Research on Multi-Mode Drive Optimization Control Strategy of Four-Wheel-Drive Electric Vehicles with Multiple Motors

Abstract

:1. Introduction

- The first category of research methods is based on physical models of the drive system. For example, Li Liang established the efficiency loss model of the in-wheel motor under consideration of the iron loss, then obtained the optimized motor torque distribution by identifying the parameters of the motor online based on the MAR theory, thereby improving the energy utilization efficiency of the vehicle [9]. Yuan Xi-bo studied the torque distribution of the front and rear motors at different vehicle velocities based on the loss model of the dual-motor drive system and verified the performance of the control strategy through the motor test bench [10]. These types of methods mainly optimize the torque distribution of the drive system by the system loss model based on the physical characteristics of the motor and controller, so they can obtain accurate and reliable optimization results because the characteristics of the drive system are accurately described. However, due to the complex structure of the physical model and a large amount of calculation, the real-time performance of this research method is poor.

- The second category is based on the efficiency map of the drive system. For instance, Pennycott Andrew optimized the steady-state and transient energy consumption of a dual-motor 4WD electric vehicle based on the motor efficiency loss map [11]. Yang Yee-Pien used the particle swarm algorithm to optimize the efficiency map of the driving motor of a 4WD electric vehicle, then established a real-time optimization allocation strategy of the driving torque, thereby effectively reducing the motor energy loss [12]. Wang Jun-min took the minimization of the weighted sum of the vehicle speed error and the power consumption of the actuators as the objective function, and globally optimized the torque distribution of the four wheels to reduce the power loss of the system for a 4WD electric vehicle [13]. Yu Zhuo-ping adopted the efficiency maximization method to optimize the torque distribution coefficient matrix of the 4WD electric vehicle, and the overall energy efficiency of the vehicle was improved by about 3% due to the reduction in the in-wheel motor heat generation and the increase in feedback braking energy recovery [14]. The methods of the second category mainly use the efficiency map of the motor or the drive system to optimize the torque distribution of the drive system. They have some advantages such as fast calculation speed and good real-time performance, which are easy to deploy in the real vehicle controller. However, since the motor efficiency map depends on the test calibration, the quality of the calibration data will have a significant impact on the control strategy.

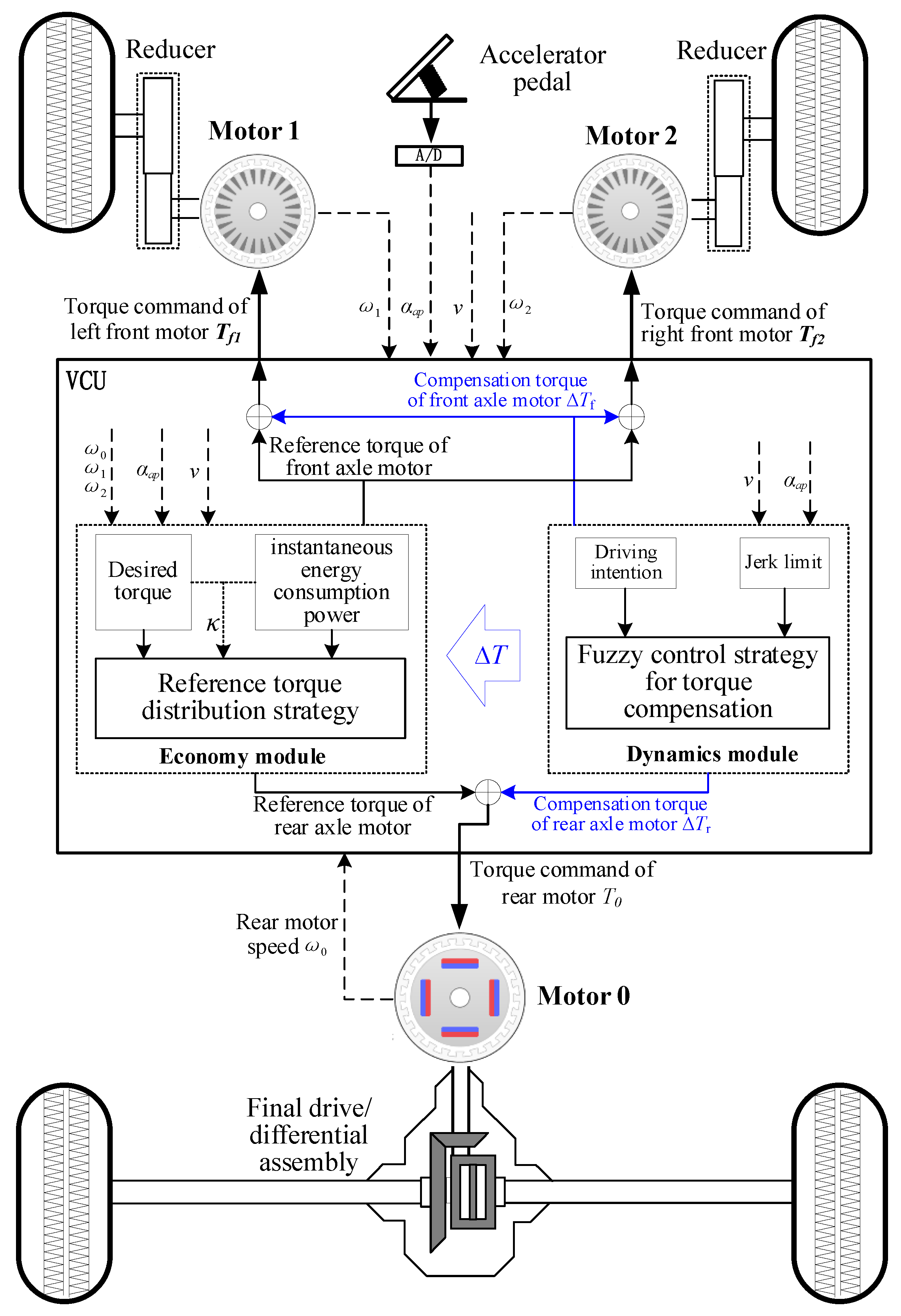

2. Architecture of Multi-Mode Drive Optimization Control Strategy for the Multi-Motor Electric Vehicle

3. Reference Torque Distribution Strategy for Front and Rear Axle Motors Based on Optimal Instantaneous Energy Consumption Power

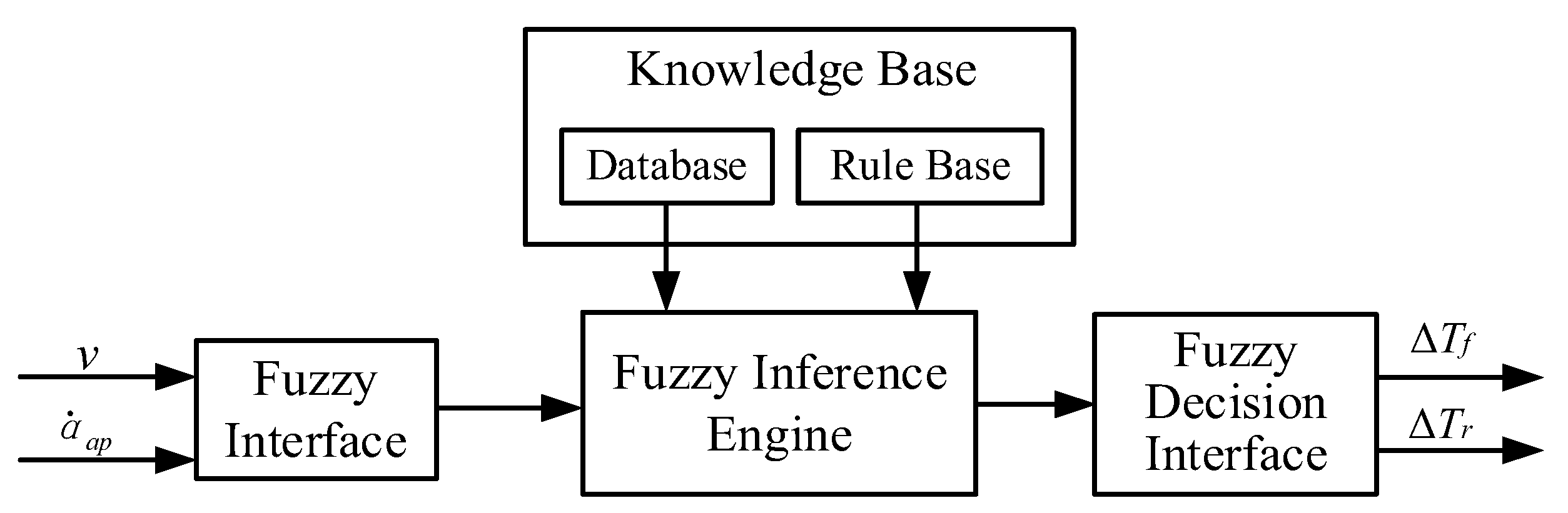

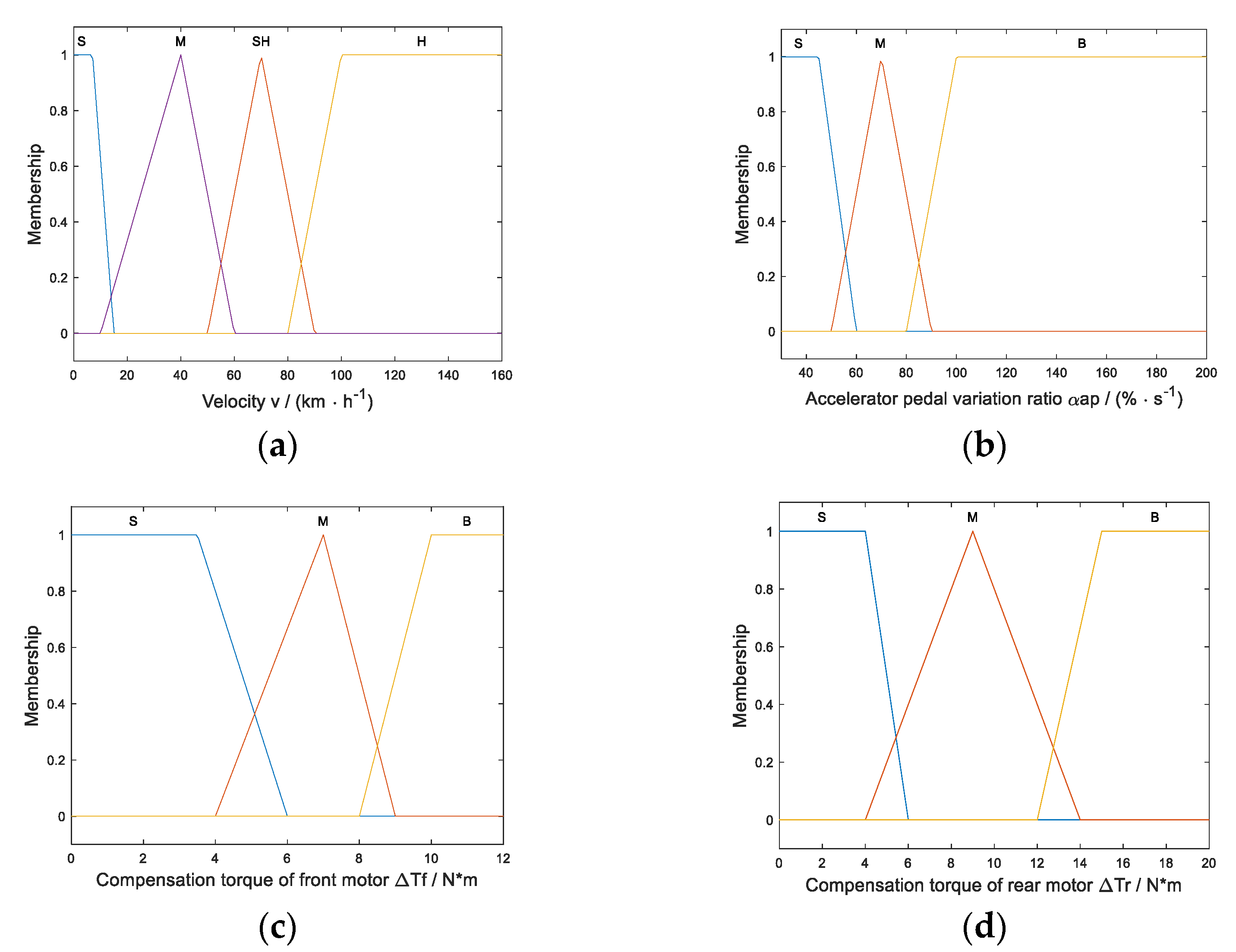

4. Torque Compensation Strategy Based on Fuzzy Control for High Power Demand Conditions

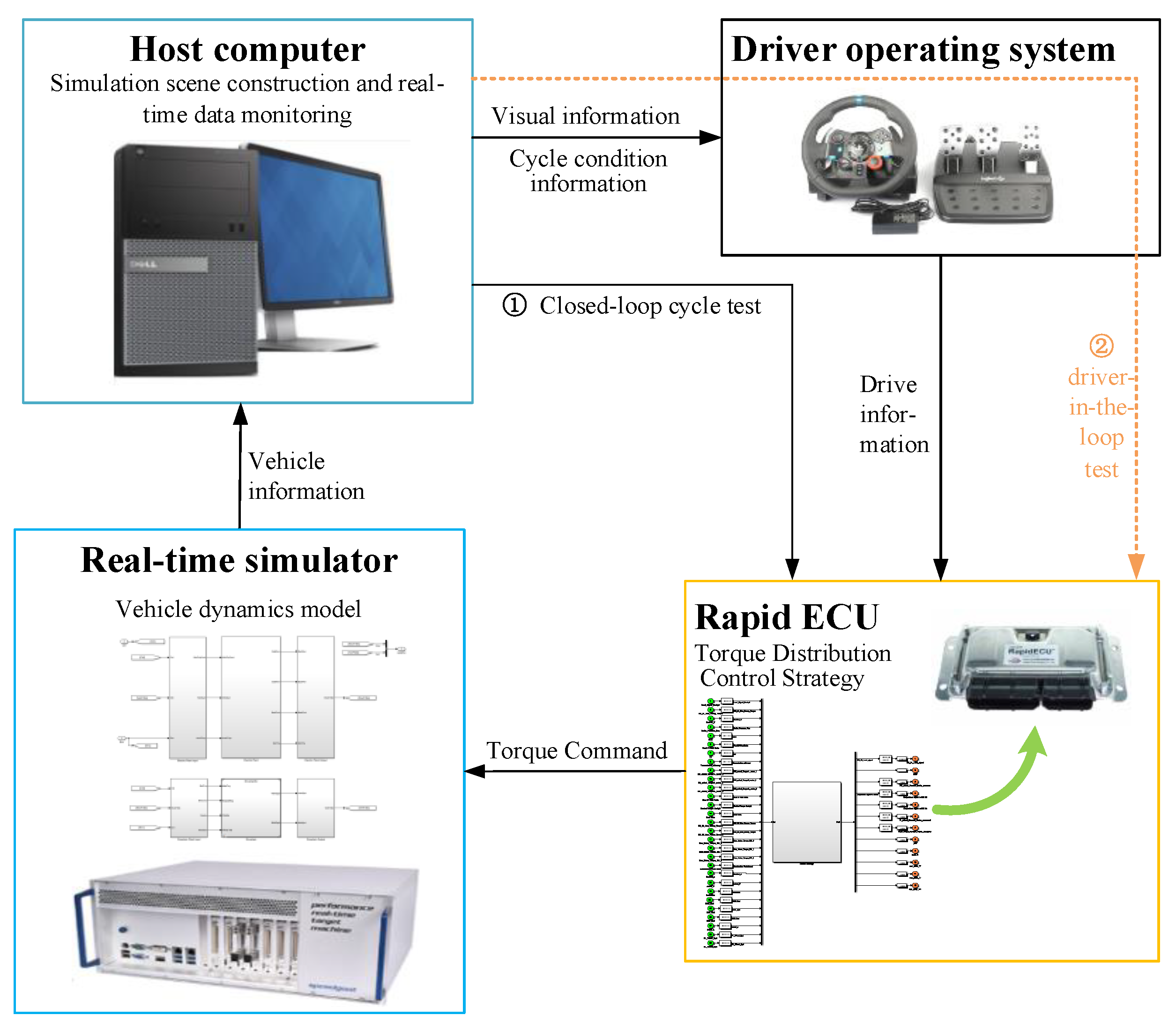

5. Hardware-in-the-Loop Simulation Results and Analysis

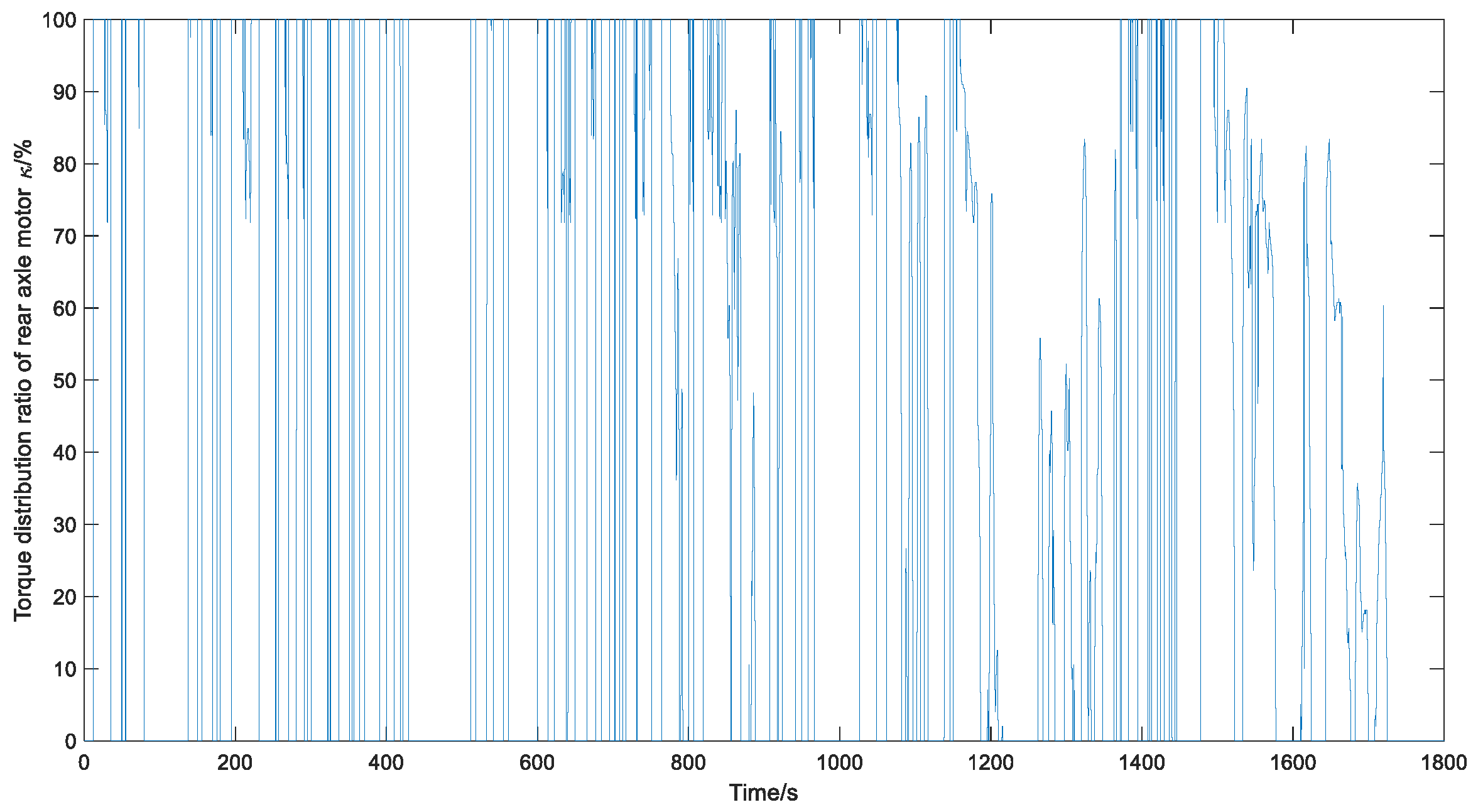

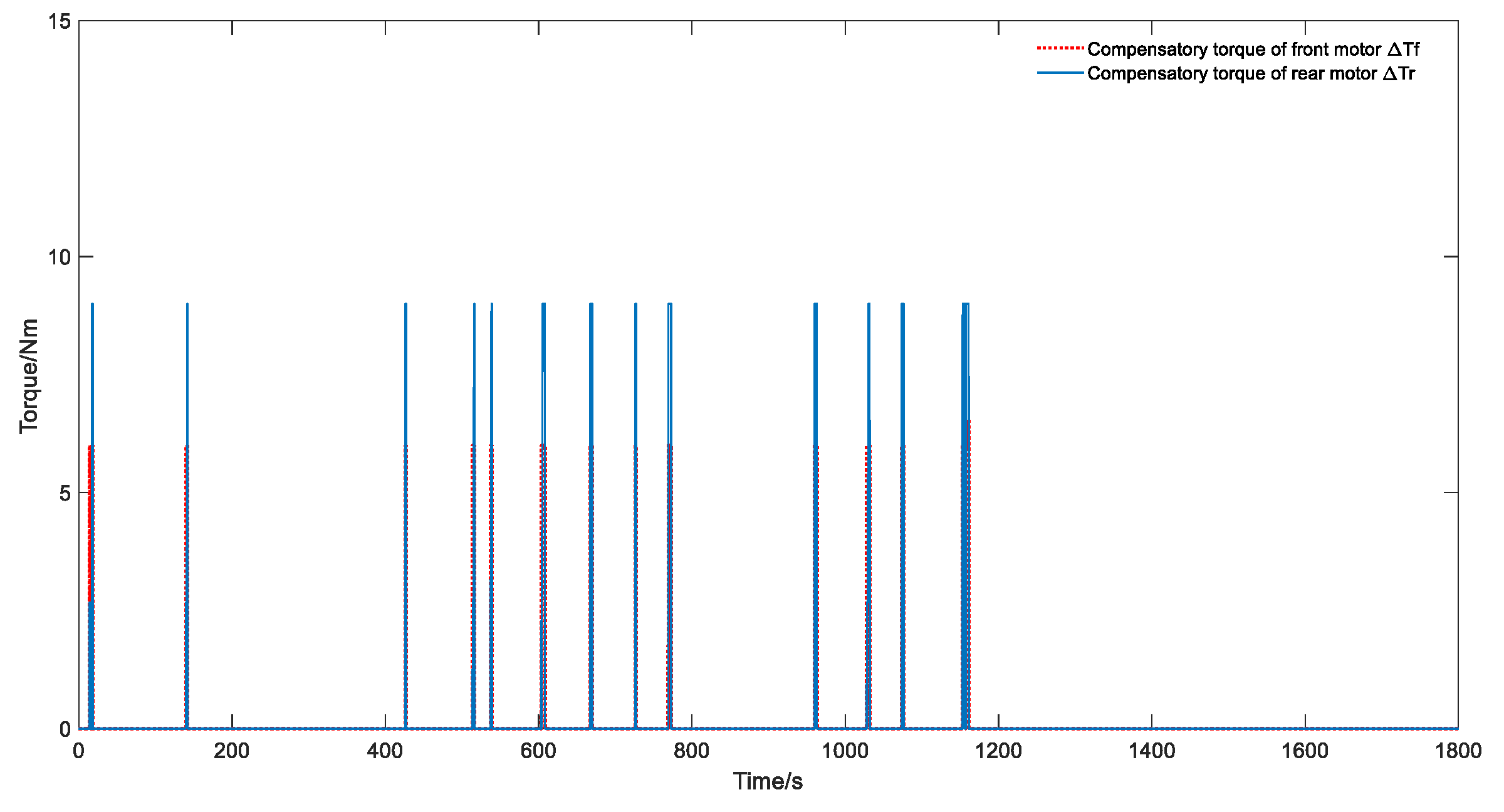

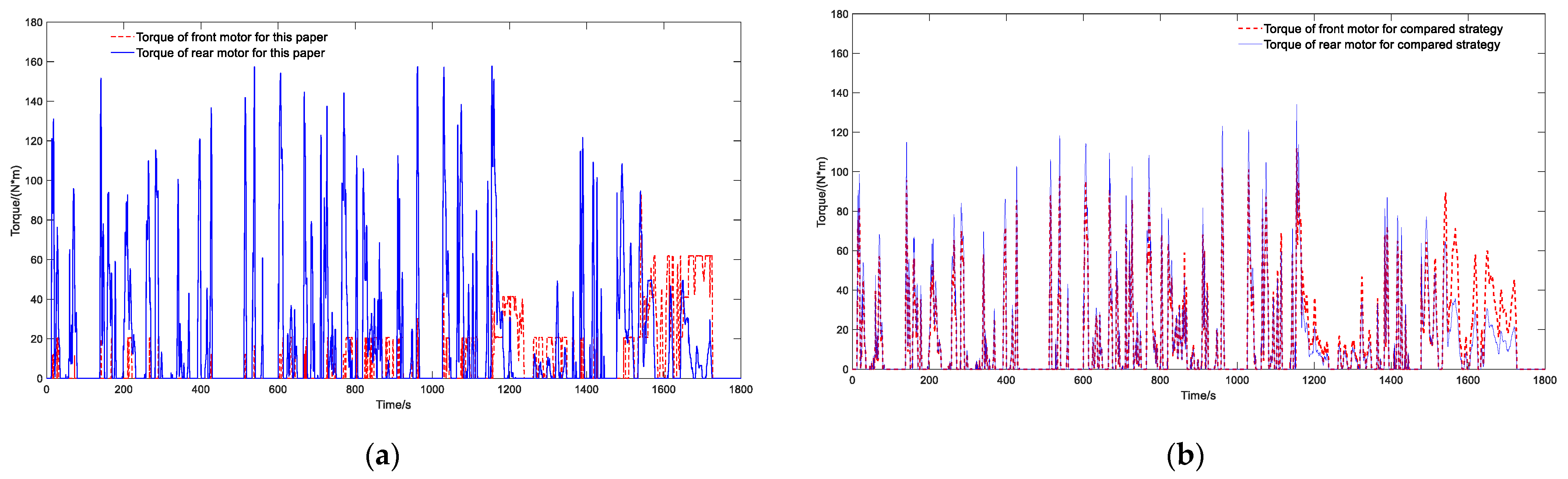

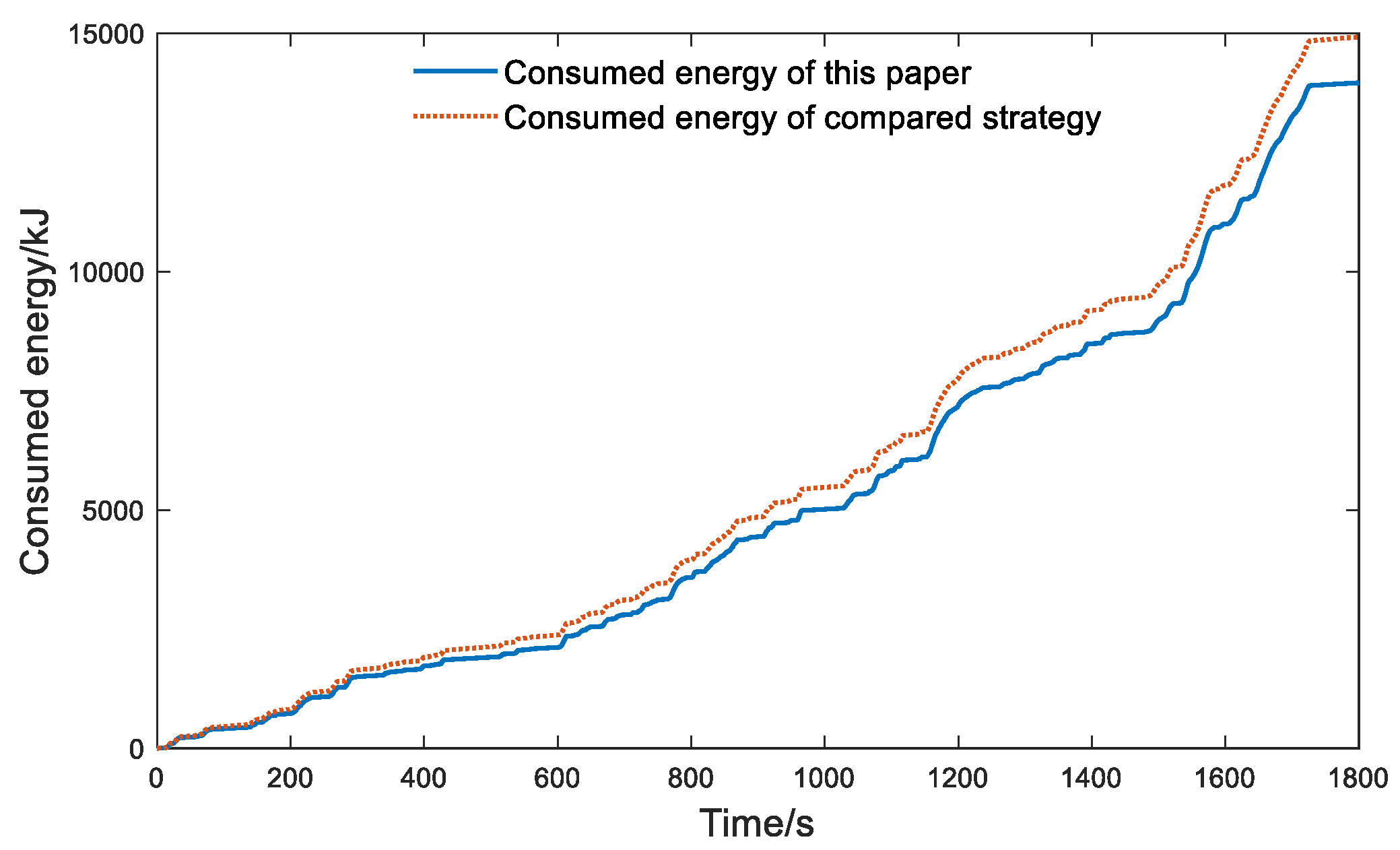

5.1. Results for WLTC

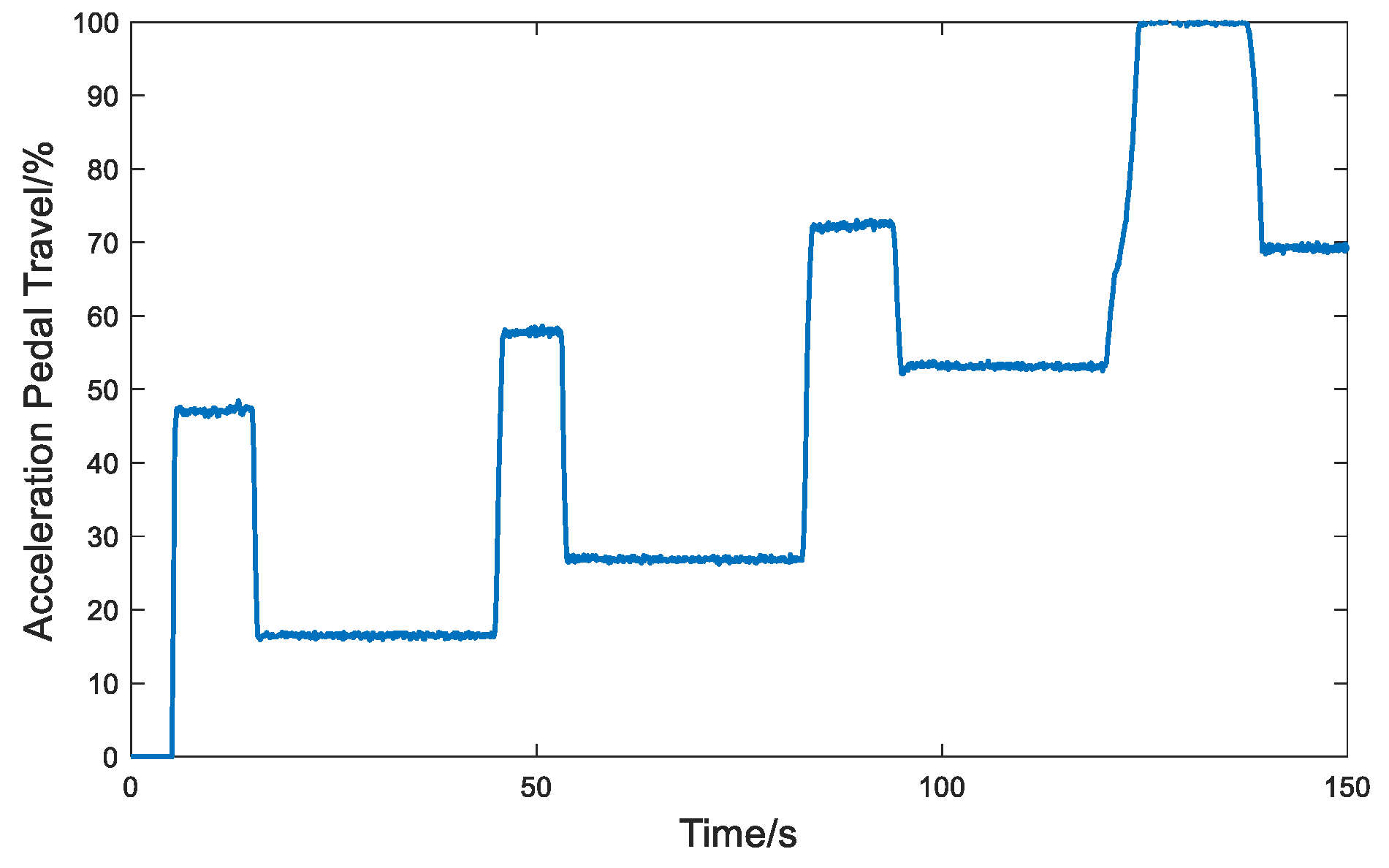

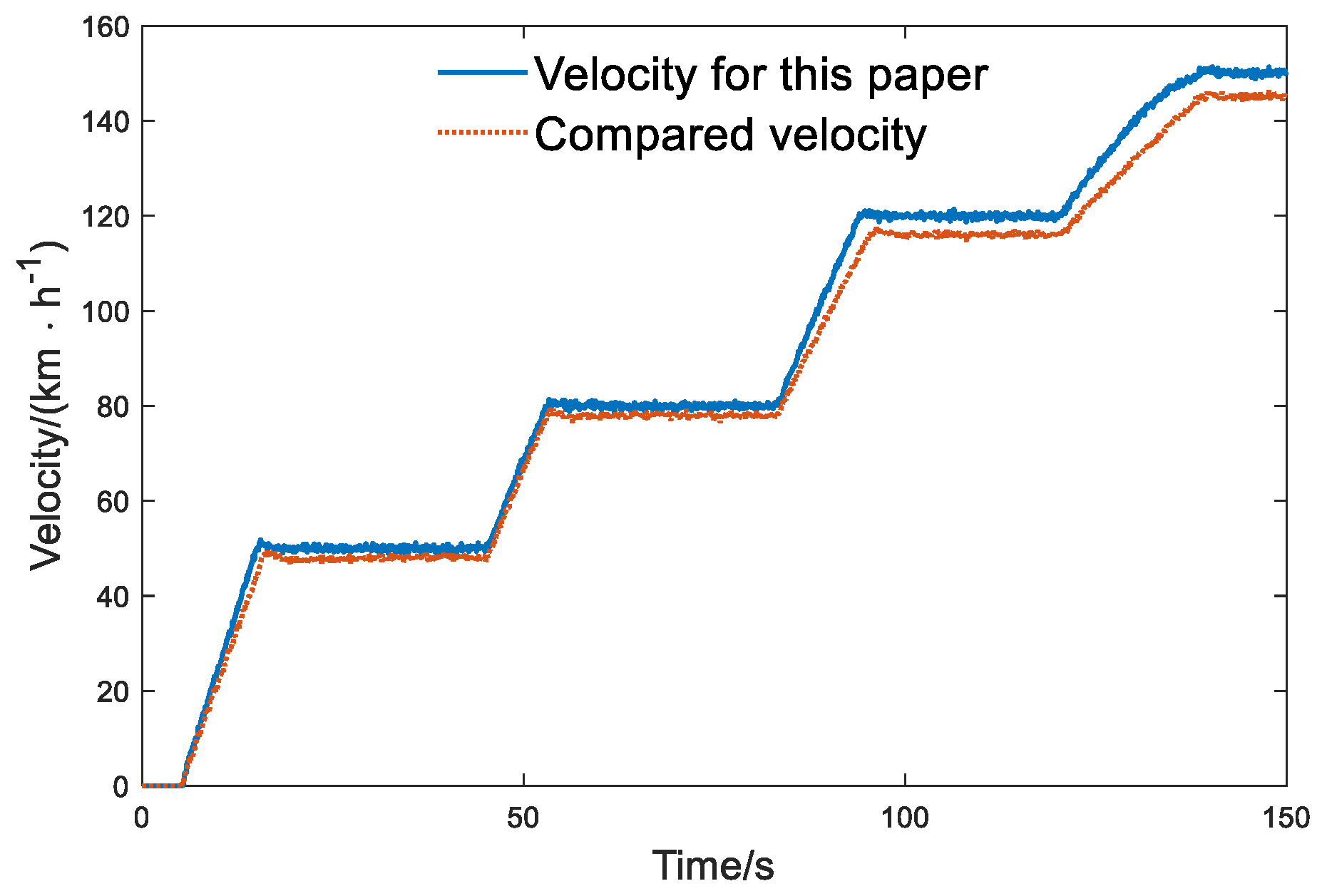

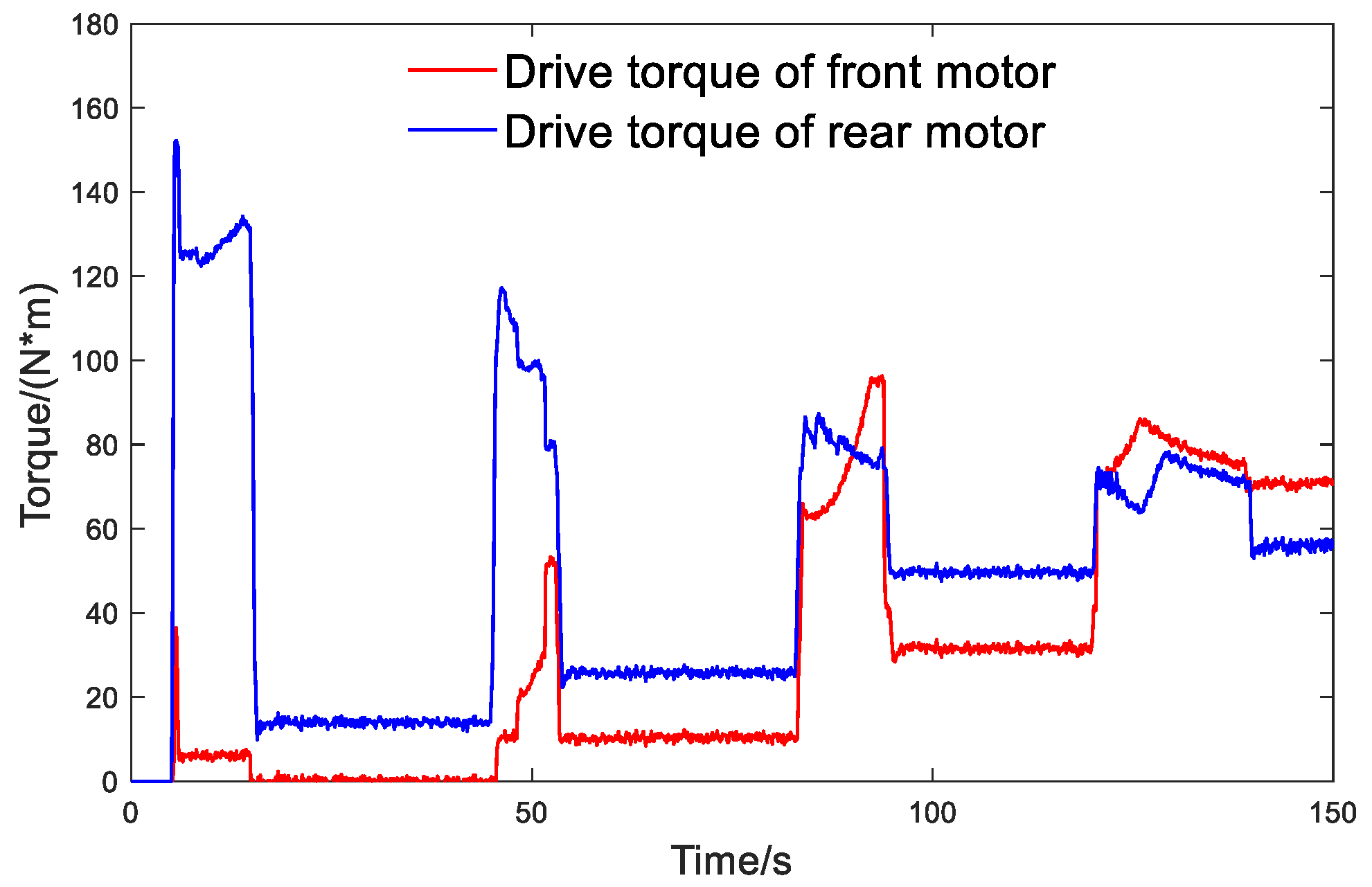

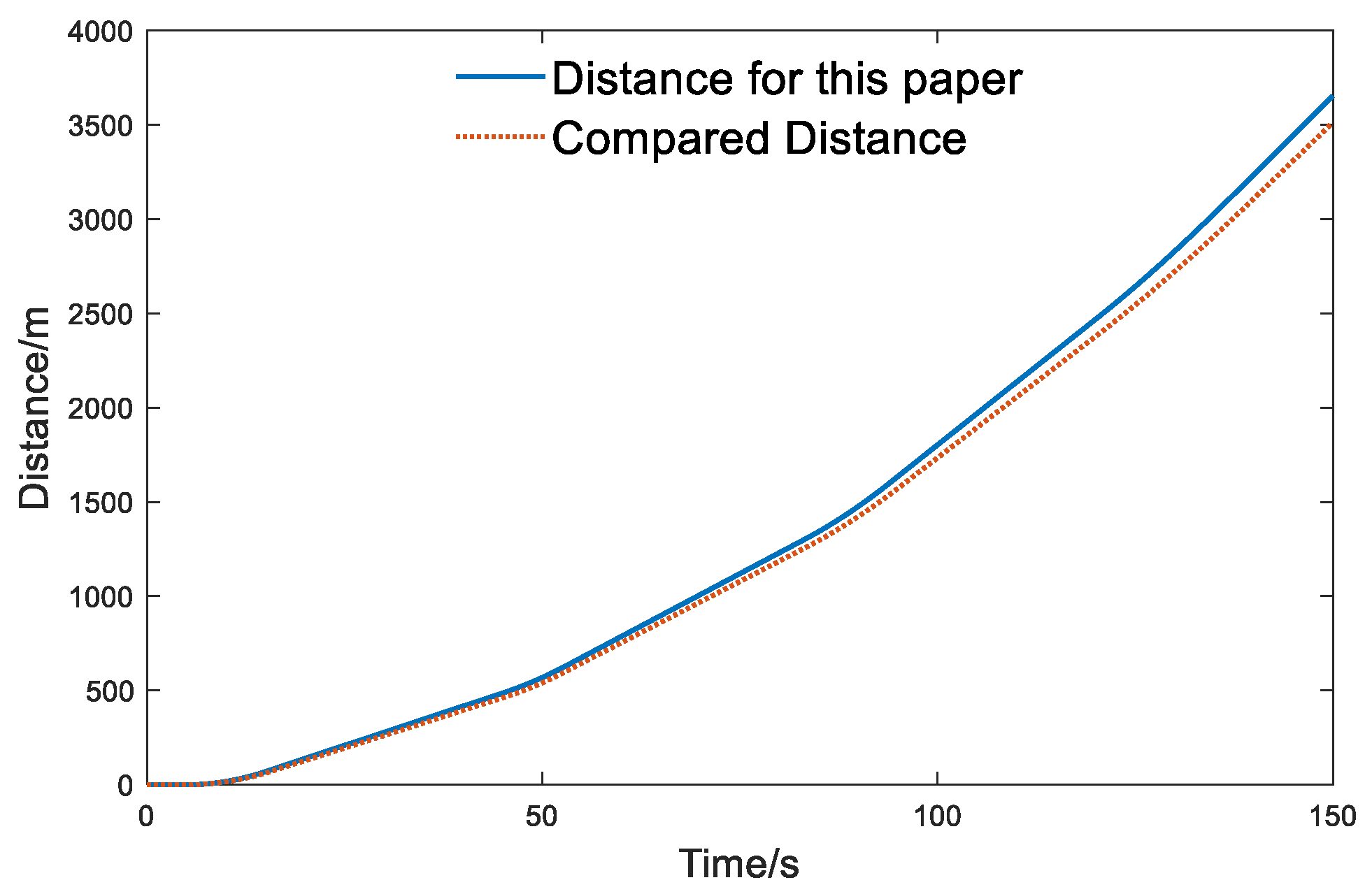

5.2. Variable Acceleration Conditions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Van Mierlo, J.; Berecibar, M.; El Baghdadi, M.; De Cauwer, C.; Messagie, M.; Coosemans, T.; Hegazy, O. Beyond the State of the Art of Electric Vehicles: A Fact-Based Paper of the Current and Prospective Electric Vehicle Technologies. World Electr. Veh. J. 2021, 12, 20. [Google Scholar] [CrossRef]

- Liu, H.; Chen, X.; Wang, X. Overview and prospects on distributed drive electric vehicles and its energy saving strategy. Prz. Elektrotechniczny 2012, 88, 122–125. [Google Scholar]

- Li, Z.; Khajepour, A.; Song, J. A comprehensive review of the key technologies for pure electric vehicles. Energy 2019, 182, 824–839. [Google Scholar] [CrossRef]

- Puma-Benavides, D.S.; Izquierdo-Reyes, J.; Calderon-Najera, J.D.D.; Ramirez-Mendoza, R.A. A systematic review of technologies, control methods, and optimization for extended-range electric vehicles. Appl. Sci. 2021, 11, 7095. [Google Scholar] [CrossRef]

- Tobolar, J.; de Castro, R.; Bleck, U.; Satzger, C.; Brembeck, J.; Hirano, Y. Comparative evaluation of energy efficiency of electrical vehicle powertrain configurations. In The Dynamics of Vehicles on Roads and Tracks, 1st ed.; CRC Press: Graz, Austria, 2016; pp. 691–699. [Google Scholar]

- Kumar, M.S.; Revankar, S.T. Development scheme and key technology of an electric vehicle: An overview. Renew. Sustain. Energy Rev. 2016, 70, 1266–1285. [Google Scholar] [CrossRef]

- Chatzikomis, C.; Zanchetta, M.; Gruber, P.; Sorniotti, A.; Modic, B.; Motaln, T.; Gotovac, G. An energy-efficient torque-vectoring algorithm for electric vehicles with multiple motors. Mech. Syst. Signal Process. 2019, 128, 655–673. [Google Scholar] [CrossRef]

- Raslavičius, L.; Keršys, A.; Makaras, R. Management of hybrid powertrain dynamics and energy consumption for 2WD, 4WD, and HMMWV vehicles. Renew. Sustain. Energy Rev. 2017, 68, 380–396. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Guo, K.; Wu, D. Optimized Torque Distribution Algorithm to Improve the Energy Efficiency of 4WD Electric Vehicle 2014-01-2374; SAE International: Pittsburgh, PA, USA, 2014. [Google Scholar]

- Yuan, X.; Wang, J. Torque Distribution Strategy for a Front- and Rear-Wheel-Driven Electric Vehicle. IEEE Trans. Veh. Technol. 2012, 61, 3365–3374. [Google Scholar] [CrossRef]

- Pennycott, A.L.; Novellis, D.; Gruber, P.; Sorniotti, A.; Goggia, T. Enhancing the Energy Efficiency of Fully Electric Vehicles via the Minimization of Motor Power Losses. In Proceedings of the 2013 IEEE International Conference on Systems, Man, and Cybernetics, Manchester, UK, 13–16 October 2013. [Google Scholar]

- Yang, Y.P.; Shih, Y.C.; Chen, J.M. Real-time torque-distribution strategy for a pure electric vehicle with multiple traction motors by particle swarm optimization. IET Electr. Syst. Transp. 2016, 6, 76–87. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, J. Fast and Global Optimal Energy-Efficient Control Allocation with Applications to Over-Actuated Electric Ground Vehicles. IEEE Trans. Control Syst. Technol. 2012, 20, 1202–1211. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, L.; Xiong, L. Optimized torque distribution control to achieve higher fuel economy of 4WD electric vehicle with four in-wheel motors. J. Tong Ji Univ. 2005, 33, 1355–1361. [Google Scholar]

- Xu, S.; Zhao, X.; Yang, N.; Bai, Z. Control Strategy of Braking Energy Recovery for Range-Extended Electric Commercial Vehicles by Considering Braking Intention Recognition and Electropneumatic Braking Compensation. Energy Technol. 2020, 8, 2000407. [Google Scholar] [CrossRef]

- Qin, D.; Zhou, M.; Hu, M.; Hu, J.; Chen, S. Strategy of Acceleration Torque Compensation Control for Electric Vehicle. J. Highw. Transp. Res. Dev. 2012, 29, 146–151. [Google Scholar]

- Wang, J.; Yang, J.; Cai, Z.; Zhang, X. The Optimum Control Strategy of Battery Electric Car Based on Fuzzy Control. Automot. Eng. 2009, 31, 362–365. [Google Scholar]

- Tseng, Y.H.; Yang, Y.P. Torque and Battery Distribution Strategy for Saving Energy of an Electric Vehicle with Three Traction Motors. Appl. Sci. 2020, 10, 2653. [Google Scholar] [CrossRef] [Green Version]

- De Filippis, G.; Lenzo, B.; Sorniotti, A.; Sannen, K.; De Smet, J.; Gruber, P. On the energy efficiency of electric vehicles with multiple motors. In Proceedings of the 2016 IEEE Vehicle Power and Propulsion Conference (VPPC), Hangzhou, China, 17–20 October 2016. [Google Scholar]

- Song, Z.; Hofmann, H.; Li, J.; Wang, Y.; Lu, D.; Ouyang, M.; Du, J. Torque Distribution Strategy for Multi-PMSM Applications and Optimal Acceleration Control for Four-Wheel-Drive Electric Vehicles. J. Dyn. Syst. Meas. Control 2020, 142, 021001. [Google Scholar] [CrossRef]

- De Pinto, S.; Camocardi, P.; Sorniotti, A.; Gruber, P.; Perlo, P.; Viotto, F. Torque-fill control and energy management for a four-wheel-drive electric vehicle layout with two-speed transmissions. IEEE Trans. Ind. Appl. 2016, 53, 447–458. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, R.; Zhang, C.; Sun, F. An optimal structure selection and parameter design approach for a dual-motor-driven system used in an electric bus. Energy 2016, 96, 437–448. [Google Scholar] [CrossRef]

- Hu, J.; Zu, G.; Jia, M.; Niu, X. Parameter matching and optimal energy management for a novel dual-motor multi-modes powertrain system. Mech. Syst. Signal Process. 2019, 116, 113–128. [Google Scholar] [CrossRef]

- Chen, S.J.; Qin, D.T.; Hu, M.H.; Wei, H.B. Ramp adaptive launch control strategy of pure electric vehicles. J. Chongqing Univ. 2012, 35, 1–7. [Google Scholar]

- Tutuianu, M.; Bonnel, P.; Ciuffo, B.; Haniu, T.; Ichikawa, N.; Marotta, A.; Steven, H. Development of the World-wide harmonized Light duty Test Cycle (WLTC) and a possible pathway for its introduction in the European legislation. Transp. Res. Part D Transp. Environ. 2015, 40, 61–75. [Google Scholar] [CrossRef]

- Jiao, Z.; Ma, J.; Zhao, X.; Zhang, K.; Meng, D.; Li, X. Development of a Rapid Inspection Driving Cycle for Battery Electric Vehicles Based on Operational Safety. Sustainability 2022, 14, 5079. [Google Scholar] [CrossRef]

| Parameter | Value | Unit | |

|---|---|---|---|

| Vehicle parameters | Curb weight m0 | 1520 | kg |

| Max. weight M | 1895 | kg | |

| wind resistance coefficient Cd | 0.29 | - | |

| Windward area A | 2.27 | m2 | |

| Tire radius R | 0.307 | m | |

| Rolling resistance coefficient f | 0.0165 | - | |

| Rotational mass conversion factor δ | 1.0425 | - | |

| Wheelbase L | 2700 | mm | |

| Front motor | Rated speed | 3000 | r∙min−1 |

| Rated torque | 57 | N∙m | |

| Peak power | 30 | kW | |

| Peak speed | 7000 | r∙min−1 | |

| Rear motor | Rated speed | 2500 | r∙min−1 |

| Rated torque | 120 | N∙m | |

| Peak power | 60 | kW | |

| Peak speed | 9500 | r∙min−1 |

| (a) | |||

| Velocity | Accelerator Pedal Opening Variation Rate | ||

| S | M | B | |

| S | - | - | - |

| M | - | - | S |

| SH | M | B | B |

| H | B | B | B |

| (b) | |||

| Velocity | Accelerator Pedal Opening Variation Rate | ||

| S | M | B | |

| S | S | M | B |

| M | M | B | B |

| SH | - | - | M |

| H | S | S | M |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Wei, L.; Zhang, X.; Bai, Z.; Jiao, Y. Research on Multi-Mode Drive Optimization Control Strategy of Four-Wheel-Drive Electric Vehicles with Multiple Motors. Sustainability 2022, 14, 7378. https://doi.org/10.3390/su14127378

Xu S, Wei L, Zhang X, Bai Z, Jiao Y. Research on Multi-Mode Drive Optimization Control Strategy of Four-Wheel-Drive Electric Vehicles with Multiple Motors. Sustainability. 2022; 14(12):7378. https://doi.org/10.3390/su14127378

Chicago/Turabian StyleXu, Shiwei, Lulu Wei, Xiaopeng Zhang, Zhifeng Bai, and Yuan Jiao. 2022. "Research on Multi-Mode Drive Optimization Control Strategy of Four-Wheel-Drive Electric Vehicles with Multiple Motors" Sustainability 14, no. 12: 7378. https://doi.org/10.3390/su14127378

APA StyleXu, S., Wei, L., Zhang, X., Bai, Z., & Jiao, Y. (2022). Research on Multi-Mode Drive Optimization Control Strategy of Four-Wheel-Drive Electric Vehicles with Multiple Motors. Sustainability, 14(12), 7378. https://doi.org/10.3390/su14127378