Analysis of the Self-Cleaning Potential of Glass Fiber Reinforced Concrete (GRC) with TiO2 Nanoparticles

Abstract

:1. Introduction

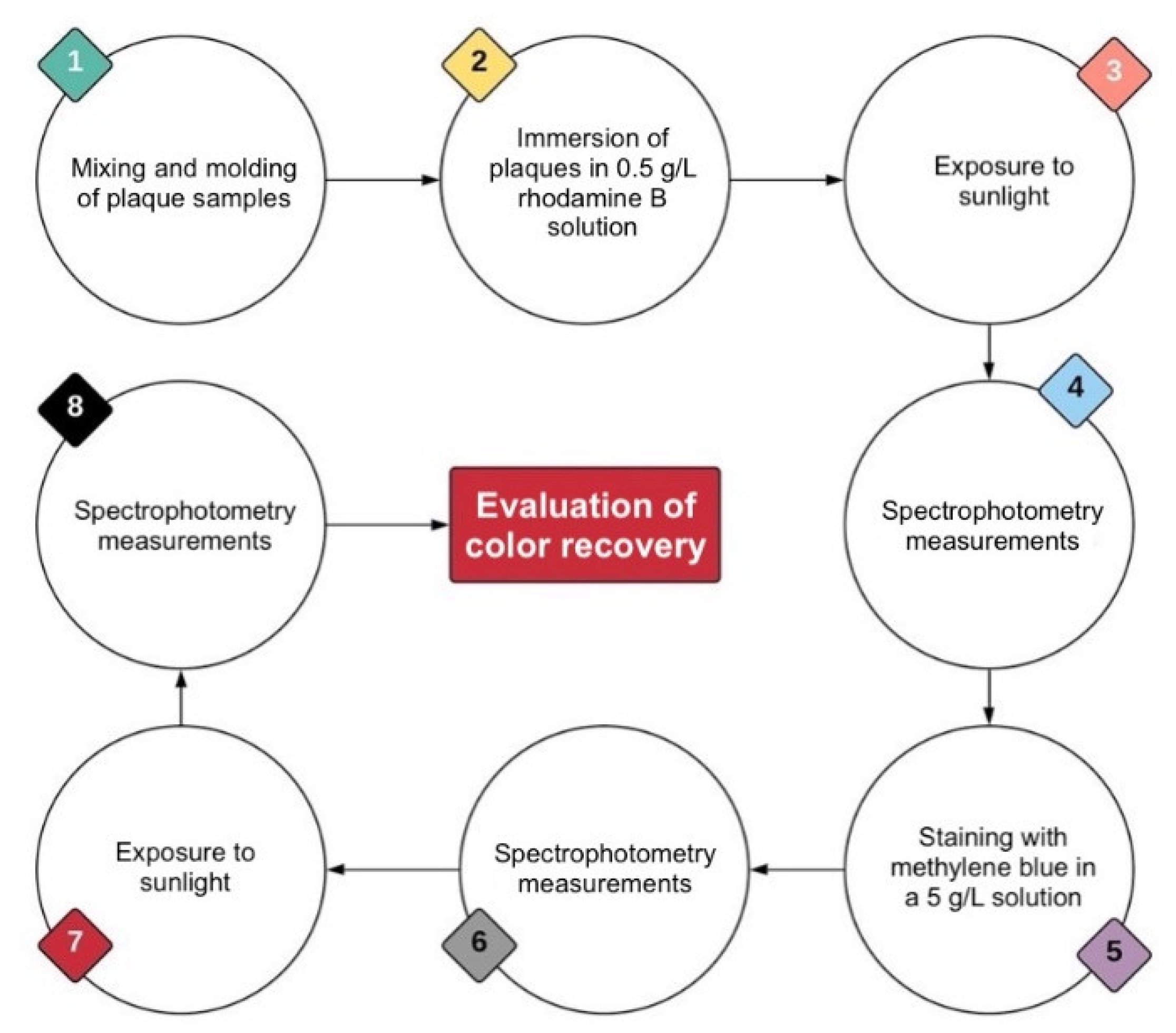

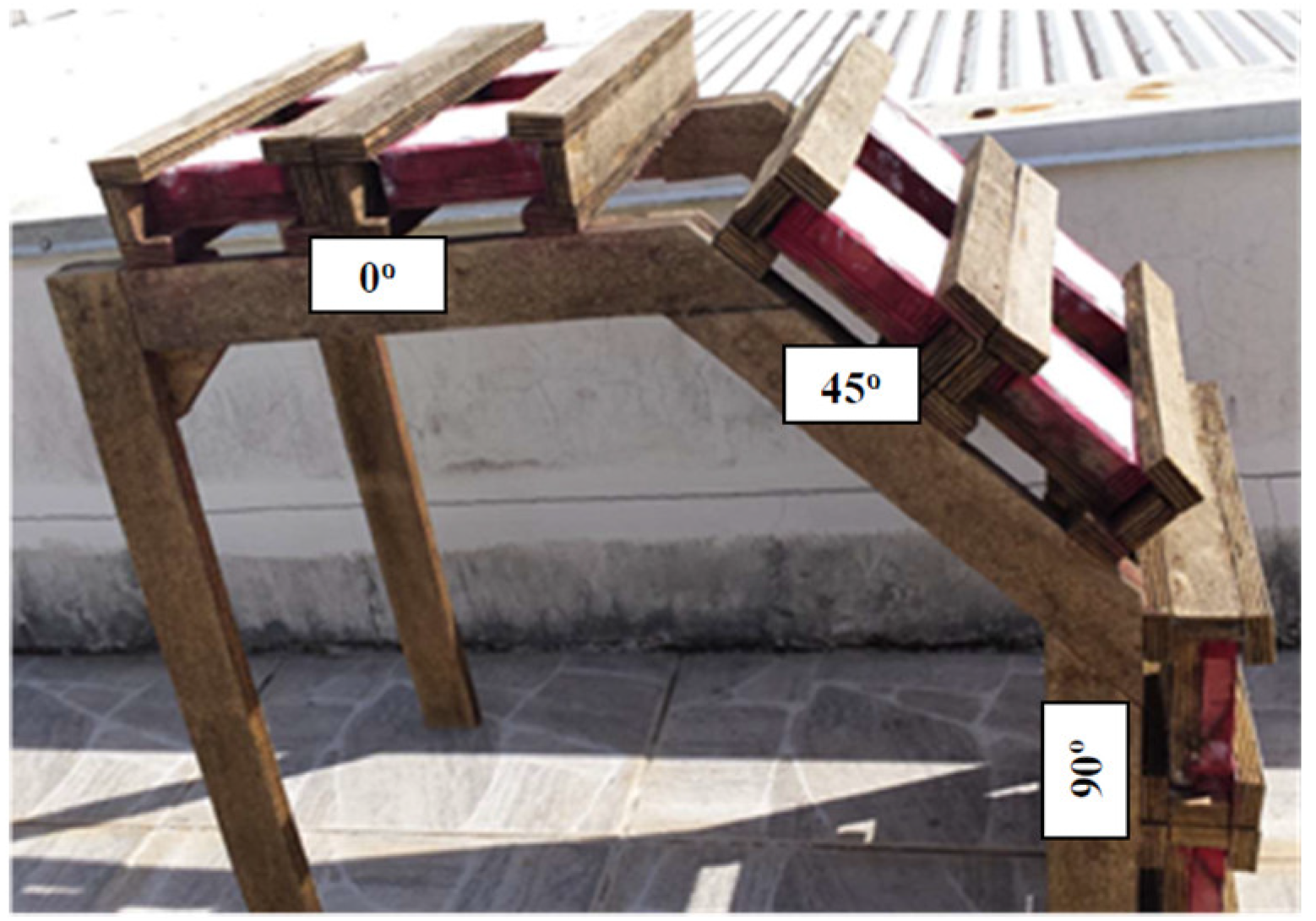

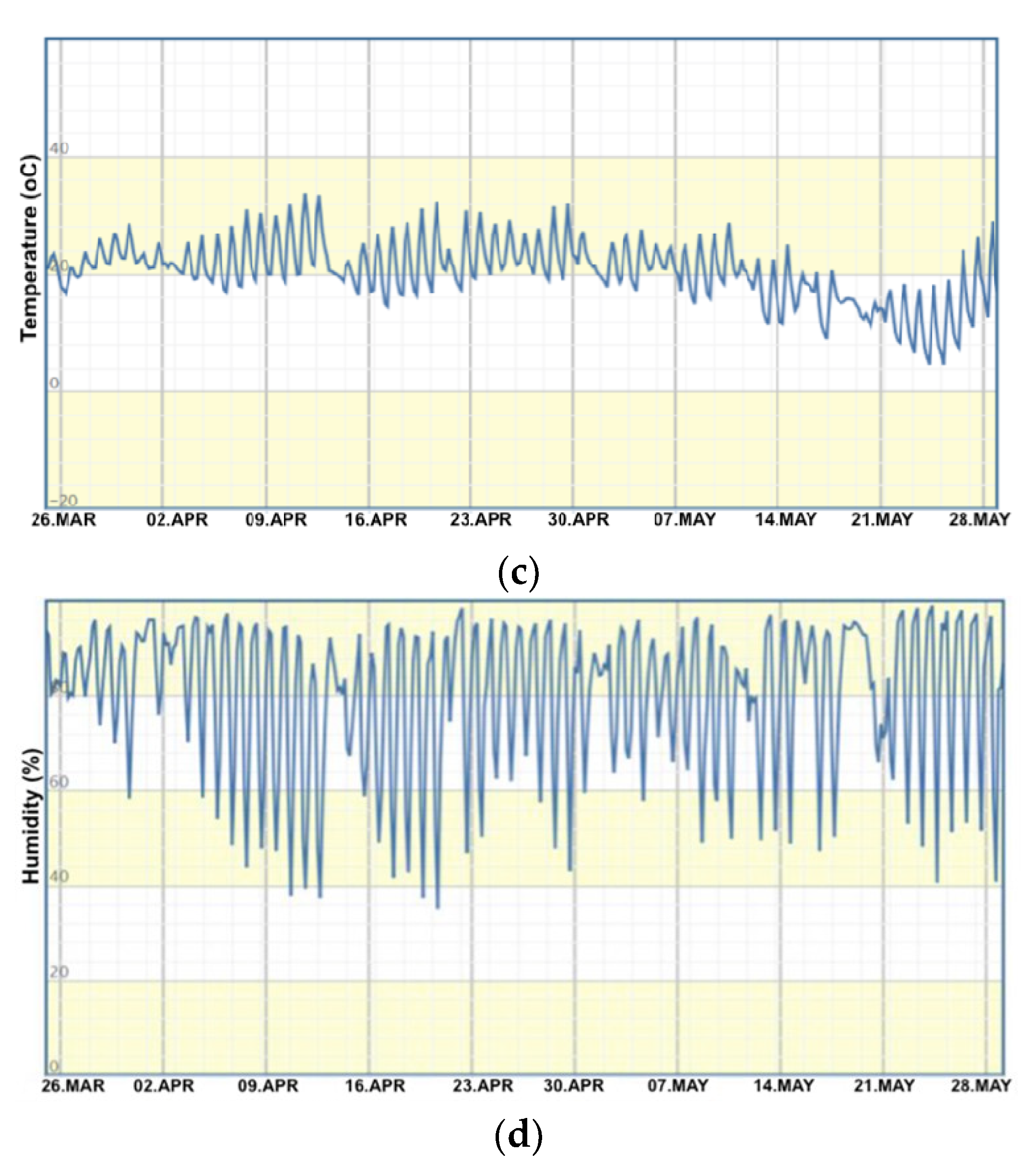

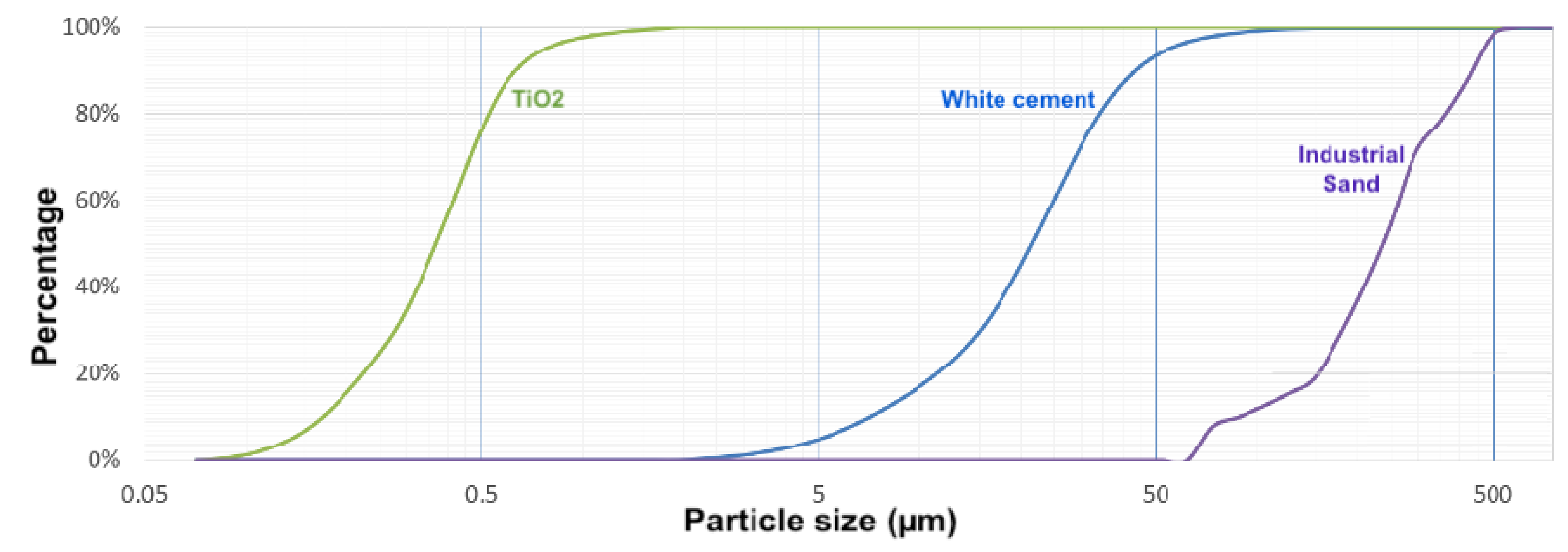

2. Materials and Methods

3. Results

3.1. Properties in the Fresh State

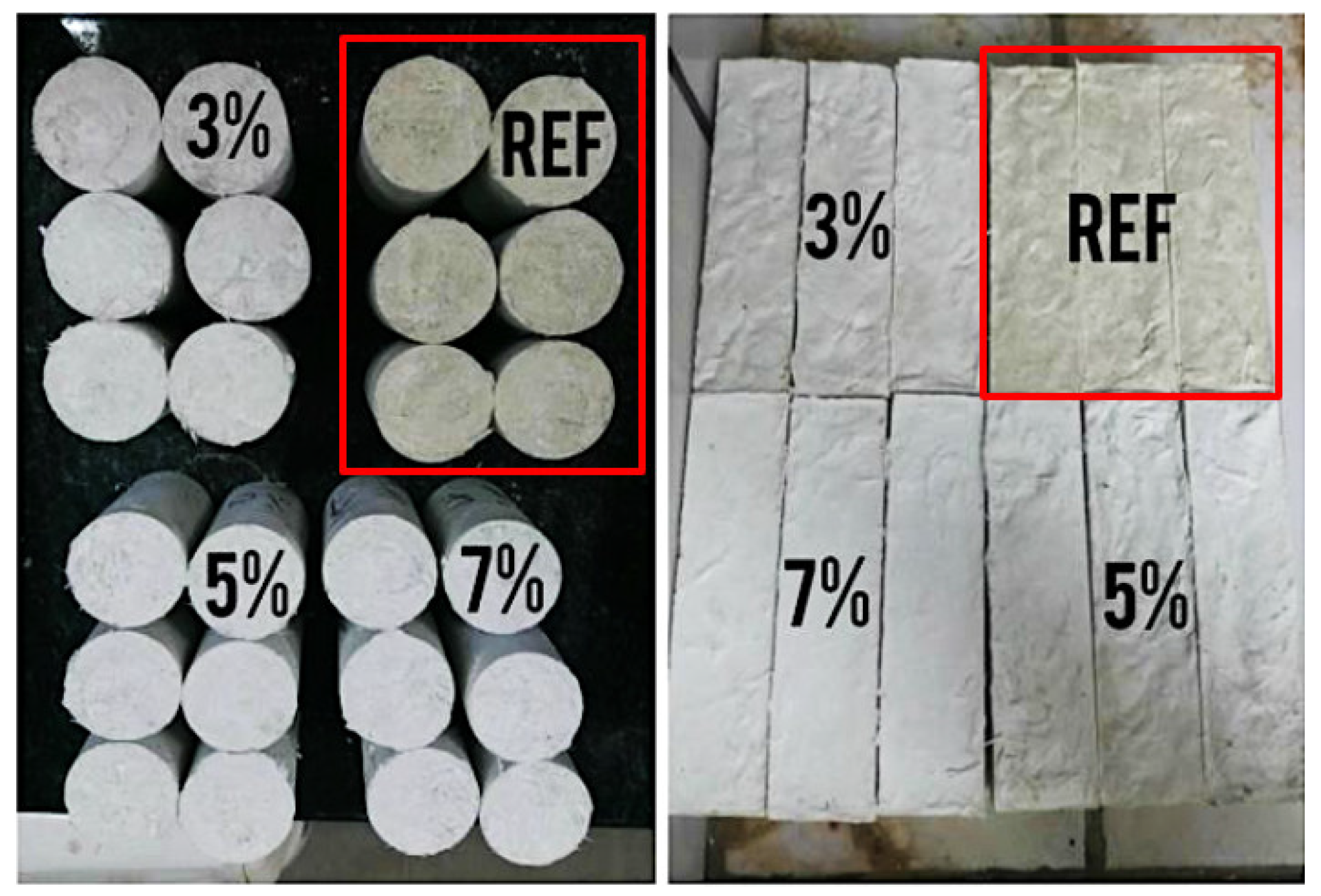

3.2. Compressive and Flexural Strength Results

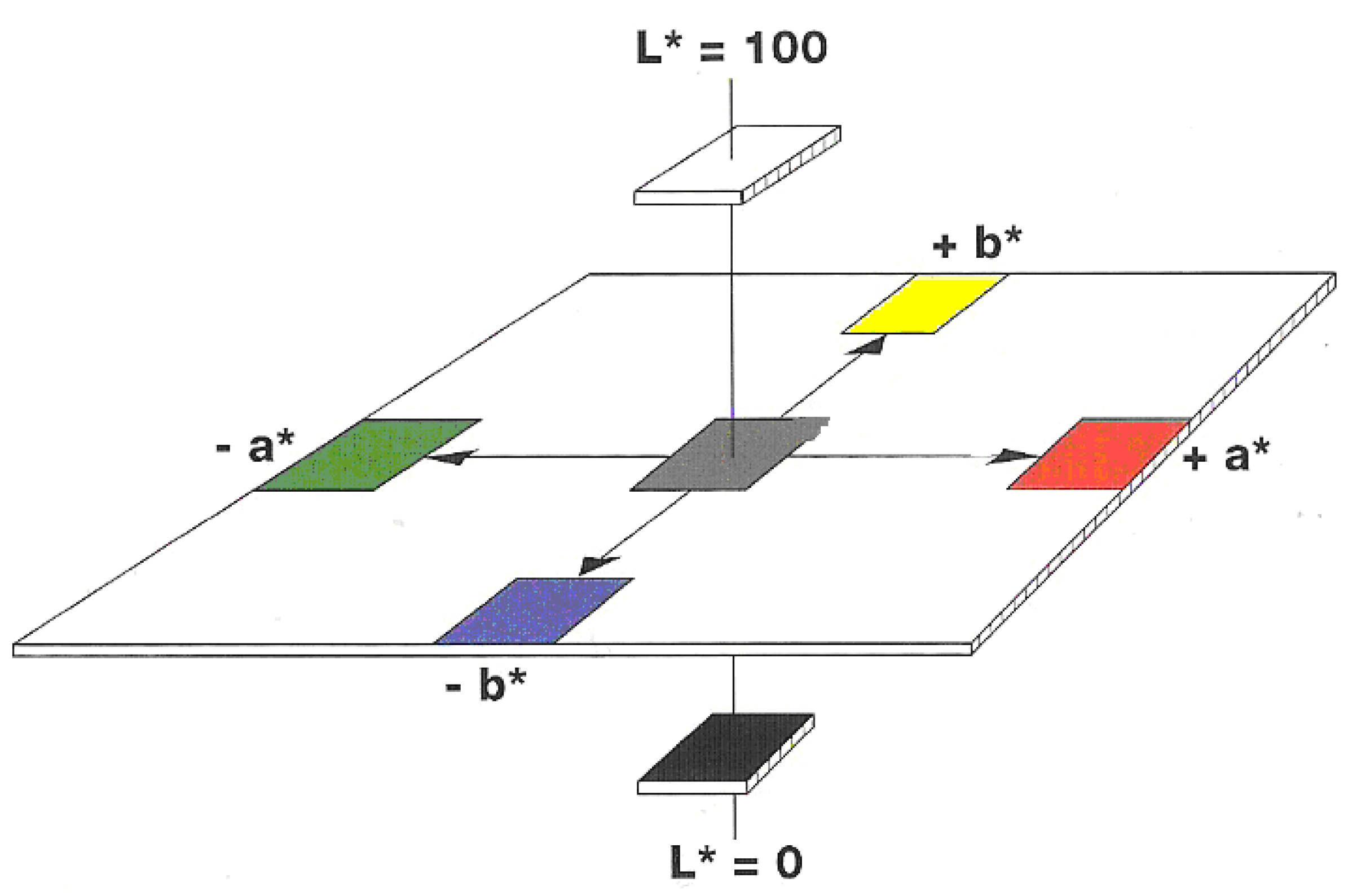

3.3. Plate Color (before Staining)

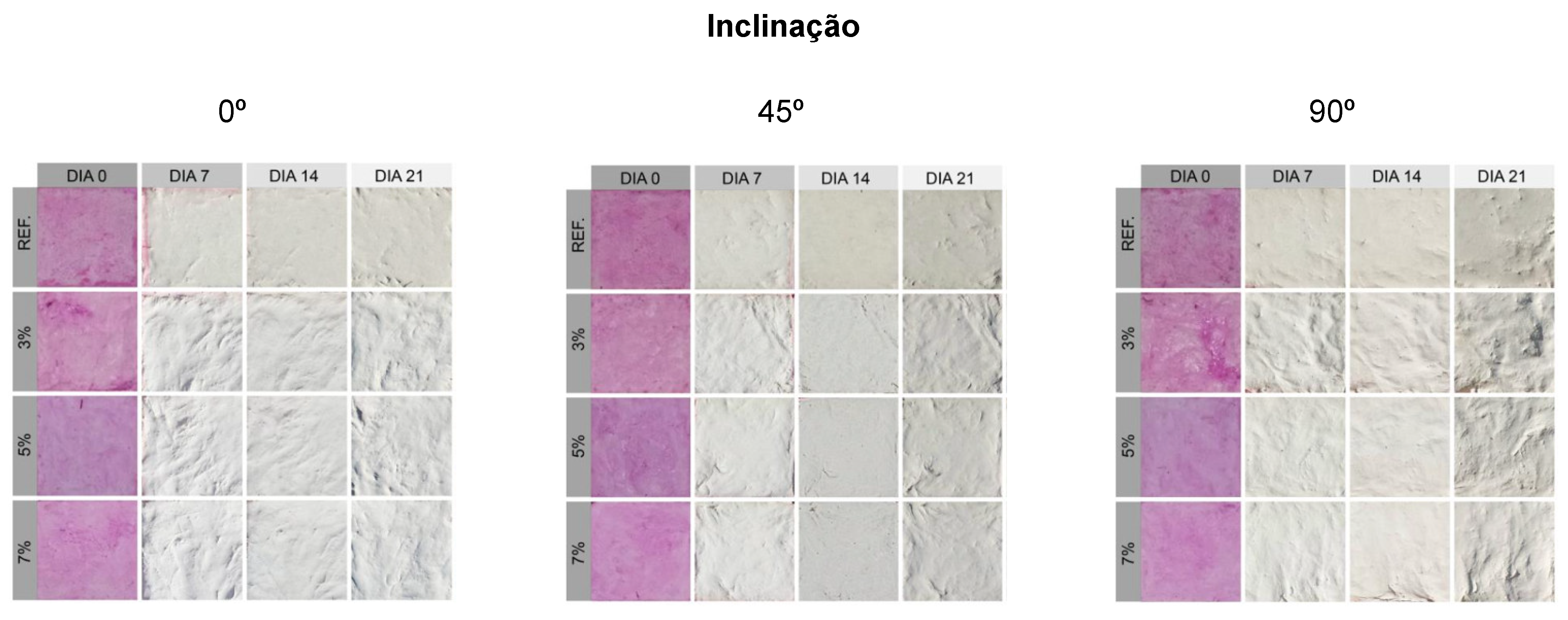

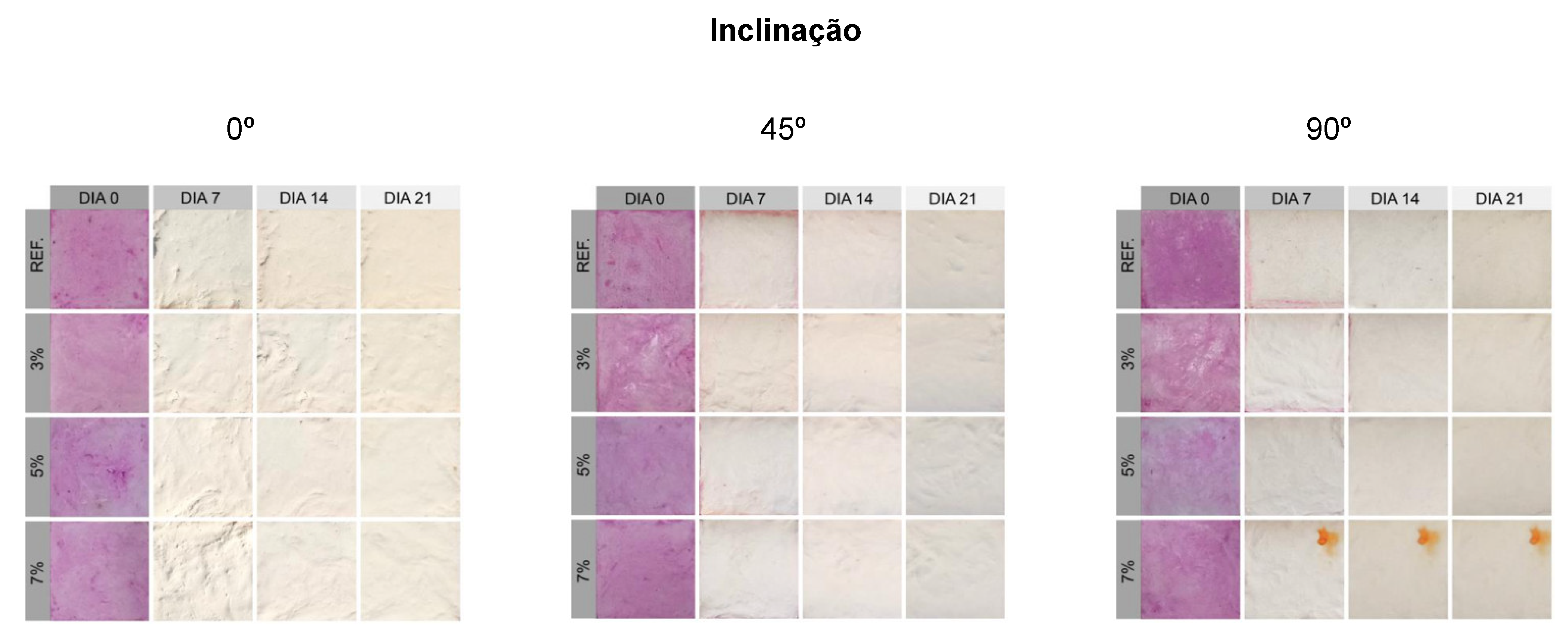

3.4. Visual Analysis with Rhodamine B

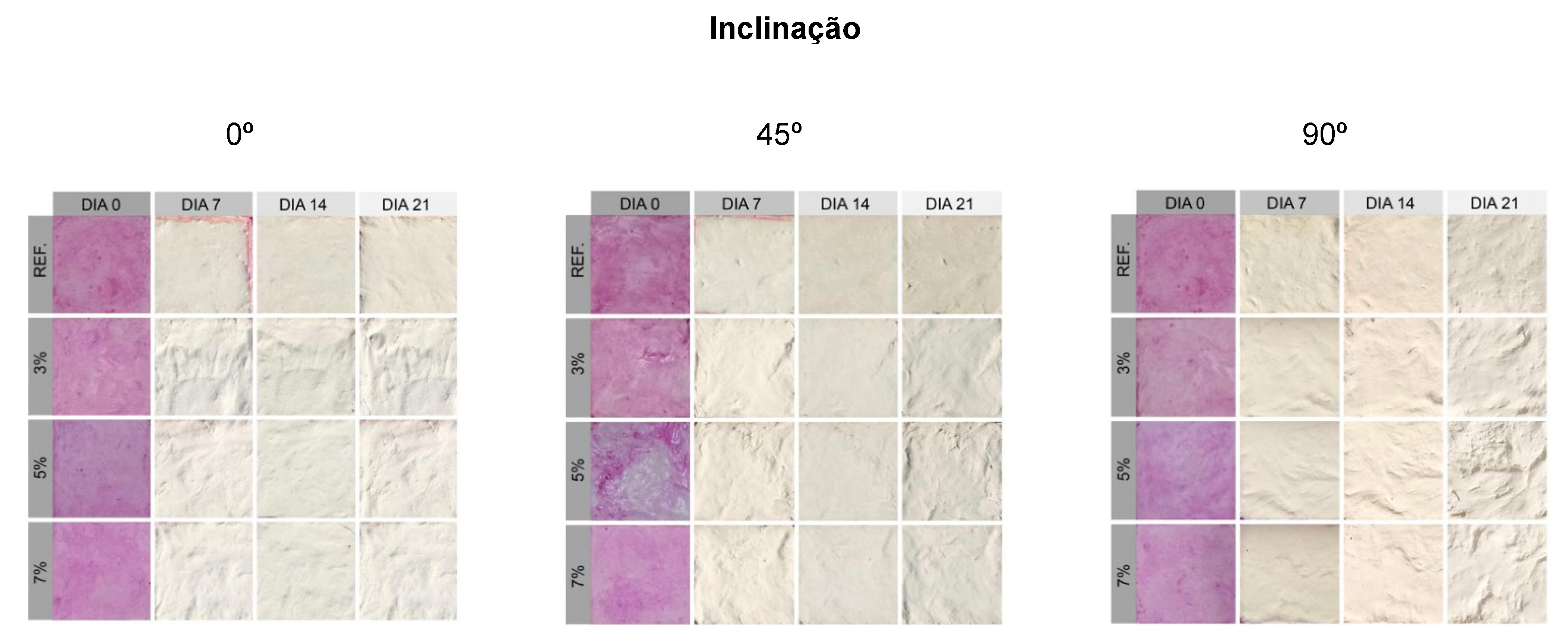

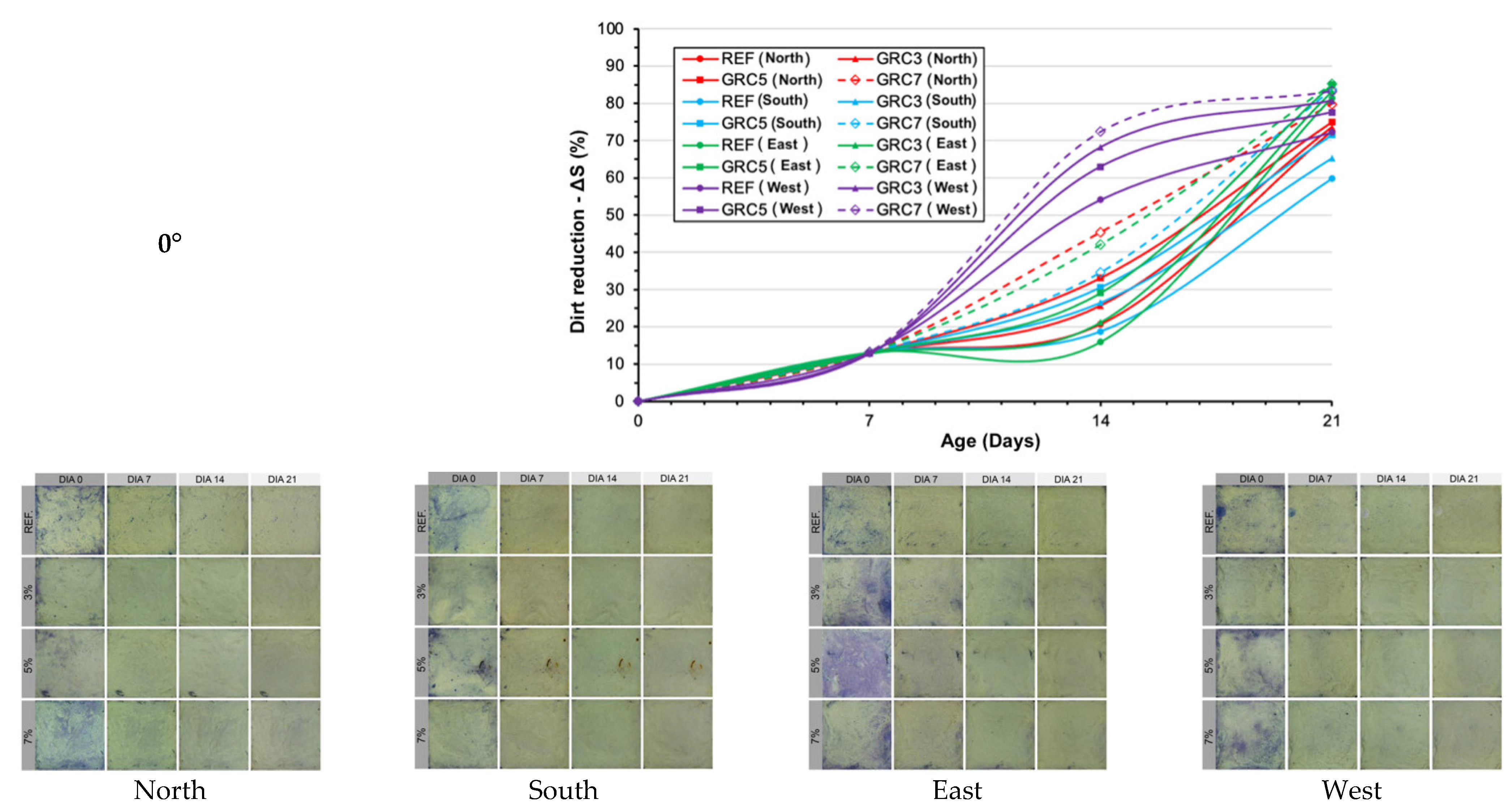

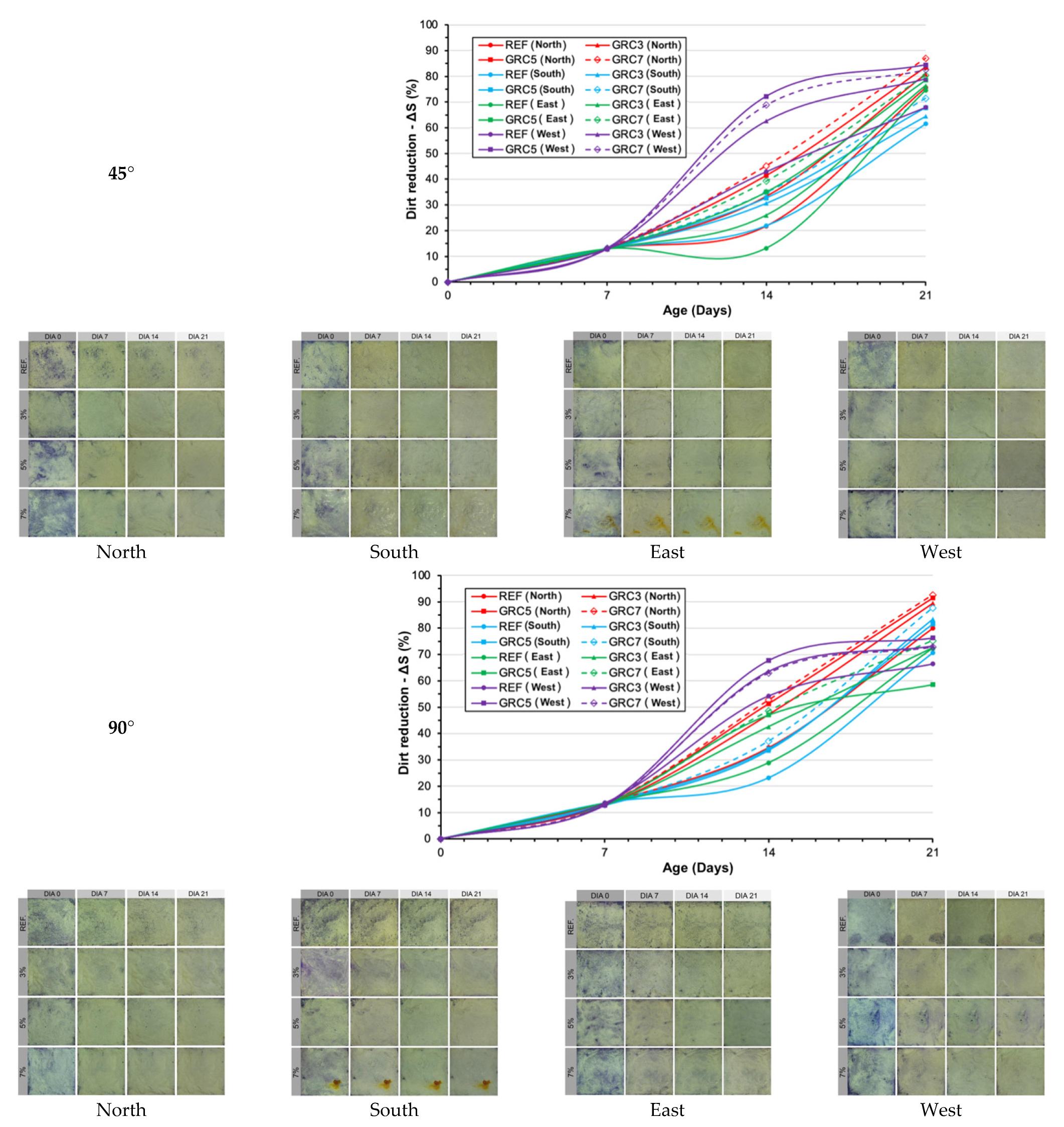

3.5. Visual and Spectrophotometric Analysis of Methylene Blue Staining

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chira, A.; Kumar, A.; Vlach, T.; Laiblová, L.; Hajek, P. Textile-reinforced concrete facade panels with rigid foam core prisms. J. Sandw. Struct. Mater. 2016, 18, 200–214. [Google Scholar] [CrossRef]

- Sayed, N.; Afify, M. The Evolution of green cladding technology for architectural façades and its role in achieving environmental integration. J. Environ. Treat. Tech. 2001, 9, 548–558. [Google Scholar]

- García, L.D.; Pastor, J.M.; Peña, J. Self-cleaning and depolluting glass reinforced concrete panels: Fabrication, optimization and durability evaluation. Constr. Build. Mater. 2018, 162, 9–19. [Google Scholar] [CrossRef]

- Cuypers, H.; Wastiels, J.; Van Itterbeeck, P.; De Bolster, E.; Orlowsky, J.; Raupach, M. Durability of glass fibre reinforced composites experimental methods and results. Compos. Part A Appl. Sci. Manuf. 2006, 37, 207–215. [Google Scholar] [CrossRef]

- Cuypers, H.; Wastiels, J. Analysis and verification of the performance of sandwich panels with textile reinforced concrete faces. J. Sandw. Struct. Mater. 2011, 13, 589–603. [Google Scholar] [CrossRef]

- Iskender, M.; Karasu, B. Glass fiber reinforced concrete pipes. Nat. Water Council Bull. 2018, 5, 136–162. [Google Scholar]

- Ortolan, V.K.; Francisco, L.W.; Cadore, B.C.; Ott, M.J.; Chritst, R. Análise da influência geométrica de fibra de vidro AR na matriz cimentícia de GRC. In Proceedings of the 59° Congresso Brasileiro do Concreto, Bento Gonçalves, Brazil, 31 October–3 November 2017; pp. 1–11. [Google Scholar]

- Pacheco, F.; Toma, N.; Ortolan, V.; Marques, M.; Ehrenbring, H.; Montelongo, A.; Christ, R.; Tutikian, B. Residual life identification of an industrial building through non-destructive tests and mathematical models of damage. In Proceedings of the 9th International Conference on Concrete under Severe Conditions—Environment & Loading, Porto Alegre, Brazil, 5–7 June 2019. [Google Scholar] [CrossRef]

- Silva, A.; De Brito, J.; Gaspar, P.L. Methodologies for Service Life Prediction of Buildings: With a Focus on Façade Claddings; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Wittmann Lanzarin, B.; Folle, L.F. Análise da estética do concreto produzido com rejeito plástico para o uso no design de interiores com viés sustentável. MIX Sustentável 2020, 6, 61–72. [Google Scholar] [CrossRef]

- Mansour, A.M.H.; Al-Dawery, S.K. Sustainable self-cleaning treatments for architectural facades in developing countries. Alex. Eng. J. 2018, 57, 867–873. [Google Scholar] [CrossRef]

- Maggonage, R.E.F.A. Performance of NO2 Sequestered Recycled Concrete Aggregate (NRCA) incorporated Ordinary Portland Cement (Opc) Concrete. Ph.D. Thesis, Clarkson University, Potsdam, NY, USA, 2020. [Google Scholar]

- Díaz-Hernández, D.Z.; Sarmiento-Alipio, J.A. Concreto a Base de Cenizas Volantes Activadas Alcalinamente, Modificado con Nanopartículas de Óxido de Silicio y Dióxido de Titanio. Master’s Thesis, Universidad Católica De Colombia, Bogota, Colombia, 2020. [Google Scholar]

- Nosrati, R.; Olad, A.; Najjari, H. Study of the effect of TiO2/polyaniline nanocomposite on the self-cleaning property of polyacrylic latex coating. Surf. Coat. Technol. 2017, 316, 199–209. [Google Scholar] [CrossRef]

- González, E.; Bonnefond, A.; Barrado, M.; Barrasa, A.M.C.; Asua, J.M.; Leiza, J.R. Photoactive self-cleaning polymer coatings by TiO2 nanoparticle Pickering miniemulsion polymerization. Chem. Eng. J. 2015, 281, 209–217. [Google Scholar] [CrossRef]

- Low, J.; Cheng, B.; Yu, J. Surface modification and enhanced photocatalytic CO2 reduction performance of TiO2: A review. Appl. Surf. Sci. 2017, 392, 658–686. [Google Scholar] [CrossRef]

- Nikokavoura, A.; Trapalis, C. Alternative photocatalysts to TiO2 for the photocatalytic reduction of CO2. Appl. Surf. Sci. 2017, 391, 149–174. [Google Scholar] [CrossRef]

- Tan, L.-L.; Ong, W.-J.; Chai, S.-P.; Mohamed, A.R. Photocatalytic reduction of CO2 with H2O over graphene oxide-supported oxygen-rich TiO2 hybrid photocatalyst under visible light irradiation: Process and kinetic studies. Chem. Eng. J. 2017, 308, 248–255. [Google Scholar] [CrossRef]

- Treviso, J.P.M. Avaliação da Eficiência de Autolimpeza em Argamassas e Pastas Contendo TiO2 Expostas ao Microclima Urbano. Master’s Thesis, Universidade Federal do Rio Grande do Sul, Porto Alegre, Brazil, 2016. [Google Scholar]

- Masheane, M.; Nthunya, L.; Mubiayi, M.; Thamae, T.; Mhlanga, S. Physico-chemical characteristics of some Lesotho’s clays and their assessment for suitability in ceramics production. Part. Sci. Technol. 2018, 36, 117–122. [Google Scholar] [CrossRef]

- Ma, B.; Li, H.; Mei, J.; Li, X.; Chen, F. Effects of nano-TiO2 on the toughness and durability of cement-based material. Adv. Mater. Sci. Eng. 2015, 2015, 583106. [Google Scholar] [CrossRef] [Green Version]

- Sikora, P.; Horszczaruk, E.; Rucinska, T. The effect of nanosilica and titanium dioxide on the mechanical and self-cleaning properties of waste-glass cement mortar. Procedia Eng. 2015, 108, 146–153. [Google Scholar] [CrossRef] [Green Version]

- Moro, C.; El Fil, H.; Francisco, V.; Velay-Lizancos, M. Influence of water-to-binder ratio on the optimum percentage of nano-TiO2 addition in terms of compressive strength of mortars: A laboratory and virtual experimental study based on ANN model. Constr. Build. Mater. 2021, 267, 120960. [Google Scholar] [CrossRef]

- BS EN 1170-1:1998; Precast Concrete Products. Test Method for Glass-Fiber Reinforced Cement. Measuring the Consistency of the Matrix. ‘Slump Test’ Method. European Standards: Pilsen, Czech Republic, 1998.

- ASTM C348:2021; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International (ASTM): West Conshohocken, PA, USA, 2021.

- Balbino, R.O. Remoção do Corante Azul de Metileno por Fotocatálise Heterogênea com Radiação UV Artificial e Dióxido de Titânio (TiO2) como Catalisador. Bachelor’s Thesis, Universidade Tecnológica Federal do Paraná (UTFPR), Campo Mourão, Brazil, 2015. [Google Scholar]

- Santos, I.P. Minicurso building-integrated photovoltaics para arquitetos e engenheiros civis. In Proceedings of the V Congresso Brasileiro de Energia Solar, Sau Paulo, Brazil, 11–12 March 2014. [Google Scholar]

- Macphee, D.; Folli, A. Photocatalytic concretes—The interface between photocatalysis and cement chemistry. In Proceedings of the Materials Research Society Meeting (ISCM), João Pessoa, Brazil, 28 September–2 October 2014. [Google Scholar]

- Folli, A. TiO2 Photocatalysis in Portland Cement Systems: Fundamentals of Self-Cleaning Effect and Air Pollution Mitigation. Ph.D. Thesis, University of Aberdeen, Aberdeen, Scotland, 2010. [Google Scholar]

- Meng, T.; Yu, Y.; Qian, X.; Zhan, S.; Qian, K. Effect of nano-TiO2 on the mechanical properties of cement mortar. Constr. Build. Mater. 2012, 29, 241–245. [Google Scholar] [CrossRef]

- Sorathiya, J.; Shah, S.; Kacha, S. Effect on addition of nano “titanium dioxide” (TiO2) on compressive strength of cementitious concrete. Kalpa Publ. Civ. Eng. 2017, 1, 219–225. [Google Scholar] [CrossRef] [Green Version]

- Khitab, A.; Anwar, W. Advanced Research on Nanotechnology for Civil Engineering Applications; Mirpur University of Science and Technology: New Mirpur City, Pakistan, 2016. [Google Scholar]

- Zapata, L.E.; Portela, G.; Suárez, O.M.; Carrasquillo, O. Rheological performance and compressive strength of superplasticized cementitious mixtures with micro/nano-SiO2 additions. Constr. Build. Mater. 2013, 41, 708–716. [Google Scholar] [CrossRef]

- Mukharjee, B.B.; Barai, S.V. Influence of nano-silica on the properties of recycled aggregate concrete. Constr. Build. Mater. 2014, 55, 29–37. [Google Scholar] [CrossRef]

- Jalal, M.; Fathi, M.; Farzad, M. Effects of fly ash and TiO2 nanoparticles on rheological, mechanical, microstructural and thermal properties of high strength self-compacting concrete. Mech. Mater. 2013, 61, 11–27. [Google Scholar] [CrossRef]

- Noorvand, H.; Ali, A.A.A.; Demirboga, R.; Farzadnia, N.; Noorvand, H. Incorporation of nano TiO2 in black rice husk ash mortars. Constr. Build. Mater. 2013, 47, 1350–1361. [Google Scholar] [CrossRef]

- Mohseni, E.; Miyandehi, B.M.; Yang, J.; Yazdi, M.A. Single and combined effects of nano-SiO2, nano-Al2O3 and nano-TiO2 on The mechanical, rheological and durability properties of self-compacting mortar containing fly ash. Constr. Build. Mater. 2015, 84, 331–340. [Google Scholar] [CrossRef]

- Linsebigler, A.L.; Lu, G.; Yates, J.T. Photocatalysis on TiO2 surfaces: Principles, mechanisms, and selected results. Chem. Rev. 1995, 95, 735–758. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Sifeng, L.; Chujie, J.; Jianzhong, L. Preparation of C200 green reactive powder concrete and its static–dynamic behaviors. Cem. Concr. Compos. 2008, 30, 831–838. [Google Scholar] [CrossRef]

- Fernandes, C. Estudo Sobre Incorporação de Nanopartículas de Dióxido de Titânio em Argamassas Fotocatalíticas. Ph.D. Thesis, Universidade Federal do Ceará, Fortaleza, Brazil, 2017. [Google Scholar]

- Austria, G.C. Argamassa Autolimpante para Revestimentos de Fachadas: O Efeito das Propriedades Fotocatalíticas do Dióxido de Titânio (TiO2). Master’s Thesis, UFRGS, Porto Alegre, Brazil, 2015. [Google Scholar]

- Quinino, U.C.M. InvestigaçÃo Experimental das Propriedades MecÂnicas de Compósitos de Concreto Com Adições Híbridas de Fibras. Ph.D. Thesis, Universidade Federal do Rio Grande do Sul, Porto Alegre, Brazil, 2015. [Google Scholar]

- De Souza, R.P.; Pacheco, F.; Prager, G.L.; Gil, A.M.; Christ, R.; de Mello, V.M.; Tutikian, B.F. Verification of the influence of loading and mortar coating thickness on resistance to high temperatures due to fire on load-bearing masonries with clay tiles. Materials 2019, 12, 3669. [Google Scholar] [CrossRef] [Green Version]

- Gázques, M.J.; Bolívar, J.P.; Tenorio, F.G.; Vaca, F. A review of the production cycle of titanium dioxide pigment. Mater. Sci. Appl. 2014, 5, 441–458. [Google Scholar] [CrossRef] [Green Version]

- Burger, B.; Ruther, R. Inverter sizing of grid-connected photovoltaic systems in the light of local solar resource distribution characteristics and temperature. Sol. Energy 2006, 80, 32–45. [Google Scholar] [CrossRef]

- Diamanti, M.V.; Del Curto, B.; Ormellese, M.; Pedeferri, M.P. Photocatalytic and self-cleaning activity of colored mortars containing TiO2. Mater. Chem. Eng. 2013, 46, 167–174. [Google Scholar] [CrossRef]

- Beeldens, A. An Environmental Friendly Solution for Air Purification and Self-Cleaning Effect: The Application of TIO2 as Photocatalyst in Concrete; Belgian Road Research Centre: Brussels, Belgium, 2006. [Google Scholar]

| Composite | Cement | Quartz Sand | TiO2 * % | Glass Fiber by % Volume ** | w/c | SP * % |

|---|---|---|---|---|---|---|

| REF | 1 | 1 | 0 | 0.5 | 0.2 | 1.5 |

| GRC3 | 1 | 1 | 3 | 0.5 | 0.2 | 1.5 |

| GRC5 | 1 | 1 | 5 | 0.5 | 0.2 | 1.5 |

| GRC7 | 1 | 1 | 7 | 0.5 | 0.2 | 1.5 |

| Composite | Ø (mm) | Image | Composite | Ø (mm) | Image |

|---|---|---|---|---|---|

| REF | 65 |  | GRC5 | 90 |  |

| GRC3 | 75 |  | GRC7 | 95 |  |

| Composite | Compressive Strength (MPa) | Flexural Strength (MPa) | ||

|---|---|---|---|---|

| 7 Days | 28 Days | 7 Days | 28 Days | |

| REF | 93.1 ± 5.0 | 118.1 ± 3.0 | 17.9 ± 3.0 | 19.7 ± 3.0 |

| GRC3 | 99.5 ± 1.1 | 118.3 ± 2.6 | 20.2 ± 4.0 | 20.8 ± 4.0 |

| GRC5 | 105.2 ± 6.0 | 120.0 ± 3.0 | 18.2 ± 1.0 | 20.3 ± 1.0 |

| GRC7 | 96.3 ± 7.0 | 121.8 ± 2.0 | 17.8 ± 3.0 | 21.4 ± 2.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ehrenbring, H.Z.; Christ, R.; Pacheco, F.; Francisco, L.W.; Bolezina, G.C.; Hanauer, N.B.; Grings, G.G.; Tutikian, B.F. Analysis of the Self-Cleaning Potential of Glass Fiber Reinforced Concrete (GRC) with TiO2 Nanoparticles. Sustainability 2022, 14, 8738. https://doi.org/10.3390/su14148738

Ehrenbring HZ, Christ R, Pacheco F, Francisco LW, Bolezina GC, Hanauer NB, Grings GG, Tutikian BF. Analysis of the Self-Cleaning Potential of Glass Fiber Reinforced Concrete (GRC) with TiO2 Nanoparticles. Sustainability. 2022; 14(14):8738. https://doi.org/10.3390/su14148738

Chicago/Turabian StyleEhrenbring, Hinoel Zamis, Roberto Christ, Fernanda Pacheco, Letícia Wilhelms Francisco, Giulia Cavagnoli Bolezina, Natália Berwanger Hanauer, Guilherme Gregio Grings, and Bernardo Fonseca Tutikian. 2022. "Analysis of the Self-Cleaning Potential of Glass Fiber Reinforced Concrete (GRC) with TiO2 Nanoparticles" Sustainability 14, no. 14: 8738. https://doi.org/10.3390/su14148738

APA StyleEhrenbring, H. Z., Christ, R., Pacheco, F., Francisco, L. W., Bolezina, G. C., Hanauer, N. B., Grings, G. G., & Tutikian, B. F. (2022). Analysis of the Self-Cleaning Potential of Glass Fiber Reinforced Concrete (GRC) with TiO2 Nanoparticles. Sustainability, 14(14), 8738. https://doi.org/10.3390/su14148738