Abstract

The tremendous urbanization pace of India calls for higher efficiency in housing development, currently typified by low productivity and poor sustainability performance. Although off-site construction (OSC) is a method of widely acknowledged efficiency, its current uptake in India is very low, and the factors hindering its wider adaptation have not been comprehensively researched. This paper employs interviews with experts, a questionnaire survey and the interpretive structural modelling (ISM) technique to achieve the following objectives: first, to reveal which factors are perceived as top barriers for OSC implementation in India; second, to develop a hierarchical model presenting the causality between these factors; and third, to propose the initiatives required for barriers with high impact on other barriers to be most efficiently tackled. The survey findings show that the barriers perceived as most important from the professionals’ point of view are design inflexibility, difficulties in storage and transportation, supply chain weaknesses, initial capital requirements and lack of skills. The ISM reveals, though, that the underlying causes for these barriers lie with factors such as public procurement regulations and the fragmentation of the sector. Therefore, the latter are the barriers that need to be targeted in priority, as per the suggested strategies.

1. Introduction

The creation of a sustainability-oriented approach in construction that simultaneously addresses economic, ecologic, and equity considerations is essential. Civil engineers in particular are in a key position to affect these three aspects given their broad roles, ranging from designing to deconstructing the built environment [1]. India is one of the fastest growing and developing economies and societies of the world. An evident consequence of this trend is urbanization, which poses an immense challenge as well as one of the most important topical research trends concerning the country [2]. According to the annual report by the Ministry of Housing and Urban Affairs (MoHUA) of India for 2020–2021 “Urbanization is gaining momentum and cities play a crucial role in the development and act as engines of growth for the country. It is estimated that more than 50% of India’s population will be living in cities by 2050” [3]. As expected, the construction output in India has been consistently rising with even higher estimates of future growth. As a result, urbanization and growing income levels have resulted in the housing business being a thriving sector of the economy [4]. Nevertheless, the current practices of conceptualizing, planning, procuring and executing construction projects in India are typified by extremely high resource consumption and waste, ignorance of wider social benefits, public opposition and protests and labour exploitation [5].

An effective response to increasing housing and construction demand around the globe can come from the resurgence of offsite construction (OSC), also known as prefabrication and construction industrialization [6]. This includes the use of structural elements (columns, floors, slabs and beams) from precast concrete, two-dimensional panelized structures designed and manufactured off-site and joined together onsite, elements of buildings such as plant rooms or bathroom pods manufactured in a factory and sub-assembled off-site and whole segments of buildings (modules) manufactured three-dimensionally and assembled off-site fitted together onsite. OSC has demonstrated significant advantages, from time and cost savings through to a reduced reliance of on-site skilled labour, improved safety performance and higher quality end-products [7]. Countries long enjoying OSC sustainability benefits such as improved quality, lower inventory costs, shorter lead times and less materials waste include the UK, Singapore, New Zealand, Australia and Malaysia [8]. Considering the global implications of India’s economic output and environmental footprint as one of the fastest growing large economies, there is an immense necessity for India to explore the true potential of construction in light of OSC sustainability gains. Additionally, India is at a demographic turning point towards an increasingly urban future, and this brings forth the importance of sustainability and its decisive role on the populations’ quality of life, on the economy’s productivity and on the environment [9]. However, although the field has seen a burst of research activity since 2012, developing countries, including India, are underrepresented in the literature, which is a serious impediment in the global trend of OSC adoption [10,11]. The limited research on the topic of OSC implementation in the Indian context means that the determinants of and barriers to environmentally and socially sustainable construction practices remain largely unexplored [5]. Specifically, a series of recent publications [7,11,12] contemplate the readiness of the Indian construction sector to implement OSC and confirm the lack of relevant literature. Besides these, there are very few publications, such as those by Nanyam et al. [13], Sherfudeen et al. [14] and Arif et al. [15], that have investigated various aspects of OSC implementation in India by the use of interviews or questionnaires. None of the latter, however, have attempted a comprehensive presentation and systematic investigation of the causal relations between the observed barriers. In the above context, this research will implement a mixed-research methods approach, culminating in the development of an interpretive structural model (ISM), with the aim to assess the barriers of OSC implementation in India, conceptualize the links between them and propose strategies that can potentially facilitate its wider adoption.

2. Literature Review

OSC describes the planning, design, fabrication and assembly of building elements at a location other than their final installed location to support the rapid and efficient construction of a permanent structure [16]. Alternative terms to describe the same approach include prefabrication, non-traditional building, modern methods of construction (MMC) and modular and industrialized building. OSC promotes design standardization, which is critical for the economy of construction and the accurate estimation of labour productivity [17,18,19]. It also allows for the development of reliable early cost predictions [20,21], facilitates construction and helps avoid unnecessary complexity and errors [22,23]. The use of OSC and of related design principles have been extensively discussed in relation to a variety of well-known sustainability-promoting practices such as value management, buildability, waste minimization and lean construction [6,8,24,25]. The biggest advantages of OSC compared with traditional construction are thought to be the decreased construction time on site, increased quality and elimination of defects [26]. A systematic presentation of the literature’s perceptions on benefits associated with the use of prefabrication in construction has also been given in Goodier et al. [27]. As it emerges from their analysis of 14 published papers, the most commonly reported benefit is the shorter schedule, followed by improved building quality and worker productivity. Next in popularity are the reductions in cost and the raising of health and safety standards, followed by improved predictability and enhanced sustainability/waste reduction. Less commonly reported benefits are those of easier testing and maintenance, enhanced opportunity for innovation and reduced project risks. The aforementioned benefits are also widely confirmed by Jansen van Vuuren and Middleton [28], who additionally note the lack of a method of measurement and lack of quantified data on completed projects to confirm these benefits in a systematic and quantified manner.

A significant phenomenon in India is the rapid strengthening of the weight of cities with populations of hundreds of thousands or millions since the mid-20th century. As Zagyi et al. [2] note, looking at the growth in the number of cities and urban agglomerations from 2001 to 2011, the most dynamic growth can be observed in the million-plus cities and agglomerations, with an increase in their number from 35 to 52 in ten years. The number of their inhabitants showed a similar growth, by approximately 50%, growing from 107.9 million to 160.7 million. There is also no doubt that the emerging wave of urbanization in India is fuelling growth in the building construction sector with a significant affordable housing deficit in urban areas [29]. The pivotal challenge faced here is how to successfully meet demand, given that conventional construction approaches entail major challenges, including not meeting quality and speed of delivery [11]. Doloi et al. [30] present evidence that Indian construction projects fail across all the key performance measures including cost, time and quality performance. Ahsan and Gunawan [31] further confirm that Indian projects showed the worst schedule performance when compared to projects delivered in China, Thailand and Bangladesh. The urgency for change is further strengthened by the need to tackle additional deficiencies currently plaguing the Indian construction sector. Goel et al. [5] find that the increasing construction output has been accompanied by multiple negative consequences for project sustainability performance, including very poor labour practices and increased occupational accidents. The latter are due to ignorance of health and safety rules, exposure to higher than usual occupational risk factors and the use of potentially dangerous tools and equipment, among others [32]. Kanchana et al. [33] and Patel and Jha [34] confirm that, despite the extremely high accident rates and the booming of the Indian construction sector, occupational health and safety has never been given prime importance. Additionally, regarding labour productivity, Patel and Jha [34] find that poor labour productivity is a chronic problem in construction sites in India, closely related to the lack of proper tools and equipment and poor material planning. Karthik and Kameswara Rao [35], focussing on masonry construction, further highlight the impact of insufficient worker skills/experience and the increased fatigue. In this context, there is an urgent need to examine alternative forms of construction [7], and it is time to rethink how construction projects could be conceived, planned and executed to achieve maximum benefits through OSC practices [12]. Sherfudeen et al. [14] also agree that moving towards large-scale mechanization and innovative construction methods such as OSC seems to be a feasible solution if planned, designed and implemented properly. Along the same lines, Sawhney et al. [36] have listed the lack of incentives for offsite construction and other modern technologies among the 15 challenges resulting in reduced efficacy and growth prospects of the Indian construction industry. Furthermore, as India has started taking steps towards sustainability and waste minimization, offsite construction has been drawing significant attention [15]. Nevertheless, OSC is still relatively new in India [7], accounting for less than 1% of the USD 100 bn Indian real estate sector [37], and the available research on OSC is currently minimal [12].

The factors adversely affecting the wider uptake of OSC in the construction industry worldwide have been well-documented in the literature. Wuni and Shen [38] presented a comprehensive review of 46 papers from 15 countries published between 2000 and 2019, where more than 100 barriers were identified and further grouped as financial, technical and aesthetic, as well as barriers relevant to knowledge, processes, policies, attitudes and the construction industry itself. Since the barriers were extracted verbatim from many different sources, there were significant similarities between them—as also acknowledged by the authors themselves. For instance, the barrier ‘expensive logistics’ placed in ‘financial barriers’ was very similar to the barrier ‘increased transportation and logistics cost’ placed in ‘process management barriers’. Similarly, the ‘conflict with traditional design and construction processes and practices’ listed in ‘process management barriers’ is very similar to the ‘dominance of conventional practices/processes and the ‘(lack of) changes to well–established practices and systems’, both included in the ‘Industry barriers’ list. Moreover, the ‘process barrier’ entitled ‘poor integration of the entire supply chain’ is very similar to the ‘industry’ barrier, ‘fragmentation of industry’. In this context, the full list of factors by Wuni and Shen [38] was carefully reviewed with the aim of detecting the most distinct barriers and combining those with high similarity in one factor. This process generated a list of around 35 barriers, which was then compared to lists of similar size presented by other researchers, i.e., Han and Wang [39] and Gan et al. [40], who identified 35 and 17 barriers, respectively, in the Chinese industry, Zhang et al. [41] and Mao et al. [42], who highlighted 6 and 18 main critical factors for China, respectively, Zhang et al. [43], who presented 6 main barriers for the building industry of Hong Kong, Hwang et al. [44], who detected 18 barriers from their research in the industry of Singapore, Bendi et al. [11] and Sherfudeen et al. [14], who identified 13 and 6 barriers, respectively, in the context of Indian industry, and Razkenari et al. [45], who reported 15 barriers/challenges from their research in the US industry. Additional relevant publications by Kamali and Hewage [46], Rahman [47], Azhar et al. [48], Jaillon and Poon [49] and Chiang et al. [50] were also reviewed. The conclusion after multiple circles of comparisons between the aforementioned papers is that all the studies have detected the same/very similar factors as the main barriers for OSC adoption, irrespective of their geographical context. For instance, the barrier ‘not easy to modify design scheme’ by Han and Wang [39] is effectively the same as all the following barriers: ‘inflexible for design change’ by Zhang et al. [43], ‘decreased flexibility for design changes later’ by Hwang et al. [44], ‘difficulty to freeze design at early stages’ and ‘inflexible to design changes’ by Razkenari et al. [45] and ‘inflexibility of design‘ by Zhang et al. [41]. At the same time, design inflexibility is related to the barrier ‘restrictive construction tolerances’ by Wuni and Shen [38] and Han and Wang [39]. This means that the concepts could be merged into the same factor. Table 1 presents the synthesis of the literature barriers as emerged from the review of the factors according to the previously explained rationale, and with the aim to avoid an overwhelmingly large number of pair comparisons for the interpretive structural modelling (ISM) analysis. This process is in line with the process of coding, which, according to Creswell and Poth [51], includes aggregating the text into categories, seeking evidence for the code from different sources, and then assigning a label to the code.

Table 1.

Synthesis of OSC implementation barriers as reported in the literature.

3. Methodology

A sequential mixed-methods research strategy with closed-ended questionnaires and semi-structured interviews followed by ISM analysis was chosen; mixed methods research allows investigators to collect a richer and stronger array of evidence than can be accomplished by any single method alone [52].

3.1. Quantitative Research

Much research in the social sciences and management spheres involves asking and obtaining answers to questions by conducting surveys of people using questionnaires [53]. Questionnaires have been commonly deployed within OSC research to establish perceptions and collect professional views (e.g., [11,43,45,54]). In this study, a systematic questionnaire aimed at identifying key barriers for the Indian OSC sector was created based on the literature findings. Prior to its distribution, the questionnaire was pretested by a team of academics with regard to its comprehensiveness and relevance. Furthermore, the draft version was sent to 2 construction professionals to make sure that the statements are clear and understandable. The feedback received helped in making some minor corrections.

The questionnaire commenced with an introductory note to the respondent, introducing the project’s aim and research team along with a brief explanation of the rationale for the study, eligibility criteria and issues associated with confidentiality. The questionnaire was aimed at construction professionals based in India only, and the survey was carried out online. The process followed to approach the potential participants could be described by snowball sampling [55], where the researcher makes initial contact with a small group of people who are relevant to the research topic and then uses these to establish contacts with others. Therefore, potential respondents from various cities in India were identified through the researchers’ professional network, and invitation emails were sent to each one of them separately. The invitations were spread to various cities of the country, some larger and more developed, as well as some smaller ones. Participants were allowed to complete the survey even if they did not have experience in OSC, as long as they confirmed that they had knowledge of the relevant concept and applications of any kind (e.g., precast elements, volumetric, modular etc). This was considered a reasonable requirement given the very low actual OSC implementation and experience of the sector. A total of 110 invitations were sent, and 68 responses were returned, indicating a 62% response rate. According to Mangione [56], response rates higher than 60% are acceptable. However, there is no doubt that a great deal of published research achieves lower response rates: matters of time and cost, as well as a growing tendency towards people refusing to participate in surveys, profoundly affect considerations of sampling size [55]. For instance, Agapiou [54] achieved 38% (69 responses), Razkenari et al. [45] achieved 43% (30 responses), Zhang et al. [43] achieved 17.5% (35 responses), Zhang et al. [41] achieved 57% (89 responses) and Gan et al. [40] achieved 40% (8 responses). In any case, Bell et al. [55] note that when samples are not selected on the basis of a probability sampling method (which is also the case with this survey), the response rate is less of an issue, because the sample would not be representative of a population even if everyone participated.

After some introductory questions on demographic information, the respondents were asked to agree or disagree with regard to the characterization of the factors of the list as important barriers to OSC implementation. The advantages of using closed questions of this kind include that they are easy and quick to complete and can also be pre-coded, thus turning the processing of data for computer analysis into a fairly simple task [55]. A Likert scale ranging from 1 to 5 (1 strongly disagree—5 strongly agree) was used to facilitate the coding of the items, as this is a scaling technique commonly employed in construction research [53] and one of the most frequently encountered formats for measuring attitudes [55].

The responses received were used for the determination of the average level of agreement (ALAi) on the importance of each factor i as per Equation (1), where LAj j = 1..n represents the alternative levels of agreement for factor i, Nj represents the number of respondents choosing the jth level of agreement, and n is the number of agreement levels provided. The ALA is the average as we commonly understand it in everyday use—that is, we add up all the values in a distribution and then divide by the number of values. The ALA allows the researchers to directly compare the scores of the answers and rank them in order of decreasing acceptance.

According to Shen and Tam [57], the commonly recognized weakness involved in using the average as a ranking criterion is that it does not consider the degree of variation between individual responses. The typical technique used to mitigate this weakness is to apply the coefficient of variation (CV), obtained through dividing the weighted average by the standard deviation (Equations (2) and (3)). Then, the final ranking of the factors emerges from the index value (IVi), which is the summation of the average level of agreement (ALAi) and coefficient of variation (CVi) (Equation (4)).

3.2. Qualitative Research

This research is a grounded theory study, i.e., seeks to generate a theory that relates to the particular situation forming the focus of the study and involves going out into ‘the field’ and collecting data [58]. The primary aim in collecting data is to maximize the amount and accuracy of transfer of meaning from the provider to the researcher [53]. Interviews represent a very common method and provide opportunities for understanding, reflection and explanation [59]. Semi-structured interviews, in particular, are two-way methods that give participants the time and opportunity to reconstruct their own experiences and reality in their own words [52]. They also permit feedback and the gathering of further data via probing [53]. For all the above reasons, interviews were selected as a suitable data collection method for this study. Sampling in grounded theory studies is purposive, as we do not seek a representative sample for its own sake; no statistical analysis is feasible with non-numerical data, nor is statistical generalization possible [58]. Instead, the inquirer selects individuals for study because they can purposefully inform an understanding of the research problem [51]. Procedurally, the researcher is expected to collect data until the categories found through analysis are ‘saturated’, i.e., no new input is being added [58].

In this research, five India-based professionals with significant experience in the offsite construction sector (chief executive officers, senior and mid-level managers) were interviewed with the aim of providing information of the current status of the OSC in India and input for the development of the model representing the causal relationships between the barriers for OSC implementation. The preliminary interview questions were organized to retrieve formal information regarding their expertise in the field and the status of the OSC implementation in the Indian construction industry. The follow-up questions included the identification of the importance of each barrier and the establishment of the contextual relationships between them, as per the requirements of the ISM. The selection of interviewees was based on a purposeful sampling strategy, not intended to achieve generalization, as explained previously. The size of the sample was initially selected due to time limitations, but its sufficiency was also confirmed from the point of view of input saturation. Indicatively, the same sample size (5 experts) was also used to represent the Indian construction sector in the research conducted by Bendi et al. [7] and Jha and Devaya [60], while Bajpai and Misra [61] used the input of 6 experts. Furthermore, Gan et al. [40] note that there is no suggested minimum number of participants for ISM in the literature.

ISM is suitable for the intended research aim, as by definition, it involves the transformation of unclear and poorly articulated mental models of systems into visible, well-defined models useful for many purposes; it identifies the structure within a system [62]. The demystification of barriers, in particular, has widely been achieved through the ISM approach in a variety of implementation areas and contexts. For instance, in the context of the Indian construction, Parida et al. [9], Qarnain et al. [63], Bajpai and Misra [61], Ambekar et al. [64] and Ganguly and Das [65] have recently used ISM to model the relationships between barriers affecting sustainability, energy, digitalization, logistics and construction activities. ISM models are based on the systematic iterative application of graph theory, resulting in directed graphs amongst the set of elements under consideration, as per the following steps [66].

3.2.1. Formation of Structural Self-Interaction Matrix (SSIM)

Four symbols are used to denote the type of relation that exists between any two elements i and j under consideration. The symbols are:

- V for the one-direction relation from element i to element j (i helps achieve j);

- A for the one-direction relation from element j to element i (j helps achieve i);

- X for bidirectional interaction between i and j;

- 0 (zero), if there is no valid relation between i and j.

The SSIM of each element emerges from all the pair-wise interactions of the respective element with the other elements. The contextual relationship that is widely used in management between different elements could be ‘i will help achieve j’. However, we also need to bring out a deeper understanding by interpreting the relationship as: ‘In what way i should/will help achieve j?’ The interpretation of the relationship would be specific for each pair of objectives so as to make the deep-rooted knowledge explicit [62].

3.2.2. Formation of Reachability Matrix

The SSIM is transformed into the reachability matrix format by replacing the symbols ‘V’, ’A’, ’X’, and ‘O’ by 1 and 0. The four situations are:

- If the (i, j) entry in the SSIM is a V, the (i, j) entry in the reachability matrix becomes 1, and the (j, i) entry becomes 0.

- If the (i, j) entry in the SSIM is an A, the (i, j) entry in the reachability matrix becomes 0, and the (j, i) entry becomes 1.

- If the (i, j) entry in the SSIM is an X, both the (i, j) entry and the (j, i) entry of the reachability matrix become 1.

- If the (i, j) entry of the SSIM is a O, then both the (i, j) and (j, i) entries of the reachability matrix become 0.

Following these rules, the direct relationship matrix (initial reachability matrix) for the elements has been formed. However, this matrix is not able to identify the indirect inter-relationships between variables, which create influence chains and reaction loops [66]. Therefore, the diffusion of impacts through reaction paths and loops needs to be checked as per the MICMAC (Matrice d’impacts Croises-Multiplication Appliquée a un Classement) principle, originally introduced by Duperrin and Godet [67]. The MICMAC principle says that if variable i directly influences variable k and if variable k directly influences variable j, any change affecting variable i can have repercussions on variable j. Therefore, there is an indirect connection between i and j, also known as transitivity (e.g., [68]). The identification of the indirect connections between all variables may need to be assisted by computers and are represented by ‘1*’ in the final reachability matrix.

3.2.3. Level Partitions for Barriers and Strategies

This task involves identifying a reachability set and an antecedent set for each barrier, as those emerge from the final reachability matrix. The reachability set of a barrier comprises the barrier itself and every other barrier that it has an impact on (‘V‘ or ‘X’ relationship), whereas the antecedent set comprises the respective barrier and all the barriers that have an impact on it (‘A’ relationship). The intersection set consists of the barriers that are common in these two sets. The first factor for which the intersection set matches the reachability set is assigned as a top-level barrier in the ISM hierarchy or in Level 1 and is disregarded in the iterations that come next. The process is repeated until all the barriers have been assigned to a level. Having identified the levels of all the elements, the array of relationships found and the subsequent hierarchy can be depicted with the help of arrows. The resulting representation is called digraph. Sushil [62] presents a detailed relevant example.

Furthermore, the variables can be classified into four categories, depending on their driving power and dependence. The former is the value representing the size of the reachability set of each barrier, while the latter represents the size of the antecedent set of each barrier, as per the final reachability matrix. In other words, the driving power is derived by summing the number of interactions in the rows, and the dependence is determined by summing the entries in the columns. The four emerging categories of the variables (barriers) are [66]:

- Autonomous variables (QI)—barriers with weak driving power and weak dependence. These factors are relatively disconnected from the system and have weak or no dependence on other factors.

- Dependent variables (QII)—barriers with weak driving power but strong dependence on other factors.

- Linkage variables (QIII)—barriers with simultaneously strong driving and dependence power. These factors should be studied more carefully, as they are unstable. Any action on these variables will have an impact on others and a feedback effect on themselves to amplify or support the initial pulse.

- Independent variables (QIV)—barriers with strong driving power and weak dependence, which condition the rest of the system.

4. Results

4.1. Quantitative Research

Overall, 110 questionnaires were distributed to construction industry professionals in India, out of which 68 were returned, indicating a response rate of 62%. According to their role, the respondents were categorized into managing directors (31%), chief executive officers (6%), project managers (41%), site engineers (15%) and architects/designers (7%). Regarding their experience in the industry, 37 (54%) had experience of between 15 and 20 years, 24 (35%) between 10 and 15 years, 7 (11%) below 10 years.

The ALA, IV and final rankings emerging from the total of the responses received are presented in Table 2. It can be observed that a very strong acceptance as OSC implementation barriers (ALA > 4.5) is observed for the lack of design flexibility, the supply chain weaknesses as well as the practical difficulties related to transportation and storage. Furthermore, the factors of limited practical experience in the industry, the lack of appropriate collaboration and procurement framework and the financial unattractiveness of OSC were also highly ranked as factors inhibiting OSC implementation (4 < ALA < 4.5). The list of top 10 barriers is completed by the lack of appropriate equipment, design complexity and resistance to change/innovation (3.5 < ALA < 4). The perceptions of OSC as of low quality/value and high cost, although not strongly confirmed by the respondents, are not rejected either (ALA > 3), and the same applies to the lack of governmental guidance, which has been ranked at the bottom of the barriers list. It can be noted in Table 2 that the rank order does not change significantly whether the criterion of ALA or IV is followed, indicating high stability in the ranking of the barriers.

Table 2.

Importance level and ranking of barriers as per the survey.

4.2. Interpretive Structural Modelling

4.2.1. Formation of Structural Self-Interaction Matrix (SSIM) and Reachability Matrix

Five experts from the Indian construction industry were interviewed with the aim to obtain insight into the current use of the OSC in India and understand the factors hindering its wider usage. The experts confirmed all the barriers highlighted by the questionnaire survey as applicable in the context of India. They emphasized the limitations of design and how these are exacerbated by the highly volatile nature of the Indian construction industry, which favours late specification changes. Furthermore, the uneven distribution of cities and rural areas throughout the country, the limited accessibility of certain locations and the inadequate transport infrastructure were mentioned as factors that increase the complexity of OSC logistics and make it difficult for high-density modules to be efficiently transported. Additionally, the scarcity of prefabrication facilities in India was mentioned as a significant obstacle to OSC adoption, as the transportation distances are typically too long and entail excessive costs. Furthermore, special mention was made by most of the experts on the financial barriers emerging due to the high initial capital requirements, the low investment returns and the lack of government incentives/subsidies.

Based on input provided by the interviewees, the contextual relationships between the 10 most important barriers of Table 2 (relevant abbreviation included in the first column of Table 3) were determined as either ‘O’, ‘V’, ’A’ or ‘X’, as explained in Section 3. Table 3 represents the SSIM, i.e., it displays the final pairwise relationship that was collectively provided by the industry experts. Following this, the reachability matrix can be developed (Table 4) as previously explained and becomes the basis for the identification of indirect (transitive) relations (represented by ‘1*’ in the matrix) that are included in the final reachability matrix (Table 5).

Table 3.

Structural self-intersection matrix (SSIM) for barriers to OSC implementation in India.

Table 4.

Initial reachability matrix for barriers to OSC implementation in India.

Table 5.

Final reachability matrix for barriers to OSC implementation in India.

Then, the values representing the driving power and the dependence of each factor are established, with the driving power being equal to the sum of the values in a row and dependency being equal to the sum of the values in a column. Practically, these values represent the number of barriers that each barrier has an impact on (driving power) and the number of barriers with an impact on this barrier (dependence), respectively.

4.2.2. Level Partition of Barriers

Referring to the final reachability matrix (Table 5), and as per the partition process previously described, the first iteration assigned barrier b1 to the top level of the model (Table 6). In the second iteration, barrier b9 was assigned to the second level (Table 7), while with the third iteration, b2, b3, b4, b6, b8 and b10 were assigned to the third level (Table 8). The fourth iteration placed b5 at level four (Table 9), while the fifth and last iteration placed b7 at level five (Table 10). The guidance provided by Sushil [68] regarding ISM model cross-checking was also followed to confirm the correctness of the model.

Table 6.

Partition of reachability matrix for barriers (first iteration).

Table 7.

Partition of reachability matrix for barriers (second iteration).

Table 8.

Partition of reachability matrix for barriers (third iteration).

Table 9.

Partition of reachability matrix for barriers (fourth iteration).

Table 10.

Partition of reachability matrix for barriers (fifth iteration).

4.2.3. Formation of the Interpretive Structural Model

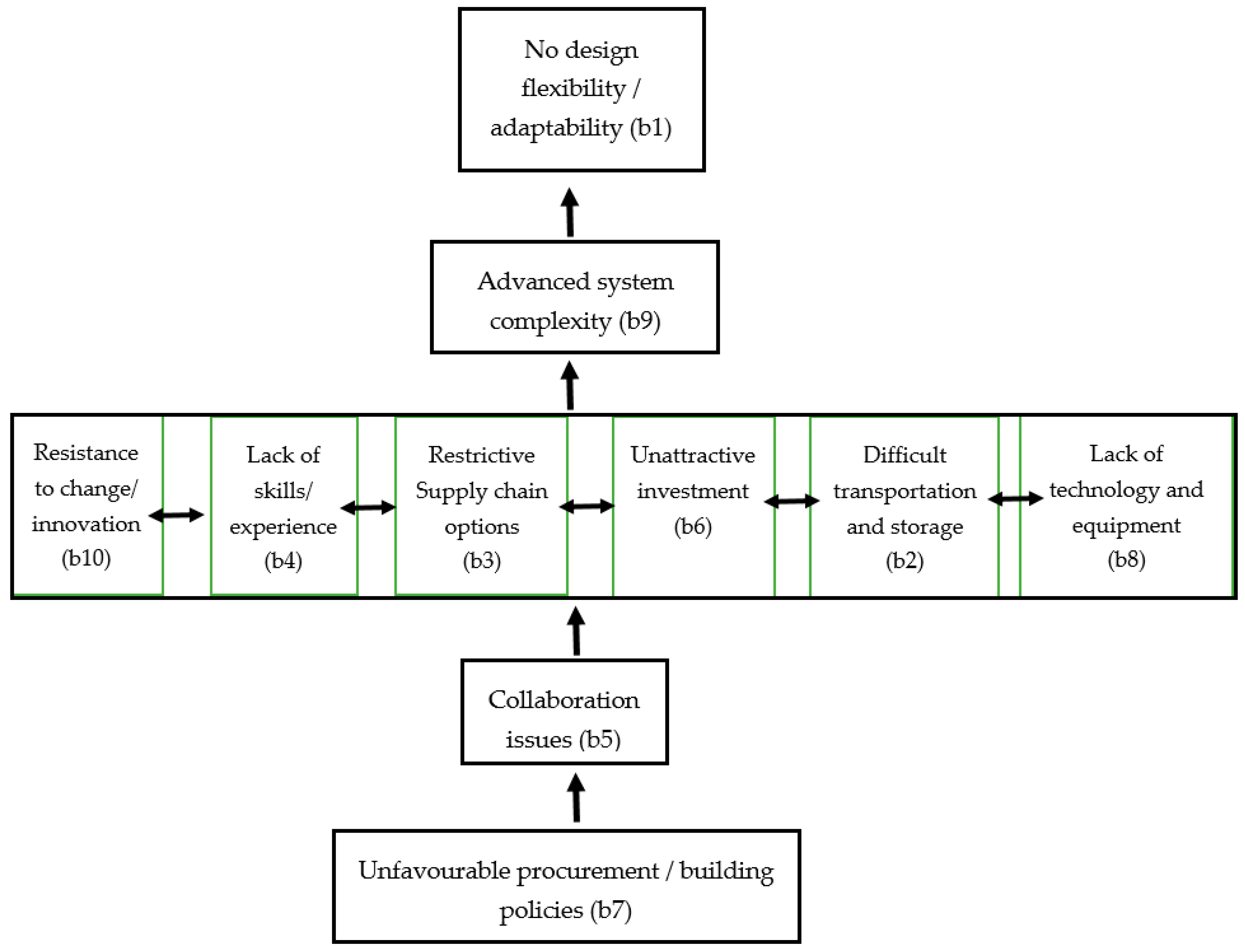

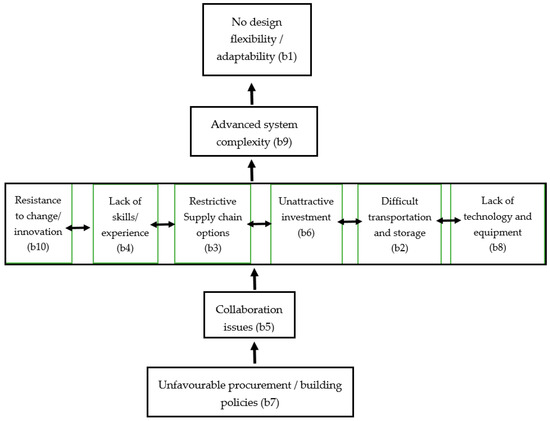

The 10 barriers were placed into five different levels, as described previously, and the final hierarchical model is represented by the graph of Figure 1.

Figure 1.

Hierarchical structure of causal relations between the OSC barriers.

The structure of the graph reveals that policy deficiencies relevant to procurement processes and building regulations (b7) nurture the immediately higher (fourth) level barrier of collaborative gap (b5), and they both directly exacerbate the barriers emerging from the transportation and storage issues (b2), the supply chain restrictions (b3), the lack of skills/experience (b4), the lack of technology and equipment (b8) and the resistance to change and innovation (b10), as well as the unattractiveness of OSC as an investment option (b6).

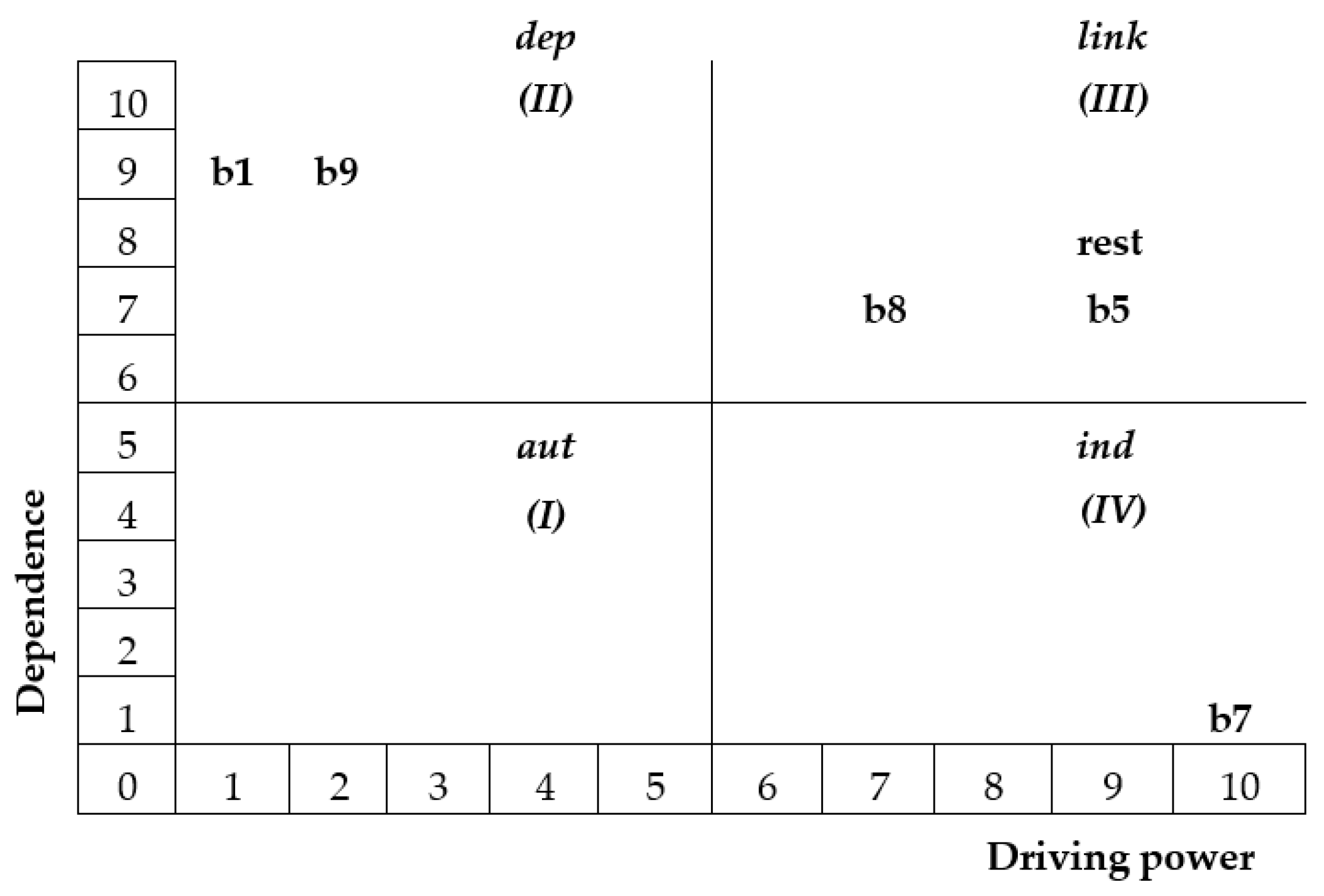

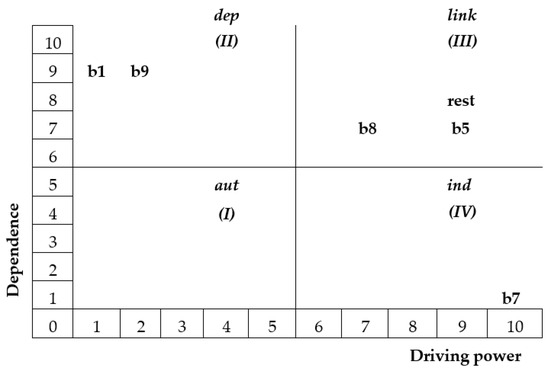

4.2.4. Classification Using MICMAC Analysis

The MICMAC analysis identified three groups of barriers (no autonomous barriers emerged), as shown in Figure 2, and according to the definitions of Section 3.

Figure 2.

Driving–dependence power diagram for OSC barriers.

Barriers b1 and b9 are categorized as dependent barriers, barriers b2, b3, b4, b5, b6, b8 and b10 are the linkage barriers, and barrier b7 is the sole independent barrier. This group formation is compatible with the allocation of b1 and b9 to levels I and II of the digraph of Figure 1, i.e., to the upper levels denoting higher dependency to other barriers. MICMAC analysis also confirms that b7—which is placed at the bottom of the digraph (level 5)—acts as the root cause of the observed barriers in OSC implementation, as it simultaneously attains the highest impact and the lowest dependency amongst all the factors.

5. Discussion

The comparison between the results of the questionnaire survey and the ISM/MICMAC analysis allows us to conclude that barriers that are perceived as most important—such as the design’s lack of flexibility for changes (b1) and the difficult transportation and storage (b2)—can only be effectively addressed if barriers of lower perceived importance (e.g., b7—deficiencies relevant to procurement processes and building regulations and b5—collaboration issues) are tackled first. The reason is that these are the barriers of highest driving power, and therefore, they exacerbate, directly or indirectly, the vast majority of the barriers, even though this may not be immediately apparent.

By placing b7 at the lowest level of the causal hierarchy of the barriers, the ISM/MICMAC analysis highlights the tremendous potential of regulatory initiatives to actively promote OSC implementation through appropriate procurement and building rules. The above is in line with the view of Mao et al. [42] and Lu et al. [69], that governmental regulations are among the strongest enablers to OSC adoption in a certain context. This results from the fact that governments, as public project clients, are in the position to generate demand for OSC by imposing the new public buildings (schools, hospitals, etc.) to be designed with the use of prefabricated components. Agapiou [54] also confirms that UK housing associations are unwilling to engage to OSC unless the volume of work is such that it can be done at scale. To achieve this, the UK government implements the “presumption in favour” of off-site construction across suitable capital programmes. This binds five Governmental Departments to include at least one off-site manufacture-based option at the development stage of their projects [70]. Furthermore, similar strategies are also reported for Finland [14], while Singapore is also a country where OSC has received official state endorsement with mandatory adoption since 2014 for developments on Government land sites [71]. Similar initiatives have been undertaken in China, with the Central Government setting forth a mid-term goal to apply prefabrication to 30% of the domestic newly constructed buildings, as well as in Malaysia and Hong Kong, where governments have also aggressively promoted the use of prefabrication [69]. Nanyam et al. [13] also confirm from an Indian perspective that government or major players have to take the lead in investing in OSC so as to utilize the economies of scale to full extent. Along the same lines, Sherfudeen et al. [14] propose the procurement of government-supported OSC mega projects in special residential zones. This can additionally allow for the creation of on-site precast facilities, which are a very efficient solution to the transportation barrier (b2) highlighted by the survey.

Besides the mandate of OSC use, another procurement-bound strategic decision advocated for facilitating its adoption is earlier engagement with supply chains [72]. The resulting early collaboration of stakeholders, such as designers, engineers, suppliers and contractors, enables the production experience to be captured and fed forward for use in design [24]. This, in turn, leads to improved design solutions, enhanced buildability, fewer design changes and disputes and cost and time savings (e.g., Bakti et al. [73]; Gerth et al. [24]; Love et al. [74]; Kifokeris and Xenidis [23]). Agapiou [54] also confirms that the UK’s housing associations are keen to be involved in decision making earlier in the planning process to involve the supply chain and develop plans and proposals around the capabilities of OSC. Given that the extent and timing of the contractor’s involvement and the subsequent benefits are subject to the selection of an appropriate procurement route, suitable governmental initiative would be needed to put aside the traditional and fragmented option of the Design–Bid–Build (DΒΒ) sequence and replace it with integrated options such as design and build (DB), early contractor involvement (ECI), competitive dialogue and alliance contracts [22,75]. The above can undoubtedly alleviate the design inflexibility/complexity (b1, b9) and collaboration (b5) barriers of the developed ISM model.

Moreover, OSC implementation is an option that needs to be very carefully considered within its political–environmental–technological and social (PEST) context, as PEST forces largely determine its success or failure [69]. Therefore, an additional suggested change also related to the procurement stage would be the replacement of the commonly used ‘lowest price’ criterion for contract award with criteria with qualitative, environmental and/or social dimensions. Such an approach is already widely implemented in the EU, where the most economically advantageous tender is identified on the basis of criteria such as the delivery date, technical and functional characteristics and environmental impact, among others [75]. In this context, an OSC-based bid would considerably increase its chances to be successful, compared to the case where the selection of award criteria align with the lowest cost mindset. Furthermore, this approach eliminates the risk of poor quality, excessive supervision, claims and disputes, which very often accompany the lowest price bids [76]. Therefore, promoting OSC through the procurement criteria also results in sustainability and value for money enhancement.

The ISM/MICMAC analysis also reveals that the fragmentation and lack of collaboration in the construction sector (b5) is a major barrier with high driving power. This can be substantially alleviated with the use of collaborative tools based on virtual design and building information modelling (BIM), which significantly increases the common understanding of the stakeholders on the project and provides a platform for identifying opportunities for improving manufacturing and assembly processes [77]. BIM generates three-dimensional digital building components with computable graphic and data attributes as well as parametric rules that allow for design changes to be shared, visualized, estimated and resolved through the prompt and automatic update of the common model as soon as a design change is entered [78]. This allows the multiple stakeholders to develop a shared understanding of the project as well as to eliminate design errors and communication issues [79]. Especially in the OSC field, BIM is an upcoming trend [80] and allows the key stakeholders to make informed decisions about design changes and the production of components [77]. This is also confirmed by Agapiou [54], presenting UK housing associations’ views.

The ISM analysis also highlights the bi-directional link between construction professionals’ limited practical experience in OSC (b4) and the sector’s resistance to innovation/change (b10); in fact, this is the only direct (non-transitive) mutual dependence found in the SSIM (relation ‘X’). The MICMAC analysis reveals that the driving power of both these barriers is very high (five direct relations and another four transitive, i.e., 9/10), which means that they need immediate and efficient tackling. Given that construction stakeholders may show an overwhelming resistance to change [6] as well as reluctance to work cooperatively and achieve the required level of integration [74,81], the culture change required for OSC integration in building is commonly perceived to be difficult and painful [72]. In this context, the establishment of appropriate mandatory policies and regulations in the sector is of utmost importance. These can concern the mandate of the aforementioned collaborative procurement routes, the establishment of effective value for money criteria for contract award and the use of BIM in design. Such mandates leave no room for resistance and can make a substantial contribution to the uptake of OSC. Additional efforts are also necessary on behalf of the government to manage the change, for instance, by increasing stakeholder awareness of the advantages of the various tools such as the design for manufacturing and assembly (DfMA) [6] and actively encouraging people to enter careers in OSC. Appropriate training and education at all levels, modern apprenticeship schemes and relevant vocational qualifications are necessary for this purpose [26]. Along the same lines, Sherfudeen et al. [14] suggest that universities should introduce related courses and workshops and motivate students’ engagement with scholarships. Furthermore, they also highlight the need for architects to receive adequate training so as to approach with creativity the design of standard elements.

The ISM model also reveals that, amongst the barriers of level III, the low attractiveness of OSC as investment (b6) has a considerable direct impact on other barriers (four direct relations). This is in line with Gao et al.’s [82] opinion that, from a holistic perspective, the overall cost intensity is the main cause of the slow uptake of OSC. This shows that the efficiency gains associated with OSC need to be particularly highlighted. The latter include the elimination of factors such as on-site accidents, unforeseen ground conditions, the improper storage of materials and extreme weather, which all exacerbate the burning issue of low productivity of Indian construction [30,83]. Furthermore, project efficiency increases can be achieved with the promotion of DfMA principles, intended to simplify the manufacturing and assembly process and eliminate non-value-adding activities [77,80]. Relevant examples of nation-wide promotional initiatives come from various countries such as the UK and Singapore. In the UK, the government is actively promoting standardization and buildability through the adoption of a ‘Platform Approach to DfMA’. This approach aims to minimize the need for bespoke components and enable digitally designed components to be used whenever possible, not only across different types of built assets, but also across different sectors. For example, a single component could be used as part of a school, hospital, prison building or station. In this context, five departments are committed to procuring designs with the use of a defined set of standardized and interoperable components [70]. Along the same lines, Finland applies open-element systems based on agreed principles [14]. Similarly, the Singapore government has introduced the Minimum Buildable Design Score (B-score) and the Minimum Constructability Score (C-score) as part of a DfMA-relevant legislative framework [8]. Sherfudeen et al. [14] further confirm the importance of such an approach in the context of India, stressing that the standardization of precast concrete elements and their certification in appropriate testing facilities is the only way for OSC to obtain professionals’ acceptance and eventually have the same level of trust as steel products. In addition, they also highlight the need to enhance R&D for monolithic water-tight connections between the precast elements. Nanyam et al. [13] also confirm the need for high quality strict checks to efficiently encounter water seepage issues.

Furthermore, another tool suitable to enhance OSC’s attractiveness as an investment is the use of BIM. BIM can show the economic business case for design alternatives [84] and can generate considerable cost savings during construction [85]. Besides BIM and DfMA, other cost engineering means for sustaining OSC’s investment attractiveness include partnering and ‘in-house’ build management. These utilize the effects of the learning curve in improving efficiency or reducing cost [86]. Furthermore, where necessary, commensurate financial support and grants need to be provided by the government to cover any expenses occurring for software/equipment purchase and relevant staff training. Moreover, it goes without saying that the establishment of economic incentives/subsidies are extremely helpful for OSC to be implemented on a scale large enough for economies of scale to be achieved and ultimately increase attractiveness and encourage adoption. This has also been confirmed by Mao et al. [42] and Lu et al. [69]. Additionally, Park et al. [87] highlighted how financial incentives such as interest-free financing proved to effectively promote the use of OSC in Singapore. However, in developing economies such as India, the dimension of financial support is of increased complexity due to resource scarcity and competing demands from a variety of sectors such as education, healthcare, agriculture and infrastructure [88]. Therefore, the private sector’s decisive response with appropriate initiatives and capital investment is equally important, provided that the government is committed to the regulatory changes required for OSC’s uptake in the country. Sherfudeen et al. [14] further expand the government’s potential facilitating initiatives for OSC adoption to include tax reliefs and reduced approval timelines. With these conditions in place, it is a matter of some years for the sector to cover the skill gap inhibiting OSC (b4) and achieve the level of experience required.

6. Conclusions

Τhe position of India as one of the fastest growing large economies and the global implications of its environmental footprint urges the true potential of OSC’s sustainability gains to be explored and leveraged. However, this requires a clear understanding of the factors currently inhibiting the efficient OSC implementation and their effective tackling. The findings of the questionnaire survey showed that the factors with the highest perceived importance as OSC implementation barriers in India are the lack of design flexibility (ALA = 4.62), the weaknesses of the supply chain (ALA = 4.46) and the practical difficulties related to the transportation and storage of the modules (ALA = 4.56). Furthermore, the industry’s lack of experience (ALA = 4.24), the lack of appropriate collaboration (ALA = 4.18) and procurement framework (ALA = 4.01), as well as financial unattractiveness (ALA = 4.18) are also highly ranked barriers. The causal relationships between the barriers, as demonstrated by the conducted ISM/MICMAC analysis and the resulting graphs (Figure 1 and Figure 2), reveal that barriers relevant to procurement processes (level 5 of the hierarchical model) and collaboration issues (level 4 of the hierarchical model) concentrate the highest driving power and lowest dependence and therefore need to be tackled first. In this context, this research demonstrated how procurement strategies can make a substantial contribution to the uptake of OSC. These include procurement routes that enhance collaboration and the early diffusion of construction input in design, along with prioritizing value for money criteria over lowest price. A similar beneficial impact was clearly established for the use of tools such as DfMA and BIM in design. Furthermore, the facilitating role of economic incentives/subsidies from the side of the government was also highlighted. Finally, the private sector’s decisive response is equally important, provided that the government is committed to the regulatory changes required. The above strategies can effectively address the barriers typifying the sector and considerably contribute to the expansion of OSC in India.

Author Contributions

Conceptualization, M.M. and R.D.; methodology, M.M., A.K. and R.D.; formal analysis, M.M., A.K. and M.J.; writing—original draft preparation, M.M. and R.D.; writing—review and editing, M.M., A.K. and M.J.; supervision, M.M. and M.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Science and Engineering, Arts, Humanities and Law Research Ethics Committee of the UNIVERSITY OF LEICESTER (protocol code 26646- 08.06.2020).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Valdes-Vasquez, R.; Klotz, L. Incorporating the social dimension of sustainability into civil engineering education. J. Prof. Issues Eng. Educ. Pract. 2011, 137, 189–197. [Google Scholar] [CrossRef]

- Zagyi, N.; Kuszinger, R.; Wilhelm, Z. Characteristics of recent urbanisation in India in light of the divergent development paths of metropolises. Reg. Stat. 2021, 11, 60–94. [Google Scholar]

- Ministry of Housing and Urban Affairs. G.o.I. Annual Report 2020–2021. Available online: https://mohua.gov.in/upload/uploadfiles/files/Annual_Report_2020_21_MoHUA_EnglishVersion%20(Final).pdf (accessed on 22 March 2022).

- Mustapha, F.; El Abbassi, I.; Kadri, E.; Darcherif, M. Strategy of Container Assembly for a Positive Energy Impact in Poona India. In Proceedings of the E3S Web of Conferences, 6th International Conference on Energy and City of the Future (EVF’2019), Pune, India, 18–20 December 2020; p. 01004. [Google Scholar]

- Goel, A.; Ganesh, L.; Kaur, A. Deductive content analysis of research on sustainable construction in India: Current progress and future directions. J. Clean. Prod. 2019, 226, 142–158. [Google Scholar] [CrossRef]

- Lu, W.; Tan, T.; Xu, J.; Wang, J.; Chen, K.; Gao, S.; Xue, F. Design for manufacture and assembly (DfMA) in construction: The old and the new. Archit. Eng. Des. Manag. 2021, 17, 77–91. [Google Scholar] [CrossRef]

- Bendi, D.; Rana, M.Q.; Arif, M.; Goulding, J.S.; Sawhney, A. An off-site construction readiness maturity model for the Indian construction sector. Constr. Innov. 2021, 21, 123–142. [Google Scholar] [CrossRef]

- Antoniou, F.; Marinelli, M. Proposal for the promotion of standardization of precast beams in highway concrete bridges. Front. Built Environ. 2020, 6, 119. [Google Scholar] [CrossRef]

- Parida, R.; Katiyar, R.; Rajhans, K. Identification and analysis of critical barriers for achieving sustainable development in India. J. Model. Manag. 2022. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Banihashemi, S.; Martek, I.; Tabadkani, A.; Shrestha, A. Sustainable construction project management critical success factors for developing countries. In Proceedings of the 22nd International Conference on Advancement of Construction Management and Real Estate, CRIOCM 2017, Melbourne, VIC, Australia, 20–23 November 2017; pp. 77–84. [Google Scholar]

- Bendi, D.; Rana, M.Q.; Arif, M.; Goulding, J.S.; Kaushik, A.K. Understanding off-site readiness in Indian construction organisations. Constr. Innov. 2021, 21, 105–122. [Google Scholar] [CrossRef]

- Bendi, D.; Rana, M.Q.; Arif, M.; Lamb, S.M.; Sawhney, A.; Kaushik, A.K. Assessing off-site readiness in construction organisations: Cases from India. Constr. Innov. 2022, 22, 320–341. [Google Scholar] [CrossRef]

- Nanyam, V.N.; Basu, R.; Sawhney, A.; Vikram, H.; Lodha, G. Implementation of precast technology in India–opportunities and challenges. Procedia Eng. 2017, 196, 144–151. [Google Scholar] [CrossRef]

- Sherfudeen, A.P.; Kumar, N.; Raghavan, N.; Pillai, R.G.; Kalidindi, S.N. Promoting precast concrete for affordable housing–An overview on promotional policies worldwide and challenges and possibilities in India. Indian Concr. J. 2016, 90, 13–25. [Google Scholar]

- Arif, M.; Bendi, D.; Sawhney, A.; Iyer, K. State of offsite construction in India-Drivers and barriers. J. Phys. Conf. Ser. 2012, 364, 012109. [Google Scholar] [CrossRef]

- Smith, R.E.; Quale, J.D. Offsite Architecture: Constructing the Future; Taylor & Francis: Abingdon, UK, 2017. [Google Scholar]

- Peurifoy, L.R.; Oberlender, D.G. Formwork for Concrete Structures, 4th ed.; The McGraw-Hill Companies: New York, NY, USA, 2011. [Google Scholar]

- Dikmen, S.U.; Sonmez, M. An artificial neural networks model for the estimation of formwork labour. J. Civ. Eng. Manag. 2011, 17, 340–347. [Google Scholar] [CrossRef]

- Kim, M.-K.; McGovern, S.; Belsky, M.; Middleton, C.; Brilakis, I. A suitability analysis of precast components for standardized bridge construction in the United Kingdom. Procedia Eng. 2016, 164, 188–195. [Google Scholar] [CrossRef]

- Dimitriou, L.; Marinelli, M.; Fragkakis, N. Early bill-of-quantities estimation of concrete road bridges: An artificial intelligence-based application. Public Work. Manag. Policy 2018, 23, 127–149. [Google Scholar] [CrossRef]

- Fragkakis, N.; Marinelli, M.; Lambropoulos, S. Preliminary cost estimate model for culverts. Procedia Eng. 2015, 123, 153–161. [Google Scholar] [CrossRef][Green Version]

- Naoum, S.G.; Egbu, C. Modern selection criteria for procurement methods in construction: A state-of-the-art literature review and a survey. Int. J. Manag. Proj. Bus. 2016, 9, 309–336. [Google Scholar] [CrossRef]

- Kifokeris, D.; Xenidis, Y. Constructability: Outline of past, present, and future research. J. Constr. Eng. Manag. 2017, 143, 04017035. [Google Scholar] [CrossRef]

- Gerth, R.; Boqvist, A.; Bjelkemyr, M.; Lindberg, B. Design for construction: Utilizing production experiences in development. Constr. Manag. Econ. 2013, 31, 135–150. [Google Scholar] [CrossRef]

- Marinelli, M. A DfX-based approach for incorporating sustainability in infrastructure project planning. Built Environ. Proj. Asset Manag. 2021, 12, 20–37. [Google Scholar] [CrossRef]

- Goodier, C.; Gibb, A. Future opportunities for offsite in the UK. Constr. Manag. Econ. 2007, 25, 585–595. [Google Scholar] [CrossRef]

- Goodier, C.; Gibb, A.; Mancini, M.; Turck, C.; Gjepali, O.; Daniels, E. Modularisation and offsite in engineering construction: An early decision-support tool. Proc. Inst. Civ. Eng. 2019, 172, 3–14. [Google Scholar] [CrossRef]

- Jansen van Vuuren, T.; Middleton, C. Methodology for Quantifying the Benefits of Offsite Construction. Buildoffsite, CIRIA. 2020. Available online: https://www.ciria.org/ItemDetail?iProductCode=C792F&Category=FREEPUBS&WebsiteKey=3f18c87a-d62b-4eca-8ef4-9b09309c1c91 (accessed on 29 March 2022).

- Gokarakonda, S.; Shrestha, S.; Caleb, P.R.; Rathi, V.; Jain, R.; Thomas, S.; Topp, K.; Niazi, Z. Decoupling in India’s building construction sector: Trends, technologies and policies. Build. Res. Inf. 2019, 47, 91–107. [Google Scholar] [CrossRef]

- Doloi, H.; Sawhney, A.; Iyer, K.; Rentala, S. Analysing factors affecting delays in Indian construction projects. Int. J. Proj. Manag. 2012, 30, 479–489. [Google Scholar] [CrossRef]

- Ahsan, K.; Gunawan, I. Analysis of cost and schedule performance of international development projects. Int. J. Proj. Manag. 2010, 28, 68–78. [Google Scholar] [CrossRef]

- Goel, A.; Ganesh, L.; Kaur, A. Sustainability assessment of construction practices in India using inductive content analysis of research literature. Int. J. Constr. Manag. 2021, 21, 802–817. [Google Scholar] [CrossRef]

- Kanchana, S.; Sivaprakash, P.; Joseph, S. Studies on labour safety in construction sites. Sci. World J. 2015, 2015, 590810. [Google Scholar] [CrossRef]

- Patel, D.A.; Jha, K.N. An estimate of fatal accidents in Indian construction. In Proceedings of the 32nd Annual ARCOM Conference, Manchester, UK, 5–7 September 2016; pp. 577–586. [Google Scholar]

- Karthik, D.; Kameswara Rao, C.B. Identifying the significant factors affecting the masonry labour productivity in building construction projects in India. Int. J. Constr. Manag. 2022, 22, 464–472. [Google Scholar] [CrossRef]

- Sawhney, A.; Agnihotri, R.; Paul, V.K. Grand challenges for the Indian construction industry. Built Environ. Proj. Asset Manag. 2014, 4, 317–334. Available online: https://www.emerald.com/insight/content/doi/10.1108/BEPAM-10-2013-0055/full/html (accessed on 29 March 2022). [CrossRef]

- Sachdev, P. Modular Construction and its Adaptation in India. Int. J. Res. Eng. Sci. Manag. 2018, 1, 2581–5782. [Google Scholar]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Han, Y.; Wang, L. Identifying barriers to off-site construction using grey DEMATEL approach: Case of China. J. Civ. Eng. Manag. 2018, 24, 364–377. [Google Scholar] [CrossRef]

- Gan, X.; Chang, R.; Zuo, J.; Wen, T.; Zillante, G. Barriers to the transition towards off-site construction in China: An Interpretive structural modeling approach. J. Clean. Prod. 2018, 197, 8–18. [Google Scholar] [CrossRef]

- Zhang, X.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialized residential building in China. Habitat Int. 2014, 41, 176–184. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Pan, W.; Ye, K. Major barriers to off-site construction: The developer’s perspective in China. J. Manag. Eng. 2015, 31, 04014043. [Google Scholar] [CrossRef]

- Zhang, W.; Lee, M.W.; Jaillon, L.; Poon, C.-S. The hindrance to using prefabrication in Hong Kong’s building industry. J. Clean. Prod. 2018, 204, 70–81. [Google Scholar] [CrossRef]

- Hwang, B.-G.; Shan, M.; Looi, K.-Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Razkenari, M.; Fenner, A.; Shojaei, A.; Hakim, H.; Kibert, C. Perceptions of offsite construction in the United States: An investigation of current practices. J. Build. Eng. 2020, 29, 101138. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Rahman, M.M. Barriers of implementing modern methods of construction. J. Manag. Eng. 2014, 30, 69–77. [Google Scholar] [CrossRef]

- Azhar, S.; Lukkad, M.Y.; Ahmad, I. An investigation of critical factors and constraints for selecting modular construction over conventional stick-built technique. Int. J. Constr. Educ. Res. 2013, 9, 203–225. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S. Design issues of using prefabrication in Hong Kong building construction. Constr. Manag. Econ. 2010, 28, 1025–1042. [Google Scholar] [CrossRef]

- Chiang, Y.-H.; Chan, E.H.-W.; Lok, L.K.-L. Prefabrication and barriers to entry—A case study of public housing and institutional buildings in Hong Kong. Habitat Int. 2006, 30, 482–499. [Google Scholar] [CrossRef]

- Creswell, J.W.; Poth, C.N. Qualitative Inquiry & Research Design: Choosing among Five Approaches; SAGE Publication Incorporated: London, UK, 2019. [Google Scholar]

- Yin, R.K. Qualitative Research from Start to Finish; Guilford Publications: New York, NY, USA, 2015. [Google Scholar]

- Fellows, R.F.; Liu, A.M. Research Methods for Construction; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Agapiou, A. Barriers to offsite construction adoption: A quantitative study among housing associations in England. Buildings 2022, 12, 283. [Google Scholar] [CrossRef]

- Bell, E.; Harley, B.; Bryman, A. Business Research Methods; Oxford University Press: Oxford, UK, 2022. [Google Scholar]

- Mangione, T.W. Mail Surveys: Improving the Quality; Sage: Thousand Oaks, CA, USA, 1995; Volume 40. [Google Scholar]

- Shen, L.; Tam, V.W. Implementation of environmental management in the Hong Kong construction industry. Int. J. Proj. Manag. 2002, 20, 535–543. [Google Scholar] [CrossRef]

- Robson, C.; McCartan, K. Real World Research, 4th ed.; Wiley: Chichester, UK, 2015. [Google Scholar]

- Tracy, S.J. Qualitative Research Methods: Collecting Evidence, Crafting Analysis, Communicating Impact; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Jha, K.N.; Devaya, M. Modelling the risks faced by Indian construction companies assessing international projects. Constr. Manag. Econ. 2008, 26, 337–348. [Google Scholar] [CrossRef]

- Bajpai, A.; Misra, S.C. Barriers to implementing digitalization in the Indian construction industry. Int. J. Qual. Reliab. Manag. 2021. [Google Scholar] [CrossRef]

- Sushil, S. Interpreting the interpretive structural model. Glob. J. Flex. Syst. Manag. 2012, 13, 87–106. [Google Scholar] [CrossRef]

- Qarnain, S.S.; Muthuvel, S.; Sankaranarayanan, B. Analysis of energy conservation factors in buildings using interpretive structural modeling methodology: An Indian perspective. J. Inst. Eng. (India) Ser. A 2021, 102, 43–61. [Google Scholar] [CrossRef]

- Ambekar, S.; Roy, D.; Hiray, A.; Prakash, A.; Patyal, V.S. Barriers to adoption of reverse logistics: A case of construction, real estate, infrastructure and project (CRIP) sectors. Eng. Constr. Archit. Manag. 2021. [Google Scholar] [CrossRef]

- Ganguly, K.K.; Das, D. Analysing the barriers in Indian stone crushing industries: An ISM and fuzzy AHP approach. Int. J. Appl. Manag. Sci. 2020, 12, 242–264. [Google Scholar] [CrossRef]

- Saxena, J.; Vrat, P. Impact of indirect relationships in classification of variables—A micmac analysis for energy conservation. Syst. Res. 1990, 7, 245–253. [Google Scholar] [CrossRef]

- Duperrin, J.; Godet, M. Methode de hierarchisation des elements d’un systeme. Rapp. Econ. Du CEA 1973, 1, 49–51. [Google Scholar]

- Sushil. How to check correctness of total interpretive structural models? Ann. Oper. Res. 2018, 270, 473–487. [Google Scholar] [CrossRef]

- Lu, W.; Chen, K.; Xue, F.; Pan, W. Searching for an optimal level of prefabrication in construction: An analytical framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- UK Goverment. Response to House of Lords Science and Technology Committee Report. Department for Business, Energy and Industrial Strategy. Available online: https://publications.parliament.uk/pa/ld201719/ldselect/ldsctech/169/16902.htm (accessed on 22 March 2022).

- Gao, S.; Low, S.P.; Nair, K. Design for manufacturing and assembly (DfMA): A preliminary study of factors influencing its adoption in Singapore. Archit. Eng. Des. Manag. 2018, 14, 440–456. [Google Scholar] [CrossRef]

- Pan, W.; Gibb, A.G.; Dainty, A.R. Strategies for integrating the use of off-site production technologies in house building. J. Constr. Eng. Manag. 2012, 138, 1331–1340. [Google Scholar] [CrossRef]

- Bakti, E.S.; bin Abdul Majid, M.Z.; Zin, R.M.; Trigunarsyah, B. Constructability improvement in seawater intake structure. Eng. Constr. Archit. Manag. 2011, 18, 595–608. [Google Scholar] [CrossRef]

- Love, P.E.; O’Donoghue, D.; Davis, P.R.; Smith, J. Procurement of public sector facilities: Views of early contractor involvement. Facilities 2014, 32, 460–471. [Google Scholar] [CrossRef]

- Marinelli, M.; Antoniou, F. Improving public works’ value for money: A new procurement strategy. Int. J. Manag. Proj. Bus. 2020, 13, 85–102. [Google Scholar] [CrossRef]

- Lambropoulos, S. Objective construction contract award using cost, time and durability utility. Procedia-Soc. Behav. Sci. 2013, 74, 123–133. [Google Scholar] [CrossRef]

- Wasim, M.; Vaz Serra, P.; Ngo, T.D. Design for manufacturing and assembly for sustainable, quick and cost-effective prefabricated construction—A review. Int. J. Constr. Manag. 2020, 1–9. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Mohammed, T.; Haron, N.; Alias, A.; Muhammad, I.B.; Baba, D. Improving Cost and Time Control in construction using Building Information Model (BIM): A Review. Pertanika J. Sci. Technol. 2018, 26, 21–36. [Google Scholar]

- Alfieri, E.; Seghezzi, E.; Sauchelli, M.; Di Giuda, G.; Masera, G. A BIM-based approach for DfMA in building construction: Framework and first results on an Italian case study. Archit. Eng. Des. Manag. 2020, 16, 247–269. [Google Scholar] [CrossRef]

- Rahman, M.; Alhassan, A. A contractor’s perception on early contractor involvement. Built Environ. Proj. Asset Manag. 2012, 2, 217–233. [Google Scholar] [CrossRef]

- Gao, S.; Jin, R.; Lu, W. Design for manufacture and assembly in construction: A review. Build. Res. Inf. 2020, 48, 538–550. [Google Scholar] [CrossRef]

- Dixit, S.; Pandey, A.K.; Mandal, S.N.; Bansal, S. A study of enabling factors affecting construction productivity: Indian scnerio. Int. J. Civ. Eng. Technol. 2017, 8, 741–758. [Google Scholar]

- Parker, J.C. Marrying cost-benefit analysis (CBA) with BIM (CBA-BIM). In Proceedings of the ICSI 2014: Creating Infrastructure for a Sustainable World, Los Angeles, CA, USA, 6–8 November 2014; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2014; pp. 760–771. [Google Scholar]

- Fanning, B.; Clevenger, C.M.; Ozbek, M.E.; Mahmoud, H. Implementing BIM on infrastructure: Comparison of two bridge construction projects. Pract. Period. Struct. Des. Constr. 2015, 20, 04014044. [Google Scholar] [CrossRef]

- Pan, W.; Sidwell, R. Demystifying the cost barriers to offsite construction in the UK. Constr. Manag. Econ. 2011, 29, 1081–1099. [Google Scholar] [CrossRef]

- Park, M.; Ingawale-Verma, Y.; Kim, W.; Ham, Y. Construction policymaking: With an example of singaporean government’s policy to diffuse prefabrication to private sector. KSCE J. Civ. Eng. 2011, 15, 771–779. [Google Scholar] [CrossRef]

- Thapar, S.; Sharma, S.; Verma, A. Economic and environmental effectiveness of renewable energy policy instruments: Best practices from India. Renew. Sustain. Energy Rev. 2016, 66, 487–498. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).