1. Introduction

The mining industry provides raw materials for socio-economic development, while unregulated mining operations may also cause serious ecological problems [

1]. China, as a major mining country, faces an even tougher situation [

2]. To solve the environmental problems and achieve sustainable development, China has proposed a green mining (GM) policy [

2,

3,

4], with financial and tax incentives. Furthermore, many mines have joined the ranks of GM construction. Now comes the question of which mine is performing better. The government has to implement policy according to green mining performance (GMP), and mine enterprises have to improve by comparison. GMP evaluation of mines using appropriate and scientific approaches becomes particularly important [

5,

6], playing a critical role in promoting GM [

6,

7].

Considering the diversity of GM evaluation criteria, this would be a complicated matter of multicriteria decision-making (MCDM). Scholars have conducted studies on specific mines using different methods. Zhou et al. [

1] adopted a fuzzy comprehensive evaluation method to assess the green surface mine in China. Chen et al. [

5] put forward a Driver–Pressure–State–Impact–Response framework to formulate the GM evaluation indicator, and the PCA method was used to evaluate the interactions between human and environmental systems. Jiskani et al. [

8] analyzed the Green and climate-smart mining of open-pit mines, fuzzy AHP was applied to determine weights, and the Grey clustering method was used to classify the result into concrete levels. Liang et al. respectively assessed the GMP through the Hesitant Fuzzy ORESTE–QUALIFLEX method [

6] and MCDM combined with a picture fuzzy information approach [

9]. Qi et al. [

10] proposed an evaluation system of GM construction, and determined the critical factor of GM by the two-step fuzzy DEMATEL model. Based on uncertainty measurement theory, Wang et al. [

11] evaluated GM grades with six coupled methods, and finally selected the optimal method by credible degree recognition.

Although the above research addressed similar GMP evaluation tasks, the criteria system and MCDM methods are quite different. This is because the mineral species and mining method have to be considered while developing the evaluation criteria, and MCDM methods are selected based on the collected indicator data. Thus, it would be significant to develop specific appropriate and efficient evaluation methods [

9,

12]. For this purpose, in order to formulate an applicable GMP evaluation system to underground gold mines, the characteristics of mines have to be fully considered [

13], and the principles of GM [

14,

15,

16,

17] are required for referencing.

The study area is located in Jiaodong Peninsula, one of the most important gold origins for China [

18]. Firstly, the geological conditions in the region are exceedingly complicated, with fault structures and fractured zones [

19] dispersed across the mining sites, posing safety risks, and the risk for accidents to occur is greater due to underground space limitations. Accordingly, safety production (SP) holds great meaning for GM, with this criterion being the basic condition for evaluating GMP [

1,

11]. Secondly, waste rock stockpiles and unregulated discharge of tailings [

20] can cause environmental damage. However, the utilization rates of solid waste are quite low in local underground gold mines. To some extent, these solid wastes can be used in alternative ways. For example, tailings can be used for underground filling, and the waste rock crushed into stone as building materials. Thus, the comprehensive utilization (CU) of mining solid wastes should be considered as the evaluation criterion for GMP [

7,

21]. Thirdly, gold ore mined by drilling and blasting, emits dust and blasting fumes [

22]. In addition, hydrogenated tailings can contaminate water bodies and soil without proper disposal [

23,

24,

25]. Green emphasizes environmental protection (EP), which is also an essential criterion for GMP. Finally, the original intention of GM is to obtainn resources in an eco-friendly and efficient manner, with mining efficiency (ME) [

26] representing the key component. In summary, SF-CU-EP-ME should be considered comprehensively to formulate a GMP evaluation criteria system for underground gold mines.

For the sake of relative fairness, indicators should be accurately calculable to eliminate subjective judgments. In terms of weight, the determination is a multilevel, complex, and comprehensive procedure, thus correlation and constraints between the indicators [

1] should be considered. However, previous GMP evaluation research works have not employed indicator correlations to calculate weights. Therefore, it is necessary to devise a method for determining weights based on the relationship between indicators. For this goal, integrated DEMATEL-ANP [

27,

28] is extremely capable of solving this issue; DEMATEL is used to determine the factors influencing interaction, with ANP used to obtain the relative weight. However, crisp values occur in this method, which is inappropriate and imprecise for describing the information [

9,

29,

30]. To conquer this limitation, the gray theory was exploited to transform crisp values into interval gray numbers, which improves the reality of decision-making data. Consequently, gray DEMATEL is adopted to examine the causal relationship in an uncertain environment, and then the ANP method to calculate the relative weight based on the influential relationship acquired from gray DEMATEL [

31,

32]. Finally, metrics need to be converted into scores. However, traditional grading methods, will yield no distinction between the same levels. A linear transformation approach would be a reasonable option.

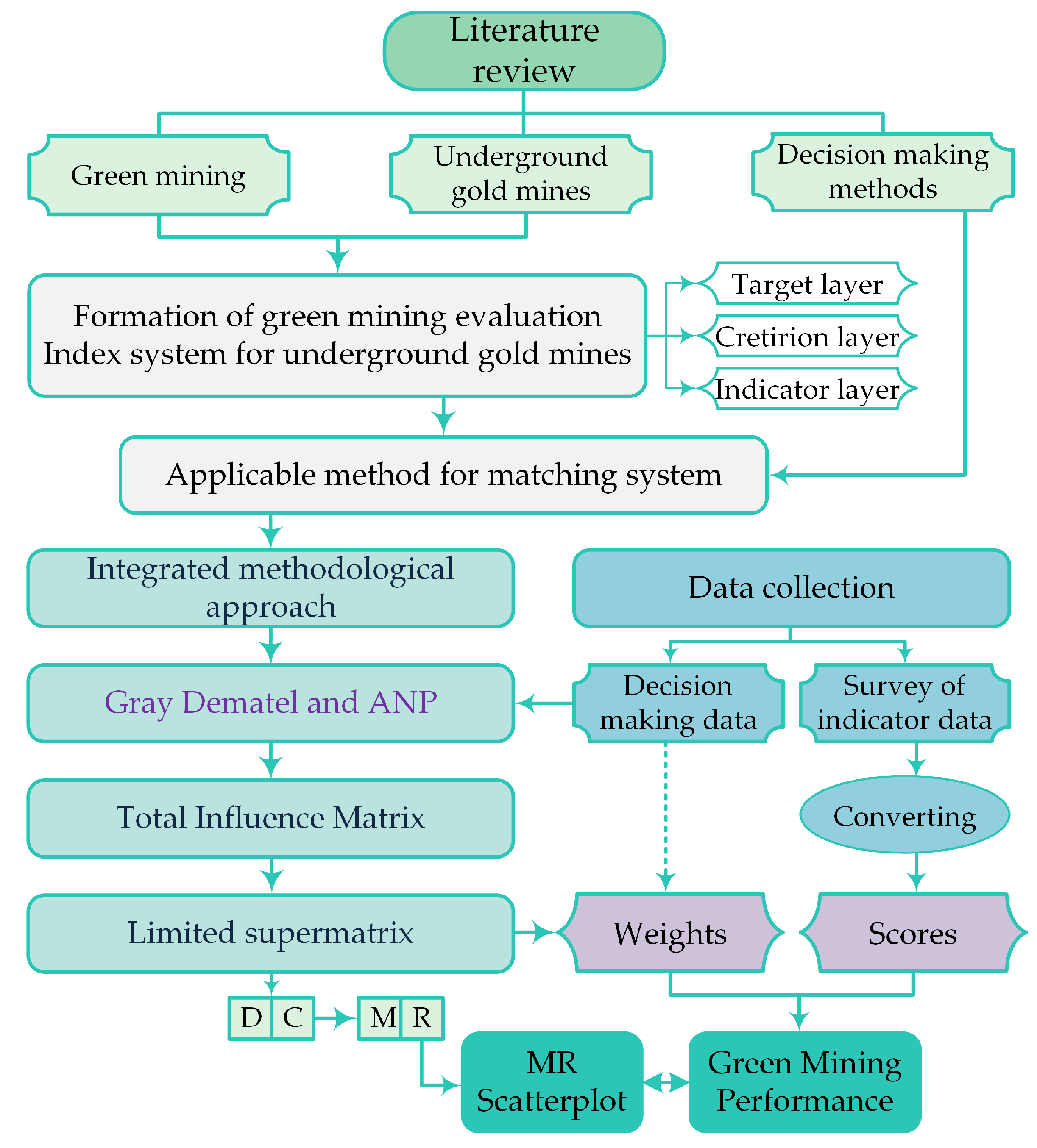

In summary, an evaluation system is established to evaluate GMP for underground gold mines. In this respect, an evaluation criteria system is formulated in consideration of the characteristics and principles of GM, while an integrated gray DEMATEL and ANP method are devised to determine the relative weights, and a linear transformation strategy is used to convert index values to corresponding scores. Compared to other methods, the criteria system constructed in this work is more target-oriented. In addition, the indicators can be calculated accurately to avoid human error, and the weighting and converting procedures of indicators are relatively fair. With regard to the above advantages, this study is rendered both feasible and reasonable.

The structure of this paper is designed as follows.

Section 2 introduces the methodology in detail, including the technical route, indicators, and method.

Section 3 provides a case study using the collected decision-making data from experts and indicator values from underground gold mines, with the results computed.

Section 4 makes cause–effect and comparative analysis based on the results, and some managerial implications are also involved.

Section 5 summarizes the paper and presents suggestions.

4. Discussions

4.1. Cause–Effect Analysis

The influence index and relationship index are the core factors of DEMATEL analysis [

10]. The former indicates the factor’s ability to influence the system. The larger the value, the higher the degree of influence. The latter has positive and negative values, belonging to the cause group and effect group, respectively. This is because the relationship index is calculated by (

), positive values indicate the influence degree exceeds the influenced degree, and negative values are dominated by the influenced degree. Theoretically, the cause group affects the factors in the effect group, thus they are the system-identified issues that demand priority improvement. The results are shown in

Table 4.

A cause–effect diagram is a tool to logically organize and graphically display the causes associated with specific effects [

29]. The influence and relationship values were used to plot the cause–effect diagram, as shown in

Figure 4. Typically, this diagram is divided into four categories, core causal, inferior causal, core effect and inferior effect.

The core causal group with large prominence and positive relation, CU5, CU4, and SP3 are concluded in this cluster, elements in this group have the topmost priority for improvement. The inferior causal group with small prominence and positive relation, SP5, CU1, CU3, ME1, ME2, ME4 are classified in this region, they require immediate improvement but with high priority. SP2, CU2, EP4, ME3, ME5 with small prominence and negative relation, affiliated to the inferior effect group, are improved indirectly with medium priority. The rest with large prominence and negative relation belong to the core effect group, which are affected by elements in other groups. In this way, the elements in the causal groups are improved, and the corresponding effect groups will be upgraded as well. Therefore, the order of improvements can be determined based on the priority of indicators, as shown in

Table A8, red for topmost priority, purple for high priority, and cyan for medium priority.

4.2. Comparative Analysis

A comparative analysis is required to understand the strengths and weaknesses of specific mines.

Figure 5 indicates the performance of the underground gold mine in different fields. From each dimension, M1 and M2 underperform in terms of SP, M4, M5, and M6 has a poor degree of CU, M6 has the lowest EP score, and M4 and M6 have significant weaknesses in terms of ME. Each mine includes aspects that need to be improved when broken down into distinct indicators.

Table A8 demonstrates the prospective improvement elements for each mine.

From a holistic view, the pilot green mines are developed in a more balanced way, and they have great advantages in terms of CU. This is because CU has a high degree of association with other indicators, especially CU4 and CU5 which are used for underground filling. These not only control ground pressure and prevent surface collapse (benefits for SP), but also solve the EP pressure, and the filling mining method improves ME. Correspondingly, these are the driving factors for green mines to enhance CU.

In terms of scores, M3 performs the best, M1 and M2 still show space for improvement, M4 and M6 perform poorly and have a large gap between the pilot green mine. M5 has the most potential to develop into a green mine.

More importantly, to validate the feasibility of this research, a comparative analysis with other related studies is crucial.

(1) Comparison of evaluation criteria

This paper proposed an evaluation criteria framework, applicable to underground metal mines. Compared with the most similar GMP evaluation study, the criteria system in the literature [

9] is very abstract, which is not conducive to the accuracy of evaluation. Meanwhile, the selection of indicators was kept simple based on the essential requirements of green mining [

7]. Thus, the easy accessibility of evaluation information is determined as a prerequisite to choosing indicators. The proposed evaluation system is flexible, and the criterion can be more specific in future studies.

(2) Comparison of weight determination methods

The analytic network process method is widely used for MCDM [

42,

43], but the calculation process is complicated. To compensate for the shortcomings of this single method, hybrid evaluation methods with ANP [

44,

45] were proposed. The weights in this research were determined using an integrated Gray DEMATEL and ANP approach, which was employed for the first time in the GMP evaluation sector. In comparison to other methods, this approach fully utilizes the correlation between indicators and simplifies the calculation process [

39]. Therefore, the calculated weights are more reasonable.

(3) Comparison of the results

The GMP evaluation studies usually assess the same type of mines [

6,

9], and this paper selected three pilot green mines as control group. The proposed method is capable of distinguishing between two types of mines, which verifies the feasibility of this research. The results show that CU is the most important criterion in GM, and this can be corroborated by the related research [

7]. Moreover, the cause–effect analysis provided a reasonable order for mine improvements, which has not been found in GMP evaluation studies. Thus, the proposed suggestions are more informative than similar studies.

To sum up, the advantages of proposed approaches summarized as follows:

Evaluation indicators are specific and data easy to obtain, the calculability of evaluation information guarantees the relative fairness of evaluation.

Weights are calculated by correlation between indicators, and with the cause–effect analysis guide for mine improvements, the suggestions are more informative.

Data of six underground gold mines were collected, the proposed method can distinguish between two types of mines, which verify the feasibility of proposed method.

4.3. Managerial Implications

Management of mining processes and monitoring of their performance is a basic prerequisite for continual improvement [

46], and the performance evaluation of mines is the key to promoting green mine construction [

7].

Figure 6 reveals the role of evaluation in GM. The evaluation has profound implications and broad application value, pushing mines to practice green mining, and serving as a strong tool for the government to encourage policy implementation.

Mines are compared in the evaluation process, and the results point out the advantages and weaknesses of mines, which indicate the way forward for improvement and upgrading. For sustainable development, mines have to identify and solve gaps; this purpose becomes the driving force for GM. When the mines have performed excellently in green mining and reached the industry-leading level, they will be recognized as green mines. The designation is certificated by the government, and evaluation plays an important role in this procedure, guiding the decision-making of the government. The mines create social environmental benefits, and the government supports financial and tax incentives to mines depending on the GMP, highlighting a mutually beneficial situation. Mines provide social and environmental benefits, while the government provides financial and tax incentives to mines based on GMP, creating a win–win scenario.

5. Conclusions

The integral elements of the GM for underground gold mines include safety production, comprehensive utilization of resources, environmental protection, and mining efficiency. In order to measure the GMP of different mines, an evaluation system is proposed in this study, which consists of four criteria and twenty indicators. Considering the correlation of indicators, an integrated GDANP method has been exploited to evaluate the GMP for six underground gold mines. The results demonstrate the rank order as well as the gap between the mines. Furthermore, the weaknesses of each mine are analyzed in a broad dimension, and the advantages of pilot green mines are explained in a reasonable manner. Subsequently, the cause–effect analysis categorizes indicators into four groups, with the priority defined by the prominence and relation of each indicator. To solve the gaps, mines have to implement improvements sensibly. Finally, this research explored the effect of evaluation on mining management and the government.

Indeed, there are some limitations to this study, e.g., the lack of evidence to prove which proposed method was the best. Perhaps the presented evaluation framework can be extended with other MCDM approaches. Indicators can be added to make the system more comprehensive, and the evaluation criteria can be improved in future studies.

In summary, this paper mainly evaluated the GMP for underground gold mines and provided ideas for improvements. The evaluation framework applies to underground metal mines, and some indicators in the formulated system are likely to work for similar environments. The proposed methodology can also be exploited in other evaluation studies where the indicators are correlated. The results of this research may be used as a reference for GM in other mines, as well as to assist government policy implementation.