Innovation and Technological Management Model in the Tequila Sector in Mexico

Abstract

:1. Introduction

- Many medium and small companies compete with large companies.

- Availability and supply of raw material, which suffers from cyclical crises that fluctuate over the years and have a considerable impact on both production levels, costs, and all the points mentioned for the production of tequila and the different distillates [6].

- The adulterations.

- Sustainability, since its treatment processes for some types of waste, such as stillage, are not yet fully efficient.

- Dissimilar use and development of technology between large and smaller companies, which continue to use old processes.

2. Theoretical Framework

2.1. Innovation and Technology Management: Key Elements

2.1.1. Management of Innovation, Technology, and Knowledge

2.1.2. Innovation in Low-Tech Industries or Non-Research-Intensive

2.2. Characterization of the Tequila Industry in Mexico

2.2.1. Cultivation and Production of The Agave Tequilana Weber Blue Variety

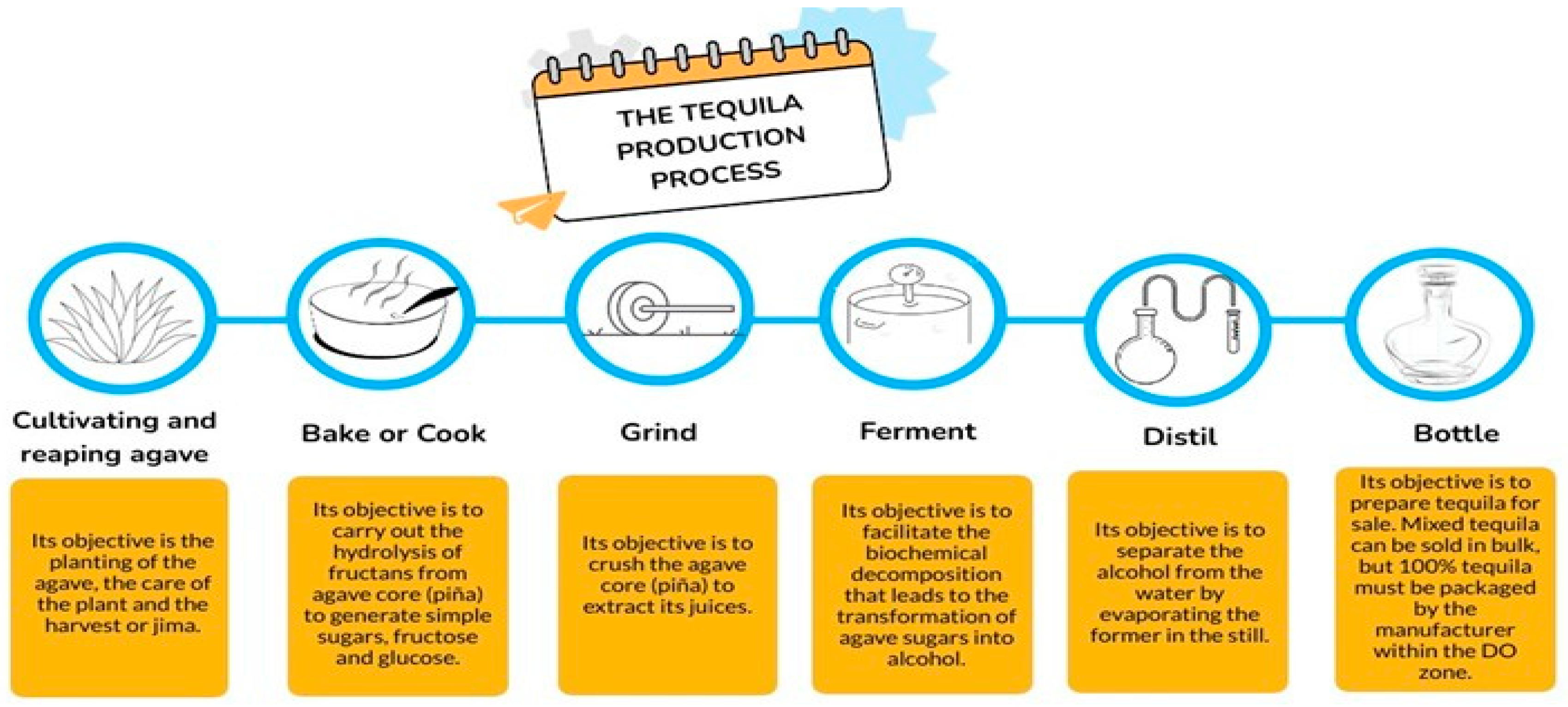

2.2.2. The Process of Elaboration and Types of Tequila

2.2.3. A Technical But Also Traditional Industry

2.2.4. Waste and Environmental Sustainability in the Tequila Industry

3. Materials and Methods

4. Results and Discussion

4.1. Management of Innovation and Technology Model Results

4.2. Innovation and Industrial Property in the Tequila Sector

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- OECD/Eurostat. Oslo Manual 2018: Guidelines for Collecting, Reporting and Using Data on Innovation. In The Measurement of Scientific, Technological and Innovation Activities, 4th ed.; OECD Publishing/Eurostat: Paris, France; Luxembourg, 2018. [Google Scholar] [CrossRef]

- Terán-Bustamante, A.; Martínez-Velasco, A.; Dávila-Aragón, G. Knowledge Management for Open Innovation: Bayesian Networks through Machine Learning. J. Open Innov. Technol. Mark. Complex. 2021, 7, 40. [Google Scholar] [CrossRef]

- Terán-Bustamante, A.; Davila, G.; Castañon, R. Management of Technology and Innovation: A Bayesian Network Model. Económia Teória Práctica 2019, 50, 63–100. [Google Scholar] [CrossRef]

- Consejo Regulador del Tequila (CRT). Producción Total: Tequila y Tequila 100%. 2022. Available online: https://www.crt.org.mx/EstadisticasCRTweb/ (accessed on 2 February 2022).

- Rosalba, C. Between traditions and modernity: Technological strategies at three tequila firms. Technol. Soc. 2006, 28, 407–419. [Google Scholar] [CrossRef]

- Herrera-Pérez, L.; Esteban Valtierra-Pacheco, E.; Ignacio Ocampo-Fletes, I.; Mario, A.; Tornero-Campante, M.; Hernández-Plascencia, J.; Rodríguez-Macías, R. Esquemas de contratos agrícolas para la producción de agave tequilana weber en la región de Tequila, Jalisco. Agric. Soc. Desarro. 2018, 15, 619–637. [Google Scholar] [CrossRef] [Green Version]

- Jasso, J. Administración: Innovación, conceptos, prácticas y tendencias. In Innovación Ante la Sociedad del Conocimiento; Disciplinas y Enfoques; Plaza y Valdés: Mexico City, Mexico, 2010; ISBN 9780070218231. [Google Scholar]

- Fundación Cotec. Pautas Metodológicas en Gestión de la Tecnología y de la Innovación para Empresas; t. II, Perspectiva Empresarial; t. III, Herramientas de Gestión de la Tecnología, Casos Prácticos de Gestión de la Tecnología; TEMAGUIDE, Cotec: Madrid, Spain, 1999. [Google Scholar]

- Solleiro, J.L.; Castañon, R. Gestión Tecnológica: Conceptos y Prácticas. Coordinadores: Solleiro, José Luís y Castañón Rosario; Plaza y Valdés: Mexico City, Mexico, 2008. [Google Scholar]

- Terán-Bustamante, A. Competencias del Talento Humano y de la Organización para la Gestión de la Tecnología: El Caso de Una Empresa Farmacéutica. 2017: XVII Congreso Latino-Iberoamericano de Gestión Tecnológica. 2021. Available online: https://repositorio.altecasociacion.org/handle/20.500.13048/1675 (accessed on 15 January 2022).

- Schumpeter, J. The Theory of Economic Development; Harvard University Press: Cambridge, UK, 1934. [Google Scholar]

- Medellín, E. Gestión de Tecnología, su Desarrollo e Implantación en la Empresa. In Gestión de la Innovación: Una Visión Actualizada para el Contexto Iberoamericano; Editorial Academia: Havana, Cuba, 2006. [Google Scholar]

- Medellín, E. Gestión Tecnológica en Empresas Innovadoras Mexicanas. Rev. Adm. Inovação 2010, 7, 58–78. [Google Scholar]

- Perozo, E.; Nava, A. El Impacto de la Gestión Tecnológica en el Contexto Empresarial. Rev. Venez. Cienc. Soc. 2005, 9, 488–504. Available online: https://www.redalyc.org/pdf/309/30990214.pdf (accessed on 10 January 2022).

- Hernández, J. Capacidades tecnológicas y organizacionales de las empresas mexicanas participantes en la cadena de valor de la industria aeronáutica. Econ. Teoría Práct. Nueva Época 2017, 47, 65–98. [Google Scholar] [CrossRef] [Green Version]

- Solleiro, J.L.; Castañón, R. Manual de Gestión Tecnológica para Pymes Mexicanas; CamBioTec: Mexico City, Mexico, 2016. [Google Scholar]

- Fundación de Premio Nacional de Tecnología e Innovación (FPNTI). Modelo Nacional de Tecnología e Innovación; Gobierno de México: Mexico City, Mexico, 2018.

- IMNC. NMX-GT-003-IMNC-2008, Norma Mexicana Sobre Gestión de la Tecnología-Sistema de Gestión Tecnológica-Requisitos; Governement of Mexico: Mexico City, Mexico, 2008. [Google Scholar]

- Barletta, F.; Suárez, D.; Yoguel, G. Teoría de la Innovación: Evolución, Tendencias y Desafíos Herramientas Conceptuales para la Enseñanza y el Aprendizaje, 1st ed.; Suárez, D., Erbes, A., Florencia Barletta, F., Eds.; Universidad Nacional de General Sarmiento: Madrid, Spain, 2020; Available online: https://www.ucm.es/ediciones-complutense/teoria-de-la-innovacion (accessed on 20 March 2022).

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Dutrénit, G.; Torres, A.; Vera-Cruz, A. Procesos de aprendizaje y construcción de capacidades tecnológicas en el nivel de empresa. In Analía Erbes y Florencia Barletta, 1st ed.; Suárez, D., Ed.; Ediciones Complutense; Universidad Nacional de General Sarmiento: Los Polvorines, Argentina, 2020; pp. 265–302. [Google Scholar]

- Hirsch-Kreinsen, H.; Jacobson, D. Innovation in Low-Tech Firms and Industries; Edward Elgar Publishing: Cheltenham, UK, 2008; ISBN 978-1-84720-823-1. [Google Scholar]

- OECD. ISIC rev.3 Technology Intensity Definition—Classification of Manufacturing Industries Into Categories Based on R&D Intensities; OECD: Paris, France, 2011. [Google Scholar]

- Tidd, J.; Bessant, J. Managing Innovation: Integrating Technological, Market and Organizational Change, 7th ed.; Wiley: Hoboken, NJ, USA, 2021. [Google Scholar]

- Bender, G. Peculiarities and Relevance of Non-Research-Intensive Industries in the Knowledge-Based Economy. Final Report of the Project Policy and Innovation in Low-Tech—Knowledge Formation, Employment & Growth Contributions of the ‘Old Economy’ Industries in Europe—Pilot; University of Dortmund: Dortmund, Germany, 2006. [Google Scholar]

- Bender, G.; Staffan, L. Non-science based innovativeness: On capabilities relevant to generate profitable novelty. Perspect. Econ. Political Soc. Integration 2005, 11, 123–170. [Google Scholar]

- Rammer, C.; Czarnitzki, D.; Spielkamp, A. Innovation Success of Non-R&D-Performers: Substituting Technology by Management in SMEs, ZEW Discussion Papers, No. 08-092, Zentrum für Europäische Wirtschaftsforschung (ZEW). Mannhei. 2008. Available online: https://www.econstor.eu/bitstream/10419/27569/1/dp08092.pdf (accessed on 3 June 2022).

- Hirsch-Kreinsen, H. Low-Tech’ Innovations. Ind. Innov. 2008, 15, 19–43. [Google Scholar] [CrossRef]

- Potters, L. R&D in low-tech sectors. In IPTS Working Papers on Corporate R&D and Innovation Sectors IPTS; European Communities: Luxembourg, 2009; Available online: https://iri.jrc.ec.europa.eu/sites/default/files/contentype/publication/workingpaper/1568810976/R%26D%20in%20LowTech%20Sectors.pdf (accessed on 4 June 2022).

- Som, O.; Kirner, E. Low-Tech Innovation; Springer International: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Som, O.; Kirner, E.; Jäger, A. The Absorptive Capacity of Non-R&D-Intensive Firms; Som, O., Kirner, E., Eds.; Low-tech Innovation; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Thomä, J. Dui mode learning and barriers to innovation—A case from Germany. Res. Policy 2017, 46, 1327–1339. [Google Scholar] [CrossRef] [Green Version]

- Zouaghi, F.; Sánchez, M.; Martínez, M.G. Did the global financial crisis impact firms’ innovation performance? The role of internal and external knowledge capabilities in high and low-tech industries. Technol. Forecast. Soc. Chang. 2018, 132, 92–104. [Google Scholar] [CrossRef]

- Law, K.M.; Lau, A.K.; Ip, A.W. The Impacts of Knowledge Management Practices on Innovation Activities in High- and Low-Tech Firms. J. Glob. Inf. Manag. 2021, 29, 1–25. [Google Scholar] [CrossRef]

- Instituto de Información Estadística y Geográfica del Estado de Jalisco (IIEG). Tequila: Diagnóstico del Municipio Agosto 2021. 2022. Available online: https://iieg.gob.mx/ns/wp-content/uploads/2021/10/Tequila.pdf (accessed on 2 June 2022).

- Olmedo-Carranza, B. El Tequila: De su Origen A su Desnaturalización. ¿A Quién le Pertenece su Conocimiento? Una Aproximación. Revista CENIC. Cienc. Quím. 2010, 41, 1–13. Available online: https://www.redalyc.org/articulo.oa?id=181620500061 (accessed on 1 June 2022).

- Cedeño, M.; Álvarez, J. Tequila production from agave: Historical influences and contemporary process. In The Alcohol Textbook, 4th ed.; Jacques, K.A., Lyons, T.P., Kelsall, D.R., Eds.; Nottingham University Press: Nottingham, UK, 2003; pp. 223–245. [Google Scholar]

- Coelho, A.; Castillo, V.M. “Mi Sueño”: Emprendedores y Tequila Artesanal en el Territorio del Agave Azul. In Proceedings of the IV Congresso Internacional de Investigação e Desenvolvimento Sócio-Cultural, Guadalajara, Mexico, 19–21 October 2006. [Google Scholar]

- Luna, R. La Historia del Tequila, de Sus Regiones y Sus Hombres; CONACULTA: Mexico City, Mexico, 1991.

- Castillo, V.; Coelho, A. Dinámicas de la cadena agave-tequila. Tendencias y adaptación a la globalización. In Agaves del Occidente de Mexico; Vázquez, A., Vargas, Y., Saldívar, S., Eds.; Universidad de Guadalajara-CUCBA, CRT, CIATEJ, LSU y CONAFOR: Mexico City, Mexico, 2007; pp. 160–182. [Google Scholar]

- Statista. Exportaciones de Tequila Desde Mexico de 1995 a 2020. 2021. Available online: https://es.statista.com/estadisticas/1170629/mexico-cantidad-exportada-tequila/ (accessed on 29 April 2022).

- Statista. Principales Países de Destino de las Exportaciones de Tequila de Mexico en 2020. 2021. Available online: https://es.statista.com/estadisticas/1058207/mexico-cantidad-exportada-tequila-pais-destino/ (accessed on 25 March 2022).

- Cámara Nacional de la Industria del Tequila. (CNIT). El Agave. 2022. Available online: https://www.tequileros.org/el-tequila/ (accessed on 26 January 2022).

- SAGARPA, Secretaría de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación. Agave Tequilero y Mezcalero Mexicano. Planeación Agrícola Nacional 2017–2030. 2017. Available online: https://www.gob.mx/cms/uploads/attachment/file/257066/Potencial-Agave_Tequilero_y_Mezcalero.pdf (accessed on 7 February 2022).

- Moreno, R.; Escalante, A.; Verdugo, A.G.; De la Rosa, M.; Ortiz Basurto, R.I.; Orantes, C.; Palafox, L.; Castro, A.S.; Lappe, P. Bebidas Refrescantes y Alcohólicas de Agave. In Panorama del Aprovechamiento de los Agaves en Mexico; Estado del Arte publicado por agared-Red Temática Mexicana; Aprovechamiento Integral Sustentable y Biotecnología de los Agaves; Centro de Investigación y Asistencia en Tecnología y Diseño del Estado de Jalisco, A.C.: Mexico City, Mexico, 2019. [Google Scholar]

- Rivera, J.; Blanco, J. Agave-Tequila Rutas Tecnológicas 2014–2018. Proyecto FINNOVA: Sistema de Inteligencia Estratégica (THINK-TANK) Para la Identificación, Impulso, Coordinación y Transferencia de la I+D Innovadora Entre el CIATEJ y su Ecosistema Biotecnológico; CIATEJ: Guadalajara, Mexico, 2013. [Google Scholar]

- Consejo Regulador del Tequila (CRT). Agave y Tequila un Binomio de Éxito; Temacilli: Guadalajara, Mexico, 2016; Available online: https://www.crt.org.mx/images/Documentos/Libro/AGAVE_TEQUILA_UN_BINOMIO_DE_EXITO.pdf (accessed on 7 February 2022).

- Ramos, J.J. Procesos Del Tequila. Opciones Para el Tratamiento de los Residuos de la Industria Tequilera. Página Corporativa de Casa Sauza. 2017. Available online: https://www.casasauza.com/procesos-tequila-sauza/opciones-tratamiento-residuos-industria-tequilera (accessed on 4 January 2022).

- Ayala, S. Destilando Saberes. Los Gajes del Oficio Tequilero; Universidad de Guadalajara, Centro Universitario de los Valle: Guadalajara, Mexico, 2016; ISBN 978-607-9470-00-3. [Google Scholar]

- Estarrón-Espinosa, M.; Ruperto-Pérez, M.; Padilla-de la Rosa, J.; Prado-Ramírez, R. Innovation in Continuous Rectification for Tequila Production. Processes 2019, 7, 283. [Google Scholar] [CrossRef] [Green Version]

- Bautista, J.; García, L.; Barboza, J.; Parra, L. El agave tequilana Weber y la producción de tequila. Acta Univ. 2001, 11, 26–34. [Google Scholar] [CrossRef]

- Warren, W.; Aguilar, D.; Zárate, A.; Campos, A.; Romero, L. Development of a Predictive Model for Agave Prices Employing Environmental, Economic, and Social Factors: Towards a Planned Supply Chain for Agave-Tequila Industry. Foods 2022, 11, 1138. [Google Scholar] [CrossRef]

- Tetreault, D.; McCulligh, C.; Lucio, C. Distilling agro-extractivism: Agave and tequila production in Mexico. J. Agrar. Chang. 2021, 21, 219–241. [Google Scholar] [CrossRef]

- Gallardo, J. Industria del Tequila y Generación de Residuos. Revista Ciencia y Desarrollo; CONACYT: Mexico City, Mexico, 2019. Available online: https://www.cyd.conacyt.gob.mx/?p=articulo&id=287 (accessed on 7 February 2022).

- Abreu, J. Aprovechamiento de Bagazo de Agave Tequilana Weber para la Producción de Biohidrógeno. Master’s Thesis, Instituto Potosino de Investigación Científica y Tecnológica (IPICYT), San Luis Potosí, Mexico, 2013. [Google Scholar]

- Íñiguez, G.; Hernández, R. Estudio Para la Rehabilitación de Una Planta de Tratamiento de Vinazas Tequileras Mediante un Floculante Polimérico de Poliacrilamida (PAM). Rev. Int. Contam. Ambient. 2010, 26, 299–311. Available online: http://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S0188-49992010000400005&lng=es&tlng=e (accessed on 2 March 2022).

- Llangovan, K.; Linerio, J.; Álvarez, E.; Briones, M.; Noyola, A. Tratamiento anaerobio de vinazas tequileras. In Biodegradación de Compuestos Orgánicos; Ilangovan, K., Briones, R., Eds.; Universidad Nacional Autónoma de Mexico-Instituto de Ingeniería: Mexico City, Mexico, 1996; pp. 42–44. [Google Scholar]

- Linerio, J.E. Selección y evaluación de un sistema de tratamiento terciario para la depuración de vinazas tequileras. In Informe Técnico; Centro de Investigación y Asistencia en Tecnología y Diseño del Estado de Jalisco/Consejo Nacional de Ciencia y Tecnología- Sistema de Investigación Regional José María Morelos: Guadalahara, Mexico, 2002. [Google Scholar]

- Íñiguez, G.; Peraza, F. Reduction of solids and organic load concentrations in tequila vinasses using a polyacrylamide (PAM) polymer flocculant. Rev. Int. Contam. Ambient 2007, 23, 17–24. [Google Scholar]

- López-López, I.A.; Dávila-Vázquez, G.; León-Becerril, E.; Villegas-García, E.; Gallardo-Valdez, J. Tequila Vinasses: Generation and Full Scale Treatment Processes. Rev. Environ. Sci. Biotechnol. 2010, 9, 109–116. [Google Scholar] [CrossRef]

- Morán, R.G.; Sánchez, A.L.; Rodríguez, J.; Dávila, G.; Marino, E.N.; Dendooven, L.; Contreras, S.M. Utilization of vinasses as soil amendment: Consequences and perspectives. SpringerPlus 2016, 5, 1007. [Google Scholar] [CrossRef] [Green Version]

- Macías, A. Organización de la Industria del Tequila. Carta Económica Regional, Nº 54, Mayo–Junio, Mexico. 1997. Available online: http://www.cartaeconomicaregional.cucea.udg.mx/index.php/CER/article/view/7643 (accessed on 15 February 2022).

- Martinez, E.; Gortares, P.; Santiago, N.; Nápoles, J.; Gabriela, R.; De la Mora, C.; Leyva, L.; Humberto, L.; Meza, E. Tequila Still Distillation Fractioned Residual Streams for Use in Biorefinery. Energies 2020, 13, 6222. [Google Scholar] [CrossRef]

- Macías, A. El cluster en la Industria del tequila en Jalisco, Mexico. Agroalimentaria 2001, 6, 55–72. Available online: http://ve.scielo.org/scielo.php?script=sci_arttext&pid=S1316-03542001000200005&lng=es&tlng=e (accessed on 15 February 2022).

- López-, A.; León, E.; Rosales, M.E.; Villegas, E. Influence of alkalinity and VFAs on the performance of an uasb reactor with recirculation for the treatment of Tequila vinasses. Environ. Technol. 2015, 36, 2468–2476. [Google Scholar] [CrossRef]

- Montes-Moncivais, A.; Moreno, G.; Buitrón, G. Biological hydrogen production from tequila industry wastewater (YWP-012). In Proceedings of the 1st IWA Mexico National Young Water Professionals Conference, Mexico City, Mexico, 5–8 November 2018; Instituto Potosino de Investigación Científica y Tecnológica: Querétaro, Mexico, 2018. [Google Scholar]

- Montoya, H.A.; Contreras, C.S.; García, V.M. Estudio Integral de la Calidad del Agua en el Estado de Jalisco; Comisión Estatal del Agua: Guadalajara, Mexico, 1997.

- Abrol, V.; Sharma, P. Resource Management for Sustainable Agriculture; BoD—Books on Demand: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

- Gradilla-Hernández, M.S.; de Anda, J.; Garcia-Gonzalez, A.; Montes, C.Y.; Barrios-Piña, H.; Ruiz-Palomino, P.; Díaz-Vázquez, D. Assessment of the Water Quality of a Subtropical Lake Using the NSF-WQI and a Newly Proposed Ecosystem Specific Water Quality Index. Environ. Monit. Assess. 2020, 192, 1–19. [Google Scholar] [CrossRef]

- Díaz-Vázquez, D.; Carrillo-Nieves, D.; Orozco-Nunnelly, D.A.; Senés-Guerrero, C.; Gradilla-Hernández, M.S. An integrated approach for the assessment of environmental sustainability in agro-industrial waste management practices: The case of the Tequila Industry. Front. Environ. Sci. 2021, 25, 2021. [Google Scholar] [CrossRef]

- Jayme-Torres, G.; Hansen, A.M. Nutrient Loads in the River Mouth of the Río Verde basin in Jalisco, Mexico: How to Prevent Eutrophication in the Future Reservoir? Environ. Sci. Pollut. Res. 2018, 25, 20497–20509. [Google Scholar] [CrossRef]

- Gabinete de Prensa ISCIII. INECC Reitera su Compromiso Ante el Acuerdo de París con Rutas de Mitigación al Cambio Climático. 2018. Available online: http://www.gob.mx/inecc/prensa/inecc-reitera-su-compromiso-ante-el-acuerdo-de-paris-conrutas-de-mitigacion-al-cambio-climatico (accessed on 18 January 2022).

- SEMADET. Inventario Estatal de Emisiones de Gases y Compuestos de Efecto Invernadero (IEEGYCEI). 2018. Available online: https://semadet.jalisco.gob.mx/gobernanza-ambiental/cambio-climatico/inventario-estatal-de-emisiones-de-gases-y-compuestos-de (accessed on 22 January 2022).

- Urbanowicz, R.J.; Meeker, M.; La Cava, W.; Olson, R.S.; Moore, J.H. Relief-based feature selection: Introduction and review. J. Biomed. Inform. 2018, 85, 189–203. [Google Scholar] [CrossRef]

- Kira, K.; Rendell, L.A. A practical approach to feature selection. In Proceedings of the Ninth International Workshop on Machine Learning, San Francisco, CA, USA, 1–3 July 1992; pp. 249–256. [Google Scholar]

- Robnik-Šikonja, M.; Kononenko, I. Theoretical and empirical analysis of ReliefF and RReliefF. Mach. Learn. 2003, 53, 23–69. [Google Scholar] [CrossRef] [Green Version]

- Syakur, M.A.; Khotimah, B.K.; Rochman, E.M.S.; Satoto, B.D. Integration k-means clustering method and elbow method for identification of the best customer profile cluster. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 336, p. 012017. [Google Scholar]

- Martínez-Velasco, A.; Terán-Bustamante, A. Business Model Innovation and Decision-Making for the Productive Sector in Times of Crisis. In Business Recovery in Emerging Markets. Palgrave Studies in Democracy, Innovation, and Entrepreneurship for Growth; López-Fernández, A.M., Terán-Bustamante, A., Eds.; Palgrave Macmillan: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Diario Oficial de la Federación (DOF). (2018: 13/03/2018). DECRETO Por el que se Reforman y Adicionan Diversas Disposiciones de la Ley de la Propiedad Industrial. Available online: https://www.dof.gob.mx/nota_detalle.php?codigo=5515853&fecha=13/03/2018#:~:text=%2D%20Se%20entiende%20por%20denominaci%C3%B3n%20de,producto%20se%20deban%20exclusiva%20o (accessed on 5 March 2022).

- Terán-Bustamante, A.; Martínez-Velasco, A.; López-Fernández, A.M. University–Industry Collaboration: A Sustainable Technology Transfer Model. Adm. Sci. 2021, 11, 142. [Google Scholar] [CrossRef]

- Cárdenas, E. Innovación en la industria del tequila: Historia y tendencias. Carta Económica Reg. 2022, 129, 93–121. [Google Scholar] [CrossRef]

- Worldwide Espacenet. Patent Search. 2022. Available online: https://worldwide.espacenet.com/patent/search?q=ctxt%20all%20%22agave%20tequilana%22 (accessed on 27 March 2022).

| Factor | Type of Tequila | Characteristics |

|---|---|---|

| By type of sugar | Tequila 100% | Made with 100% Weber Azul tequilana agave, sugar. |

| Tequila | Made with 51% sugar from the blue Weber tequilana agave and the rest (49%) of total reducers, expressed in mass units, come from other sources (except other agave species). | |

| By the rest time | Mixed tequila | Clear and transparent in color, it is bottled immediately after being distilled. |

| White tequila | This tequila is softened with colorants and flavors, such as caramel. | |

| Young tequila | White tequila that is left to rest in oak barrels for more than two months and up to a year. It maintains its blue agave flavor. | |

| Rested tequila | Aged in oak barrels for over a year. It has an amber color and a woody flavor. |

| Type of Process | Phases of Production | ||||

|---|---|---|---|---|---|

| Cultivating | Baking or Cooking | Grinding | Fermenting | Distilling | |

| Traditional | Basic, rudimentary agricultural tools, i.e., machete and tillage stick (coa). | Underground ovens are covered with stones on the inside. The oven consists of a circular cavity 4.60 m in diameter and 0.50 m deep. Wood fuel. | A rolling stone pulled by oxen and/or mules grinds the baked agave cores. | Wooden vats with a capacity of approximately 1500 L. The saccharimeter, an instrument locally called pesamiel, “weighs” the sugar concentration of the juices. | Metal pots containing must are placed on the fire. They are heated until the alcohol reaches the point of evaporation. |

| From 10 to 12 years. | Four days. | From two to three days. | From 12 days in summer up to 18 days in winter. | From one to two days. | |

| Hybrid | Basic agricultural tools, i.e., machete and coa, are prioritized. | Masonry oven with a thermometer on the door. Fuel from diesel, tar, and pig manure. | An agave core shredder. Grinding machines were introduced in the 1950s. | Stainless steel tubs with a capacity of up to 20,000 L. | Steam-based copper or steel stills. |

| From 7 to 10 years. | From 36 to 38 h. | From one to two days. | 72 h. | From one to two days. | |

| Technicalized | New machinery is designed internally for planting and harvesting. | Autoclaves bake or cook the agave at 90 to 110 degrees Celsius temperatures. | An extruder grinds the agave. The raw agave enters on one end, and must, mezcal juices, and fiber come out on the opposite end. This machine has a high rate of extraction efficiency. | The fermentation process is automated. | Column distillation; allows a continuous process and reduces costs and distillation times. |

| Maturity mechanisms reduce the cycle to 5.5 years. | 18 h. | 15 h. | The fermentation time is considerably reduced. | The distillation time is considerably reduced. | |

| # | Variable | Concept | Dimension |

|---|---|---|---|

| 1 | Competitive and Technological Intelligence | The process of identifying, collecting, and analyzing information about the environment and the activities of an organization, as well as to time use of such information for decision-making. | Optimum Regular Deficient |

| 2 | Strategic Planning | It is the plan that presents the strategy planning, defined for the organization, as the guiding thread. | Yes/No |

| 3 | Technological Planning | It is the development of a strategic technology plan that allows selecting lines of action in the development of products/services according to the market’s needs and that focus on developing competitive advantages. | Yes/No |

| 4 | Human Capital | People with their talent translate into valuing the knowledge and skills that each worker has in a company. | Qualified Not Qualified |

| 5 | Protection of Intellectual property | Safeguard all intangible assets of the company. The protection of innovation seeks to prevent the unauthorized use of an organization’s developments. It includes all the measures that the organization takes to ensure the benefits of exploiting the innovation. | Yes No |

| 6 | Quality and Risk Management | Coordinated activities to direct and control in an organization the possible risks to guarantee quality. | Optimum Deficient |

| 7 | Customer Needs and Opportunity Detection | Analysis of customer needs and opportunities of the market. Who? What? How? Analytics. | Optimum Regular Deficient |

| 8 | Mission, Vision, and Values | Entreprise philosophy. A firm’s statements are based on the core ethical values of an organization and are essential to its success because they give it direction. | Yes No |

| 9 | Strategy Model | A plan that integrates and provides tools for decision-making and action plans in the face of a given scenario. | Yes/No |

| 10 | R+D*I | Research, development, and innovation. | Optimum Regular Deficient |

| 11 | Best Production Practices | The norms and standards of quality and best manufacturing practices. | Optimum Regular Deficient |

| 12 | Compliance with Legal and Regulatory Material | Activities and processes to comply with legal and regulatory standards. | Yes/No |

| 13 | Organizational and Technological Architecture | It integrates a complete vision of the company, its processes, and the available resources. It describes the strategy of products and services of the company, as well as the organizational, functional, process, and information aspects. | Optimum Deficient |

| 14 | Business Intelligence | Set of strategies, procedures, and activities whose objective is to present relevant business data and its environment for decision-making. | Optimum Regular Deficient |

| 15 | Universities and Research Centers Linkage/collaboration | Linkage is the set of relationships established between universities and the productive sector, and its purpose is to transfer knowledge and technology. | Yes/ No |

| 16 | Designation of Origin | The name of a geographical area that contains that name, or another well-known denomination that refers to the area mentioned above, serves to designate a product as originating from the same, when the quality or characteristics of the product are due exclusively or essentially to the environment geographical, including natural and human factors, and which has given the product its reputation [79]. | Yes/No |

| 17 | Trademarks and Patents | A trademark is a sign that makes it possible to differentiate the products or services of one company from those of another. Trademarks are intellectual property rights (IP). A patent is an exclusive right granted over an invention. | Yes/No |

| 18 | Sustainability and the Environment | The harmonious coexistence of society and its environment, where the current population can satisfy its needs and improve its well-being using the available natural resources, but without compromising the quality of life of future generations. | Optimum Regular Deficient |

| 19 | Core Competences | It refers to the unique and differential knowledge or skills that a company has and that give it a competitive advantage. | Optimum Deficient |

| 20 | Business Model Structure | Design process to create a widely new business model in the market, which is accompanied by a value proposition that generates or ensures a sustainable competitive advantage. | Optimum Regular Deficient |

| 21 | Official Standard | Certifications, norms, standards, and rules. | Optimum Regular Deficient |

| 22 | Cultivation of Raw Material Agave | Knowledge of the soil and planting of agave. It includes all activities from planting to harvest. | Optimum Regular Deficient |

| 23 | Tequila Manufacturing | -Knowledge of handling agave pineapples -Pineapple crushing/cooking/grinding/agave juice extraction -Fermentation -Distillation | Optimum Regular Deficient |

| 24 | Tequila Packaging | Tequila packaging according to official standards: NOM-006-SCFI-2012, Alcoholic Beverages-tequila-Specifications. | Optimum Regular Deficient |

| 25 | Commercialization an Marketing (MKT) Capacity | Understand and satisfy customer needs. The process by which companies create value for customers and build strong relationships with them to capture their value in return. Search, promote, serve, and adapt markets. | Optimum Regular Deficient |

| 26 | Management and Use of Waste | Waste collection and processing methods combine management options that include reuse and recycling efforts. | Optimum Regular Deficient |

| 27 | Ancestral Technical Knowledge | Techniques applied to the production of tequila based on ancient knowledge. | Optimum Regular Deficient |

| 28 | Modern Technologies | Modern techniques applied to tequila production based on technology. | Optimum Regular Deficient |

| 29 | Process Management | It is the management model of all value chain processes. | Optimum Regular Deficient |

| 30 | Customers II Experience | Whom? How? Delivery and capture value proposal. Here is the customer experience perceived by the customer. The definition of the product or service I sell to clients. I and II are the most important detonators of the model. | Optimum Regular Deficient |

| 31 | Value System Model | Structure of value proposition, value creation, value and delivery, value capture, topology of value chain partners. The value propositions. What are we offering to whom? Target segment(s). Product or service offering. Revenue model. | Optimum Deficient |

| 32 | Positioning | The product’s positioning is divided first in terms of the product type: White, Young, Reposado, Añejo, or Extra Añejo. Moreover, second to the market to which it is directed: premium, superpremium, and ultra-premium. The companies promote the development of their brands through differentiated and defined positioning and marketing strategies for each product, trying to give a different brand essence and avoid positioning coincidences, and try to give value to the customer. | Optimum Regular Deficient |

| 33 | National and International Markets | Set of real and potential buyers both nationally and internationally. | Optimum Regular Deficient |

| 34 | Commercialization Capacity/MKT | Actions and procedures effectively introduce products/services to the market to satisfy customer needs. | Optimum Regular Deficient |

| 35 | Knowledge Management | Knowledge management is the company’s ability to put the knowledge it has acquired at the service of those who need it within the company to develop new solutions and innovate. A systematic process of dissemination, use, generation, documentation, and enhancement of individual and organizational knowledge. It search like this knowledge is used methodically for competitive advantages for the firm. [2,3,10,78,80]. | Optimum Regular Deficient |

| 36 | Innovation | It is the implementation of significant changes in its product, process, marketing, or organization. Innovation is a product or process (or a combination of both) that differs significantly from previous products and processes; it adds value. | Yes/No |

| 37 | Management of Innovation and Technology | The learning process accelerates the transformation of ideas into innovations. It is the organization and management of resources to increase the creation of new knowledge and technical ideas toward making new products, processes, and services or improving existing ones [2,3,10,78,80]. | Optimum Regular Deficient |

| Variable 1 | Variable 2 | Strength |

|---|---|---|

| Protection of Intellectual property | Designation of Origin | 1.000 |

| Strategic Planning | Mission, Vision, Values | 0.588 |

| Value System Model | Clients | 0.404 |

| Protection of Intellectual property | Sales and MKT | 0.402 |

| Quality and Risk Management | Legal Compliance | 0.400 |

| Business Model Structure | Tequila Manufacturing | 0.313 |

| Quality and Risk Management | Sustainability and Environment | 0.311 |

| Technological Planning | Human Capital | 0.302 |

| Sales and MKT | National and International Markets | 0.280 |

| Competitive and Technological Intelligence | Customer Needs Detection | 0.275 |

| Process Management | Management of Innovation and Technology | 0.241 |

| Value System Model | National and international markets | 0.224 |

| Legal Compliance | Official Rules | 0.192 |

| Value System Model | Positioning | 0.184 |

| Business Model Structure | Packing | 0.167 |

| Knowledge Management | Management of Innovation and Technology | 0.160 |

| Sustainability and Environment | Official Rules | 0.151 |

| Sustainability and Environment | Management and Use of Waste | 0.132 |

| Brands and Patents | Official Rules | 0.119 |

| Universities and Research Centers Linkage/collaboration | Management and Use of Waste | 0.118 |

| Packing | Value System Model | 0.111 |

| Variable | RelieF |

|---|---|

| Knowledge Management | 0.082 |

| MKT | 0.066 |

| Organizational and Technological Architecture | 0.06 |

| National and International Markets | 0.052 |

| Cultivation of Raw Materials Agave | 0.046 |

| Management and Use of Waste | 0.046 |

| Human Capital | 0.044 |

| Best Production Practices | 0.042 |

| Competitive and Technological Intelligence | 0.03 |

| Tequila Manufacturing | 0.018 |

| Business Intelligence | 0.016 |

| Official Rules | 0.01 |

| Value System Model | 0.008 |

| Process Management | 0.006 |

| Packing | 0.004 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Terán-Bustamante, A.; Martínez-Velasco, A.; Castillo-Girón, V.M.; Ayala-Ramírez, S. Innovation and Technological Management Model in the Tequila Sector in Mexico. Sustainability 2022, 14, 7450. https://doi.org/10.3390/su14127450

Terán-Bustamante A, Martínez-Velasco A, Castillo-Girón VM, Ayala-Ramírez S. Innovation and Technological Management Model in the Tequila Sector in Mexico. Sustainability. 2022; 14(12):7450. https://doi.org/10.3390/su14127450

Chicago/Turabian StyleTerán-Bustamante, Antonia, Antonieta Martínez-Velasco, Víctor Manuel Castillo-Girón, and Suhey Ayala-Ramírez. 2022. "Innovation and Technological Management Model in the Tequila Sector in Mexico" Sustainability 14, no. 12: 7450. https://doi.org/10.3390/su14127450

APA StyleTerán-Bustamante, A., Martínez-Velasco, A., Castillo-Girón, V. M., & Ayala-Ramírez, S. (2022). Innovation and Technological Management Model in the Tequila Sector in Mexico. Sustainability, 14(12), 7450. https://doi.org/10.3390/su14127450