Evaluation of Co-Composting as an Alternative for the Use of Agricultural Waste of Spring Onions, Chicken Manure and Bio-Waste Produced in Moorland Ecosystems

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Units

2.2. Characterization of Substrates and Co-Substrates

2.3. Analytical Methods

2.4. Monitoring of the Composting Process

2.5. Analysis of End-Product Quality

2.6. Statistical Processing

3. Results and Discussion

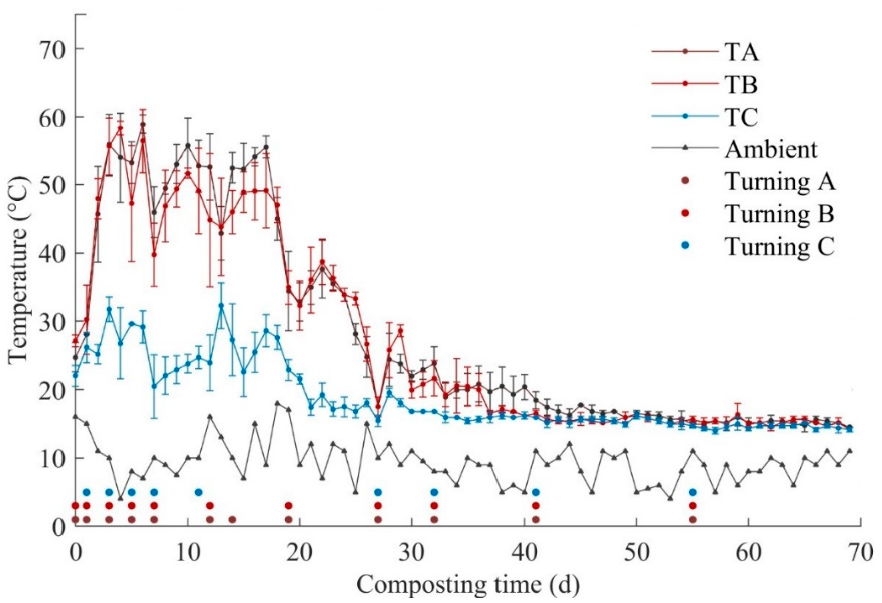

3.1. Process Monitoring

3.2. End Product Quality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Amendment materials |

| AW | agricultural waste |

| BA | Bulking agents |

| Bw | Biowaste |

| CEC | cation exchange capacity |

| CM | Chicken manure |

| EC | Electrical conductivity |

| FI | Fertility index |

| GI | Germination index |

| GS | Number of germinated seeds in the extract of the end-product |

| GSC | Number of germinated seeds in the control |

| GR | Root growth in the extract of the end-product |

| GRC | Root growth in the control |

| RGP | Relative germination percentage |

| RRG | Relative root growth |

| TA | Treatment A |

| TB | Treatment B |

| TC | Treatment C |

| TK | Total Potassium |

| TN | Total nitrogen |

| TOC | Total Organic Carbon |

| TP | Total Phosphorous |

| SO | Spring onions |

| Wc | Woodchips |

| WRC | Water retention capacity |

Appendix A

References

- De Corato, U.; De Bari, I.; Viola, E.; Pugliese, M. Assessing the main opportunities of integrated biorefining from agro-bioenergy co/by-products and agroindustrial residues into high-value added products associated to some emerging markets: A review. Renew. Sustain. Energy Rev. 2018, 88, 326–346. [Google Scholar] [CrossRef]

- Calabi-Floody, M.; Medina, J.; Suazo, J.; Ordiqueo, M.; Aponte, H.; Mora, M.d.L.L.; Rumpel, C. Optimization of wheat straw co-composting for carrier material development. Waste Manag. 2019, 98, 37–49. [Google Scholar] [CrossRef] [PubMed]

- Bian, B.; Hu, X.; Zhang, S.; Lv, C.; Yang, Z.; Yang, W.; Zhang, L. Pilot-scale composting of typical multiple agricultural wastes: Parameter optimization and mechanisms. Bioresour. Technol. 2019, 287, 121482. [Google Scholar] [CrossRef] [PubMed]

- Esparza, I.; Jiménez-Moreno, N.; Bimbela, F.; Ancín-Azpilicueta, C.; Gandía, L.M. Fruit and vegetable waste management: Conventional and emerging approaches. J. Environ. Manag. 2020, 265, 110510. [Google Scholar] [CrossRef]

- Chen, H.; Awasthi, M.K.; Liu, T.; Zhao, J.; Ren, X.; Wang, M.; Duan, Y.; Awasthi, S.K.; Zhang, Z. Influence of clay as additive on greenhouse gases emission and maturity evaluation during chicken manure composting. Bioresour. Technol. 2018, 266, 82–88. [Google Scholar] [CrossRef]

- Muscolo, A.; Papalia, T.; Settineri, G.; Mallamaci, C.; Jeske-Kaczanowska, A. Are raw materials or composting conditions and time that most influence the maturity and/or quality of composts? Comparison of obtained composts on soil properties. J. Clean. Prod. 2018, 195, 93–101. [Google Scholar] [CrossRef]

- Tamaquiza, P.P.; Parco-Asitimbay, X. Efectos socio-ambientales de la intensificación de la ganadería en ecosistemas de altura (paramos) del sur-oeste de Tungurahua. Ecosistemas 2022, 31, 2296. [Google Scholar] [CrossRef]

- Henao-Díaz, L.F.; Arroyo, S.; Cárdenas-Posada, G.; Fernández, M.; López, J.P.; Martínez, D.C.; Mendoza, J.S.; Mondragón-Botero, A.; León, O.; Pulido-Herrera, K.L.; et al. Caracterización biológica en la zona de transición bosque-páramo del Complejo de Páramos Chingaza, Colombia. Biota Colomb. 2019, 20, 132–145. [Google Scholar] [CrossRef]

- Patiño, S.; Hernández, Y.; Plata, C.; Domínguez, I.; Daza, M.; Oviedo-Ocaña, R.; Buytaert, W.; Ochoa-Tocachi, B.F. Influence of land use on hydro-physical soil properties of Andean páramos and its effect on streamflow buffering. Catena 2021, 202, 105227. [Google Scholar] [CrossRef]

- Pomboza-Tamaquiza, P.; Parco-Asitimbay, A. Socio-environmental effects of livestock intensification in high altitude ecosystems (paramos) of southwestern Tungurahua. Ecosistemas 2022, 31, 1–8. [Google Scholar] [CrossRef]

- Kumari, S.; Manyapu, V.; Kumar, R. Recent advances in composting and vermicomposting techniques in the cold region: Resource recovery, challenges, and way forward. Adv. Org. Waste Manag. Sustain. Pract. Approaches 2022, 1, 131–154. [Google Scholar] [CrossRef]

- Romano, R.T.; Zhang, R. Anaerobic digestion of onion residuals using a mesophilic Anaerobic Phased Solids Digester. Biomass Bioenergy 2011, 35, 4174–4179. [Google Scholar] [CrossRef]

- Nile, A.; Nile, S.H.; Kim, D.H.; Keum, Y.S.; Seok, P.G.; Sharma, K. Valorization of onion solid waste and their flavonols for assessment of cytotoxicity, enzyme inhibitory and antioxidant activities. Food Chem. Toxicol. 2018, 119, 281–289. [Google Scholar] [CrossRef] [PubMed]

- Horiuchi, J.-i.; Tada, K.; Kobayashi, M.; Kanno, T.; Ebie, K. Biological approach for effective utilization of worthless onions—vinegar production and composting. Resour. Conserv. Recycl. 2004, 40, 97–109. [Google Scholar] [CrossRef]

- Rizzo, P.F.; Della Torre, V.; Riera, N.I.; Crespo, D.; Barrena, R.; Sánchez, A. Co-composting of poultry manure with other agricultural wastes: Process performance and compost horticultural use. J. Mater. Cycles Waste Manag. 2013, 17, 42–50. [Google Scholar] [CrossRef] [Green Version]

- Onwosi, C.O.; Igbokwe, V.C.; Odimba, J.N.; Eke, I.E.; Nwankwoala, M.O.; Iroh, I.N.; Ezeogu, L.I. Composting technology in waste stabilization: On the methods, challenges and future prospects. J. Environ. Manag. 2017, 190, 140–157. [Google Scholar] [CrossRef]

- Pellejero, G.; Miglierina, A.; Aschkar, G.; Turcato, M.; Jiménez-Ballesta, R. Effects of the onion residue compost as an organic fertilizer in a vegetable culture in the Lower Valley of the Rio Negro. Int. J. Recycl. Org. Waste Agric. 2017, 6, 159–166. [Google Scholar] [CrossRef]

- Pellejero, G.; Rodriguez, K.; Ashchkar, G.; Vela, E.; García-Delgado, C.; Jiménez-Ballesta, R. Onion waste recycling by vermicomposting: Nutrients recovery and agronomical assessment. Int. J. Environ. Sci. Technol. 2020, 17, 3289–3296. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Sarsaiya, S.; Awasthi, M.K.; Liu, T.; Zhao, J.; Kumar, S.; Zhang, Z. Changes in global trends in food waste composting: Research challenges and opportunities. Bioresour. Technol. 2020, 299, 122555. [Google Scholar] [CrossRef]

- Li, Z.; Lu, H.; Ren, L.; He, L. Experimental and modeling approaches for food waste composting: A review. Chemosphere 2013, 93, 1247–1257. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Oviedo-Ocaña, R.; Marmolejo-Rebellón, L.F.; Manyoma-Velásquez, P.C. Compostaje de biorresiduos: Tendencias de investigación y pertinencia en países en desarrollo. Dyna 2017, 84, 334–342. [Google Scholar] [CrossRef]

- Oviedo-Ocaña, E.; Dominguez, I.; Komilis, D.; Sánchez, A. Co-composting of Green Waste Mixed with Unprocessed and Processed Food Waste: Influence on the Composting Process and Product Quality. Waste Biomass Valorizat. 2019, 10, 63–74. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Oviedo-Ocaña, E.R.; Manyoma, P.C.; Gaviría-Cuevas, J.F.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P.; Sánchez, A.; Komilis, D. A Multi-criteria Decision Analysis of Co-substrate Selection to Improve Biowaste Composting: A Mathematical Model Applied to Colombia. Environ. Processes 2019, 6, 673–694. [Google Scholar] [CrossRef]

- Dias, B.O.; Silva, C.A.; Higashikawa, F.S.; Roig, A.; Sánchez-Monedero, M.A. Use of biochar as bulking agent for the composting of poultry manure: Effect on organic matter degradation and humification. Bioresour. Technol. 2010, 101, 1239–1246. [Google Scholar] [CrossRef]

- Bres, P.; Beily, M.E.; Young, B.J.; Gasulla, J.; Butti, M.; Crespo, D.; Candal, R.; Komilis, D. Performance of semi-continuous anaerobic co-digestion of poultry manure with fruit and vegetable waste and analysis of digestate quality: A bench scale study. Waste Manag. 2018, 82, 276–284. [Google Scholar] [CrossRef]

- Edjabou, M.E.; Jensen, M.B.; Götze, R.; Pivnenko, K.; Petersen, C.; Scheutz, C.; Astrup, T.F. Municipal solid waste composition: Sampling methodology, statistical analyses, and case study evaluation. Waste Manag. 2015, 36, 12–23. [Google Scholar] [CrossRef] [Green Version]

- ICONTEC (2011) Norma Técnica Colombiana 5167. Productos para la Industria Agrícola, Productos Orgánicos Usados como Abonos o Fertilizantes y Enmiendas de Suelo. Available online: https://tienda.icontec.org/gp-fertilizantes-y-acondicionadores-de-suelos-definiciones-y-clasificacion-ntc1927-2019.html (accessed on 22 May 2022).

- Lü, F.; Shao, L.-M.; Zhang, H.; Fu, W.-D.; Feng, S.-J.; Zhan, L.-T.; Chen, Y.-M.; He, P.-J. Application of advanced techniques for the assessment of bio-stability of biowaste-derived residues: A minireview. Bioresour. Technol. 2018, 248, 122–133. [Google Scholar] [CrossRef]

- Komilis, D.P.; Tziouvaras, I.S. A statistical analysis to assess the maturity and stability of six composts. Waste Manag. 2009, 29, 1504–1513. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V.; Guida, M. Compost from organic solid waste: Quality assessment and European regulations for its sustainable use. Resour. Conserv. Recycl. 2015, 94, 72–79. [Google Scholar] [CrossRef]

- Saha, J.; Panwar, N.; Singh, M. An assessment of municipal solid waste compost quality produced in different cities of India in the perspective of developing quality control indices. Waste Manag. 2010, 30, 192–201. [Google Scholar] [CrossRef]

- Waqas, M.; Nizami, A.S.; Aburiazaiza, A.S.; Barakat, M.A.; Rashid, M.I.; Ismail, I.M.I. Optimizing the process of food waste compost and valorizing its applications: A case study of Saudi Arabia. J. Clean. Prod. 2018, 176, 426–438. [Google Scholar] [CrossRef]

- Zheng, J.; Liu, J.; Han, S.; Wang, Y.; Wei, Y. N2O emission factors of full-scale animal manure windrow composting in cold and warm seasons. Bioresour. Technol. 2020, 316, 123905. [Google Scholar] [CrossRef] [PubMed]

- Huanng, Q.; Chen, T.; Gao, D.; Huang, Z. Ambient air temperature effects on the temperature of sewage composting processs. J. Environ. Sci. 2005, 17, 1004–1007. [Google Scholar]

- Soobhany, N. Assessing the physicochemical properties and quality parameters during composting of different organic constituents of Municipal Solid Waste. J. Environ. Chem. Eng. 2018, 6, 1979–1988. [Google Scholar] [CrossRef]

- Hemidat, S.; Jaar, M.; Nassour, A.; Nelles, M. Monitoring of Composting Process Parameters: A Case Study in Jordan. Waste Biomass Valorization 2018, 9, 2257–2274. [Google Scholar] [CrossRef]

- Lasaridi, K.; Protopapa, I.; Kotsou, M.; Pilidis, G.; Manios, T.; Kyriacou, A. Quality assessment of composts in the Greek market: The need for standards and quality assurance. J. Environ. Manag. 2006, 80, 58–65. [Google Scholar] [CrossRef] [PubMed]

- Cáceres, R.; Coromina, N.; Malińska, K.; Martínez-Farré, F.X.; López, M.; Soliva, M.; Marfà, O. Nitrification during extended co-composting of extreme mixtures of green waste and solid fraction of cattle slurry to obtain growing media. Waste Manag. 2016, 58, 118–125. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, Y.; Li, M.; Yuan, Z. Aeration rate improves the compost quality of food waste and promotes the decomposition of toxic materials in leachate by changing the bacterial community. Bioresour. Technol. 2021, 340, 125716. [Google Scholar] [CrossRef]

- Mortola, N.; Romaniuk, R.; Cosentino, V.; Eiza, M.; Carfagno, P.; Rizzo, P.; Bres, P.; Riera, N.; Roba, M.; Butti, M.; et al. Potential Use of a Poultry Manure Digestate as a Biofertiliser: Evaluation of Soil Properties and Lactuca sativa Growth. Pedosphere 2019, 29, 60–69. [Google Scholar] [CrossRef]

- Rizzo, P.F.; Young, B.J.; Viso, N.P.; Carbajal, J.; Martínez, L.E.; Riera, N.I.; Bres, P.A.; Beily, M.E.; Barbaro, L.; Farber, M.; et al. Integral approach for the evaluation of poultry manure, compost, and digestate: Amendment characterization, mineralization, and effects on soil and intensive crops. Waste Manag. 2022, 139, 124–135. [Google Scholar] [CrossRef]

- Bernal, M.P.; Sommer, S.G.; Chadwick, D.; Qing, C.; Guoxue, L.; Michel, F.C. Current Approaches and Future Trends in Compost Quality Criteria for Agronomic, Environmental, and Human Health Benefits. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Cambridge, MA, USA, 2017; Volume 144, pp. 143–233. [Google Scholar] [CrossRef]

- Gong, X.; Li, S.; Sun, X.; Zhang, L.; Zhang, T.; Wei, L. Maturation of green waste compost as affected by inoculation with the white-rot fungi Trametes versicolor and Phanerochaete chrysosporium. Environ. Technol. 2017, 38, 872–879. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Wang, S.; Guo, X.; Wang, H. Comparison of the effects of different maturity composts on soil nutrient, plant growth and heavy metal mobility in the contaminated soil. J. Environ. Manag. 2019, 250, 109525. [Google Scholar] [CrossRef] [PubMed]

- Puyuelo, B.; Arizmendiarrieta, J.S.; Irigoyen, I.; Plana, R. Quality assessment of composts officially registered as organic fertilisers in Spain. Span. J. Agric. Res. 2019, 17, 1101. [Google Scholar] [CrossRef] [Green Version]

- Jiangming, Z. Effect of turning frequency on co-composting pig manure and fungus residue. J. Air Waste Manag. Assoc. 2017, 67, 313–321. [Google Scholar] [CrossRef]

- Ravindran, B.; Karmegam, N.; Awasthi, M.K.; Chang, S.W.; Selvi, P.K.; Balachandar, R.; Chinnappan, S.; Azelee, N.I.W.; Munuswamy-Ramanujam, G. Valorization of food waste and poultry manure through co-composting amending saw dust, biochar and mineral salts for value-added compost production. Bioresour. Technol. 2022, 346, 126442. [Google Scholar] [CrossRef] [PubMed]

- Kalemelawa, F.; Nishihara, E.; Endo, T.; Ahmad, Z.; Yeasmin, R.; Tenywa, M.M.; Yamamoto, S. An evaluation of aerobic and anaerobic composting of banana peels treated with different inoculums for soil nutrient replenishment. Bioresour. Technol. 2012, 126, 375–382. [Google Scholar] [CrossRef]

- Kebibeche, H.; Khelil, O.; Kacem, M.; Harche, M.K. Addition of wood sawdust during the co-composting of sewage sludge and wheat straw influences seeds germination. Ecotoxicol. Environ. Saf. 2019, 168, 423–430. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Oviedo-Ocaña, E.R.; Manyoma-Velásquez, P.C.; Torres-Lozada, P.; Gea, T. Evaluation of mixing ratio and frequency of turning in the co-composting of biowaste with sugarcane filter cake and star grass. Waste Manag. 2019, 96, 86–95. [Google Scholar] [CrossRef]

- Hargreaves, J.; Adl, M.; Warman, P. A review of the use of composted municipal solid waste in agriculture. Agric. Ecosyst. Environ. 2008, 123, 1–14. [Google Scholar] [CrossRef]

- Nigussie, A.; Bruun, S.; Kuyper, T.W.; de Neergaard, A. Delayed addition of nitrogen-rich substrates during composting of municipal waste: Effects on nitrogen loss, greenhouse gas emissions and compost stability. Chemosphere 2017, 166, 352–362. [Google Scholar] [CrossRef]

- Centre HKOR. Compost and Soil Conditioner Quality Standards; Hong Kong Organic Resource Centre: Kowlong Tong, Hong Kong, 2005. [Google Scholar]

| Parameter | SO | CM | BW | WC |

|---|---|---|---|---|

| pH | 6.6 ± 0.2 | 8.5 ± 0.3 | 5.7 ± 0.8 | 6.3 ± 0.1 |

| Water content (%) | 67.5 ± 1.3 | 74.6 ± 1.8 | 78.3 ± 2.1 | 10.8 ± 0.3 |

| TOC (% C dw) | 18.8 ± 0.4 | 44.2 ± 7.7 | 24.1 ± 1.5 | 33.7 ± 3.4 |

| TN (% N dw) | 1.6 ± 0.2 | 3.6 ± 0.7 | 1.4 ± 0.5 | 0.8 ± 0.1 |

| TP (% P2O5 dw) | 0.20 ± 0.0 | 1.05 ± 0.0 | 0.2 ± 0.1 | 1.33 ± 0.0 |

| EC (mS/cm) | 1.2 ± 0.3 | 6.2 ±1.1 | 3.5 ± 0.4 | 0.3 ± 0.1 |

| C/N | 11.6 ± 0.8 | 12.3 ± 0.6 | 17.2 ± 0.6 | 13.5 ± 0.5 |

| Parameter | Scores (Si) | Weights | ||||

|---|---|---|---|---|---|---|

| 5 | 4 | 3 | 2 | 1 | (Wi) | |

| Total Organic Carbon (%) | >20.0 | 15.1–20.0 | 12.1–15.0 | 9.1–12.0 | <9.1 | 5 |

| Total Nitrogen (%) | >1.25 | 1.01–1.25 | 0.81–1.00 | 0.51–0.80 | <0.51 | 3 |

| Total Phosphorus (%) | >0.60 | 0.41–0.60 | 0.21–0.40 | 0.11–0.20 | <0.11 | 3 |

| Total Potassium (%) | >1.00 | 0.76–1.00 | 0.51–0.75 | 0.26–0.50 | <0.26 | 1 |

| Carbon/Nitrogen | <10.1 | 10.1–15 | 15.1–20 | 20.1–25 | >25 | 3 |

| Treatment | Time to the Start of the ThermoPhilic Phase (Days) | TMAX (°C) | Time to TMAX (Days) | Duration of the ThermoPhilic Phase (Days) | Time to Tamb ± 3 °C from Process Start (Days) | Added Water (L) | pH-Initial | pH Final |

|---|---|---|---|---|---|---|---|---|

| TA | 2 | 57.3 | 4 | 17 | 54 | 72.0 | 8.4 | 8.9 |

| TB | 2 | 57.0 | 4 | 17 | 49 | 75.3 | 8.4 | 8.8 |

| TC | 2 | 33.3 | 3 | 0 | 47 | 78.7 | 8.5 | 8.7 |

| Parameter | Treatment A | Treatment B | Treatment C | NTC 5167 |

|---|---|---|---|---|

| Water content (%) | 56.1 ± 2.1 a | 52.3 ± 3.6 b | 47.5 ± 3.2 b | <35 |

| pH (%) | 8.9 ± 0.2 a | 8.6 ± 0.1 a | 7.9 ± 0.1 b | >4–<9 |

| Density (g/cm3) | 0.2 ± 0.1 a | 0.2 ± 0.1 a | 0.3 ± 0.1 a | <0.6 |

| WRC (%) | 287.3 ± 26.3 a | 322.7 ± 44.8 b | 317.3 ± 37.0 b | >100 |

| CEC (meq/100 g) | 51.3 ± 3.0 a | 52.9 ± 3.3 a | 44.1 ± 1.5 b | >30 |

| EC (mS/cm) | 4.6 ± 0.6 a | 4.5 ± 0.8 a | 0.5 ± 0.4 b | - |

| Ashes (%) | 18.2 ± 1.3 a | 25.0 ± 2.2 a | 27.5 ± 3.6 a | <60 |

| TOC (%) | 38.0 ± 1.8 a | 35.5 ± 1.8 a | 36.0 ± 0.9 a | >15 |

| TN (%) | 1.7 ± 0.1 a | 1.6 ± 0.1 a | 0.6 ± 0.1 b | >1 |

| C/N ratio | 22.5 ± 2.0 a | 21.7 ± 1.9 a | 57.7 ± 2.9 b | - |

| TP (%) | 0.7 ± 0.2 a | 0.7 ± 0.1 a | 0.1 ± 0.1 b | >1 |

| TK (%) | 2.1 ± 0.4 a | 2.1 ± 0.1 a | 0.7 ± 0.1 b | >1 |

| Total Ca (%) | 1.8 ± 0.5 a | 1.9 ± 0.2 a | 1.5 ± 0.9 a | - |

| Total Mg (%) | 0.4 ± 0.2 a | 0.5 ± 0.1 a | 0.1 ± 0.1 a | - |

| Total Na (%) | 1.0 ± 0.1 a | 1.1 ± 0.1 a | 0.9 ± 0.1 a | - |

| Total Zn (%) | 0 | 0 | 0 | - |

| FI | 4.3 ± 0.1 a | 4.3 ± 0.3 a | 2.5 ± 0.1 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oviedo-Ocaña, E.R.; Hernández-Gómez, A.; Dominguez, I.; Alexis Parra-Orobio, B.; Soto-Paz, J.; Sánchez, A. Evaluation of Co-Composting as an Alternative for the Use of Agricultural Waste of Spring Onions, Chicken Manure and Bio-Waste Produced in Moorland Ecosystems. Sustainability 2022, 14, 8720. https://doi.org/10.3390/su14148720

Oviedo-Ocaña ER, Hernández-Gómez A, Dominguez I, Alexis Parra-Orobio B, Soto-Paz J, Sánchez A. Evaluation of Co-Composting as an Alternative for the Use of Agricultural Waste of Spring Onions, Chicken Manure and Bio-Waste Produced in Moorland Ecosystems. Sustainability. 2022; 14(14):8720. https://doi.org/10.3390/su14148720

Chicago/Turabian StyleOviedo-Ocaña, Edgar Ricardo, Angelica Hernández-Gómez, Isabel Dominguez, Brayan Alexis Parra-Orobio, Jonathan Soto-Paz, and Antoni Sánchez. 2022. "Evaluation of Co-Composting as an Alternative for the Use of Agricultural Waste of Spring Onions, Chicken Manure and Bio-Waste Produced in Moorland Ecosystems" Sustainability 14, no. 14: 8720. https://doi.org/10.3390/su14148720

APA StyleOviedo-Ocaña, E. R., Hernández-Gómez, A., Dominguez, I., Alexis Parra-Orobio, B., Soto-Paz, J., & Sánchez, A. (2022). Evaluation of Co-Composting as an Alternative for the Use of Agricultural Waste of Spring Onions, Chicken Manure and Bio-Waste Produced in Moorland Ecosystems. Sustainability, 14(14), 8720. https://doi.org/10.3390/su14148720