Bibliometric Method for Manufacturing Servitization: A Review and Future Research Directions

Abstract

1. Introduction

2. Material and Methodology

2.1. Literature Source

2.2. Search Strategy

2.3. Analysis Methods

3. Results and Discussions

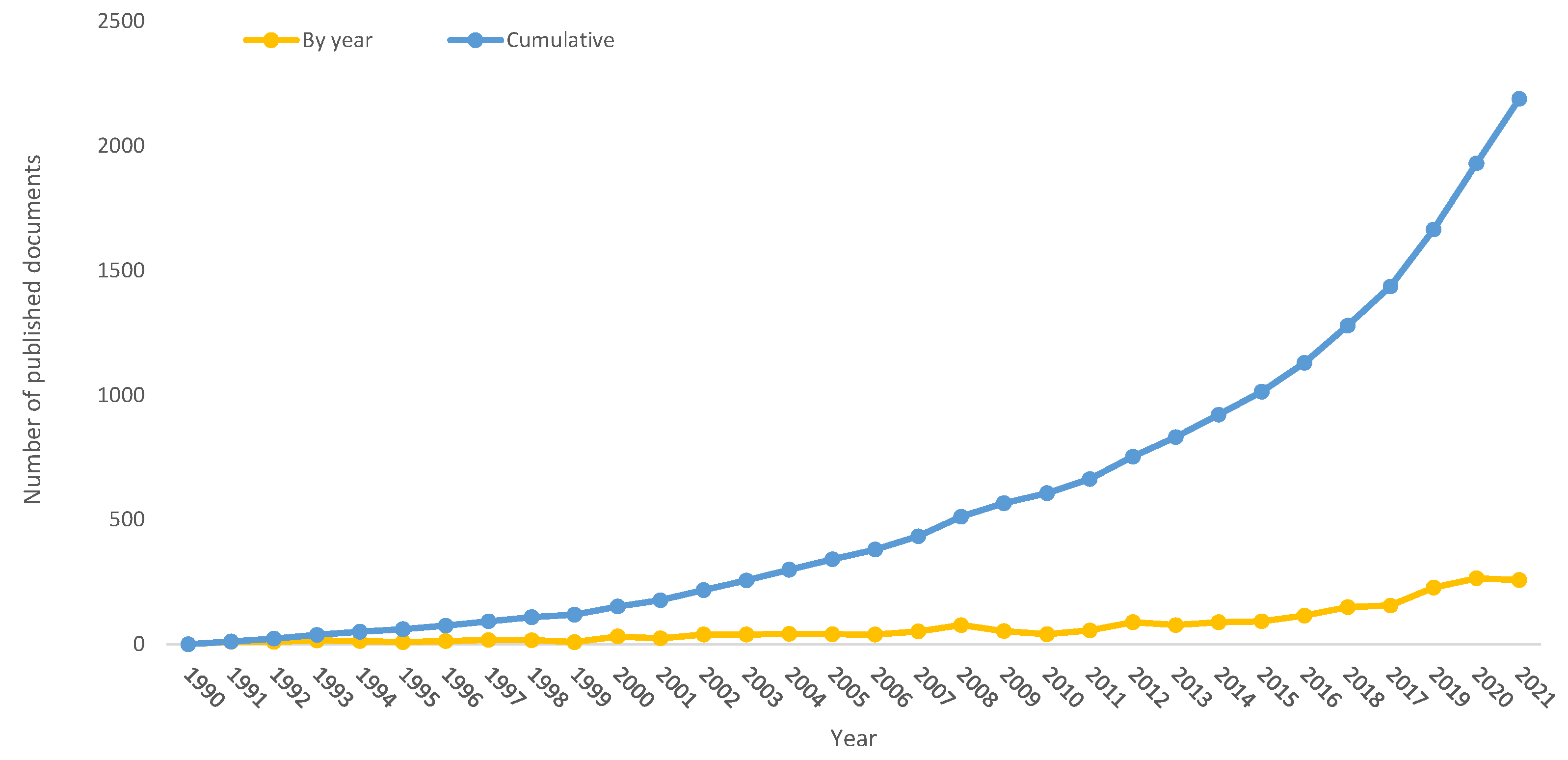

3.1. The Global Research Status

3.2. The Main Research Fileds

3.3. The Leading Journals

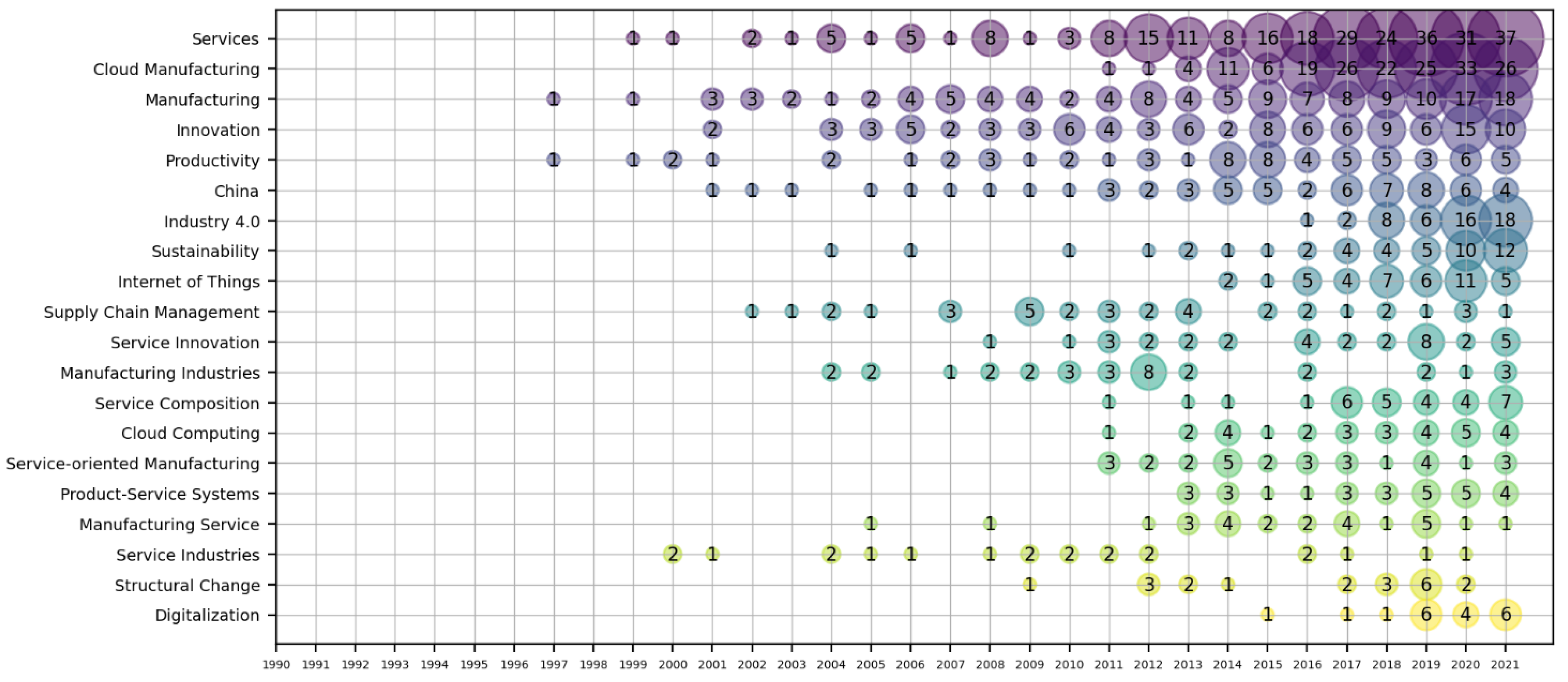

3.4. Analysis of Keywords

3.5. The Leading Institutions

3.6. The Leading Authors

3.7. The Most Cited Publications

4. Implication for Future Research

4.1. A Research Areas Perspective

4.2. A Cooperative Perspective

4.3. The Future Application Trends Perspective

5. Conclusions and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vandermerwe, S.; Rada, J. Servitization of business: Adding value by adding services. Eur. Manag. J. 1988, 6, 314–324. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Benedettini, O.; Kay, J.M. The servitization of manufacturing: A review of literature and reflection on future challenges. J. Manuf. Technol. Manag. 2009, 20, 547–567. [Google Scholar] [CrossRef]

- Opresnik, D.; Taisch, M. The value of big data in servitization. Int. J. Prod. Econ. 2015, 165, 174–184. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Parida, V.; Patel, P.C.; Gebauer, H. The relationship between digitalization and servitization: The role of servitization in capturing the financial potential of digitalization. Technol. Forecast. Soc. Chang. 2020, 151, 119804. [Google Scholar] [CrossRef]

- Rymaszewska, A.; Helo, P.; Gunasekaran, A. IoT powered servitization of manufacturing–an exploratory case study. Int. J. Prod. Econ. 2017, 192, 92–105. [Google Scholar] [CrossRef]

- Coreynen, W.; Matthyssens, P.; Van Bockhaven, W. Boosting servitization through digitization: Pathways and dynamic resource configurations for manufacturers. Ind. Mark. Manag. 2017, 60, 42–53. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X.; Zhang, L.; Wang, L.; Zhong, R.Y. Workload-based multi-task scheduling in cloud manufacturing. Robot. Comput. Integr. Manuf. 2017, 45, 3–20. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Einola, S.; Rabetino, R. Exploring servitization through the paradox lens: Coping practices in servitization. Int. J. Prod. Econ. 2020, 226, 107619. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, F. What does the China’s economic recovery after COVID-19 pandemic mean for the economic growth and energy consumption of other countries? J. Clean. Prod. 2021, 295, 126265. [Google Scholar] [CrossRef]

- Wang, Q.; Su, M. A preliminary assessment of the impact of COVID-19 on environment–A case study of China. Sci. Total Environ. 2020, 728, 138915. [Google Scholar] [CrossRef]

- Rousseau, R. Forgotten founder of bibliometrics. Nature 2014, 510, 218. [Google Scholar] [CrossRef]

- Pritchard, A. Statistical bibliography or bibliometrics. J. Doc. 1969, 25, 348–349. [Google Scholar]

- Ali, F.; Park, E.O.; Kwon, J.; Chae, B.K. 30 Years of contemporary hospitality management: Uncovering the bibliometrics and topical trends. Int. J. Contemp. Hosp. Manag. 2019, 31, 2641–2665. [Google Scholar] [CrossRef]

- Mora, L.; Deakin, M.; Reid, A. Combining co-citation clustering and text-based analysis to reveal the main development paths of smart cities. Technol. Forecast. Soc. Chang. 2019, 142, 56–69. [Google Scholar] [CrossRef]

- Sugimoto, C.R.; Ahn, Y.Y.; Smith, E.; Macaluso, B.; Larivière, V. Factors affecting sex-related reporting in medical research: A cross-disciplinary bibliometric analysis. Lancet 2019, 393, 550–559. [Google Scholar] [CrossRef]

- Ellemers, N.; Toorn, J.; Paunov, Y.; Leeuwen, T.V. The Psychology of Morality: A Review and Analysis of Empirical Studies Published From 1940 Through 2017. Pers. Soc. Psychol. Rev. 2019, 23, 332–366. [Google Scholar] [CrossRef]

- Sharifi, A. Urban sustainability assessment: An overview and bibliometric analysis. Ecol. Indic. 2020, 121, 107102. [Google Scholar] [CrossRef]

- Ferasso, M.; Beliaeva, T.; Kraus, S.; Clauss, T.; Ribeiro-Soriano, D. Circular economy business models: The state of research and avenues ahead. Bus. Strategy Environ. 2020, 29, 3006–3024. [Google Scholar] [CrossRef]

- Tooley, U.A.; Bassett, D.S.; Mackey, A.P. Environmental influences on the pace of brain development. Nat. Rev. Neurosci. 2021, 22, 372–384. [Google Scholar] [CrossRef]

- Mao, G.; Hu, H.; Liu, X.; Crittenden, J.; Huang, N. A bibliometric analysis of industrial wastewater treatments from 1998 to 2019. Environ. Pollut. 2021, 275, 115785. [Google Scholar] [CrossRef]

- Ji, B.; Zhao, Y.; Vymazal, J.; Mander, Ü.; Lust, R.; Tang, C. Mapping the field of constructed wetland-microbial fuel cell: A review and bibliometric analysis. Chemosphere 2021, 262, 128366. [Google Scholar] [CrossRef]

- Franceschini, F.; Maisano, D.A. Analysis of the Hirsch index’s operational properties. Eur. J. Oper. Res. 2010, 203, 494–504. [Google Scholar] [CrossRef]

- Geng, S.; Wang, Y.; Zuo, J.; Zhou, Z.; Du, H.; Mao, G. Building life cycle assessment research: A review by bibliometric analysis. Renew. Sust. Energ. Rev. 2017, 76, 176–184. [Google Scholar] [CrossRef]

- Hirsch, J.E. An index to quantify an individual’s scientific research output that takes into account the effect of multiple coauthorship. Scientometrics 2010, 85, 741–754. [Google Scholar] [CrossRef]

- Zyoud, S.H.; Fuchs-Hanusch, D. A bibliometric-based survey on AHP and TOPSIS techniques. Expert Syst. Appl. 2017, 78, 158–181. [Google Scholar] [CrossRef]

- Hirsch, J.E. An index to quantify an individual’s scientific research output. Proc. Natl. Acad. Sci. USA 2005, 102, 16569–16572. [Google Scholar] [CrossRef]

- Meho, L.I.; Yang, K. Impact of data sources on citation counts and rankings of LIS faculty: Web of Science versus Scopus and Google Scholar. J. Am. Soc. Inf. Sci. Tec. 2007, 58, 2105–2125. [Google Scholar] [CrossRef]

- Egghe, L. An improvement of the h-index: The g-index. ISSI Newsl. 2006, 2, 8–9. [Google Scholar]

- Meho, L.I.; Rogers, Y. Citation counting, citation ranking, and h-index of human-computer interaction researchers: A comparison of Scopus and Web of Science. J. Am. Soc. Inf. Sci. Tec. 2008, 59, 1711–1726. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, L.; Mao, G.; Zuo, J.; Du, H. Way to accomplish low carbon development transformation: A bibliometric analysis during 1995–2014. Renew. Sust. Energ. Rev. 2017, 68, 57–69. [Google Scholar] [CrossRef]

- Tan, J.; Fu, H.Z.; Ho, Y.S. A bibliometric analysis of research on proteomics in Science Citation Index Expanded. Scientometrics 2014, 98, 1473–1490. [Google Scholar] [CrossRef]

- Goldhar, J.D.; Jelinek, M. Manufacturing as a Service Business: CIM in the 21st Century. Comput. Ind. 1990, 14, 225–245. [Google Scholar] [CrossRef]

- Ageron, B.; Gunasekaran, A.; Spalanzani, A. Sustainable supply management: An empirical study. Int. J. Prod. Econ. 2012, 140, 168–182. [Google Scholar] [CrossRef]

- Blome, C.; Schoenherr, T. Supply chain risk management in financial crises—A multiple case-study approach. Int. J. Prod. Econ. 2011, 134, 43–57. [Google Scholar] [CrossRef]

- Saccani, N.; Johansson, P.; Perona, M. Configuring the after-sales service supply chain: A multiple case study. Int. J. Prod. Econ. 2007, 110, 52–69. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Ngai, E.W. The future of operations management: An outlook and analysis. Int. J. Prod. Econ. 2012, 135, 687–701. [Google Scholar] [CrossRef]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Ardolino, M.; Rapaccini, M.; Saccani, N.; Gaiardelli, P.; Crespi, G.; Ruggeri, C. The role of digital technologies for the service transformation of industrial companies. Int. J. Prod. Res. 2018, 56, 2116–2132. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Yusuf, Y.Y. Agile manufacturing: A taxonomy of strategic and technological imperatives. Int. J. Prod. Res. 2002, 40, 1357–1385. [Google Scholar] [CrossRef]

- Theorin, A.; Bengtsson, K.; Provost, J.; Lieder, M.; Johnsson, C.; Lundholm, T.; Lennartson, B. An event-driven manufacturing information system architecture for Industry 4.0. Int. J. Prod. Res. 2016, 55, 1297–1311. [Google Scholar] [CrossRef]

- Meyer, M.H. The strategic integration of markets and competencies. Int. J. Technol. Manag. 1999, 17, 677–695. [Google Scholar] [CrossRef]

- Tao, F.; Zhao, D.; Hu, Y.; Zhou, Z. Resource service composition and its optimal-selection based on particle swarm optimization in manufacturing grid system. IEEE Trans. Industr. Inform. 2008, 4, 315–327. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Gao, J.; Yao, Y.; Zhu, V.C.; Sun, L.; Lin, L. Service-oriented manufacturing: A new product pattern and manufacturing paradigm. J. Intell. Manuf. 2011, 22, 435–446. [Google Scholar] [CrossRef]

- Damanpour, F. Organizational complexity and innovation: Developing and testing multiple contingency models. Manag. Sci. 1996, 42, 693–716. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, L.; Venkatesh, V.; Luo, Y.; Cheng, Y. Cloud manufacturing: A computing and service-oriented manufacturing model. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2011, 225, 1969–1976. [Google Scholar] [CrossRef]

- Wu, D.; Greer, M.J.; Rosen, D.W.; Schaefer, D. Cloud manufacturing: Strategic vision and state-of-the-art. J. Manuf. Syst. 2013, 32, 564–579. [Google Scholar] [CrossRef]

- Wang, X.V.; Xu, X.W. An interoperable solution for cloud manufacturing. Robot. Comput. Integr. Manuf. 2013, 29, 232–247. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Low, M.K.; Lamvik, T.; Walsh, K.; Myklebust, O. Manufacturing a green service: Engaging the TRIZ model of innovation. IEEE Trans. Electron. Packag. Manuf. 2001, 24, 10–17. [Google Scholar]

- Van de Vrande, V.; De Jong, J.P.; Vanhaverbeke, W.; De Rochemont, M. Open innovation in SMEs: Trends, motives and management challenges. Technovation 2009, 29, 423–437. [Google Scholar] [CrossRef]

- Arnold, J.M.; Javorcik, B.S.; Mattoo, A. Does services liberalization benefit manufacturing firms? Evidence from the Czech Republic. J. Int. Econ. 2011, 85, 136–146. [Google Scholar] [CrossRef]

- Wang, C. Guanxi vs. relationship marketing: Exploring underlying differences. Ind. Mark. Manag. 2007, 36, 81–86. [Google Scholar] [CrossRef]

- Frohlich, M.T.; Westbrook, R. Demand chain management in manufacturing and services: Web-based integration, drivers and performance. J. Oper. Manag. 2002, 20, 729–745. [Google Scholar] [CrossRef]

- Olhager, J. Strategic positioning of the order penetration point. Int. J. Prod. Econ. 2003, 85, 319–329. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. Ensuring supply chain resilience: Development and implementation of an assessment tool. J. Bus. Logist. 2013, 34, 46–76. [Google Scholar] [CrossRef]

- Yue, X.; Cai, H.; Yan, H.; Zou, C.; Zhou, K. Cloud-assisted industrial cyber-physical systems: An insight. Microprocess. Microsyst. 2015, 39, 1262–1270. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Da Xu, L.; Zhang, L.; Li, B.H. CCIoT-CMfg: Cloud computing and internet of things-based cloud manufacturing service system. IEEE Trans. Industr. Inform. 2014, 10, 1435–1442. [Google Scholar]

- Tao, F.; Zuo, Y.; Da Xu, L.; Zhang, L. IoT-based intelligent perception and access of manufacturing resource toward cloud manufacturing. IEEE Trans. Industr. Inform. 2014, 10, 1547–1557. [Google Scholar]

- Huang, B.; Li, C.; Tao, F. A chaos control optimal algorithm for QoS-based service composition selection in cloud manufacturing system. Enterp. Inf. Syst. 2014, 8, 445–463. [Google Scholar] [CrossRef]

- Schmenner, R.W. Manufacturing, service, and their integration: Some history and theory. Int. J. Oper. Prod. Manag. 2009, 29, 431–443. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT driven service-oriented smart manufacturing: Framework and characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 81–91. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, Y.; Lv, L.; Liu, J.; Tao, F.; Zhang, L. Analysis of cloud service transaction in cloud manufacturing. In Proceedings of the IEEE 10th International Conference on Industrial Informatics, Beijing, China, 13 September 2012; pp. 320–325. [Google Scholar]

- Tao, F.; Cheng, Y.; Zhang, L.; Zhao, D. Utility modelling, equilibrium, and coordination of resource service transaction in service-oriented manufacturing system. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2012, 226, 1099–1117. [Google Scholar] [CrossRef]

- Tao, F.; Guo, H.; Zhang, L.; Cheng, Y. Modelling of combinable relationship-based composition service network and the theoretical proof of its scale-free characteristics. Enterp. Inf. Syst. 2012, 6, 373–404. [Google Scholar] [CrossRef]

- Cheng, Y.; Tao, F.; Liu, Y.; Zhao, D.; Zhang, L.; Xu, L. Energy-aware resource service scheduling based on utility evaluation in cloud manufacturing system. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2013, 227, 1901–1915. [Google Scholar] [CrossRef]

- Laili, Y.; Tao, F.; Zhang, L.; Cheng, Y.; Luo, Y.; Sarker, B.R. A ranking chaos algorithm for dual scheduling of cloud service and computing resource in private cloud. Comput. Ind. 2013, 64, 448–463. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, Y.; Tao, F.; Li, B.H.; Ren, L.; Zhang, X.; Guo, H.; Cheng, Y.; Hu, A.; Liu, Y. Cloud manufacturing: A new manufacturing paradigm. Enterp. Inf. Syst. 2014, 8, 167–187. [Google Scholar] [CrossRef]

- Cheng, Y.; Tao, F.; Zhang, L.; Zhao, D. Dynamic supply-demand matching for manufacturing resource services in service-oriented manufacturing systems: A hypernetwork-based solution framework. In Proceedings of the ASME 2015 International Manufacturing Science and Engineering Conference, Charlotte, NC, USA, 8–12 June 2015; Volume 56833, p. V002T04A017. [Google Scholar]

- Cheng, Y.; Tao, F.; Zhang, L.; Zuo, Y. Supply-demand matching of manufacturing service in service-oriented manufacturing systems. Comput. Integr. Manuf. Syst. 2015, 21, 1930–1940. [Google Scholar]

- Cheng, Y.; Zhao, D.; Tao, F.; Zhang, L.; Liu, Y. Complex networks based manufacturing service and task management in cloud environment. In Proceedings of the 2015 10th IEEE Conference on Industrial Electronics and Applications, ICIEA 2015, Auckland, New Zealand, 15–17 June 2015; pp. 242–247. [Google Scholar]

- Tao, F.; Zhang, L.; Liu, Y.; Cheng, Y.; Wang, L.; Xu, X. Manufacturing service management in cloud manufacturing: Overview and future research directions. J. Manuf. Sci. Eng. 2015, 137. [Google Scholar] [CrossRef]

- Cheng, Y.; Tao, F.; Zhao, D.; Zhang, L. Modeling of manufacturing service supply–demand matching hypernetwork in service-oriented manufacturing systems. Robot. Comput. Integr. Manuf. 2017, 45, 59–72. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, S.; Cai, M.; Liu, Y. A reputation-based peer-to-peer architecture for semantic service discovery in distributed manufacturing environments. Concurr. Eng. Res. Appl. 2012, 20, 237–253. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, S.; Qi, F.; Cai, M. Self-Organized P2P Approach to Manufacturing Service Discovery for Cross-Enterprise Collaboration. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 263–276. [Google Scholar] [CrossRef]

- Zhang, W.; Guo, S.; Zhang, S. Personalized manufacturing service recommendation using semantics-based collaborative filtering. Concurr. Eng. Res. Appl. 2015, 23, 166–179. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, S.; Cai, M.; Jian, W. An agent-based peer-to-peer architecture for semantic discovery of manufacturing services across virtual enterprises. Enterp. Inf. Syst. 2015, 9, 233–256. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, Y.; Zhang, S.; Yu, D.; Xu, Y. A new manufacturing service selection and composition method using improved flower pollination algorithm. Math. Probl. Eng. 2016, 2016, 7343794. [Google Scholar] [CrossRef]

- Wang, Y.; Dai, Z.; Zhang, W.; Zhang, S.; Xu, Y.; Chen, Q. Urgent task-aware cloud manufacturing service composition using two-stage biogeography-based optimisation. Int. J. Comput. Integr. Manuf. 2018, 31, 1034–1047. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, S.; Zhang, W.; Yu, D.; Chen, K. A hybrid approach combining an extended BBO algorithm with an intuitionistic fuzzy entropy weight method for QoS-aware manufacturing service supply chain optimization. Neurocomputing 2018, 272, 439–452. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, Y.; Zhang, S.; Yu, D.; Chen, Y. A new three-dimensional manufacturing service composition method under various structures using improved Flower Pollination Algorithm. Enterp. Inf. Syst. 2018, 12, 620–637. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, Y.; Zhang, S.; Yu, D.; Li, Y. Correlation-aware manufacturing service composition model using an extended flower pollination algorithm. Int. J. Prod. Res. 2017, 56, 4676–4691. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, W.; Zhang, S.; Zhuang, X. Game theory–based multi-task scheduling in cloud manufacturing using an extended biogeography-based optimization algorithm. Concurr. Eng. Res. Appl. 2019, 27, 314–330. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, S.; Huang, X.; Zhang, W.; Chen, M. Networked correlation-aware manufacturing service supply chain optimization using an extended artificial bee colony algorithm. Appl. Soft Comput. 2019, 76, 121–139. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, Y.; Zhang, W.; Yu, D. A new fuzzy QoS-aware manufacture service composition method using extended flower pollination algorithm. J. Intell. Manuf. 2017, 30, 2069–2083. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, W.; Zhang, W.; Chen, M. A collaborative service group-based fuzzy QoS-aware manufacturing service composition using an extended flower pollination algorithm. Nonlinear. Dyn. 2019, 95, 3091–3114. [Google Scholar] [CrossRef]

- Zhang, W.; Ding, J.; Wang, Y.; Zhang, S.; Zhuang, X. Energy-efficient bi-objective manufacturing scheduling with intermediate buffers using a three-stage genetic algorithm. J. Intel. Fuzzy. Syst. 2020, 39, 289–304. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, Y.; Zhang, W. Multitask-oriented manufacturing service composition in an uncertain environment using a hyper-heuristic algorithm. J. Manuf. Syst. 2021, 60, 138–151. [Google Scholar] [CrossRef]

- Parida, V.; Sjödin, D.R.; Wincent, J.; Kohtamäki, M. Mastering the transition to product-service provision: Insights into business models, learning activities, and capabilities. Res. Technol. Manage. 2014, 57, 44–52. [Google Scholar]

- Kohtamaki, M.; Hakala, H.; Partanen, J.; Parida, V.; Wincent, J. The performance impact of industrial services and service orientation on manufacturing companies. J. Serv. Theory Pract. 2015, 25, 463–485. [Google Scholar] [CrossRef]

- Sjödin, D.R.; Parida, V.; Kohtamäki, M. Capability configurations for advanced service offerings in manufacturing firms: Using fuzzy set qualitative comparative analysis. J. Bus. Res. 2016, 69, 5330–5335. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Parida, V.; Oghazi, P.; Gebauer, H.; Baines, T. Digital servitization business models in ecosystems: A theory of the firm. J. Bus. Res. 2019, 104, 380–392. [Google Scholar] [CrossRef]

- Sjödin, D.; Parida, V.; Kohtamäki, M. Relational governance strategies for advanced service provision: Multiple paths to superior financial performance in servitization. J. Bus. Res. 2019, 101, 906–915. [Google Scholar] [CrossRef]

- Sjödin, D.; Parida, V.; Kohtamäki, M.; Wincent, J. An agile co-creation process for digital servitization: A micro-service innovation approach. J. Bus. Res. 2020, 112, 478–491. [Google Scholar] [CrossRef]

- Khanra, S.; Dhir, A.; Parida, V.; Kohtamäki, M. Servitization research: A review and bibliometric analysis of past achievements and future promises. J. Bus. Res. 2021, 131, 151–166. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Rabetino, R.; Einola, S.; Parida, V.; Patel, P. Unfolding the digital servitization path from products to product-service-software systems: Practicing change through intentional narratives. J. Bus. Res. 2021, 137, 379–392. [Google Scholar] [CrossRef]

- Korkeamki, L.; Kohtamäki, M.; Parida, V. Worth the risk? The profit impact of outcome-based service offerings for manufacturing firms. J. Bus. Res. 2021, 131, 92–102. [Google Scholar] [CrossRef]

- Gebauer, H. An investigation of antecedents for the development of customer support services in manufacturing companies. J. Bus.-Bus. Mark. 2007, 14, 59–96. [Google Scholar] [CrossRef]

- Gebauer, H.; Fleisch, E. An investigation of the relationship between behavioral processes, motivation, investments in the service business and service revenue. Ind. Mark. Manag. 2007, 36, 337–348. [Google Scholar] [CrossRef]

- Gebauer, H.; Fleisch, E. Managing sustainable service improvements in manufacturing companies. Kybernetes 2007, 36, 583–595. [Google Scholar] [CrossRef]

- Gebauer, H.; Wang, C.; Beckenbauer, B.; Krempl, R. Business-to-business marketing as a key factor for increasing service revenue in China. J. Bus. Ind. Mark. 2007, 22, 126–137. [Google Scholar] [CrossRef]

- Combs, J.; Liu, Y.; Hall, A.; Ketchen, D. How much do high-performance work practices matter? A meta-analysis of their effects on organizational performance. Pers. Psychol. 2006, 59, 501–528. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Peters, G.P. Carbon footprint of nations: A global, trade-linked analysis. Environ. Sci. Technol. 2009, 43, 6414–6420. [Google Scholar] [CrossRef]

- Desimone, J.M. Practical Approaches to Green Solvents. Science 2002, 297, 799–803. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industrie 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Grant, A.M.; Parker, S.K. 7 Redesigning Work Design Theories: The Rise of Relational and Proactive Perspectives. Acad. Manag. Ann. 2009, 3, 317–375. [Google Scholar] [CrossRef]

- Holweg, M. The genealogy of lean production. J. Oper. Manag. 2007, 25, 420–437. [Google Scholar] [CrossRef]

- Westhead, P.; Wright, M.; Ucbasaran, D. The internationalization of new and small firms: A resource-based view. J. Bus. Ventur. 2001, 16, 333–358. [Google Scholar] [CrossRef]

- Colombo, M.G.; Grilli, L. Founders’ human capital and the growth of new technology-based firms: A competence-based view. Res. Policy 2005, 34, 795–816. [Google Scholar] [CrossRef]

- Rose, J.L. A baseline and vision of ultrasonic guided wave inspection potential. J. Press. Vessel Technol. 2002, 124, 273–282. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Boyer, R. Is a finance-led growth regime a viable alternative to Fordism? A preliminary analysis. Econ. Soc. 2000, 29, 111–145. [Google Scholar] [CrossRef]

- Homburg, C.; Fürst, A. How organizational complaint handling drives customer loyalty: An analysis of the mechanistic and the organic approach. J. Mark. 2005, 69, 95–114. [Google Scholar] [CrossRef]

- Oliveira, T.; Thomas, M.; Espadanal, M. Assessing the determinants of cloud computing adoption: An analysis of the manufacturing and services sectors. Inf. Manag. 2014, 51, 497–510. [Google Scholar] [CrossRef]

- Riezebos, J.; Klingenberg, W.; Hicks, C. Lean production and information technology: Connection or contradiction? Comput. Ind. 2009, 60, 237–247. [Google Scholar] [CrossRef]

- Davies, A. Moving base into high-value integrated solutions: A value stream approach. Ind. Corp. Chang. 2004, 13, 727–756. [Google Scholar] [CrossRef]

- Kastalli, I.V.; Van Looy, B. Servitization: Disentangling the impact of service business model innovation on manufacturing firm performance. J. Oper. Manag. 2013, 31, 169–180. [Google Scholar] [CrossRef]

- Kongsamut, P.; Rebelo, S.; Xie, D. Beyond balanced growth. Rev. Econ. Stud. 2001, 68, 869–882. [Google Scholar] [CrossRef]

- Bendoly, E.; Donohue, K.; Schultz, K.L. Behavior in operations management: Assessing recent findings and revisiting old assumptions. J. Oper. Manag. 2006, 24, 737–752. [Google Scholar] [CrossRef]

- Rajak, S.; Vimal, K.; Arumugam, S.; Parthiban, J.; Sivaraman, S.K.; Kandasamy, J.; Duque, A.A. Multi-objective mixed-integer linear optimization model for sustainable closed-loop supply chain network: A case study on remanufacturing steering column. Environ. Dev. Sustain. 2022, 24, 6481–6507. [Google Scholar] [CrossRef]

- Rajak, S.; Parthiban, P.; Dhanalakshmi, R. Selection of transportation channels in closed-loop supply chain using meta-heuristic algorithm. Int. J. Inf. Syst. Supply Chain Manage. 2018, 11, 64–86. [Google Scholar] [CrossRef]

- Cano, C.R.; Carrillat, F.A.; Jaramillo, F. A meta-analysis of the relationship between market orientation and business performance: Evidence from five continents. Int. J. Res. Mark. 2004, 21, 179–200. [Google Scholar] [CrossRef]

- Lan, H.; Ding, Y.; Hong, J.; Huang, H.; Lu, B. A web-based manufacturing service system for rapid product development. Comput. Ind. 2004, 54, 51–67. [Google Scholar] [CrossRef]

- Gebauer, H.; Fleisch, E.; Friedli, T. Overcoming the service paradox in manufacturing companies. Eur. Manag. J. 2005, 23, 14–26. [Google Scholar] [CrossRef]

- Neely, A. Exploring the financial consequences of the servitization of manufacturing. Oper. Manag. Res. 2008, 1, 103–118. [Google Scholar] [CrossRef]

- Huxtable, J.; Schaefer, D. On Servitization of the Manufacturing Industry in the UK. Procedia Cirp 2016, 52, 46–51. [Google Scholar] [CrossRef]

- Lu, C.; Li, X.; Gao, L.; Liao, W.; Yi, J. An effective multi-objective discrete virus optimization algorithm for flexible job-shop scheduling problem with controllable processing times. Comput. Ind. Eng. 2017, 104, 156–174. [Google Scholar] [CrossRef]

- Lim, C.; Kim, K.H.; Kim, M.J.; Heo, J.Y.; Kim, K.J.; Maglio, P.P. From data to value: A nine-factor framework for data-based value creation in information-intensive services. Int. J. Inf. Manag. 2018, 39, 121–135. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 9. [Google Scholar] [CrossRef]

- Sholihah, M.; Maezono, T.; Mitake, Y.; Shimomura, Y. Formulating Service-Oriented Strategies for Servitization of Manufacturing Companies. Sustainability 2020, 12, 9657. [Google Scholar] [CrossRef]

- Yu, C.; Tang, D.; Tenkorang, A.P.; Bethel, B.J. The Impact of the Opening of Producer Services on the International Competitiveness of Manufacturing Industry. Sustainability 2021, 13, 11224. [Google Scholar] [CrossRef]

- Liang, H.; Wen, X.; Liu, Y.; Zhang, H.; Wang, L. Logistics-involved QoS-aware service composition in cloud manufacturing with deep reinforcement learning. Robot. Comput. Integr. Manuf. 2021, 67, 101991. [Google Scholar] [CrossRef]

- Zhang, J. Impact of Manufacturing Servitization on Factor Productivity of Industrial Sector Using Global Value Chain. Sustainability 2022, 14, 5354. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Scavarda, L.F.; Azevedo, B.D.; Nascimento, D.L.d.M.; Quelhas, O.L.G. Challenges and Benefits of Sustainable Industry 4.0 for Operations and Supply Chain Management—A Framework Headed toward the 2030 Agenda. Sustainability 2022, 14, 830. [Google Scholar] [CrossRef]

- Szalavetz, A. `Tertiarization’ of Manufacturing Industry in the New Economy-Experiences in Hungarian Companies; IWE Working Papers; Institute for World Economics-Centre for Economic and Regional Studies-Hungarian Academy of Sciences: Budapest, Hungary, 2003. [Google Scholar]

- Temouri, Y.; Driffield, N.L.; Higón, D.A. The futures of offshoring FDI in high-tech sectors. Futures 2010, 42, 960–970. [Google Scholar] [CrossRef][Green Version]

- Kowalkowski, C.; Kindström, D.; Alejandro, T.B.; Brege, S.; Biggemann, S. Service infusion as agile incrementalism in action. J. Bus. Res. 2012, 65, 765–772. [Google Scholar] [CrossRef]

| Rank | Country/Region | TP 1 | TC 2 | ACPP 3 | IF 4 |

|---|---|---|---|---|---|

| 1 | USA | 930 | 34,142 | 36.71 | 4.88 |

| 2 | China Mainland | 760 | 16,071 | 21.15 | 4.62 |

| 3 | UK | 501 | 20,349 | 40.62 | 5.13 |

| 4 | Italy | 198 | 5319 | 26.86 | 4.48 |

| 5 | Spain | 196 | 4362 | 22.72 | 4.45 |

| 6 | Germany | 184 | 5906 | 32.10 | 4.73 |

| 7 | Sweden | 148 | 6470 | 43.72 | 5.68 |

| 8 | Canada | 136 | 3716 | 27.32 | 4.65 |

| 9 | Taiwan | 134 | 2447 | 18.26 | 4.07 |

| 10 | Australia | 122 | 3158 | 25.89 | 4.56 |

| 11 | South Korea | 116 | 1108 | 9.55 | 3.91 |

| 12 | France | 112 | 5378 | 48.02 | 5.08 |

| 13 | Netherlands | 111 | 5115 | 46.08 | 6.61 |

| 14 | Finland | 110 | 4319 | 39.26 | 6.21 |

| 15 | India | 92 | 2673 | 29.05 | 4.35 |

| 16 | Switzerland | 73 | 4082 | 55.92 | 5.08 |

| 17 | Japan | 64 | 939 | 14.67 | 3.88 |

| 18 | Turkey | 62 | 768 | 12.39 | 3.82 |

| 19 | Singapore | 60 | 1794 | 29.90 | 4.88 |

| 20 | Iran | 59 | 964 | 16.34 | 4.03 |

| Rank | WoS Research Area | TP | TPR (%) 1 | TC | ACPP |

|---|---|---|---|---|---|

| 1 | Business & Economics | 1565 | 41.54 | 57,329 | 36.63 |

| 2 | Engineering | 1262 | 33.50 | 39,433 | 31.25 |

| 3 | Operations Research & Management Science | 564 | 14.97 | 22,453 | 39.81 |

| 4 | Computer Science | 550 | 14.60 | 16181 | 29.42 |

| 5 | Environmental Sciences & Ecology | 366 | 9.72 | 10,196 | 27.86 |

| 6 | Science & Technology | 212 | 5.63 | 4905 | 23.14 |

| 7 | Materials Science | 167 | 4.43 | 5359 | 32.09 |

| 8 | Automation & Control Systems | 135 | 3.58 | 5577 | 41.31 |

| 9 | Public Administration | 118 | 3.13 | 3228 | 27.36 |

| 10 | Geography | 103 | 2.73 | 3101 | 30.11 |

| 11 | Mathematics | 89 | 2.36 | 1592 | 17.89 |

| 12 | Telecommunications | 77 | 2.04 | 1638 | 21.27 |

| 13 | Public, Environmental & Occupational Health | 70 | 1.86 | 1723 | 24.61 |

| 14 | Development Studies | 65 | 1.73 | 1135 | 17.46 |

| 15 | International Relations | 65 | 1.73 | 899 | 13.83 |

| 16 | Urban Studies | 60 | 1.59 | 1840 | 30.67 |

| 17 | Social Sciences | 55 | 1.46 | 1366 | 24.84 |

| 18 | Physics | 53 | 1.41 | 771 | 14.55 |

| 19 | Information Science & Library Science | 50 | 1.33 | 1671 | 33.42 |

| 20 | Robotics | 48 | 1.27 | 1927 | 40.15 |

| Rank | Journal | TP | TPR (%) | TC | ACPP | IF |

|---|---|---|---|---|---|---|

| 1 | International Journal of Production Research | 80 | 2.12 | 2346 | 29.33 | 6.091 |

| 2 | International Journal of Production Economics | 78 | 2.07 | 4843 | 62.09 | 7.079 |

| 3 | Sustainability | 77 | 2.04 | 645 | 8.38 | 2.355 |

| 4 | International Journal of Advanced Manufacturing Technology | 77 | 2.04 | 2761 | 35.86 | 2.406 |

| 5 | International Journal of Computer Integrated Manufacturing | 62 | 1.65 | 1201 | 19.37 | 2.795 |

| 6 | Journal of Business Research | 54 | 1.43 | 2235 | 41.40 | 6.74 |

| 7 | Journal of Cleaner Production | 54 | 1.43 | 2250 | 41.67 | 7.597 |

| 8 | International Journal of Operations & Production Management | 49 | 1.30 | 3086 | 62.98 | 5.937 |

| 9 | Industrial Marketing Management | 45 | 1.19 | 2512 | 55.82 | 4.95 |

| 10 | Computers & Industrial Engineering | 44 | 1.17 | 1018 | 23.14 | 4.728 |

| 11 | Robotics and Computer-integrated Manufacturing | 36 | 0.96 | 1557 | 43.25 | 4.753 |

| 12 | IEEE Access | 34 | 0.90 | 388 | 11.41 | 2.454 |

| 13 | Journal of Intelligent Manufacturing | 31 | 0.82 | 732 | 23.61 | 5.107 |

| 14 | Regional Studies | 31 | 0.82 | 785 | 25.31 | 4.033 |

| 15 | Total Quality Management & Business Excellence | 30 | 0.80 | 626 | 20.85 | 3.223 |

| 16 | Computers in Industry | 30 | 0.80 | 1222 | 40.73 | 7.247 |

| 17 | Service Industries Journal | 27 | 0.72 | 536 | 19.85 | 5.275 |

| 18 | M&SOM-Manufacturing & Service Operations Management | 26 | 0.69 | 472 | 18.14 | 6.32 |

| 19 | Research Policy | 26 | 0.69 | 399 | 15.33 | 4.725 |

| 20 | Small Business Economics | 26 | 0.69 | 1156 | 44.45 | 7.005 |

| Rank | Institutions | TP | TPR (%) | TC | ACPP | H-Index | Country/Region |

|---|---|---|---|---|---|---|---|

| 1 | Beihang University | 71 | 1.88 | 4752 | 66.93 | 29 | China Mainland |

| 2 | University of Vaasa | 47 | 1.25 | 1970 | 41.91 | 26 | Finland |

| 3 | University of California System | 47 | 1.25 | 1616 | 34.38 | 18 | USA |

| 4 | University of London | 44 | 1.17 | 1665 | 37.84 | 19 | UK |

| 5 | University of Cambridge | 44 | 1.17 | 2771 | 62.98 | 24 | UK |

| 6 | Lulea University of Technology | 43 | 1.14 | 1585 | 36.86 | 23 | Sweden |

| 7 | University of Birmingham | 42 | 1.11 | 1295 | 30.83 | 19 | UK |

| 8 | Xi’an Jiaotong University | 41 | 1.09 | 875 | 21.34 | 16 | China Mainland |

| 9 | Zhejiang University | 40 | 1.06 | 663 | 16.58 | 14 | China Mainland |

| 10 | Shanghai Jiao Tong University | 39 | 1.04 | 1389 | 35.62 | 14 | China Mainland |

| 11 | Linkoping University | 38 | 1.01 | 2492 | 65.58 | 25 | Sweden |

| 12 | State University System of Florida | 37 | 0.98 | 2523 | 68.19 | 16 | USA |

| 13 | Hong Kong Polytechnic University | 35 | 0.93 | 1229 | 35.11 | 16 | Hong Kong |

| 14 | Tsinghua University | 34 | 0.90 | 789 | 23.21 | 13 | China Mainland |

| 15 | Chinese Academy of Sciences | 33 | 0.88 | 1457 | 44.15 | 16 | China Mainland |

| 16 | University of Manchester | 32 | 0.85 | 1827 | 57.09 | 20 | UK |

| 17 | University System of Georgia | 31 | 0.82 | 1722 | 55.55 | 15 | USA |

| 18 | University of Michigan System | 30 | 0.80 | 1412 | 47.07 | 19 | USA |

| 19 | Aston University | 29 | 0.77 | 1573 | 54.24 | 19 | UK |

| 20 | University of Michigan | 28 | 0.74 | 1288 | 46.00 | 18 | USA |

| Rank | Author | TP | TPR (%) | TC | ACPP | H-index | Institution, Country/Region |

|---|---|---|---|---|---|---|---|

| 1 | Tao, Fei | 37 | 0.98 | 3929 | 106.19 | 22 | Beihang University, China Mainland |

| 2 | Zhang, Lin | 32 | 0.85 | 2673 | 83.53 | 21 | Beihang University, China Mainland |

| 3 | Parida, Vinit | 24 | 0.64 | 885 | 36.86 | 16 | Lulea University of Technology, Sweden |

| 4 | Gebauer, Heiko | 21 | 0.56 | 1915 | 91.20 | 10 | Swiss Federal Institute of Aquatic Science & Technology (EAWAG), Swizerland |

| 5 | Kohtamaki, Marko | 20 | 0.53 | 836 | 41.81 | 14 | University of Vaasa, Finland |

| 6 | Cheng, Ying | 15 | 0.40 | 1160 | 77.33 | 13 | Beihang University, China Mainland |

| 7 | Zhang, Wenyu | 15 | 0.40 | 168 | 11.20 | 8 | Zhejiang University of Finance & Economics, China Mainland |

| 8 | Zhang, Shuai | 15 | 0.40 | 168 | 11.20 | 8 | Zhejiang University of Finance & Economics, China Mainland |

| 9 | Vendrell-Herrero, Ferran | 14 | 0.37 | 557 | 39.80 | 10 | University of Birmingham, UK |

| 10 | Baines, Tim | 13 | 0.35 | 1301 | 100.09 | 11 | Aston University, UK |

| 11 | Zhang, Yingfeng | 13 | 0.35 | 452 | 34.79 | 9 | Northwestern Polytechnical University, China Mainland |

| 12 | Bustinza, Oscar F. | 13 | 0.35 | 776 | 59.73 | 12 | University of Granada, Spain |

| 13 | Yao, Xifan | 12 | 0.32 | 475 | 39.58 | 8 | South China University of Technology, China Mainland |

| 14 | Wang, Lihui | 12 | 0.32 | 1060 | 88.36 | 9 | Royal Institute of Technology, Sweden |

| 15 | Huang, George Q. | 11 | 0.29 | 544 | 49.42 | 9 | University of Hong Kong, Hong Kong |

| 16 | Zhou, Zude | 11 | 0.29 | 268 | 24.40 | 7 | Wuhan University of Technology, China Mainland |

| 17 | Jiang, Pingyu | 11 | 0.29 | 221 | 20.09 | 7 | Xi’an Jiaotong University, China Mainland |

| 18 | Kowalkowski, Christian | 10 | 0.27 | 903 | 90.30 | 9 | Linkoping University, Sweden |

| 19 | Xu, Xun | 10 | 0.27 | 775 | 77.50 | 10 | University of Auckland, New Zealand |

| 20 | Jiang, Zhibin | 10 | 0.27 | 107 | 10.73 | 6 | Shanghai Jiao Tong University, China Mainland |

| Rank | Author | Journal | TC | TCY 1 | Year |

|---|---|---|---|---|---|

| 1 | Combs et al. [102] | Pers. Psychol. | 1118 | 74.53 | 2006 |

| 2 | Van de Vrande et al. [51] | Technovation | 1024 | 68.27 | 2009 |

| 3 | Hertwich and Peters [103] | Environ. Sci. Technol. | 967 | 64.47 | 2009 |

| 4 | Desimone [104] | Science | 829 | 55.27 | 2002 |

| 5 | Tukker [43] | J. Clean. Prod. | 768 | 51.20 | 2015 |

| 6 | Tao et al. [49] | J. Adv. Manuf. Technol. | 756 | 50.40 | 2018 |

| 7 | Wang et al. [105] | Int. J. Distrib. Sens. Netw. | 734 | 48.93 | 2016 |

| 8 | Grant and Parker [106] | Acad. Manag. Ann. | 612 | 40.80 | 2009 |

| 9 | Holweg [107] | J. Oper. Manag. | 587 | 39.13 | 2007 |

| 10 | Westhead et al. [108] | J. Bus. Ventur. | 579 | 38.60 | 2001 |

| 11 | Colombo and Grilli [109] | Res. Policy | 560 | 37.33 | 2005 |

| 12 | Rose [110] | J. Press. Vess.-T. ASME | 533 | 35.53 | 2002 |

| 13 | Frank et al. [111] | Int. J. Prod. Econ. | 505 | 33.67 | 2019 |

| 14 | Siddique et al. [112] | Waste Manag | 472 | 31.47 | 2008 |

| 15 | Boyer [113] | Econ. Soc. | 466 | 31.07 | 2000 |

| 16 | Tao et al. [58] | IEEE Trans. Ind. Inform. | 459 | 30.60 | 2014 |

| 17 | Homburg andFurst [114] | J. Mark. | 448 | 29.87 | 2005 |

| 18 | Oliveira et al. [115] | Inf. Manage. | 435 | 29.00 | 2014 |

| 19 | Ageron et al. [33] | Int. J. Prod. Econ. | 429 | 28.60 | 2012 |

| 20 | Tao et al. [59] | IEEE Trans. Ind. Inform. | 421 | 28.07 | 2014 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Wu, Z.; Yi, W.; Wang, B.; Yao, J.; Pei, Z.; Chen, J. Bibliometric Method for Manufacturing Servitization: A Review and Future Research Directions. Sustainability 2022, 14, 8743. https://doi.org/10.3390/su14148743

Chen Y, Wu Z, Yi W, Wang B, Yao J, Pei Z, Chen J. Bibliometric Method for Manufacturing Servitization: A Review and Future Research Directions. Sustainability. 2022; 14(14):8743. https://doi.org/10.3390/su14148743

Chicago/Turabian StyleChen, Yong, Zhengjie Wu, Wenchao Yi, Bingjia Wang, Jianhua Yao, Zhi Pei, and Jiaoliao Chen. 2022. "Bibliometric Method for Manufacturing Servitization: A Review and Future Research Directions" Sustainability 14, no. 14: 8743. https://doi.org/10.3390/su14148743

APA StyleChen, Y., Wu, Z., Yi, W., Wang, B., Yao, J., Pei, Z., & Chen, J. (2022). Bibliometric Method for Manufacturing Servitization: A Review and Future Research Directions. Sustainability, 14(14), 8743. https://doi.org/10.3390/su14148743