgaard, B. Logistics in Denmark: A survey of the industry. Int. J. Logist. Manag. 2001, 4, 191–206. [Google Scholar] [CrossRef]

- Lieb, R.C. The use of third-party logistics services by large American. J. Bus. Logist. 1992, 13, 29–42. [Google Scholar]

- Hong, J.; Chin, A.T.; Liu, B. Logistics outsourcing by manufacturers in China: A survey of the industry. Transp. J. 2004, 43, 17–25. [Google Scholar]

- Sohail, M.S.; Bhatnagar, R.; Sohal, A.S. A comparative study on the use of third party logistics services by Singaporean and Malaysian firms. Int. J. Phys. Distrib. Logist. Manag. 2006, 36, 690–701. [Google Scholar] [CrossRef] [Green Version]

- Arroyo, P.; Gaytan, J.; de Boer, L. A survey of third party logistics in Mexico and a comparison with reports on Europe and USA. Int. J. Oper. Prod. Manag. 2006, 26, 639–667. [Google Scholar] [CrossRef]

- Selviaridis, K.; Spring, M. Third party logistics: A literature review and research agenda. Int. J. Logist. Manag. 2007, 18, 125–150. [Google Scholar] [CrossRef]

- Kagono, T. The Japanese business system. Kokumin-Keizai-Zasshi 2009, 6, 1–10. (In Japanese) [Google Scholar]

- Asanuma, B. Japanese Corporate Organization: Innovative Adaptation Mechanism; Toyokeizai-Shinposya: Tokyo, Japan, 1997. (In Japanese) [Google Scholar]

- Ito, M. Business relationship and long-term transaction. In Japanese Enterprises; Imai, K., Komiya, T., Eds.; Tokyo University Press: Tokyo, Japan, 1989; pp. 109–130. (In Japanese) [Google Scholar]

- Chiba, T. Market and Trust: Focusing on Intercompany Transactions. Shakaigaku-Hyouron 1997, 48, 317–333. (In Japanese) [Google Scholar] [CrossRef]

- Sako, S. The role of trust in Japanese supplier relationships. In Supplier System; Fujimoto, T., Ito, H., Eds.; Yuhigaku: Tokyo, Japan, 1998; pp. 91–118. (In Japanese) [Google Scholar]

- Um, K.-H.; Kim, S.-M. The effects of supply chain collaboration on performance and transaction cost advantage: The moderation and nonlinear effects of governance mechanisms. Int. J. Prod. Econ. 2019, 217, 97–111. [Google Scholar] [CrossRef]

- Shin, N.; Park, S.H.; Park, S. Partnership-based supply chain collaboration: Impact on commitment, innovation, and firm performance. Sustainability 2019, 11, 449. [Google Scholar] [CrossRef] [Green Version]

- Fujimoto, T.; Park, Y.W. Balancing supply chain competitiveness and robustness through “virtual dual sourcing”: Lessons from the great east Japan earthquake. Int. J. Product. Econ. 2014, 147, 429–436. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the concept of supply chain resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. Ensuring supply chain resilience: Development and implementation of an assessment tool. J. Bus. Logist. 2013, 34, 46–76. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of quantitative methods for supply chain resilience analysis. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 285–307. [Google Scholar] [CrossRef]

- Kamalahmadi, M.; Parast, M.M. A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. Int. J. Prod. Res. 2016, 171, 116–133. [Google Scholar] [CrossRef]

- Wilding, R.D. Supply chain temple of resilience. Logist. Trasp. Focus 2013, 15, 54–59. [Google Scholar]

- Simatupang, T.M.; Sridharan, R. Design for supply chain collaboration. Bus. Process Manag. J. 2008, 14, 401–418. [Google Scholar] [CrossRef]

- Soni, U.; Jain, V.; Kumar, S. Measuring supply chain resilience using a deterministic modeling approach. Comput. Ind. Eng. 2014, 74, 11–25. [Google Scholar] [CrossRef]

- Scholten, K.; Schilder, S. The role of collaboration in supply chain resilience. Supply Chain Manag. Int. J. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Mandal, S.; Sarathy, R.; Korasiga, V.; Bhattacharya, S.; Dastidar, S. Achieving supply chain resilience: The contribution of logistics and supply chain capabilities. Int. J. Disaster Resil. Built Environ. 2016, 7, 544–562. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, Q. Supply chain collaboration: Impact on collaborative advantage and firm performance. J. Oper. Manag. 2011, 29, 163–180. [Google Scholar] [CrossRef]

- Cao, M.; Vonderembse, M.A.; Zhang, Q.; Ragu-Nathan, T.S. Supply chain collaboration: Conceptualisation and instrument development. Int. J. Prod. Res. 2010, 48, 6613–6635. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Fahimnia, B.; Jabbarzadeh, A. Marrying supply chain sustainability and resilience: A match made in heaven. Transp. Res. Part E Logist. Transp. Rev. 2016, 91, 306–324. [Google Scholar] [CrossRef]

- Koberg, E.; Longoni, A. A systematic review of sustainable supply chain management in global supply chains. J. Clean. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Yu, Z.; Golpira, H.; Sharif, A.; Mardani, A. A state-of-the-art review and meta-analysis on sustainable supply chain management: Future research directions. J. Clean. Prod. 2021, 278, 123357. [Google Scholar] [CrossRef]

- Wang, Y.; Iqbal, U.; Gong, Y. The Performance of resilient supply chain sustainability in COVID-19 by sourcing technological integration. Sustainability 2021, 13, 6151. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating sustainability and resilience in the supply chain: A systematic literature review and a research agenda. Bus Strategy Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Zavala-Alcívar, A.; Verdecho, M.J.; Alfaro-Saiz, J.J. A conceptual framework to manage resilience and increase sustainability in the supply chain. Sustainability 2020, 12, 6300. [Google Scholar] [CrossRef]

- Kayikci, Y. Sustainability impact of digitization in logistics. Procedia Manuf. 2018, 21, 782–789. [Google Scholar] [CrossRef]

- Frankel, R.; Naslund, D.; Bolumole, Y. The “white space” of logistics research: A look at the role of methods usage. J. Bus. Logist. 2005, 26, 185–209. [Google Scholar] [CrossRef]

- Marasco, A. Third-party logistics: A literature review. Int. J. Prod. Econ. 2008, 113, 127–147. [Google Scholar] [CrossRef]

- The World Bank. The Logistics Performance Index. 2019. Available online: https://lpi.worldbank.org/international/scorecard/radar/254/C/JPN/2018#chartarea (accessed on 28 March 2022).

- Japan Institute of Logistics Systems. Logistics Cost Research Report 2019. 2020. Available online: https://www1.logistics.or.jp/Portals/0/News/%E6%A6%82%E8%A6%81%E7%89%88%EF%BC%9A2019%E3%82%B3%E3%82%B9%E3%83%88%E8%AA%BF%E6%9F%BB%E5%A0%B1%E5%91%8A%E6%9B%B8.pdf (accessed on 28 March 2022).

- Miles, M.B.; Huberman, A.M. Qualitative Data Analysis: An Expanded Sourcebook; Sage Publications Inc.: Newbury Park, CA, USA, 1994. [Google Scholar]

- Fukuzawa, M.; Sugie, R.; Park, Y.; Shi, J. An Exploratory Case Study on the Metrics and Performance of IoT Investment in Japanese Manufacturing Firms. Sustainability 2022, 14, 2708. [Google Scholar] [CrossRef]

| Research | Lieb & Bentz (2005) [12] | Jaafa & Rafio (2005) [11] | Rahman (2011) [10] | Sohail et al. (2006) [20] | Hong et al. (2004) [19] | Arroyo et al. (2006) [21] | ||

|---|---|---|---|---|---|---|---|---|

| Target Country | US | UK | Australia | Singapore | Malaysia | China | Mexico | |

| Time | 2004 | 2003–2004 | N.A. | 1998 | 2000 | 2002 | N.A. | |

| Over-view of the survey | Respondents | 500 major American manufacturing companies | 1258 logistics-related managers, selected from the Institute of Logistics and Transport Members’ Directory 2000 | 216 companies from Australia’s top 500 excluding banks, finance, insurance, and real estate companies | 1000 randomly selected companies from Singapore | 800 randomly selected companies from Malaysia | 1010 randomly selected manufacturing companies from China | 243 companies in various sectors (mainly medium to large companies) |

| Valid samples | 65 | 336 | 36 | 126 | 124 | 192 | 94 | |

| Percentage of firms using logistics outsourcing | 80% | 81.7% | 66% | 60.3% | 67.7% | 59.4% | 78.7% | |

| Percentage of firms using multiple 3PL companies | 60% | 75% (55% of respondents use three or more LSPs) | 74% | 73.7% | 63% | 89% (31% of respondents deal with five or more LSPs) | ||

| Most-often outsourced logistics activities | Transport, customs clearance, freight payment, inventory control, shipping, tracking, and tracing | Warehouse management, inventory management, handling of raw materials and parts, and order processing | Warehouse management, order processing, vehicle/operation control, and shipment | Selection of shipping and transportation companies, order processing, and freight payment | Shipping, vehicle/operation management, freight payment, carrier selection, and inventory management | Freight forwarding, transport, and inventory management | Custom clearance, product delivery, fleet management and operations, supplier payment and auditing, shipment planning and consolidation | |

| Motivations for, or benefits of, logistics outsourcing | Improved service, cost (the service factor exceeded the cost factor for the first time and became the most motivating factor) | Cost reduction, reduction of capital investment, focus on core business | Cost reduction, capital investment reduction, increased operational flexibility, new technologies, new skills and expertise, access to new markets, focus on core businesses | Increased flexibility, reduction of fixed investment | Saving time, improved customer service, payment and credit benefits | N.A. | Increased flexibility, focus on core business, customer service improvement | |

| Outsourcing contract duration | Relatively long-term | Relatively long-term; however, a recent downward trend in long-term contracts of more than 5 years | Relatively long-term, however, significant increase in short-term contracts | N.A. | N.A. | Relatively short-term, more than 60% are temporary or contracts less than six month | N.A. | |

| Company A | Company B | Company C | Company D | Company E | Company F | ||

|---|---|---|---|---|---|---|---|

| Over-view of the company | Description of the company | Japanese subsidiary of a global healthcare equipment manufacturing company | A global company with main products including chemical materials, medical devices, and cameras | A global company with main products including turbines, rotary machines, inverters, and semiconductors | A global car audio manufacturer | A global company with main products including power cables, automotive parts, and electronic components | A global company providing a wide range of factory-automation-related products |

| Sales (FY2021, consolidated, approximate number, JPY) | 100 billion | 2000 billion | 800 billion | 250 billion | 800 billion | 600 billion | |

| Employees (FY2021, consolidated, approximate number) | 1700 | 70,000 | 25,000 | 10,000 | 48,000 | 28,000 | |

| Position of the interviewee | Logistics manager | Corporate planning manager | Procurement and production manager | Supply chain manager | Production planning manager | Supply chain manager | |

| Inter-view | Date | 27 August 2020 18 February 2021 | 15 October 2020 18 February 2021 | 13 November 2020 18 February 2021 | 13 November 2020 18 February 2021 | 13 November 2020 18 February 2021 | 15 October 2020 18 February 2021 |

| Length | 120 min | 80 min | 100 min | 60 min | 45 min | 120 min | |

| Company A | Company B | Company C | Company D | Company E | Company F | ||

|---|---|---|---|---|---|---|---|

| Outsourced logistics activities | Transport, warehouse management, manufacturing logistics, information management, installation of the finished products | Transport, warehouse management, manufacturing logistics, information management, forwarding, repair | Transport, warehouse management, manufacturing logistics, information management, forwarding, distribution processing | Transport, warehouse management, manufacturing logistics, information management, forwarding, distribution processing | Transport, warehouse management, manufacturing logistics, information management, forwarding, distribution processing | Transport, warehouse management, manufacturing logistics, information management, forwarding, distribution processing | |

| Outsourced company | 3PL | Logistics subsidiary, 3PL | 3PL (used to be the subsidiary belonging to the same group) | 3PL | Logistics subsidiary, 3PL | Logistics subsidiary, 3PL | |

| Outsourced companyselection method | Bid | Consigning to the logistics subsidiary | Consigning to the former logistics subsidiary | Bid | Consigning to the logistics subsidiary | Consigning to the logistics subsidiary; bid for 3PL | |

| Logistics contract type/duration | Long-term | Long-term, including some short-term contracts for global logistics | Long-term | Long-term | Long-term | Long-term | |

| Ware-house management system | Have WMS or not | No | Yes | Yes | Yes | No | Yes |

| Introduction of the system | There is a warehouse management module in the system, but it is currently unused | Both the company and the LSP have the system. Through the system, operations such as giving commands, placing orders, payment, and cost analysis are performed | Both the company and the LSP have the system. The warehouse-related operations are dealt with by the LSP’s system, while the manufacturing-related operations are dealt with by the company’s own WMS. | The system was introduced and is managed by the LSP firm. | The system was introduced by the LSP | ||

| System integration | Have EDI or not | Yes | Yes | Yes | Yes | Yes | Yes |

| Over-view of system integration | The system is partly open to LSPs. | Through the EDI, LSPs access the company’s ERP data. | Through the EDI, the company shares manufacturing, warehousing, and sales data with LSPs, which report shipment data to the company through it. | The warehouse system is integrated to the company’s system. | The systems for plants and warehouses are integrated into the systems of the headquarters and LSPs. | The LSP’s systems are linked to the company’s ERP system. | |

| Performance metric indica-tors | Economic | Lead-time, rate of on-time delivery | Ratio of logistics cost for sales, cost analysis, lead time, service quality, customer satisfaction | Ratio of logistics cost for sales, analysis of logistics costs, service quality, individual operation efficiency | Lead time compliance rate, logistics cost, rate of joint delivery | No clear criteria | Ratio of logistics cost for sales, lead time, compliance rate, logistics quality, cost analysis |

| Environmental | No clear criteria | Co2 reduction, use of green energy | Co2 reduction, use of green energy | Co2 reduction, ratio of joint delivery | No clear criteria | Co2 reduction | |

| Social | No clear criteria | CSR, SDGs | Human rights of workers | No clear criteria | SDGs | CRS, SDGs | |

| Data Reduction: Quotes and Sentences in Relation to Collaboration with Logistics Partners | Coding: Management Effects of Collaboration | Re-Coding: Classifying the Types of Collaboration |

|---|---|---|

| “We work closely with our logistics partner and set a cost reduction goal every year. To achieve that, we conduct Kaizen. As continuous improvement is accumulated, significant cost reduction can be achieved... I think it is a better way (to realize cost reduction) compared to the traditional way of just asking the partner for a lower price.” (Company B). | Cost reduction | Trust-based collaboration |

| “We don’t just focus on the logistics cost itself. Rather, we try to realize the optimization of the whole process and minimization of total cost by implementing JIT production system...As the total cost decreases, the logistics cost is also reduced.” (Company C). | Trust-based collaboration | |

| “We implement joint deliveries as a means of reducing costs.” (Company D). | Technology-enabled collaboration | |

| “The sophisticated information system we have put in place is very helpful in reducing costs.” (Company F). | Technology-enabled collaboration | |

| “Almost all the logistics-related data are available in the system, so we can grasp the whole flow and almost every detail.” (Company F). | Information sharing and visibility | Technology-enabled collaboration |

| “We adopt Activity-based costing, named the ABC approach, that divides the cost into activity units and calculates the cost for each activity, which enables us to negotiate the cost with the LSP.” (Company B). | Technology-enabled and trust-based collaboration | |

| “The information system is quite helpful in preventing the logistics process from being a black-box.” (Company D). | Technology-enabled collaboration | |

| “We entrust the logistics management to our logistics subsidiary, a non-asset 4PL specializing in management. I think it [putting it in charge of logistics outsourcing] is an efficient way to keep the operations under control.” (Company B). | Trust-based collaboration | |

| “Sometimes they [the LSP firm] offer extra services for us, and it really helps.” (Company A) | Flexibility and Agility | Trust-based collaboration |

| “...when changes occur on our side, they [the LSP [ can always modify the logistics service in a quick manner accordingly.” (Company B). | Trust-based collaboration | |

| “The logistics partner with [which we have] a long relationship responds to us very kindly. They are quite flexible.” (Company D). | Trust-based collaboration | |

| “Their [the LSP firms’] biggest advantage is flexibility.” (Company E). | Trust-based collaboration | |

| “Amid the Corona disaster, freight rates have skyrocketed and flights have been difficult to obtain, but we have maintained our current logistics service level by utilizing our information system and working with LSPs.” (Company F). | Technology-enabled and trust-based collaboration | |

| “We work closely with them (the LSP firm) to conduct kaizen and rationalization. Such efforts lasting over the long term have a significant effect on cost reduction and competence enhancement.” (Company C). | Innovations | Trust-based collaboration |

| “We send technical staff to the LSP firm. By working with people from a different point of view, we get more opportunities to generate innovations.” (Company C). | Trust-based collaboration |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, J.; Park, Y.; Sugie, R.; Fukuzawa, M. Long-Term Partnerships in Japanese Firms’ Logistics Outsourcing: From a Sustainable Perspective. Sustainability 2022, 14, 6376. https://doi.org/10.3390/su14106376

Shi J, Park Y, Sugie R, Fukuzawa M. Long-Term Partnerships in Japanese Firms’ Logistics Outsourcing: From a Sustainable Perspective. Sustainability. 2022; 14(10):6376. https://doi.org/10.3390/su14106376

Chicago/Turabian StyleShi, Jin, Youngwon Park, Ryosuke Sugie, and Mitsuhiro Fukuzawa. 2022. "Long-Term Partnerships in Japanese Firms’ Logistics Outsourcing: From a Sustainable Perspective" Sustainability 14, no. 10: 6376. https://doi.org/10.3390/su14106376

APA StyleShi, J., Park, Y., Sugie, R., & Fukuzawa, M. (2022). Long-Term Partnerships in Japanese Firms’ Logistics Outsourcing: From a Sustainable Perspective. Sustainability, 14(10), 6376. https://doi.org/10.3390/su14106376