Intelligent Process Automation: An Application in Manufacturing Industry

Abstract

:1. Introduction

2. The Basic of Robotic Process Automation

- -

- RPAs do not require an entirely new software system to be developed; in contrast, it assumes that IT systems are already developed and running.

- -

- These systems should not be replaced or changed; instead, they should be manipulated by the RPA.

- -

- RPAs aim to produce software programs that run through the user interface of other computer systems in the way a human would use the system.

- -

- Detailed and accurate process mining is mandatory for successful RPA implementation. Relevant activities to be automated must be clarified to generate actionable business insights.

- -

- The input–output rules must be clearly defined regarding synchronization between dependencies and external systems involved. RPAs do not know how to handle scenarios that have not been mapped before. New cases or scenarios would entail changes in the robot’s logic, rules, or inputs.

- -

- Voluminous activities should be accompanied by rigorous technological infrastructure. RPAs are excellent at applying rule-based reasoning, but they are limited to enhancing decision making in complex processes involving a higher abstraction level.

- -

- RPAs are not suitable when working with judgment-related tasks, and AI addition must be considered.

3. Intelligent Process Automation

- -

- The input data source is unstructured, and it is thus necessary to use NLP algorithms to extract the information and carry out the task efficiently.

- -

- The RPA cannot adapt to changing conditions.

- -

- The RPA cannot deal with any data.

- -

- The RPA is unable to turn data into insights.

- -

- The RPA is unable to enhance decision-making- and judgment-related tasks.

4. Methodology

4.1. The Implementation of Digital Technologies in the Industries

- -

- Process (reduction of manual tasks).

- -

- Organization (new ways of doing things and new services).

- -

- Business (changing roles in the value chain).

- -

- Society (changing social structures).

4.2. Intelligent Process Automation in the Literature and Consulting Websites

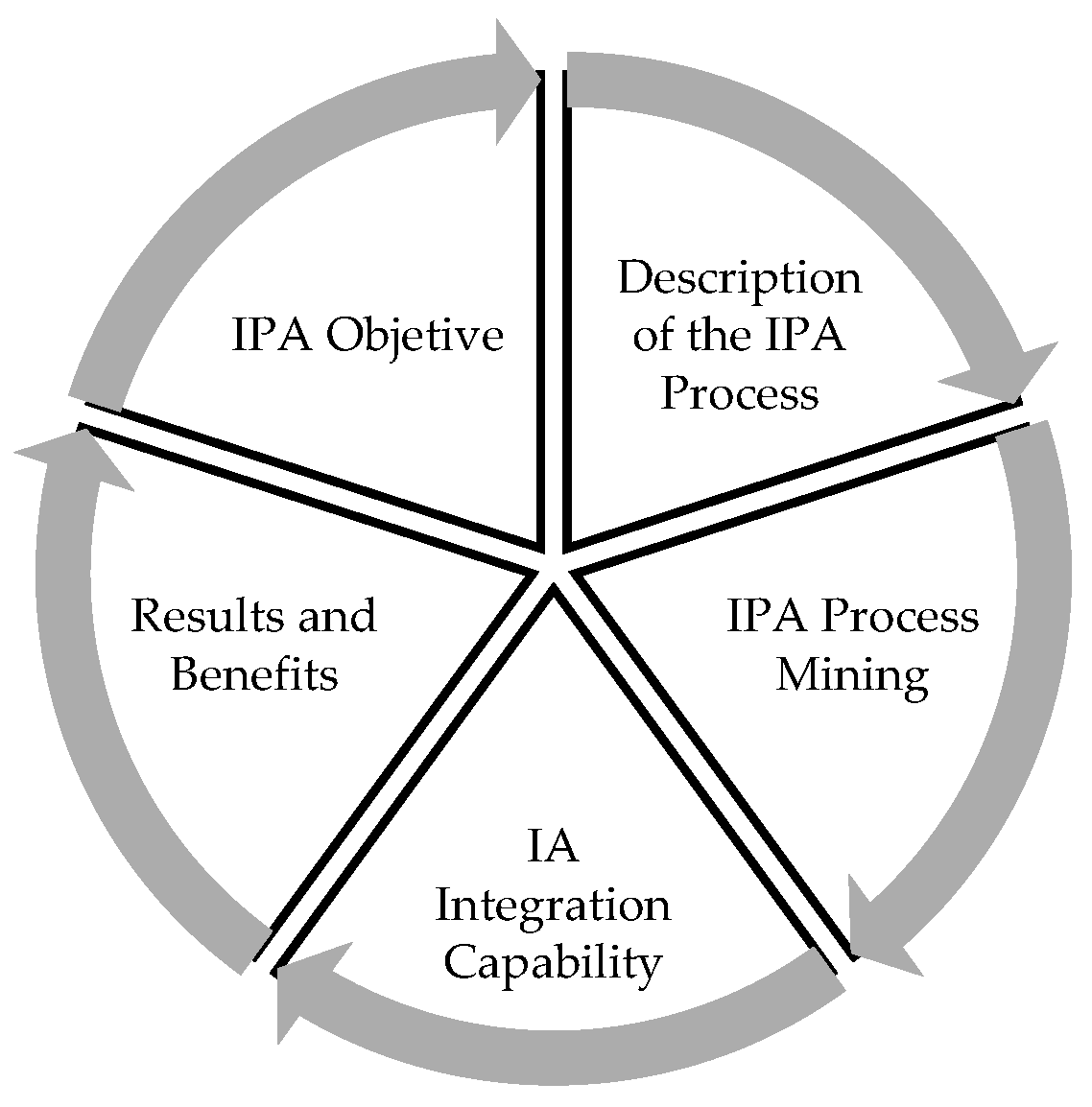

5. Framework to Implement IPA in Industries

5.1. Create an IPA Implementation Roadmap

5.2. From Process Discovery to Process Mining

- -

- Is key to understanding the current state of the processes and identifying inefficiencies and optimizations that can be covered using IA.

- -

- Streamlines the identification of parts of the process where IA could be crucial.

- -

- Identifies where IA should be implemented.

- -

- Monitors automation rates, process compliance, and other KPIs.

- -

- Can be very costly if IPA is implemented without sufficient understanding of your business processes.

5.3. AI Analysis and RPA Estimation

- -

- Prioritize stable applications and high ROI projects (investment return) for RPA and AI implementation.

- -

- Measure insights and KPIs that justify and support AI implementation.

- -

- Define the cost–benefit of implementing AI platforms; sometimes, the implementation is more expensive than profit.

- -

- Be sure to have enough good quality data to run algorithms, especially if you use self-learning algorithms or machine learning applications.

- -

- Be sure to have IT resources that ensure sustainable solutions and input–output transitions.

- -

- Define an exemplary architecture of the solution that allows smooth deployment and robustness.

- -

- Finally, try to have a robust solution focus. It is better to have a robust but straightforward AI implementation than complex algorithms that reduce the RPA’s sustainability.

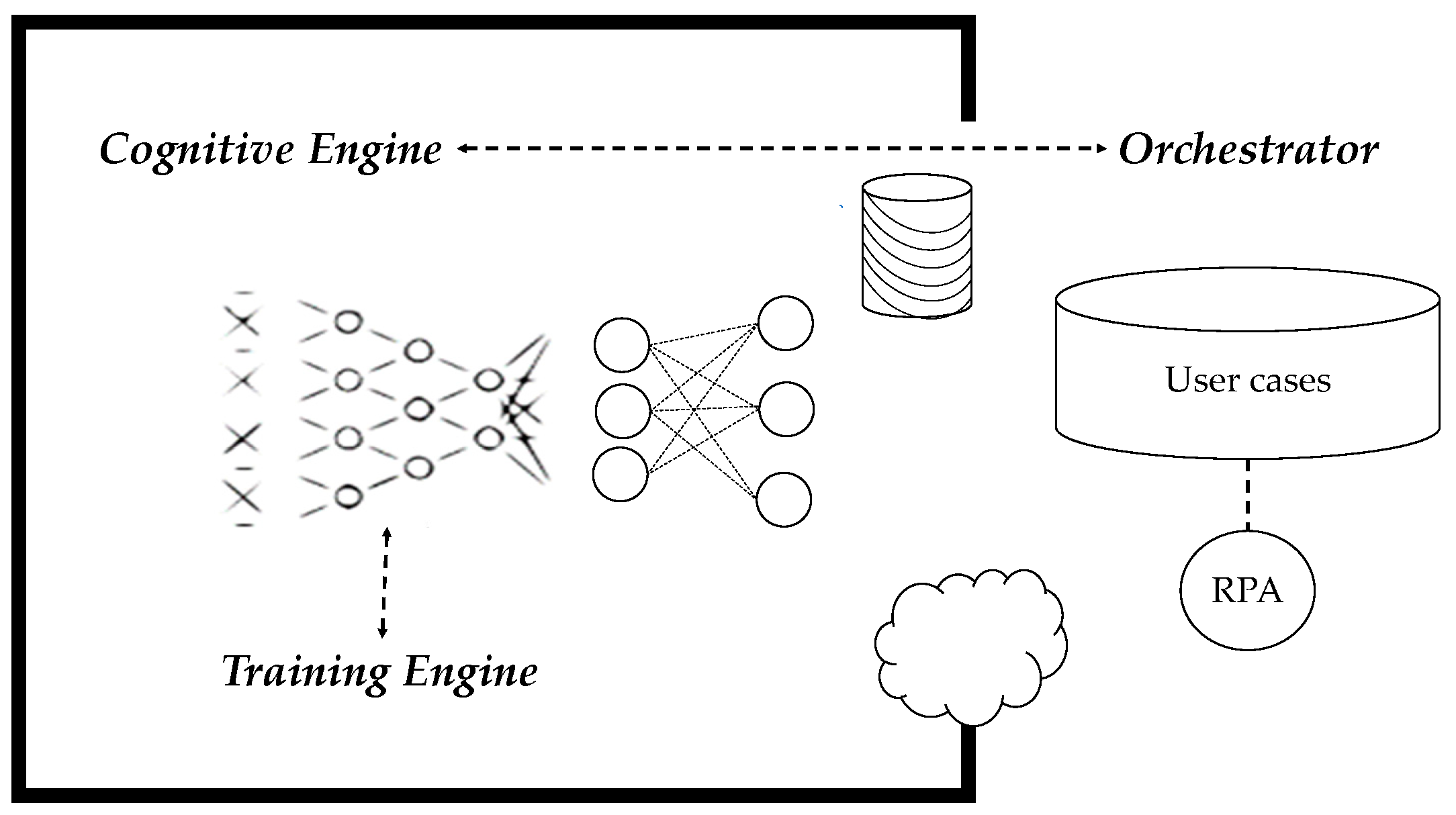

5.4. Define a Suitable Solution Architecture

- -

- The data is the core of the AI algorithms; for this reason, try to choose optimal databases to store and expose the data according to the nature (structured, semi-structured, or unstructured) of the data.

- -

- It is possible to implement ETLs inside the core of the robots; this facilitates the integration with other data sources and AI and APIs.

- -

- Store the inputs and outputs of the AI algorithms in efficient data repository technology (as far as possible columnar and using distributed computing). This practice drastically improves the performance of the IPAs.

- -

- If a cloud architecture is used to develop the AI component, it is vital to choose a cloud provider according to the IT scheme of the company. This method facilitates the integration and sustainability of the solution.

- -

- Finally, making the IT area an integral part of projects is an exceptional decision. The IPAs must be co-created by the business and IT teams to ensure the success of the projects. Below in Figure 2, a typical architecture to develop IPAs under a holistic scheme is shown.

5.5. RPA Design First, Then AI Capability Integration

6. Application in the Manufacturing Industry

6.1. IPA Objective

6.2. Description of the IPA Process

6.3. IPA Process Mining

6.4. AI Integration Capability

- -

- The rolls of the same batch should be consumed.

- -

- The roll can be picked from its warehouse or an external supplier. If the case is an external supplier, rolls cannot be split.

- -

- Rolls cannot be left with less than 50 m.

- -

- If the fabric requirement ranges from 0 to 600 m, the order cannot exceed 10% additional fabric.

- -

- If the fabric requirement ranges from 601 to 1000 m, the order cannot exceed 6% additional fabric.

- -

- If the fabric requirement exceeds 1000 m, the order cannot exceed 2% of additional fabric.

6.5. Results and Benefits

- -

- Freed up two employees’ time.

- -

- The process reduced the time spent on each order from 12–15 min to 5.1 min.

- -

- The implementation of AI software reduces wasted fabric by 30%, generating economic benefits.

- -

- The prioritization of the orders made by the IPA allowed them to meet urgent requirements and streamline the processing pipeline; see Table 5.

7. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Asquith, A.; Horsman, G. Let the robots do it!—Taking a look at Robotic Process Automation and its potential application in digital forensics. Forensic Sci. Int. Rep. 2019, 1, 100007. [Google Scholar] [CrossRef]

- Leshob, A.; Bourgouin, A.; Renard, L. Towards a Process Analysis Approach to Adopt Robotic Process Automation. In Proceedings of the 2018 IEEE 15th International Conference on e-Business Engineering (ICEBE), ICEBE 2018, Xi’an, China, 12–14 October 2018; pp. 46–53. [Google Scholar] [CrossRef]

- Aguirre, S.; Rodriguez, A. Automation of a business process using robotic process automation (RPA): A case study. Commun. Comput. Inf. Sci. 2017, 742, 65–71. [Google Scholar] [CrossRef]

- Anagnoste, S. Setting Up a Robotic Process Automation Center of Excellence. Manag. Dyn. Knowl. Econ. 2013, 6, 307–322. [Google Scholar] [CrossRef]

- Asatiani, A.; Penttinen, E. Turning robotic process automation into commercial success—Case OpusCapita. J. Inf. Technol. Teach. Cases 2016, 6, 67–74. [Google Scholar] [CrossRef]

- Remane, G.; Hanelt, A.; Nickerson, R.C.; Kolbe, L.M. Discovering digital business models in traditional industries. J. Bus. Strategy 2017, 38, 41–51. [Google Scholar] [CrossRef]

- Anagnoste, S. Robotic Automation Process—The next major revolution in terms of back office operations improvement. In Proceedings of the 11th International Conference on Business Excellence, Bucharest, Romania, 22–23 March 2018; Springer: Berlin/Heidelberg, Germany, 2017; Volume 11, pp. 676–686. [Google Scholar] [CrossRef] [Green Version]

- Ivančić, L.; Suša Vugec, D.; Bosilj Vukšić, V. Robotic Process Automation: Systematic Literature Review. Lect. Notes Bus. Inf. Process. 2019, 361, 280–295. [Google Scholar] [CrossRef]

- Geyer-Klingeberg, J.; Nakladal, J.; Baldauf, F.; Veit, F. Process mining and Robotic process automation: A perfect match. CEUR Workshop Proc. 2018, 2196, 124–131. [Google Scholar]

- Heinrich, B.; Klier, M.; Zimmermann, S. Automated planning of process models: Design of a novel approach to construct exclusive choices. Decis. Support Syst. 2015, 78, 1–14. [Google Scholar] [CrossRef]

- Fettke, P.; Loos, P. “Strukturieren, Strukturieren, Strukturieren” in the Era of Robotic Process Automation. In The Art of Structuring; Springer International Publishing: New York, NY, USA, 2019; pp. 191–201. [Google Scholar] [CrossRef]

- IEEE Std 2755-2017; IEEE Guide for Terms and Concepts in Intelligent Process Automation. IEEE: New York, NY, USA, 2017; pp. 1–16. Available online: https://ieeexplore.ieee.org/document/8070671 (accessed on 5 April 2022).

- Lin, S.C.; Shih, L.H.; Yang, D.; Lin, J.; Kung, J.F. Apply RPA (Robotic Process Automation) in Semiconductor Smart Manufacturing. In Proceedings of the 2018 E-Manufacturing and Design Collaboration Symposium EMDC 2018, Hsinchu, Taiwan, 7 September 2018. [Google Scholar]

- Ribeiro, J.; Lima, R.; Eckhardt, T.; Paiva, S. Robotic Process Automation and Artificial Intelligence in Industry 4.0—A Literature review. Procedia Comput. Sci. 2021, 181, 51–58. [Google Scholar] [CrossRef]

- Sönmez, Ö.E.; Börekçi, D.Y. A conceptual study on RPAs as of intelligent automation. Adv. Intell. Syst. Comput. 2020, 1029, 65–72. [Google Scholar] [CrossRef]

- Berman, S.J. Digital transformation: Opportunities to create new business models. Strategy Leadersh. 2012, 40, 16–24. [Google Scholar] [CrossRef]

- Matt, C.; Hess, T.; Benlian, A. Digital Transformation Strategies. In Business and Information Systems Engineering; Gabler Verlag: Wiesbaden, Germany, 2015; Volume 57, pp. 339–343. [Google Scholar] [CrossRef]

- Parviainen, P.; Tihinen, M.; Kääriäinen, J.; Teppola, S. Tackling the digitalization challenge: How to benefit from digitalization in practice. Int. J. Inf. Syst. Proj. Manag. 2017, 5, 63–77. [Google Scholar] [CrossRef]

- Canetta, L.; Barni, A.; Montini, E. Development of a Digitalization Maturity Model for the Manufacturing Sector. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation, ICE/ITMC, Stuttgart, Germany, 17–20 June 2018. [Google Scholar] [CrossRef]

- Ardolino, M.; Rapaccini, M.; Saccani, N.; Gaiardelli, P.; Crespi, G.; Ruggeri, C. The role of digital technologies for the service transformation of industrial companies. Int. J. Prod. Res. 2018, 56, 2116–2132. [Google Scholar] [CrossRef]

- Ziyadin, S.; Suieubayeva, S.; Utegenova, A. Digital Transformation in Business. In Lecture Notes in Networks and Systems; Springer: Berlin/Heidelberg, Germany, 2020; Volume 84, pp. 408–415. [Google Scholar] [CrossRef]

- Munir, M.; Shafaq, K. Building an Integrated Digital Transformation System Framework: A Design Science Research, the Case of FedUni. Sustainability 2022, 14, 6121. [Google Scholar] [CrossRef]

- Ebert, C.; Duarte, C.H.C. Requirements Engineering for the Digital Transformation: Industry Panel. In Proceedings of the 2016 IEEE 24th International Requirements Engineering Conference, Beijing, China, 12–16 September 2016; pp. 4–5. [Google Scholar] [CrossRef]

- Chakraborti, T.; Isahagian, V.; Khalaf, R.; Khazaeni, Y.; Muthusamy, V.; Rizk, Y.; Unuvar, M. From Robotic Process Automation to Intelligent Process Automation: Emerging Trends. Lect. Notes Bus. Inf. Process. 2020, 393, 215–228. [Google Scholar] [CrossRef]

- Rizk, Y.; Isahagian, V.; Boag, S.; Khazaeni, Y.; Unuvar, M.; Muthusamy, V.; Khalaf, R. A Conversational Digital Assistant for Intelligent Process Automation. Lect. Notes Bus. Inf. Process. 2020, 393, 85–100. [Google Scholar] [CrossRef]

- Masood, A.; Hashmi, A. Cognitive Robotics Process Automation: Automate This! In Cognitive Computing Recipes; Apress: New York, NY, USA, 2019; pp. 225–287. [Google Scholar] [CrossRef]

- Richardson, S. Cognitive automation: A new era of knowledge work? Bus. Inf. Rev. 2020, 37, 182–189. [Google Scholar] [CrossRef]

- Intelygenz. Achieve Efficiency with Intelligent Process Automation. Available online: https://intelygenz.com/intelligent-process-automation/ (accessed on 7 April 2022).

- Cognizant. Intelligent Process Automation. Available online: https://www.cognizant.com/us/en/services/intelligent-process-automation (accessed on 23 April 2022).

- Madakam, S.; Holmukhe, R.M.; Kumar Jaiswal, D. The Future Digital Work Force: Robotic Process Automation (RPA). J. Inf. Syst. Technol. Manag. 2019, 16, e201916001. [Google Scholar] [CrossRef]

- Schmitz, M.; Dietze, C.; Czarnecki, C. Enabling Digital Transformation through Robotic Process Automation. In Deutsche Telekom; Springer: Cham, Switzerland, 2019; pp. 15–33. [Google Scholar] [CrossRef]

- Van Der Aalst, W. Process mining: Overview and opportunities. ACM Trans. Manag. Inf. Syst. 2012, 3, 1–17. [Google Scholar] [CrossRef]

- Van der Aalst, W.M.P.; Bichler, M.; Heinzl, A. Robotic Process Automation. In Business and Information Systems Engineering; Gabler Verlag: Wiesbaden, Germany, 2018; Volume, 60, pp. 269–272. [Google Scholar] [CrossRef] [Green Version]

- Varaniūtė, V.; Žičkutė, I. The Changing Role of Management Accounting in Product Development: Directions to Digitalization, Sustainability, and Circularity. Sustainability 2022, 14, 4740. [Google Scholar] [CrossRef]

| Feature | Simple RPA | Cognitive RPA or IPA |

|---|---|---|

| Type of tasks | Routine tasks | Non-routine tasks |

| Capability of robot | Follow instructions | Come to conclusions |

| Application focus | Broader | Narrower |

| Market offerings | Maturing | Emerging |

| Implementation and ongoing costs | Lower | Higher |

| Implementation timeframe | Weeks | Months |

| Authors | Topic | Implementation |

|---|---|---|

| [14] | The main contribution of this paper is providing a review of AI and RPA contributions to Industry 4.0. | No applied cases are presented. |

| [24] | Study how recent advances in machine intelligence are disrupting the world of business processes. | No applied cases are presented. |

| [25] | Present a framework that combines RPAs with conversational agents (or chatbots) to create an interactive business process automation solution. | The Bank customer is submitting a loan application, and IPA is processing this request to determine approbation or rejection. |

| [26] | Provide building blocks using Microsoft Azure for intelligent or cognitive robotics process automation. However, the integrations with RPA are not exposed. | Five applications are presented: extract intent from audio, email classification and triage for automated support-ticket generation, a case of fraudulent credit card transactions, cross-correlation in time series problem, and understanding traffic patterns. |

| [27] | This article considers the potential for cognitive algorithms to disrupt knowledge work in the modern workplace. | No applied cases are presented. |

| [28] | Framework to implement IPA in business. | Two business cases are presented: A communications company using IPA to respond to customer queries and resolve service issues; and an event ticketing company using IPA to automate one of their most important weekly tasks related to queries to the database. |

| [29] | Framework to implement IPA in business. | Two business cases are presented: IPA to reduce the need for manual work in US grocery delivery and a second solution for an RCM (revenue cycle management) service provider’s complete eligibility and benefits verification process. |

| Steps | Process Description of the IPA Case |

|---|---|

| 1 | The RPA software checks if there are unread emails in the mailbox. |

| 2 | If there are new unread emails, the request type is identified by the email subject. If the issue does not exist or is not within the standards, a notification email is sent back requesting the email information to be corrected. |

| 3 | After the subject is correctly identified, the RPA software verifies that the email attachment is in a xlsx format. |

| 4 | Mandatory parameters are verified. If the file contains invalid parameters, the RPA sends the information rows with problems back to the sender. |

| 5 | If all parameters contained in the file are correct, the requested orders are sorted and prioritized by date. |

| 6 | Key process information from the file is sent to the RPA orchestrator: material, delivery cycle, value, brand, quality, the quantity of fabric required, ID of the fabric supplier, minimum quantity to take, and priority of the order, among others. |

| 7 | If there are no unread emails, the RPA checks for pending orders in the orchestrator’s queue. |

| 8 | The RPA logs into SAP. |

| 9 | The RPA searches for the transaction code. |

| 10 | Material numbers and order due dates are entered into the system. |

| 11 | The RPA verifies the existence of the required material in SAP. If it does not exist in SAP or the due date is a non-working day, then an email is sent informing of the error, and this task is marked as failed. |

| 12 | Value, required quantity, brand, and quality of the raw material are entered into the system. |

| 13 | The RPA verifies if the data was entered correctly. |

| 14 | Fabric supplier ID, order number, arrival warehouse, brand, and fabric quality information are entered. |

| 15 | Fabric batches are assigned according to business rules and restrictions, assuring that available fabric meets the minimum required quantity in the order. |

| 16 | The AI software is invoked to find the set of batches that together meet the amount of required fabric and minimize waste the most. |

| 17 | The output of the AI software is put into an Excel file that contains the information of the batches to be taken and the quantities for each one. |

| 18 | Specified fabric batches and quantities are selected in SAP. |

| 19 | The order is saved, and the order number is extracted. |

| 20 | The order is generated, and a PDF is saved. |

| 21 | The supplier email is extracted. |

| 22 | An email is sent to the supplier and buyer with the order and the generated PDF. |

| 23 | The RPA software checks if there are unread emails in the mailbox. |

| 24 | If there are new unread emails, the request type is identified by the email subject. If the issue does not exist or is not under the standards, a notification email is sent back, requesting email information to be corrected. |

| 25 | After the subject is correctly identified, the RPA software verifies that the email attachment is in a xlsx format. |

| 26 | Mandatory parameters are verified. If the file contains invalid parameters, the RPA sends the information rows with problems back to the sender. |

| 27 | If all parameters contained in the file are correct, the requested orders are sorted and prioritized by date. |

| 28 | Key process information from the file is sent to the RPA orchestrator: material, delivery cycle, value, brand, quality, the quantity of fabric required, ID of the fabric supplier, minimum quantity to take, and priority of the order, among others. |

| 29 | If there are no unread emails, the RPA checks for pending orders in the orchestrator’s queue. |

| Steps | Explanation |

|---|---|

| 1 | The RPA software generates a query to the company’s WMS system, which stores inventory information, and exports it to a SQL database, appending detailed requirement information to the data dump. |

| 2 | The RPA software calls the AI software using the server console where the system is housed. |

| 3 | The AI software reads the SQL database generated in step 1. |

| 4 | The AI software creates a global query, considering demand and inventory rolls available that contain over 30 m of fabric. If the inventory is more extensive than demand, the AI software starts execution. Otherwise, it stops and sends an error email to the RPA software console, finishing execution. |

| 5 | The AI software then sorts existing fabric categories in the different business units of the company. Each business unit stores a different fabric quality. To optimize the inventory and reduce waste, they need to be consumed in a specific order (First A, then B, and C). |

| 6 | The AI software takes a subset of the fabric of category A. |

| 7 | The AI software executes three possible scenarios, defined in the business requirements as rules to optimize waste and keep the fabric batches homogeneous. |

| 8 | First scenario: AI software finds the identical quantity within one single batch. A heuristic algorithm is applied to minimize the difference between a total requirement and the combination of rolls of the same batch that gets close to the requirement with a delta that ranges from −10 m to +50 m. If it does not find a solution for the first scenario, it moves to the second one. Second scenario: the AI software must decide how much fabric to take from each roll within every batch. In this case, the delta does not apply to the requirement established by the business. Therefore, the AI software needs to virtually “cut” a fabric amount from a roll of any batch. In this case, the AI algorithm decides the right amount and selects from multiple rolls the right one to minimize the fabric waste after the cutting process. For this scenario, the AI software needs to leave more than 50 m of fabric in the roll after the cut to be utilized in further requirements and not treated as waste. The amount of fabric (of a single category) required is not within a single roll, so the AI software needs to pick from different rolls until the requirement is met or the closest amount to the requirement is found, always keeping the business deltas. |

| 9 | The AI software generates a JSON file containing the execution message according to the scenario. |

| 10 | The AI software sends a message to the RPA software with the execution results through the RPA software console. |

| 11 | The RPA decides what to do next according to the message received. It can stop the execution and communicate errors or continue with reserving the fabric in the system by choosing the amount of fabric that the AI software indicated in the message. |

| Requirements | Fabric Inventory Available | Fabric Selected by the IPA | Comments |

|---|---|---|---|

| 120 m Just one category type should be picked. | Ten different of fabric rolls with different categories are available. | The IPA chose 101.57 m of Batch 8000504453 18.43 m was cut of Batch 8000504452 | The IPA met the requirement with zero fabric waste. |

| 125 m Two types of categories should be picked. | Seven different fabric rolls with two types of categories are available. | The IPA selected in total 52.60 m of batch with code 8000504455 and 72.4 m of batch with code 8000504516. Here, it was not necessary to cut any roll. | Out of seven different fabric rolls, the automation picked the categories expected by the user according to the business rules. The selected fabric rolls minimize the waste to 5%. Before this automation, the average waste percentage was 12%. |

| 300 m Just one type of categories should be picked. | Five different rolls of the same categories are available. | The IPA chose the entire 102.9 m of Batch 8000504516 Additionally, 147 m of Batch 8000504522 50.1 m was cut of Batch 8000504529 | The IPA met the requirement with 0 fabric waste. |

| 465.38 m Just one type of categories should be picked. | 124 different rolls of the same categories are available. | The IPA chose the entire 75.18 m of Batch 8000501572 76.86 m of Batch 8000501574 77.7 m of Batch 8000501585 78.54 m of Batch 8000501575 78.54 m of Batch 8000501578 Additionally, 78.54 m of Batch 8000501583 | The absolute difference with the total required amount is: −0.02 m. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lievano-Martínez, F.A.; Fernández-Ledesma, J.D.; Burgos, D.; Branch-Bedoya, J.W.; Jimenez-Builes, J.A. Intelligent Process Automation: An Application in Manufacturing Industry. Sustainability 2022, 14, 8804. https://doi.org/10.3390/su14148804

Lievano-Martínez FA, Fernández-Ledesma JD, Burgos D, Branch-Bedoya JW, Jimenez-Builes JA. Intelligent Process Automation: An Application in Manufacturing Industry. Sustainability. 2022; 14(14):8804. https://doi.org/10.3390/su14148804

Chicago/Turabian StyleLievano-Martínez, Federico A., Javier D. Fernández-Ledesma, Daniel Burgos, John W. Branch-Bedoya, and Jovani A. Jimenez-Builes. 2022. "Intelligent Process Automation: An Application in Manufacturing Industry" Sustainability 14, no. 14: 8804. https://doi.org/10.3390/su14148804

APA StyleLievano-Martínez, F. A., Fernández-Ledesma, J. D., Burgos, D., Branch-Bedoya, J. W., & Jimenez-Builes, J. A. (2022). Intelligent Process Automation: An Application in Manufacturing Industry. Sustainability, 14(14), 8804. https://doi.org/10.3390/su14148804