Circular Economy of Construction and Demolition Waste: A Case Study of Colombia

Abstract

:1. Introduction

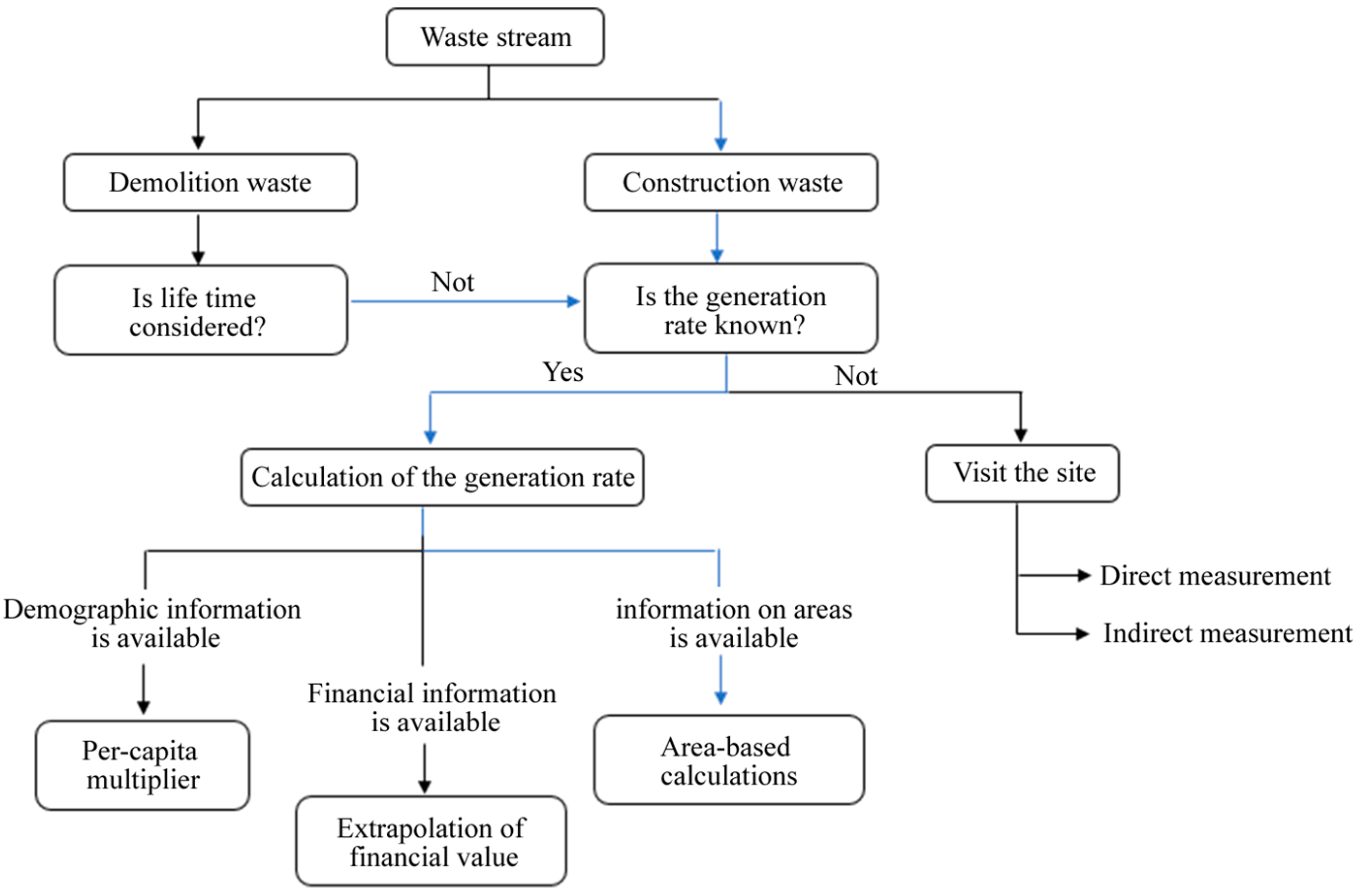

2. Materials and Methods

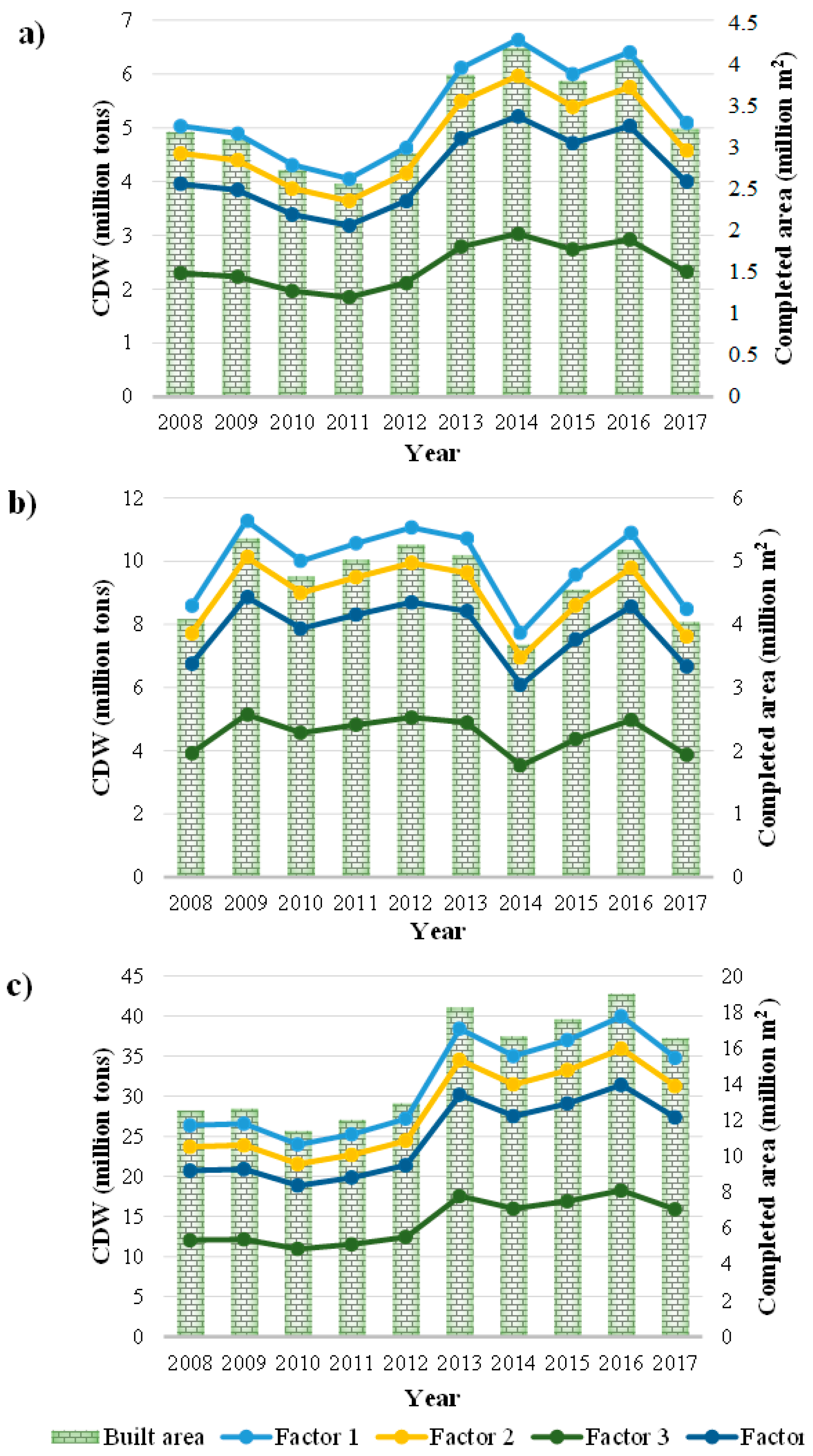

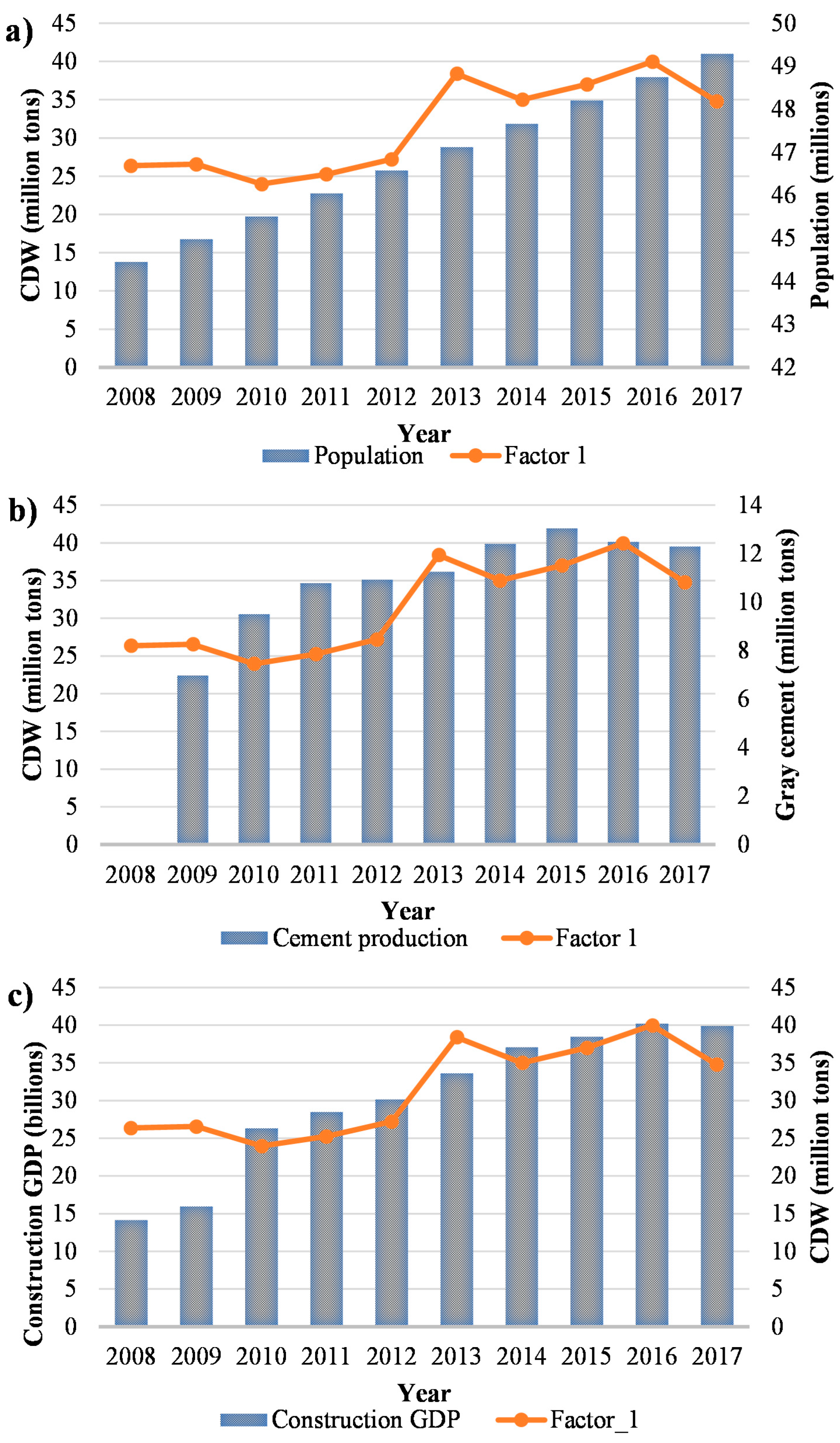

- Factor 1: based on the quantitative data of the rubble generated by the private sector which has been obtained from the building censuses available in DANE and in the Colombian Chamber of Construction (CAMACOL) [28].

- Factor 2: obtained from an article published by the University of Eafit [29].

- Factor 3: based on the Fatta model, in which the amount of CDW is calculated from the density and the factor presented by the author [30].

- Factor 4: based on the law of mixtures according to the composition of waste in Bogotá.

- The value of the factors used in the quantification of CDW in Colombia used in this research is summarized in Table 1.

Econometric Analysis

3. Results and Analysis

3.1. Construction Waste Management in Colombia

3.2. CDW Quantification

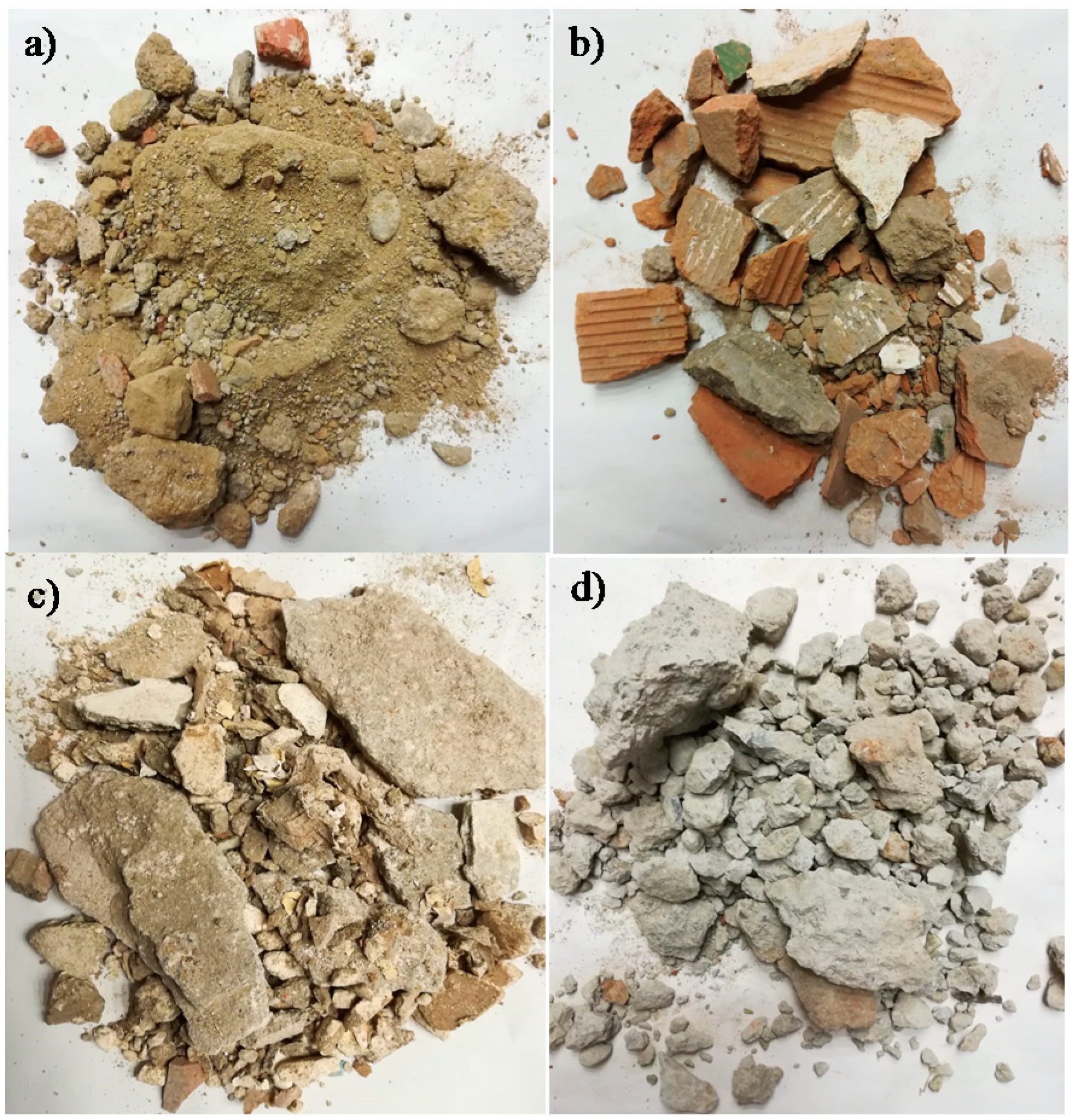

3.3. CDW Characterization in Colombia

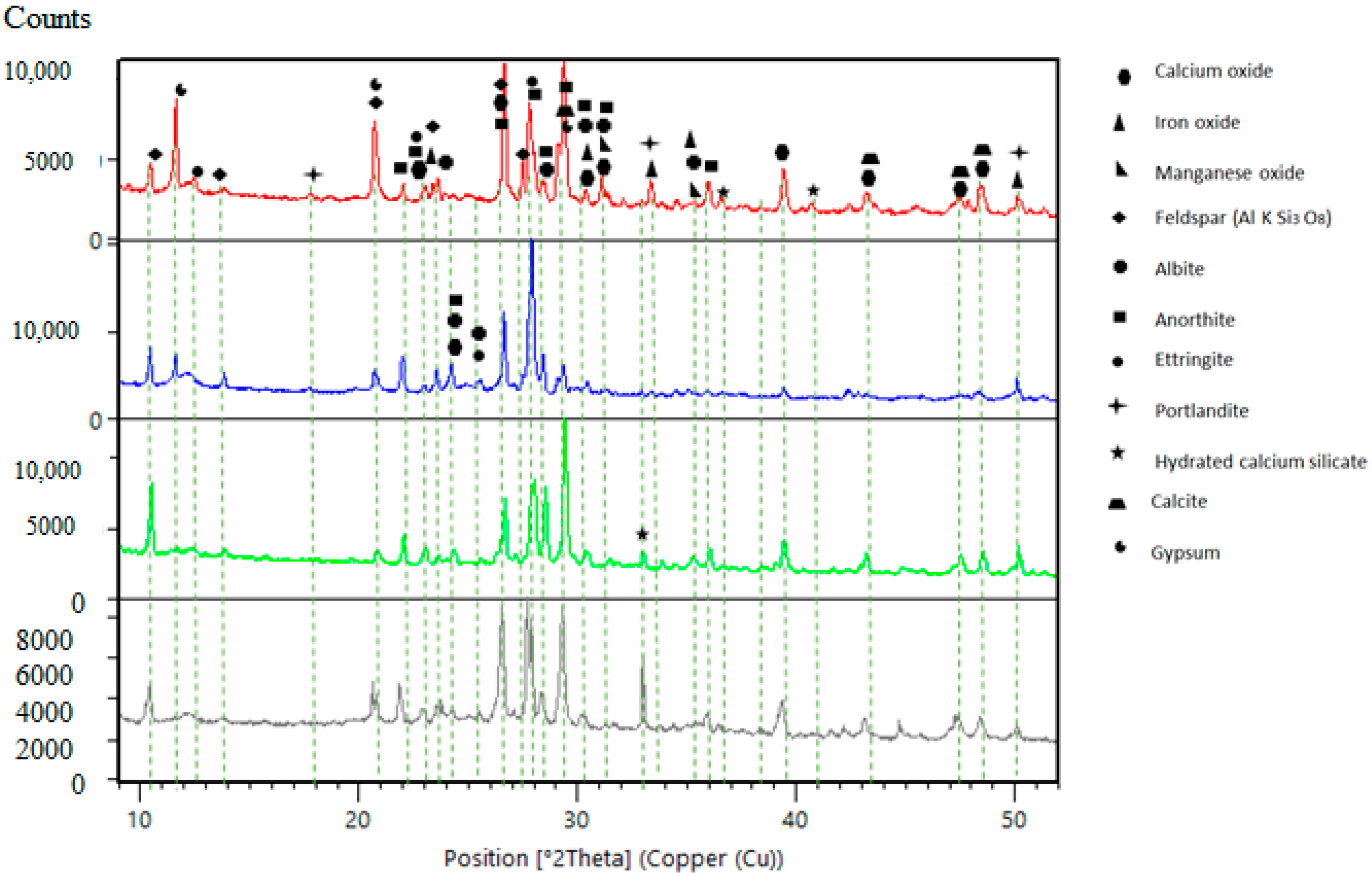

3.3.1. X-ray Diffraction (XRD)

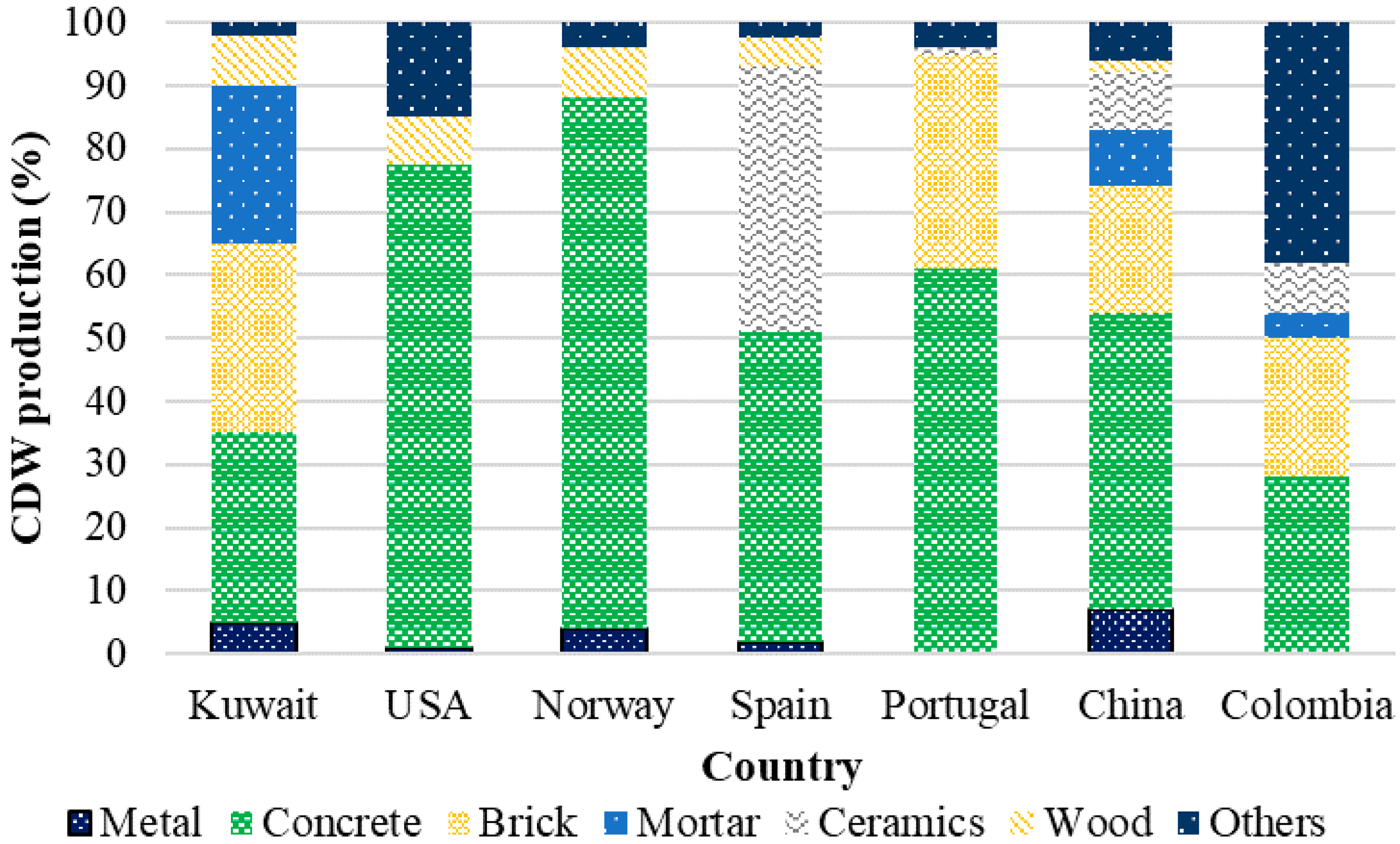

3.3.2. Comparison of CDW Composition

3.4. Econometric Analysis

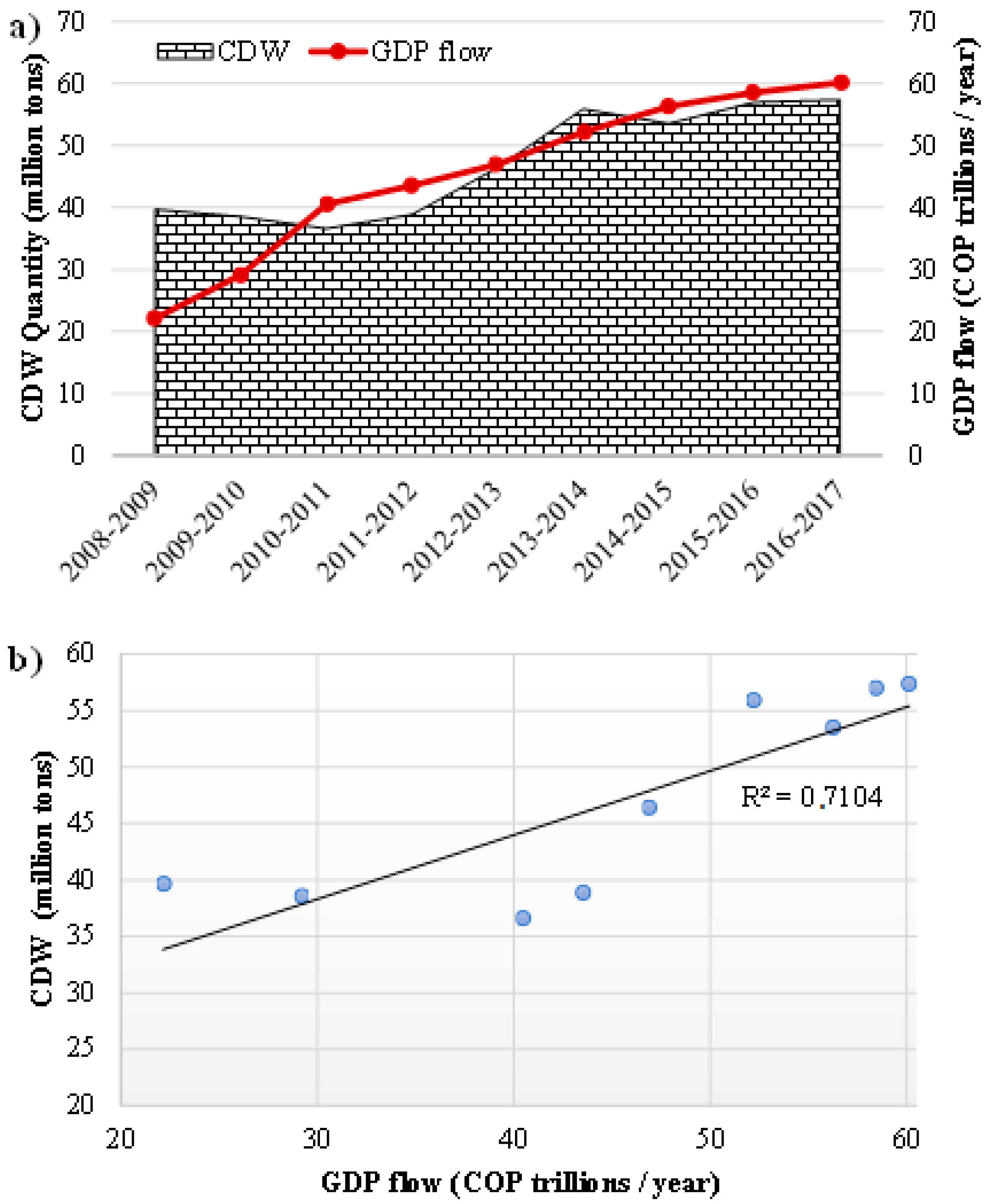

3.4.1. Correlation Analysis

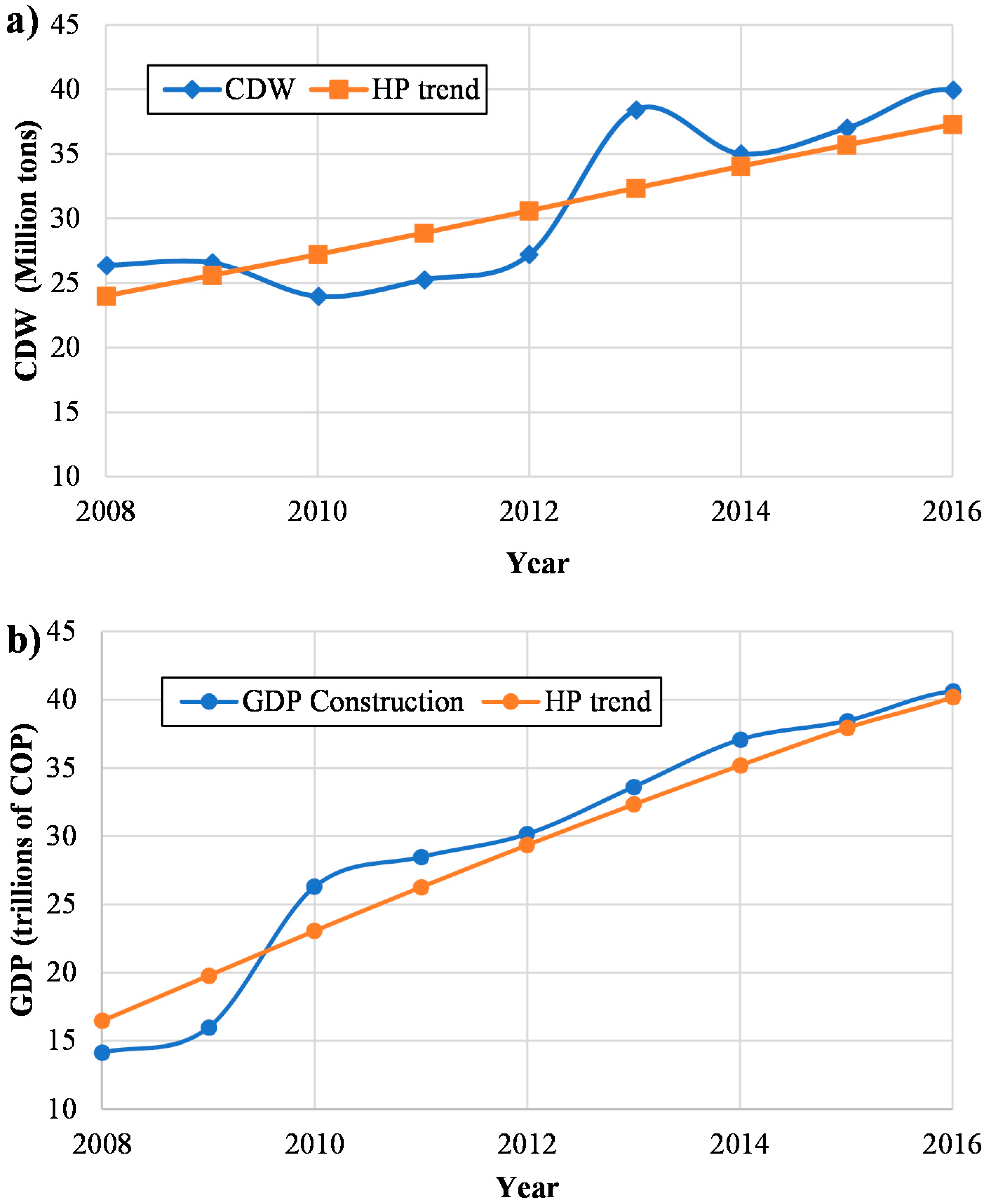

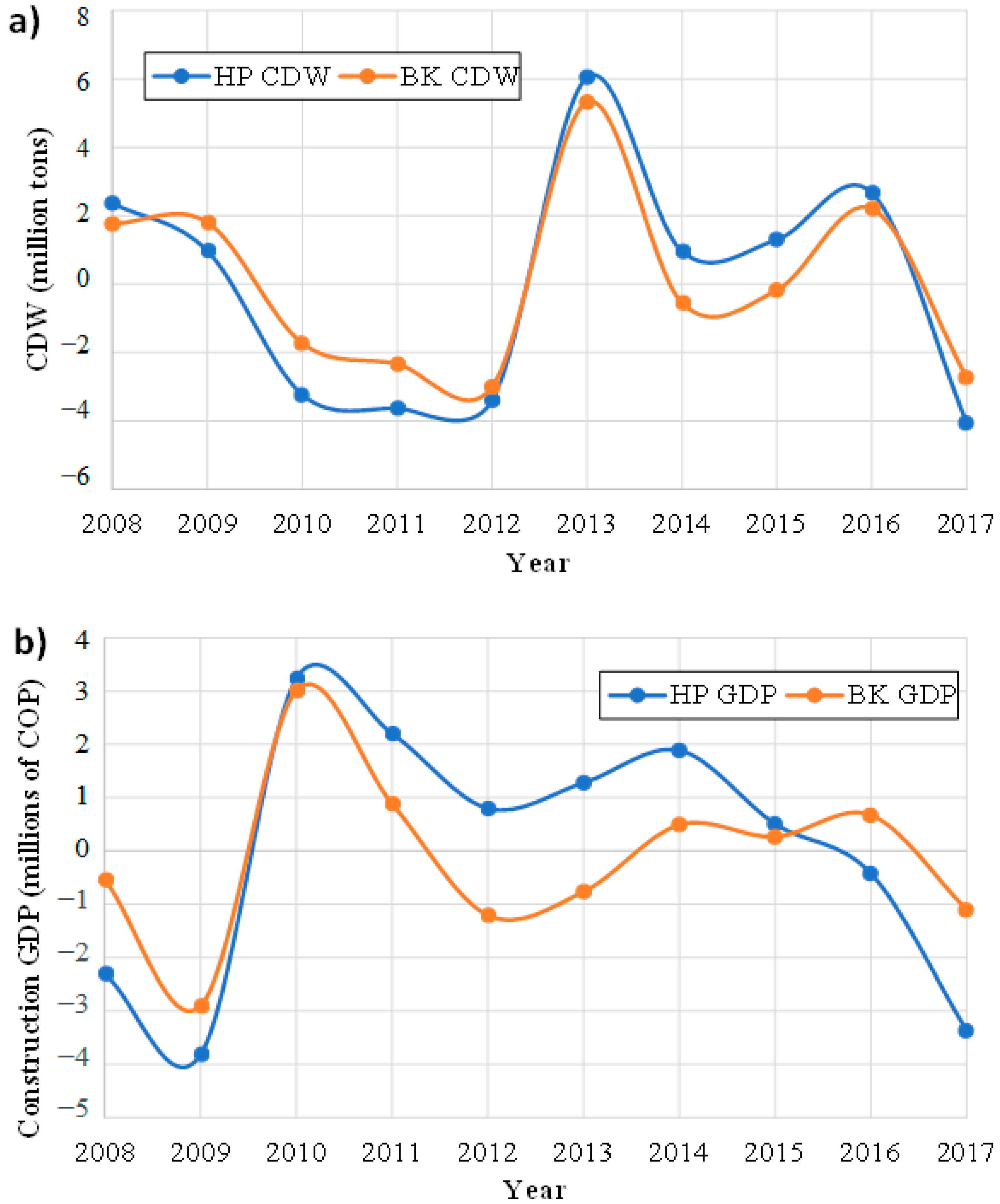

3.4.2. Filters for Cyclic Components

3.5. Information Available in other Countries

3.5.1. CDW in the Latin American framework

- Argentina

- Bolivia

- Brazil

- Chile

- Costa Rica

- Ecuador

- Mexico

- Panama

- Peru

- Dominican Republic

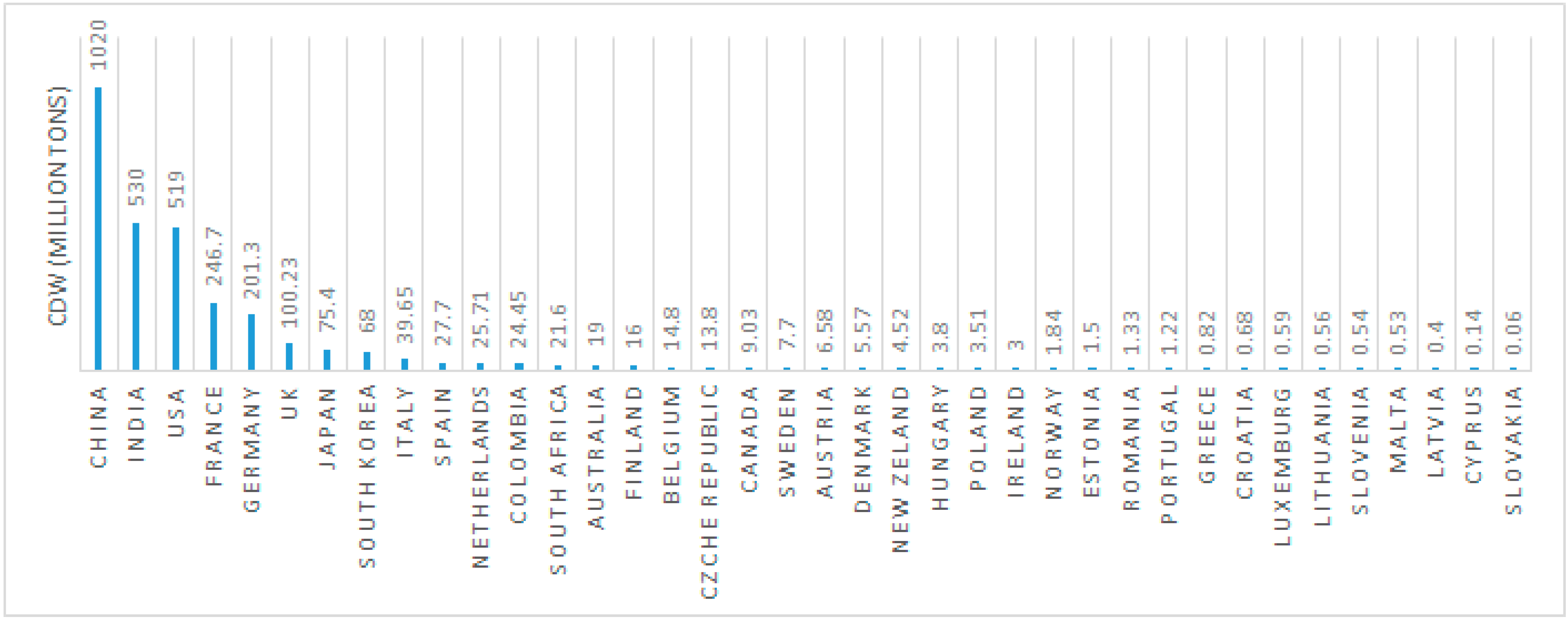

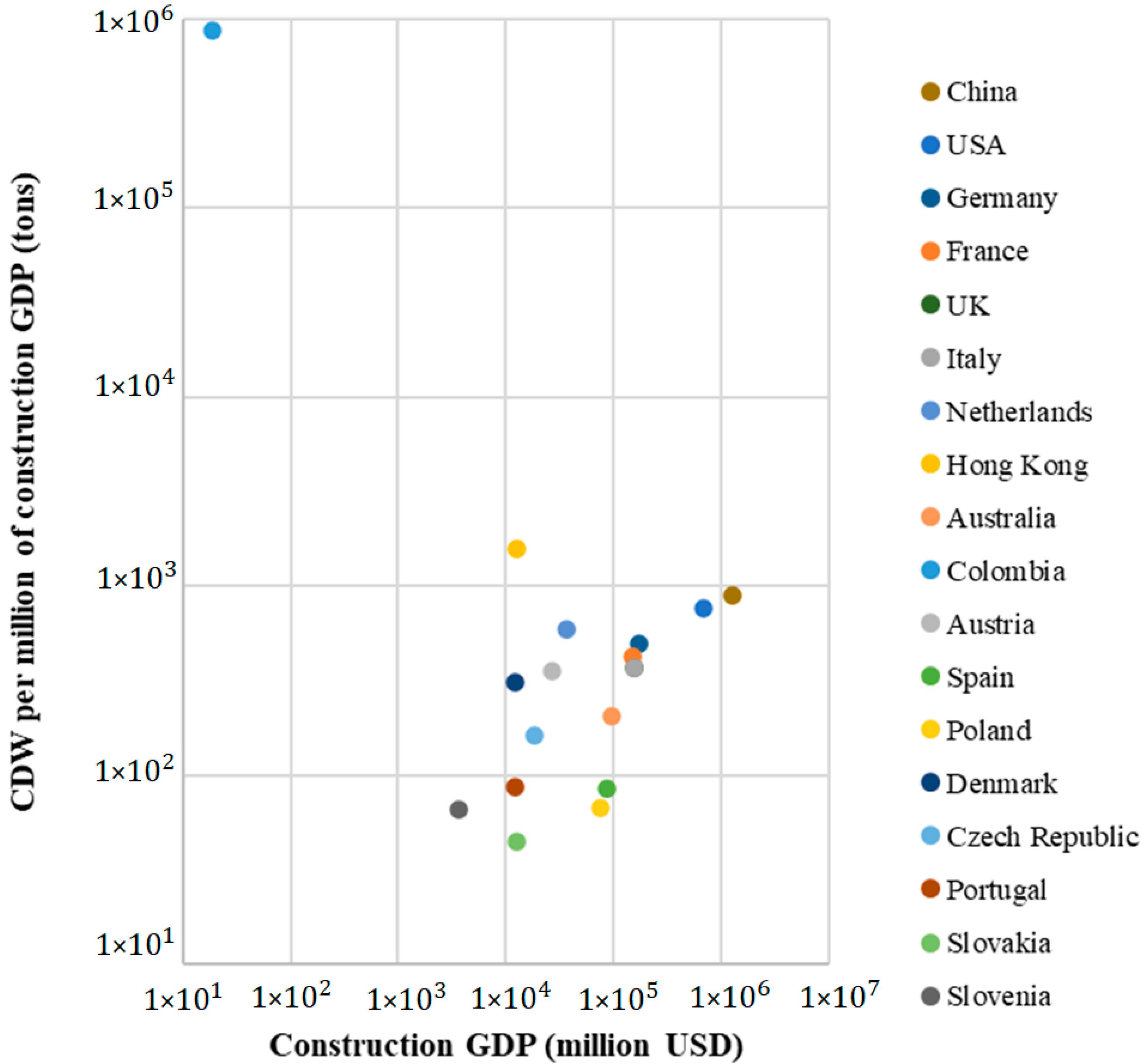

3.5.2. CDW in the World

Construction and Demolition Waste Management

Legislative Framework for the Management of Construction and Demolition Waste

3.5.3. Comparison of CDW in Colombia and Other Countries

4. Conclusions

- The information available on the management of construction and demolition waste in Colombia is very scarce. There is no reliable data on the amount of CDW generated annually. However, taking into account the data that are available, it was concluded that the method used for the quantification of CDW was correct. In addition, when comparing the results of the different factors used for quantification, it was found that Factor 1 best fits with the government data.

- From the case study, the X-ray diffraction results agree with the information found on the composition of CDW in Colombia, where 62% of the residue is made up of brick, concrete, and ceramic. Subsequently, comparing the composition of CDW in Colombia with that of other countries, little similarity was found in composition. This is because the structures and construction materials used in different countries vary from country to country due to the different construction materials, motivated by variations in climates, cultures, and types of construction.

- The cycles obtained by the Hodrick–Prescott and Baxter–King filters show similar patterns when describing the movement of the GDP from construction and the CDW generated. However, the Hodrick–Prescott filter gives a smoother graph than the Baxter–King filter. In addition, this research showed several factors that affect both the GDP from construction and the CDW generated.

- When searching for information on CDW in Latin America, it should be noted that most countries do not have solid data on its generation and quantification. However, with the little information found, it can be concluded that the situation in the region is similar to Colombia in terms of CDW management, which is very limited. It should also be noted that Brazil is the Latin American country that has the best management of this type of waste.

- Education is one of the most important aspects for the implementation of a sustainable economy, but education is poorly funded in developing countries. Perhaps active learning methods [64] and technologies such as additive manufacturing [65] could contribute to the rapid implementation of circular economy models.

- It was found that both the management and the legislation of CDW is much more advanced in countries such as the United States, Germany, Portugal, and Spain because they use the 4R system, which minimizes the generation of CDW and reuses the greatest amount of waste possible. In Latin America, CDW management is just starting; thus, there is a lack of any real plans in this area.

- The differences among the different countries shown in this research revealed that many aspects have to be considered to effectively manage CDW. It is not only the economic aspects of different regions that have a profound impact on waste, but also climate and culture. Thus, the problem should not be left solely to experts and politicians; the real solution will require a multidisciplinary team.

- The uniformity of materials found in CDW is certainly one of the biggest concerns for its use on a large scale, as the variability from building to building can be high. Using CDW directly from the construction site can optimize transportation but limits its application due to the high variability. Therefore, it is more strategic to process CDW in a large facility in which thousands of tons of materials are mixed and the uniformity can be improved. The experimental case study shown in this research confirms the particularly of the phases found, which may vary significantly not only from region to region but also from country to country.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barbarossa, V.; Bosmans, J.; Wanders, N.; King, H.; Bierkens, M.F.P.; Huijbregts, M.A.J.; Schipper, A.M. Threats of Global Warming to the World’s Freshwater Fishes. Nat. Commun. 2021, 12, 1701. [Google Scholar] [CrossRef] [PubMed]

- Magomedov, I.A.; Dzhabrailov, Z.A.; Bagov, A.M. Subsistence Agriculture|and Global Warming. IOP Conf. Ser. Earth Environ. Sci. 2021, 677, 032109. [Google Scholar] [CrossRef]

- Nukusheva, A.; Ilyassova, G.; Rustembekova, D.; Zhamiyeva, R.; Arenova, L. Global Warming Problem Faced by the International Community: International Legal Aspect. Int. Environ. Agreem. Politics Law Econ. 2020, 21, 219–233. [Google Scholar] [CrossRef]

- Shang, W.; Peng, Z.; Huang, Y.; Gu, F.; Zhang, J.; Tang, H.; Yang, L.; Tian, W.; Rao, M.; Li, G.; et al. Production of Glass-Ceramics from Metallurgical Slags. J. Clean. Prod. 2021, 317, 128220. [Google Scholar] [CrossRef]

- Colorado, H.A.; Garcia, E.; Buchely, M.F. White Ordinary Portland Cement Blended with Superfine Steel Dust with High Zinc Oxide Contents. Constr. Build. Mater. 2016, 112, 816–824. [Google Scholar] [CrossRef]

- Hittini, W.; Mourad, A.H.I.; Abu-Jdayil, B. Utilization of Devulcanized Waste Rubber Tire in Development of Heat Insulation Composite. J. Clean. Prod. 2021, 280, 124492. [Google Scholar] [CrossRef]

- Revelo, C.F.; Colorado, H.A. A Green Composite Material of Calcium Phosphate Cement Matrix with Additions of Car Tire Waste Particles. Int. J. Appl. Ceram. Technol. 2021, 18, 182–191. [Google Scholar] [CrossRef]

- Agudelo, G.; Cifuentes, S.; Colorado, H.A. Ground Tire Rubber and Bitumen with Wax and Its Application in a Real Highway. J. Clean. Prod. 2019, 228, 1048–1061. [Google Scholar] [CrossRef]

- Dhanya, B.S.; Mishra, A.; Chandel, A.K.; Verma, M.L. Development of Sustainable Approaches for Converting the Organic Waste to Bioenergy. Sci. Total Environ. 2020, 723, 138109. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of Construction and Demolition Waste Management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef]

- Munir, M.T.; Mohaddespour, A.; Nasr, A.T.; Carter, S. Municipal Solid Waste-to-Energy Processing for a Circular Economy in New Zealand. Renew. Sustain. Energy Rev. 2021, 145, 111080. [Google Scholar] [CrossRef]

- Colorado-Lopera, H.A.; Echeverri-Lopera, G.I. The Solid Waste in Colombia Analyzed via Gross Domestic Product: Towards a Sustainable Economy. Rev. Fac. De Ing. Univ. De Antioq. 2020, 96, 51–63. [Google Scholar] [CrossRef]

- Sumter, D.; de Koning, J.; Bakker, C.; Balkenende, R. Circular Economy Competencies for Design. Sustainability 2020, 12, 1561. [Google Scholar] [CrossRef] [Green Version]

- Colorado, H.A.; Gutiérrez-Velásquez, E.I.; Monteiro, S.N. Sustainability of Additive Manufacturing: The Circular Economy of Materials and Environmental Perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Zapata, J.F.; Azevedo, A.; Fontes, C.; Monteiro, S.N.; Colorado, H.A. Environmental Impact and Sustainability of Calcium Aluminate Cements. Sustainability 2022, 14, 2751. [Google Scholar] [CrossRef]

- Villegas, J.E.; Camilo, J.; Gutierrez, R.; Colorado, H.A. Active Materials for Adaptive Building Envelopes: A Review. J. Mater. Environ. Sci. 2020, 2020, 988–1009. [Google Scholar]

- Castañeda, M.; Gutiérrez-Velásquez, E.I.; Aguilar, C.E.; Monteiro, S.N.; Amell, A.A.; Colorado, H.A. Sustainability and Circular Economy Perspectives of Materials for Thermoelectric Modules. Sustainability 2022, 14, 5987. [Google Scholar] [CrossRef]

- Miller, P.; de Barros, A.G.; Kattan, L.; Wirasinghe, S.C. Public Transportation and Sustainability: A Review. KSCE J. Civ. Eng. 2016, 20, 1076–1083. [Google Scholar] [CrossRef]

- Heidari, R.; Yazdanparast, R.; Jabbarzadeh, A. Sustainable Design of a Municipal Solid Waste Management System Considering Waste Separators: A Real-World Application. Sustain. Cities Soc. 2019, 47, 101457. [Google Scholar] [CrossRef]

- Shekdar, A.V. Sustainable Solid Waste Management: An Integrated Approach for Asian Countries. Waste Manag. 2009, 29, 1438–1448. [Google Scholar] [CrossRef]

- Alsheyab, M.A.T. Recycling of Construction and Demolition Waste and Its Impact on Climate Change and Sustainable Development. Int. J. Environ. Sci. Technol. 2021, 19, 2129–2138. [Google Scholar] [CrossRef]

- Menegaki, M.; Damigos, D. A Review on Current Situation and Challenges of Construction and Demolition Waste Management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Dahlbo, H.; Bachér, J.; Lähtinen, K.; Jouttijärvi, T.; Suoheimo, P.; Mattila, T.; Sironen, S.; Myllymaa, T.; Saramäki, K. Construction and Demolition Waste Management—A Holistic Evaluation of Environmental Performance. J. Clean. Prod. 2015, 107, 333–341. [Google Scholar] [CrossRef]

- Galvez-Martos, J.L.; Styles, D.; Shoenberger, H. Best Environmental Management Practice in the Building and Construction Sector. Available online: https://susproc.jrc.ec.europa.eu/product-bureau/sites/default/files/inline-files/ConstructionSector.pdf (accessed on 22 April 2022).

- Bergsdal, H.; Bohne, R.A.; Brattebø, H. Projection of Construction and Demolition Waste in Norway. J. Ind. Ecol. 2007, 11, 27–39. [Google Scholar] [CrossRef]

- Wu, Z.; Yu, A.T.W.; Shen, L.; Liu, G. Quantifying Construction and Demolition Waste: An Analytical Review. Waste Manag. 2014, 34, 1683–1692. [Google Scholar] [CrossRef]

- DANE Departamento Administrativo Nacional de Estadística (National Administrative Department of Statistics). Available online: https://www.dane.gov.co/ (accessed on 25 March 2020).

- Cámara Colombiana de La Construcción-Camacol. Available online: https://camacol.co/ (accessed on 6 October 2021).

- Vásquez Hernández, A.; Botero Botero, L.F.; Carvajal Arango, D. Fabricación de Bloques de Tierra Comprimida Con Adición de Residuos de Construcción y Demolición Como Reemplazo Del Agregado Pétreo Convencional. Ing. Y. Cienc-Ing. Cienc. 2014, 11, 197–220. [Google Scholar] [CrossRef] [Green Version]

- Fatta, D.; Papadopoulos, A.; Avramikos, E.; Sgourou, E.; Moustakas, K.; Kourmoussis, F.; Mentzis, A.; Loizidou, M. Generation and Management of Construction and Demolition Waste in Greece—An Existing Challenge. Resour. Conserv. Recycl. 2003, 40, 81–91. [Google Scholar] [CrossRef]

- Minambiente Colombia Ministerio de Ambiente y Desarrollo Sostenible. Available online: https://www.minambiente.gov.co/ (accessed on 6 February 2020).

- Orozco Gutiérrez, C.J.; Gómez Rodríguez, F.S.; Severiche Ramírez, J.A.; Rico Gómez, K.J.; Pinto Fajardo, N.A.; Zambrano Echeverría, V.A.; Alarcón, W.A.; Elorza López, Y.A.; Figueroa García, Y.X. Guía Para la Elaboración del Plan de Gestión Integral de Residuos de Construcción y Demolición (RCD) en Obra; Secretaría Distrital de Ambiente: Bogota, Colombia, 2014. [Google Scholar]

- Ministerio del Medio Ambiente. Resolución 541; Ministerio del Medio Ambiente: Bogota, Colombia, 1994. [Google Scholar]

- Minambiente Colombia. Decreto 948 de 1995; Minambiente: Bogota, Colombia, 1995. [Google Scholar]

- Pastrana Arango, A.; Pizano de Narváez, E.; Mayr Maldonado, J. Decreto 1713 de 2002; El Ministro de Desarrollo Económico: Bogota, Colombia, 2002. [Google Scholar]

- Congreso de Colombia. Ley 1259 de 2008; Congreso de Colombia: Bogota, Colombia, 2008. [Google Scholar]

- Presidencia de la Republica de Colombia. Decreto 2981 de 2013; Presidencia de la Republica de Colombia: Bogota, Colombia, 2013. [Google Scholar]

- Minambiente Colombia. Resolución 472 de 2017–Manejo y Disposición de Residuos de Construcción–Solames; Minambiente: Bogota, Colombia, 2017. [Google Scholar]

- Porras, Á.C.; Cortes, N.L.G.; Duarte, M.C.C. Determinación de Propiedades Físico-Químicas de Los Materiales Agregados En Muestra de Escombros En La Ciudad de Bogotá D. C. Rev. Ing. 2013, 12, 45–58. [Google Scholar] [CrossRef] [Green Version]

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the Generation and Flows of Construction and Demolition Waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef] [Green Version]

- Hodrick, R.J.; Prescott, E.C. Postwar U.S. Business Cycles: An Empirical Investigation. J. Money Credit Bank. 1997, 29, 1–16. [Google Scholar] [CrossRef]

- Baxter, M.; King, R.G. Measuring Business Cycles Approximate Band-Pass Filters for Economic Time Series; National Bureau of Economic Reserch: Cambridge, MA, USA, 1995. [Google Scholar] [CrossRef]

- Gisela, I.; González, L. Residuos Solidos Urbanos Argentina Tratamiento y Disposicion Final Situacion Actual y Alternativas Futuras; Camara Argentina de la Construcción: Buenos Aires, Argentina, 2010. [Google Scholar]

- Ferré Olive, E.H. Foro Virtual de Contabilidad Ambiental y Social; Facultad de Ciencias Económicas de la Universidad de Buenos Aires: Buenos Aires, Argentina, 2010. [Google Scholar]

- Vaca Zelaya, J.L.; Sánchez, M.J.C. Manual Educativo Manejo de Residuos Sólidos; Abbase Ltda: La Paz, Bolivia, 2007. [Google Scholar]

- Conselho Nacional do Meio Ambiente. Resolução Conama No 307 de 05/07/2002; Conselho Nacional do Meio Ambiente: Brasilia, Brazil, 2002. [Google Scholar]

- Gobierno de Chile. CORFO. Available online: https://www.corfo.cl/sites/cpp/quienessomos (accessed on 19 October 2021).

- REGEMAC Gestión Sustentable de Residuos Sólidos Inertes. Available online: https://regemac.cl/home/ (accessed on 19 October 2021).

- Morales Alpízar, M.; Flórez-Estrada, M.V. Guía de Manejo de Escombros y Otros Residuos de La Construcción; Oficina Regional para Mesoamérica y la Iniciativa Caribe, Unión Internacional para la Conservación de la Naturaleza UICN: San José, Costa Rica, 2011. [Google Scholar]

- Ministerio del Ambiente Gestión Integral de Desechos Sólidos (PNGIDS). Available online: http://inabio.biodiversidad.gob.ec/2019/01/30/26-gestion-integral-de-desechos-solidos-pngids/# (accessed on 28 July 2021).

- Cámara Mexicana de la Industria de la Construcción. Plan de Manejo de Residuos de La Construcción y La Demolición; Cámara Mexicana de la Industria de la Construcción: Mexico City, Mexico, 2014. [Google Scholar]

- Gobierno Del Estado De México. Infraestructura Para El Manejo de Residuos Peligrosos. In Bases Conceptuales y de Diagnóstico del Programa Para la Prevención y Manejo Integral de Residuos Peligrosos en la Zona Metropolitana del Valle de México; Gobierno del Estado de México: Toluca, Mexico, 2013. [Google Scholar]

- Consejo Municipal de Panama. Acuerdo N° 124; Consejo Municipal de Panama: Panama City, Panama, 2015. [Google Scholar]

- Ministerio de Vivienda, Construcción y Saneamiento VIVIENDA. Decreto Supremo N° 003-2013-VIVIENDA. Available online: http://sial.segat.gob.pe/normas/aprueba-reglamento-gestion-manejo-residuos-las-actividades-las (accessed on 28 July 2021).

- Organismo de Evaluación y Fiscalización Ambiental–OEFA. La Fiscalización Ambiental en Residuos Sólidos; Organismo de Evaluación y Fiscalización Ambiental–OEFA: Chachapoyas, Peru, 2014. [Google Scholar]

- Gobierno de la Republica Dominicana Ministerio de Medio Ambiente y Recursos Naturales. Available online: https://ambiente.gob.do/transparencia/ (accessed on 28 July 2021).

- Esa, M.R.; Halog, A.; Rigamonti, L. Strategies for Minimizing Construction and Demolition Wastes in Malaysia. Resour. Conserv. Recycl. 2017, 120, 219–229. [Google Scholar] [CrossRef]

- Yang, H.; Xia, J.; Thompson, J.R.; Flower, R.J. Urban Construction and Demolition Waste and Landfill Failure in Shenzhen, China. Waste Manag. 2017, 63, 393–396. [Google Scholar] [CrossRef] [PubMed]

- Gálvez-Martos, J.L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and Demolition Waste Best Management Practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef] [Green Version]

- Alexandridou, C.; Angelopoulos, G.N.; Coutelieris, F.A. Mechanical and Durability Performance of Concrete Produced with Recycled Aggregates from Greek Construction and Demolition Waste Plants. J. Clean. Prod. 2018, 176, 745–757. [Google Scholar] [CrossRef]

- Lai, Y.-Y.; Yeh, L.-H.; Chen, P.-F.; Sung, P.-H.; Lee, Y.-M. Management and Recycling of Construction Waste in Taiwan. Proc. Environ. Sci. 2016, 35, 723–730. [Google Scholar] [CrossRef]

- U.S. Environmental Erotection Agency. Reduce, Reuse, Recycle. Available online: https://www.epa.gov/recycle (accessed on 19 October 2021).

- Akhtar, A.; Sarmah, A.K. Construction and Demolition Waste Generation and Properties of Recycled Aggregate Concrete: A Global Perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Lopera, H.A.C.; Gutierrez-Velasquez, E.; Ballesteros, N. Bridging the Gap between Theory and Active Learning: A Case Study of Project-Based Learning in Introduction to Materials Science and Engineering. IEEE Rev. Iberoam. de Tecnol. del Aprendiz. 2022, 17, 160–169. [Google Scholar] [CrossRef]

- Colorado, H.A.; Mendoza, D.E.; Valencia, F.L. A Combined Strategy of Additive Manufacturing to Support Multidisciplinary Education in Arts, Biology, and Engineering. J. Sci. Educ. Technol. 2020, 30, 58–73. [Google Scholar] [CrossRef]

| Name | Volume (m3/m2) | Density (ton/m3) |

|---|---|---|

| Factor 1 | 1.42 | 1.48 |

| Factor 2 | 1.35 | 1.40 |

| Factor 3 | 0.6 | 1.6 |

| Factor 4 | 1.12 | 1.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colorado, H.A.; Muñoz, A.; Neves Monteiro, S. Circular Economy of Construction and Demolition Waste: A Case Study of Colombia. Sustainability 2022, 14, 7225. https://doi.org/10.3390/su14127225

Colorado HA, Muñoz A, Neves Monteiro S. Circular Economy of Construction and Demolition Waste: A Case Study of Colombia. Sustainability. 2022; 14(12):7225. https://doi.org/10.3390/su14127225

Chicago/Turabian StyleColorado, Henry A., Andrea Muñoz, and Sergio Neves Monteiro. 2022. "Circular Economy of Construction and Demolition Waste: A Case Study of Colombia" Sustainability 14, no. 12: 7225. https://doi.org/10.3390/su14127225

APA StyleColorado, H. A., Muñoz, A., & Neves Monteiro, S. (2022). Circular Economy of Construction and Demolition Waste: A Case Study of Colombia. Sustainability, 14(12), 7225. https://doi.org/10.3390/su14127225