A New Longevity Design Methodology Based on Consumer-Oriented Quality for Fashion Products

Abstract

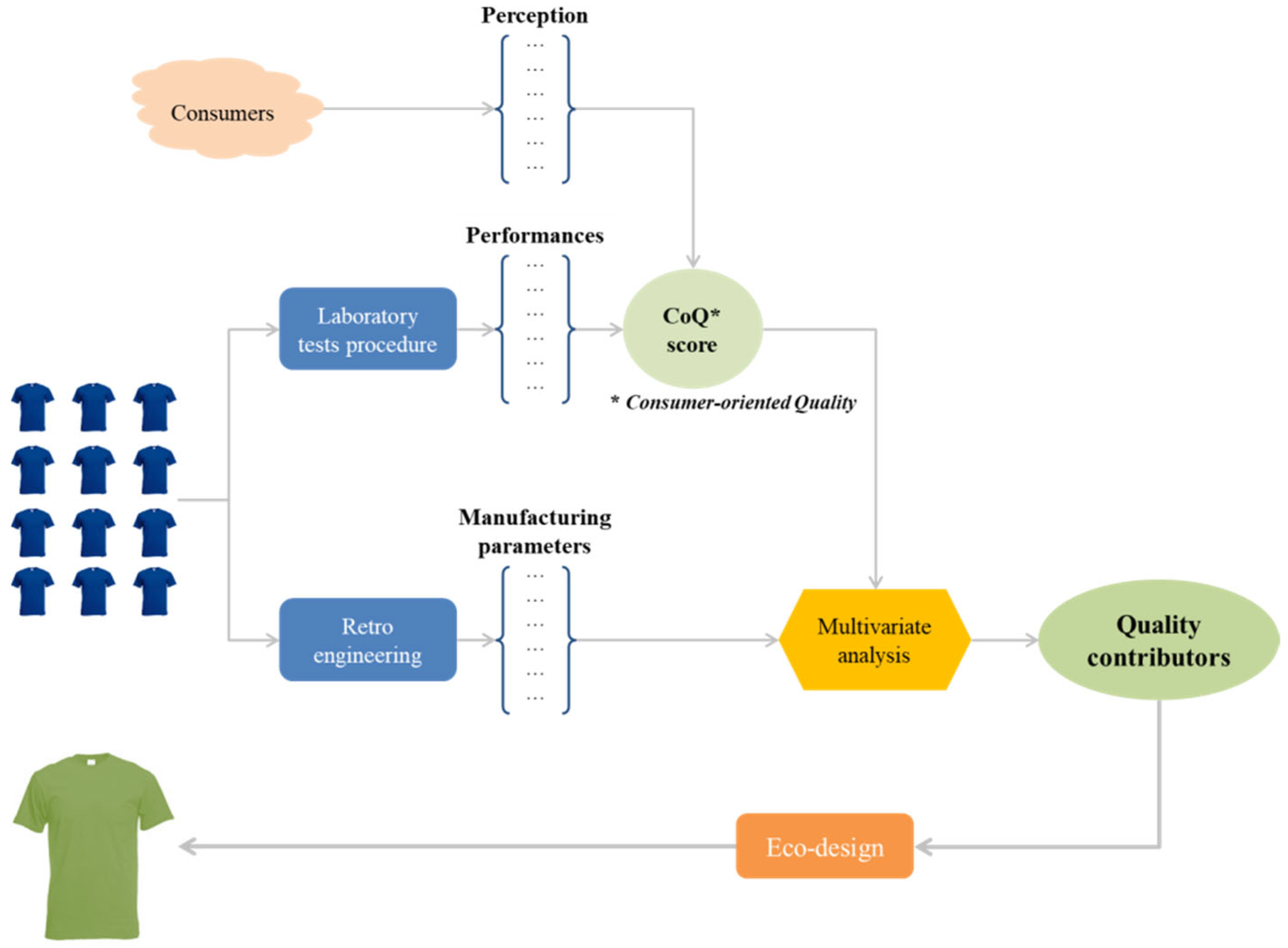

:1. Introduction

2. Materials and Methods

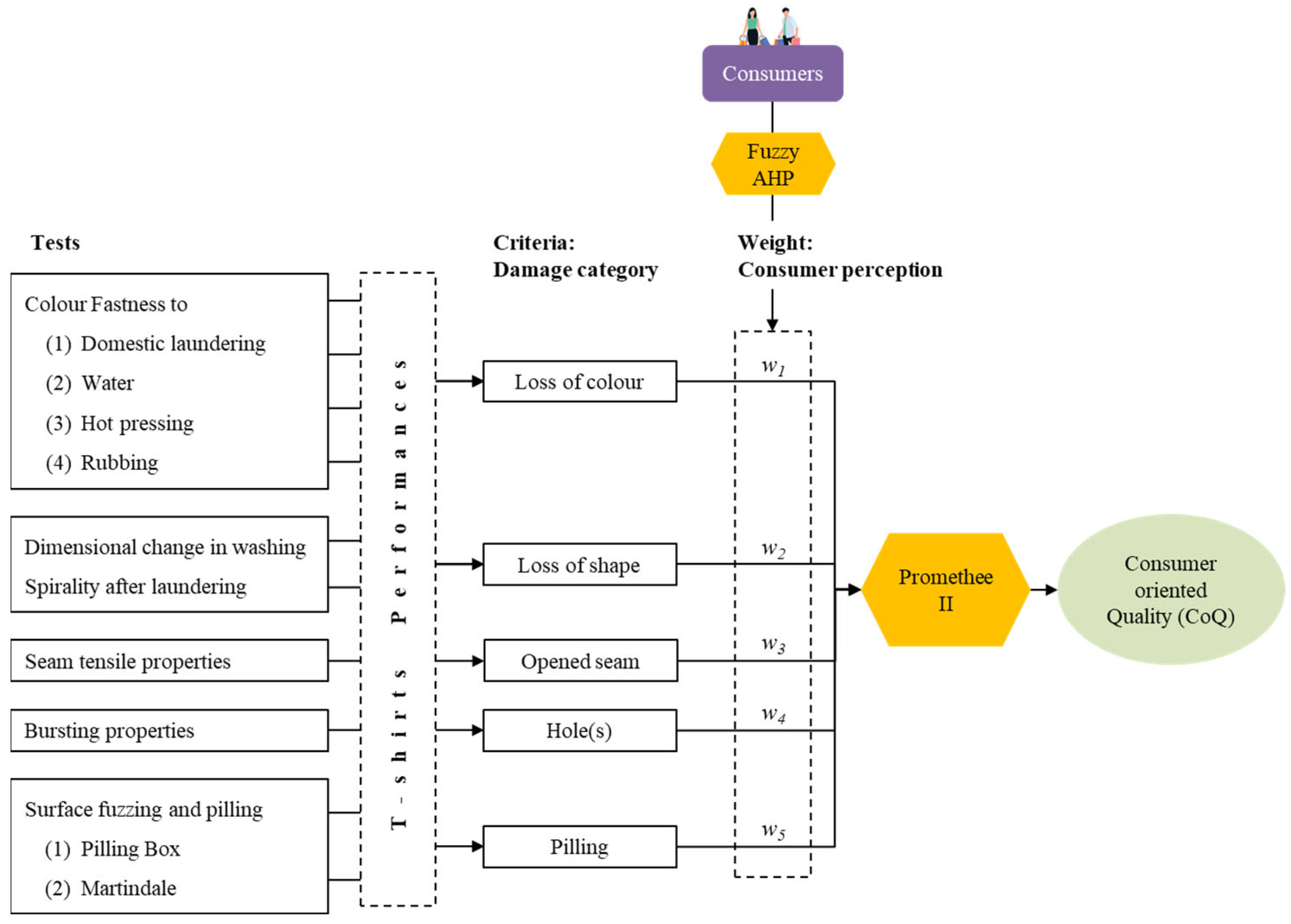

2.1. Consumer-Oriented Quality (CoQ) Computation Method

2.2. Collection of Manufacturing Parameters

2.3. Identification of Quality Contributors

2.4. Case Study: T-Shirt

3. Results

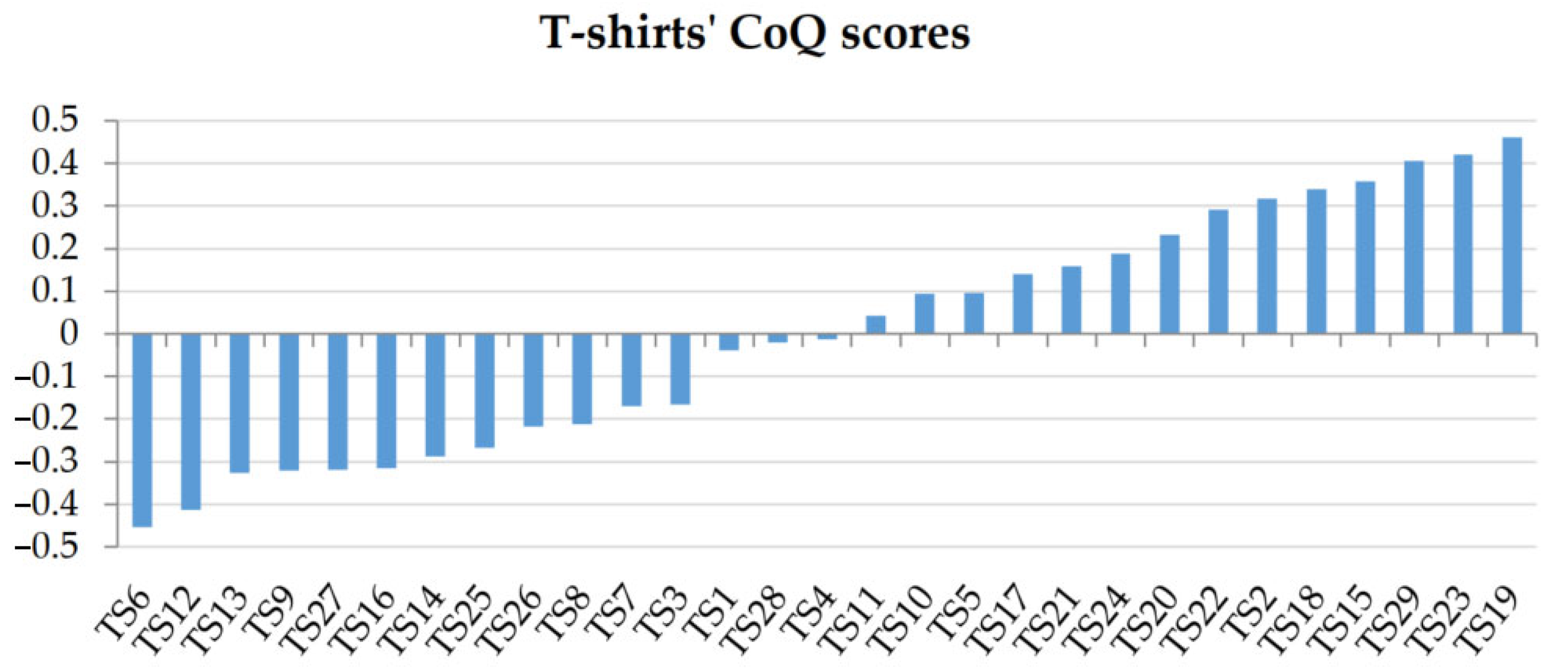

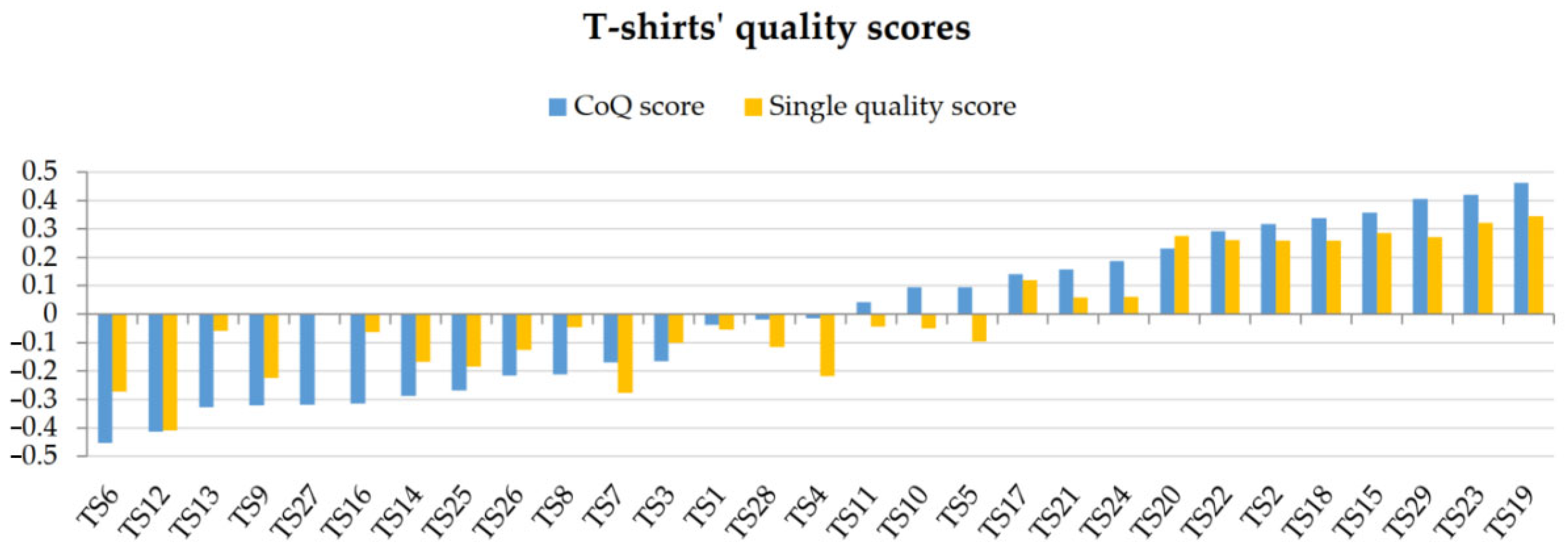

3.1. Computed Consumer-Oriented Quality Score

3.2. Manufacturing and Structural Parameters

3.2.1. T-Shirts Population: An Overview

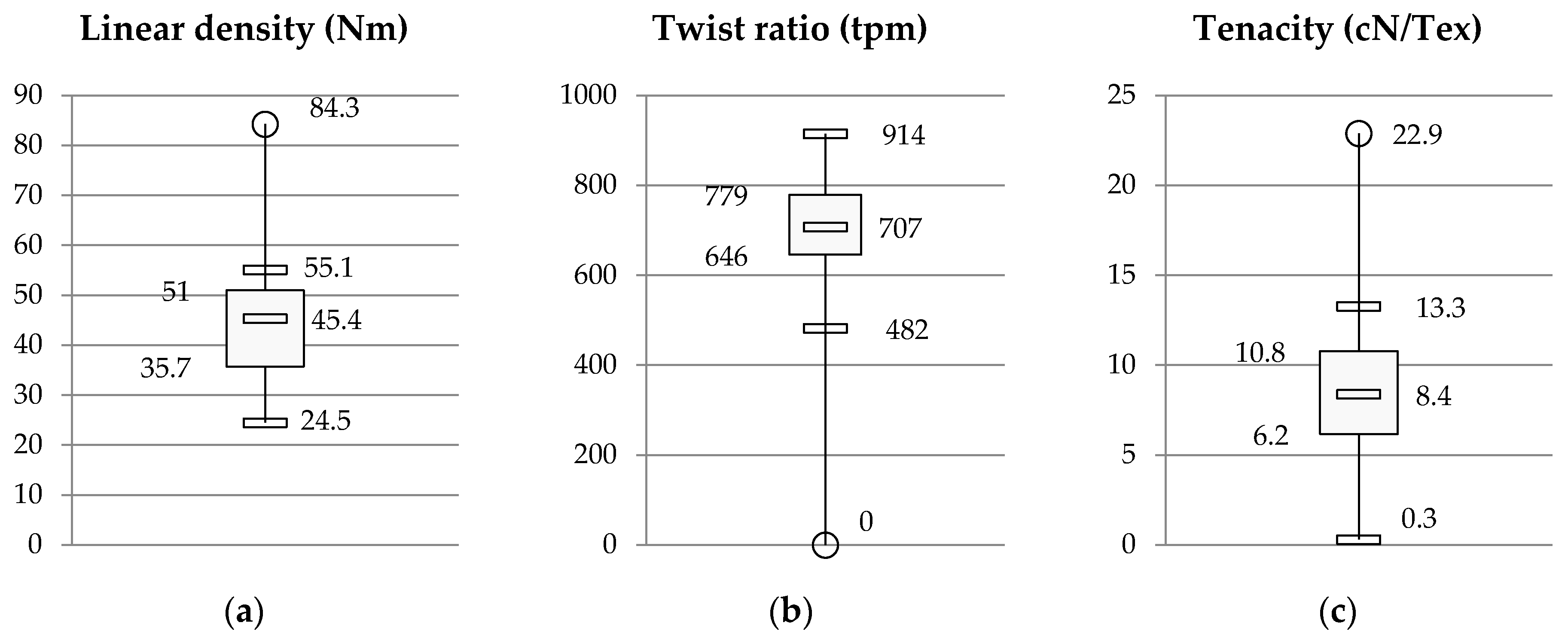

3.2.2. Fabric Yarn

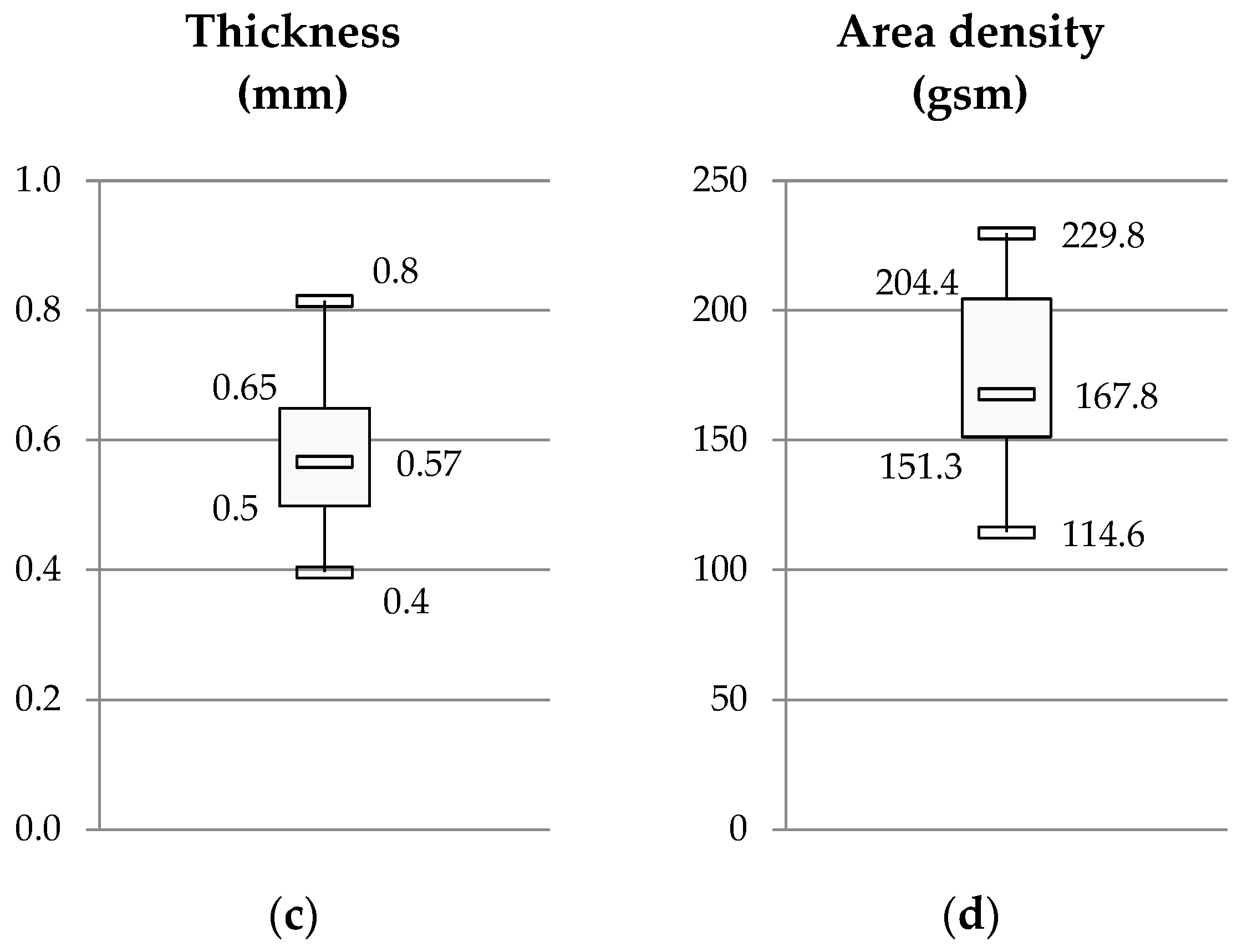

3.2.3. Main Fabric

3.2.4. Machine Parameters

3.3. Identification of Critical Quality Contributors

3.3.1. Variables Selection

- the yarn and fabric manufacturing processes, which are both qualitative;

- structure, which is qualitative and implied in the stitch length;

- the direction of twist, which is identical for all yarns (Z twist direction was found);

- the number of single yarns twisted together, which is also identical for all.

3.3.2. Validation of the PCA Process

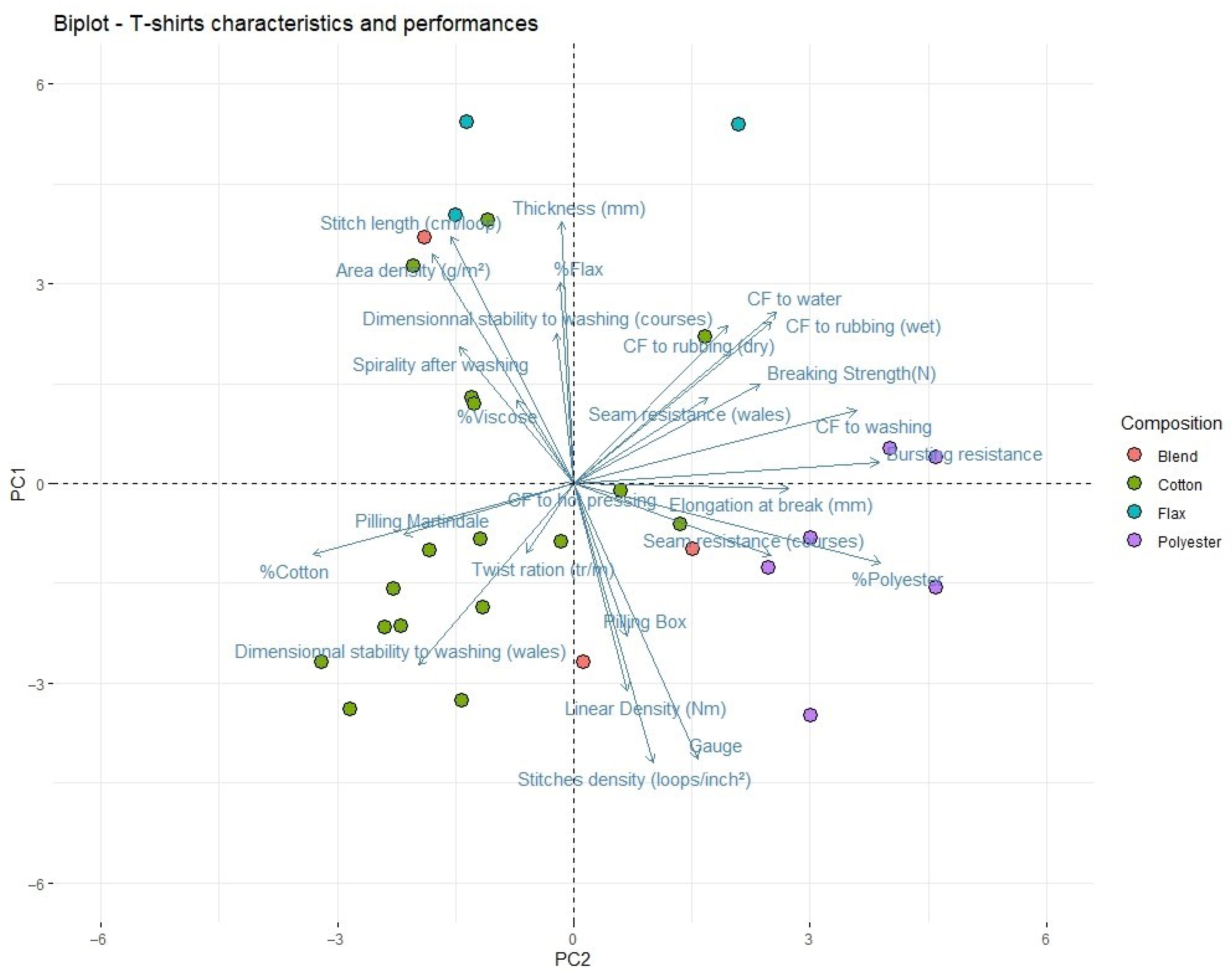

3.3.3. Interpretation

- Statistically, the cotton products seem not to be related to any structural parameters. However, being the most represented category and with a wide range of characteristics, no obvious observations appear.

- The polyester products are knitted on the finest gauges and consequently are thinner and the denser. Combined with a high yarn tenacity and elongation at break, the polyester products appear to be the most resistant to bursting.

- The flax products are made from the thicker yarns and represent the highest values of area density and thickness. One of them presents a good yarn tenacity, however, due to technical limits they are also characterized by low stitches density values, which transcribes an opened structure.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- UNEP. UN Alliance For Sustainable Fashion Addresses Damage of ‘Fast Fashion’. 2019. Available online: https://www.unenvironment.org/news-and-stories/press-release/un-alliance-sustainable-fashion-addresses-damage-fast-fashion (accessed on 17 March 2020).

- UNEP. UN Launches Drive to Highlight Environmental Cost of Staying Fashionable. 2019. Available online: https://news.un.org/en/story/2019/03/1035161 (accessed on 17 March 2020).

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef] [Green Version]

- Quantis. Measuring Fashion: Environmental Impact of the Global Apparel and Footwear Industries Study; Quantis: Lausanne, Switzerland, 2018. [Google Scholar]

- Boucher, J.; Friot, D. Microplastiques Primaires Dans les Océans: Évaluation Mondiale des Sources; UICN: Gland, Switzerland, 2020. [Google Scholar]

- Herrmann, S. A New Textiles Economy: Redesigning Fashion’s Future. Ellen MacArthur Foundation, Rapport, 150. 2017. Available online: http://www.ellenmacarthurfoundation.org/publications (accessed on 17 March 2020).

- Anguelov, N. The Dirty Side of the Garment Industry. Fast Fashion and Its Negative Impact on Environment and Society; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Remy, N.; Speelman, E.; Swartz, S. Style That’s Sustainable: A New Fast-Fashion Formula; McKinsey & Company: New York, NY, USA, 2016; Available online: https://www.mckinsey.com/business-functions/sustainability/our-insights/style-thats-sustainable-a-new-fast-fashion-formula (accessed on 17 March 2020).

- Beton, A.; Dias, D.; Farrant, L.; Gibon, T.; Le Guern, Y.; Desaxce, M.; Perwuelz, A.; Boufateh, I. Environmental Improvement Potential of Textiles (IMPRO-Textiles); Wolf, O., Kougoullis, J., Cordella, M., Dodd, N., Eds.; JRC Scientific And Policy Reports; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Cotton Incorporated. LCA Update of Cotton Fiber and Fabric Life Cycle Inventory; Cotton Incorporated: Cary, NC, USA, 2017. [Google Scholar]

- Roos, S.; Sandin, G.; Zamani, B.; Peters, G. Environmental Assessment of Swedish Fashion Consumption Five Garments—Sustainable Futures; Mistra Future Fashion: Göteborg, Sweden, 2015. [Google Scholar]

- Sandin, G.; Roos, S.; Spak, B.; Zamani, B.; Peters, G. Environmental Assessment of Swedish Clothing Consumption: Six Garments—Sustainable Futures; Mistra Future Fashion: Göteborg, Sweden, 2019. [Google Scholar]

- Steinberger, J.K.; Friot, D.; Jolliet, O.; Erkman, S. A spatially explicit life cycle inventory of the global textile chain. Int. J. Life Cycle Assess. 2009, 14, 443–455. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Xiao, R.; Yuan, Z. Life cycle assessment of cotton T-shirts in China. Int. J. Life Cycle Assess. 2015, 20, 994–1004. [Google Scholar] [CrossRef]

- Ellebaek Larsen, S.; Hansen, J.; Knudsen, H.H.; Wenzel, H.; Larsen, H.F.; Moller Kristensen, F. EDIPTEX—Environmental Assessment of Textiles. 2007. Available online: http://orbit.dtu.dk/en/publications/ediptex--environmental-assessment-of-textiles(fa09875a-d870-47d7-bcc1-b6be72c992bf).html (accessed on 17 March 2020).

- Bakker, C.; Schuit, C.S. The Long View: Exploring Product Lifetime Extension; United Nations Environment Programme: Nairobi, Kenya, 2017; pp. 1–74. [Google Scholar]

- Böckin, D.; Willskytt, S.; André, H.; Tillman, A.; Söderman, M.L. How product characteristics can guide measures for resource efficiency—A synthesis of assessment studies. Resour. Conserv. Recycl. 2020, 154, 104582. [Google Scholar] [CrossRef]

- Cooper, T. Beyond Recycling: The Longer Life Option; The New Economics Foundation: London, UK, 1994. [Google Scholar]

- De Saxce, M.; Pesnel, S.; Perwuelz, A. LCA of bed sheets—Some relevant parameters for lifetime assessment. J. Clean. Prod. 2012, 37, 221–228. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Suarez-Eiroa, B.; Fernandez, E.; Méndez-Martinez, G.; Soto-Oñate, D. Operational principles of circular economy for sustainable development: Linking theory and practice. J. Clean. Prod. 2019, 214, 952–961. [Google Scholar] [CrossRef]

- Cox, J.; Griffith, S.; Giorgi, S.; King, G. Consumer understanding of product lifetimes. Resour. Conserv. Recycl. 2013, 79, 21–29. [Google Scholar] [CrossRef]

- Cooper, T.; Hill, H.; Kininmonth, J.; Townsend, K.; Hughes, M. Design for Longevity: Guidance on Increasing the Active Life of Clothing; WRAP: London, UK, 2013. [Google Scholar]

- Laitala, K.; Boks, C.; Klepp, I.G. Making Clothing Last: A Design Approach for Reducing the Environmental Impacts. Int. J. Des. 2015, 9, 93–107. [Google Scholar]

- Niinimäki, K.; Hassi, L. Emerging design strategies in sustainable production and consumption of textiles and clothing. J. Clean. Prod. 2011, 19, 1876–1883. [Google Scholar] [CrossRef]

- Maldini, I.; Stappers, P.J.; Gimeno-martinez, J.C.; Daanen, H.A.M. Assessing the impact of design strategies on clothing lifetimes, usage and volumes: The case of product personalisation. J. Clean. Prod. 2019, 210, 1414–1424. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Lionberger, R.A.; Lee, S.L.; Lee, L.; Raw, A.; Yu, L.X. Quality by Design: Concepts for ANDAs. AAPS J. 2008, 10, 268–276. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, L.X.; Amidon, G.; Khan, M.A.; Hoag, S.W.; Polli, J.; Raju, G.K.; Woodcock, J. Understanding Pharmaceutical Quality by Design. AAPS J. 2014, 16, 771–783. [Google Scholar] [CrossRef] [Green Version]

- Afifi, A.; May, S.; Clark, V.A. Chapter 1: What is multivariate analysis? In Computer-Aided Multivariate Analysis, 4th ed.; Taylor & Francis: Abingdon, UK, 2003; Available online: https://books.google.fr/books?id=Gejr3I40mHsC (accessed on 17 March 2020).

- Hamdi, T.; Ghith, A.; Fayala, F. A principal component analysis (PCA) method for predicting the correlation between some fabric parameters and the drap. AUTEX Res. J. 2014, 14, 10–15. [Google Scholar] [CrossRef] [Green Version]

- Umair, M.; Shaker, K.; Ahmad, N.; Hussain, M.; Jabbar, M.; Nawab, Y. Simultaneous Optimization of Woven Fabric Properties Using Principal Component Analysis. J. Nat. Fibers 2017, 14, 846–857. [Google Scholar] [CrossRef]

- Bertaux, E.; Lewandowski, M.; Derler, S. Relationship between Friction and Tactile Properties for Woven and Knitted Fabrics. Text. Res. J. 2007, 77, 387–396. [Google Scholar] [CrossRef]

- Bacci, L.; Camilli, F.; Drago, S.; Magli, M.; Vagnoni, E.; Mauro, A.; Predieri, S. Sensory evaluation and instrumental measurements to determine tactile properties of wool fabrics. Text. Res. J. 2012, 82, 1430–1441. [Google Scholar] [CrossRef]

- Jollife, I.T.; Cadima, J. Principal component analysis: A review and recent developments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374. [Google Scholar] [CrossRef]

- Muñoz, A.M. Universal, product and attribute specific scaling and the development of common lexicons in descriptive analysis. J. Sens. Stud. 1997, 13, 57–75. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy Sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef] [Green Version]

- Kahraman, C.; Onar, S.C.; Oztaysi, B. Fuzzy Multicriteria Decision-Making: A Literature Review. Int. J. Comput. Intell. Syst. 2015, 8, 637–666. [Google Scholar] [CrossRef] [Green Version]

- Zeng, X.; Koehl, L.; Sanoun, M.; Bueno, M.A.; Renner, M. Integration of human knowledge and measured data for optimization of fabric hand. Int. J. Gen. Syst. 2004, 33, 243–258. [Google Scholar] [CrossRef]

- He, Y.; Tang, X.; Chang, W. Technical Decomposition Approach of Critical to Quality Characteristics for Product Design for Six Sigma. Qual. Reliab. Eng. Int. 2010, 26, 325–339. [Google Scholar] [CrossRef]

- Benkirane, R.; Thomassey, S.; Koehl, L.; Perwuelz, A. A consumer-based textile quality scoring model using multi-criteria decision making. J. Eng. Fiber. Fabr. 2019, 14, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Benkirane, R.; Thomassey, S.; Koehl, L.; Perwuelz, A. Standards Selection Approach for Clothing Longevity Indicators. In Proceedings of the 4th PLATE 2021 Virtual Conference, Limerick, Ireland, 26–28 May 2021; p. 7. [Google Scholar]

- Benkirane, R.; Thomassey, S.; Koehl, L.; Perwuelz, A. A Performance and Consumer-based Lifespan Evaluation for T-shirt Eco-design. In Proceedings of the 3rd PLATE 2019 Conference, Berlin, Germany, 18–20 September 2019; pp. 59–63. [Google Scholar]

- Bide, M. Testing textile durability. In Understanding and Improving the Durability of Textiles; Annis, P.A., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2012; pp. 126–142. [Google Scholar]

- Fulton, M.; Rezazadeh, M.; Torvi, D. Tests for evaluating textile aging. In Advanced Characterization and Testing of Textiles; Jackson, D., Webber, S., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 93–125. [Google Scholar]

- Ray, S.C. Process control in knitting. In Process Control in Textile Manufacturing; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 243–264. [Google Scholar]

- Saville, B.P. Serviceability. In Physical Testing of Textiles, 1st ed.; Saville, B.P., Ed.; The Textile Institute Book Series; Woodhead Publishing Limited: Cambridge, UK, 1999; pp. 184–208. [Google Scholar]

- Shaw, A. Durability of protective clothing. In Understanding and Improving the Durability of Textiles; Annis, P.A., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2012; pp. 174–183. [Google Scholar]

- Nayak, R.K.; Padhye, R. The care of apparel products. In Textiles and Fashion: Materials, Design and Technology; Sinclair, R., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 799–822. [Google Scholar]

- Raja, V. Introduction to reverse engineering. In Reverse Engineering: An Industrial Perspective; Fernandes, K.J., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; p. 242. [Google Scholar]

- Das Gupta, S.; Mukhopadhyay, R.; Baranwal, K.C.; Bhowmick, A.K. Reverse engineering concepts. In Reverse Engineering of Rubber Products: Concepts, Tools, and Techniques; CRC Press: Boca Raton, FL, USA, 2013; pp. 109–132. [Google Scholar]

- Elhawary, I.A. Fibre to yarn: Staple-yarn spinning. In Textiles and Fashion: Materials, Design and Technology; Sinclair, R., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 191–212. [Google Scholar]

- Power, E.J. Yarn to fabric: Knitting. In Textiles and Fashion: Materials, Design and Technology; Sinclair, R., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 289–305. [Google Scholar]

- FD CEN ISO/TR 11827; Textiles—Composition Testing—Identification of Fibres. ISO: London, UK, 2016.

- NF EN ISO 5084; Textiles. Determination of Thickness of Textiles and Textile Products. ISO: London, UK, 1996.

- NF EN 12127; Textiles. Fabrics. Determination of Mass per Unit Area Using Small Samples. ISO: London, UK, 1998.

- Ucar, N.; Ertugrul, S. Predicting Circular Knitting Machine Parameters for Cotton Plain Fabrics Using Conventional and Neuro-Fuzzy Methods. Text. Res. 2002, 72, 361–366. [Google Scholar] [CrossRef]

- NF EN 14971; Textiles—Knitted Fabrics—Determination of Number of Stitches per Unit Length and Unit Area. AFNOR: Paris, France, 2006.

- NF EN 14970; Textiles—Knitted Fabrics—Determination of Stitch Length and Yarn Linear Density in Weft Knitted Fabrics. AFNOR: Paris, France, 2006.

- NF ISO 4915; Textiles—Stitch Types—Classification and Terminology. AFNOR: Paris, France, 2015.

- NF G 07-079; Textiles—Testing Threads—Determining the Twisting of Threads by Untwisting/Retwisting with a Double Re-Test. AFNOR: Paris, France, 2011.

- NF EN ISO 2062; Textiles—Yarns from Packages—Determination of Single-End Breaking Force and Elongation at Break Using Constant Rate of Extension (CRE) Tester. ISO: London, UK, 2010.

- Mardia, K.V.; Kent, J.T.; Bibby, J. Introduction. In Multivariate Analysis; Academic Press. Inc.: London, UK, 1979; p. 518. [Google Scholar]

- Jolliffe, I.T.; Morgan, B. Principal component analysis and exploratory factor analysis. Stat. Methods Med. Res. 1992, 1, 69–95. [Google Scholar] [CrossRef]

- Lebart, L.; Morineau, A.; Piron, M. Analyse en composantes principales. In Statistique Exploratoire Multidimensionnelle; Dunod: Paris, France, 1995; pp. 32–57. [Google Scholar]

- Mardia, K.V.; Kent, J.T.; Bibby, J.M. Principal component analysis. In Multivariate Analysis; Academic Press Inc.: London, UK, 1979; p. 518. [Google Scholar]

- WRAP; Gray, S. Mapping Clothing Impacts in Europe: The Environmental Cost; WRAP: London, UK, 2017. [Google Scholar]

- Brans, J.P. L’ingénièrie de la décision; Elaboration d’instruments d’aide à la décision. La méthode PROMETHEE. In L’Aide à la Décision: Nature, Instruments et Perspectives d’Avenir; Nadeau, R., Landry, M., Eds.; Presses de l’Université Laval: Québec, Canada, 1982; pp. 183–213. [Google Scholar]

- Brans, J.P.; Vincke, P.; Mareschal, B. How to select and how to rank projects: The PROMETHEE method. Eur. J. Oper. Res. 1986, 24, 228–238. [Google Scholar] [CrossRef]

- Kaiser, H.F. An index of factorial simplicity. Psychometrika 1974, 39, 31–36. [Google Scholar] [CrossRef]

- Tripathi, M.; Singal, S.K. Use of Principal Component Analysis for parameter selection for development of a novel Water Quality Index: A case study of river Ganga India. Ecol. Indic. 2019, 96, 430–436. [Google Scholar] [CrossRef]

- Sinclair, R. (Ed.) Understanding textile fibres and their properties: What is a textile fibre? In Textiles and Fashion; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; pp. 3–27. [Google Scholar]

- Mee-sung, C.; Ashdown, S.P. Effect of Changes in Knit Structure and Density on the Mechanical and. Text. Res. J. 2000, 12, 1033–1045. [Google Scholar]

- Ramey, H.H.; Lawson, R.; Worley, S. Relationship of cotton fiber properties to yarn tenacity. Text. Res. J. 1977, 685–691. [Google Scholar] [CrossRef]

- De Araujo, M.D.; Smith, G.W. Spirality of knitted fabrics—Part I: The nature of spirality. Text. Res. J. 1989, 247–256. [Google Scholar] [CrossRef]

- Kothari, V.K.; Singh, G.; Roy, K.; Varshney, R. Spirality of cotton plain knitted fabrics with respect to variation in yarn and machine parameters. Indian J. Fibre Text. Res. 2011, 36, 227–233. [Google Scholar]

- Oinuma, R.; Takeda, H. Spirality in plain-jersey fabrics knitted of three-ply cotton yarns. J. Text. Mach. Soc. Japan 1988, 39, 65–71. [Google Scholar] [CrossRef]

- Geršak, J. Key issues in developing a garment collection. In Design of Clothing Manufacturing Processes; The Textile Institute Book Series; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 53–86. [Google Scholar]

- Allwood, J.M.; Laursen, S.E. Well Dressed? The Present and Future Sustainability of Clothing and Textiles in the United Kingdom; University of Cambridge: Mill Lane, CA, USA, 2006. [Google Scholar]

| Test | Direction of Measurement | Unit | Best Grade |

|---|---|---|---|

| Loss of color | |||

| Color fastness to domestic laundering | /5 | To be maximized | |

| Color fastness to water | |||

| Color fastness to ironing | |||

| Color fastness to dry rubbing | |||

| Color fastness to wet rubbing | |||

| Loss of shape | |||

| Dimensional changes in washing and drying | Wales | % | To be minimized |

| Courses | |||

| Spirality after laundering | % | ||

| Opened seam | |||

| Seam tensile properties | Wales | % | To be maximized |

| Courses | |||

| Hole(s) | |||

| Bursting resistance (pneumatic method) | kPa | To be maximized | |

| Pilling | |||

| Surface fuzzing and pilling (Pilling box) | /5 | To be maximized | |

| Surface fuzzing and pilling (Martindale) |

| Collected Data | Unit | Data Collection Process |

|---|---|---|

| End-Product | ||

| Composition | % | FD CEN ISO/TR 11,827 [54] |

| Manufacturing process | - | |

| Thickness | mm | NF EN ISO 5084 [55] |

| Area density | gsm | NF EN 12,127 [56] |

| Knitted fabric | ||

| Structure (pattern) | - | Visual observation |

| Machine gauge | needle/inch | Computed from [57] |

| Wale density | wales/inch | NF EN 14,971 [58] |

| Courses density | courses/inch | |

| Stitches density 1 | stitches/inch2 | |

| Stitch length 2 | cm/loop | NF EN 14,970 [59] |

| Side seam | ||

| Seam type | - | NF ISO 4915 [60] |

| Number of sewing threads | - | |

| Seam density | seam/inch | |

| Fabric yarn | ||

| Manufacturing process | - | |

| Number of single yarns twisted together | - | |

| Linear density | Nm (km/kg) | NF EN 14,970 [59] |

| Twist ratio | Tpm | NF G 07-079 [61] |

| Tenacity | cN/Tex | NF EN ISO 2062 [62] |

| Elongation at break | mm | NF EN ISO 2062 [62] |

| Number of T-Shirts | (%) | |

|---|---|---|

| Composition | ||

| Cotton | 17 | 58.6 |

| Polyester | 6 | 20.8 |

| Flax | 3 | 10.3 |

| Blend | 3 | 10.3 |

| Main fabric manufacturing process | ||

| Weft knitting | 26 | 89.6 |

| Warp knitting | 3 | 10.3 |

| Structure | ||

| Jersey | 24 | 82.7 |

| Ribs 1 × 1 | 2 | 6.9 |

| Undefined | 3 | 10.3 |

| Yarn manufacturing process | ||

| Ring Spinning (RS) | 20 | 69 |

| Rotor | 2 | 6.9 |

| Multifilament yarn (MTFT) | 1 | 3.4 |

| Wet Spinning (WS) | 3 | 10.3 |

| Undefined | 3 | 10.3 |

| Thickness | Area Density | Wales per inch | Courses per inch | Stitches Density | Stitch Length | Gauge | Linear Density | Twist Ratio | Breaking Strength | Elongation at Break | Tenacity | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | - | |||||||||||

| Area density | 0.69 | - | ||||||||||

| Wales per inch | −0.76 | −0.82 | - | |||||||||

| Courses per inch | −0.65 | −0.57 | 0.81 | - | ||||||||

| Stitches density | −0.75 | −0.74 | 0.95 | 0.95 | - | |||||||

| Stitch length | 0.76 | 0.70 | −0.83 | −0.56 | −0.72 | - | ||||||

| Gauge | −0.71 | −0.80 | 0.92 | 0.80 | 0.89 | −0.81 | - | |||||

| Linear Density | −0.53 | −0.68 | 0.69 | 0.79 | 0.79 | −0.31 | 0.72 | - | ||||

| Twist ratio | 0.01 | −0.04 | 0.14 | 0.16 | 0.09 | −0.09 | 0.17 | −0.06 | - | |||

| Breaking Strength | 0.21 | 0.14 | −0.23 | −0.36 | −0.32 | −0.06 | −0.17 | −0.44 | 0.03 | - | ||

| Elongation at break | 0.10 | −0.14 | 0.13 | −0.06 | 0.00 | −0.27 | 0.14 | −0.13 | 0.30 | 0.58 | - | |

| Tenacity | 0.11 | −0.08 | 0.02 | −0.11 | −0.08 | −0.20 | 0.11 | −0.19 | 0.28 | 0.91 | 0.71 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benkirane, R.; Thomassey, S.; Koehl, L.; Perwuelz, A. A New Longevity Design Methodology Based on Consumer-Oriented Quality for Fashion Products. Sustainability 2022, 14, 7696. https://doi.org/10.3390/su14137696

Benkirane R, Thomassey S, Koehl L, Perwuelz A. A New Longevity Design Methodology Based on Consumer-Oriented Quality for Fashion Products. Sustainability. 2022; 14(13):7696. https://doi.org/10.3390/su14137696

Chicago/Turabian StyleBenkirane, Romain, Sébastien Thomassey, Ludovic Koehl, and Anne Perwuelz. 2022. "A New Longevity Design Methodology Based on Consumer-Oriented Quality for Fashion Products" Sustainability 14, no. 13: 7696. https://doi.org/10.3390/su14137696

APA StyleBenkirane, R., Thomassey, S., Koehl, L., & Perwuelz, A. (2022). A New Longevity Design Methodology Based on Consumer-Oriented Quality for Fashion Products. Sustainability, 14(13), 7696. https://doi.org/10.3390/su14137696