Fractals for the Sustainable Design of Engineered Particulate Systems

Abstract

:1. Introduction

1.1. Forms and Behavioral Traits

1.2. Biomimicry, Sustainability, and Design

1.2.1. Fractals for Relaxing Randomness

1.2.2. Imitation of Fractals

1.3. Forms and Behavioral Traits: A Particulate Matters Perspective

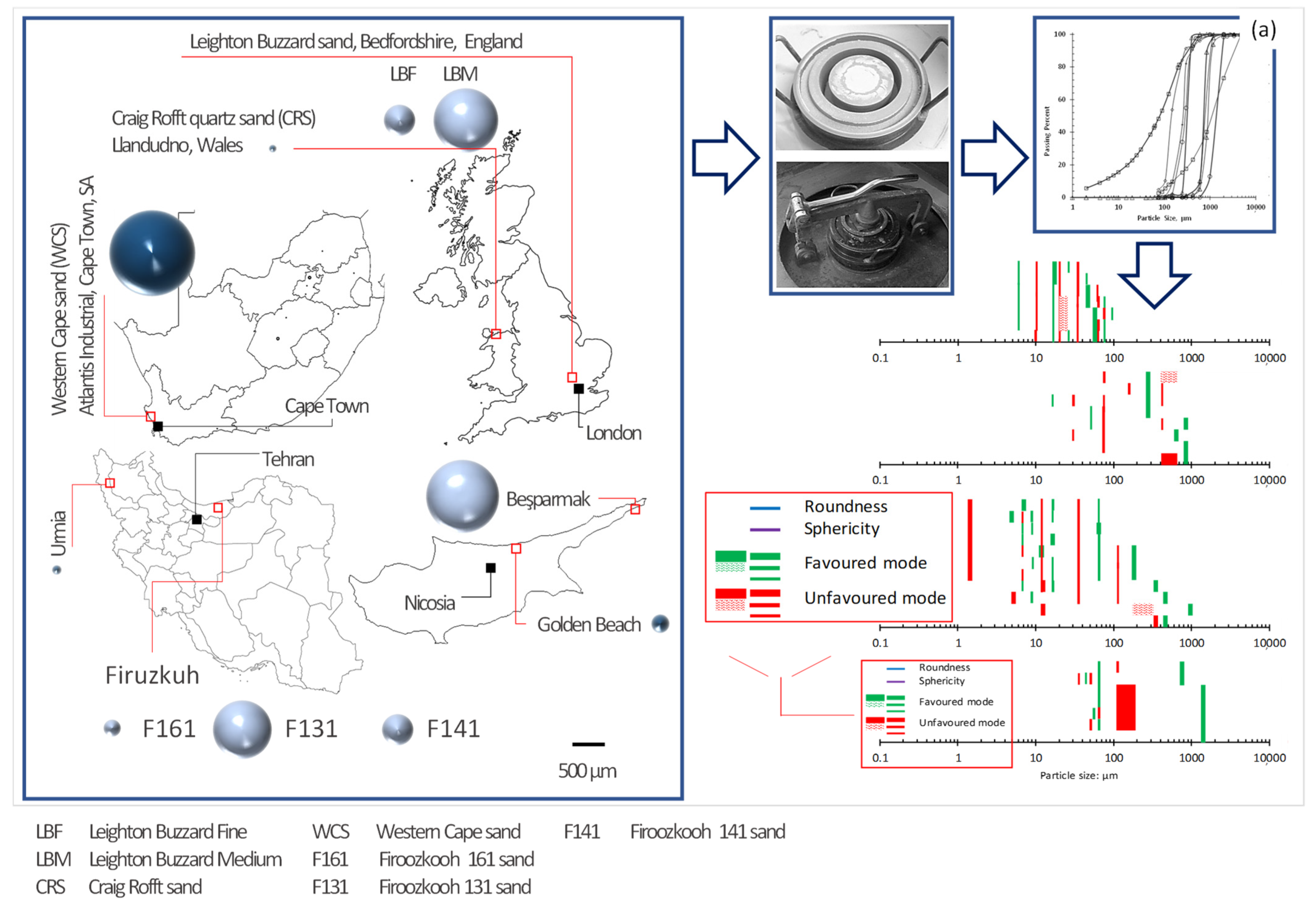

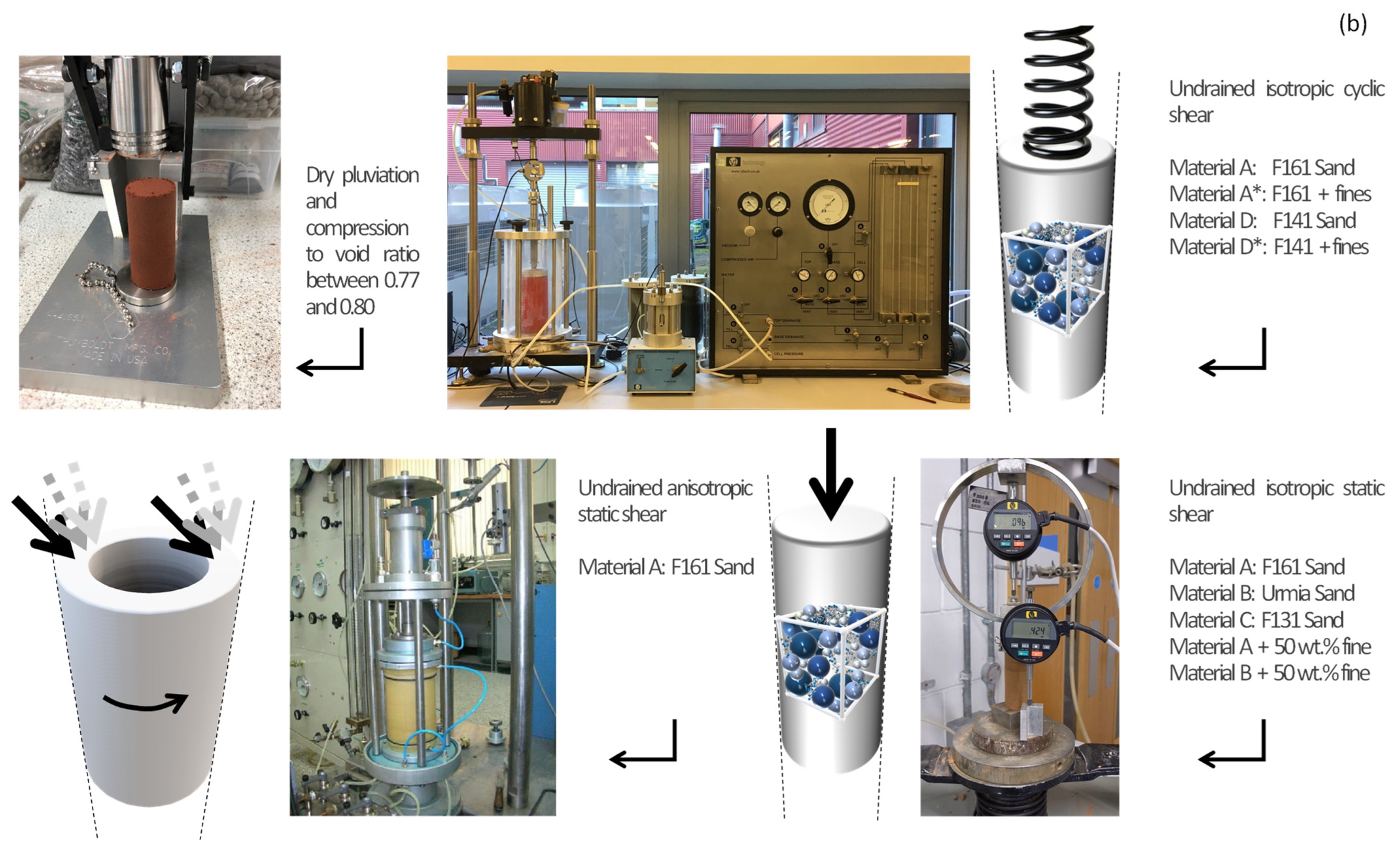

2. Materials and Methods

2.1. Experiment Method

3. Fractals at Particle Level

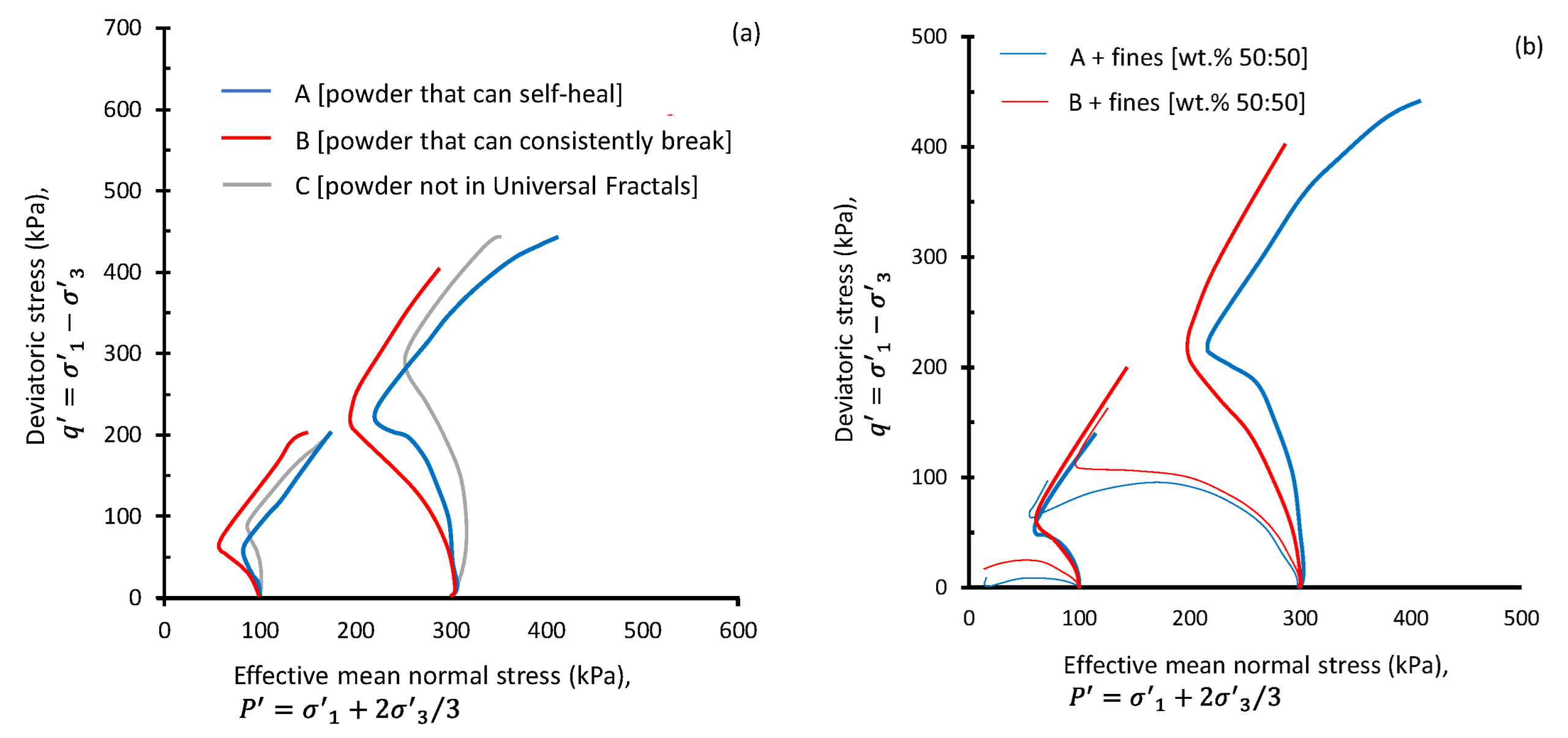

3.1. Universal Fractals for Dry Crystalline Solid Particles

3.1.1. Steady-State Traits

3.1.2. Loading Scenarios

- Scenario 1: Isotropic static stresses

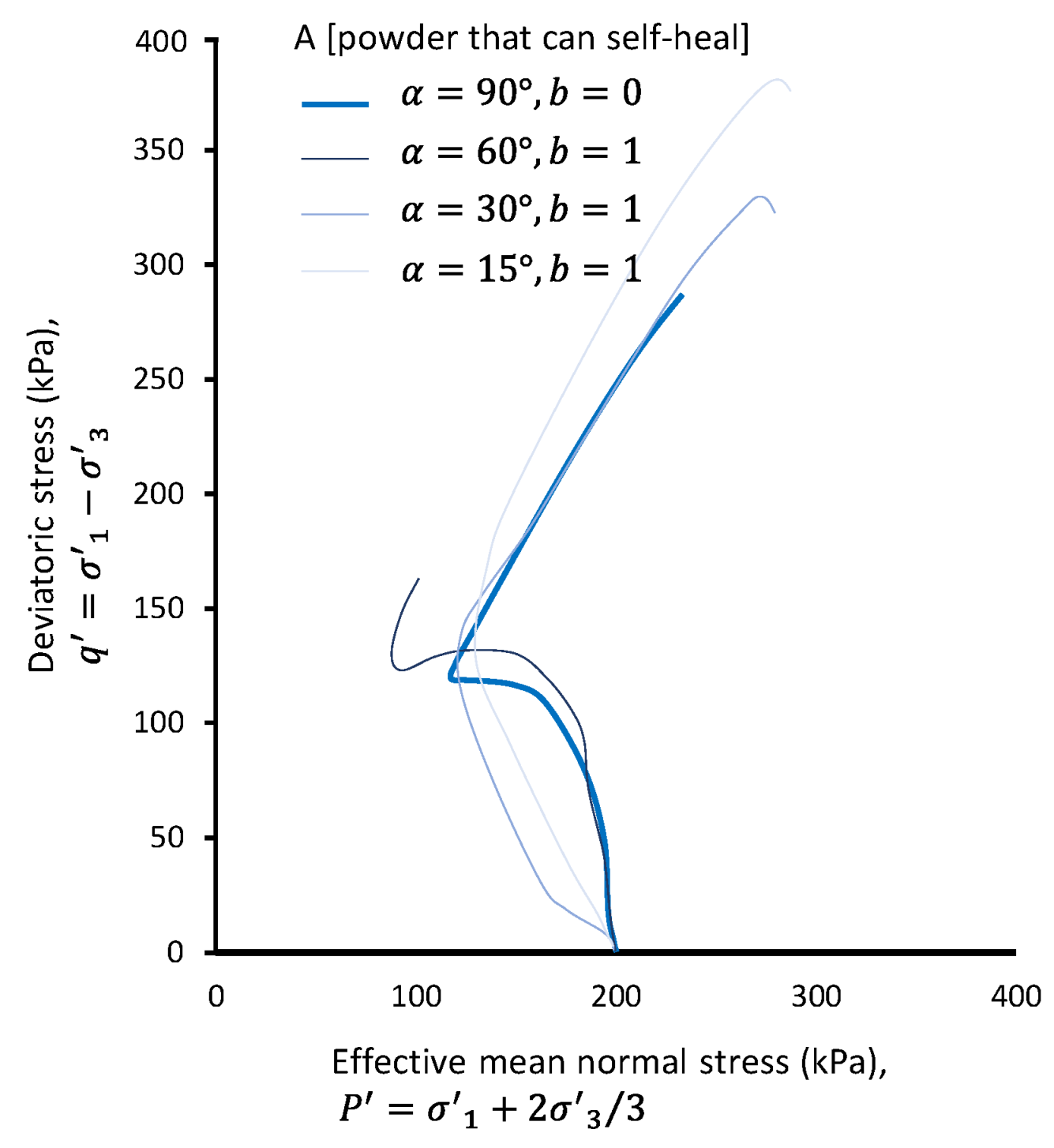

- Scenario 2: Anisotropic static stresses

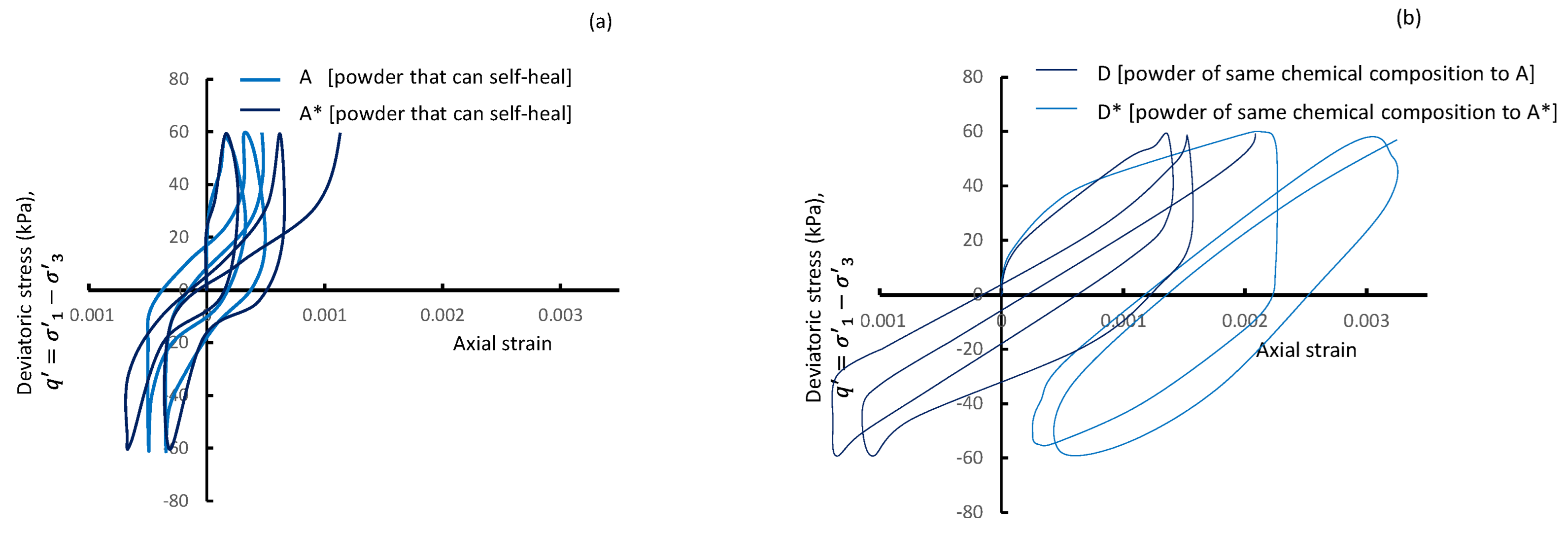

- Scenario 3: Isotropic cyclic stresses

3.2. Universal Fractals for Granular Materials at Large

3.3. Universal Fractal Structures

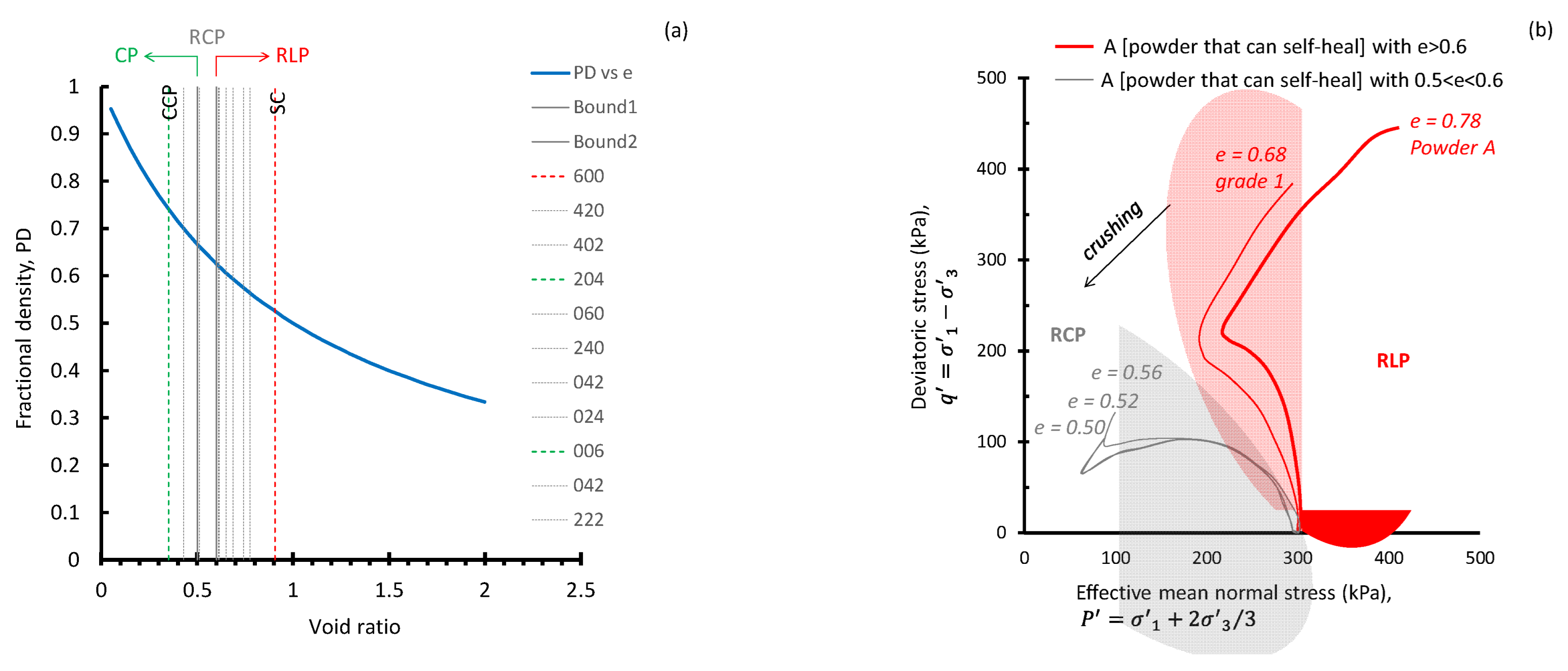

3.3.1. Packing Qualities

3.3.2. Fractals at Particle and Structure Levels

4. Discussion: Fractals and Biomimetic Design

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fagg, R.; Smalley, I. ‘Hardcastle Hollows’ in loess landforms: Closed depressions in aeolian landscapes—In a geoheritage context. Open Geosci. 2018, 10, 58–63. [Google Scholar] [CrossRef] [Green Version]

- Zeeden, C.; Hark, M.; Hambach, U.; Markovic, S.; Zöller, L. Depressions on the Titel loess plateau: Form, pattern, genesis. Geogr. Pannonica 2007, 11, 4–8. [Google Scholar] [CrossRef] [Green Version]

- Hardcastle, J. Origin of the loess deposit of the Timaru plateau. Trans. N. Z. Inst. 1889, 22, 406–414. [Google Scholar]

- Vanwalleghem, T.; Poesen, J.; Vitse, I.; Bork, H.R.; Dotterweich, M.; Schmidtchen, G.; Deckers, J.; Lang, A.; Mauz, B. Origin and evolution of closed depressions in central Belgium, European loess belt. Earth Surf. Process. Landf. 2007, 32, 574–586. [Google Scholar] [CrossRef]

- Prince, H.C. Some reflections on the origin of hollows in Norfolk compared with those in the Paris region. Rev. Géomorphologie Dyn. 1961, 12, 110–117. [Google Scholar]

- Derbyshire, E.; Wang, J.T.; Meng, X.M. The environment: Geology, geomorphology, climate and land use. In Landslides in the Thick Loess Terrain of Northwest China; Derbyshire, E., Meng, X., Dijkstra, T.A., Eds.; Wiley-Blackwell: Chichester, UK, 1999; pp. 22–46. [Google Scholar]

- Etienne, D.; Ruffaldi, P.; Goepp, S.; Ritz, F.; Georges-Leroy, M.; Pollier, B.; Dambrine, E. The origin of closed depressions in Northeastern France: A new assessment. Geomorphology 2011, 126, 121–131. [Google Scholar] [CrossRef]

- Dibben, S. A microstructural model for collapsing soils. Ph.D. Thesis, Nottingham Trent University, Nottingham, UK, 1998. [Google Scholar]

- Zuriguel, I.; Garcimartín, A.; Maza, D.; Pugnaloni, L.A.; Pastor, J.M. Jamming during the discharge of granular matter from a silo. Phys. Rev. E 2005, 71, 051303. [Google Scholar] [CrossRef] [Green Version]

- Trogadas, P.; Cho, J.I.S.; Neville, T.P.; Marquis, J.; Wu, B.; Brett, D.J.L.; Coppens, M.-O. A lung-inspired approach to scalable and robust fuel cell design. Energy Environ. Sci. 2018, 11, 136–143. [Google Scholar] [CrossRef] [Green Version]

- Rian, I.; Sassone, M. Tree-inspired dendriforms and fractal-like branching structures in architecture: A brief historical overview. Front. Arch. Res. 2014, 3, 298–323. [Google Scholar] [CrossRef] [Green Version]

- Tang, D.; Marangoni, A.G. Microstructure and fractal analysis of fat crystal networks. J. Am. Oil Chem. Soc. 2006, 83, 377–388. [Google Scholar] [CrossRef]

- Otto, T.; Baik, B.-K.; Czuchajowska, Z. Microstructure of Seeds, Flours, and Starches of Legumes. Cereal Chem. 1997, 74, 445–451. [Google Scholar] [CrossRef]

- Nair, S.; Knoblauch, M.; Ullrich, S.; Baik, B.-K. Microstructure of hard and soft kernels of barley. J. Cereal Sci. 2011, 54, 354–362. [Google Scholar] [CrossRef]

- Lee, W.E.; Rainforth, M. Ceramic Microstructures: Property Control by Processing, 1st ed.; Chapman and Hall: London, UK, 1994; p. 602. [Google Scholar]

- Morris, V.J.; Gunning, A.P. Microscopy, microstructure and displacement of proteins from interfaces: Implications for food quality and digestion. Soft Matter 2008, 4, 943–951. [Google Scholar] [CrossRef] [PubMed]

- West, G. Scale: The Universal Laws of Life and Death in Organisms, Cities and Companies; Orion Publishing Co.: London, UK, 2018. [Google Scholar]

- Chaudhry, Q.; Watkins, R.; Castle, L. Knowns, Unknowns, and Unknown Unknowns. In Nanotechnologies in Food; Royal Society of Chemistry: London, UK, 2010; pp. 212–214. [Google Scholar] [CrossRef]

- Thomas, M.E.; Scher, J.; Desobry-Banon, S.; Desobry, S. Milk powders ageing: Effect on physical and functional proper-ties. Crit. Rev. Food Sci. Nutr. 2004, 44, 297–322. [Google Scholar] [CrossRef]

- Boiarkina, I.; Sang, C.; Depree, N.; Prince-Pike, A.; Yu, W.; Wilson, D.; Young, B.R. The significance of powder breakdown during conveying within industrial milk powder plants. Adv. Powder Technol. 2016, 27, 2363–2369. [Google Scholar] [CrossRef] [Green Version]

- Variankaval, N.; Cote, A.S.; Doherty, M.F. From form to function: Crystallization of active pharmaceutical ingredi-ents. AIChE J. 2008, 54, 1682–1688. [Google Scholar] [CrossRef]

- Assadi-Langroudi, A.; O’Kelly, B.C.; Barreto, D.; Cotecchia, F.; Dicks, H.; Ekinci, A.; Garcia, F.E.; Harbottle, M.; Tagarelli, V.; Jefferson, I.; et al. Recent Advances in Nature-Inspired Solutions for Ground Engineering (NiSE). Int. J. Geosynth. Ground Eng. 2021, 8, 3. [Google Scholar] [CrossRef]

- Langroudi, A.A.; Jefferson, I.; O’Hara-Dhand, K.; Smalley, I. Micromechanics of quartz sand breakage in a fractal context. Geomorphology 2014, 211, 1–10. [Google Scholar] [CrossRef]

- Assadi Langroudi, A.; Theron, E. Gaps in particulate matters: Formation, mechanisms, implications. In Proceedings of the 17th African Regional Conference on Soil Mechanics and Geotechnical Engineering, Cape Town, South Africa, 6–10 October 2019; pp. 169–174. [Google Scholar]

- Ghadr, S.; Bahadori, H.; Assadi-Langroudi, A. Anisotropy in Sand–Fibre Composites and Undrained Stress–Strain Implications. Int. J. Geosynth. Ground Eng. 2019, 5, 23. [Google Scholar] [CrossRef]

- Ghadr, S.; Samadzadeh, A.; Bahadori, H.; O’Kelly, B.C.; Assadi-Langroudi, A. Liquefaction Resistance of Silty Sand with Ground Rubber Additive. Int. J. Géoméch. 2021, 21, 04021076. [Google Scholar] [CrossRef]

- Rasenack, N.; Müller, B.W. Micron-Size Drug Particles: Common and Novel Micronization Techniques. Pharm. Dev. Technol. 2004, 9, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Moss, A.J. Origin, shaping and significance of quartz sand grains. J. Geol. Soc. Aust. 1966, 13, 97–136. [Google Scholar] [CrossRef]

- Smalley, I.J. Formation of Quartz Sand. Nature 1966, 211, 476–479. [Google Scholar] [CrossRef]

- Blatt, H. Original Characteristics of Clastic Quartz Grains. J. Sediment. Res. 1967, 37, 401–424. [Google Scholar] [CrossRef]

- Ghadr, S.; Assadi-Langroudi, A. Effect of Grain Size and Shape on Undrained Behaviour of Sands. Int. J. Geosynth. Ground Eng. 2019, 5, 18. [Google Scholar] [CrossRef]

- Assadi-Langroudi, A.; Jefferson, I. Collapsibility in calcareous clayey loess: A factor of stress-hydraulic history. Int. J. Geomate 2013, 5, 620–627. [Google Scholar]

- Assadi-Langroudi, A.; Ng’Ambi, S.; Smalley, I. Loess as a collapsible soil: Some basic particle packing aspects. Quat. Int. 2018, 469, 20–29. [Google Scholar] [CrossRef]

- Dijkstra, T.; Smalley, I.; Rogers, C. Particle packing in loess deposits and the problem of structure collapse and hydroconsolidation. Eng. Geol. 1995, 40, 49–64. [Google Scholar] [CrossRef]

- Dicks, H. The philosophy of biomimicry. Philos. Technol. 2016, 29, 223–243. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Assadi-Langroudi, A.; Abdalla, H.; Ghadr, S. Fractals for the Sustainable Design of Engineered Particulate Systems. Sustainability 2022, 14, 7287. https://doi.org/10.3390/su14127287

Assadi-Langroudi A, Abdalla H, Ghadr S. Fractals for the Sustainable Design of Engineered Particulate Systems. Sustainability. 2022; 14(12):7287. https://doi.org/10.3390/su14127287

Chicago/Turabian StyleAssadi-Langroudi, Arya, Hassan Abdalla, and Soheil Ghadr. 2022. "Fractals for the Sustainable Design of Engineered Particulate Systems" Sustainability 14, no. 12: 7287. https://doi.org/10.3390/su14127287

APA StyleAssadi-Langroudi, A., Abdalla, H., & Ghadr, S. (2022). Fractals for the Sustainable Design of Engineered Particulate Systems. Sustainability, 14(12), 7287. https://doi.org/10.3390/su14127287