Supply Chain Diversification, Digital Transformation, and Supply Chain Resilience: Configuration Analysis Based on fsQCA

Abstract

:1. Introduction

- (1)

- What are the dimensions of supply chain diversification and digital transformation?

- (2)

- Are the dimensions of supply chain diversification and digital transformation necessary for achieving high supply chain resilience?

- (3)

- How can supply chain diversification and digital transformation be configured to achieve high supply chain resilience?

2. Literature Review

2.1. Supply Chain Diversification and Supply Chain Resilience

2.2. Digital Transformation and Supply Chain Resilience

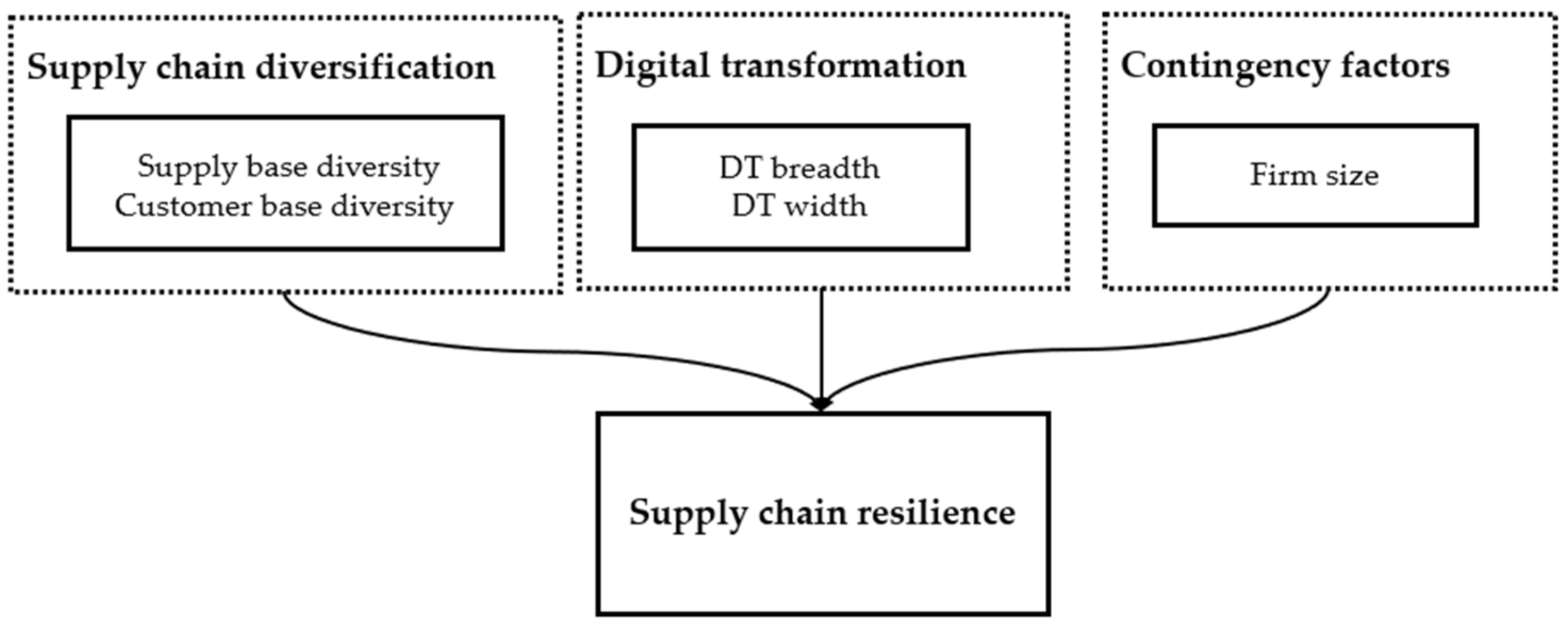

2.3. Conceptual Model

3. Methods

3.1. Introduction to QCA Methods

3.2. Sample Selection and Data Sources

3.3. Measurement and Calibration of Results and Antecedent Conditions

3.3.1. Measurement of Results and Antecedent Conditions

3.3.2. Calibration of Results and Antecedent Conditions

4. Results

4.1. Analysis of Necessary Conditions

4.2. Analysis of Sufficient Conditions for Supply Chain Resilience

4.2.1. Configurations That Lead to High Supply Chain Resilience

4.2.2. Configurations That Lead to Low Supply Chain Resilience

4.3. Robustness Test

5. Discussion

6. Implications

6.1. Theoretical Implications

6.2. Practical Implications

6.3. Limitations and Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Garti, A.; Dolan, S.L.; Using the Triaxial Model of Values to Build Resilience in a COVID-19 VUCA World. Eur. Bus. Rev. 2021. Available online: https://www.researchgate.net/publication/353795548_Using_the_triaxial_model_of_values_to_build_resilience_in_a_COVID-19_VUCA_world (accessed on 14 May 2022).

- Nasir, S.B.; Ahmed, T.; Karmaker, C.L.; Ali, S.M.; Paul, S.K.; Majumdar, A. Supply chain viability in the context of COVID-19 pandemic in small and medium-sized enterprises: Implications for sustainable development goals. J. Enterp. Inf. Manag. 2021, 35, 100–124. [Google Scholar] [CrossRef]

- Kamalahmadi, M.; Shekarian, M.; Mellat Parast, M. The impact of flexibility and redundancy on improving supply chain resilience to disruptions. Int. J. Prod. Res. 2022, 60, 1992–2020. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Wamba, S.F.; Jabbour, C.J.C.; Machado, M.C. Supply chain resilience in the UK during the coronavirus pandemic: A resource orchestration perspective. Int. J. Prod. Econ. 2022, 245, 108405. [Google Scholar] [CrossRef] [PubMed]

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply chain resilience: Definition, review and theoretical foundations for further study. Int. J. Prod. Res. 2015, 53, 5592–5623. [Google Scholar] [CrossRef]

- Scholten, K.; Scott, P.S.; Fynes, B. Mitigation processes–antecedents for building supply chain resilience. Supply Chain. Manag. : Int. J. 2014, 19, 211–228. [Google Scholar] [CrossRef]

- Agrawal, N.; Pingle, S. Mitigate supply chain vulnerability to build supply chain resilience using organisational analytical capability: A theoretical framework. Int. J. Logist. Econ. Glob. 2020, 8, 272–284. [Google Scholar] [CrossRef]

- Adobor, H. Supply chain resilience: A multi-level framework. Int. J. Logist. Res. Appl. 2019, 22, 533–556. [Google Scholar] [CrossRef]

- Sodhi, M.S.; Son, B.G.; Tang, C.S. Researchers’ perspectives on supply chain risk management. Prod. Oper. Manag. 2012, 21, 1–13. [Google Scholar] [CrossRef]

- Adobor, H.; McMullen, R. Supplier diversity and supply chain management: A strategic approach. Bus. Horiz. 2007, 50, 219–229. [Google Scholar] [CrossRef]

- Lin, Y.; Fan, D.; Shi, X.; Fu, M. The effects of supply chain diversification during the COVID-19 crisis: Evidence from Chinese manufacturers. Transp. Res. Part E Logist. Transp. Rev. 2021, 155, 102493. [Google Scholar] [CrossRef]

- Priyono, A.; Moin, A.; Putri, V.N.A.O. Identifying digital transformation paths in the business model of SMEs during the COVID-19 pandemic. J. Open Innov. Technol. Mark. Complex. 2020, 6, 104. [Google Scholar] [CrossRef]

- Creazza, A.; Colicchia, C.; Spiezia, S.; Dallari, F. Who cares? Supply chain managers’ perceptions regarding cyber supply chain risk management in the digital transformation era. Supply Chain. Manag. Int. J. 2021, 27, 30–53. [Google Scholar] [CrossRef]

- Sirmon, D.G.; Hitt, M.A.; Ireland, R.D.; Gilbert, B.A. Resource orchestration to create competitive advantage: Breadth, depth, and life cycle effects. J. Manag. 2011, 37, 1390–1412. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Fosso Wamba, S.; Roubaud, D.; Foropon, C. Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. Int. J. Prod. Res. 2021, 59, 110–128. [Google Scholar] [CrossRef]

- Wieland, A.; Durach, C.F. Two Perspectives on Supply Chain Resilience. J. Bus. Logist. 2021, 42, 315–322. [Google Scholar] [CrossRef]

- Nyström, M. Redundancy and response diversity of functional groups: Implications for the resilience of coral reefs. Ambio 2006, 35, 30–35. [Google Scholar] [CrossRef]

- Folke, C. Resilience: The emergence of a perspective for social–ecological systems analyses. Glob. Environ. Change 2006, 16, 253–267. [Google Scholar] [CrossRef]

- Ekanayake, E.; Shen, G.Q.; Kumaraswamy, M.M. Identifying supply chain capabilities of construction firms in industrialized construction. Prod. Plan. Control. 2021, 32, 303–321. [Google Scholar] [CrossRef]

- Ezaki, T.; Imura, N.; Nishinari, K. Towards understanding network topology and robustness of logistics systems. Commun. Transp. Res. 2022, 2, 100064. [Google Scholar] [CrossRef]

- Gomez, M.; Mejia, A.; Ruddell, B.L.; Rushforth, R.R. Supply chain diversity buffers cities against food shocks. Nature 2021, 595, 250–254. [Google Scholar] [CrossRef]

- Folke, C.; Carpenter, S.R.; Walker, B.; Scheffer, M.; Chapin, T.; Rockström, J. Resilience thinking: Integrating resilience, adaptability and transformability. Ecol. Soc. 2010, 15, 20. [Google Scholar] [CrossRef]

- Ramos, E.; Patrucco, A.S.; Chavez, M. Dynamic capabilities in the “new normal”: A study of organizational flexibility, integration and agility in the Peruvian coffee supply chain. Supply Chain. Manag. Int. J. 2021. [CrossRef]

- Ivanov, D.; Sokolov, B.; Dolgui, A. The Ripple effect in supply chains: Trade-off ‘efficiency-flexibility-resilience’in disruption management. Int. J. Prod. Res. 2014, 52, 2154–2172. [Google Scholar] [CrossRef]

- Hanelt, A.; Bohnsack, R.; Marz, D.; Antunes Marante, C. A Systematic Review of the Literature on Digital Transformation: Insights and Implications for Strategy and Organizational Change. J. Manag. Stud. 2021, 58, 1159–1197. [Google Scholar] [CrossRef]

- Sharma, A.; Pathak, S.; Borah, S.B.; Adhikary, A. Is it too complex? The curious case of supply network complexity and focal firm innovation. J. Oper. Manag. 2019, 66, 839–865. [Google Scholar] [CrossRef]

- Ritter, T.; Pedersen, C.L. Digitization capability and the digitalization of business models in business-to-business firms: Past, present, and future. Ind. Mark. Manag. 2020, 86, 180–190. [Google Scholar] [CrossRef]

- Hamburg, I. Implementation of a digital workplace strategy to drive behavior change and improve competencies. In Strategy and Behaviors in the Digital Economy; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef] [Green Version]

- Shashi; Centobelli, P.; Cerchione, R.; Ertz, M. Agile supply chain management: Where did it come from and where will it go in the era of digital transformation? Ind. Mark. Manag. 2020, 90, 324–345. [Google Scholar] [CrossRef]

- Zouari, D.; Ruel, S.; Viale, L. Does digitalising the supply chain contribute to its resilience? Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 149–180. [Google Scholar] [CrossRef]

- Balakrishnan, A.; Ramanathan, U. The role of digital technologies in supply chain resilience for emerging markets’ automotive sector. Supply Chain. Manag. Int. J. 2021, 26, 654–671. [Google Scholar]

- Faruquee, M.; Paulraj, A.; Irawan, C.A. Strategic supplier relationships and supply chain resilience: Is digital transformation that precludes trust beneficial? Int. J. Oper. Prod. Manag. 2021, 41, 1192–1219. [Google Scholar] [CrossRef]

- Wieland, A.; Wallenburg, C.M. The influence of relational competencies on supply chain resilience: A relational view. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 300–320. [Google Scholar] [CrossRef] [Green Version]

- Talluri, S.; Kull, T.J.; Yildiz, H.; Yoon, J. Assessing the efficiency of risk mitigation strategies in supply chains. J. Bus. Logist. 2013, 34, 253–269. [Google Scholar] [CrossRef]

- Ivanov, D. Viable supply chain model: Integrating agility, resilience and sustainability perspectives—lessons from and thinking beyond the COVID-19 pandemic. Ann. Oper. Res. 2020, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Scholten, K.; Schilder, S. The role of collaboration in supply chain resilience. Supply Chain. Manag. Int. J. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, X.; Tang, O.; Price, L.; Zhang, S.; Zhu, W. Supply chain collaboration for sustainability: A literature review and future research agenda. Int. J. Prod. Econ. 2017, 194, 73–87. [Google Scholar] [CrossRef]

- Stank, T.P.; Keller, S.B.; Daugherty, P.J. Supply chain collaboration and logistical service performance. J. Bus. Logist. 2001, 22, 29–48. [Google Scholar] [CrossRef]

- Ragin, C. The Comparative Method: Moving Beyond Qualitative and Quantitative Methods; University of California Press: Berkeley, CA, USA, 1987. [Google Scholar] [CrossRef]

- Rihoux, B.; Ragin, C.C. Configurational Comparative Methods: Qualitative Comparative Analysis (QCA) and Related Techniques; Sage Publications: Thousand Oaks, CA, USA, 2008. [Google Scholar] [CrossRef]

- Ragin, C.C. Qualitative comparative analysis using fuzzy sets (fsQCA). Config. Comp. Methods Qual. Comp. Anal. (QCA) Relat. Technol. 2009, 51, 87–121. [Google Scholar]

- Charles, R. Redesigning Social Inquiry: Fuzzy Sets and Beyond; University of Chicago Press: Chicago, IL, USA, 2008. [Google Scholar]

- Al-Najjar, B.; Taylor, P. The relationship between capital structure and ownership structure: New evidence from Jordanian panel data. Manag. Financ. 2008, 34, 919–933. [Google Scholar]

- Schneider, C.Q.; Wagemann, C. Set-Theoretic Methods for the Social Sciences: A Guide to Qualitative Comparative Analysis; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Furnari, S.; Crilly, D.; Misangyi, V.F.; Greckhamer, T.; Fiss, P.C.; Aguilera, R. Capturing causal complexity: Heuristics for configurational theorizing. Acad. Manag. Rev. 2020, 46, 778–799. [Google Scholar] [CrossRef]

- Greckhamer, T.; Furnari, S.; Fiss, P.C.; Aguilera, R.V. Studying configurations with qualitative comparative analysis: Best practices in strategy and organization research. Strateg. Organ. 2018, 16, 482–495. [Google Scholar] [CrossRef] [Green Version]

| Sets | Fuzzy Set Calibration | ||

|---|---|---|---|

| Full In | Crossover Point | Full Out | |

| Firm size | 24.1 | 22.22 | 20.8 |

| DT breadth | 4 | 3 | 1 |

| DT depth | 61 | 11 | 2 |

| Customer concentration | 74.35 | 40.28 | 13.853 |

| Supplier concentration | 54.182 | 28.02 | 15.43 |

| High Supply Chain Resilience | Low Supply Chain Resilience | |||

|---|---|---|---|---|

| Consistency | Coverage | Consistency | Coverage | |

| Firm size | 0.670655 | 0.622703 | 0.587007 | 0.657952 |

| ~Firm size | 0.631611 | 0.558866 | 0.663385 | 0.708587 |

| DT breadth | 0.621110 | 0.619606 | 0.570782 | 0.687364 |

| ~DT breadth | 0.686605 | 0.569918 | 0.684123 | 0.685502 |

| DT depth | 0.608029 | 0.599938 | 0.558647 | 0.665410 |

| ~DT depth | 0.660897 | 0.553661 | 0.664126 | 0.671630 |

| Customer concentration | 0.633993 | 0.598506 | 0.671630 | 0.693860 |

| ~Customer concentration | 0.675708 | 0.588657 | 0.647690 | 0.681145 |

| Supplier concentration | 0.603511 | 0.565489 | 0.606532 | 0.686060 |

| ~Supplier concentration | 0.664951 | 0.583324 | 0.615857 | 0.652182 |

| High Supply Chain Resilience | |||

|---|---|---|---|

| Digital Transformation Driven | Supply Chain Diversification Driven | Supplier Concentration and Customer Base Diversification Driven | |

| Firm size | ⬤ | ⊗ | ⬤ |

| DT breadth | ● | ⊗ | ⊗ |

| DT depth | ⬤ | ⮾ | ⊗ |

| Customer concentrate | ⊗ | ⊗ | |

| Supplier concentrate | ⊗ | ⬤ | |

| Raw coverage | 0.432094 | 0.278673 | 0.23396 |

| Unique coverage | 0.252733 | 0.0804921 | 0.0410069 |

| Consistency | 0.75657 | 0.860561 | 0.840603 |

| Solution coverage | 0.598782 | ||

| Solution consistency | 0.753042 | ||

| Low Supply Chain Resilience | |||||

|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | S5 | |

| Firm size | ⊗ | ● | ⊗ | ⬤ | |

| DT breadth | ⮾ | ● | ⮾ | ⬤ | |

| DT depth | ⊗ | ⬤ | ⮾ | ⊗ | |

| Customer concentrate | ⬤ | ● | ⮾ | ||

| Supplier concentrate | ⬤ | ⮾ | |||

| Raw coverage | 0.414542 | 0.363781 | 0.306976 | 0.2719 | 0.233889 |

| Unique coverage | 0.0921795 | 0.116997 | 0.008593 | 0.0439774 | 0.0218636 |

| Consistency | 0.78112 | 0.829614 | 0.822759 | 0.861959 | 0.842227 |

| Solution coverage | 0.704533 | ||||

| Solution consistency | 0.785463 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, W.; Ran, W. Supply Chain Diversification, Digital Transformation, and Supply Chain Resilience: Configuration Analysis Based on fsQCA. Sustainability 2022, 14, 7690. https://doi.org/10.3390/su14137690

Yin W, Ran W. Supply Chain Diversification, Digital Transformation, and Supply Chain Resilience: Configuration Analysis Based on fsQCA. Sustainability. 2022; 14(13):7690. https://doi.org/10.3390/su14137690

Chicago/Turabian StyleYin, Weili, and Wenxue Ran. 2022. "Supply Chain Diversification, Digital Transformation, and Supply Chain Resilience: Configuration Analysis Based on fsQCA" Sustainability 14, no. 13: 7690. https://doi.org/10.3390/su14137690

APA StyleYin, W., & Ran, W. (2022). Supply Chain Diversification, Digital Transformation, and Supply Chain Resilience: Configuration Analysis Based on fsQCA. Sustainability, 14(13), 7690. https://doi.org/10.3390/su14137690