Field Measurement of Central CO2 Heat Pump Water Heater for Multifamily Retrofit

Abstract

:1. Introduction

2. Methodology

2.1. Background and Target Building

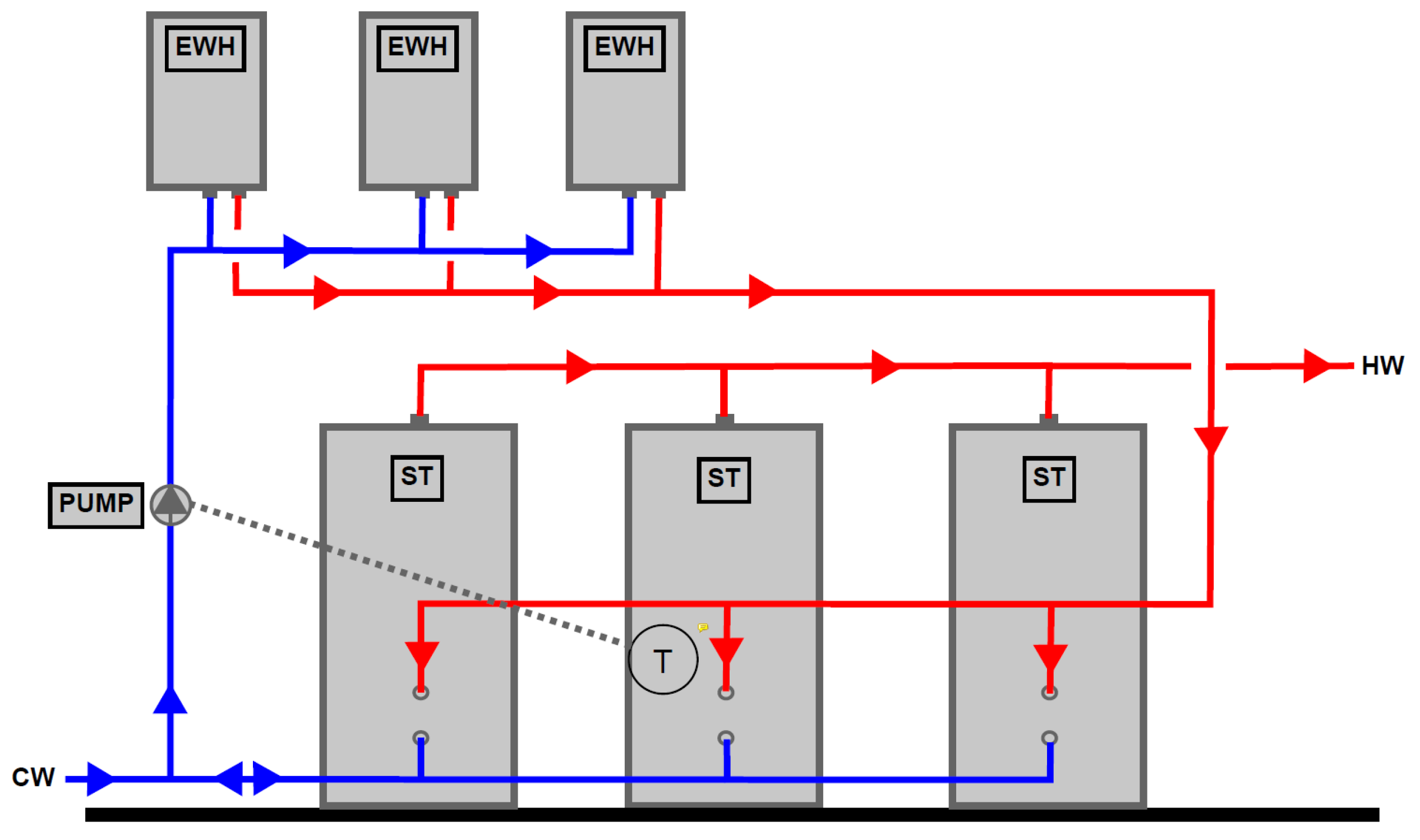

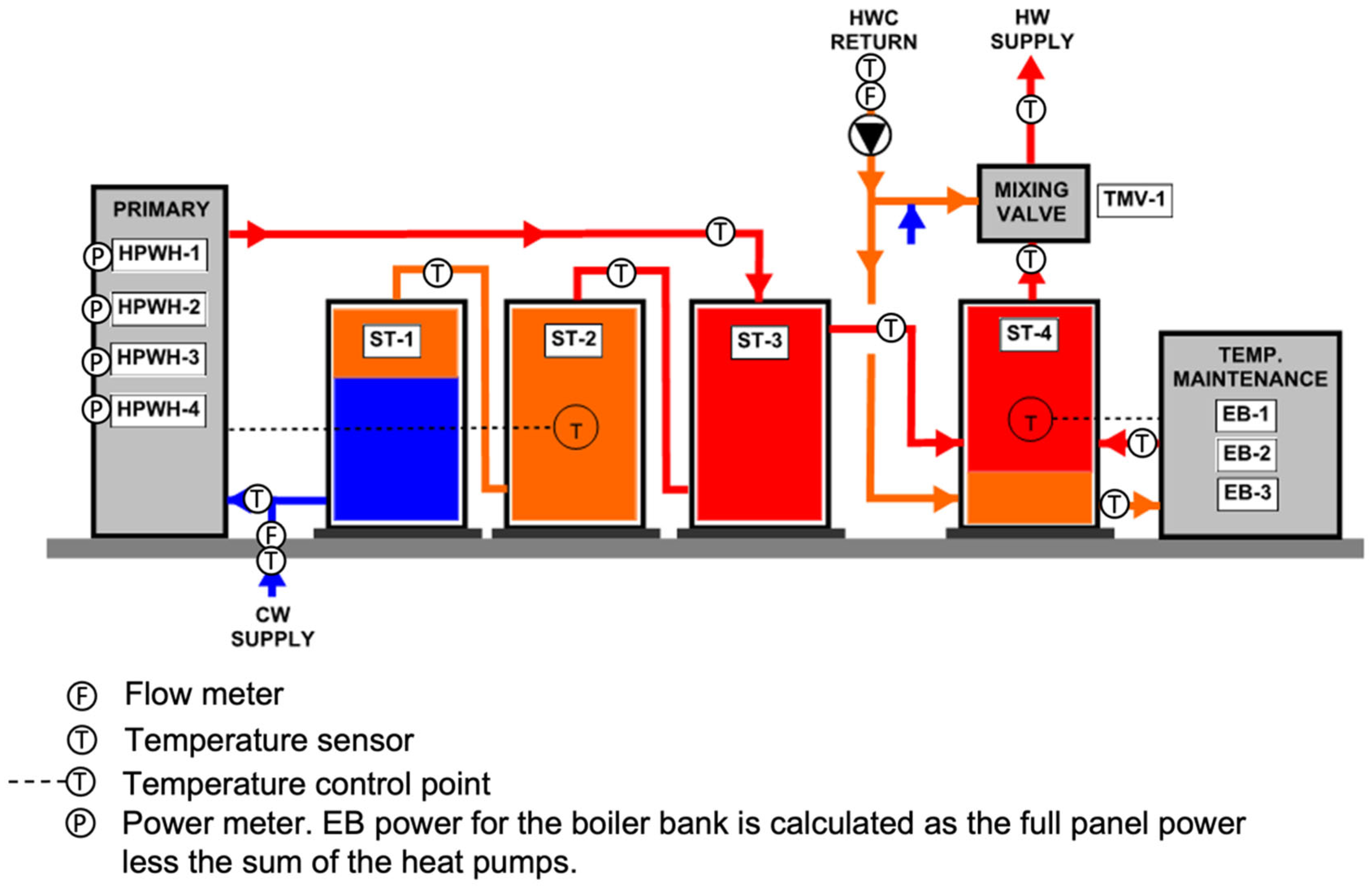

2.2. System Design

2.3. Measurement

- Inlet and outlet water temperatures of the HPWH heaters;

- Inlet and outlet water temperatures of the electric boilers;

- Inlet and outlet water temperatures of the recirculation loop;

- Water temperatures exiting each storage tank;

- Flow of incoming city water;

- Flow in the recirculation loop;

- Temperature of city (cold) water entering the system;

- Electricity used to heat water (by each HPWH and the bank of three boilers); and

- Outdoor air temperature from a nearby National Oceanic and Atmospheric Administration (NOAA) weather station.

3. Measurement Results

3.1. Water Temperatures Results

3.2. Water Use Results

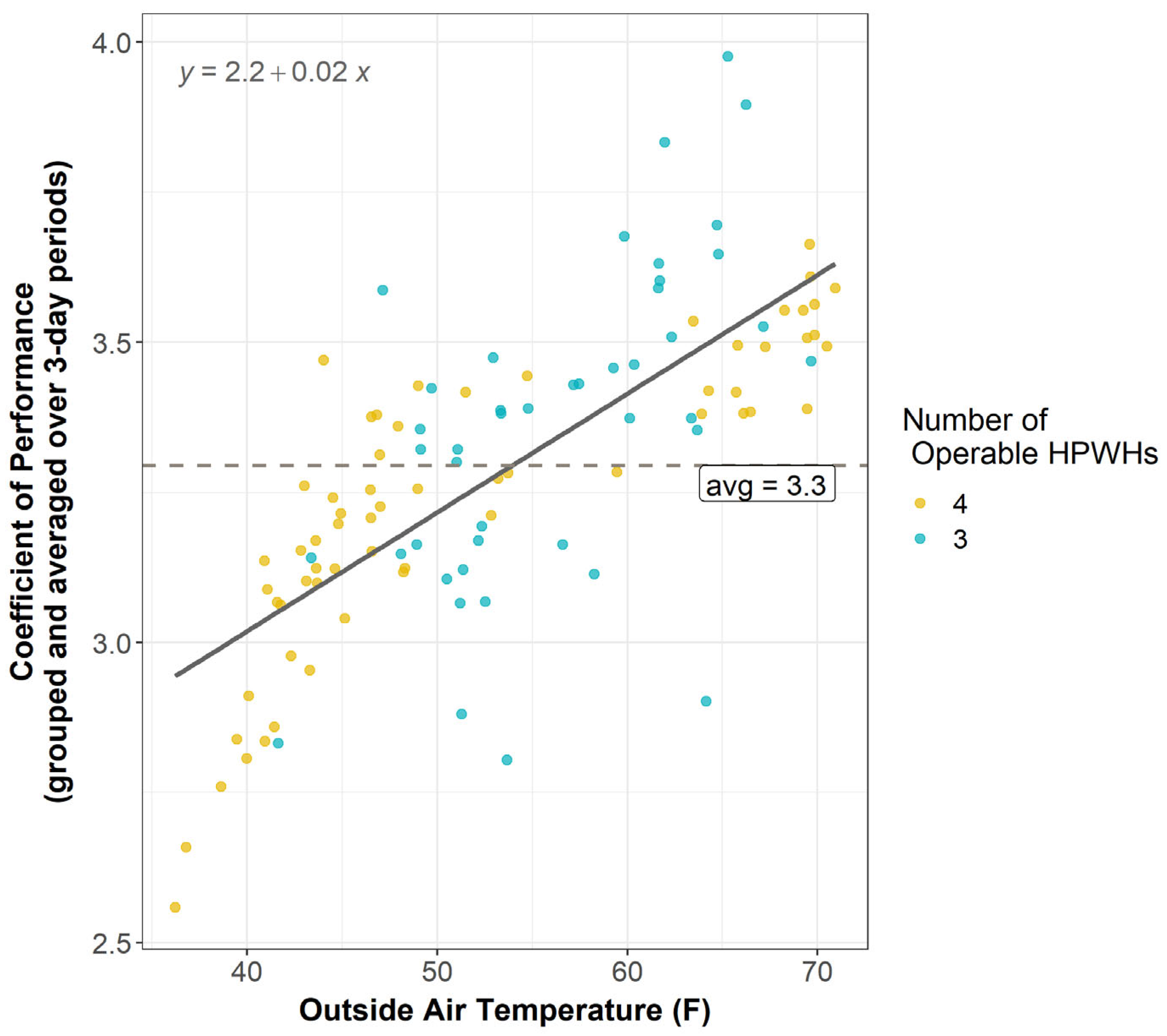

3.3. DHW System Performance

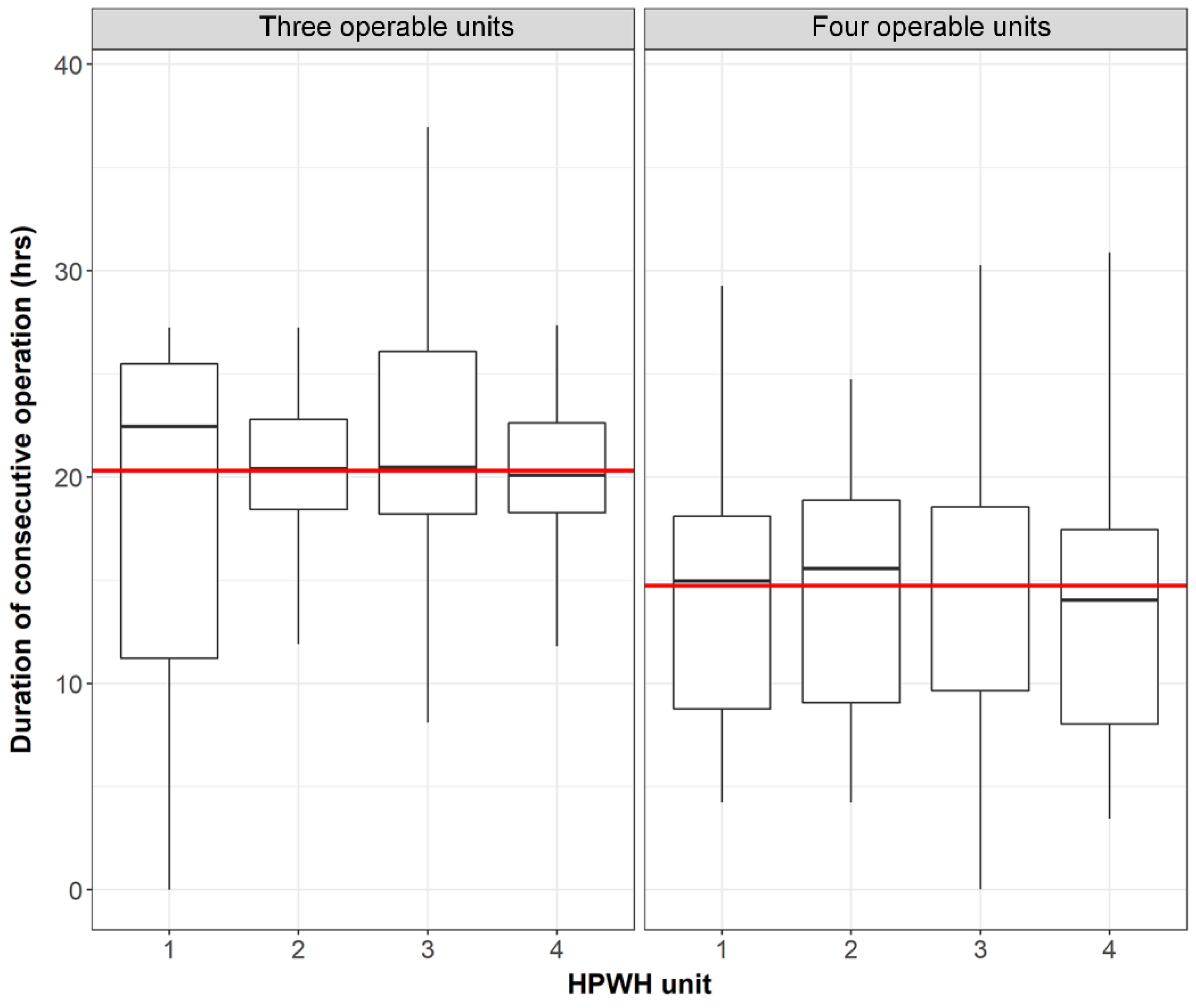

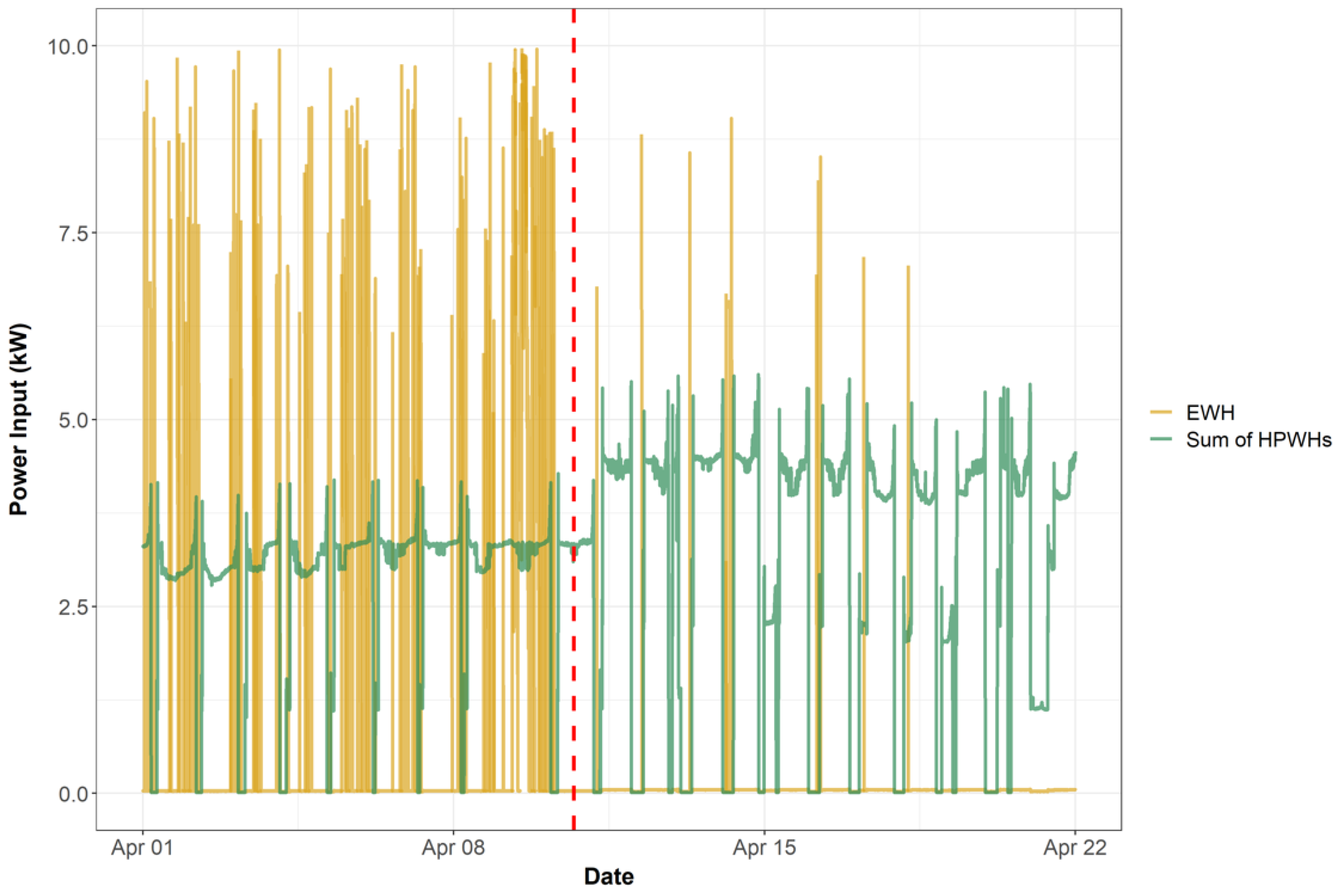

3.4. Duty Cycle of HPWH

3.5. Temperature Maintenance and Swing Tank Operation

3.6. Backup System

3.7. Financial Analysis

4. Key Design Principles

- This study has demonstrated that DHW for a large residential building can be supplied from a remarkably small heat pump plant. The hot water used in the 60 households in the target building is supplied with a nominal capacity of 5 tons, and it can be used for a long time with a capacity of less than 4 tons. Designing to industry standards leads to much larger systems. This can be demonstrated by the capacity of electric resistance water heaters of 120 kW design in the existing system. This is more than five times the current output capacity.

- HPWHs and water storage systems should be sized according to the “Low water usage” methodology of ASHRAE 2015.

- The number of HPWHs specified was based on the building hot water load and the existing storage tanks at the site. The engineering team specified four HPWHs which include one redundant (or backup) HPHW. This proved to be a good design as multiple times one of the four HPWHs had issues. The tenants did not realize the issue or have HW issues due to the redundancy in equipment specified. Redundancy is common in gas and electric resistance system. This approach should be used for HPWH systems as the equipment can have longer lead times than GWHs or EWHs.

- Storage and controls must be configured to store large amounts of cold water before starting the heat pumps. That way, the heat pump does not get the water too hot and allows for longer cycle lengths, which can result in reduced efficiency and higher head pressure. The location of the thermostat is also very important: It must be positioned far enough away from the incoming water to prevent the thermostat from tripping whenever water is used.

- The hydraulic layout configured the HPWHs in parallel, similar to the existing EWH hydraulic layout. The storage tanks were reconfigured into a series layout to prioritize stratification. This also leads to a higher effective storage volume for all tanks.

- If a building has a hot water recirculation system, temperature maintenance consumes a significant portion of the system’s energy usage, so using electrical resistance greatly reduces efficiency. Returning a lot of warm water from the recirculation loop to the primary reservoir and HPWHs degrades the performance of the system. An effective way to alleviate this is to decouple the temperature maintenance load from the primary load so that the primary HPWH system can run at maximum efficiency.

- The heat lost through circulation loop and distribution pipework can account for 25 through 50% of the total heat required for the water heating system. If possible, all areas of thermal bridges should be removed, and the circulation and distribution piping insulation should be strengthened.

- Conventional non-electric tempering valves do not perform well at various inlet water temperatures. One should thus consider using electronic tempering valves.

- The “swing tank” design philosophy is a proven concept and works to minimize the electric resistance temperature maintenance of the recirculation loop.

- When possible, in retrofit projects, repurposing existing equipment (e.g., the original system for backup, storage tanks, or recirculation reheat) can reduce the initial costs.

- In any emerging technology design, it is important to include robust measurement, verification, monitoring, and automatic alerts to building personnel upon detection of a fault in the HPWH system to assist in the diagnosis of issues and the improvement of future designs.

5. Conclusions and Recommendations

- Annual monitoring showed that the DHW system had an average coefficient of performance of 3.3. The annual operating results showed that HPWHs used an average of 68 kWh/day.

- The average water use at this location is 20 GPD (75.7 LPD) per apartment or per person (as each apartment had one occupant in this case). This is slightly greater than earlier multifamily studies of bigger market-rate buildings, which indicated values of 13–19 GPD (49.2–71.9 LPD) per person [33]. Further, this site’s peak demand periods are less pronounced, and weekend and weekday usage are nearly identical. The increased usage and shifted daily patterns are likely due to the retired senior demographic at this building versus the workforce populations at the other sites that have previously been studied.

- Although the installed M&V metering equipment was primarily designed to evaluate the performance of the equipment, it also served to diagnose and resolve operational issues. Without the M&V equipment, it would have been impossible to detect and address system concerns promptly. Future designs of central heat pump water heating systems should include a method for automatic remote alarms to be transmitted to building owners and maintenance people to avoid lengthy durations of backup heating equipment operation (current generation products from this (and other) HPWH manufacturers now offer automatic remote alarming functions for equipment faults as well as low delivery temperatures, with additional alarms that can be configured by the user).

- With the introduction of the “swing tank” concept, warm recirculation water has been successfully separated from the HPWH. The water tank specializing in temperature maintenance was designed and sized as a “swing tank” that uses overheated water from primary water storage tanks to mix with cooler water returning from the recirculation loop. The over-heated water from the primary tanks was periodically drawn into the “swing tank” to keep it above the temperature at which the backup electric boiler would start operating. This idea was found to be a successful strategy in this site because it minimized the reheating of the electric resistance heaters and the circulation loss was small.

- The existing electric resistance water heaters were preserved during the HPWH retrofit with the aim of assisting “swing tank” operation and providing backup water heating in the case of equipment failure. During the monitoring period of this site, the operation of electric water heaters was confirmed for both of these tasks, but the electric water heaters contributed only about 3% of the total water heating energy. Future projects can avoid using a full backup by installing an additional redundant stage of heat pumps and a larger “swing tank”.

- The median run times with four operable heat pumps were 15 h per day, which was 63% of the duty cycle. This includes the warmest environment and the coldest environmental conditions, summer and winter. Having fewer operable units led to longer median duty cycles (83% or 20 h). In extreme situations, such as when a leak occurs and multiple heat pumps fail, the uptime can exceed 24 h.

- The increasing costs of HPWH systems are still high compared to those of conventional equipment; however, the cost of heat pump water heating systems is expected to drop significantly as the product enters the mainstream market. Until then, payback periods for early adoption can be reduced through utilities and other incentive programs. However, even without incentives, the high efficiency of the HPWH system provides significant energy savings and reduced operating costs, making it an attractive water heating option for renovations and new construction.

- The average hot water usage on the peak day was almost double the daily average usage. Therefore, the HPWH system designers should consider the integration of less expensive backup electrical resistance water heaters. This allows for cost-effective operation on most days and smoother hot water supply to residents on fewer peak days.

- For the designs and applications of future “swing tanks”, a method for predicting recirculation losses is needed so that the reliable sizing of the temperature maintenance system can be achieved. This requires further studies into temperature maintenance systems and recirculation losses.

- Extend the application of this hot water technology through additional pilot studies in other multi-family buildings (low- and medium-rise buildings) and contribute to the utility’s program planning. In particular, future pilots should incorporate redundant heat pump stages and automatic alert capabilities.

- This project included the minimum heat pump capacity required to deliver the project. During the study, the site experienced intermittent periods in which one or more HPWHs were inoperable. This problem could often be swiftly resolved by mechanical contractors or skilled maintenance staff. However, the inclusion of additional CO2 HPWH units in the system design provides some measure of resilience to the output capacity. This could reduce the overall HWPH run times and further reduce backup system operation, as well as provide adequate heat pump capacity for periods when one of the units is offline. There is a need for future studies examining the impacts of this “factor of safety” approach to HPWH system design on cost and performance.

- The installation of initial emerging technology should include a level of M&V equipment to detect and solve possible problems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Measurement Items | Instrument Model | Specifications |

|---|---|---|

| Water meter | EKM-SPWM-200-CF | Pulse rate: 1 pulse/0.10 ft3 (1 pulse/0.003 m3) Accuracy: ±5% from Qmin to Qt, ±2% from Qt to Qs Minimum flow (Qmin): 15.89 ft3/h (0.45 m3/h) Transitional Flow (Qt): 105.94 m3/h Overload flow (Qs): 1059.44 ft3/hr (30 m3/h) Temperature range: 32–122℉ (0–50 °C) |

| Data logger | EG4130 | AC Voltage: L1: 85–277 Vrms L2: 0–277 Vrms L3: 0–277 Vrms DC Voltage: 42 Vrms Power: 9–60 Vdc Measurement: +/−60 Vdc |

References

- US EIA. 2015 RECS Survey Data. 2015. Available online: https://www.eia.gov/consumption/residential/ (accessed on 21 May 2022).

- US EIA. Use of Energy Explained Energy Use in Homes. 2015. Available online: https://www.eia.gov/energyexplained/use-of-energy/homes.php (accessed on 21 May 2022).

- Nijs, W.; Tarvydas, D.; Toleikyte, A. EU Challenges of Reducing Fossil Fuel Use in Buildings; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Zhang, J.-F.; Qin, Y.; Wang, C.-C. Review on CO2 heat pump water heater for residential use in Japan. Renew. Sustain. Energy Rev. 2015, 50, 1383–1391. [Google Scholar] [CrossRef]

- Zheng, X.; Wei, C.; Qin, P.; Guo, J.; Yu, Y.; Song, F.; Chen, Z. Characteristics of residential energy consumption in China: Findings from a household survey. Energy Policy 2014, 75, 126–135. [Google Scholar] [CrossRef]

- Energy Information Administration (EIA). About the Residential Energy Consumption Survey (RECS) Table HC8.1 Water Heating in U.S. Homes by Housing Unit Type, 2015. Energy Inf. Adm. 2015. Available online: https://www.eia.gov/consumption/residential/data/2015/hc/php/hc8.1.php (accessed on 26 February 2022).

- Treichel, C.; Cruickshank, C.A. Energy analysis of heat pump water heaters coupled with air-based solar thermal collectors in Canada and the United States. Energy 2021, 221, 119801. [Google Scholar] [CrossRef]

- Li, H.; Sun, Y. Performance optimization and benefit analyses of a photovoltaic loop heat pipe/solar assisted heat pump water heating system. Renew. Energy 2018, 134, 1240–1247. [Google Scholar] [CrossRef]

- Shan, M.; Yu, T.; Yang, X. Assessment of an integrated active solar and air-source heat pump water heating system operated within a passive house in a cold climate zone. Renew. Energy 2016, 87, 1059–1066. [Google Scholar] [CrossRef]

- Buker, M.S.; Riffat, S.B. Solar assisted heat pump systems for low temperature water heating applications: A systematic review. Renew. Sustain. Energy Rev. 2016, 55, 399–413. [Google Scholar] [CrossRef]

- Chyng, J.; Lee, C.; Huang, B. Performance analysis of a solar-assisted heat pump water heater. Sol. Energy 2003, 74, 33–44. [Google Scholar] [CrossRef]

- Huchtemann, K.; Müller, D. Evaluation of a field test with retrofit heat pumps. Build. Environ. 2012, 53, 100–106. [Google Scholar] [CrossRef]

- Marinelli, S.; Lolli, F.; Butturi, M.A.; Rimini, B.; Gamberini, R. Environmental performance analysis of a dual-source heat pump system. Energy Build. 2020, 223, 110180. [Google Scholar] [CrossRef]

- Chao, S.; Yiqiang, J.; Yang, Y.; Shiming, D.; Xinlei, W. A field study of a wastewater source heat pump for domestic hot water heating. Build. Serv. Eng. Res. Technol. 2012, 34, 433–448. [Google Scholar] [CrossRef]

- Hepbasli, A.; Biyik, E.; Ekren, O.; Gunerhan, H.; Araz, M. A key review of wastewater source heat pump (WWSHP) systems. Energy Convers. Manag. 2014, 88, 700–722. [Google Scholar] [CrossRef]

- Grist, C.; Heller, J.; Banks, A.; Spielman, S.; Davis, B. Sitka Apartments Wastewater Heat Pump Measurement and Verification. 2020. Available online: https://www.bpa.gov/-/media/Aep/energy-efficiency/emerging-technologies/sitka-wwhpwh-report.pdf (accessed on 21 May 2022).

- Willem, H.; Lin, Y.; Lekov, A. Review of energy efficiency and system performance of residential heat pump water heaters. Energy Build. 2017, 143, 191–201. [Google Scholar] [CrossRef] [Green Version]

- Atasoy, E.; Çetin, B.; Bayer, Ö. Experiment-based optimization of an energy-efficient heat pump integrated water heater for household appliances. Energy 2022, 245, 123308. [Google Scholar] [CrossRef]

- Shen, B.; Nawaz, K.; Elatar, A. Parametric studies of heat pump water heater using low GWP refrigerants. Int. J. Refrig. 2021, 131, 407–415. [Google Scholar] [CrossRef]

- Ibrahim, O.; Fardoun, F.; Younes, R.; Louahlia-Gualous, H. Review of water-heating systems: General selection approach based on energy and environmental aspects. Build. Environ. 2014, 72, 259–286. [Google Scholar] [CrossRef]

- Nawaz, K.; Shen, B.; Elatar, A.; Baxter, V.; Abdelaziz, O. Performance optimization of CO2 heat pump water heater. Int. J. Refrig. 2018, 85, 213–228. [Google Scholar] [CrossRef]

- Lorentzen, G. Revival of carbon dioxide as a refrigerant. Int. J. Refrig. 1994, 17, 292–301. [Google Scholar] [CrossRef]

- Lorentzen, G. The use of natural refrigerants: A complete solution to the CFC/HCFC predicament (Utilisation des frigorigénes naturels: Une solution complete au problme des CFC et des HCFC). Int. J. Refrig. 1995, 18, 190–197. [Google Scholar] [CrossRef]

- Yokoyama, R.; Shimizu, T.; Ito, K.; Takemura, K. Influence of ambient temperatures on performance of a CO2 heat pump water heating system. Energy 2007, 32, 388–398. [Google Scholar] [CrossRef]

- Yokoyama, R.; Wakui, T.; Kamakari, J.; Takemura, K. Performance analysis of a CO2 heat pump water heating system under a daily change in a standardized demand. Energy 2010, 35, 718–728. [Google Scholar] [CrossRef]

- Rony, R.; Yang, H.; Krishnan, S.; Song, J. Recent Advances in Transcritical CO2 (R744) Heat Pump System: A Review. Energies 2019, 12, 457. [Google Scholar] [CrossRef] [Green Version]

- Dai, B.; Qi, H.; Dou, W.; Liu, S.; Zhong, D.; Yang, H.; Nian, V.; Hao, Y. Life cycle energy, emissions and cost evaluation of CO2 air source heat pump system to replace traditional heating methods for residential heating in China: System configurations. Energy Convers. Manag. 2020, 218, 112954. [Google Scholar] [CrossRef]

- Energy350. CO2 Integrated Heat Pump Water Heater Performance Report. 2018. Available online: https://energy350.com/wp-content/uploads/2018/11/CO2-Integrated-Heat-Pump-Water-Heater-Performance-Report-FINAL.pdf (accessed on 21 May 2022).

- CO2 Takes Heat Pump Water Heaters to the Next Level—Zero Energy Project, (n.d.). Available online: http://zeroenergyproject.org/2017/05/22/CO2-takes-heat-pump-water-heaters-next-level/ (accessed on 21 May 2022).

- Banks, A.; Grist, C.; Heller, J. CO2 Heat Pump Water Heater Multifamily Retrofit: Seattle WA. 2020. Available online: https://www.bpa.gov/EE/Technology/EE-emerging-technologies/Documents/CO2_Heat_Pump_Water_Heater_Final.pdf. (accessed on 21 May 2022).

- Larson, B.; Lodgson, M.; Kvaltine, N. Laboratory Assessment of Combination Space and Water Heating Applications of a CO2 Heat Pump Water Heater. Available online: https://energy.wsu.edu/Documents/Sanden_Combi_HPWH_lab_report_final_2016-07-05.pdf (accessed on 21 May 2022).

- Spielman, S.; Heilbrunn, L.; Heller, J. Nyle e60A R513a HPWH Feasibility Study. 2021. Available online: https://www.nyle.com/wp-content/uploads/2022/01/FINAL_20211020-Nyle-Feasibility-Study.pdf (accessed on 21 May 2022).

- Heller, J.; Oram, S. RCC Pilot Project: Multifamily Heat Pump Water Heaters in Below Grade Parking Garages in the Pacific Northwest, Bonneville Power Administration (BPA). 2015. Available online: https://ecotope-publications-database.ecotope.com/2015_004_RCCPilotMFHPWH.pdf (accessed on 21 May 2022).

- Sanden International (USA) Inc. Sanden SANCO2 Heat Pump Water Heater Technical Information. 2017. Available online: https://www.sandenwaterheater.com (accessed on 21 May 2022).

| Site Information | ||

|---|---|---|

| Annual water usage | 438,000 | Gal/yr. |

| Annual EWH electric use | 76,083 | kWh/yr. |

| Electricity cost | 0.11 (https://www.bls.gov/regions/west/news-release/averageenergyprices_seattle.htm, accessed on 23 February 2022) | USD/kWh |

| Equipment Efficiency | ||

| HPWH DHW System | 3.3 | COP |

| EWH | 0.98 | COP |

| Hot Water Circulation System | ||

| Annual HWC losses | 7700 | kWh/yr. |

| Baseline Electric Water Heating (EWH) System | ||

| Annual EWH electric use | 76,083 | kWh/yr. |

| Annual HWC EWH temperature maintenance | 7857 | kWh/yr. |

| Proposed Heat Pump Water Heating (HPWH) System | ||

| Annual HPWH electric use | 23,055 | kWh/yr. |

| Annual HWC HPWH reheat | 2333 | kWh/yr. |

| Proposed HPWH System Savings | ||

| Electric savings | 58,511 | kWh/yr. |

| Bill savings (at USD 0.11/kWh) | USD6441 | USD/yr. |

| Proposed HPWH System Savings | ||

| Retrofit installation costs | USD117,840 | USD |

| potential incentive | USD30,000 | USD |

| net cost (w/incentives) | USD87,840 | USD |

| Simple payback | 13.6 | yr. |

| Simple payback w/o incentives | 18.3 | yr. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banks, A.; Grist, C.; Heller, J.; Lim, H. Field Measurement of Central CO2 Heat Pump Water Heater for Multifamily Retrofit. Sustainability 2022, 14, 8048. https://doi.org/10.3390/su14138048

Banks A, Grist C, Heller J, Lim H. Field Measurement of Central CO2 Heat Pump Water Heater for Multifamily Retrofit. Sustainability. 2022; 14(13):8048. https://doi.org/10.3390/su14138048

Chicago/Turabian StyleBanks, Adria, Colin Grist, Jonathan Heller, and Hyunwoo Lim. 2022. "Field Measurement of Central CO2 Heat Pump Water Heater for Multifamily Retrofit" Sustainability 14, no. 13: 8048. https://doi.org/10.3390/su14138048

APA StyleBanks, A., Grist, C., Heller, J., & Lim, H. (2022). Field Measurement of Central CO2 Heat Pump Water Heater for Multifamily Retrofit. Sustainability, 14(13), 8048. https://doi.org/10.3390/su14138048