Sustainable Product Innovation and Consumer Communication

Abstract

:1. Introduction

2. Sustainable Product Innovation through Product Development and Service

2.1. Sustainable Product Design and Manufacture

2.2. Product–Service System

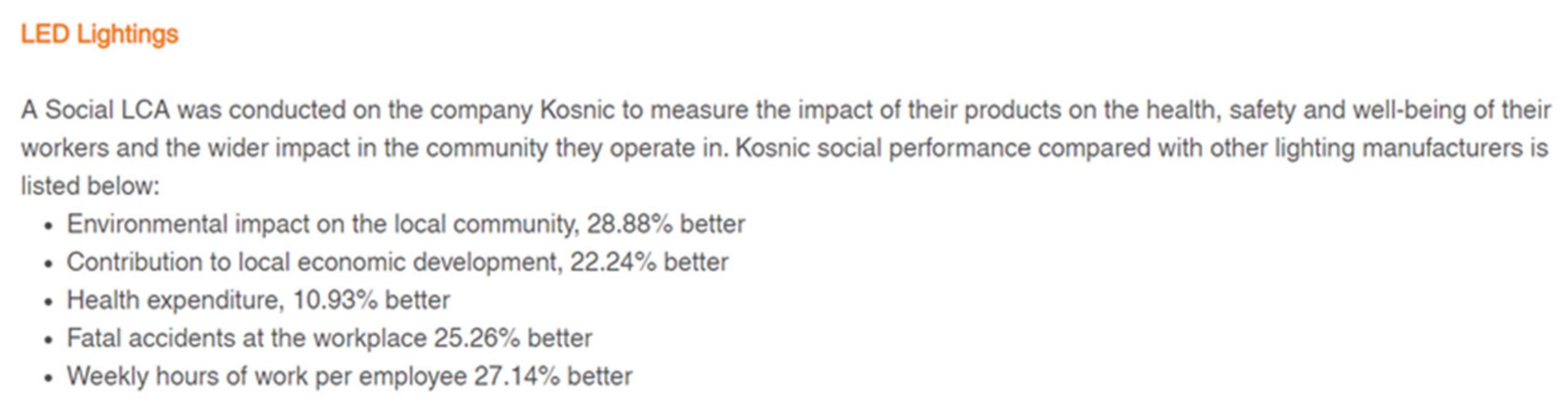

2.3. Social Impact

2.4. Environmental and Social Life-Cycle Assessment in Sustainable Product Development

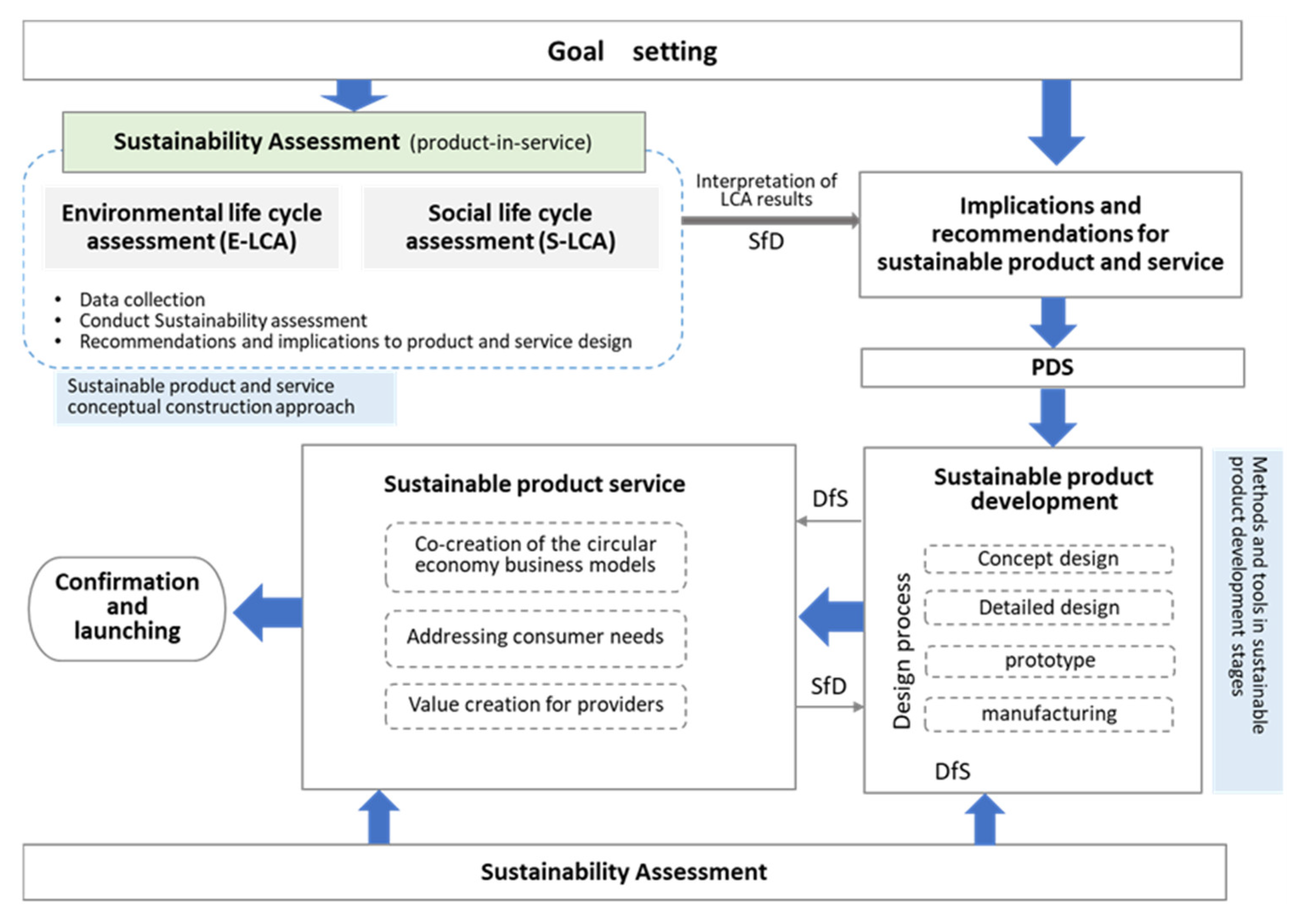

2.5. Sustainable Product Development and Service Approach

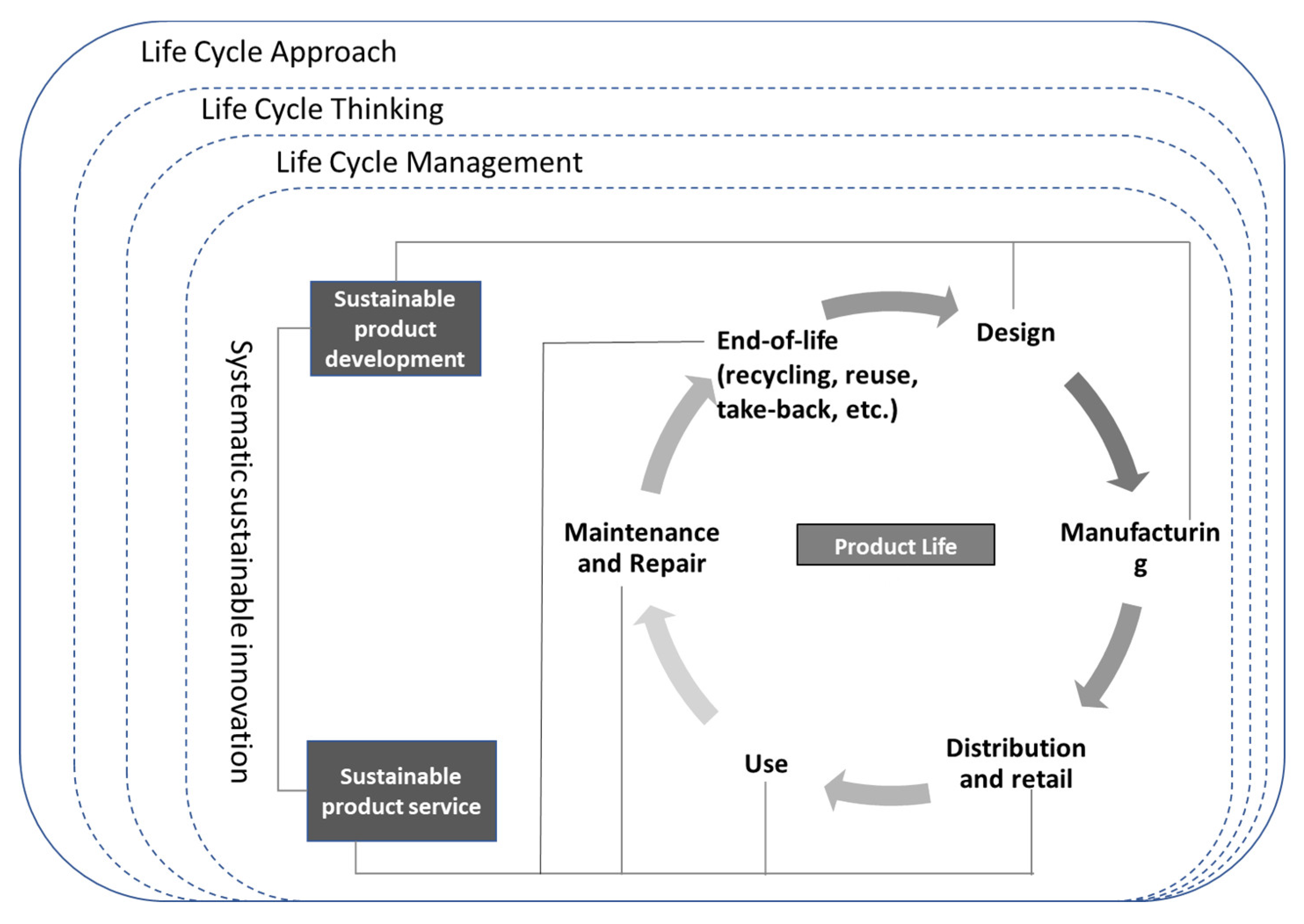

2.5.1. Overview

- As a life-cycle approach developed based on the existing frameworks and approaches, the SPDS is more advanced than the existing LCM and PSS applications.

- It considers all stages of the product life-cycle, from product design, manufacture, distribution, retail, use, maintenance, and repair, to EoL.

- The TBL of sustainability is addressed in both products and services.

- The interaction between product development and service phases enhances sustainability performance.

2.5.2. Implementing the Approach

3. Communication of Product Sustainability with Consumers

3.1. Ecolabelling and Declaration

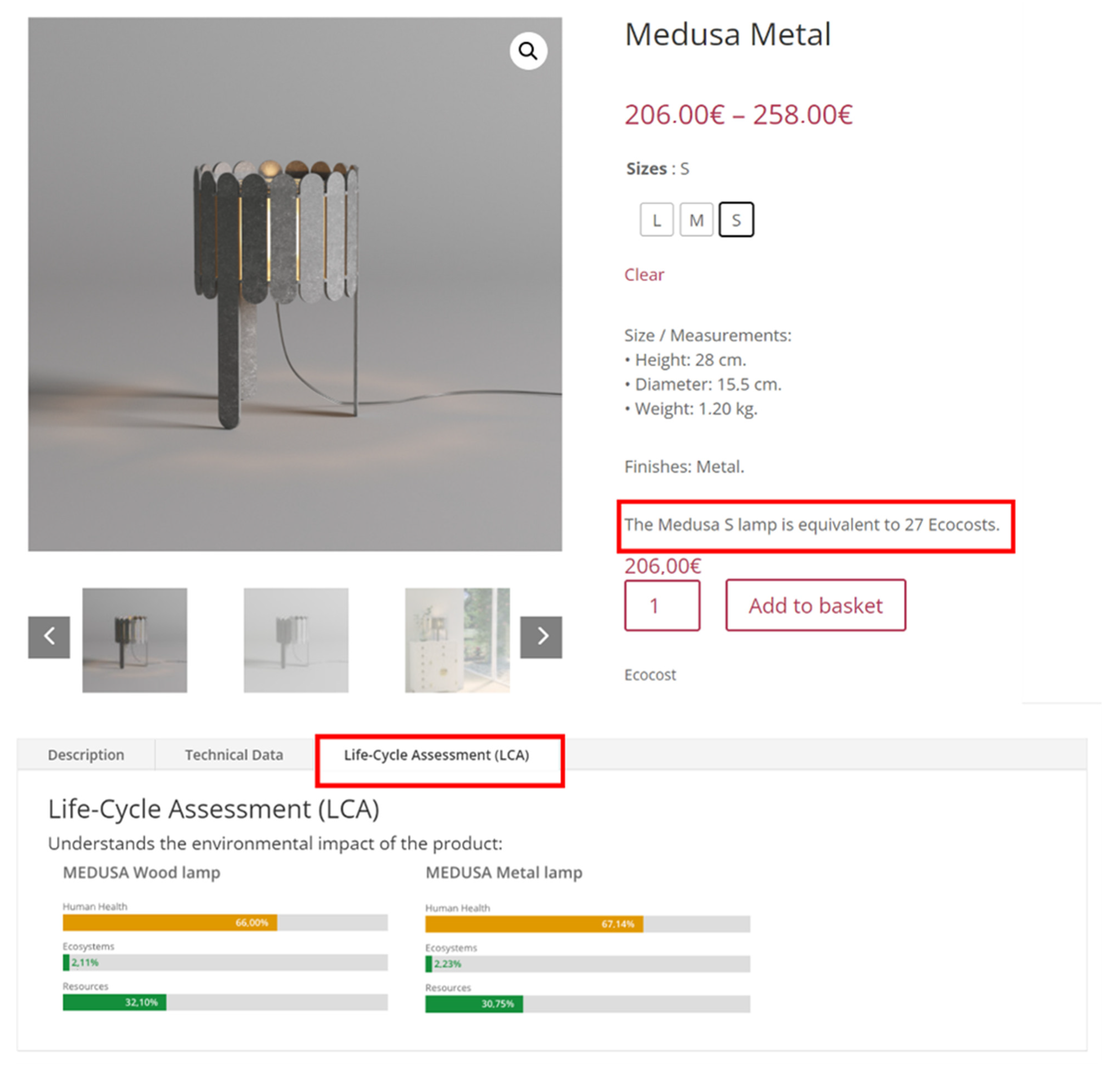

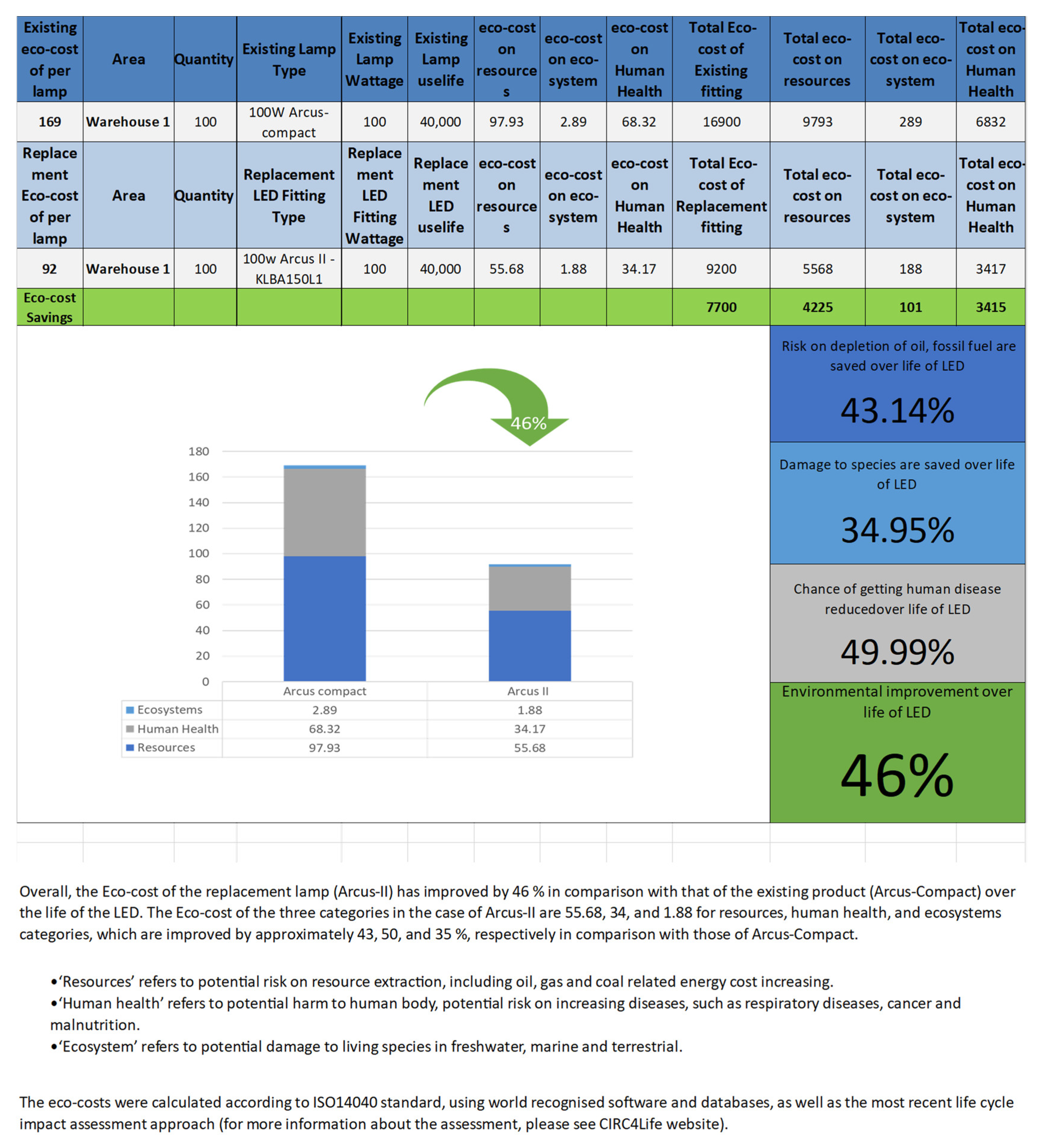

3.2. Eco-Cost Based Consumer Communication Methods

3.2.1. Eco-Cost Based Ecolabelling

3.2.2. Communication of Product Sustainability with Product Descriptions

4. Discussion

4.1. Sustainable Product Development and Service

4.2. Ecolabelling and Declaration

5. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Brundtland, G. Our Common Future: The World Commission on Environment and Development; Oxford University Press: Oxford, UK, 1987; p. 43. [Google Scholar]

- United Nation Development Project (UNDP). Sustainable Development Goals. Available online: http://www.undp.org/content/undp/en/home/sustainable-development-goals.html (accessed on 8 January 2019).

- Elkington, J. Cannibals with Forks—Triple Bottom Line of 21st Century Business; New Society Publishers: Stoney Creek, CT, USA, 1997. [Google Scholar]

- Boks, C.; McAloone, T.C. Transitions in sustainable product design research. Int. J. Prod. 2009, 9, 429–449. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Agudelo, L.M.; Nadeau, J.P.; Pailhes, J.; Mejía-Gutiérrez, R. A taxonomy for product shape analysis to integrate in early environmental impact estimations. Int. J. Interact. Des. Manuf. 2017, 11, 397–413. [Google Scholar] [CrossRef] [Green Version]

- Kravchenko, M.; Pigosso, D.C.; McAloone, T.C. Towards the ex-ante sustainability screening of circular economy initiatives in manufacturing companies: Consolidation of leading sustainability-related performance indicators. J. Clean. Prod. 2019, 241, 118318. [Google Scholar] [CrossRef]

- Stahel, W. Sustainability and Services. In Sustainable Solutions–Developing Products and Services for the Future; Charter, M.U., Tischner, U., Eds.; Greenleaf Publishing: Sheffield, UK, 2001; pp. 151–162. [Google Scholar]

- Lindhqvist, T. Extended Producer Responsibility in Cleaner Production. Ph.D. Dissertation, IIIEE Lund University, Lund, Sweden, 2000. [Google Scholar]

- Goedkoop, M.J.; Van Halen, C.J.; Te Riele, H.R.; Rommens, P.J. Product Service Systems, Ecological and Economic Basics Report for Dutch Ministries of Environment (VROM) and Economic Affairs (EZ); Ruimtelijke Ordening en Milieubeheer: The Hague, The Netherlands, 1999; Volume 36, pp. 1–122. [Google Scholar]

- UNEP. Eco-Labelling. Available online: https://www.unep.org/explore-topics/resource-efficiency/what-we-do/responsible-industry/eco-labelling (accessed on 13 July 2021).

- Wang, S.; Su, D.; Ma, M.; Kuang, W. Sustainable Product Development and Service Approach for Application in Industrial Lighting Products. Sustain. Prod. Consum. 2021, 27, 1808–1821. [Google Scholar] [CrossRef]

- McAloone, T.C.; Bey, N. Environmental Improvement through Product Development—A Guide; Danish EPA: Copenhagen, Denmark, 2009; p. 46. [Google Scholar]

- Fava, J.A.; Denison, R.; Jones, B.; Curran, M.A.; Vigon, B.; Selke, S.; Barnum, J. A Technical Framework for Life-Cycle Assessment: Workshop Report; Society of Environmental Toxicology and Chemistry: Washington, DC, USA, 1991. [Google Scholar]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment–Requirements and Guidelines. ISO (International Organization for Standardization): Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html?browse=tc (accessed on 1 April 2018).

- PRé. SimaPro Database Manual Methods Library. pp. 1–82. Available online: https://www.pre-sustainability.com/download/DatabaseManualMethods.pdf (accessed on 19 December 2015).

- THINKSTEP. Gabi DfX Software. Available online: http://www.gabi-software.com/software/gabi-dfx/ (accessed on 10 August 2015).

- GreenDelta. OpenLCA Software. Available online: http://www.openlca.org/ (accessed on 1 January 2018).

- Su, D.; Ren, Z.; Wu, Y. Guidelines for Selection of Life Cycle Impact Assessment Software Tools. In Sustainable Product Development: Tools, Methods and Example; Su, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Baumann, H.; Anne-Marie, T. The Hitch Hiker’s Guide to LCA: An Orientation in Life Cycle Assessment Methodology and Application; Studentlitteratur: Lund, Sweden, 2004. [Google Scholar]

- Zarandi, M.H.F.; Mansour, S.; Hosseinijou, S.A.; Avazbeigi, M. A material selection methodology and expert system for sustainable product design. Int. J. Adv. Manuf. Technol. 2011, 57, 885–903. [Google Scholar] [CrossRef]

- Sakundarini, N.; Taha, Z.; Abdul-Rashid, S.H.; Ghazila, R.A.R. Optimal multi-material selection for lightweight design of automotive body assembly incorporating recyclability. Mater. Des. 2013, 50, 846–857. [Google Scholar] [CrossRef]

- Andriankaja, H.; Vallet, F.; Le Duigou, J.; Eynard, B. A method to ecodesign structural parts in the transport sector based on product life cycle management. J. Clean. Prod. 2015, 94, 165–176. [Google Scholar] [CrossRef]

- Zhang, Y.; Luo, X.; Buis, J.J.; Sutherland, J.W. LCA-oriented semantic representation for the product life cycle. J. Clean. Prod. 2015, 86, 146–162. [Google Scholar] [CrossRef]

- González-García, S.; Lozano, R.G.; Buyo, P.; Pascual, R.C.; Gabarrell, X.; Pons, J.R.I.; Moreira, M.T.; Feijoo, G. Eco-innovation of a wooden based modular social playground: Application of LCA and DfE methodologies. J. Clean. Prod. 2012, 27, 21–31. [Google Scholar] [CrossRef]

- Spangenberg, J.H.; Fuad-Luke, A.; Blincoe, K. Design for Sustainability (DfS): The interface of sustainable production and consumption. J. Clean. Prod. 2010, 18, 1485–1493. [Google Scholar] [CrossRef]

- Besharati, B.; Azarm, S.; Kannan, P.K. A decision support system for product design selection: A generalized purchase modeling approach. Decis. Support Syst. 2006, 42, 333–350. [Google Scholar] [CrossRef]

- Buchert, T.; Neugebauer, S.; Schenker, S.; Lindow, K.; Stark, R. Multi-criteria Decision Making as a Tool for Sustainable Product Development—Benefits and Obstacles. Procedia CIRP 2015, 26, 70–75. [Google Scholar] [CrossRef] [Green Version]

- Heintz, J.; Belaud, J.P.; Gerbaud, V. Chemical enterprise model and decision-making framework for sustainable chemical product design. Comput. Ind. 2014, 65, 505–520. [Google Scholar] [CrossRef] [Green Version]

- Manzini, E. Design Research for Sustainable Social Innovation. In Design Research Now Board of International Research in Design; Michel, R., Ed.; Birkhäuser: Basel, Switzerland, 2007; pp. 233–245. [Google Scholar]

- United Nations General Assembly (UNGA). 2005 World Summit Outcome, Resolution A/60/1; United Nations General Assembly (UNGA): New York, NY, USA, 2005. [Google Scholar]

- Bogue, R. Sustainable manufacturing: A critical discipline for the twenty-first century. Assemb. Autom. 2014, 34, 117–122. [Google Scholar] [CrossRef]

- Malek, J.; Desai, T.N. A systematic literature review to map literature focus of sustainable manufacturing. J. Clean. Prod. 2020, 256, 120345. [Google Scholar] [CrossRef]

- Chan, F.; Li, N.; Chung, S.H.; Saadat, M. Management of sustainable manufacturing systems-a review on mathematical problems. Int. J. Prod. Res. 2017, 55, 1148–1163. [Google Scholar] [CrossRef]

- Rashid, S.H.A.; Evans, S.; Longhurst, P.; Abdul, S.H.; Evans, S. A comparison of four sustainable manufacturing strategies. Int. J. Sustain. Eng. 2008, 1, 214–229. [Google Scholar] [CrossRef]

- Ball, P.D.; Despeisse, M.; Mbaye, F.; Levers, A. The emergence of sustainable manufacturing practices. Prod. Plann. Contr. 2012, 23, 354–376. [Google Scholar] [CrossRef]

- Gupta, K.; Laubscher, R.F.; Davim, J.P.; Jain, N.K. Recent developments in sustainable manufacturing of gears: A review. J. Clean. Prod. 2016, 112, 3320–3330. [Google Scholar] [CrossRef]

- Ahmad, S.; Wong, K.Y.; Rajoo, S. Sustainability indicators for manufacturing sectors: A literature survey and maturity analysis from the triple-bottom line perspective. J. Manuf. Technol. Manag. 2018, 30, 312–334. [Google Scholar] [CrossRef]

- Gbededo, M.A.; Liyanage, K.; Garza-Reyes, J.A. Towards a Life Cycle Sustainability Analysis: A systematic review of approaches to sustainable manufacturing. J. Clean. Prod. 2018, 184, 1002–1015. [Google Scholar] [CrossRef] [Green Version]

- Vezzoli, C.; Kohtala, C.; Srinivasan, A.; Xin, L.; Fusakul, M.; Sateesh, D.; Diehl, J.C. Product-Service System Design for Sustainability; Greenleaf Pub.: Sheffield, UK, 2014; pp. 29–42. [Google Scholar]

- Behrendt, S.; Jasch, C.; Kortman, J.; Hrauda, G.; Pfitzner, R.; Velte, D. Eco-Service Development: Reinventing Supply and Demand in the European Union; Greenleaf Publishing: Sheffield, UK, 2003. [Google Scholar]

- Brezet, J.C.; Bijma, A.S.; Ehrenfeld, J.; Silvester, S. The Design of Eco-Efficient Services: Method, Tools and Review of the Case Study Based Designing Eco-Efficient Services; Dutch Ministries of Environment VROM & Delft University of Technology: Delft, The Netherlands, 2001. [Google Scholar]

- Zaring, O. Creating Eco-Efficient Producer Services; Goteborg Research Institute: Goteborg, Sweden, 2001. [Google Scholar]

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Tukker, A.; Tischner, U. Product-services as a research field: Past, present and future. Reflections from a decade of research. J. Clean. Prod. 2006, 14, 1552–1556. [Google Scholar] [CrossRef]

- Annarelli, A.; Battistella, C.; Nonino, F. Product service system: A conceptual framework from a systematic review. J. Clean. Prod. 2016, 139, 1011–1032. [Google Scholar] [CrossRef]

- Mont, O.; Lindhqvist, T. The role of public policy in advancement of product service systems. J. Clean. Prod. 2003, 11, 905–914. [Google Scholar] [CrossRef]

- Backhaus, J.; Genus, A.; Lorek, S.; Vadovics, E.; Wittmayer, J.M. (Eds.) Social Innovation and Sustainable Consumption: Research and Action for Societal Transformation; Routledge: London, UK, 2017; p. 2. [Google Scholar]

- Santillo, D. Reclaiming the Definition of Sustainability. Environ. Sci. Pollut. Res. 2007, 14, 60–66. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Halog, A.; Cloutier, S. Systems Thinking for Life Cycle Sustainability Assessment: A Review of Recent Developments, Applications, and Future Perspectives. Sustainability 2017, 9, 706. [Google Scholar] [CrossRef] [Green Version]

- Partridge, E. Social Sustainability. In Encyclopedia of Quality of Life and Well-Being Research; Michalos, A.C., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 6178–6186. [Google Scholar] [CrossRef]

- D’Eusanio, M.; Zamagni, A.; Petti, L. Social sustainability and supply chain management: Methods and tools. J. Clean. Prod. 2019, 235, 178–189. [Google Scholar] [CrossRef]

- Hutchins, M.J.; Sutherland, J.W. An exploration of measures of social sustainability and their application to supply chain decisions. J. Clean. Prod. 2008, 16, 1688–1698. [Google Scholar] [CrossRef]

- Vachon, S.; Mao, Z. Linking supply chain strength to sustainable development: A country-level analysis. J. Clean. Prod. 2008, 16, 1552–1560. [Google Scholar] [CrossRef]

- Chou, C.J.; Chen, C.W.; Conley, C. An approach to assessing sustainable product-service systems. J. Clean. Prod. 2015, 86, 277–284. [Google Scholar] [CrossRef]

- Costa, F.; Prendeville, S.; Beverley, K.; Teso, G.; Brooker, C. Sustainable Product-service Systems for an Office Furniture Manufacturer: How Insights from a Pilot Study can Inform PSS Design. Procedia CIRP 2015, 30, 66–71. [Google Scholar] [CrossRef] [Green Version]

- Petersen, M.; Brockhaus, M. Dancing in the dark: Challenges for product developers to improve and communicate product sustainability. J. Clean. Prod. 2017, 161, 345–354. [Google Scholar] [CrossRef]

- UNEP; Social LC Alliance. Guideline for Social Life Cycle Assessment of Products and Organisations 2020. Available online: https://wedocs.unep.org/20.500.11822/34554 (accessed on 2 August 2021).

- Arcese, G.; Lucchetti, M.C.; Massa, I.; Valente, C. State of the art in S-LCA: Integrating literature review and automatic text analysis. Int. J. Life Cycle Assess. 2018, 23, 394–405. [Google Scholar] [CrossRef]

- Franze, J.; Ciroth, A. A comparison of cut roses from Ecuador and the Netherlands. Int. J. Life Cycle Assess. 2011, 16, 366–379. [Google Scholar] [CrossRef]

- Ciroth, A.; Franze, J. LCA of An Eco-Labelled Notebook—Consideration of Social and Environmental Impacts along the Entire Life Cycle. Available online: https://www.greendelta.com/wp-content/uploads/2017/03/LCA_laptop_final.pdf (accessed on 6 February 2019).

- Foolmaun, R.K.; Ramjeeawon, T. Comparative life cycle assessment and social life cycle assessment of used polyethylene terephthalate (PET) bottles in Mauritius. Int. J. Life Cycle Assess. 2013, 18, 155–171. [Google Scholar] [CrossRef]

- Agyekum, E.O.; Fortuin, K.P.J.; Van Der Harst, E. Environmental and Social Life Cycle Assessment of Bamboo Bicycle Frames Made in Ghana. J. Clean. Prod. 2017, 143, 1069–1080. [Google Scholar] [CrossRef]

- Chongyang, D.; Luis, C.D.; Fausto, F. Robust multi-criteria weighting in comparative LCA and S-LCA: A case study of sugarcane production in Brazil. J. Clean. Prod. 2019, 218, 708–717. [Google Scholar] [CrossRef]

- Khorassani, S.M.; Ferrari, A.M.; Pini, M.; Blundo, D.S.; Muiña, F.E.G.; García, J.F. Environmental and social impact assessment of cultural heritage restoration and its application to the uncastillo fortress. Int. J. Life Cycle Assess. 2019, 24, 1297–1318. [Google Scholar] [CrossRef]

- Giachetti, R.E.; Young, R.E.; Roggatz, A. A Methodology for the reduction of Imprecision in the engineering process. Eur. J. Oper. Res. 1997, 100, 277–292. [Google Scholar] [CrossRef]

- Alblas, A.; Peters, K.; Wortmann, H. Fuzzy sustainability incentives in new product development—An empirical exploration of sustainability challenges in manufacturing companies. Int. J. Oper. Prod. Manag. 2014, 34, 513–545. [Google Scholar] [CrossRef]

- Brockhaus, S.; Petersen, M.; Kersten, W. A crossroads for bioplastics: Exploring product developers’ challenges to move beyond petroleum-based plastics. J. Clean. Prod. 2016, 127, 84–95. [Google Scholar] [CrossRef]

- UNEP/SETAC. Guidelines for Social Life Cycle Assessment of Products. Available online: http://www.unep.fr/shared/publications/pdf/dtix1164xpa-guidelines_slca.pdf (accessed on 3 April 2019).

- SETAC CPR. Life Cycle Assessment and Conceptually Related Programmes; Report of SETAC Conceptually Related Programmes Working Group; European Environment Agency: Copenhagen, Denmark, 1997. [Google Scholar]

- SETAC. Life Cycle Approaches-the Road from Analysis to Practice. Available online: http://lcastudio.cz/dokumenty/Life%20Cycle%20Approaches%20-%20The%20road%20from%20analysis%20to%20practice.pdf (accessed on 12 October 2020).

- Aurich, J.C.; Wolf, N.; Siener, M.; Schweitzer, E. Configuration of product-service systems. J. Manuf. Tehnol. Manag. 2009, 20, 591–605. [Google Scholar] [CrossRef]

- Maussang, N.; Zwolinski, P.; Brissaud, D. Product-service system design methodology: From the PSS architecture design to the products specifications. J. Eng. Des. 2009, 20, 349–366. [Google Scholar] [CrossRef]

- Wang, S.; Su, D.; Wu, Y. Environmental and social life cycle assessments of an industrial LED lighting product. Environ. Impact Assess. Rev. 2022, 95, 106804. [Google Scholar] [CrossRef]

- ISO (International Standardisation Organisation). Environmental Labels and Declarations—General Principles; ISO (International Standardisation Organisation): Geneva, Switzerland, 2000. [Google Scholar]

- ISO 14024:2018; Environmental Labels and Declarations: Type I Environmental Labelling: Principles and Procedures. ISO (International Standardisation Organisation): Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/72458.html?browse=tc (accessed on 3 March 2018).

- ISO 14021:2016; Environmental Labels and Declarations: Self-Declared Environmental Claims (Type II Environmental Labelling. ISO (International Standardisation Organisation): Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/66652.html?browse=tc (accessed on 3 March 2018).

- Allison, C.; Carter, A. Study on Different Types of Environmental Labelling (ISO Type II and III Labels): Proposal for an Environmental Labelling Strategy. 2000. Available online: https://ec.europa.eu/environment/archives/ecolabel/pdf/studies/erm.pdf (accessed on 13 July 2021).

- ISO 14025:2006; Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. ISO (International Standardisation Organisation): Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38131.html (accessed on 11 June 2022).

- EU Ecolabel. Available online: https://ec.europa.eu/environment/ecolabel/ (accessed on 5 August 2021).

- Global Green Tag. Available online: https://www.globalgreentag.com/ (accessed on 5 August 2021).

- Climatop. Available online: https://www.myclimate.org/de/aktiv-werden/firmenkundenclimatop-label/ (accessed on 9 May 2020).

- GreenCircle Certified. Available online: https://www.greencirclecertified.com/ (accessed on 25 July 2021).

- EPD. Available online: https://www.environdec.com/home/ (accessed on 25 July 2021).

- Whittaker, C.; McManus, M.C.; Smith, P. A comparison of carbon accounting tools forarable crops in the United Kingdom. Environ. Model. Softw. 2013, 46, 228–239. [Google Scholar] [CrossRef] [Green Version]

- LEAF. Available online: https://leaf.eco/farming/leaf-marque (accessed on 9 August 2021).

- Soil Association. Available online: https://www.soilassociation.org/ (accessed on 25 July 2021).

- Von Geibler, J.; Wiesen, K.; Werner, M.; Riera, N.; Su, D.Z.; Björling, S.E.; Domen, T.; Smith, J.; Jenkins, A.; Kresse, S. Forming the Nucleus of a Novel Ecological Accounting System: The myEcoCost Approach. Key Eng. Mater. 2014, 572, 78–83. [Google Scholar] [CrossRef] [Green Version]

- Su, D.; Peng, W. Eco-Accounting Infrastructure. In Sustainable Product Development; Su, D., Ed.; Springer: Cham, Switzerland, 2020; pp. 73–84. [Google Scholar] [CrossRef]

- Golsteijn, L. Updated Impact Assessment Methodology ReCiPe2016. 2017. Available online: https://simapro.com/2017/updated-impact-assessment-methodology-recipe-2016/ (accessed on 26 May 2022).

- CIRC4Life. CIRC4Life: A Circular Economy Approach for Lifecycles of Products and Services. Available online: https://www.circ4life.eu (accessed on 26 May 2022).

- Huang, H.; Su, D.; Peng, W.; Wu, Y. Development of a mobile application system for eco-accounting. Sustainability 2020, 22, 9675. [Google Scholar] [CrossRef]

- Peng, W.; Su, D. Novel ICT system for recycling and eco-shopping. Sustainability 2022, 14, 7687. [Google Scholar] [CrossRef]

- Peng, W.; Su, D.; Wang, S. Development of the Innovative ICT Infrastructure for an Eco-cost System with Life Cycle Assessment. Sustainability 2021, 6, 3118. [Google Scholar] [CrossRef]

- ALIA. CIRC4Life Deliverable 6.4: On Site Demonstration of CEBM for Meat Supply Chain. Available online: https://25cd04c9-5fc8-4b44-8c3c-9ad39fc8bbac.usrfiles.com/ugd/25cd04_b9087f4e816d40a185fe5a59e4a49d50.pdf (accessed on 26 May 2022).

- Smith, J. CIRC4Life Deliverable D6.3: On-Site Demonstration of CEBM with Vegetable Foods. Available online: https://25cd04c9-5fc8-4b44-8c3c-9ad39fc8bbac.usrfiles.com/ugd/25cd04_988d1325e9344e61b0c2e8e32be2c3aa.pdf (accessed on 26 May 2022).

- European Commission (EU). About the Energy Label and Ecodesign. Available online: https://ec.europa.eu/info/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/energy-label-and-ecodesign/about_en (accessed on 25 July 2021).

- ONA. Circular Economy Program for the Life Cycle of Products and Services. Available online: https://onaemotion.com/en/recyclable-lamps/9 (accessed on 20 July 2021).

- Kosnic. CIRC4Life Deliverable D6.1a: On Site Demonstration of CEBM for Industrial Lights. Available online: https://25cd04c9-5fc8-4b44-8c3c-9ad39fc8bbac.usrfiles.com/ugd/25cd04_b077218483c04369a082367384410947.pdf (accessed on 26 May 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Su, D. Sustainable Product Innovation and Consumer Communication. Sustainability 2022, 14, 8395. https://doi.org/10.3390/su14148395

Wang S, Su D. Sustainable Product Innovation and Consumer Communication. Sustainability. 2022; 14(14):8395. https://doi.org/10.3390/su14148395

Chicago/Turabian StyleWang, Shuyi, and Daizhong Su. 2022. "Sustainable Product Innovation and Consumer Communication" Sustainability 14, no. 14: 8395. https://doi.org/10.3390/su14148395

APA StyleWang, S., & Su, D. (2022). Sustainable Product Innovation and Consumer Communication. Sustainability, 14(14), 8395. https://doi.org/10.3390/su14148395