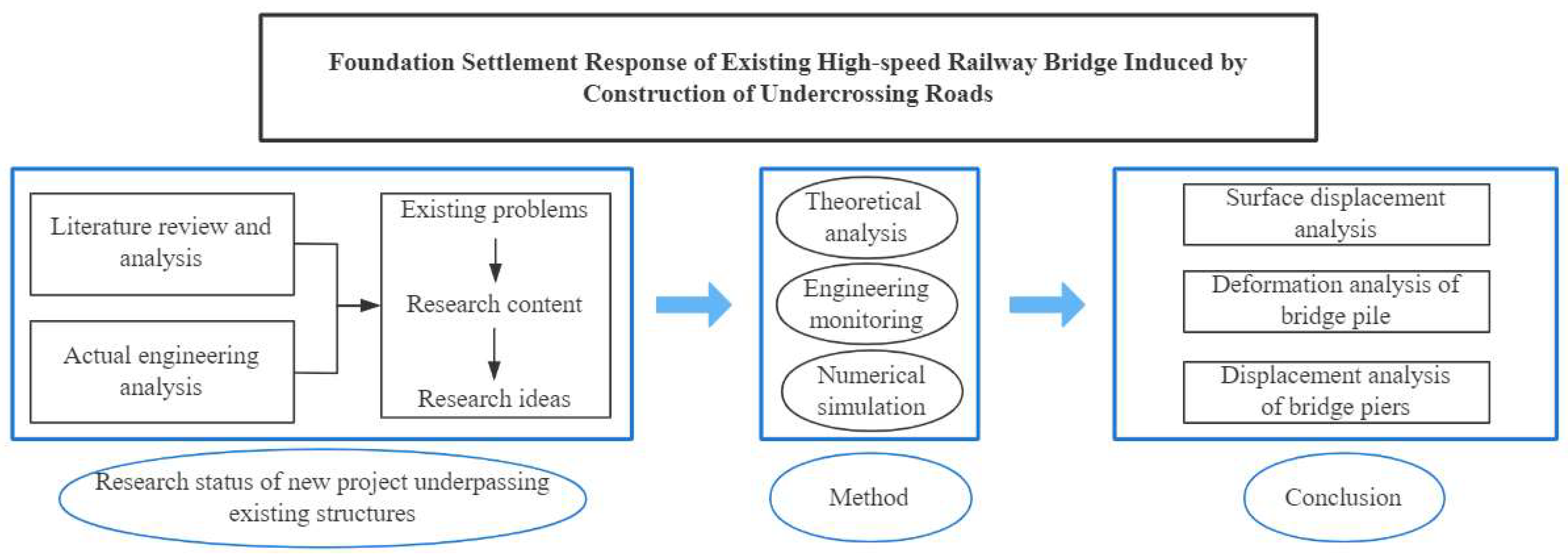

Foundation Settlement Response of Existing High-Speed Railway Bridge Induced by Construction of Undercrossing Roads

Abstract

:1. Introduction

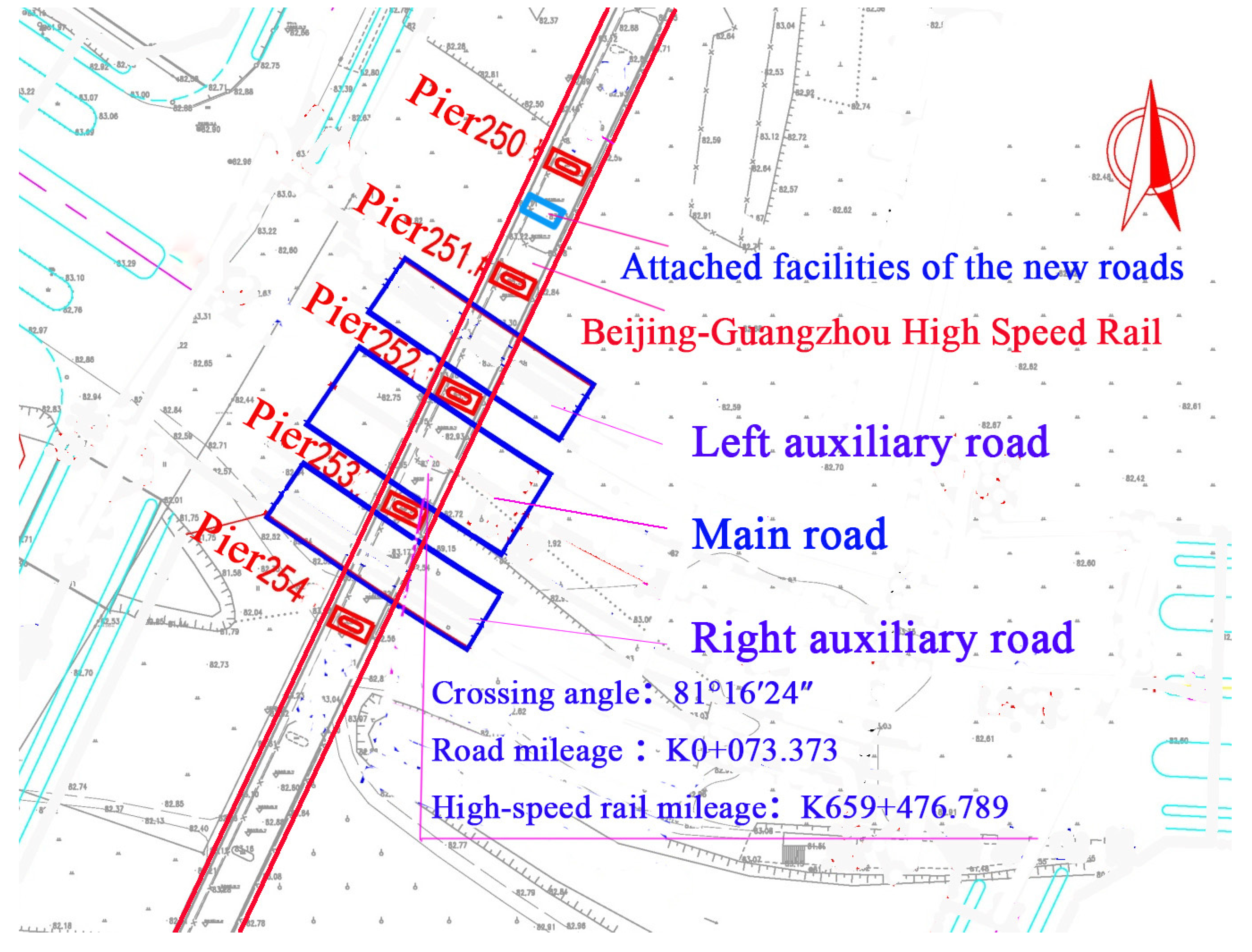

2. Overview of Study Area

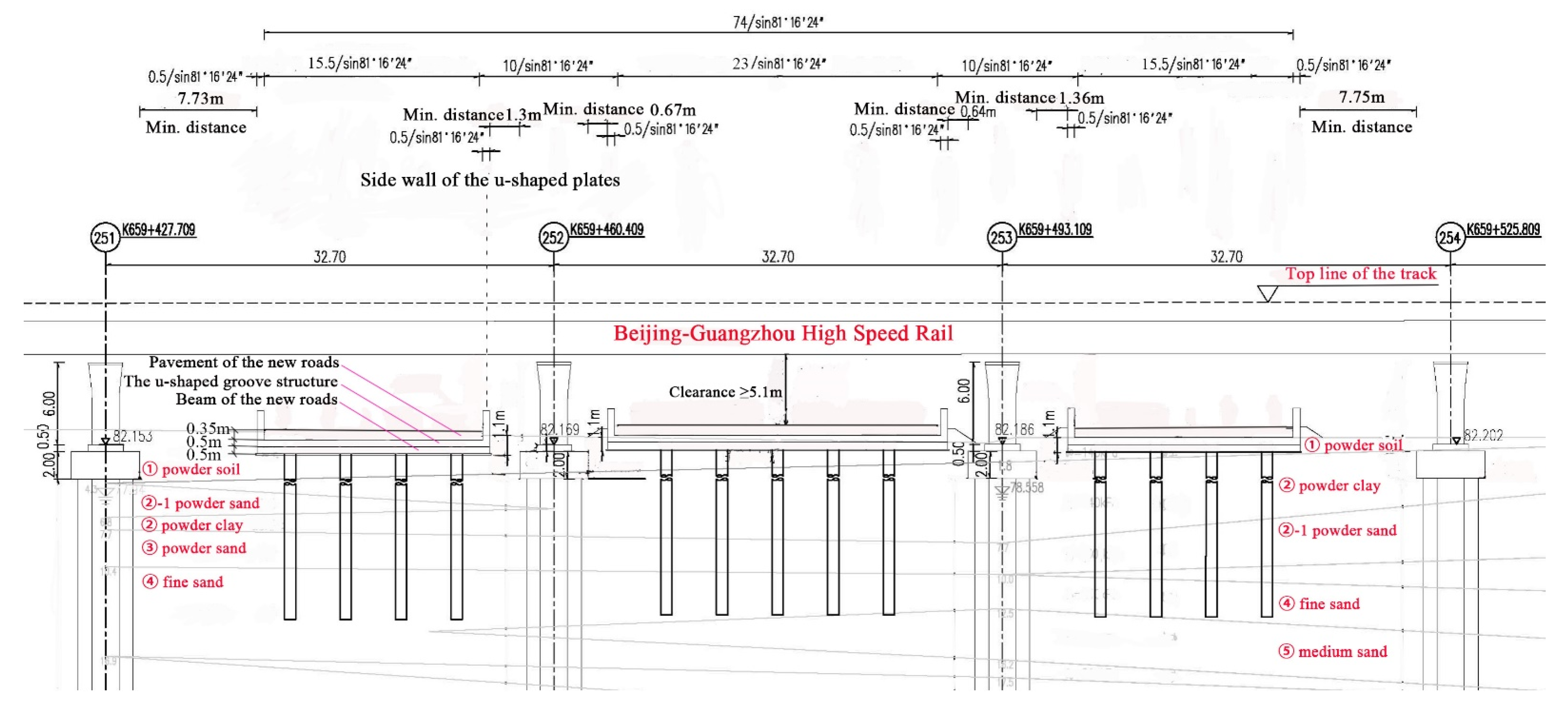

2.1. Project Overview

2.2. Hydrogeological Overview

3. Theory of Pile-Soil Interaction

3.1. Analysis of Soil Displacement Caused by Pit Excavation

3.2. Analysis of Pile-Soil Interaction Induced by Foundation Excavation

4. Numerical Simulation

4.1. Calculation Model and Parameters Setting

4.2. Boundary and Calculation Settings of the Model

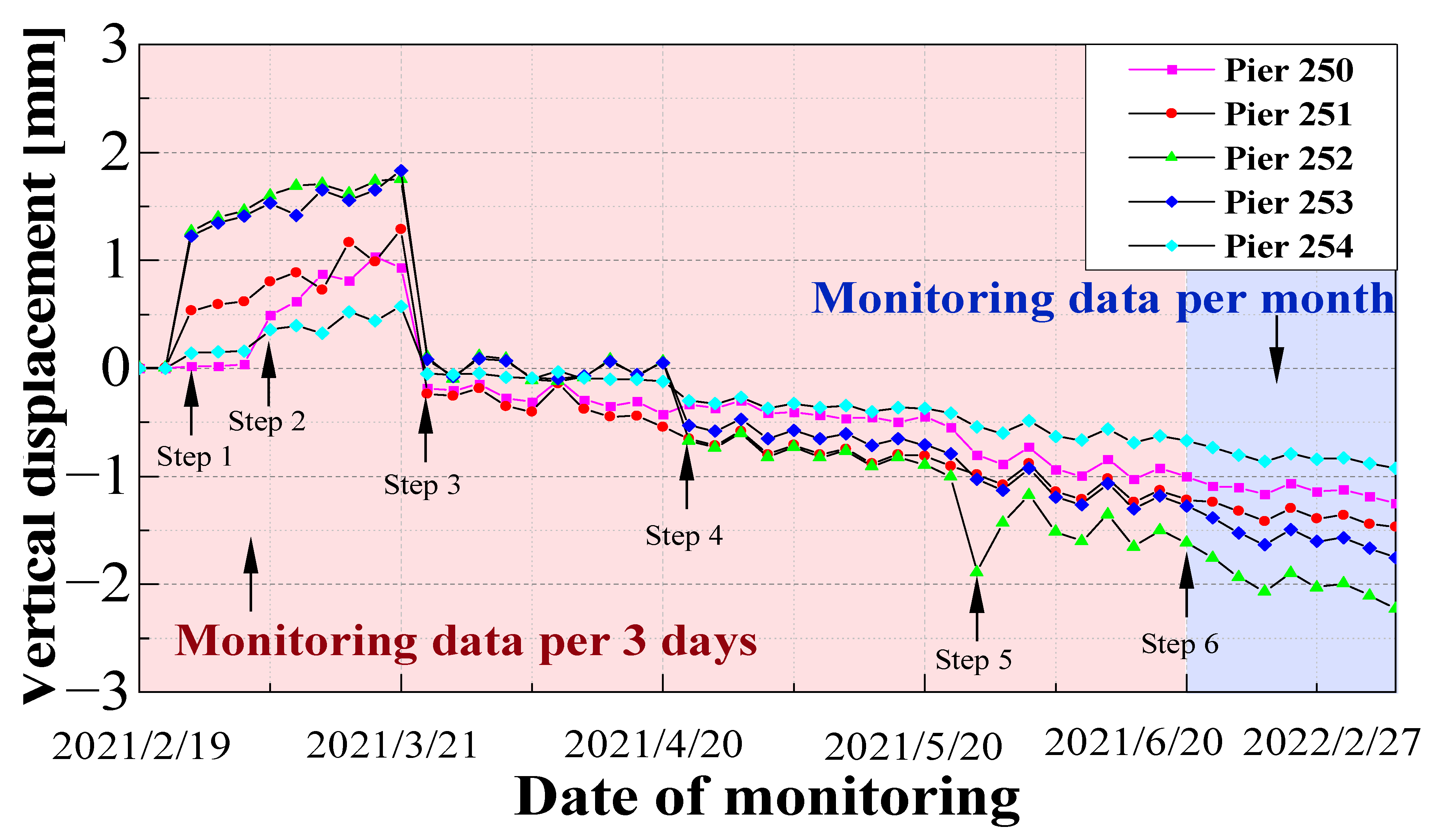

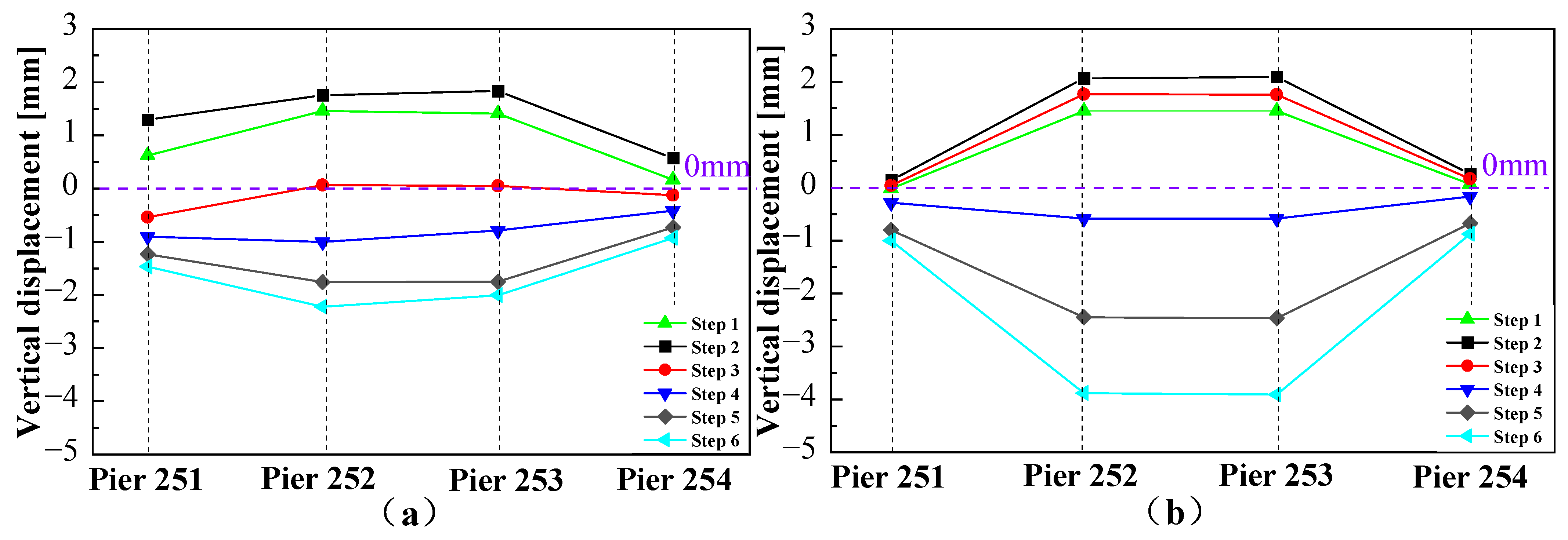

4.3. Monitoring Results and Validation of Numerical Simulation Model

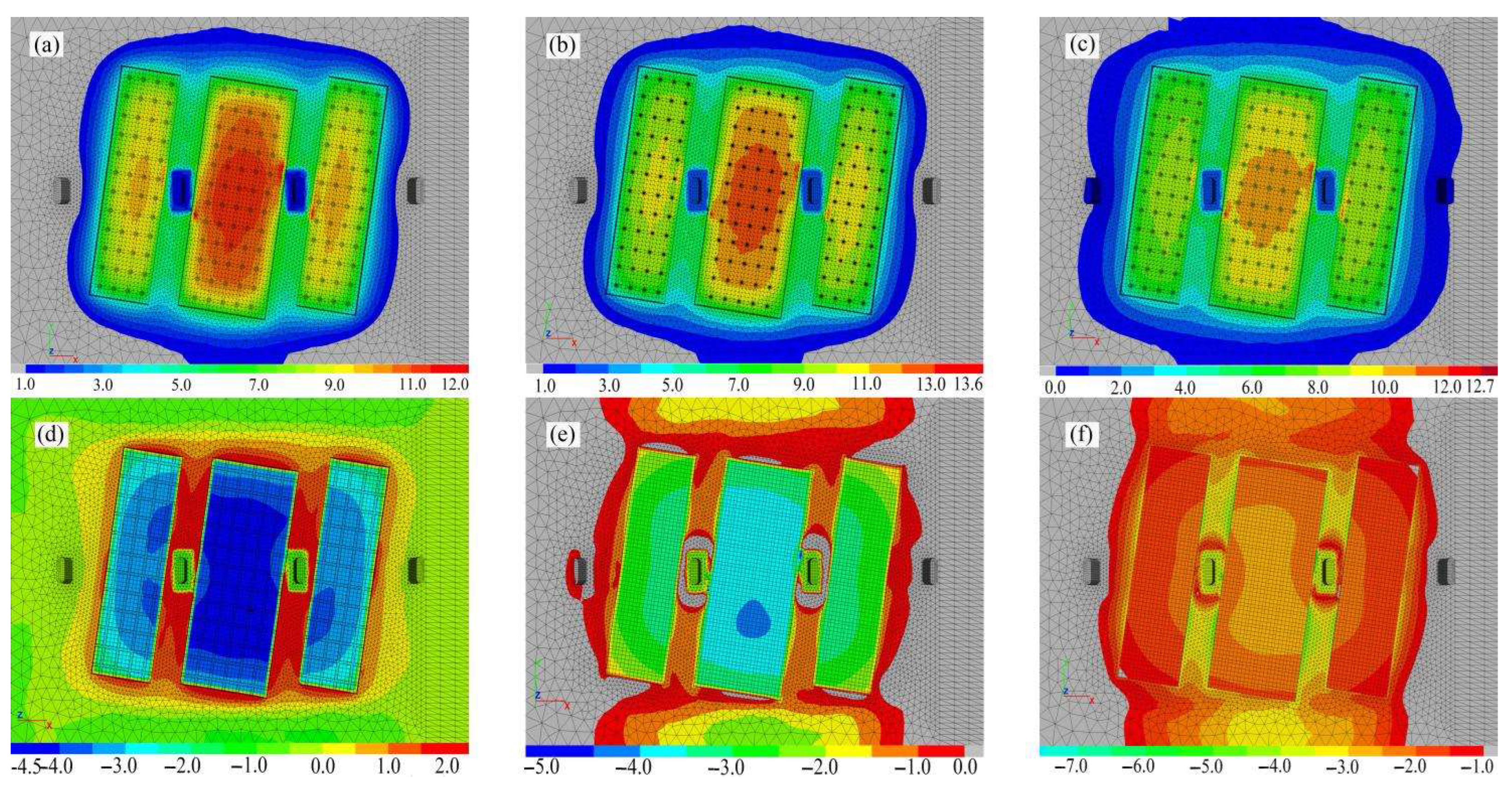

4.4. Ground Surface Settlement

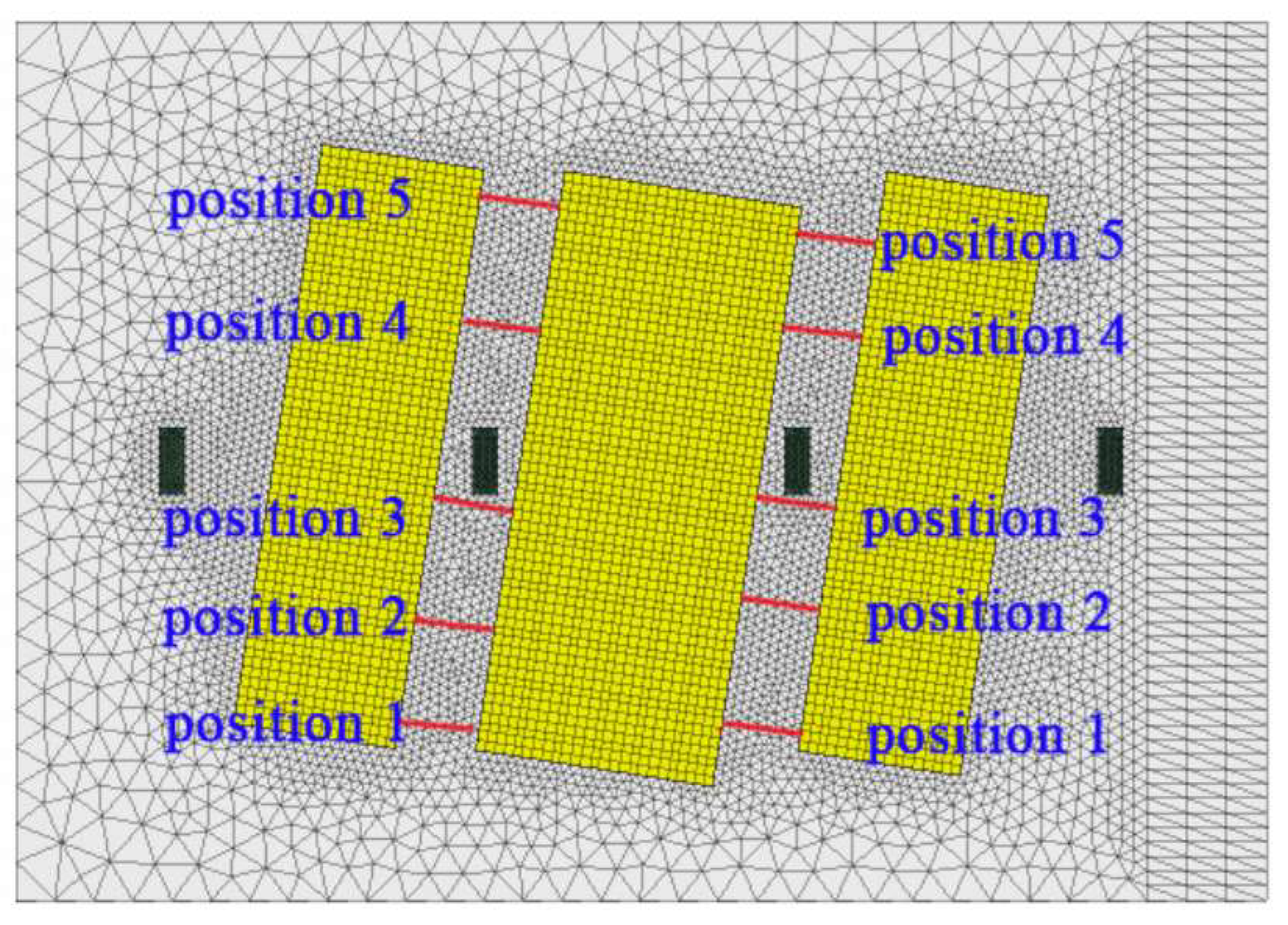

4.5. Surface Displacement of Soil Layers between Pits

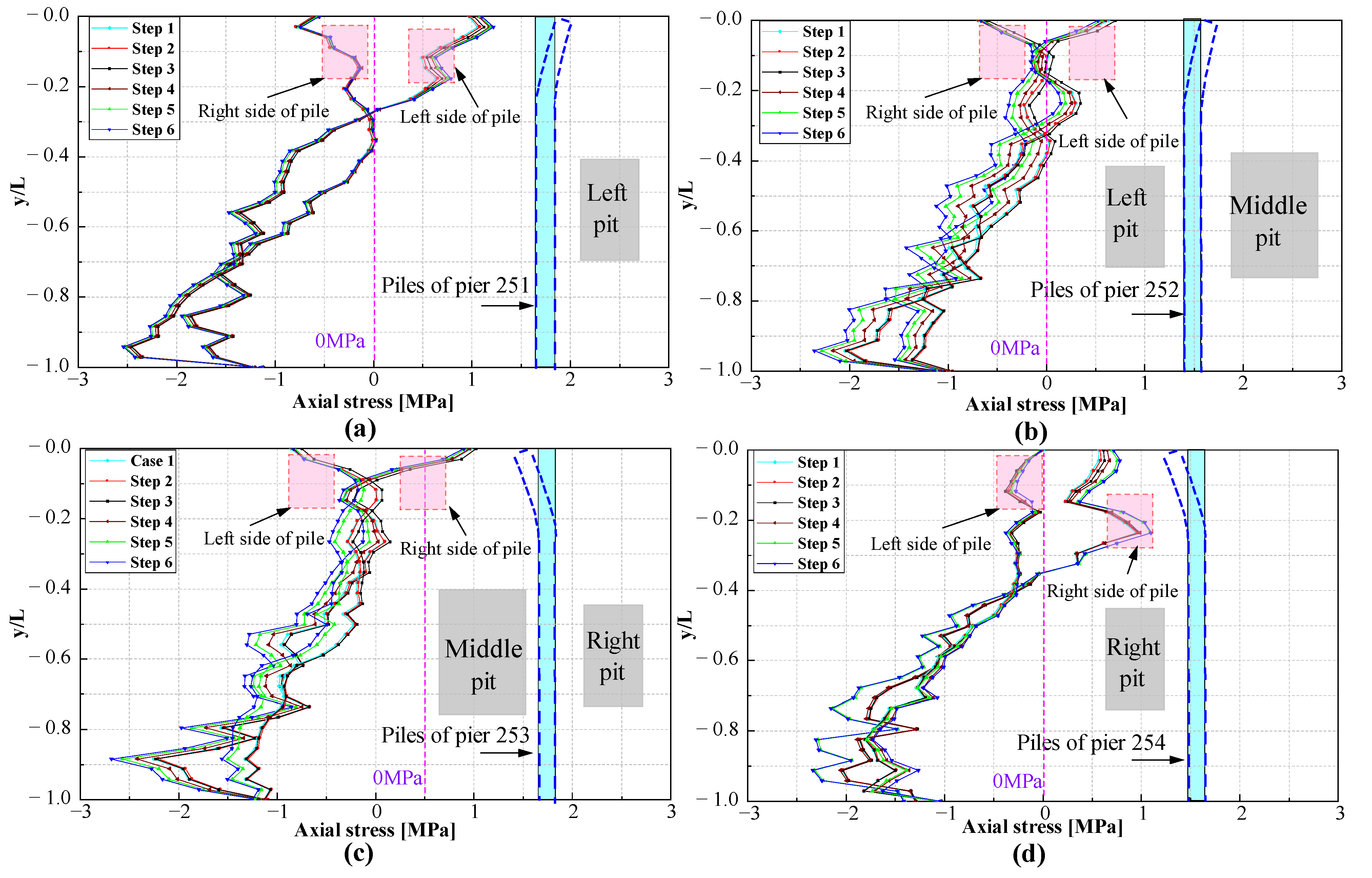

4.6. Deformation Analysis of Bridge Pile

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Empirical formula for ground settlement | |

| The clear distance from the edge of the pit | |

| The depth of pit excavation | |

| Equation for the lateral displacement of the free field soil | |

| Any point of the free field soil outside the foundation pit | |

| The fitted curve function of the horizontal displacement of a support pile | |

| The integral variable | |

| L | The depth of the support pile |

| Pile deflection | |

| hs | Thickness of the laterally displaced soil layer |

| hp | Length of the pile adjacent to the pit excavation |

| Relative stiffness of pile and soil | |

| k | Deformation force per unit volume of soil within each width of the pile |

| kh | Horizontal foundation reaction coefficient |

| Ep | Modulus of elasticity of the adjacent pile |

| Ip | Moment of inertia of the adjacent pile |

| ai, bj | The constant coefficients |

References

- Xu, K.; Li, H.M.; Lu, S.S. Study on Safety Risk Evaluation of High-Way Under-Passing Railroad. Adv. Mater. Res. 2014, 838, 1263–1267. [Google Scholar] [CrossRef]

- Gao, S.Q. Safety Analysis of New Highway Passing under High-speed Railway Viaduct. Railw. Stand. Des. 2015, 59, 63–67. [Google Scholar] [CrossRef]

- Zuo, Y.F. Research on the Influence of New Highway Under-Crossing Existing High-Speed Railway Bridge. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2016. [Google Scholar]

- Peck, R.B. Deep excavations and tunneling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, Mexico City, Mexico, 29 August 1969. [Google Scholar] [CrossRef]

- Caspe, M.S. Surface settlement adjacent to braced open cuts. J. Soil Mech. Found. Div. 1966, 92, 51–59. [Google Scholar] [CrossRef]

- Clough, G.W. Construction induced movements of in situ walls. In Proceedings of the Design and Performance of Earth Retaining Structures, New York, NY, USA, 18–21 June 1990; pp. 439–470. [Google Scholar] [CrossRef]

- Chen, Y.F.; Cao, M.B. The Deformation Characteristics of Soft Clay under Unloading and Reloading in Shanghai. Chin. J. Geotech. Eng. 1990, 12, 9–18. [Google Scholar] [CrossRef]

- Huang, M.; Liu, X.R.; Zhang, N.Y.; Shen, Q.W. Calculation of foundation pit deformation caused by deep excavation considering influence of loading and unloading. J. Cent. South Univ. 2017, 24, 2164–2171. [Google Scholar] [CrossRef]

- Gao, X.H.; Tian, W.P.; Zhang, Z.P. Analysis of deformation characteristics of foundation-pit excavation and circular wall. Sustainability 2020, 12, 3164. [Google Scholar] [CrossRef] [Green Version]

- Yi, S.; Lin, W.N.; Chen, J.; Huang, J.H.; Li, J.B.; Wu, J.M. Deformation analysis of surface and retaining wall induced by braced excavation based on random field theory. Chin. J. Rock Mech. Eng. 2021, 40, 3389–3398. [Google Scholar] [CrossRef]

- Liang, F.Y.; Chu, F.; Song, Z.; Li, Y.S. Centrifugal model test research on deformation behaviors of deep foundation pit adjacent to metro stations. Rock Soil Mech. 2012, 33, 657–664. [Google Scholar] [CrossRef]

- Xue, X.L.; Liao, H.; Zeng, C.F.; Liu, Y.S.; Zeng, X. Barrier effect of existing underground structure on strata deformation induced by foundation pit dewatering. Chin. J. Geotech. Eng. 1–9. Available online: http://kns.cnki.net/kcms/detail/32.1124.TU.20220217.1111.002.html (accessed on 19 June 2022).

- Luo, K.; Lei, X.Y. The Dynamic Analysis of The Existing Railway’s Subgrade Settlement Caused by Excavation Pit on Hu-Ning Line. J. Railw. Eng. Soc. 2010, 27, 5–8. [Google Scholar] [CrossRef]

- Yu, C. Numerical Analysis of Deep Foundation Pit Excavation Supported by Large Diameter Ring Beam. IOP Conf. Ser. Earth Environ. Sci. 2019, 242, 062033. [Google Scholar] [CrossRef]

- Yuan, C.F.; Hu, Z.H.; Zhu, Z.J.; Yuan, Z.; Fan, Y.X.; Guan, H.; Li, L. Numerical simulation of seepage and deformation in excavation of a deep foundation pit under water-rich fractured intrusive rock. Geofluids 2021, 2021, 6628882. [Google Scholar] [CrossRef]

- Bai, H.W. Study on Longitudinal Deformation of Existing Metro Tunnel Caused by Undercrossing Construction and Engineering Measures. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2008. [Google Scholar]

- Wang, Z.C.; Hu, Z.; Lai, J.X.; Wang, H.; Wang, K.; Zan, W. Settlement characteristics of jacked box tunneling underneath a highway embankment. J. Perform. Constr. Facil. 2019, 33, 04019005. [Google Scholar] [CrossRef]

- Yin, M.L.; Jiang, H.; Jiang, Y.S.; Sun, Z.Y.; Wu, Q.L. Effect of the excavation clearance of an under-crossing shield tunnel on existing shield tunnels. Tunn. Undergr. Space Technol. 2018, 78, 245–258. [Google Scholar] [CrossRef]

- Wei, X.J.; Zhang, M.B.; Ma, S.J.; Xia, C.; Liu, X.W.; Ding, Z. Deformation Characteristics of Existing Twin Tunnels Induced by Double Shield Undercrossing with Prereinforcement: A Case Study in Hangzhou. Adv. Civ. Eng. 2021, 2021, 7869899. [Google Scholar] [CrossRef]

- Liu, B.; Yu, Z.W.; Zhang, R.H.; Han, Y.H.; Wang, Z.L.; Wang, S.J. Effects of Undercrossing Tunneling on Existing Shield Tunnels. Int. J. Geomech. 2021, 21, 04021131. [Google Scholar] [CrossRef]

- Wang, G.F.; Wang, J.; Lu, L.H. Rules and control technology of deformation caused by shield tunnel under-passing the railway bridge culvert. J. Railw. Sci. Eng. 2016, 13, 2471–2477. [Google Scholar] [CrossRef]

- Wang, J.C.; Liu, X.F.; Hou, W.H. Research on the Influence of Construction of New Bridge on Foundation Displacement of High-speed Railway in Service. J. Railw. Eng. Soc. 2017, 34, 60–65, 83. [Google Scholar]

- Xiao, H.; Ling, X.; Lv, S. Field Test Study on Influence of Undercrossing Construction on Safety of Existing High-Speed Railway. In Proceedings of the International Symposium on Environmental Vibration and Transportation Geodynamics, Hangzhou, China, 28–30 October 2016; pp. 167–179. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Wang, X.T. Influence of Metro tunnel excavation on deformation of existing pedestrian underpass in changzhou railway station platform. IEEE Access 2020, 8, 55860–55871. [Google Scholar] [CrossRef]

- Zhao, M.J.; Cheng, Y.; Song, Z.P.; Wang, T.; Zhang, Y.W.; Gong, Y.T.; Song, Y.C. Stability Analysis of TBM Tunnel Undercrossing Existing High-Speed Railway Tunnel: A Case Study from Yangtaishan Tunnel of Shenzhen Metro Line 6. Adv. Civ. Eng. 2021, 2021, 6674862. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, H.; Long, Z.; Qiu, W.G.; Meng, G.W.; Zhu, L.C. Field Test Optimization of Shield Tunnelling Parameters Undercrossing an Existing High-Speed Railway Tunnel: A Case Study. Geotech. Geol. Eng. 2021, 39, 1381–1398. [Google Scholar] [CrossRef]

- Lee, D. Analysis on the Influence and Reinforcement Effect of Adjacent Pier Structures according to the Underpass Construction. J. Korean GEO-Environ. Soc. 2022, 23, 29–39. [Google Scholar]

- Ding, Y.C. Excavation-Induced Deformation and Control in Soft Deposits. Ph.D. Thesis, Shanghai Jiao Tong University, Shanghai, China, 2009. [Google Scholar]

- Wang, C.; Yan, S.W.; Zhang, Q.B. Study of Influence of Deep Pit Excavation on Adjacent Bridge Foundation Piles. Chin. J. Rock Mech. Eng. 2010, 29, 2994–3000. [Google Scholar]

- Chen, L.J.; Yu, Q.F.; Dai, Z.H. 3D finite element analysis of the influence of excavation in soft soil areas in Fuzhou on the surrounding buildings. J. Railw. Sci. Eng. 2015, 12, 79–85. [Google Scholar] [CrossRef]

- Fan, S.Y.; Song, Z.P.; Xu, T.; Wang, K.M.; Zhang, Y.W. Tunnel deformation and stress response under the bilateral foundation pit construction: A case study. Arch. Civ. Mech. Eng. 2021, 21, 109. [Google Scholar] [CrossRef]

- National Railway Administration of the People’s Republic of China. Technical Specification for Highway and Municipal Engineering under Crossing High Speed Railway; China Railway Publishing House: Beijing, China, 2018. [Google Scholar]

- Sagaseta, C. Analysis of undraind soil deformation due to ground loss. Géotechnique 1987, 37, 301–320. [Google Scholar] [CrossRef]

- Zhang, A.J.; Mo, H.H.; Li, A.G.; Gao, W.; Xiang, W. Two-stage Analysis Method for Behavior of Adjacent Piles due to Foundation Pit Excavation. Chin. J. Rock Mech. Eng. 2013, 32, 2746–2750. [Google Scholar] [CrossRef]

- Dong, L.L. Study on Geotechnical Constitutive Models and Parameters Commonly Used in Numerical Simulation. Master’s Thesis, Qingdao Technological University, Qingdao, China, 2011. [Google Scholar]

- Shan, Y.; Xiao, W.X.; Xiang, K.; Wang, B.L.; Zhou, S.H. Semi-automatic construction of pile-supported subgrade adjacent to existing railway. Autom. Constr. 2022, 134, 104085. [Google Scholar] [CrossRef]

- Li, L.J.; Yang, H.W.; Li, Z.L.; Cai, Y.C. Numerical Analysis of the Influence of Unsupported Excavation on Adjacent Viaduct Foundation. Chin. J. Undergr. Space Eng. 2011, 7, 1697–1701. [Google Scholar] [CrossRef]

- Yi, L.B.; Du, M.F.; Meng, X.Y.; Jiang, M.M. Influence of the construction of deep foundation pit of subway on foundation deformation of interchange in ultra-short distance. J. Hefei Univ. Technol. (Nat. Sci.) 2022, 45, 785–792. [Google Scholar]

- Liu, X.; Jiang, A.N.; Fang, Q.; Wan, Y.S.; Li, J.Y.; Guo, X.P. Spatiotemporal Deformation of Existing Pipeline Due to New Shield Tunnelling Parallel Beneath Considering Construction Process. Appl. Sci. 2022, 12, 500. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Khan, T.Y.; Javed, S.; Baig, R.U. Optimization of Alkaline Activator on the Strength Properties of Geopolymer Concrete. Polymers 2022, 14, 2434. [Google Scholar] [CrossRef] [PubMed]

| Layer Number | Type | Thickness (m) | Weight (kN/m3) | Poisson’s Ratio | Bulk (MPa) | Shear (MPa) | Cohesion (kPa) | Fric (°) |

|---|---|---|---|---|---|---|---|---|

| 1 | Silty soil | 4 | 18 | 0.3 | 23.33 | 10.77 | 10 | 20 |

| 2 | Silty sand | 2 | 18 | 0.35 | 36.28 | 12.09 | 2 | 30 |

| 3 | Silty clay | 1 | 18 | 0.3 | 12.17 | 5.62 | 10 | 20 |

| 4 | Silty sand | 2 | 18 | 0.35 | 36.28 | 12.09 | 2 | 30 |

| 5 | Medium sand | 5 | 18 | 0.35 | 61.11 | 20.37 | 3 | 30 |

| Bridge | C50 | - | 25 | 0.2 | 19,166.67 | 14,375 | - | - |

| Pier | C30 | 60 | 25 | 0.2 | 16,666.67 | 12,500 | - | - |

| Bridge base | C30 | 2.5 | 25 | 0.2 | 16,666.67 | 12,500 | - | - |

| Pile of the bridge | C35 | 42 | 25 | 0.2 | 17,500 | 13,125 | - | - |

| Pavement of the new roads | Asphalt concrete | 0.35 | 24.5 | 0.35 | 1666.67 | 555.56 | - | - |

| The u-shaped groove structure | C35 | 0.5 | 25 | 0.2 | 17,500 | 13,125 | - | - |

| Beam of the new roads | C35 | 0.5 | 25 | 0.2 | 17,500 | 13,125 | - | - |

| Pile of the new roads | C25 | 13 | 25 | 0.2 | 15,555.56 | 11,666.67 | - | - |

| Serial Number | Construction Sequence | Step |

|---|---|---|

| 1 | Excavation of the road foundation pits | Step 1 |

| 2 | Drilling of the road piles | Step 2 |

| 3 | Grouting of the road piles | Step 3 |

| 4 | Pouring of the road beams | Step 4 |

| 5 | Pouring of the u-shaped plates | Step 5 |

| 6 | Paving of the road surfaces | Step 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liang, S.; Huang, C.; Wang, R. Foundation Settlement Response of Existing High-Speed Railway Bridge Induced by Construction of Undercrossing Roads. Sustainability 2022, 14, 8700. https://doi.org/10.3390/su14148700

Wang Y, Liang S, Huang C, Wang R. Foundation Settlement Response of Existing High-Speed Railway Bridge Induced by Construction of Undercrossing Roads. Sustainability. 2022; 14(14):8700. https://doi.org/10.3390/su14148700

Chicago/Turabian StyleWang, You, Shaohua Liang, Changxi Huang, and Rui Wang. 2022. "Foundation Settlement Response of Existing High-Speed Railway Bridge Induced by Construction of Undercrossing Roads" Sustainability 14, no. 14: 8700. https://doi.org/10.3390/su14148700

APA StyleWang, Y., Liang, S., Huang, C., & Wang, R. (2022). Foundation Settlement Response of Existing High-Speed Railway Bridge Induced by Construction of Undercrossing Roads. Sustainability, 14(14), 8700. https://doi.org/10.3390/su14148700