Design and Repair Strategies Based on Product–Service System and Remanufacturing for Value Preservation

Abstract

:1. Introduction

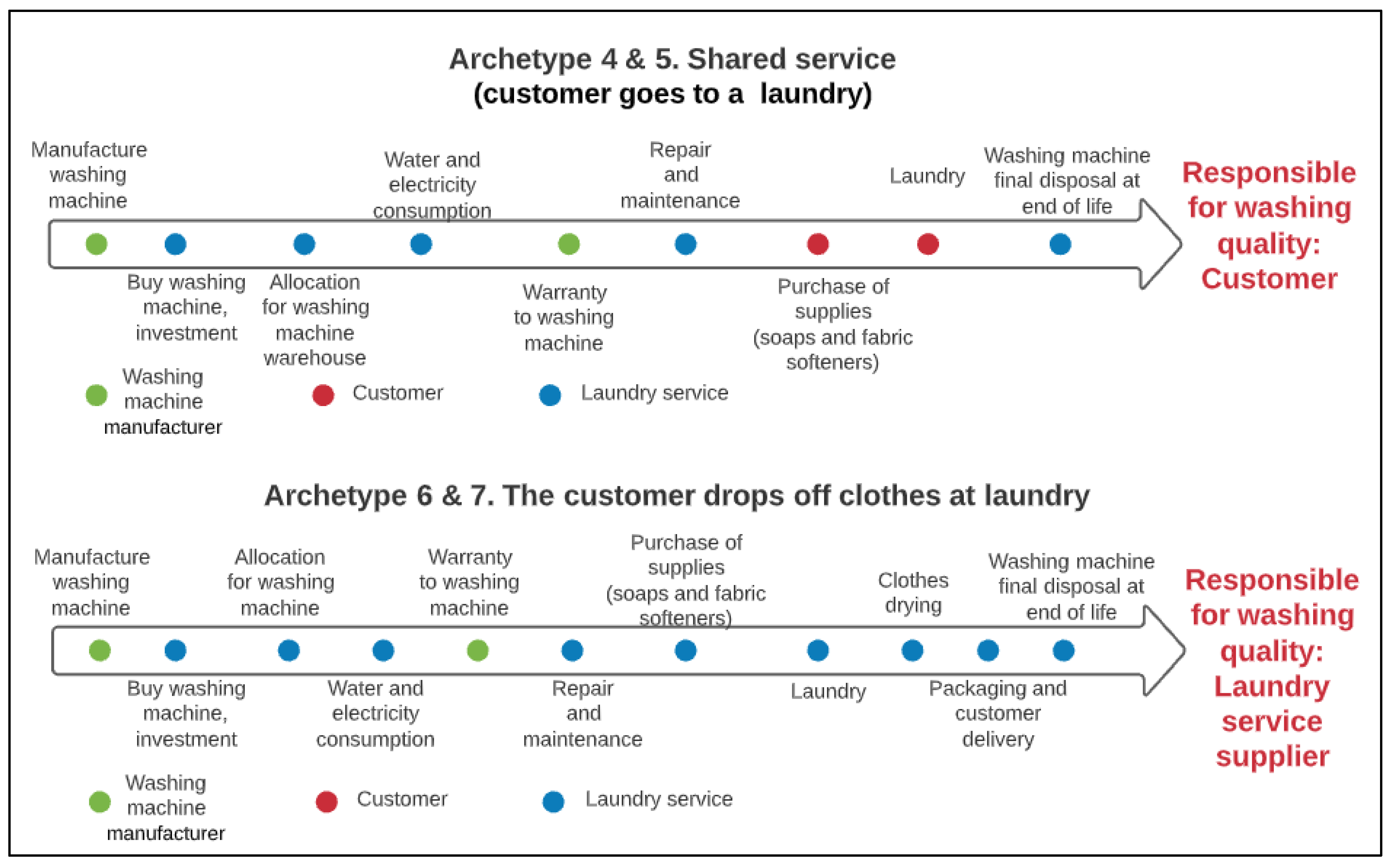

1.1. Product–Service System (PSS)

1.2. PSS and Original Equipment Manufacturer (OEM)

1.3. Previous Research

1.4. Research Problem and Objective

2. Methodology

2.1. Survey Development

2.2. Survey Application

2.3. Preliminary Model and Hypotheses

2.4. Data Debugging and Information Validation

- Identify extreme values and the 36 items are standardized.

- Identification of missing values, which are replaced by the median.

- Identification of uncommitted respondents, for which each case is standardized.

2.5. Hypotheses Validation

- Average path coefficient (APC) and p < 0.05

- Average R-squared (ARS) and p < 0.05

- Average adjusted R-squared (AARS) > 0.02 and p < 0.05

- Average block VIF (AVIF), acceptable if ≤5, ideally ≤ 3.3

- Average full collinearity VIF (AFVIF), acceptable if ≤5, ideally ≤ 3.3

- Tenenhaus GoF (GoF), small ≥ 0.1, medium ≥ 0.25, large ≥ 0.36

3. Results

3.1. Sample Description

3.2. Variables Validation

3.3. Preliminary Model Evaluation

- Average path coefficient (APC) = 0.296, p < 0.001

- Average R-squared (ARS) = 0.597, p < 0.001

- Average adjusted R-squared (AARS) = 0.594, p < 0.001

- Average block VIF (AVIF) = 2.955, acceptable if ≤ 5, ideally ≤ 3.3

- Average full collinearity VIF (AFVIF) = 3.320, acceptable if ≤ 5, ideally ≤ 3.3

- Tenenhaus GoF (GoF) = 0.706, small ≥ 0.1, medium ≥0.25, large ≥ 0.36

3.4. Direct Effects—Hypotheses Validation

3.5. Indirect Effects and Total Effect

3.6. Canvas Model

4. Discussion of Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Colglazier, W. Sustainable development agenda: 2030. Science 2015, 349, 1048–1050. [Google Scholar] [CrossRef]

- Sala, S.; Castellani, V. The consumer footprint: Monitoring sustainable development goal 12 with process-based life cycle assessment. J. Clean. Prod. 2019, 240, 118050. [Google Scholar] [CrossRef] [PubMed]

- Sanyé-Mengual, E.; Secchi, M.; Corrado, S.; Beylot, A.; Sala, S. Assessing the decoupling of economic growth from environmental impacts in the European Union: A consumption-based approach. J. Clean. Prod. 2019, 236, 117535. [Google Scholar] [CrossRef] [PubMed]

- Nieto, A.T. Crecimiento Económico e industrialización en la agenda 2030: PERSPECTIVAS para méxico. Probl. Del Desarro. 2017, 48, 83–111. [Google Scholar] [CrossRef]

- Arredondo-Soto, K.C.; Realyvasquez-Vargas, A.; Maldonado-Macías, A.A.; García-Alcaraz, J. Impact of human resources on remanufacturing process, internal complexity, perceived quality of core, numerosity, and key process indicators. Robot. Comput.-Integr. Manuf. 2019, 59, 168–176. [Google Scholar] [CrossRef]

- Khor, K.S.; Hazen, B.T. Remanufactured products purchase intentions and behaviour: Evidence from Malaysia. Int. J. Prod. Res. 2017, 55, 2149–2162. [Google Scholar] [CrossRef]

- Guide, V.D.R. Production planning and control for remanufacturing: Industry practice and research needs. J. Oper. Manag. 2000, 18, 467–483. [Google Scholar] [CrossRef]

- Besch, K. Product-service systems for office furniture: Barriers and opportunities on the European market. J. Clean. Prod. 2005, 13, 1083–1094. [Google Scholar] [CrossRef] [Green Version]

- Zhu, X.; Yu, L. The Impact of Warranty Efficiency of Remanufactured Products on Production Decisions and Green Growth Performance in Closed-Loop Supply Chain: Perspective of Consumer Behavior. Sustainability 2019, 11, 1420. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Hazen, B.T. Consumer product knowledge and intention to purchase remanufactured products. Int. J. Prod. Econ. 2016, 181, 460–469. [Google Scholar] [CrossRef]

- Wang, Y.; Wiegerinck, V.; Krikke, H.R.; Zhang, H. Understanding the purchase intention towards remanufactured product in closed-loop supply chains: An empirical study in China. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 866–888. [Google Scholar] [CrossRef]

- Singhal, D.; Tripathy, S.; Jena, S.K. Acceptance of remanufactured products in the circular economy: An empirical study in India. Manag. Decis. 2019, 57, 953–970. [Google Scholar] [CrossRef]

- Matsumoto, M.; Chinen, K.; Endo, H. Remanufactured auto parts market in Japan: Historical review and factors affecting green purchasing behavior. J. Clean. Prod. 2018, 172, 4494–4505. [Google Scholar] [CrossRef]

- Matsumoto, M.; Chinen, K.; Endo, H. Paving the way for sustainable remanufacturing in Southeast Asia: An analysis of auto parts markets. J. Clean. Prod. 2018, 205, 1029–1041. [Google Scholar] [CrossRef]

- Hazen, B.T.; Boone, C.A.; Wang, Y.; Khor, K.S. Perceived quality of remanufactured products: Construct and measure development. J. Clean. Prod. 2017, 142 Pt 2, 716–726. [Google Scholar] [CrossRef]

- Sabbaghi, M.; Behdad, S.; Zhuang, J. Managing consumer behavior toward on-time return of the waste electrical and electronic equipment: A game theoretic approach. Int. J. Prod. Econ. 2016, 182, 545–563. [Google Scholar] [CrossRef] [Green Version]

- Hazen, B.T.; Mollenkopf, D.A.; Wang, Y. Remanufacturing for the Circular Economy: An Examination of Consumer Switching Behavior. Bus. Strategy Environ. 2017, 26, 451–464. [Google Scholar] [CrossRef]

- van Weelden, E.; Mugge, R.; Bakker, C. Paving the way towards circular consumption: Exploring consumer acceptance of refurbished mobile phones in the Dutch market. J. Clean. Prod. 2016, 113, 743–754. [Google Scholar] [CrossRef] [Green Version]

- Kapetanopoulou, P.; Tagaras, G. An empirical investigation of value-added product recovery activities in SMEs using multiple case studies of OEMs and independent remanufacturers. Flex. Serv. Manuf. J. 2009, 3–4, 92–113. [Google Scholar] [CrossRef]

- Arredondo-Soto, K.C.; Reyes-Martínez, R.M.; Sánchez-Leal, J.; De la Riva Rodríguez, J. Methodology to apply design for remanufacturing in product development. In Handbook of Research on Ergonomics and Product Design; IGI Global: Hershey, PA, USA, 2018; pp. 347–363. [Google Scholar]

- Esquer, J.; Arvayo, J.A.; Alvarez-Chavez, C.R.; Munguia-Vega, N.E.; Velazquez, L. Cleaner production in a remanufacturing process of air compressors. Int. J. Occup. Saf. Ergon. 2017, 23, 83–91. [Google Scholar] [CrossRef]

- Cordova-Pizarro, D.; Aguilar-Barajas, I.; Romero, D.; Rodriguez, C.A. Circular Economy in the Electronic Products Sector: Material Flow Analysis and Economic Impact of Cellphone E-Waste in Mexico. Sustainability 2019, 11, 1361. [Google Scholar] [CrossRef] [Green Version]

- Maussang, N.; Zwolinski, P.; Brissaud, D. Product-service system design methodology: From the PSS architecture design to the products specifications. J. Eng. Des. 2009, 20, 349–366. [Google Scholar] [CrossRef]

- Byrne, B.M. Structural Equation Modeling with AMOS: Basic Concepts. 2002. Available online: https://www.narcis.nl/publication/RecordID/oai:repository.ubn.ru.nl:2066%2F62519 (accessed on 24 November 2021).

- Kock, N. Advanced Mediating Effects Tests, Multi-Group Analyses, and Measurement Model Assessments in PLS-Based SEM. IJEC 2014, 10, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Schumacker, R.E.; Lomax, R.G. A Beginner’s Guide to Structural Equation Modeling; Psychology Press: New York, NY, USA, 2004. [Google Scholar]

- Jiménez-Parra, B.; Rubio, S.; Vicente-Molina, M.-A. Key drivers in the behavior of potential consumers of remanufactured products: A study on laptops in Spain. J. Clean. Prod. 2014, 85, 488–496. [Google Scholar] [CrossRef]

- Bensmain, Y.; Dahane, M.; Bennekrouf, M.; Sari, Z. Preventive remanufacturing planning of production equipment under operational and imperfect maintenance constraints: A hybrid genetic algorithm based approach. Reliab. Eng. Syst. Saf. 2019, 185, 546–566. [Google Scholar] [CrossRef]

- Govindan, K.; Jiménez-Parra, B.; Rubio, S.; Vicente-Molina, M.-A. Marketing issues for remanufactured products. J. Clean. Prod. 2019, 227, 890–899. [Google Scholar] [CrossRef]

- Choi, T.-M. Pricing and branding for remanufactured fashion products. J. Clean. Prod. 2017, 165, 1385–1394. [Google Scholar] [CrossRef]

- Liao, B.; Li, B.; Cheng, J. A warranty model for remanufactured products. J. Ind. Prod. Eng. 2015, 32, 551–558. [Google Scholar] [CrossRef]

- Sinha, P.; Muthu, S.S.; Dissanayake, G. Systems Requirements for Remanufactured Fashion as an Industry. In Remanufactured Fashion; Environmental Footprints and Eco-design of Products and Processes; Springer: Singapore, 2016; pp. 45–71. ISBN 978-981-10-0295-3. [Google Scholar]

- Pandey, V.; Thurston, D. Effective Age of Remanufactured Products: An Entropy Approach. J. Mech. Des. 2009, 131, 031008. [Google Scholar] [CrossRef]

- Ferrer, G.; Swaminathan, J.M. Managing new and differentiated remanufactured products. Eur. J. Oper. Res. 2010, 203, 370–379. [Google Scholar] [CrossRef] [Green Version]

- Inderfurth, K.; Mukherjee, K. Decision support for spare parts acquisition in post product life cycle. Cent. Eur. J. Oper. Res. 2008, 16, 17–42. [Google Scholar] [CrossRef]

- Frota Neto, J.Q.; Bloemhof, J.; Corbett, C. Market prices of remanufactured, used and new items: Evidence from eBay. Int. J. Prod. Econ. 2016, 171, 371–380. [Google Scholar] [CrossRef]

- Abbey, J.D.; Blackburn, J.D.; Guide, V.D.R. Optimal pricing for new and remanufactured products. J. Oper. Manag. 2015, 36, 130–146. [Google Scholar] [CrossRef]

- Alqahtani, A.Y.; Gupta, S.M. Warranty and Preventive Maintenance for Remanufactured Products: Modeling and Analysis; CRC Press: Boca Raton, FL, USA, 2018; ISBN 978-1-351-59920-7. [Google Scholar]

- Aljuneidi, T.; Bulgak, A.A. Carbon footprint for designing reverse logistics network with hybrid manufacturing-remanufacturing systems. J. Remanufactur. 2020, 10, 107–126. [Google Scholar] [CrossRef]

- Sarigöllü, E.; Hou, C.; Ertz, M. Sustainable product disposal: Consumer redistributing behaviors versus hoarding and throwing away. Bus Strat. Env. 2021, 30, 340–356. [Google Scholar] [CrossRef]

- Sundin, E.; Lee, H.M. In what way is remanufacturing good for the environment? In Design for Innovative Value Towards a Sustainable Society; Matsumoto, M., Umeda, Y., Masui, K., Fukushige, S., Eds.; Springer: Dordrecht, The Netherlands, 2012; pp. 552–557. ISBN 978-94-007-3010-6. [Google Scholar]

- Ardente, F.; Talens Peiró, L.; Mathieux, F.; Polverini, D. Accounting for the environmental benefits of remanufactured products: Method and application. J. Clean. Prod. 2018, 198, 1545–1558. [Google Scholar] [CrossRef]

- Georgiadis, P.; Vlachos, D. The effect of environmental parameters on product recovery. Eur. J. Oper. Res. 2004, 157, 449–464. [Google Scholar] [CrossRef]

- Testa, F.; Iraldo, F.; Vaccari, A.; Ferrari, E. Why Eco-labels can be Effective Marketing Tools: Evidence from a Study on Italian Consumers: Why Eco-Labels can be Effective Marketing Tools. Bus. Strat. Environ. 2015, 24, 252–265. [Google Scholar] [CrossRef]

- Salimi, A.R. Effects of environmental concerns and green knowledge on green product consumptions with an emphasis on mediating role of perceived behavioral control, perceived value, attitude and subjective norm. Int. Trans. J. Eng. 2019, 10, 651661. [Google Scholar] [CrossRef]

- Xu, Q.; Shao, Z.; He, Y. Optimal delivery strategies for packing box recycling in online platforms. J. Clean. Prod. 2020, 276, 124273. [Google Scholar] [CrossRef]

- Gaur, J.; Amini, M.; Banerjee, P.; Gupta, R. Drivers of consumer purchase intentions for remanufactured products: A study of Indian consumers relocated to the USA. Qual. Mark. Res. Int. J. 2015, 18, 30–47. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, Y.; Chen, H.; Guo, S.; Lu, Y. Selling Remanufactured Products under One Roof or Two? A Sustainability Analysis on Channel Structures for New and Remanufactured Products. Sustainability 2018, 10, 2427. [Google Scholar] [CrossRef] [Green Version]

- Singhal, D.; Jena, S.K.; Tripathy, S. Factors influencing the purchase intention of consumers towards remanufactured products: A systematic review and meta-analysis. Int. J. Prod. Res. 2019, 57, 7289–7299. [Google Scholar] [CrossRef]

- Van Nguyen, T.; Zhou, L.; Chong, A.Y.L.; Li, B.; Pu, X. Predicting customer demand for remanufactured products: A data-mining approach. Eur. J. Oper. Res. 2020, 281, 543–558. [Google Scholar] [CrossRef]

- Kock, N. Factor-based structural equation modeling with WarpPLS. Australas. Mark. J. AMJ 2019, 27, 57–63. [Google Scholar] [CrossRef]

- Shrafat, F.D.; Ismail, M. Structural equation modeling of lean manufacturing practices in a developing country context. J. Manuf. Technol. Manag. 2018, 30, 122–145. [Google Scholar] [CrossRef]

- García-Alcaraz, J.L.; Realyvazquez Vargas, A.; Hernandez Escobedo, G.; Arredondo Soto, K.; Garcia Ortiz, J.E.; Blanco Fernandez, J.; Jimenez Macias, E. The DMAIC Methodology as a Tool for Process Improvement: The Case of a Mexican Maquiladora Company. Available online: http://cathi.uacj.mx/handle/20.500.11961/19668 (accessed on 13 April 2022).

- Factors Affecting the Adoption of e-Learning Technologies among Higher Education Students in Nigeria: A Structural Equation Modelling Approach—M Nasiru Yakubu, Salihu Ibrahim Dasuki. 2019. Available online: https://journals.sagepub.com/doi/abs/10.1177/0266666918765907 (accessed on 24 November 2021).

- Khwaja, M.G.; Mahmood, S.; Zaman, U. Examining the Effects of eWOM, Trust Inclination, and Information Adoption on Purchase Intentions in an Accelerated Digital Marketing Context. Information 2020, 11, 478. [Google Scholar] [CrossRef]

- del Valls Martínez, M.C.; Martín-Cervantes, P.A.; Sánchez Pérez, A.M.; del Martínez Victoria, M.C. Learning Mathematics of Financial Operations during the COVID-19 Era: An Assessment with Partial Least Squares Structural Equation Modeling. Mathematics 2021, 9, 2120. [Google Scholar] [CrossRef]

- INEGI. Instituto Nacional de Estadística y Geografía. INEGI. 2021. Available online: https://www.inegi.org.mx/ (accessed on 24 November 2021).

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley & Sons: Hoboken, NJ, USA, 2010; ISBN 978-0-470-87641-1. [Google Scholar]

- Tukker, A. Eight types of product–service system: Eight ways to sustainability? Experiences from SusProNet. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Q.; Liu, Z.; Chang, C.-T. Optimal pricing and remanufacturing mode in a closed-loop supply chain of WEEE under government fund policy. Comput. Ind. Eng. 2021, 151, 106951. [Google Scholar] [CrossRef]

- Milios, L.; Matsumoto, M. Consumer Perception of Remanufactured Automotive Parts and Policy Implications for Transitioning to a Circular Economy in Sweden. Sustainability 2019, 11, 6264. [Google Scholar] [CrossRef] [Green Version]

| Indicators | Critical Variables | Research |

|---|---|---|

| Risk perception, personal benefits, knowledge about remanufactured products, environmental concerns, market strategy, attitude, subjective norms, control of perceived behavior, and purchase intention. | Risk perception Personal benefits Knowledge about products | Acceptance of remanufactured products in the circular economy: an empirical study in India [12]. |

| Knowledge about products Personal benefits Risk perception | Knowledge about products Personal benefits Risk perception | Consumer Perception of Remanufactured Automotive Parts and Policy Implications for Transitioning to a Circular Economy in Sweden [27]. |

| Subjective norms, motives, marketing mix factors, and purchase intention all influence how people feel about buying a refurbished laptop. | Attitude toward the purchase of a remanufactured laptop Subjective norms Motivations | Key drivers in the behavior of potential consumers of remanufactured products: a study on laptops in Spain [10]. |

| Attitude, subjective norms, control of perceived behavior, purchase intention of remanufactured products, purchase-energy efficiency, new condition, and remanufactured. | Attitude, Subjective norms, purchase intention of remanufactured products. Purchase-energy efficiency, -new condition and remanufactured | Remanufactured products purchase intentions and behavior: Evidence from Malaysia [6]. |

| Perceived value, perceived risk, purchase intention, knowledge about cost, environment knowledge, and quality knowledge. | Perceived value Perceived risk Purchase intention | Consumer product knowledge and intention to purchase remanufactured products [10]. |

| Risk Perception (RP) Arguments Considered in the Instrument | Variable Evaluated and Author |

|---|---|

| 1. I have my doubts about the quality of remanufactured goods. | Quality [17]. |

| 2. I have to spend a lot and money on remanufactured product maintenance. | Maintenance expenses [28]. |

| 3. Remanufactured products, in my opinion, function poorly. | Performance [5]. |

| 4. If I purchase these items, others will ridicule me. | Self-perception [29]. |

| 5. Remanufactured products aren’t as excellent as new ones, which could endanger my health. | Security [29]. |

| 6. Because remanufactured items may not function as well as new ones, their performance may be affected. | Functioning [13]. |

| 7. Buying remanufactured products is a bad investment. | Investment [30]. |

| Remanufactured Products Knowledge (RPK) | |

| 8. If remanufactured items come with a specified guarantee, I’ll purchase them. | Warranty [31]. |

| 9. If remanufactured items offer the newest features, I will purchase them. | Modernity [32]. |

| 10. I’m acquainted with remanufactured items’ performance and qualities. | Features [33]. |

| 11. I am aware of the differences in quality between remanufactured and new items. | Comparison [34]. |

| 12. I understand the distinctions between remanufactured and new items. | Differences [34]. |

| 13. I will purchase remanufactured products if replacement parts for critical components are available. | Spare parts [35]. |

| Personal Benefits Focused on Design Strategy (PBFDS) | |

| 14. Because of their reduced pricing, I will purchase remanufactured items. | Price [36]. |

| 15. I can obtain government subsidies if I purchase remanufactured items. | Government incentives [12]. |

| 16. If I consume remanufactured products, I may have additional discounts. | Discounts [37]. |

| 17. Buying remanufactured products instead of new ones saves me. | Savings [38]. |

| 18. I am willing to purchase remanufactured products if maintenance services increase the product’s useful life. | Maintenance services [38]. |

| Concern for the Environment (CE) | |

| 19. I would buy remanufactured products because they lower the carbon footprint. | Carbon footprint [39]. |

| 20. I would buy remanufactured products because they decrease global warming. | Global warming [40]. |

| 21. I would purchase remanufactured items since they are environmentally friendly. | Concern for the environment [40]. |

| 22. If I buy remanufactured products instead of new ones, I can save resources and energy in the environment. | Resource-saving [40]. |

| 23. Buying remanufactured products reduces adverse effects on the environment. | Effects on the environment [41]. |

| 24. Buying remanufactured products reduces the over-extraction of primary (virgin) resources. | Resource extraction [42]. |

| 25. Buying remanufactured products help partially or recover their components at their end of useful life to reinsert them into the production process. | Recovery [43]. |

| Market Strategy (MS) | |

| 26. If remanufactured items had eco-labels, I would purchase them. | Eco-labels [44]. |

| 27. I would purchase remanufactured items from a more ecologically conscious brand. | Trademarks [45]. |

| 28. If the packing material for refurbished items is ecologically friendly, I would purchase them. | Packing [46]. |

| Attitude (A) | |

| 29. I’d want to see the number of remanufactured items expand. | Offer [38]. |

| 30. I am willing to purchase remanufactured products. | Will [47]. |

| Subjective Standards (SS) | |

| 31. I would purchase these items if my friends did as well. | Friendships [10]. |

| 32. I would purchase these items if my immediate and extended family members did. | Relatives [27]. |

| Perceived Control of Behavior (PCB) | |

| 33. I know where I can find remanufactured products for purchase. 34. I have enough time and money to purchase these remanufactured products. | Location [48]. Time and money [49]. |

| Intent to Purchase Remanufactured Products (IPRP) | |

| 35. I am motivated to start buying remanufactured products. | Purchase motivation [50]. |

| 36. In the future, I will purchase remanufactured items. | Future purchases [47]. |

| Index | Validation | Best If |

|---|---|---|

| R-squared | Parametric predictive validity | >0.02 |

| Adjusted R-squared | Parametric predictive validity | >0.02 |

| Composite reliability | Internal validity | >0.7 |

| Cronbach Alpha | Internal validity | >0.7 |

| Average variance extracted (AVE) | Convergent validity | >0.5 |

| Full collinearity Variance Inflation Factor (VIF) | Collinearity | <5 |

| Q-squared | Nonparametric validity | >0 |

| City | Population | Percentage | Informants |

| Ensenada | 536,143 | 14.75% | 57 |

| Mexicali | 1,087,578 | 29.91% | 115 |

| Tijuana | 1,789,531 | 49.23% | 190 |

| Playas de Rosarito | 107,859 | 2.97% | 11 |

| Tecate | 113,857 | 3.13% | 12 |

| Totals | 3,634,968 | 100.00% | 385 |

| Age | Percentage (by Age) | Education | Percentage (by Education) |

| <21 | 2.50% | Undergraduate | 57.10% |

| 21–25 | 8.40% | Technician | 22.10% |

| 26–30 | 25.10% | High School | 10.40% |

| 31–40 | 40.90% | Postgraduate | 8.70% |

| >40 | 23.10% | Basic education | 1.70% |

| Index | RPK | A | RP | PBFDS | IPRP | SS | CE | MS | PCB |

|---|---|---|---|---|---|---|---|---|---|

| R-squared | 0.558 | 0.32 | 0.607 | 0.772 | 0.726 | ||||

| Adjusted R-squared | 0.557 | 0.314 | 0.606 | 0.767 | 0.725 | ||||

| Composite reliability | 0.923 | 0.947 | 0.957 | 0.925 | 0.951 | 0.98 | 0.927 | 0.959 | 0.899 |

| Cronbach Alpha | 0.9 | 0.887 | 0.946 | 0.892 | 0.897 | 0.959 | 0.843 | 0.936 | 0.774 |

| Average variance extracted | 0.669 | 0.899 | 0.765 | 0.755 | 0.907 | 0.96 | 0.864 | 0.886 | 0.816 |

| Full Collinearity VIF | 3.074 | 4.192 | 1.342 | 4.489 | 4.792 | 1.211 | 5.044 | 4.079 | 1.658 |

| Q-squared | 0.567 | 0.296 | 0.602 | 0.797 | 0.718 |

| Hi | Relationship | β Value (p-Value) | Conclusion | Hi | Relationship | β Value (p-Value) | Conclusion |

|---|---|---|---|---|---|---|---|

| H1 | RPK→PBFDS | 0.779 (p < 0.001) | Accept | H8 | PBFDS→IPRP | 0.346 (p < 0.001) | Accept |

| H2 | RPK→IPRP | 0.182 (p < 0.001) | Accept | H9 | CE→IPRP | −0.028 (p = 0.284) | Reject |

| H3 | RPK→RP | −0.237 (p < 0.001) | Accept | H10 | CE→MS | 0.852 (p < 0.001) | Accept |

| H4 | RPK→A | 0.747 (p < 0.001) | Accept | H11 | MS→IPRP | 0.100 (p = 0.021) | Accept |

| H5 | A→RP | −0.181 (p < 0.001) | Accept | H12 | PBC→IPRP | 0.086 (p = 0.042) | Accept |

| H6 | RP→IPRP | −0.029 (p = 0.278) | Reject | H13 | SS→RP | 0.273 (p < 0.001) | Accept |

| H7 | A→IPRP | 0.281 (p < 0.001) | Accept | H14 | SS→IPRP | −0.028 (p = 0.283) | Reject |

| Relationship | β Value (p-Value) | Conclusion | Relationship | β Value (p-Value) | Conclusion |

|---|---|---|---|---|---|

| RPK→RP | −0.135 (p < 0.001) | Significant | SS→IPRP | −0.008 (p = 0.410) | No significant |

| RPK→IPRP | 0.491 (p < 0.001) | Significant | CE→IPRP | 0.086 (p = 0.007) | Significant |

| A→IPRP | 0.005 (p = 0.440) | No significant |

| Relationship | β Value (p-Value) | Conclusion | Relationship | β Value (p-Value) | Conclusion |

|---|---|---|---|---|---|

| RPK→PBFDS | 0.779 (p < 0.001) | Significant | PBFDS→IPRP | 0.346 (p < 0.001) | Significant |

| RPK→IPRP | 0.673 (p < 0.001) | Significant | CE→IPRP | −0.057 (p = 0.231) | No significant |

| RPK→RP | −0.372 (p < 0.001) | Significant | CE→MS | 0.852 (p < 0.001) | Significant |

| RPK→A | 0.747 (p < 0.001) | Significant | MS→IPRP | 0.100 (p = 0.021) | Significant |

| A→RP | −0.181 (p < 0.001) | Significant | PBC→IPRP | 0.086 (p = 0.042) | Significant |

| RP→IPRP | −0.029 (p = 0.278) | No significant | SS→RP | 0.273 (p < 0.001) | Significant |

| A→IPRP | 0.286 (p < 0.001) | Significant | SS→IPRP | −0.036 (p = 0.124) | No significant |

| Problem | Solution | Value Propositions | Customer Relationships | Customers Segments |

|---|---|---|---|---|

| There is pollution and waste of natural and economic resources due to excessive washing machines and programmed obsolescence. Key Partners: Mobile application provider Washing machine suppliers Maintenance technicians | Application of a business model based on remanufacturing where washing machine rentals are generated (individual or private service) the washing machine is delivered, installed, maintained, and leased to a private home. | Your washing machine is always in optimal conditions, having access to maintenance, repair, and replacement of washing machines. At the end of its life cycle, the final disposal is the company’s responsibility for providing the service. Affordable price Efficient response time Safety in products and services. | Personalized service. The convenience of service. Social, economic, and environmental awareness. Efficient service. Guarantee of the conditions of the leased washing machines. | Men and women between the ages of 18 and 65 from the middle class and up. Occupation: Employees Entrepreneurs Retail Self-employed Marital status: Single, separated-divorced. |

| Metrics | Channels | |||

| People who do not have their own washing machine and are looking for personalized attention in the installation and maintenance of the product. | Personal home care Internet Social Networking | |||

| Cost structure | Revenue streams | |||

| Management fees, insurance, advertising, warehouse. | Commission for leasing services, more advanced service plans | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arredondo-Soto, K.C.; Jiménez-Zaragoza, A.; Miranda-Ackerman, M.A.; Blanco-Fernández, J.; García-Lechuga, A.; Hernández-Escobedo, G.; García-Alcaraz, J.L. Design and Repair Strategies Based on Product–Service System and Remanufacturing for Value Preservation. Sustainability 2022, 14, 8560. https://doi.org/10.3390/su14148560

Arredondo-Soto KC, Jiménez-Zaragoza A, Miranda-Ackerman MA, Blanco-Fernández J, García-Lechuga A, Hernández-Escobedo G, García-Alcaraz JL. Design and Repair Strategies Based on Product–Service System and Remanufacturing for Value Preservation. Sustainability. 2022; 14(14):8560. https://doi.org/10.3390/su14148560

Chicago/Turabian StyleArredondo-Soto, Karina Cecilia, Alejandro Jiménez-Zaragoza, Marco Augusto Miranda-Ackerman, Julio Blanco-Fernández, Alejandra García-Lechuga, Guadalupe Hernández-Escobedo, and Jorge Luis García-Alcaraz. 2022. "Design and Repair Strategies Based on Product–Service System and Remanufacturing for Value Preservation" Sustainability 14, no. 14: 8560. https://doi.org/10.3390/su14148560

APA StyleArredondo-Soto, K. C., Jiménez-Zaragoza, A., Miranda-Ackerman, M. A., Blanco-Fernández, J., García-Lechuga, A., Hernández-Escobedo, G., & García-Alcaraz, J. L. (2022). Design and Repair Strategies Based on Product–Service System and Remanufacturing for Value Preservation. Sustainability, 14(14), 8560. https://doi.org/10.3390/su14148560