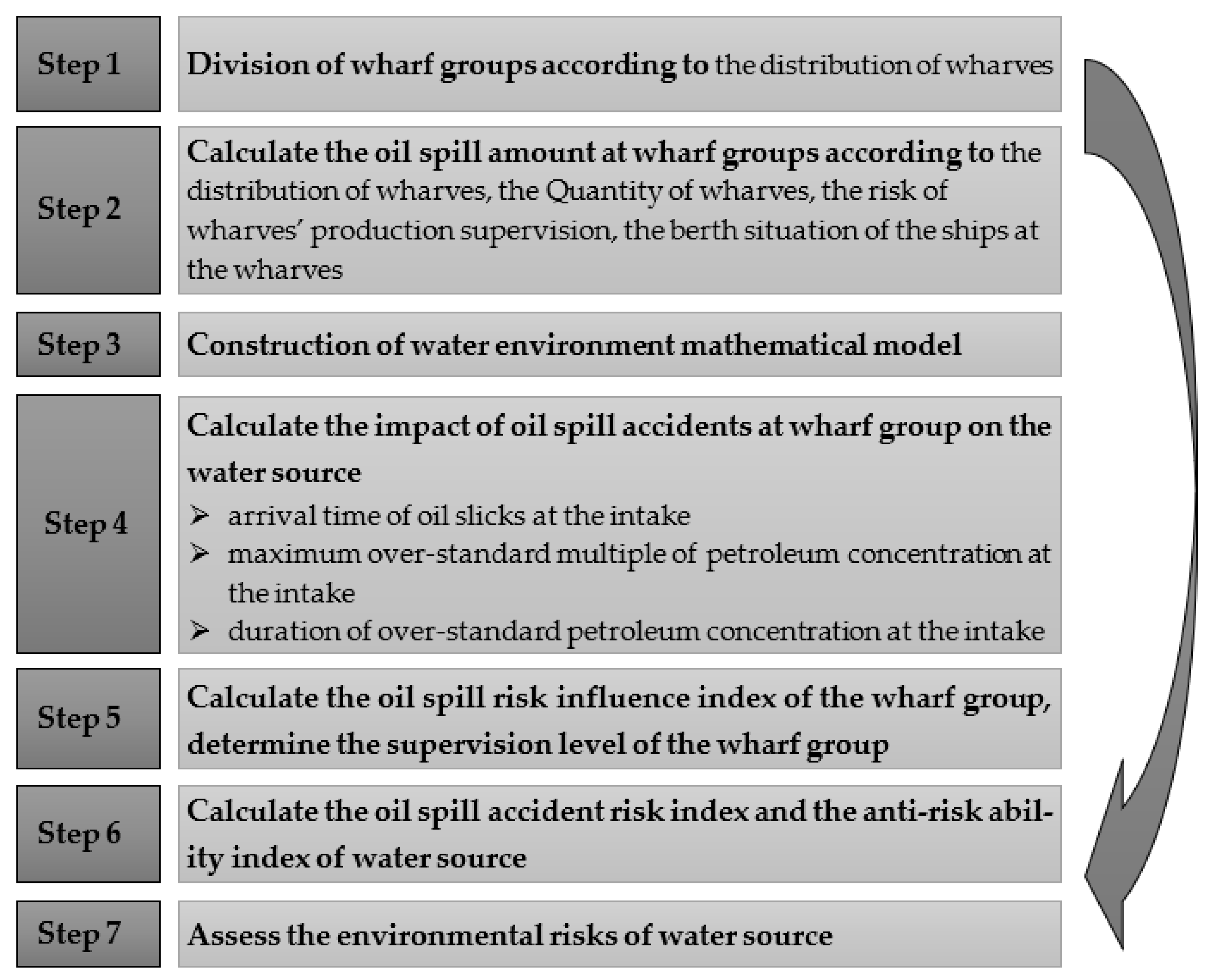

5.2. Location and Amount of Oil Spill at Wharf Groups

The risk index method [

24] is employed to evaluate the production supervision risk of each wharf, and the results are shown in

Table 8. Among the 27 wharves, 25 belong to the high-risk level, while JE13 and JE14 belong to the high-risk level, with the risk index of 3.057, distributed in the wharf group of SD03. The two high-risk wharves are the respective logistics wharves of two petrochemical enterprises, respectively, with the berthing capacity of above 40,000 t. Their loading and unloading of goods are mainly dangerous goods like benzene, xylene, phenol, cyclohexanone, and oil. However, the anti-pollution facilities of the two wharves are relatively simple, with only concise oil absorption felt, and the two wharves have not installed automatic water quality detectors, and thus their sensitivity to sudden environmental accidents is poor, resulting in the highest risk index. Other wharves are mostly bulk cargo, general cargo and outfitting wharves, whose loading and unloading goods do little harm to the water environment. Simple anti-pollution facilities and automatic water quality detection equipment make their risks relatively low.

The type and tonnage of main ships berthed at each wharf are obtained through field research. Referring to the statistical data of tonnage and oil tank capacity of different ship types, the oil tank capacity is obtained by the interpolation method, and the oil spill amount of oil spill accidents at wharves is determined by 4%/h of the oil tank capacity, as shown in

Table 8. To be specific, there are huge differences in the oil spill amount of 27 wharves. Wharf JE25 is the outfitting wharf of Jinling Shipyard, with the 100,000-t tonnage of its main ship type and its maximum oil spill amount of 93.636 t/h, which is nearly three times that of wharf JE07 (the secondary large one). As the main ship type of wharf JE18, a bulk cargo wharf, has only 400 t tonnage, its possible oil spill amount is the least, at only 0.207 t/h.

WQI, WRDI and oil spill position of the wharf group are calculated according to the number, location, and risk index of the wharves in the wharf group, and subsequently the oil spill amount of each wharf is considered, and the oil spill amount of each wharf group has been calculated, as shown in

Table 9. It can be observed from

Table 9 that WRDI varies widely among various wharf groups, ranging from 0.3 to 0.6. The main reason is that the length of wharf accident chains within each wharf group varies greatly. For instance, Wharf SD01 is densely distributed, and the length of three accident chains is less than 500 m, with an average length of only 307 m. Consequently, its WRDI, 0.549, is the largest. Relatively speaking, although the average risk index of SD03 is the largest (2.833), due to its relatively sparse distribution, its 1041 m average length of the accident chain, and less than 500 m length for only four of the 15 accident chains, and thus its WRDI is relatively small at 0.375. Owing to the largest number of wharves at SD03, its WQI is two to eight times that of the other wharf group. Therefore, although its WRDI is relatively small, its risk increment is the largest, which is reflected in the oil spill amount, increasing from 15.016 t/h of the weighted average value of wharf oil spill amount to 18.773 t/h of the oil spill amount at the wharf group. However, for SD06, with a small number of wharves, although the oil spill amount of JE23 and JE24 is very small, the oil spill amount of JE25 reaches 93.636 t/h, resulting in the largest oil spill amount of SD06 wharf group, reaching 32.207 t/h. Comparing the oil spill volume of each wharf group, it is observed that compared with the wharf number and distribution location, the wharf oil spill volume has the greatest influence on the oil spill volume of the wharf group, and the determination of the oil spill volume of the wharf group is related to the main ship tonnage and wharf production supervision risk. In the long run, the main ship tonnage seldom changes, but production regulatory risk will fluctuate. Consequently, the supervision risk of wharf production is the most important in determining the oil spill volume of the wharf. To reduce oil spill accidents and the oil spill volume, the risk of wharf production supervision should be kept at a low risk level in the long term.

5.3. Simulation Results of Oil Spill Accidents at Wharf Groups

Based on the two-dimensional hydrodynamic model, the oil particle model is adopted to simulate the drift and diffusion process of oil slicks after oil spill accidents occur in different working conditions of each wharf group (

Table 2). After the oil spill accident, the oil slick drifts and spreads along the coastline of the Yangtze River. Affected by the ebb and flow tide, the oil slick oscillates back and forth and drifts downstream. The drift trend of the oil slick is roughly the same under different flow and wind fields. The simulated changes of petroleum concentration at the intake of the water source are shown in

Figure 5, where the time refers to the experience time after the oil spill accident, FRT represents sharp rise, and FET denotes sharp ebb.

As

Figure 5 reveals, the water quality standard (Class II) of water source intakes stipulated in the

Environmental quality standards for surface water (GB3838-2002) [

42] is used as the threshold value to judge the calculation results, and the five wharf groups SD01~SD04 and SD07, which are on the same bank as the water source, present influences on the water source intakes after oil spill accidents, respectively. However, for SD05 and SD06, located in the north bank of the north branch of the Yangtze River, where the south branch flow is approximately twice the north branch flow, although the width of the river surface at the water intake is relatively small, the huge flow of the south branch makes it hard for oil slicks formed after oil spill accidents to affect intake. Moreover, after the oil spill accident occurs at SD06, due to its large oil spill amount, the petroleum concentration at the intake fluctuates slightly, but not exceeding the water quality standard of Class II. Located downstream of the water source, SD07 only affects the water source during rising tide.

According to the simulation results of the model, the specific values of the influence index on the water source after oil spill accidents in various wharf groups under different working conditions can be obtained, as shown in

Table 10.

By comparing the calculation results of the three wind field conditions in

Table 10, it can be observed that either during sharp rise or sharp ebb, the maximum over-standard multiple of petroleum concentration at the intake after an oil spill accident is the largest in the northeast wind condition, while it is the smallest in the west wind condition, which is mainly attributed to the influence of wind field on flow field and oil slick drift and diffusion velocity. Compared with the other two wind fields, the west wind direction is the same as ebb tide direction and opposite to rising tide direction, and thus the velocity is relatively large during sharp ebb and relatively small during sharp rise in the west wind condition. Simultaneously, wind force also accelerates the drift and diffusion of oil slicks. Relevant studies prove that the motion speed of oil slicks is about 3% of the wind speed above 10 m on the water surface [

43]. Hence, compared with the northeast wind and calm wind, the oil slick drifts and spreads faster in the west wind. With a larger area and relatively sparse distribution of oil particles, it has a smaller maximum petroleum concentration at the intake, which also leads to an earlier arrival time of oil slicks at the intake and a longer duration of over-standard petroleum concentration at the intake. On the contrary, the direction of the northeast wind is opposite to the direction of the ebb tide but the same as the rising tide. Therefore, after the oil spill accident occurs in the northeast wind, the maximum petroleum concentration at the intake is larger, the arrival time of the oil slicks at the intake is later, and the duration of over-standard petroleum concentration at the intake is shorter.

However, there are exceptions for the above situations. For example, SD03 is far away from the intake, but when the oil spill accident occurs during sharp ebb, the duration of over-standard petroleum concentration at the intake under the northeast wind condition is apparently longer than the west wind condition, and under the calm wind the condition is longer than the west wind condition. The main reason is that when the oil slicks drift to the intake, the intake and the downstream flow field are in rising tide. Consequently, under the calm wind condition, the oil slick oscillates back and forth here. Under the northeast wind condition, the oil slick oscillates back and forth here for a longer time. However, under the west wind condition, due to the faster drift speed of oil slick downstream, the oil slick has drifted downstream of the intake. Although affected by the rising tide, some oil slicks drift upstream, which does not affect the intake. SD04 is farther away from the intake. When the oil spill accident occurs during sharp ebb fall, the oil slicks drift to the intake. The intake and the downstream flow field are in rising tide. Therefore, no matter the kind of wind field condition, the oil slick will oscillate here. In the west wind condition, the oil slick has a larger area and longer length, thus longer influence on the water source. By contrast, SD01 and SD02 are close to the water source, and when oil spill accidents occur during sharp ebb, the oil slick drifts away a long distance from the intake with ebb tide and will not reach the intake when it drifts upstream with rising tide. Hence, the location of oil spill and the flow field are also important factors influencing the differences of oil spill accidents on the water source, of which SD01~SD04 upstream of the same bank of the water source are typical.

According to

Figure 4 and

Table 10, compared with the sharp rise, when SD01~SD04 upstream of the water source suffer oil spill accidents during sharp ebb, the petroleum concentration at the intake further exceeds the standard, the location of oil spill is closer to the intake, and their difference is more obvious. For instance, under the west wind condition, SD01~SD04 suffer oil spill accidents during sharp ebb and rise, respectively. For their maximum over-standard multiple of petroleum concentration at the water intake, the former is 3.49, 2.02, 1.53 and 1.45 times the latter. The farther away from the water source, the smaller the multiple will be. The main reason for the trend is that the closer the location of oil spill to the water source, the shorter the time of oil slick diffusion and weathering. When reaching the intake, the oil slick area is relatively small, the oil particles are relatively concentrated, and thus the oil slick concentration is relatively high. However, when the oil spill accident occurs during rising tide, the oil slick drifts upstream and then downstream, with enough diffusion and weathering time. When the oil slick reaches the intake, it has spread to a large area, with small thickness and low concentration of oil slick, leading to the shorter duration of over-standard petroleum concentration at the intake for oil spill accidents occurring during the sharp rise compared with that during the sharp ebb.

As shown in

Figure 6, the closer the oil spill location to the intake, the shorter the drift distance of the oil slick, and thus the arrival time of oil slicks at the intake will be less. In addition, when the oil spill accident occurs during sharp rise, the oil slick drifts upstream first, making the arrival time of oil slicks at the intake longer than that during sharp ebb. By comparing the time difference between the two, it can be concluded that the closer the oil spill location to the water intake, the greater the time difference will be. This is because the upstream Yangtze River suffers fewer jacking effects of sea tide, which is characterized by the shorter time of rise in a tidal cycle [

44]. Therefore, when SD01, closest to the intake, suffers an oil spill accident during sharp rise, its oil slick drifts upstream for the longest time, resulting in the largest time difference in the arrival time of oil slicks at the intake than that during the sharp ebb.

The oil spill amount also affects the maximum over-standard multiple of petroleum concentration at the intake. As

Figure 7 reveals, for the oil spill accidents occurring during the sharp rise under the three wind field conditions, the maximum over-standard multiple of petroleum concentration at the intake is basically in a linear relationship with the oil spill amount, but it is not the case for the oil spill accidents occurring during the sharp ebb. The main reason is that SD01 and SD02 are close to the intake, and the oil slick diffusion and weathering time is relatively short.

Located at the downstream of the water source, SD07 only affects the intake when its oil spill accidents occur during sharp rise. Since the rising tide direction is in the same direction as the northeast wind, but opposite to the west wind, under the northeast wind condition, the oil slick area is larger, the petroleum concentration in the middle of the oil slick is lower, and the duration of over-standard petroleum concentration is longer after the oil spill accidents occur during sharp rise, compared with the west wind and calm wind conditions. In the west wind condition, it is opposite. Close to the intake, the arrival time of oil slicks at the water intake has little difference in the three wind field conditions for SD07. In addition, similar to the oil spill accidents occurring in SD03 and SD04, when oil spill accidents occur at SD07 during the sharp rise, the oil slick drifts upstream to the intake with the tide, and then passes through the intake with the ebb tide. Therefore, the duration of over-standard petroleum concentration at the intake is long.

5.4. Judgment Results of Supervision Level at Wharf Groups

According to the simulation results of the influence indexes of oil spill accidents shown in

Table 10, the risk influence level of each influence index and the risk influence score are determined based on

Table 3. According to the weight of the indexes shown in

Table 3, the OSRI of each wharf group under different working conditions is obtained by weighted sum. Subsequently, the supervision level of the wharf group is determined by referring to

Table 4. Please refer to

Figure 8 for detailed results.

As

Figure 8 reveals, the OSRI of each wharf group under different working conditions are all less than 3, some of which are even less than 1.5, indicating that the supervision level is sub-key or non-key. The OSRI of SD07 during sharp rise is the largest, at 2.856, approaching the key supervision standard level. Therefore, the management department of the water source should appropriately strengthen the corresponding regulation. However, the OSRI of SD07 during sharp ebb is the smallest, at 1. The main reason is that located downstream of the water source, SD07 is close to the intake. When oil spill accidents occur during sharp rise, petroleum concentration of oil slick is high, which can reach the intake quickly, and the duration of over-standard petroleum concentration at the intake is long. The score values of the three influence indexes of oil spill accidents are 4, 2 and 2, respectively. However, when the oil spill accidents occur during sharp ebb, the oil slick will not reach the water source, and the score values of the three influence indexes of oil spill accidents are all 1. Located on the opposite side of the water source, SD05 and SD06 basically exert no influence on the intake. Therefore, the risk index of oil spill accidents in six working conditions is 1.

The influence index of oil spill accidents at SD01~SD03 of the same upstream bank of the water source among the four wharf groups, which is the maximum over-standard multiple of petroleum concentration at the intake, has a high-risk influence with a score of 4 under all working conditions, either due to close location to the intake or the large oil spill amount. However, SD04 is farthest away from the water source with the smallest oil spill amount, and thus its influence index of oil spill accidents—the risk influence level of the maximum over-standard multiple of petroleum concentration at the intake is high-risk influence during sharp ebb working conditions and low risk influence during sharp rise working condition, with the score values of 3 and 2, respectively. The influence index of oil spill accidents from SD01 to SD04—the risk influence level for the arrival time of oil slicks at the intake varies little, which is low or very low risk influence, with the risk value of 2 or 1. As SD01 and SD02 are close to the intake, the risk influence level for the arrival time of oil slicks at the intake under sharp ebb working conditions is the low-risk influence. Being far away from the intake, when SD03 and SD04 suffer oil spill accidents during sharp ebb, the oil slick will oscillate back and forth at the intake. Consequently, the risk influence level for the duration of over-standard petroleum concentration at the intake under sharp ebb working condition is bigger, belonging to low-risk influence or high-risk influence, with the risk value of 2 or 3. However, when SD01 and SD02 suffer oil spill accidents during sharp ebb, the oil slick will quickly pass through the intake without oscillating back and forth. Therefore, the risk influence level for the duration of over-standard petroleum concentration at the intake under sharp ebb working condition is extremely low risk influence. When the oil spill accidents occur at SD01~SD04 during sharp rise, the duration of over-standard petroleum concentration at the intake is also very short, and the risk influence level is also extremely low, with the score value of 1. Comprehensively considering the score values of the three indexes of oil spill accidents, we can determine that the OSRI of SD01~SD04 under each working condition is 2~3. Only the OSRI of SD04 during the sharp rise working condition is 1.428, and the supervision level is non-key supervision, because the arrival time of oil slicks at the water intake and the duration of over-standard petroleum concentration at the intake are extremely low risk influences.

5.5. Results of Environmental Risk Assessment of Water Sources

According to OSRI calculation results of each wharf group under different working conditions, this paper employs Formulas (9) and (10) to calculate WORI and determine the risk level, as shown in

Table 11.

As the 2010~2020 Environmental Bulletin of Zhenjiang City reveals, the water quality of the Zhenrunzhou water source of the Yangtze River satisfies the water standard of class III, with 100% of the water qualification rate. Given that there are no large tributaries in the Jiangsu section of the Yangtze River, the annual average flow of the water source can be taken as 28,600 m

3/s by referring to the annual average flow of Datong Hydrological Station in the upstream of the Jiangsu section of the Yangtze River [

20]. According to the field investigation results, the daily supervision capacity and emergency response capacity of Zhenrunzhou water source have reached 100%. Referring to the risk level classification standard and index weight (

Table 5) of the anti-risk ability assessment index of the water source, the value of each index can be obtained, and the anti-risk ability index of the water source can be obtained by weighted sum, as shown in

Table 11.

Based on the risk index of oil spill accidents and the anti-risk ability index of the water source, the environmental risk index of the water source is determined by the weighted sum of 0.65:0.35, and the environmental risk level of the water source is determined, as shown in

Table 11.

As

Table 11 reveals, owing to the excellent water quality and hydrology conditions of the water source, its supervision and emergency indexes reach 100%, and the anti-risk index of the water source under various working conditions is 1, with extremely strong anti-risk ability. Under each working condition, the risk index of oil spill accidents at the water source ranges from 3.1 to 3.3, which are all high-risk levels. However, due to the strong anti-risk ability of the water source, the environmental risk index of the water source under each working condition is less than 3, within 2.4~2.5, and the risk level is medium. Since the influence index of oil spill accidents at SD07 is the largest, which is 2.856, the risk index of oil spill accidents during the sharp rise and the environmental risk index of the water source at SD07 are slightly larger than those during the sharp ebb.