Exploring the Dynamic of a Circular Ecosystem: A Case Study about Drivers and Barriers

Abstract

:1. Introduction

2. Literature Review

2.1. Drivers and Barriers of a Circular Economy

2.2. From a Business Ecosystem to a Circular Ecosystem

3. Materials and Methods

3.1. Data Collection

3.2. Data Analysis

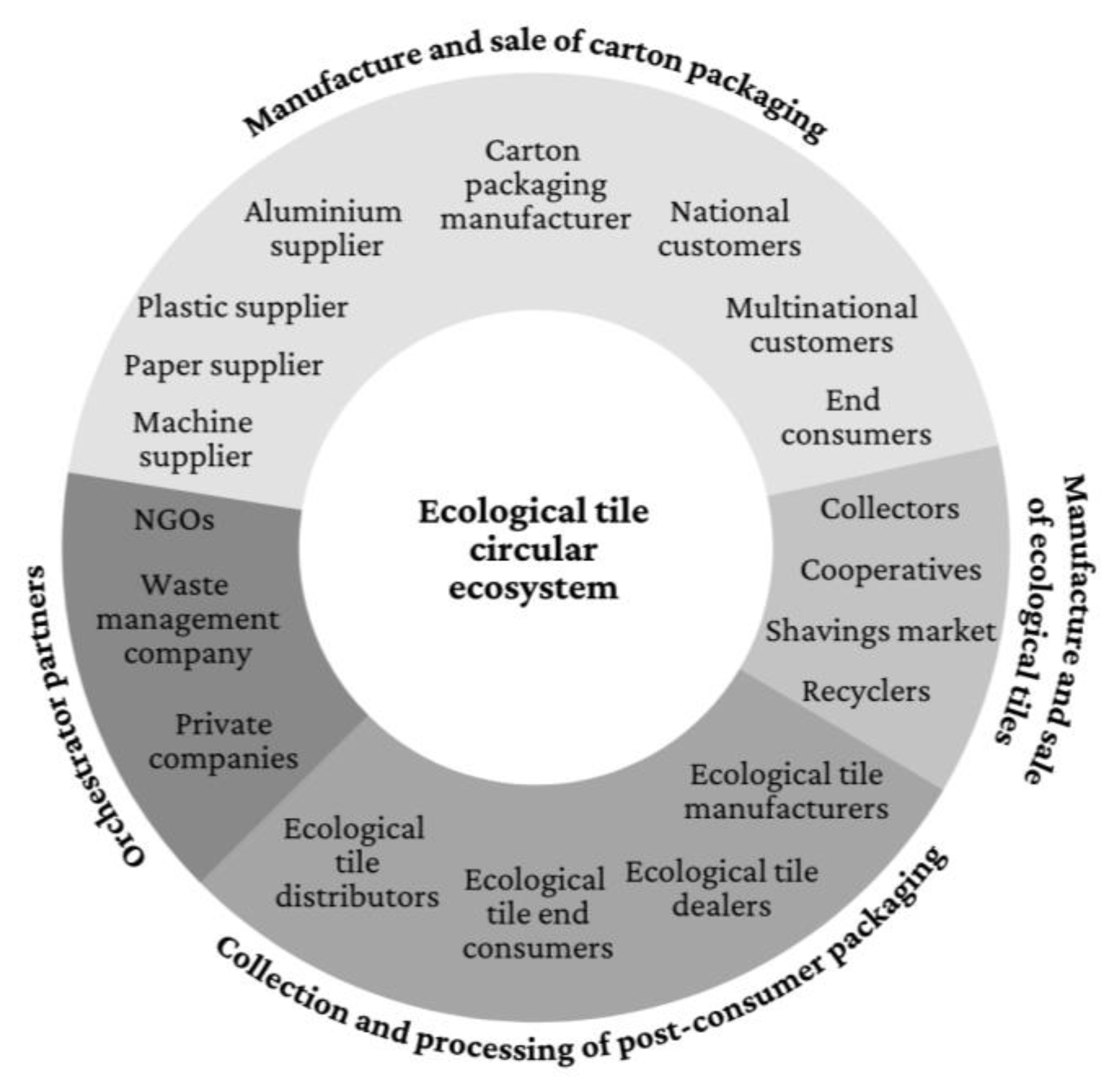

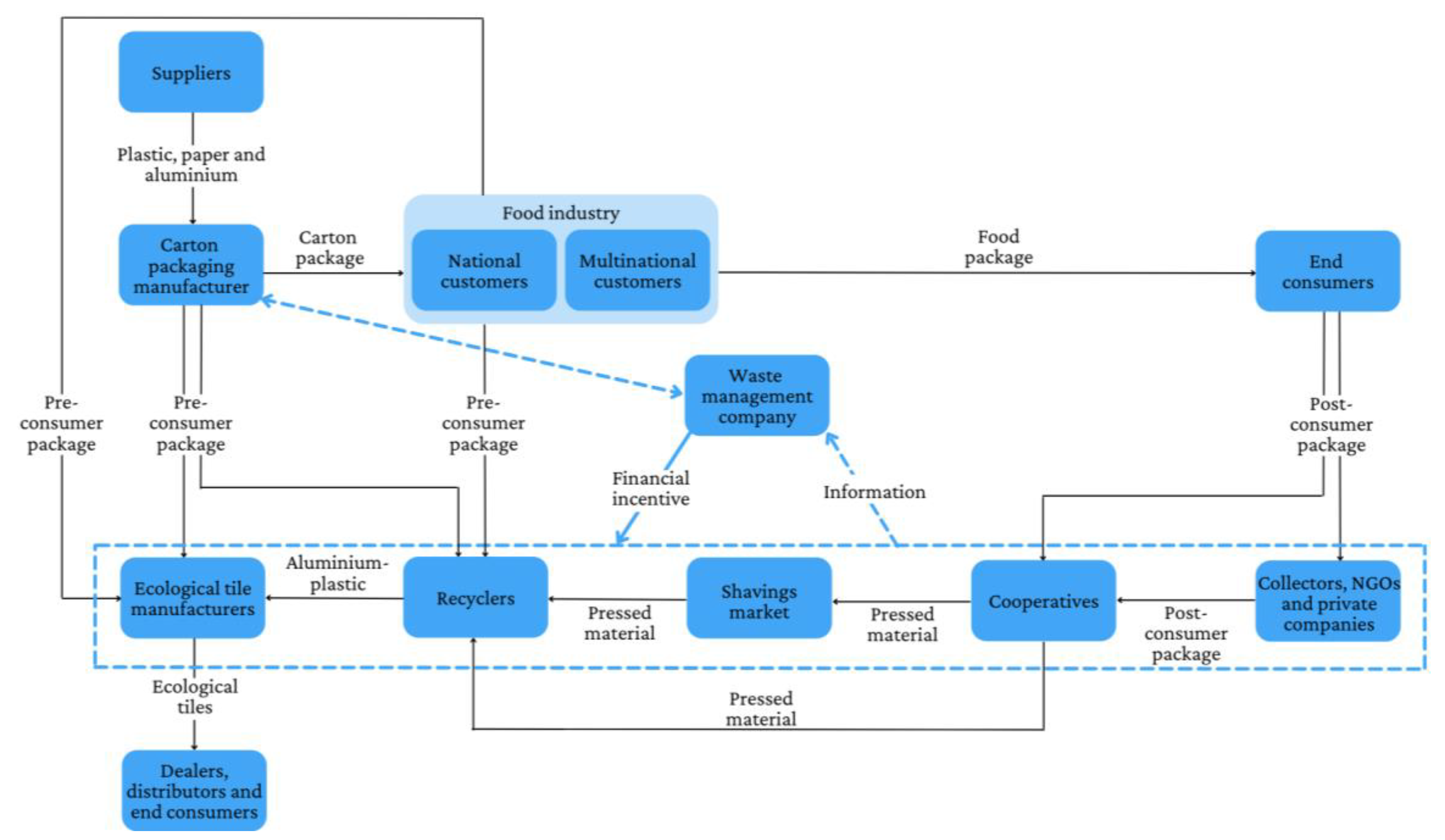

3.3. Case Description—Ecological Tiles Circular Ecosystem Characterization

4. Results

4.1. Drivers and Barriers in a Circular Ecosystem

4.1.1. Drivers

4.1.2. Barriers

5. Discussion

6. Theoretical Contributions

7. Practical Implications

8. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Ritala, P.; Mäkinen, S.J. Exploring Institutional Drivers and Barriers of the Circular Economy: A Cross-Regional Comparison of China, the US, and Europe. Resour. Conserv. Recycl. 2018, 135, 70–82. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking Circular Business: A Framework of Barriers and Drivers. J. Clean. Prod. 2019, 212, 90–98. [Google Scholar] [CrossRef]

- Agyemang, M.; Kusi-Sarpong, S.; Khan, S.A.; Mani, V.; Rehman, S.T.; Kusi-Sarpong, H. Drivers and Barriers to Circular Economy Implementation: An Explorative Study in Pakistan’s Automobile Industry. Manag. Decis. 2019, 57, 971–994. [Google Scholar] [CrossRef]

- Galvão, G.D.A.; Evans, S.; Ferrer, P.S.S.; de Carvalho, M.M. Circular Business Model: Breaking down Barriers towards Sustainable Development. Bus. Strategy Environ. 2022, 31, 1504–1524. [Google Scholar] [CrossRef]

- Oxford Learner’s Dictionaries. Available online: https://www.oxfordlearnersdictionaries.com/us/definition/english/driver?q=driversURL (accessed on 12 May 2022).

- Ahlborg, H.; Hammar, L. Drivers and Barriers to Rural Electrification in Tanzania and Mozambique-Grid Extension, Off-Grid and Renewable Energy Sources. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011. [Google Scholar]

- García-Quevedo, J.; Jové-Llopis, E.; Martínez-Ros, E. Barriers to the Circular Economy in European Small and Medium-Sized Firms. Bus. Strategy Environ. 2020, 29, 2450–2464. [Google Scholar] [CrossRef]

- Antikainen, M.; Valkokari, K. A Framework for Sustainable Circular Business Model Innovation. Technol. Innov. Manag. Rev. 2016, 6, 5–12. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Valkokari, K.; Valkokari, P.; Palomäki, K.; Uusitalo, T.; Reunanen, M.; Macchi, M.; Rana, P.; Liyanage, J.P. Road-Mapping the Business Potential of Sustainability within the European Manufacturing Industry. Foresight 2014, 16, 360–384. [Google Scholar] [CrossRef]

- Pieroni, M.P.P.; McAloone, T.C.; Pigosso, D.C.A. Business Model Innovation for Circular Economy and Sustainability: A Review of Approaches. J. Clean. Prod. 2019, 215, 198–216. [Google Scholar] [CrossRef]

- Bertassini, A.C.; Zanon, L.G.; Azarias, J.G.; Gerolamo, M.C.; Ometto, A.R. Circular Business Ecosystem Innovation: A Guide for Mapping Stakeholders, Capturing Values, and Finding New Opportunities. Sustain. Prod. Consum. 2021, 27, 436–448. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013; Volume 40, pp. 201–205. [Google Scholar]

- Almpanopoulou, A.; Ritala, P.; Blomqvist, K. Innovation Ecosystem Emergence Barriers: Institutional Perspective. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Hawaii, HI, USA, 8–11 January 2019. [Google Scholar]

- Tate, W.L.; Bals, L.; Bals, C.; Foerstl, K. Seeing the Forest and Not the Trees: Learning from Nature’s Circular Economy. Resour. Conserv. Recycl. 2019, 149, 115–129. [Google Scholar] [CrossRef]

- Hsieh, Y.C.; Lin, K.Y.; Lu, C.; Rong, K. Governing a Sustainable Business Ecosystem in Taiwan’s Circular Economy: The Story of Spring Pool Glass. Sustainability 2017, 9, 1068. [Google Scholar] [CrossRef] [Green Version]

- Adner, R.; Kapoor, R. Value Creation in Innovation Ecosystems: How the Structure of Technological Interdependence Affects Firm Performance in New Technology Generations. Strateg. Manag. J. 2010, 31, 306–333. [Google Scholar] [CrossRef]

- Jacobides, M.G.; Cennamo, C.; Gawer, A. Towards a Theory of Ecosystems. Strateg. Manag. J. 2018, 39, 2255–2276. [Google Scholar] [CrossRef] [Green Version]

- De Vasconcelos Gomes, L.A.; Facin, A.L.F.; Salerno, M.S.; Ikenami, R.K. Unpacking the Innovation Ecosystem Construct: Evolution, Gaps and Trends. Technol. Forecast. Soc. Change 2018, 136, 30–48. [Google Scholar] [CrossRef]

- Adner, R. Ecosystem as Structure: An Actionable Construct for Strategy. J. Manag. 2017, 43, 39–58. [Google Scholar] [CrossRef]

- Thomas, L.D.W.; Autio, E. Innovation Ecosystems in Management: An Organizing Typology. In Oxford Research Encyclopedia of Business and Management; Oxford University Press: Oxford, UK, 2020. [Google Scholar]

- Pidun, U.; Reeves, M.; Schüssler, M. Do you need a business ecosystem? BCG Henderson Inst. 2019. Available online: https://www.bcg.com/en-br/publications/2019/do-you-need-business-ecosystem (accessed on 1 September 2020).

- Iansiti, M.; Levien, R. Strategy as ecology. Harv. Bus. Rev. 2004, 82, 68–78. [Google Scholar]

- Trevisan, A.H.; Castro, C.G.; Gomes, L.A.V.; Mascarenhas, J. Unlocking the Circular Ecosystem Concept: Evolution, Current Research, and Future Directions. Sustain. Prod. Consum. 2022, 29, 286–298. [Google Scholar] [CrossRef]

- Trevisan, A.H.; Zacharias, I.S.; Castro, C.G.; Mascarenhas, J. Circular economy actions in business ecosystems driven by digital technologies. Procedia CIRP 2021, 100, 325–330. [Google Scholar] [CrossRef]

- Ta, A.H.; Aarikka-Stenroos, L.; Litovuo, L. Customer Experience in Circular Economy: Experiential Dimensions among Consumers of Reused and Recycled Clothes. Sustainability 2022, 14, 509. [Google Scholar] [CrossRef]

- Aminoff, A.; Valkokari, K.; Antikainen, M.; Kettunen, O. Exploring Disruptive Business Model Innovation for the Circular Economy. In Proceedings of the Smart Innovation, Systems and Technologies, Bologna, Italy, 26–28 April 2017. [Google Scholar]

- Konietzko, J.; Bocken, N.; Hultink, E.J. Circular Ecosystem Innovation: An Initial Set of Principles. J. Clean. Prod. 2020, 253, 119942. [Google Scholar] [CrossRef]

- Brasil. Decreto Nº 11.043, de 13 de abril de 2022. Available online: https://www.in.gov.br/en/web/dou/-/decreto-n-11.043-de-13-de-abril-de-2022-393566799 (accessed on 13 June 2022).

- Ministério do Meio Ambiente–Secretaria de Qualidade Ambiental. Plano Nacional de Resíduos Sólidos; Ministério do Meio Ambiente (MMA): Brasília, Brazil, 2022. [Google Scholar]

- Silva, W.D.O.; Morais, D.C. Transitioning to a Circular Economy in Developing Countries: A Collaborative Approach for Sharing Responsibilities in Solid Waste Management of a Brazilian Craft Brewery. J. Clean. Prod. 2021, 319, 128703. [Google Scholar] [CrossRef]

- Mancini, S.D.; de Medeiros, G.A.; Paes, M.X.; de Oliveira, B.O.S.; Antunes, M.L.P.; de Souza, R.G.; Ferraz, J.L.; Bortoleto, A.P.; de Oliveira, J.A.P. Circular Economy and Solid Waste Management: Challenges and Opportunities in Brazil. Circ. Econ. Sustain. 2021, 1, 261–282. [Google Scholar] [CrossRef]

- Planalto. Available online: www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm (accessed on 13 April 2022).

- Jabbour, C.J.C.; de Camargo Fiorini, P.; Wong, C.W.Y.; Jugend, D.; De Sousa Jabbour, A.B.L.; Seles, B.M.R.P.; Pinheiro, M.A.P.; da Silva, H.M.R. First-Mover Firms in the Transition towards the Sharing Economy in Metallic Natural Resource-Intensive Industries: Implications for the Circular Economy and Emerging Industry 4.0 Technologies. Resour. Policy 2020, 66, 101596. [Google Scholar] [CrossRef]

- Sehnem, S.; Chiappetta Jabbour, C.J.; Farias Pereira, S.C.; de Sousa Jabbour, A.B.L. Improving Sustainable Supply Chains Performance through Operational Excellence: Circular Economy Approach. Resour. Conserv. Recycl. 2019, 149, 236–248. [Google Scholar] [CrossRef]

- Ito, H.; Alelweet, N.; Harrison, R.; Mitchell, A.; Parker, E. Should IKEA Expand into Brazil: A Study of Brazilian Consumer Behaviours. Int. J. Econ. Financ. Issues 2015, 5, 69–74. [Google Scholar]

- de Oliveira, F.R.; dos Santos, R.F.; França, S.L.B.; Rangel, L.A.D. Strategies and Challenges for the Circular Economy: A Case Study in Portugal and a Panorama for Brazil. Braz. Arch. Biol. Technol. 2020, 63, 646. [Google Scholar] [CrossRef]

- Guldmann, E.; Huulgaard, R.D. Barriers to Circular Business Model Innovation: A Multiple-Case Study. J. Clean. Prod. 2020, 243, 118160. [Google Scholar] [CrossRef]

- Govindan, K.; Nasr, A.K.; Karimi, F.; Mina, H. Circular Economy Adoption Barriers: An Extended Fuzzy Best–Worst Method Using Fuzzy DEMATEL and Supermatrix Structure. Bus. Strategy Environ. 2022, 31, 1566–1586. [Google Scholar] [CrossRef]

- Schmutz, M.; Som, C. Identifying the Potential for Circularity of Industrial Textile Waste Generated within Swiss Companies. Resour. Conserv. Recycl. 2022, 182, 106132. [Google Scholar] [CrossRef]

- Mangla, S.K.; Luthra, S.; Mishra, N.; Singh, A.; Rana, N.P.; Dora, M.; Dwivedi, Y. Barriers to Effective Circular Supply Chain Management in a Developing Country Context. Prod. Plan. Control 2018, 29, 551–569. [Google Scholar] [CrossRef] [Green Version]

- Rizos, V.; Behrens, A.; Kafyeke, T.; Hirschnitz Garbers, M.; Ioannou, A. The Circular Economy: Barriers and Opportunities for SMEs; CEPS: Brussels, Belgium, 2015. [Google Scholar]

- Rizos, V.; Behrens, A.; van der Gaast, W.; Hofman, E.; Ioannou, A.; Kafyeke, T.; Flamos, A.; Rinaldi, R.; Papadelis, S.; Hirschnitz-Garbers, M.; et al. Implementation of Circular Economy Business Models by Small and Medium-Sized Enterprises (SMEs): Barriers and Enablers. Sustainability 2016, 8, 1212. [Google Scholar] [CrossRef] [Green Version]

- Ormazabal, M.; Prieto-Sandoval, V.; Puga-Leal, R.; Jaca, C. Circular Economy in Spanish SMEs: Challenges and Opportunities. J. Clean. Prod. 2018, 185, 157–167. [Google Scholar] [CrossRef]

- Baldwin, C.Y. Bottlenecks, Modules and Dynamic Architectural Capabilities. In Harvard Business School Working Paper; Harvard Business School: Boston, MA, USA, 2015. [Google Scholar]

- Mäkinen, S.J.; Dedehayir, O. Business Ecosystem Evolution and Strategic Considerations: A Literature Review. In Proceedings of the 2012 18th International Conference on Engineering, Technology and Innovation, Munich, Germany, 18–20 June 2012. [Google Scholar]

- Hannah, D.P.; Eisenhardt, K.M. How Firms Navigate Cooperation and Competition in Nascent Ecosystems. Strateg. Manag. J. 2018, 39, 3163–3192. [Google Scholar] [CrossRef]

- Masucci, M.; Brusoni, S.; Cennamo, C. Removing Bottlenecks in Business Ecosystems: The Strategic Role of Outbound Open Innovation. Res. Policy 2020, 49, 103823. [Google Scholar] [CrossRef]

- Hannah, D.P.; Bremner, R.P.; Eisenhardt, K.M. Resource Redeployment in Business Ecosystems. Adv. Strateg. Manag. 2016, 35, 19–48. [Google Scholar] [CrossRef]

- Dąbrowska, J.; Almpanopoulou, A.; Brem, A.; Chesbrough, H.; Cucino, V.; Di Minin, A.; Giones, F.; Hakala, H.; Marullo, C.; Mention, A.-L.; et al. Digital transformation, for better or worse: A critical multi-level research agenda. RD Manag. 2022. [Google Scholar] [CrossRef]

- Shipilov, A.; Gawer, A. Integrating Research on Inter-Organizational Networks and Ecosystems. Acad. Manag. Ann. 2020, 14, 92–121. [Google Scholar] [CrossRef]

- Shi, Y.; Lu, C.; Hou, H.; Zhen, L.; Hu, J. Linking Business Ecosystem and Natural Ecosystem Together—A Sustainable Pathway for Future Industrialization. J. Open Innov. Technol. Mark. Complex. 2021, 7, 38. [Google Scholar] [CrossRef]

- Parida, V.; Burström, T.; Visnjic, I.; Wincent, J. Orchestrating Industrial Ecosystem in Circular Economy: A Two-Stage Transformation Model for Large Manufacturing Companies. J. Bus. Res. 2019, 101, 715–725. [Google Scholar] [CrossRef]

- Castro, C.G.; Trevisan, A.H.; Pigosso, D.C.A.; Mascarenhas, J. The Rebound Effect of Circular Economy: Definitions, Mechanisms and a Research Agenda. J. Clean. Prod. 2022, 345, 131136. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research Design and Methods, 4th ed.; SAGE: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Rong, K.; Hu, G.; Lin, Y.; Shi, Y.; Guo, L. Understanding Business Ecosystem Using a 6C Framework in Internet-of-Things-Based Sectors. Int. J. Prod. Econ. 2015, 159, 41–55. [Google Scholar] [CrossRef] [Green Version]

- Moore, J.F. Predators and Prey: A New Ecology of Competition; Moore, J.F. Predators and prey: A new ecology of competition. Harv. Bus. Rev. 1993, 71, 75–83. [Google Scholar]

- Eisenhardt, K.M.; Graebner, M.E. Theory Building from Cases: Opportunities and Challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Parker, C.; Scott, S.; Geddes, A. Snowball Sampling; Atkinson, P., Delamont, S., Cernat, A., Sakshaug, J.W., Williams, R.A., Eds.; SAGE Research Methods Foundations: New York, NY, USA, 2019; p. 2. [Google Scholar]

- Carter, N.; Bryant-Lukosius, D.; Dicenso, A.; Blythe, J.; Neville, A.J. The Use of Triangulation in Qualitative Research. Oncol. Nurs. Forum 2014, 41, 545–547. [Google Scholar] [CrossRef]

- MAXQDA. Available online: https://www.maxqda.com/brasil (accessed on 3 March 2022).

- Miles, M.B.; Huberman, A.M.; Saldaña, J. Qualitative Data Analysis—A Methods Sourcebook; SAGE Publications: New York, NY, USA, 2014. [Google Scholar]

- Gioia, D.A.; Corley, K.G.; Hamilton, A.L. Seeking Qualitative Rigor in Inductive Research: Notes on the Gioia Methodology. Organ. Res. Methods 2013, 16, 15–31. [Google Scholar] [CrossRef]

- Brasil. Lei Nº 12.305, de 2 de agosto de 2010. Available online: http://www.planalto.gov.br/ccivil_03/_ato2007-2010/2010/lei/l12305.htm (accessed on 4 April 2022).

- ISO. Available online: https://www.iso.org/iso-14001-environmental-management.html (accessed on 13 March 2022).

- Brasil. Auxílio emergencial 2021. Available online: https://www.gov.br/cidadania/pt-br/servicos/auxilio-emergencial (accessed on 2 April 2022).

- Bening, C.R.; Kahlert, S.; Asiedu, E. The True Cost of Solving the Plastic Waste Challenge in Developing Countries: The Case of Ghana. J. Clean. Prod. 2022, 330, 129649. [Google Scholar] [CrossRef]

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the Circular Economy to the UN Sustainable Development Goals through Sustainable Construction. Resour. Conserv. Recycl. 2022, 178, 106023. [Google Scholar] [CrossRef]

- King, A.M.; Burgess, S.C.; Ijomah, W.; McMahon, C.A. Reducing Waste: Repair, Recondition, Remanufacture or Recycle? Sustain. Dev. 2006, 14, 257–267. [Google Scholar] [CrossRef] [Green Version]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the Circular Economy: An Analysis of 114 Definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Hannah, D.P.; Eisenhardt, K.M. Bottlenecks, Cooperation, and Competition in Nascent Ecosystems. Strateg. Manag. J. 2019, 40, 1333–1335. [Google Scholar] [CrossRef]

| Interviewee’s Identification | Company | Interviewee’s Position | Method |

|---|---|---|---|

| Interviewee 1 | Carton Packaging Manufacturer–Orchestrator | Sustainability Manager | Sustainability report and interview |

| Interviewee 2 | Carton Packaging Manufacturer–Orchestrator | Sustainability Manager | Sustainability report and interview |

| Interviewee 3 | Ecological Tiles Manufacturer–1 | Specialist | Interview and site visit |

| Interviewee 4 | Ecological Tiles Manufacturer–2 | Administrative Manager | Interview |

| Interviewee 5 | Ecological Tiles Manufacturer–2 | CEO | Interview |

| Interviewee 6 | Recycling Company | Business Specialist | Interview and secondary data (website) |

| Interviewee 7 | Waste Management Company | Marketing Manager | Interview and secondary data (website) |

| 6C Element | Description | Characterization |

|---|---|---|

| Context | The basis for the network to develop | Boom in the civil construction after 2007 and the subsequent Brazilian legislation on solid waste (National Policy on Solid Waste-PNRS). The mission of the ecosystem is to recycle the carton package and prevent it to go to the landfill. |

| Construct | The skeleton of the network | Legislation, carton packaging manufacturers, food industries, collectors and recyclers, ecological tiles manufacturers, sellers, NGOs, waste management companies; development of technology to process the carton packaging; traceability of post-consumer carton packs. |

| Cooperation | Mechanisms behind partners interactions | The orchestrator started to establish different partnerships to promote the recycling of its product. Both contractual and non-contractual were found. |

| Configuration | The way the construct elements are combined | The orchestrator created the ecosystem and is still driving its development. They fund technology for partners and share the responsibility of attracting more players into the ecosystem with the tiles manufacturers. |

| Capability | The reflection of the configuration | There is a vicious circle of the orchestrator pushing their partners intellectually and financially; The partners are able to collect and process more material; the orchestrator and the food industries can correctly dispose of the waste, complying with legislation. The orchestrator also developed technologies for partners in the ecosystem. |

| Change | The necessary changes in order to evolve—renewal, co-evolution | Existing partnerships evolved to supply other materials for product diversification due to the orchestrator’s low supply of carton packs. Investment in product development with the market downturn due to COVID 19. |

| Category | Drivers | Description |

|---|---|---|

| Birth context of the ecosystem | Emergence of carton packages (D1) | The emergence of the orchestrator company, a large manufacturer of carton packaging, influenced the search for recycling its waste. |

| Emergence of processes and equipment for carton packaging recycling and ecological tiles manufacturing (D2) | Development of processes and equipment for both the recycling of carton packaging and the manufacture of ecological tiles for the orchestrator. | |

| Heated civil construction market (D3) | The booming civil construction market between 2007 and 2008, with a large number of houses being built, influenced the development and commercialization of ecological tiles due to the recycling of carton packaging. | |

| Legislations and standards | National Policy on Solid Waste (D4) | The policy imposes mandatory collection and recycling of products and their waste after consumption by the end customer, by manufacturers, importers, distributors and traders of these products. |

| European legislations (D5) | Europe, the continent where the orchestrating company comes from, influences Brazilian subsidiaries in adopting circular economy practices in accordance with its laws. | |

| ISO 14000 standards (D6) | ISO 14000 consists of a serie of standards that establish guidelines to ensure that a particular company (public or private) practices environmental management. | |

| Pressure from environmental issues | Environmental impacts (D7) | Environmental impacts, such as climate change, influence the adoption of a more responsible production chain, concerned with the generation of waste and pollutants. |

| Internal goals related to sustainability (D8) | Orchestrator’s internal goals to promote the circular economy through the manufacture of more sustainable carton packs and the support for selective collection and recycling strategies. | |

| Pressure for the adoption of sustainable solutions (D9) | Pressure from the carton manufacturer’s customers and end consumers to adopt sustainable measures with regard to waste carton packs. | |

| Demand for green products (D10) | Demand for greener and more sustainable products by society. | |

| Impossibility of discarding carton packages in landfills (D11) | Given the large scale of carton packaging production, it is necessary to think about reverse logistics solutions within the ecosystem, rather than just disposing of waste in landfills. | |

| Easily disposal provided by the ecosystem for the correct destination of pre- and post-consumer packages (D12) | The ecosystem provides an accessible solution for the correct disposal of carton packaging waste, both pre- and post-consumer, offering a facility for actors that generate this waste and, consequently, encouraging their participation. | |

| Cooperation among actors | Incentive for recycling carton packages and producing ecological tiles (D13) | After developing processes and equipment for recycling carton packs and manufacturing ecological tiles, the orchestrator sought partners to put these processes into practice, providing technical and financial assistance. |

| Loan and sale of equipment (D14) | Orchestrator lends or sells equipment to partners willing to carry out the processes of recycling carton packaging or manufacturing ecological tiles. | |

| Incentive for the active participation of end consumers (D15) | Encouragement by ecosystem actors so that end consumers dispose of post-consumer packaging correctly to promote the collection and recycling of material. | |

| Establishment of post-consumer packages recycling stations (D16) | Assistance on how to deal with post-consumer packaging and where to dispose of them, given mainly by the orchestrator, as the manufacturer of the carton packs, through its own application that shows the location of the various recycling stations. | |

| Financial incentive for selective collection (D17) | The orchestrating company financially rewards partners who correctly collect and dispose of their waste. | |

| Properties of carton packages and ecological tiles | Design for environment of carton packages (D18) | Constant readjustments are made in the design and composition of the carton packages, in order to facilitate the collection and recycling of the material. |

| Differences of ecological tiles in relation to other tiles options (D19) | Ecological tiles are durable and guarantee thermal comfort, which drives its choice among less sustainable ones and guarantees demand for what the ecosystem generates as an output. | |

| Possibility of cyclic recycling of ecological tiles (D20) | Eco-friendly tiles can be recycled cyclically, which means that tiles used after years or those manufactured with defects can be used as input for the manufacture of new tiles. |

| Category | Barriers | Description |

|---|---|---|

| Lack of material | COVID-19 pandemic (B1) | Due to the pandemic, many collectors were unable to collect waste, resulting in a decreased volume of recycled cartons. |

| Replacement of carton packages (B2) | In the food industry, carton packages are being replaced by other packages (e.g., plastics). | |

| Materials that do not meet the specifications (B3) | Often, materials are declined because they do not meet the specifications required by the company (e.g., humidity). | |

| Low availability of pre-consumer packages (B4) | One of the main sources of material acquisition are the pre-consumer packaging, discarded by industries. With the investment in improvements for the reduction of operational costs, the industrial disposal is getting smaller. | |

| Difficulty of small collection (B5) | Recycling companies do not take advantages of small collection, as such work requires high cost of transportation and available labor. | |

| High cost | High cost of material transportation (B6) | The high cost of transportation makes it difficult to collect materials in regions far from where the recycling company is located. |

| High cost of cleaning the post-consumer packages (B7) | The use of post-consumer packaging is little encouraged due to the need to clean the material, increasing the operational cost. | |

| High cost for digital transformation (B8) | Software purchasing and production line changes require large investments by companies, making the transition to the digital world difficult. | |

| High cost for separating plastic and aluminum (B9) | Despite the encouragement of research for the separation of aluminum and plastic in carton packages, this process has a high cost, making it unattractive to recycling companies. | |

| Market fragility | Market limitation (B10) | The market for recycling carton packages is limited to the manufacture of ecological roof tiles, with few applications. |

| Lack of structure in cooperatives (B11) | Many cooperatives are not yet as well structured and professionalized as the private market, which makes it difficult to trade with them. | |

| Low marketing value of post-consumer packages (B12) | Due to the higher sales value, collectors prefer to collect other materials (e.g., cardboard, iron) rather than carton package. | |

| Poor alignment among actors | Lack of consumer awareness (B13) | Many consumers do not dispose of the packaging correctly, making it impossible to recycle and reinsert it in new products. |

| Lack of awareness of companies within the ecosystem (B14) | The concept of sustainability is not yet widely adopted by companies. | |

| Lack of inspection (B15) | Despite the existence of legislation, the enforcement of environmental laws is still very mild by the government. | |

| Difficulties in the manufacture of ecological tiles | Manual manufacturing process (B16) | The production volume of ecological tiles is lower, if compared to fiber cement tiles, because it is still a very artisanal process. |

| Lack of labor (B17) | Due to the manual process, the demand for labor is high, but difficult to find in the regions near the manufacturing companies. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barquete, S.; Shimozono, A.H.; Trevisan, A.H.; Castro, C.G.; Gomes, L.A.d.V.; Mascarenhas, J. Exploring the Dynamic of a Circular Ecosystem: A Case Study about Drivers and Barriers. Sustainability 2022, 14, 7875. https://doi.org/10.3390/su14137875

Barquete S, Shimozono AH, Trevisan AH, Castro CG, Gomes LAdV, Mascarenhas J. Exploring the Dynamic of a Circular Ecosystem: A Case Study about Drivers and Barriers. Sustainability. 2022; 14(13):7875. https://doi.org/10.3390/su14137875

Chicago/Turabian StyleBarquete, Sophia, Ana Hiromi Shimozono, Adriana Hofmann Trevisan, Camila Gonçalves Castro, Leonardo Augusto de Vasconcelos Gomes, and Janaina Mascarenhas. 2022. "Exploring the Dynamic of a Circular Ecosystem: A Case Study about Drivers and Barriers" Sustainability 14, no. 13: 7875. https://doi.org/10.3390/su14137875