Study on Influence Factors of Compressive Strength of Low Density Backfill Foamed Concrete Used in Natural Gas Pipeline Tunnel

Abstract

:1. Introduction

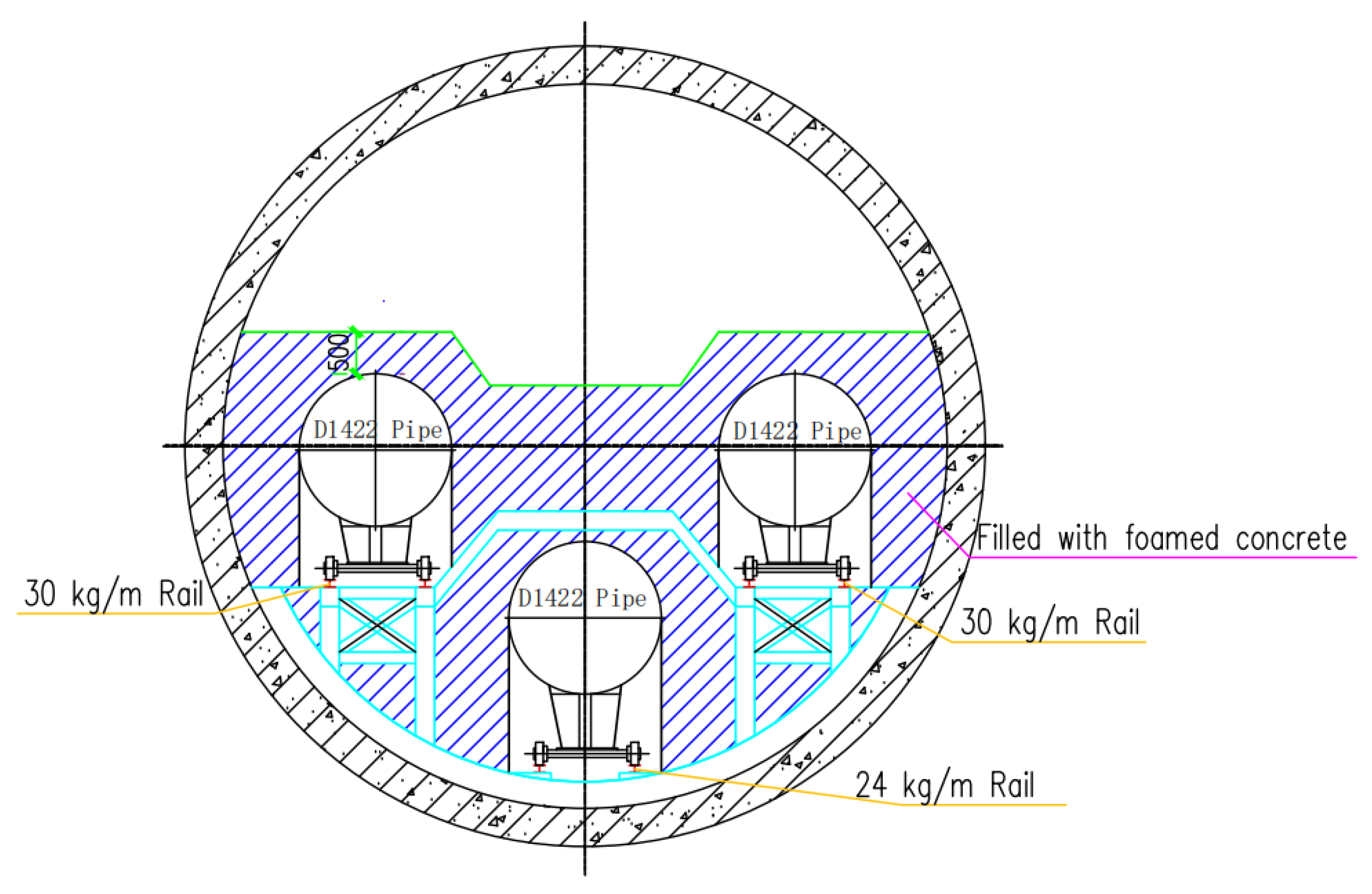

2. Analysis of Engineering Background and Difficulties

3. Experimental Section

3.1. Experimental Design

- The dry density of pre-designed foamed concrete is 1100 kg/m3 and the compressive strength is greater than 2 MPa. By adjusting the mixing proportion of cement and admixture, the appropriate admixture content was determined;

- The foam content was determined by changing the mixing ratio of foam and cement slurry;

- The effect of different types of cement on compressive strength and dry density of foamed concrete was compared by changing the types of cement;

- The suitable foaming agent for foamed concrete was determined by changing the type of foaming agent and testing the compressive strength and dry density of foamed concrete.

3.2. Material

3.2.1. Cement

3.2.2. Foaming Agent

3.2.3. Fly Ash

3.2.4. HTFC Admixture for Foamed Concrete

3.2.5. Addition Agent

3.2.6. Water for Mixing

3.3. Preparation of Test Block

- According to the predetermined mix ratio, dry mix cement, fly ash, and other dry materials were stirred for 1 min to make the dry materials evenly mixed;

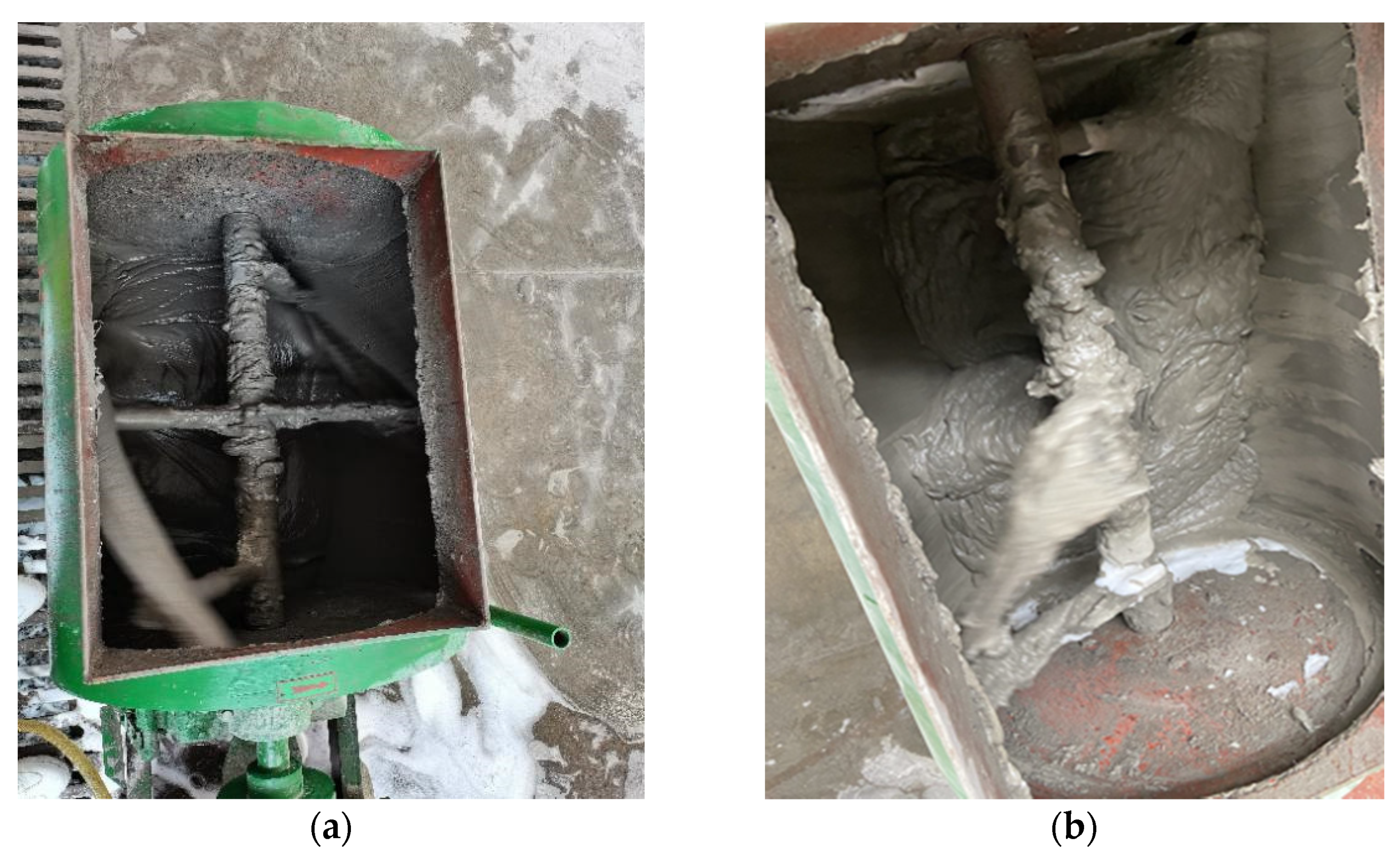

- After mixing the dry ingredients evenly, water was added as the designed water–cement ratio and the mixture was then stirred for three minutes to form a uniform slurry (Figure 2);

- In the process of mixing cement slurry, foams were prepared. HT foam agent was firstly diluted by 20 times by adding water, and the foaming agent and water were evenly mixed. Then, the cement foaming machine was used to prepare the foam. Foam was used immediately after foaming;

- The foams were added to cement slurry, and the mixture was mixed evenly;

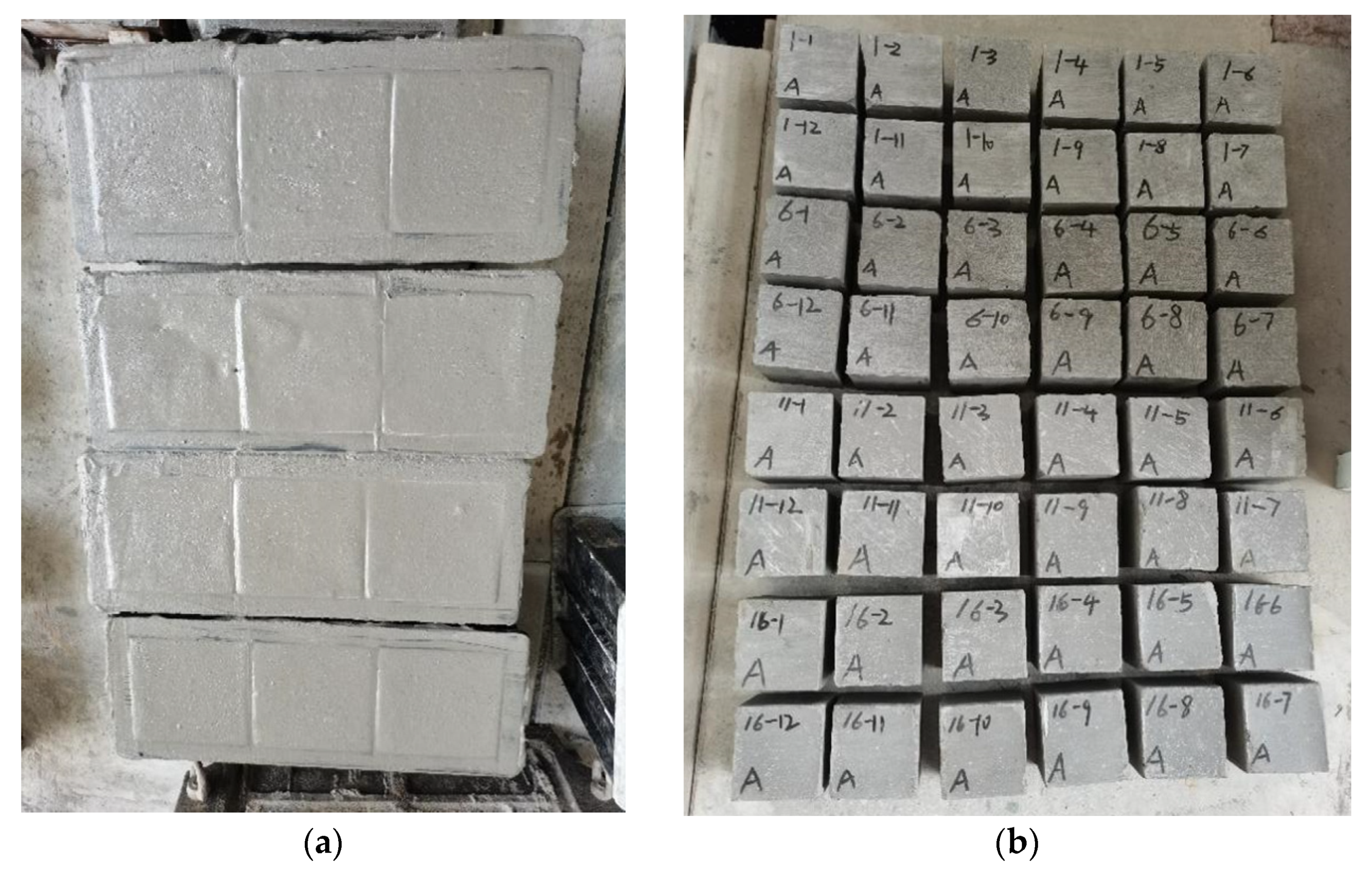

- The mixed foamed concrete was injected into the 100 mm × 100 mm × 100 mm triplet test mold, and the mold was removed 48 h later (Figure 3);

- The specimens were cured under 25 ± 2 °C and 70 ± 5% humidity. The compressive strengths were measured at 7 d, 14 d and 28 d, respectively.

4. Test Implementation

4.1. Mixing Proportion Design of Foamed Concrete

4.2. Test Results

4.2.1. Measurement Steps

- The compressive strengths of the specimen at 3 d were not measured, because the early strengths of the test blocks were too small to be detected. At the age of 7 d, 14 d and 28 d, three test blocks in each group were taken out from the maintaining box, respectively, for the compressive strength test. The moisture on the surface was wiped dry, and the compression area of the test blocks was measured. At the same time, the dry densities of the 28 d foamed concrete test blocks were measured.

- The testing machine used in this compressive strength test was SANS microcomputer controlled electro-hydraulic testing machine (Figure 4). The foamed concrete test block was placed in the center of the downforce plate (the forming surface is not used as the force surface), and the test block was adjusted to remain in the center of the pressure plate. The height of the pressure plate was adjusted until it contacted the test block surface, and the lower plate was adjusted to ensure the test block was uniformly compressed.

- The compressive strengths of the test blocks were very small, so the load was applied continuously and uniformly at the speed of 2 kN/s (Figure 5). When the curve dropped rapidly, the loading was stopped, and the failure of the test block under pressure was observed. The loading force was then unloaded by controlling the displacement speed until the pressure value decreased to zero.

4.2.2. Test Details

4.3. Analysis of Test Results

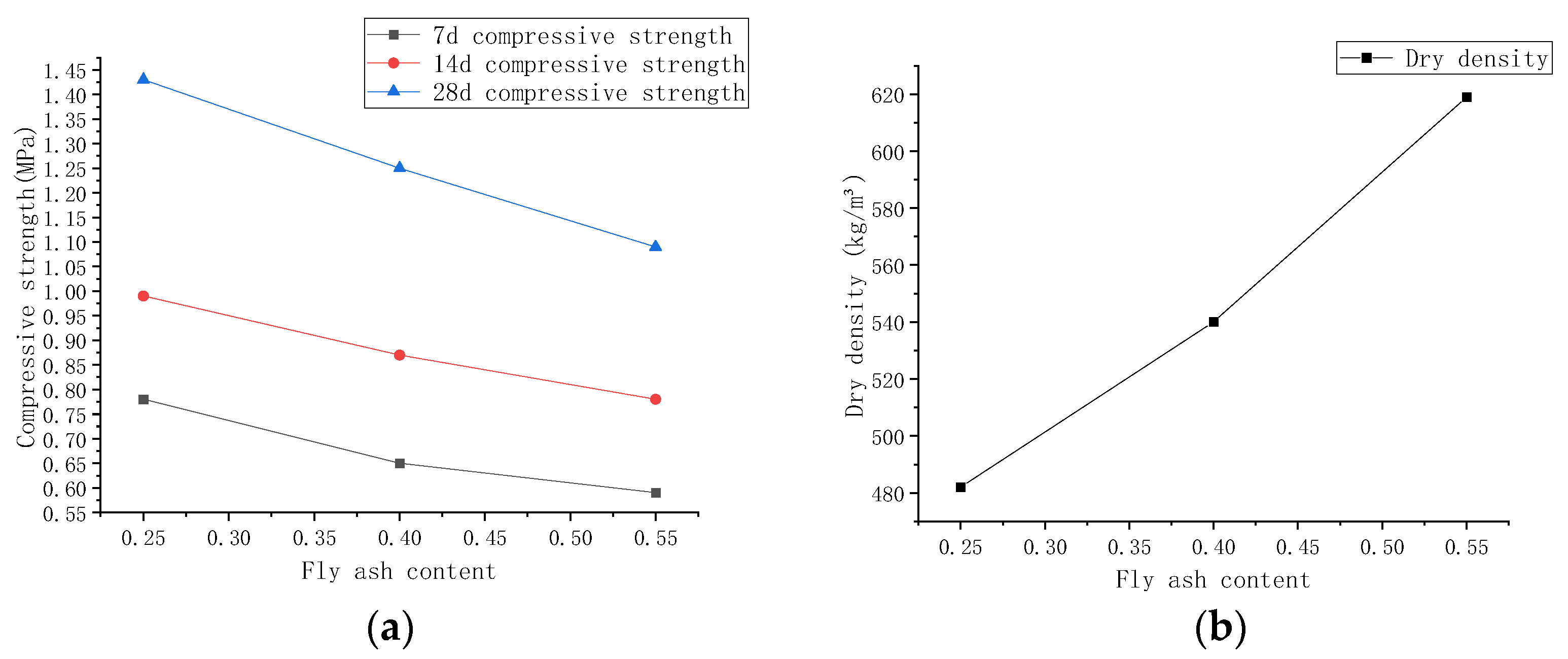

4.3.1. Influence of Fly Ash Content on Performance of Foamed Concrete

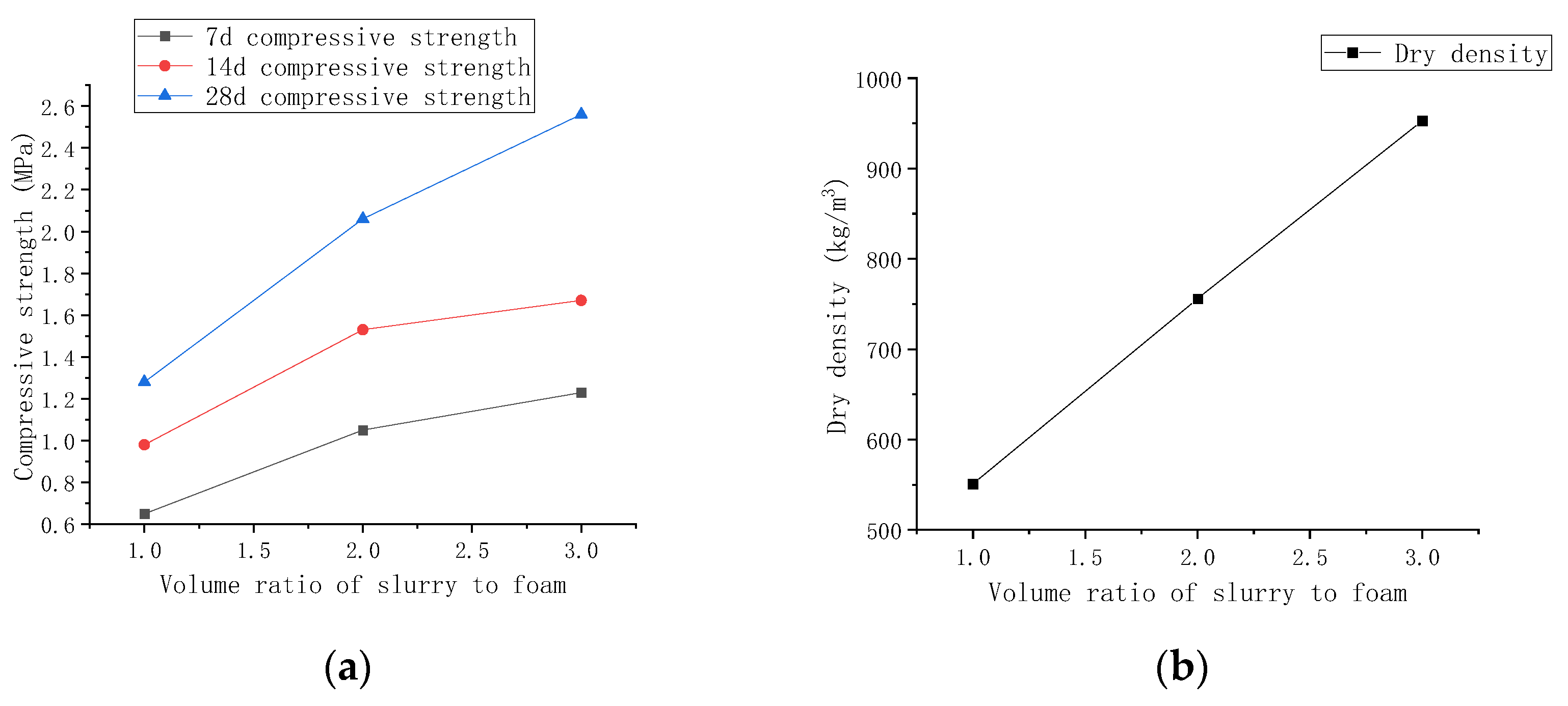

4.3.2. Effect of Volume Ratio of Slurry to Foam on Performance of Foamed Concrete

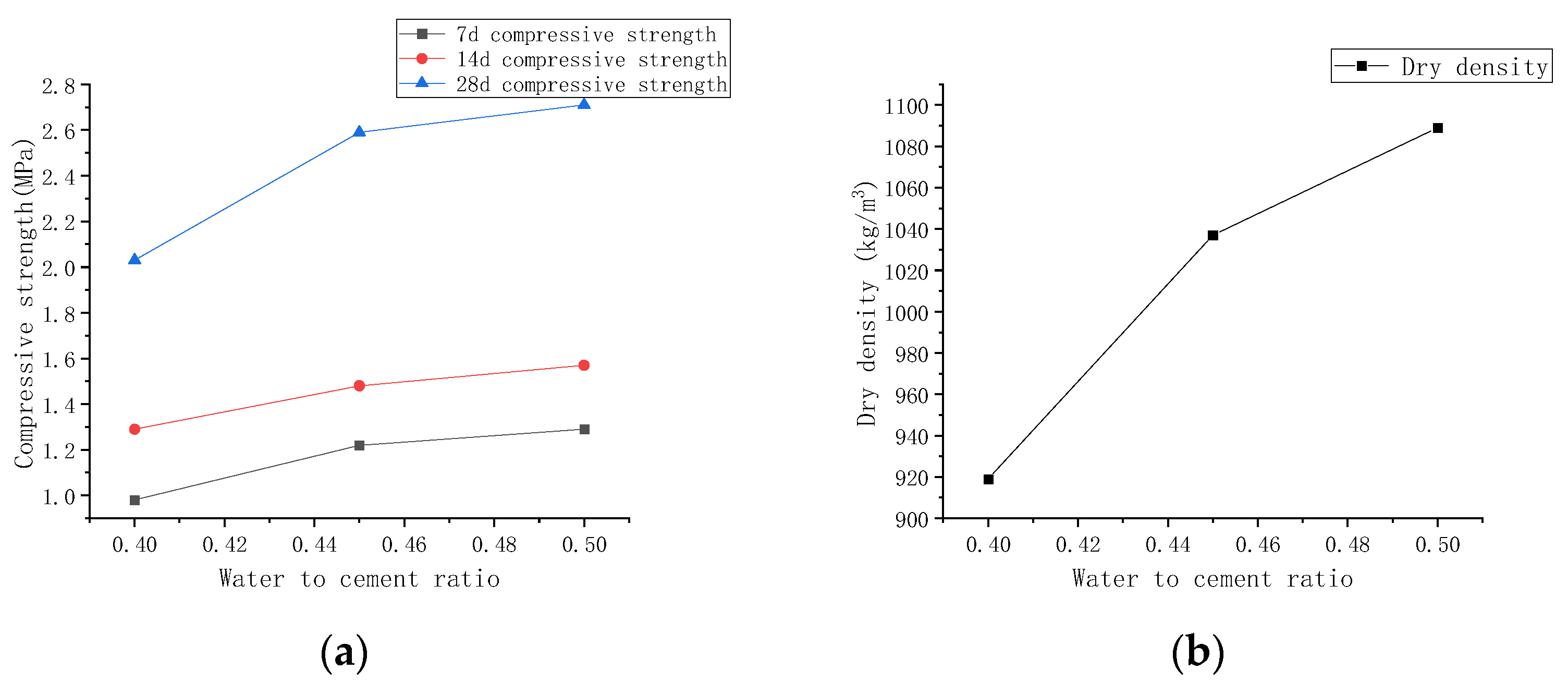

4.3.3. Influence of Water to Cement Ratio on Performance of Foamed Concrete

4.3.4. Influence of Cement Type on Performance of Foamed Concrete

4.3.5. Optimal Mixing Proportion

4.4. Foamed Concrete with Different Foaming Agents

4.4.1. Preparation and Maintenance of Test Blocks

- According to the P4-2 mixing ratio, the dry material was mixed and the net cement slurry was prepared;

- The concentration of sodium dodecyl sulfate foam was 3 g/L, and the foaming factor was 20 times. The modified silicone polyether microemulsion was used as foam stabilizer to make the foam more compact and stable. The additional content of modified silicone polyether microemulsion was 2 g/L according to the instructions. The foams were prepared according to the above mixture ratio;

- The cement slurries and foams were mixed evenly according to the volume ratio of 1:1, and then the mixtures were injected into the 100 mm × 100 mm × 100 mm triplet test mold, and the mold was removed after 48 h. The specimens were cured under the same conditions as that of foamed concrete prepared with an HT foaming agent.

4.4.2. Test Data

4.4.3. Analysis of Test Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, Y.Z. Characteristics of lightweight foamed concrete and its application in road construction. Anhui Archit. 2021, 28, 189–190. [Google Scholar]

- Shah, S.N.; Kim, H.M.; Yap, S.P.; Yang, J.; Ling, T.C. Lightweight foamed concrete as a promising avenue for incorporating waste materials: A review. Resour. Conserv. Recycl. 2021, 164, 105103. [Google Scholar] [CrossRef]

- Ni, J.J.; Ma, C.; Yang, J.; Chen, Z.; Zhou, W.B. Construction technology of basement exterior wall backfill foamed concrete. Build. Technol. Dev. 2022, 49, 46–49. [Google Scholar]

- Yang, Z.H.; Li, T.T.; Yu, L. Research on thermal conductivity model of low density foamed concrete. J. Build. Mater. 2020, 23, 322–327. [Google Scholar]

- Zhao, W.S.; Chen, W.Z.; Tan, X.J.; Huang, S. Study on high performance foamed concrete tunnel isolation material. Chin. J. Geotech. Eng. 2013, 35, 1544–1552. [Google Scholar]

- Chung, S.Y.; Kim, J.S.; Han, T.S.; Stephan, D.; Kamm, P.H.; Elrahman, M.A. Characterization of foamed concrete with different additives using multi-scale micro-computed tomography. Constr. Build. Mater. 2022, 319, 125953. [Google Scholar] [CrossRef]

- Zhang, D.; Shahin, M.A.; Yang, Y.; Liu, H.L.; Cheng, L. Effect of microbially induced calcite precipitation treatment on the bonding properties of steel fiber in ultra-high performance concrete. J. Build. Eng. 2022, 50, 104132. [Google Scholar] [CrossRef]

- Shang, X.Y.; Qu, N.; Li, J.S. Development and functional characteristics of novel foam concrete. Constr. Build. Mater. 2022, 324, 12666. [Google Scholar] [CrossRef]

- Xi, H.F.; Liu, Y.P.; Ma, H.W.; Luo, S.H.; Wang, Z.G.; Huang, Q. Study on compressive strength and thermal conductivity of foamed concrete. China Concr. Cem. Prod. 2016, 2, 77–79. [Google Scholar]

- Sim, J.I.; Yang, K.H.; Kim, H.Y.; Choi, B.J. Size and shape effects on compressive strength of lightweight concrete. Constr. Build. Mater. 2013, 38, 854–864. [Google Scholar] [CrossRef]

- Huang, H.J.; Gong, N.P.; Mu, C.M.; Zhou, H.; Liu, W. Dynamic mechanical properties and constitutive relationship of foamed concrete. J. Build. Mater. 2020, 23, 466–472. [Google Scholar]

- Ma, Y.J.; Yang, A.; Hong, F.; Chen, L.T.; Wang, J.; Qiao, H.X. Mix proportion design of foamed concrete based on orthogonal test. Concrete 2021, 7, 147–150. [Google Scholar]

- Shi, C.; Chen, Y. The calculation of hole wall thickness of foamed concrete and the influence of fly ash content on hole wall thickness. Guangdong Build. Mater. 2021, 37, 10–13. [Google Scholar]

- Liu, D.Z.; Pan, S.; Li, Z.Y. Effect of density on compressive strength of foamed concrete. World Build. Mater. 2016, 37, 25–27. [Google Scholar]

- Zhan, S.W.; Wang, Q.; Zhao, Y.; Ren, W.M.; Kang, H.S.; Wang, L.; You, W.X. Shear performance test of foamed concrete in shield tunnel of Yangtze River on China to Russian east Line. Oil Gas Storage Transp. 2022, in press. [Google Scholar]

- Xiao, W.Q.; Zhao, H.K. Research and analysis based on the performance influence of foamed concrete. North. Archit. 2016, 6, 5–8. [Google Scholar]

- Ye, C.B.; Yang, H.P.; Chen, Q.Q.; Zhong, L.Y.; Xu, L.F.; Ying, S.Q. Effect of HPMC modified foam on performance of foamed concrete. New Build. Mater. 2022, 49, 72–80. [Google Scholar]

- Hao, Y.H.; Li, Y.R.; Qin, L.D.; Sun, H.; Wu, Z.X. Mix test of magnesium base foamed concrete. Adv. Eng. Sci. 2021, 53, 72–80. [Google Scholar]

- Deng, Y.; Ren, J.; Tan, C.L.; Zhang, P.; Huang, F.R.; Zuo, R.S.; Li, H.K. Determination of optimal mix ratio of foamed concrete block. China Concr. Cem. Prod. 2018, 10, 64–67. [Google Scholar]

- Guo, L.Y.; Zhao, Y.P.; Zhang, D.W.; Chai, H.J. Study on preparation and strength influence of foamed concrete. Concrete 2011, 10, 133–135. [Google Scholar]

- Wang, J.; Fan, S.; Wang, X.Q.; Du, H.W. Experimental analysis of influence of water temperature on properties and pore size of foamed concrete. Ind. Constr. 2021, 51, 267. [Google Scholar]

- Li, J. Experimental study on density and compressive strength of foamed concrete. Build. Struct. 2021, 51, 1327–1331. [Google Scholar]

- Zhang, T.Y. Study on preparation and properties of new low density foamed concrete building insulation materials. Synth. Mater. Aging Appl. 2021, 50, 103–105. [Google Scholar]

- CTJ/T177-2012; Technical Specification for Foamed Mixing Lightweight Soil Filling Engineering. Architecture & Building Press: Beijing, China, 2012.

- JGJ 63-2006; Standard of Water for Concrete. Architecture & Building Press: Beijing, China, 2006.

| Number | Initial Setting Time /Min | Final Setting Time /Min | Bulk Density kg/m3 | Compressive Strength/MPa | Flexural Strength/MPa | ||||

|---|---|---|---|---|---|---|---|---|---|

| 3 d | 7 d | 28 d | 3 d | 7 d | 28 d | ||||

| Composite Portland cement | 70 | 240 | 1175 | 19.2 | 29.2 | 48.2 | 3.5 | 5.0 | 7.2 |

| Ordinary Portland cement | 70 | 242 | 1137 | 18.5 | 28.0 | 47.0 | 3.6 | 5.1 | 7.3 |

| Composition | ρ kg/m3 | SiO2 | Al2O3 | CaO | Fe2O3 |

|---|---|---|---|---|---|

| Content (%) | 2400–2600 | 50.76 | 30.37 | 3.53 | 4.04 |

| Appearance | Bulk Density/(g/L) | PH(20% Solution) | SO42− Content/% | Cl- Content/% |

|---|---|---|---|---|

| White | 500~600 | 6~8 | 2.6 | 0.01 |

| Groups | Cement/kg | HTFC Amount/kg | Fly Ash/kg | Admixture Content | Water/kg | Water to Cement Ratio | Volume Ratio of Slurry to Foam | |

|---|---|---|---|---|---|---|---|---|

| Change the amount of admixture | P1-1 | 27 | 8.1 | 0.9 | 0.25 | 16.2 | 0.45 | 1:1 |

| P1-2 | 21.6 | 6.48 | 7.92 | 0.4 | 16.2 | 0.45 | 1:1 | |

| P1-3 | 16.2 | 4.86 | 14.9 | 0.55 | 16.2 | 0.45 | 1;1 | |

| Change the slurry–foam ratio | P2-1 | 21.6 | 6.48 | 7.92 | 0.4 | 16.2 | 0.45 | 1:2 |

| P2-2 | 21.6 | 6.48 | 7.92 | 0.4 | 16.2 | 0.45 | 1:1 | |

| P2-3 | 21.6 | 6.48 | 7.92 | 0.4 | 16.2 | 0.45 | 2:1 | |

| P2-4 | 21.6 | 6.48 | 7.92 | 0.4 | 16.2 | 0.45 | 3:1 | |

| Change the water–cement ratio | P3-1 | 21.6 | 6.48 | 7.92 | 0.4 | 14.4 | 0.4 | 3:1 |

| P3-2 | 21.6 | 6.48 | 7.92 | 0.4 | 16.2 | 0.45 | 3:1 | |

| P3-3 | 21.6 | 6.48 | 7.92 | 0.4 | 18 | 0.5 | 3:1 | |

| Change cement type | P4-1 | 21.6 | 6.48 | 7.92 | 0.4 | 18 | 0.5 | 3:1 |

| P4-2 | 21.6 | 6.48 | 7.92 | 0.4 | 18 | 0.5 | 3:1 |

| The Surrounding Environment of the Yangtze River Shield for Maintenance | ||||

|---|---|---|---|---|

| Num | 7 d Compressive Strength /MPa | 14 d Compressive Strength /MPa | 28 d Compressive Strength /MPa | Dry Density /kg/m3 |

| P1-1 | 0.78 | 0.99 | 1.43 | 482 |

| P1-2 | 0.65 | 0.87 | 1.25 | 540 |

| P1-3 | 0.59 | 0.78 | 1.09 | 619 |

| P2-1 | collapse | |||

| P2-2 | 0.65 | 0.98 | 1.28 | 551 |

| P2-3 | 1.05 | 1.53 | 2.06 | 756 |

| P2-4 | 1.23 | 1.67 | 2.56 | 953 |

| P3-1 | 0.98 | 1.29 | 2.03 | 919 |

| P3-2 | 1.22 | 1.48 | 2.59 | 1037 |

| P3-3 | 1.29 | 1.57 | 2.71 | 1089 |

| P4-1 | 1.42 | 1.61 | 2.82 | 1096 |

| P4-2 | 1.44 | 1.65 | 2.86 | 1103 |

| Dry Material /kg | Water–Cement Ratio | HTFC Content | Admixture Content | Volume Ratio of Slurry to Foam | Water Reducing Agent |

|---|---|---|---|---|---|

| 948 | 0.45~0.6 | 30~40% | 40~55% | 2:1~3:1 | 0.05~1.5% |

| Number | 7 d Compressive Strength/MPa | 14 d Compressive Strength/MPa | 28 d Compressive Strength/MPa | Dry Density kg/m3 |

|---|---|---|---|---|

| K12 | 0.7 | 1.08 | 1.59 | 509 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Li, X.; Guan, D.; Li, S.; Lv, W.; Cong, Z.; Soloveva, V.Y.; Dalerjon, H.; Qin, P.; Liu, X. Study on Influence Factors of Compressive Strength of Low Density Backfill Foamed Concrete Used in Natural Gas Pipeline Tunnel. Sustainability 2022, 14, 8333. https://doi.org/10.3390/su14148333

Li C, Li X, Guan D, Li S, Lv W, Cong Z, Soloveva VY, Dalerjon H, Qin P, Liu X. Study on Influence Factors of Compressive Strength of Low Density Backfill Foamed Concrete Used in Natural Gas Pipeline Tunnel. Sustainability. 2022; 14(14):8333. https://doi.org/10.3390/su14148333

Chicago/Turabian StyleLi, Chunbao, Xiaotian Li, Di Guan, Shen Li, Wenpu Lv, Ziqin Cong, Valentina Y. Soloveva, Hojiboev Dalerjon, Pengju Qin, and Xiaohui Liu. 2022. "Study on Influence Factors of Compressive Strength of Low Density Backfill Foamed Concrete Used in Natural Gas Pipeline Tunnel" Sustainability 14, no. 14: 8333. https://doi.org/10.3390/su14148333

APA StyleLi, C., Li, X., Guan, D., Li, S., Lv, W., Cong, Z., Soloveva, V. Y., Dalerjon, H., Qin, P., & Liu, X. (2022). Study on Influence Factors of Compressive Strength of Low Density Backfill Foamed Concrete Used in Natural Gas Pipeline Tunnel. Sustainability, 14(14), 8333. https://doi.org/10.3390/su14148333