A Comprehensive Review on Utilization of Slaughterhouse By-Product: Current Status and Prospect

Abstract

:1. Introduction

2. Overview of the Slaughterhouse Processing Industry

Slaughterhouse by Product

3. Current Disposal Techniques of Slaughterhouse By-Products

3.1. Burial and Landfilling

3.2. Incineration

4. Utilization of Slaughterhouse By-Product: Present Scenario

4.1. Slaughterhouse By-Product for Fertilizer

4.2. Slaughterhouse By-Product for Animal Feed

4.3. Slaughterhouse By-Product for Glue Application

4.4. Slaughterhouse By-Product for Accessories

5. Physiochemical Properties

5.1. Physical Properties

5.2. Compositions

6. Utilization of Slaughterhouse By-Product: Prospects

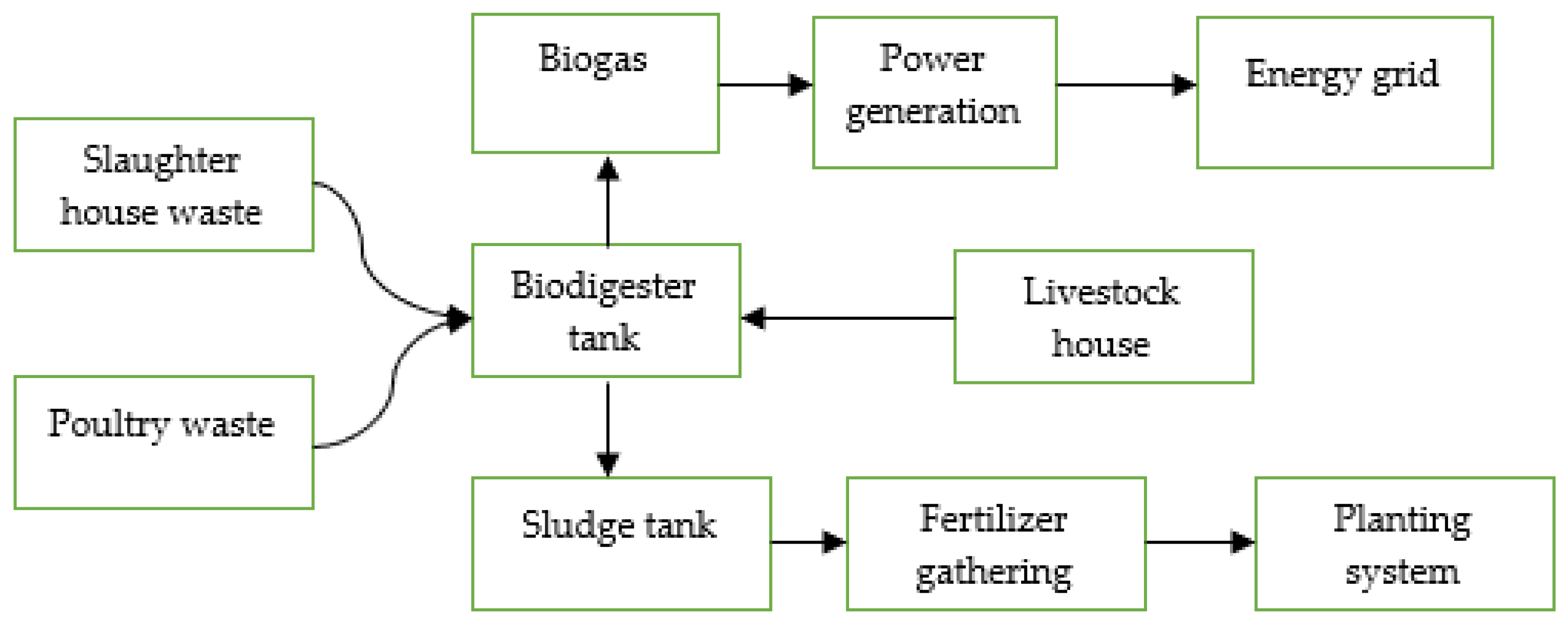

6.1. Biogas Production

6.2. Keratin

6.2.1. Edible Packaging

6.2.2. Tissue Engineering

6.2.3. Drug Delivery

6.2.4. For Textile Application

6.2.5. Medical Application

6.2.6. Fire Extinguishers

6.3. Collagen

6.3.1. Skin Revitalization

6.3.2. Medical Application

6.3.3. Pharmaceutical Industries

6.4. Cosmetics Application

6.5. Food Industry

6.6. Surgical Sutures

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ware, A.; Power, N. Biogas from cattle slaughterhouse waste: Energy recovery towards an energy self-sufficient industry in Ireland. Renew. Energy 2016, 97, 541–549. [Google Scholar] [CrossRef] [Green Version]

- Salminen, E.; Rintala, J. Anaerobic digestion of organic solid poultry slaughterhouse waste—A review. Bioresour. Technol. 2002, 23, 8313–8326. [Google Scholar] [CrossRef]

- Bharathy, N.; Sakthivadivu, R.; Sivakumar, K.; Saravanakumar, V.R. Disposal and utilization of broiler slaughter waste by composting. Vet. World 2012, 5, 359–368. [Google Scholar] [CrossRef]

- Klintenberg, P.; Jamieson, M.; Kinyaga, V.; Odlare, M. Assessing biogas potential of slaughter waste: Can biogas production solve a serious waste problem at abattoirs? Energy Proc. 2014, 61, 2600–2603. [Google Scholar] [CrossRef] [Green Version]

- Ek, A.; Hallin, S.; Vallin, L.; Schnurer, A.; Karlsson, M. Slaughterhouse waste co-digestion-Experiences from 15 years of full-scale operation. World Renew. Energy Congr.-Swed. 2011, 9, 64–71. [Google Scholar]

- Ali, M.M.; Hossain, M.M.; Akhter, S.; Islam, M.S.; Hashem, M.A. Effect of age on slaughterhouse by-products of indigenous cattle of Bangladesh. Bangladesh J. Anim. Sci. 2013, 42, 62–75. [Google Scholar] [CrossRef] [Green Version]

- Selmane, D.; Christophe, V.; Gholamreza, D. Extraction of proteins from slaughterhouse by-products: Influence of operating conditions on functional properties. Meat Sci. 2008, 79, 640–647. [Google Scholar] [CrossRef]

- Gómez-Juárez, C.; Castellanos, R.; Ponce-Noyola, T.; Calderón, V.; Figueroa, J. Protein recovery from slaughterhouse wastes. Bioresour. Technol. 1999, 70, 129–133. [Google Scholar] [CrossRef]

- Hejnfelt, A.; Angelidaki, I. Anaerobic digestion of slaughterhouse by-products. Biomass Bioenergy 2009, 33, 1046–1054. [Google Scholar] [CrossRef]

- Bhaskar, N.; Modi, V.K.; Govindaraju, K.; Radha, C.; Lalitha, R.G. Utilization of meat industry by-products: Protein hydrolysate from sheep visceral mass. Bioresour. Technol. 2007, 98, 388–394. [Google Scholar] [CrossRef]

- Irshad, A.; Sharma, B.D. Abattoir by-product utilization for sustainable meat industry: A review. J. Anim. Prod. Adv. 2015, 5, 681–696. [Google Scholar]

- FAO. The State of World Fisheries and Aquaculture 2020; Sustainability in Action; FAO: Rome, Italy, 2020. [Google Scholar] [CrossRef]

- Tesfaye, T.; Sithole, B.; Ramjugernath, D. Valorisation of chicken feathers: A review on recycling and recovery route—Current status and future prospects. Clean Technol. Environ. Policy 2017, 19, 2363–2378. [Google Scholar] [CrossRef]

- Huang, J. Enough for everyone. Growth 2013, 40, 50. [Google Scholar]

- Bustillo-Lecompte, C.F.; Mehrvar, M. Treatment of actual slaughterhouse wastewater by combined anaerobic–aerobic processes for biogas generation and removal of organics and nutrients: An optimization study towards a cleaner production in the meat processing industry. J. Clean. Prod. 2017, 141, 278–289. [Google Scholar] [CrossRef]

- Toldrá, F.; Mora, L.; Reig, M. New insights into meat by-product utilization. Meat Sci. 2016, 120, 54–59. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saeed, S.M.; Abdel-Mageed, S.A. Impact of Poultry Slaughterhouse By-Product on the Aquatic Environment of Fish Ponds. Environment 2011, 6, 1–18. [Google Scholar]

- Meeker, D.L. North American Rendering: Processing high quality protein and fats for feed. Rev. Bras. Zootec. 2009, 38, 432–440. [Google Scholar] [CrossRef] [Green Version]

- Van Sonsbeek, J.T.; van Beek, P.; Urlings, H.A.; Bijker, P.G.; Hagelaar, J.F. Mixed integer programming for strategic decision support in the slaughter by-product chain. Oper.-Res.-Spektrum 1997, 19, 159–168. [Google Scholar] [CrossRef]

- Urlings, H.A.; Van Logtestijn, J.G.; Bijker, P.G. Slaughter by-products: Problems, preliminary research and possible solutions. Vet. Q. 1992, 14, 34–38. [Google Scholar] [CrossRef]

- Kupusovic, T.; Midzic, S.; Silajdzic, I.; Bjelavac, J. Cleaner production measures in small-scale slaughterhouse industry—Case study in Bosnia and Herzegovina. J. Clean. Prod. 2007, 15, 378–383. [Google Scholar] [CrossRef]

- Al Yaqout, A.F. Assessment and analysis of industrial liquid waste and sludge disposal at unlined landfill sites in arid climate. Waste Manag. 2003, 23, 817–824. [Google Scholar] [CrossRef]

- Chen, S.; Sun, D.; Chung, J.S. Simultaneous removal of COD and ammonium from landfill leachate using an anaerobic–aerobic moving-bed biofilm reactor system. Waste Manag. 2008, 28, 339–346. [Google Scholar] [CrossRef] [PubMed]

- Stewart, B.A.; Robinson, C.A.; Parker, D.B. Examples and case studies of beneficial reuse of beef cattle by-products. Land Appl. Agric. Ind. Munic. Prod. 2000, 6, 387–407. [Google Scholar]

- Kanatt, S.R.; Chander, R.; Radhakrishna, P.; Sharma, A. Potato peel extract a natural antioxidant for retarding lipid peroxidation in radiation processed lamb meat. J. Agric. Food Chem. 2005, 53, 1499–1504. [Google Scholar] [CrossRef]

- Álvarez, J.M.; Iglesias, R.R.; Vinent, J.G.; Giorgetti, H.; Rodríguez, G.; Baselga, M. Introduction of sheep meat breeds in extensive systems: Lamb carcass characteristics. Small Rumin. Res. 2013, 109, 9–14. [Google Scholar] [CrossRef]

- Dwyer, C.M.; Lawrence, A.B. Introduction to animal welfare and the sheep. In The Welfare of Sheep; Springer: Dordrecht, The Netherlands, 2008; pp. 1–40. [Google Scholar]

- Esposito, G.; Irons, P.C.; Webb, E.C.; Chapwanya, A. Interactions between negative energy balance, metabolic diseases, uterine health and immune response in transition dairy cows. Anim. Reprod. Sci. 2014, 144, 60–71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Houessou, S.O.; Vanvanhossou, S.F.; Yassegoungbe, F.P.; Adenile, A.D.; Dahouda, M.; Guimaraes, V.P.; Dossa, L.H. A typological characterization of rural goat production systems of Benin prior to their sustainability assessment. Arch. Zootec. 2021, 70, 318–330. [Google Scholar] [CrossRef]

- Kwak, W.S.; Kang, J.S. Effect of feeding food waste-broiler litter and bakery by-product mixture to pigs. Bioresour. Technol. 2006, 97, 243–249. [Google Scholar] [CrossRef]

- Shapawi, R.; Ng, W.K.; Mustafa, S. Replacement of fish meal with poultry by-product meal in diets formulated for the humpback grouper, Cromileptes altivelis. Aquaculture 2007, 273, 118–126. [Google Scholar] [CrossRef]

- Adeoti, I.A.; Hawboldt, K. A review of lipid extraction from fish processing by-product for use as a biofuel. Biomass Bioenergy 2014, 63, 330–340. [Google Scholar] [CrossRef]

- De Oliveira, D.A.; Minozzo, M.G.; Licodiedoff, S.; Waszczynskyj, N. Physicochemical and sensory characterization of refined and deodorized tuna (Thunnus albacares) by-product oil obtained by enzymatic hydrolysis. Food Chem. 2016, 207, 187–194. [Google Scholar] [CrossRef] [PubMed]

- Bandaw, T.; Herago, T. Review on abattoir waste management. Glob. Vet. 2017, 19, 517–524. [Google Scholar]

- Franke-Whittle, I.H.; Insam, H. Treatment alternatives of slaughterhouse wastes, and their effect on the inactivation of different pathogens: A review. Crit. Rev. Microbiol. 2013, 39, 139–151. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adesokan, H.K.; Sulaimon, M.A. Poor slaughterhouse waste management: Empirical evidences from Nigeria and implications on achieving millennium development goals. AFRREV STECH Int. J. Sci. Technol. 2014, 3, 110–127. [Google Scholar]

- Rodríguez-Abalde, Á.; Fernández, B.; Silvestre, G.; Flotats, X. Effects of thermal pre-treatments on solid slaughterhouse waste methane potential. Waste Manag. 2011, 31, 1488–1493. [Google Scholar] [CrossRef]

- Pitk, P.; Kaparaju, P.; Vilu, R. Methane potential of sterilized solid slaughterhouse wastes. Bioresour. Technol. 2012, 116, 42–46. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, V.V.; Devatkal, S.K. Utilization of byproducts and waste materials from meat and poultry processing industry: A review. J. Meat Sci. 2015, 11, 1–9. [Google Scholar]

- Tchobanoglous, G.; Theisen, H.; Vigil, S.A. Integrated Solid Waste Management: Engineering Principle and Management Issue. McGraw Hill Inc.: New York, NY, USA, 1993. [Google Scholar]

- Moukazis, I.; Pellera, F.M.; Gidarakos, E. Slaughterhouse by-products treatment using anaerobic digestion. Waste Manag. 2018, 71, 652–662. [Google Scholar] [CrossRef]

- Hamer, G. Solid waste treatment and disposal: Effects on public health and environmental safety. Biotechnol. Adv. 2003, 22, 71–79. [Google Scholar] [CrossRef]

- Ali, A.; Hashmi, H.N.; Akber, H. The Slaughter House Waste Management. Hydro Nepal J. Water Energy Environ. 2010, 7, 48–53. [Google Scholar] [CrossRef]

- Wilson, J.F. Phillips Petroleum Co. Fertilizer. U.S. Patent 1962.3,050,383, 1993. [Google Scholar]

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management. 2012. Available online: https://openknowledge.worldbank.org/handle/10986/17388 (accessed on 14 February 2022).

- Fulhage, C.D. Dead Animal Disposal Laws in Missouri. 2018. Available online: https://mospace.umsystem.edu/xmlui/handle/10355/69219 (accessed on 13 February 2022).

- Nwanta, J.A.; Onunkwo, J.I.; Ezenduka, V.E.; Phil-Eze, P.O.; Egege, S.C. Abattoir operations and waste management in Nigeria: A review of challenges and prospects. Sokoto J. Vet. Sci. 2008, 7, 72757. [Google Scholar]

- Adeyemi, I.G.; Adeyemo, O.K. Waste management practices at the Bodija abattoir, Nigeria. Int. J. Environ. Stud. 2007, 64, 71–82. [Google Scholar] [CrossRef]

- Roberts, H.A.; de Jager, L. Current meat-related waste disposal practices of free state red-meat abattoirs, South Africa. WIT Trans. Ecol. Environ. 2004, 23, 78. [Google Scholar]

- Molapo, N.A. Waste Handling Practices in the South African High-Throughput Poultry Abattoirs. Doctoral Thesis, Central University of Technology, Bloemfontein, South Africa, 2009. [Google Scholar]

- Ockerman, H.W.; Hansen, C.L. Animal by-Product Processing & Utilization; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Hyun, C.K.; Shin, H.K. Utilization of bovine blood plasma obtained from a slaughterhouse for economic production of probiotics. J. Ferment. Bioeng. 1998, 86, 34–37. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. Meat and Dairy Production. Our World in Data. 2017. Available online: https://ourworldindata.org/meat-production?fbclid=IwAR2I4y82fsZxHORHLWnsxcoeVKc9mSnMSURqynKD9AMtmttZ54a0GjXSYRU (accessed on 15 February 2022).

- Garnett, T. Meat and Dairy Production and Consumption. In Food Climate Research Network; University of Surrey: Guildford, UK, 2007; pp. 54–55. [Google Scholar]

- Säll, S.; Gren, M. Effects of an environmental tax on meat and dairy consumption in Sweden. Food Policy 2015, 55, 41–53. [Google Scholar] [CrossRef]

- Zhang, H. Fertilizer Nutrients in Animal Manure. 2002. Available online: https://shareok.org/bitstream/handle/11244/317943/oksa_pss_2228_2002-07.pdf?sequence=1 (accessed on 1 January 2020).

- Van Slyke, V.; ATD Waste Systems Inc. System and Method for Producing an Organic Based Fertilizer and Usable Water from Animal Waste. U.S. Patent 8,685,131, 1 April 2014. [Google Scholar]

- Marculescu, C.; Stan, C. Non-oxidant thermal treatment for organic waste neutralization. Energy Proc. 2012, 18, 545–551. [Google Scholar] [CrossRef] [Green Version]

- Skaarup, T. Slaughterhouse Cleaning and Sanitation; Food and Agriculture Organization of the United Nations: Rome, Italy, 1985. [Google Scholar]

- Adhikari, B.B.; Chae, M.; Bressler, D.C. Utilization of slaughterhouse waste in value-added applications: Recent advances in the development of wood adhesives. Polymers 2018, 10, 176. [Google Scholar] [CrossRef] [Green Version]

- Edström, M.; Nordberg, Å.; Thyselius, L. Anaerobic treatment of animal byproducts from slaughterhouses at laboratory and pilot scale. Appl. Biochem. Biotechnol. 2003, 109, 127–138. [Google Scholar] [CrossRef]

- Hadush, A.; Hagos, Z.; Gebrehawaria, G.; Brhane, Y.; Gopalakrishnan, V.K.; Krishna Chaithanya, K. Production and characterization of animal glue from solid skin waste of Axum town, Ethiopia. J. Pharm. Res. 2018, 12, 174–177. [Google Scholar]

- Latifi, P.; Karrabi, M.; Danesh, S. Anaerobic co-digestion of poultry slaughterhouse wastes with sewage sludge in batch-mode bioreactors (effect of inoculum-substrate ratio and total solids). Renew. Sustain. Energy Rev. 2019, 107, 288–296. [Google Scholar] [CrossRef]

- Schrag, M.H. The Brethren in Christ Attitude Toward the ’World’: A Historical Study of the Movement from Separation to an Increasing Acceptance of American Society; Temple University: Philadelphia, PA, USA, 1967. [Google Scholar]

- Tseghai, G.B.; Wangatia, L.M. Surface modification of cotton using slaughterhouse wastes. Int. J. Mater. Text. Eng. 2015, 9, 3011–3015. [Google Scholar]

- Zeller, H.; Zah, R.; Gioacchini, M.; Faist, M. Of the Environmental Impact Valuation as Base for a Sustainable Fashion Strategy. 2016. Available online: http://naturalcapitalcoalition.org/wp-content/uploads/2017/07/2nd_White_Paper_EIV.pdf (accessed on 15 February 2022).

- Lee, P.Y. (Ed.) Meat, Modernity, and the Rise of the Slaughterhouse; UPNE: Lebanon, NH, USA, 2008. [Google Scholar]

- Mitchell, J.L. Method for Packaging Perishable Products. U.S. Patent 4,919,955, 24 April 1990. [Google Scholar]

- Maysonnave, G.S.; Mello, R.D.; Vaz, F.N.; Ávila, M.M.; Pascoal, L.L.; Rodrigues, A.C. Physicochemical characterization of by-products from beef cattle slaughter and economic feasibility of commercialization. Acta Sci. Anim. Sci. 2020, 42. [Google Scholar] [CrossRef]

- Yaakob, M.A.; Mohamed, R.M.; Al-Gheethi, A.A.; Kassim, A.H. Characteristics of chicken slaughterhouse wastewater. Chem. Eng. Trans. 2018, 63, 637–642. [Google Scholar]

- Cunha, A., Jr.; Feddern, V.; Marina, C.; Higarashi, M.M.; De Abreu, P.G.; Coldebella, A. Synthesis and characterization of ethylic biodiesel from animal fat wastes. Fuel 2013, 105, 228–234. [Google Scholar] [CrossRef] [Green Version]

- Bah, C.S.; Bekhit, A.E.; Carne, A.; McConnell, M.A. Slaughterhouse blood: An emerging source of bioactive compounds. Compr. Rev. Food Sci. Food Saf. 2013, 12, 314–331. [Google Scholar] [CrossRef]

- Darine, S.; Christophe, V.; Gholamreza, D. Production and functional properties of beef lung protein concentrates. Meat Sci. 2010, 84, 315–322. [Google Scholar] [CrossRef]

- Mittal, G.S. Characterization of the effluent wastewater from abattoirs for land application. Food Rev. Int. 2004, 20, 229–256. [Google Scholar] [CrossRef]

- Cu, T.T.; Nguyen, T.X.; Triolo, J.M.; Pedersen, L.; Le, V.D.; Le, P.D.; Sommer, S.G. Biogas production from Vietnamese animal manure, plant residues and organic waste: Influence of biomass composition on methane yield. Asian-Australas. J. Anim. Sci. 2015, 28, 280. [Google Scholar] [CrossRef] [Green Version]

- Rosentrater, K.A.; Flores, R.A.; Richard, T.L.; Bern, C.J. Physical and nutritional properties of corn masa by-product streams. Appl. Eng. Agric. 1999, 15, 515. [Google Scholar] [CrossRef]

- Da Silva Bambirra Alves, F.E.; Carpiné, D.; Teixeira, G.L.; Goedert, A.C.; de Paula Scheer, A.; Ribani, R.H. Valorization of an Abundant Slaughterhouse By-product as a Source of Highly Technofunctional and Antioxidant Protein Hydrolysates. Waste Biomass Valoriz. 2021, 12, 263–279. [Google Scholar] [CrossRef]

- Przybylski, R.; Bazinet, L.; Firdaous, L.; Kouach, M.; Goossens, J.F.; Dhulster, P.; Nedjar-Arroume, N. Electroseparation of slaughterhouse by-product: Antimicrobial peptide enrichment by pH modification. Membranes 2020, 10, 90. [Google Scholar] [CrossRef]

- Leiva, A.; Granados-Chinchilla, F.; Redondo-Solano, M.; Arrieta-González, M.; Pineda-Salazar, E.; Molina, A. Characterization of the animal by-product meal industry in Costa Rica: Manufacturing practices through the production chain and food safety. Poult. Sci. 2018, 97, 2159–2169. [Google Scholar] [CrossRef] [PubMed]

- Valta, K.; Kosanovic, T.; Malamis, D.; Moustakas, K.; Loizidou, M. Overview of water usage and wastewater management in the food and beverage industry. Desalination Water Treat. 2015, 53, 3335–3347. [Google Scholar] [CrossRef]

- Fountoulakis, M.S.; Drakopoulou, S.; Terzakis, S.; Georgaki, E.; Manios, T. Potential for methane production from typical Mediterranean agro-industrial by-products. Biomass Bioenergy 2008, 32, 155–161. [Google Scholar] [CrossRef]

- Martinez, E.; Marcos, A.; Al-Kassir, A.; Jaramillo, M.A.; Mohamad, A.A. Mathematical model of a laboratory-scale plant for slaughterhouse effluents biodigestion for biogas production. Appl. Energy 2012, 95, 210–219. [Google Scholar] [CrossRef]

- Mann, S.; Harris, I.; Harris, J. Renewable and Sustainable Energy Reviews; Elsevier: Amsterdam, The Netherlands, 2004; Volume 8, pp. 303–399. [Google Scholar]

- Dincer, I. Renewable energy and sustainable development: A crucial review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Yazdani, M.; Ebrahimi-Nik, M.; Heidari, A.; Abbaspour-Fard, M.H. Improvement of biogas production from slaughterhouse wastewater using biosynthesized iron nanoparticles from water treatment sludge. Renew. Energy 2019, 135, 496–501. [Google Scholar] [CrossRef]

- Afazeli, H.; Jafari, A.; Rafiee, S.; Nosrati, M. An investigation of biogas production potential from livestock and slaughterhouse wastes. Renew. Sustain. Energy Rev. 2014, 34, 380–386. [Google Scholar] [CrossRef]

- Budiyono, B.; Seno, J.; Sunarso, S. Study on slaughterhouse wastes potency and characteristic for biogas production. Int. J. Waste Resour. 2011, 1, 4–7. [Google Scholar]

- Pazera, A.; Slezak, R.; Krzystek, L.; Ledakowicz, S.; Bochmann, G.; Gabauer, W.; Helm, S.; Reitmeier, S.; Marley, L.; Gorga, F.; et al. Biogas in Europe: Food and beverage (FAB) waste potential for biogas production. Energy Fuels 2015, 29, 4011–4021. [Google Scholar] [CrossRef]

- Moreda, I.L. The potential of biogas production in Uruguay. Renew. Sustain. Energy Rev. 2016, 54, 1580–1591. [Google Scholar] [CrossRef]

- Abdeshahian, P.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T. Potential of biogas production from farm animal waste in Malaysia. Renew. Sustain. Energy Rev. 2016, 60, 714–723. [Google Scholar] [CrossRef]

- Tanase, C.E.; Spiridon, I. PLA/chitosan/keratin composites for biomedical applications. Mater. Sci. Eng. 2014, 40, 242–247. [Google Scholar] [CrossRef] [PubMed]

- Shavandi, A.; Silva, T.H.; Bekhit, A.A.; Bekhit, A.E. Keratin: Dissolution, extraction and biomedical application. Biomater. Sci. 2017, 5, 1699–1735. [Google Scholar] [CrossRef] [Green Version]

- Gadhave, R.V.; Das, A.; Mahanwar, P.A.; Gadekar, P.T. Starch Based Bio-Plastics: The Future of Sustainable Packaging. 2018. Available online: http://www.repository.embuni.ac.ke/handle/123456789/1895 (accessed on 25 December 2015).

- Shi, W.; Dumont, M.J. Bio-based films from zein, keratin, pea, and rapeseed protein feedstocks. J. Mater. Sci. 2014, 49, 1915–1930. [Google Scholar] [CrossRef]

- McLellan, J.; Thornhill, S.G.; Shelton, S.; Kumar, M. Keratin-based biofilms, hydrogels, and biofibers. In Keratin as a Protein Biopolymer; Springer: Cham, Switzerland, 2019; pp. 187–200. [Google Scholar]

- Eduardo Piontelli, L.; Giusiano, G. Mycological notes: A selection of microfungi associated with vegetal material and keratine from Argentina and Chile. Boletín Micol. 2003, 18, 89–99. [Google Scholar]

- Carpentieri-Rodrigues, L.N.; Zanluchi, J.M.; Grebogi, I.H. Percutaneous absorption enhancers: Mechanisms and potential. Braz. Arch. Biol. Technol. 2007, 50, 949–961. [Google Scholar] [CrossRef] [Green Version]

- Lei, Y.; Tang, L.; Xie, Y.; Xianyu, Y.; Zhang, L.; Wang, P.; Hamada, Y.; Jiang, K.; Zheng, W.; Jiang, X. Gold nanoclusters-assisted delivery of NGF siRNA for effective treatment of pancreatic cancer. Nat. Commun. 2017, 8, 15130. [Google Scholar] [CrossRef]

- Hadadi, A. Understanding the Effect of Amide and Amine Groups on the Structural and Thermal Properties of Biomaterials as a Function of Ionic Liquids. Doctoral Thesis, Camden Graduate School, Rutgers University, Camden, NJ, USA, 2018. [Google Scholar]

- Akter, N.; Chakma, S.; Fatema, K.; Azad, A.K.; Jaman Chowdhury, M.; Abu Sayid Mia, M. Alkali Enzymatic Extraction of Keratin Protein from Chicken Feather Waste in Bangladesh. Iran. J. Energy Environ. 2019, 10, 235–241. [Google Scholar]

- Yuxin, C.Y.W. Keratin and Its Extraction. Mater. Rev. 2002, 12. [Google Scholar]

- Arivithamani, N.; Agnes Mary, S.; Senthil Kumar, M.; Giri Dev, V.R. Keratin hydrolysate as an exhausting agent in textile reactive dyeing process. Clean Technol. Environ. Policy 2014, 16, 1207–1215. [Google Scholar] [CrossRef]

- Wang, C.; Mao, Z. Preparation of aqueous solution of keratin and its application on wool fiber’s surface modification. Wool Text. J. 2007, 7. [Google Scholar]

- Konop, M.; Sulejczak, D.; Czuwara, J.; Kosson, P.; Misicka, A.; Lipkowski, A.W.; Rudnicka, L. The role of allogenic keratin-derived dressing in wound healing in a mouse model. Wound Repair Regen. 2017, 25, 62–74. [Google Scholar] [CrossRef]

- Sharma, S.; Gupta, A. Sustainable management of keratin waste biomass: Applications and future perspectives. Braz. Arch. Biol. Technol. 2016, 59. [Google Scholar] [CrossRef] [Green Version]

- Ferraro, V.; Anton, M.; Santé-Lhoutellier, V. The “sisters” α-helices of collagen, elastin and keratin recovered from animal by-products: Functionality, bioactivity and trends of application. Trends Food Sci. Technol. 2016, 51, 65–75. [Google Scholar] [CrossRef]

- Bhargava, K.K.; O’Neil, J.B. Composition and utilization of poultry by-product and hydrolyzed feather meal in broiler diets. Poult. Sci. 1975, 54, 1511–1518. [Google Scholar] [CrossRef]

- Zoccola, M.; Aluigi, A.; Patrucco, A.; Vineis, C.; Forlini, F.; Locatelli, P.; Sacchi, M.C.; Tonin, C. Microwave-assisted chemical-free hydrolysis of wool keratin. Text. Res. J. 2012, 82, 2006–2018. [Google Scholar] [CrossRef]

- Hoshino, M. Extinguishing Performance of Fractionated Keratin Hydrolysates and of Various Petroleum-Fire Fighting Foams-Extinguishment of Gasoline Fires by the Plugging Application. Bull. Jpn. Assoc. Fire Sci. Eng. 1994, 42, 13–19. [Google Scholar]

- Feroz, S.; Muhammad, N.; Ratnayake, J.; Dias, G. Keratin-Based materials for biomedical applications. Bioact. Mater. 2020, 5, 496–509. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Hillas, P.J.; Báez, J.A.; Nokelainen, M.; Balan, J.; Tang, J.; Spiro, R.; Polarek, J.W. The application of recombinant human collagen in tissue engineering. BioDrugs 2004, 18, 103–119. [Google Scholar] [CrossRef] [PubMed]

- Bayon, Y.; Ladet, S.; Lefranc, O.; Gravagna, P.; Sofradim Production SAS. Medical Implant Including a 3D Mesh of Oxidized Cellulose and a Collagen Sponge. U.S. Patent 9,119,898, 2015. [Google Scholar]

- Rahman, M.A. Collagen of extracellular matrix from marine invertebrates and its medical applications. Mar. Drugs 2019, 17, 118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silvipriya, K.S.; Kumar, K.K.; Bhat, A.R.; Kumar, B.D.; John, A.; Lakshmanan, P. Collagen: Animal sources and biomedical application. J. Appl. Pharm. Sci. 2015, 5, 123–127. [Google Scholar] [CrossRef] [Green Version]

- Mandal, A.; Panigrahi, S.; Zhang, C. Collagen as Biomaterial for Medical Application—Drug Delivery and Scaffolds for Tissue Regeneration: A Review. Biol. Eng. Trans. 2010, 2, 63–88. [Google Scholar] [CrossRef]

- Jeevithan, E.; Qingbo, Z.; Bao, B.; Wu, W. Biomedical and pharmaceutical application of fish collagen and gelatin: A review. J. Nutr. Ther. 2013, 2, 218–227. [Google Scholar]

- Pati, F.; Dhara, S.; Adhikari, B. Fish collagen: A potential material for biomedical application. In Proceedings of the 2010 IEEE Students Technology Symposium (TechSym), Kharagpur, India, 3–4 April 2010; pp. 34–38. [Google Scholar]

- Ur Rahman, U.; Sahar, A.; Khan, M.A. Recovery and utilization of effluents from meat processing industries. Food Res. Int. 2014, 65, 322–328. [Google Scholar] [CrossRef]

- Corbin, J.E. Inedible meat, poultry and fish by-products in pet foods. In Inedible Meat by-Products; Springer: Dordrecht, The Netherlands, 1992; pp. 329–347. [Google Scholar]

- Shen, X.; Zhang, M.; Bhandari, B.; Gao, Z. Novel technologies in utilization of byproducts of animal food processing: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 3420–3430. [Google Scholar] [CrossRef]

- Covington, A.D.; Wise, W.R. Current trends in leather science. J. Leather Sci. Eng. 2020, 2, 28. [Google Scholar] [CrossRef]

- Sionkowska, A.; Skrzyński, S.; Śmiechowski, K.; Kołodziejczak, A. The review of versatile application of collagen. Polym. Adv. Technol. 2017, 28, 4–9. [Google Scholar] [CrossRef]

- Balata, G.F.; Shamardl, H.E.; Abd Elmoneim, H.M.; Hakami, A.A.; Almodhwahi, M.A. Propolis emulgel: A natural remedy for burn and wound. Drug Dev. Ind. Pharm. 2018, 44, 1797–1808. [Google Scholar] [CrossRef]

- Sahraei, M.; Ghanbari, A.; Lootfollahian, H. Effects of inclusion of poultry slaughterhouse by product meals in diet on performance, serum uric acid and carcass traits of broilers. Glob. Vet. 2012, 8, 270–275. [Google Scholar]

- Kale, M.C.; Aral, Y.; Aydin, E.; Cevger, Y.; Sakarya, E.; Güloglu, S.C. Determination of by-product economic values for slaughtered cattle and sheep. Kafkas Univ. Vet. Fak. Derg. 2011, 17, 551–556. [Google Scholar]

- Prevel, C.D.; Eppley, B.L.; Summerlin, D.J.; Sidner, R.; Jackson, J.R.; McCarty, M.; Badylak, S.F. Small intestinal submucosa: Utilization as a wound dressing in full-thickness rodent wounds. Ann. Plast. Surg. 1995, 35, 381–388. [Google Scholar] [CrossRef] [PubMed]

- Rutner, A.B.; Levine, S.R.; Schmaelzle, J.F. Processed porcine small intestine submucosa as a graft material for pubovaginal slings: Durability and results. Urology 2003, 62, 805–809. [Google Scholar] [CrossRef]

- Strate, L.L.; Syngal, S. Predictors of utilization of early colonoscopy vs. radiography for severe lower intestinal bleeding. Gastrointest. Endosc. 2005, 61, 46–52. [Google Scholar] [CrossRef]

- Benicewicz, B.C.; Hopper, P.K. Polymers for absorbable surgical sutures—Part I. J. Bioact. Compat. Polym. 1990, 5, 453–472. [Google Scholar] [CrossRef]

| Slaughtered Animal | Classification | Utilization | |||

|---|---|---|---|---|---|

| Animal | Dressed carcass part (meat) | Used for human consumption | |||

| Non-carcass part (by-products) | Edible | Red offal | Liver. kidney, heart. tongue, trachea, lung and spleen | Human consumption | |

| White offal | Stomach, intestine, Gizzard | ||||

| Dark offal | Head, Neck, Trotter, shank | ||||

| Non-edible | Re-processed | Blood, hoof, horns, Gland, Bones, fats and skin/hide | Used in animal feed industry, Fabric/Cosmetic/Pharmaceutical industry | ||

| Discard | Gastrointestinal tract content, trimming, fetus | Used in biogas/fertilizer industry and animal feed industry | |||

| Condiment part | Discard | Gastrointestinal tract content, trimming, fetus | Used in biogas/fertilizer industry and animal feed industry | ||

| By-Product Percentage | References | ||

|---|---|---|---|

| Abattoirs | Cattle | 40–60 | [16,21,24] |

| Lamb | 45–65 | [21,25] | |

| Sheep | 25–35 | [26,27] | |

| Goat | 20.5–30 | [28,29] | |

| Beef | 30–42 | [24] | |

| Buffaloes | 65–75 | [11,16] | |

| Pork | 47–61 | [21,30] | |

| Poultry | Chicken | 10–45 | [16,31] |

| Fish processing industry | Fish | 30–80 | [32,33] |

| By Product/Meat | Yield Percentage | References |

|---|---|---|

| Boneless meat | 28.5–32 | [22,55,56] |

| By product/waste percent | 16 | [22,55] |

| Bone, head, and feat | 23–25 | [55,57] |

| Hide | 7–8 | [55,74,75] |

| Lunges and blood | 5–5.5 | [22,55] |

| Liver and stomach | 2–2.5 | [55,57] |

| Head meat and brain | 0.2–0.4 | [22,55] |

| Heart, tongue, spleen, kidney, and far | 2.5–3.3 | [22,55] |

| Casings, Urine, bile, dung, and body fluid | 5.1–5.5 | [55,56] |

| Other red, white, and dark offal | 4 | [55] |

| Raw Material | Quantity (Kg) | Proteins (Kg) | Mineral Matter (Kg) | Fat (Kg) | Water (Kg) |

|---|---|---|---|---|---|

| Animal carcasses | 1000 | 278 | 72 | 236 | 696 |

| Slaughterhouse waste | 1000 | 180 | 40 | 274 | 748 |

| Bones, blood, and bristles | 1000 | 241 | 127 | 47 | 573 |

| Poultry waste | 1000 | 124 | 32 | 181 | 663 |

| Fishery | 1000 | 280 | 7 | 23 | 690 |

| Substrates | Percentage of By-Products | Biogas Yield (m3/Kg) |

|---|---|---|

| By product from cattle (fresh) | 25–30 | 0.6–0.8 |

| By-products from sheep (Fresh) | 18–25 | 0.3–0.4 |

| Byproducts from poultry | 10–29 | 0.3–0.8 |

| Blood Liquid | 18 | 0.3–0.6 |

| Rumen Content | 12–16 | 0.3–0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Limeneh, D.Y.; Tesfaye, T.; Ayele, M.; Husien, N.M.; Ferede, E.; Haile, A.; Mengie, W.; Abuhay, A.; Gelebo, G.G.; Gibril, M.; et al. A Comprehensive Review on Utilization of Slaughterhouse By-Product: Current Status and Prospect. Sustainability 2022, 14, 6469. https://doi.org/10.3390/su14116469

Limeneh DY, Tesfaye T, Ayele M, Husien NM, Ferede E, Haile A, Mengie W, Abuhay A, Gelebo GG, Gibril M, et al. A Comprehensive Review on Utilization of Slaughterhouse By-Product: Current Status and Prospect. Sustainability. 2022; 14(11):6469. https://doi.org/10.3390/su14116469

Chicago/Turabian StyleLimeneh, Derseh Yilie, Tamrat Tesfaye, Million Ayele, Nuredin Muhammed Husien, Eyasu Ferede, Adane Haile, Wassie Mengie, Amare Abuhay, Gemeda Gebino Gelebo, Magdi Gibril, and et al. 2022. "A Comprehensive Review on Utilization of Slaughterhouse By-Product: Current Status and Prospect" Sustainability 14, no. 11: 6469. https://doi.org/10.3390/su14116469

APA StyleLimeneh, D. Y., Tesfaye, T., Ayele, M., Husien, N. M., Ferede, E., Haile, A., Mengie, W., Abuhay, A., Gelebo, G. G., Gibril, M., & Kong, F. (2022). A Comprehensive Review on Utilization of Slaughterhouse By-Product: Current Status and Prospect. Sustainability, 14(11), 6469. https://doi.org/10.3390/su14116469