Derivation of Risk Factors to Quantify the Risk of Safety Accidents for Small and Medium-Sized Enterprises in Construction Industry

Abstract

:1. Introduction

2. Literature Review

3. Data Collection

4. Analysis

4.1. Comparison between SME and Large Enterprise

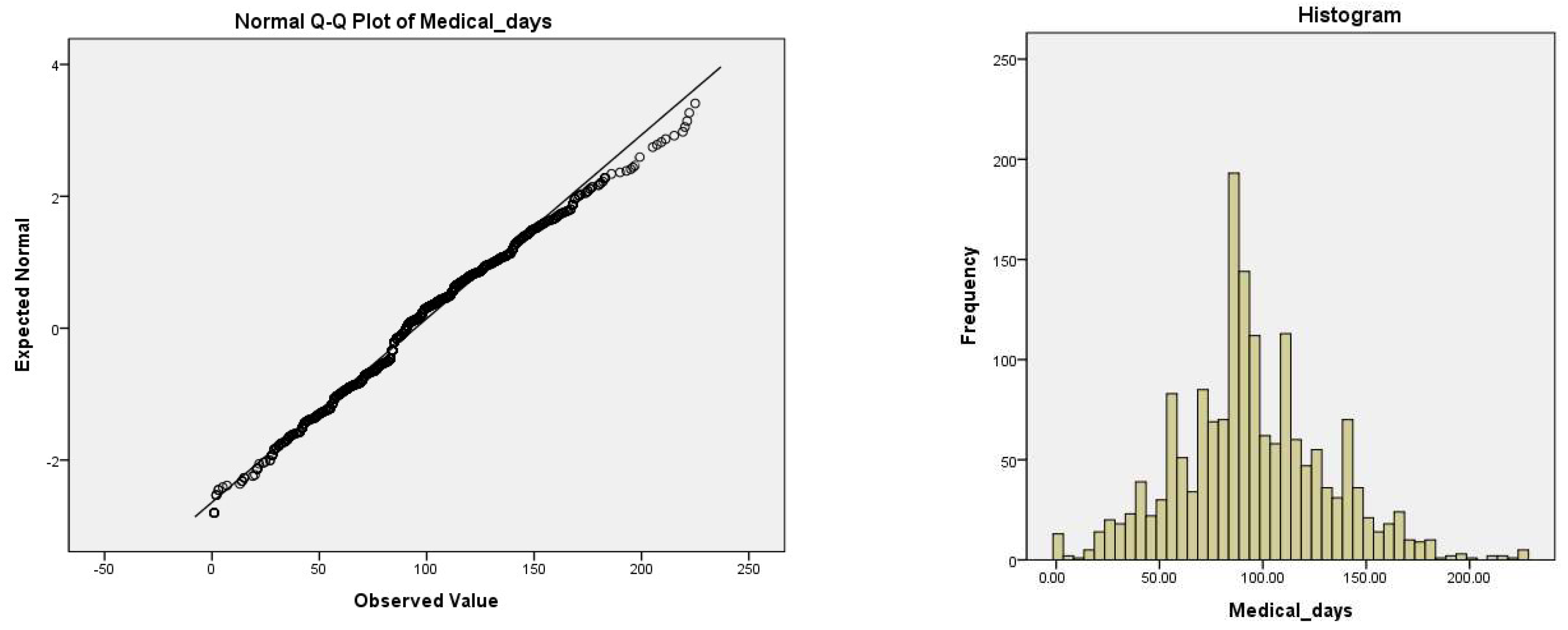

4.2. Normality

4.3. Multiple Regression Analysis

5. Result

6. Discussion

7. Conclusions

Limitation and Future Research

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sørensen, O.H.; Hasle, P.; Bach, E. Working in small enterprises–is there a special risk? Saf. Sci. 2007, 45, 1044–1059. [Google Scholar] [CrossRef]

- Kheni, N.A.; Gibb, A.G.; Dainty, A.R. Health and safety management within small-and medium-sized enterprises (SMEs) in developing countries: Study of contextual influences. J. Constr. Eng. Manag. 2010, 136, 1104–1115. [Google Scholar] [CrossRef] [Green Version]

- Gunduz, M.; Laitinen, H. Observation based safety performance indexing method for construction industry–validation with SMEs. KSCE J. Civ. Eng. 2018, 22, 440–446. [Google Scholar] [CrossRef]

- Belayutham, S.; Ibrahim, C.K.I.C. Barriers and strategies for better safety practices: The case of construction SMEs in Malaysia. Constr. Econ. Build. 2019, 19, 1–20. [Google Scholar] [CrossRef]

- Badi, S.; Wang, L.; Pryke, S. Relationship marketing in Guanxi networks: A social network analysis study of Chinese construction small and medium-sized enterprises. Ind. Mark. Manag. 2017, 60, 204–218. [Google Scholar] [CrossRef]

- Korea Occupational Safety and Health Agency. 2020 Industrial Accident Status Analysis. 2020. Available online: https://www.kosha.or.kr/kosha/data/industrialAccidentStatus.do?mode=view&articleNo=427416&article.offset=0&articleLimit=10 (accessed on 15 April 2022).

- Wu, C.; Song, X.; Wang, T.; Fang, D. Core dimensions of the construction safety climate for a standardized safety-climate measurement. J. Constr. Eng. Manag. 2015, 141, 04015018. [Google Scholar] [CrossRef]

- Sunindijo, R.Y. Improving safety among small organisations in the construction industry: Key barriers and improvement strategies. Procedia Eng. 2015, 125, 109–116. [Google Scholar] [CrossRef] [Green Version]

- Tam, C.M.; Zeng, S.X.; Deng, Z.M. Identifying elements of poor construction safety management in China. Saf. Sci. 2004, 42, 569–586. [Google Scholar] [CrossRef]

- Raheem, A.A.; Hinze, J. Reasons for the poor implementation of worker safety in the construction industry of Pakistan: A contractor’s prospective. In Proceedings of the CIB W099 International Conference “Modeling and Building Health and Safety”, Singapore, 10–11 September 2012; pp. 10–11. [Google Scholar]

- Gunduz, M.; Laitinen, H. Construction safety risk assessment with introduced control levels. J. Civ. Eng. Manag. 2018, 24, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Kamal, E.M.; Lou, E.C.; Yusof, N.A.; Osmadi, A. Absorptive capacity of Malaysian SME construction organisations. Archit. Eng. Des. Manag. 2021, 18, 313–324. [Google Scholar] [CrossRef]

- Jang, Y.; Go, S. A Study on the Success Factors Impacting on the Small Construction Projects. Korean J. Constr. Eng. Manag. 2018, 19, 90–100. [Google Scholar]

- Yoon, S.J.; Lin, H.K.; Chen, G.; Yi, S.; Choi, J.; Rui, Z. Effect of occupational health and safety management system on work-related accident rate and differences of occupational health and safety management system awareness between managers in South Korea’s construction industry. Saf. Health Work 2013, 4, 201–209. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bennett, B.; Deitch, N. OSHA’s Voluntary Protection Programs (VPP) Continue to Bring Value. In Proceedings of the ASSE Professional Development Conference and Exposition, Chicago, IL, USA, 12–15 June 2011. [Google Scholar]

- Grant, A.; Hinze, J. Construction worker fatalities related to trusses: An analysis of the OSHA fatality and catastrophic incident database. Saf. Sci. 2014, 65, 54–62. [Google Scholar] [CrossRef]

- Safety and Health Add Value, 2004 OSHA. Available online: https://www.thevillageslink.com/osha/materialHandling/Publications/safety-health-addvalue.pdf (accessed on 17 April 2022).

- Lamm, F. Occupational Health and Safety in Queensland and New Zealand Small Businesses: Influential Factors That Lead to Occupational Health and Safety Compliance and Practice; School of Industrial Relations and Organizational Behaviour, Faculty of Commerce and Economics, The University of New South Wales: Sydney, Australia, 2000. [Google Scholar]

- Eakin, J.; Lamm, F.; Limborg, H.J. International perspective on the promotion of health and safety in small workplace. In Systematic Occupational Health and Safety-Perspectives on an International Development; Frick, K., Jensen, P.L., Quinlan, M., Wilthagen, T., Eds.; Pergamon: Amsterdam, The Netherlands, 2000; pp. 227–247. [Google Scholar]

- Schlunssen, V.; Vinzents, P.S.; Mikkelsen, A.E.; Schaumburg, I. Wood dust exposure in the Danish furniture industry using conventional and passive monitors. Ann. Occup. Hyg. 2001, 45, 157–164. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hasle, P.; Limborg, H.J. A review of the literature on preventive occupational health and safety activities in small enterprises. Ind. Health 2006, 44, 6–12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gunduz, M.; Laitinen, H. A 10-step safety management framework for construction SMEs. Int. J. Occup. Saf. Ergon. 2017, 23, 353–359. [Google Scholar] [CrossRef]

- Ozmec, M.N.; Karlsen, I.L.; Kines, P.; Andersen, L.P.S.; Nielsen, K.J. Negotiating safety practice in small construction companies. Saf. Sci. 2015, 71, 275–281. [Google Scholar] [CrossRef] [Green Version]

- Legg, S.; Laird, I.; Olsen, K.; Hasle, P. Creating healthy work in small enterprises—From understanding to action: Summary of current knowledge. Small Enterp. Res. 2014, 21, 139–147. [Google Scholar] [CrossRef]

- Ram, M.; Edwards, P.; Gilman, M.; Arrowsmith, J. The dynamics of informality: Employment relations in small firms and the effects of regulatory change. Work. Employ. Soc. 2001, 15, 845–861. [Google Scholar] [CrossRef]

- Staniewski, M.W.; Nowacki, R.; Awruk, K. Entrepreneurship and innovativeness of small and medium-sized construction enterprises. Int. Entrep. Manag. J. 2016, 13, 861–877. [Google Scholar] [CrossRef] [Green Version]

- Mallett, O.; Wapshott, R. Informality and employment relationships in small firms: Humour, ambiguity and straight-talking. Br. J. Manag. 2014, 25, 118–132. [Google Scholar] [CrossRef] [Green Version]

- Nyirendaavwil, V.; Chinniah, Y.; Agard, B. Identifying Key Factors for an Occupational Health and Safety Risk estimation Tool in Small and Medium-size Enterprises. IFAC Pap. 2015, 48, 541–546. [Google Scholar] [CrossRef]

- Holte, K.A.; Kjestveit, K.; Lipscomb, H.J. Company size and differences in injury prevalence among apprentices in building and construction in Norway. Saf. Sci. 2015, 71, 205–212. [Google Scholar] [CrossRef] [Green Version]

- Cheng, C.W.; Leu, S.S.; Lin, C.C.; Fan, C. Characteristic analysis of occupational accidents at small construction enterprises. Saf. Sci. 2010, 48, 698–707. [Google Scholar] [CrossRef]

- Hasle, P.; Kines, P.; Andersen, L.P. Small enterprise owners’ accident causation attribution and prevention. Saf. Sci. 2009, 47, 9–19. [Google Scholar] [CrossRef]

- Tang, L.C.M.; Leung, A.Y.T.; Wong, C.W.Y. Entropic risk analysis by a high level decision support system for construction SMEs. J. Comput. Civ. Eng. 2010, 24, 81–94. [Google Scholar] [CrossRef]

- Korkmaz, S.; Park, D.J. Comparison of safety perception between foreign and local workers in the construction industry in Republic of Korea. Saf. Health Work. 2018, 9, 53–58. [Google Scholar] [CrossRef]

- International Labour Organisation (ILO). ILO Global Estimates on Migrant Workers: Results and Methodology. Special Focus on Migrant Domestic Workers; ILO: Geneva, Switzerland, 2015. [Google Scholar]

- Nevada Department of Transportation. Risk Management and Risk-Based Cost Estimation Guidelines; Nevada Department of Transport: Carson City, NV, USA, 2012; p. 42.

- Kim, J.M.; Kim, T.; Bae, J.; Son, K.; Ahn, S. Analysis of plant construction accidents and loss estimation using insurance loss records. J. Asian Archit. Build. 2019, 18, 507–516. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.M.; Woods, P.K.; Park, Y.J.; Kim, T.; Son, K. Predicting hurricane wind loss by claim payout based on Hurricane Ike in Texas. Geomat. Nat. Haz. Risk 2015, 7, 1513–1525. [Google Scholar] [CrossRef] [Green Version]

- Ryu, H.; Son, K.; Kim, J.M. Loss Prediction Model for Building Construction Projects Using Insurance Claim Payout. J. Asian Archit. Build. 2016, 15, 441–446. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, S. Causes and Effects of Accident at Construction Site: A Study for the Construction Industry in Bangladesh. Int. J. Civ. Eng. Technol. 2019, 10, 18–40. [Google Scholar]

- Kwon, S.C. Use of Frequency Analysis of Exposure of Hazards by Occupations: Findings from the Third and Fourth Korean Working Conditions Survey. Soonchunhyang Med. Sci. 2019, 25, 37–45. [Google Scholar] [CrossRef]

- Gambatese, J.A.; Behm, M.; Hinze, J.W. Viability of designing for construction worker safety. J. Constr. Eng. Manag. ASCE 2005, 131, 1029–1036. [Google Scholar] [CrossRef] [Green Version]

- Cho, J. A study on the cause analysis and preventive measures for each type of disaster at the construction site. J. Korea Saf. Manag. Sci. 2012, 14, 7–13. [Google Scholar]

- Moyce, S.C.; Schenker, M. Migrant workers and their occupational health and safety. Annu. Rev. Public Health 2018, 39, 351–365. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sousa, E.; Agudelo-Suárez, A.; Benavides, F.G.; Schenker, M.; García, A.M.; Benach, J.; Porthé, V. Immigration, work and health in Spain: The influence of legal status and employment contract on reported health indicators. Int. J. Public Health 2010, 55, 443–451. [Google Scholar] [CrossRef] [Green Version]

- Lim, B. Comparison of Occupational Accidents According to the Type of Employment of Safety and Health Managers. [Linked to Public Works] Korea Occupational Safety and Health Agency Published Data. 2015. Available online: http://oshri.kosha.or.kr/oshri/publication/researchReportSearch.do?mode=view&articleNo=63449&article.offset=0&articleLimit=10&srSearchVal=%EA%B3%A0%EC%9A%A9%ED%98%95%ED%83%9C (accessed on 15 April 2022).

- Chong, H.Y.; Low, T.S. Accidents in Malaysian construction industry: Statistical data and court cases. Int. J. Occup. Saf. Ergon. 2014, 20, 503–513. [Google Scholar] [CrossRef]

- Zerguine, H.; Tamrin, S.B.M.; Jalaludin, J. Prevalence, source and severity of work-related injuries among “foreign” construction workers in a large Malaysian organisation: A cross-sectional study. Ind. Health 2018, 56, 264–273. [Google Scholar] [CrossRef] [Green Version]

- Ramos, D.; Afonso, P.; Rodrigues, M.A. Integrated management systems as a key facilitator of occupational health and safety risk management: A case study in a medium sized waste management firm. J. Clean. Prod. 2020, 262, 121346. [Google Scholar] [CrossRef]

- Langford, D.; Dimitrijevic, B. Construction Creativity Casebook; Thomas Telford: London, UK, 2002. [Google Scholar]

- Hasan, A.; Baroudi, B.; Elmualim, A.; Rameezdeen, R. Factors affecting construction productivity: A 30 year systematic review. Eng. Constr. Archit. Manag. 2018, 25, 916–937. [Google Scholar] [CrossRef]

- Shapira, A.; Rosenfeld, Y. Achieving construction innovation through academia-industry cooperation—Keys to success. J. Prof. Issues Eng. Educ. Practice 2011, 137, 223–231. [Google Scholar] [CrossRef]

- Zhi, M.; Hua, G.B.; Wang, S.Q.; Ofori, G. Total factor productivity growth accounting in the construction industry of Singapore. Constr. Manag. Econ. 2003, 21, 707–718. [Google Scholar] [CrossRef]

- Bankvall, L.; Bygballe, L.E.; Dubois, A.; Jahre, M. Interdependence in supply chains and projects in construction. Supply Chain. Manag. Int. J. 2010, 15, 385–393. [Google Scholar] [CrossRef]

- Tran, V.D.; Tookey, J.E. Labour productivity in the New Zealand construction industry: A thorough investigation. Australas. J. Constr. Econ. Build. 2011, 11, 41–60. [Google Scholar] [CrossRef] [Green Version]

- Esmaeili, B.; Hallowell, M.R. Diffusion of safety innovations in the construction industry. J. Constr. Eng. Manag. 2012, 138, 955–963. [Google Scholar] [CrossRef]

- Bos-Brouwers, H.E.J. Corporate sustainability and innovation in SMEs: Evidence of themes and activities in practice. Bus. Strategy Environ. 2009, 19, 417–435. [Google Scholar] [CrossRef]

- Forbes, D.; Milliken, F. Cognition and corporate governance: Understanding boards of directors as strategic decision-making groups. Acad. Manag. Rev. 1999, 12, 117–132. [Google Scholar]

- Busenitz, L.; Barney, J. Differences between entrepreneurs and managers in large organizations: Biases and heuristics in strategic decision making. J. Bus. Ventur. 1997, 12, 9–30. [Google Scholar] [CrossRef]

- Amiri, M.; Ardeshir, A.; Zarandi, M.H. Risk-based analysis of construction accidents in Iran during 2007–2011-meta analyze study. Iran. J. Public Health 2014, 43, 507. [Google Scholar]

- Camino López, M.A.; Fontaneda, I.; Alcántara, O.J.; Ritzel, D.O. The special severity of occupational accidents in the afternoon:“The lunch effect”. Accid. Anal. Prev. 2011, 43, 1104–1116. [Google Scholar] [CrossRef]

- Arezes, P.M.; Bizarro, M. Alcohol consumption and risk perception in the Portuguese construction industry. Open Occup. Health Saf. J. 2011, 3, 10–17. [Google Scholar] [CrossRef]

- Chan, M. Fatigue: The most critical accident risk in oil and gas construction. Constr. Manag. Econ. 2011, 29, 341–353. [Google Scholar] [CrossRef]

- Fang, D.; Jiang, Z.; Zhang, M.; Wang, H. An experimental method to study the effect of fatigue on construction workers’ safety performance. Saf. Sci. 2015, 73, 80–91. [Google Scholar] [CrossRef]

- Namian, M.; Taherpour, F.; Ghiasvand, E.; Turkan, Y. Insidious Safety Threat of Fatigue: Investigating Construction Workers’ Risk of Accident Due to Fatigue. J. Constr. Eng. Manag. 2021, 147, 04021162. [Google Scholar] [CrossRef]

- Fabiano, B.; Currò, F.; Pastorino, R. A study of the relationship between occupational injuries and firm size and type in the Italian industry. Saf. Sci. 2004, 42, 587–600. [Google Scholar] [CrossRef]

- Haslam, R.A.; Hide, S.A.; Gibb, A.G.; Gyi, D.E.; Pavitt, T.; Atkinson, S.; Duff, A.R. Contributing factors in construction accidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef] [Green Version]

- Son, H.Y. The Study of the Links between Contingent Workers and Industrial Accidnet—Using Workplace Panel Survery for Analizing the Moderation Effect of Labor Union. Doctoral Dissertation, Seoul National University, Seoul, Korea, 2017. [Google Scholar]

- Kamal, E.M.; Flanagan, R. Understanding absorptive capacity in Malaysian small and medium sized (SME) construction companies. J. Eng. Des. Technol. 2012, 10, 180–198. [Google Scholar]

- Van Klyton, A.; Rutabayiro-Ngoga, S. SME finance and the construction of value in Rwanda. J. Small Bus. Enterp. Dev. 2017, 25, 628–643. [Google Scholar] [CrossRef]

- Juanzon, J.B.; Muhi, M.M. Significant factors to motivate small and medium enterprise (SME) construction firms in the Philippines to implement ISO9001: 2008. Procedia Eng. 2017, 171, 354–361. [Google Scholar] [CrossRef]

| Construction Site | N | Mean | Standard Deviation | t | p |

|---|---|---|---|---|---|

| SMEs | 1483 | 99.69 | 37.75 | −3.919 | 0.000 |

| Large Enterprises | 125 | 107.28 | 34.190 |

| Variables | Factors | Explanation | Unit |

|---|---|---|---|

| Dependent | Treatment days | Days of treatment indicated in the medical billing statement in order to quantify the severity of accident | Ln(Days) |

| Independent | Progress rate of project | the completed construction progress at the time when the accident happened | % |

| Employees number | Total number of employees at the construction site(Company size) | Number | |

| Citizenship | The citizenship of the victims | 0: Locals (Korean) 1: Foreigners | |

| Work contents | Application of Korean Standard Classification of Occupations | 1: Equipment, machine operating and assembling worker 2: Professionals and related workers 3: Craft and related trades workers 4: Manager 5: Elementary workers | |

| Day of week | The day of the week when the accident occurred. | 1: Monday 2: Tuesday 3: Sunday 4: Wednesday 5: Friday 6: Saturday 7: Thursday | |

| Accident time | The time when the accident occurred. | 1: Dawn (0~6) 2: Evening and Night (18~24) 3: Afternoon (13~18) 4: Morning (6~12) | |

| Contract type | Employment contract type. | 0: Regular contract workers 1: Contingent workers |

| Small and Medium Construction Site | Large Contruction Site | |||||||

|---|---|---|---|---|---|---|---|---|

| Variables | Coef. | Beta Coef. | p > |z| | VIF | Coef. | Beta Coef. | p > |z| | VIF |

| Constant | 4.349 | 0.000 | 4.938 | 0.000 | ||||

| Progress rate | 0.000 | −0.009 | 0.739 | 1.026 | 0.001 | 0.069 | 0.479 | 1.041 |

| Number of employee | 0.000 | −0.016 | 0.571 | 1.031 | 0.000 | 0.149 | 0.134 | 1.069 |

| Nationality | 0.026 | 0.016 | 0.577 | 1.026 | 0.061 | 0.082 | 0.393 | 1.008 |

| Work Contents | 0.020 | 0.055 | 0.166 | 1.012 | −0.064 | −0.267 | 0.245 | 1.007 |

| Day of week | 0.010 | 0.056 | 0.046 * | 1.003 | 0.004 | 0.033 | 0.736 | 1.022 |

| Accident time | 0.037 | 0.058 | 0.040 * | 1.015 | 0.005 | 0.011 | 0.911 | 1.030 |

| Contract type | 0.063 | 0.039 | 0.050 * | 1.004 | 0.141 | 0.114 | 0.006 * | 1.049 |

| F | 2.191 | 1.748 | ||||||

| Adj-R2 | 0.218 | 0.244 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, S. Derivation of Risk Factors to Quantify the Risk of Safety Accidents for Small and Medium-Sized Enterprises in Construction Industry. Sustainability 2022, 14, 7306. https://doi.org/10.3390/su14127306

Ahn S. Derivation of Risk Factors to Quantify the Risk of Safety Accidents for Small and Medium-Sized Enterprises in Construction Industry. Sustainability. 2022; 14(12):7306. https://doi.org/10.3390/su14127306

Chicago/Turabian StyleAhn, Sungjin. 2022. "Derivation of Risk Factors to Quantify the Risk of Safety Accidents for Small and Medium-Sized Enterprises in Construction Industry" Sustainability 14, no. 12: 7306. https://doi.org/10.3390/su14127306