Sustainable Adaptive Cycle Pavements Using Composite Foam Concrete at High Altitudes in Central Europe

Abstract

:1. Introduction

2. Methods

- Statistical analyses of the evolution of relevant climatic characteristics of Central Europe between 1971 and 2020 for altitudes above 330 m a.s.l.;

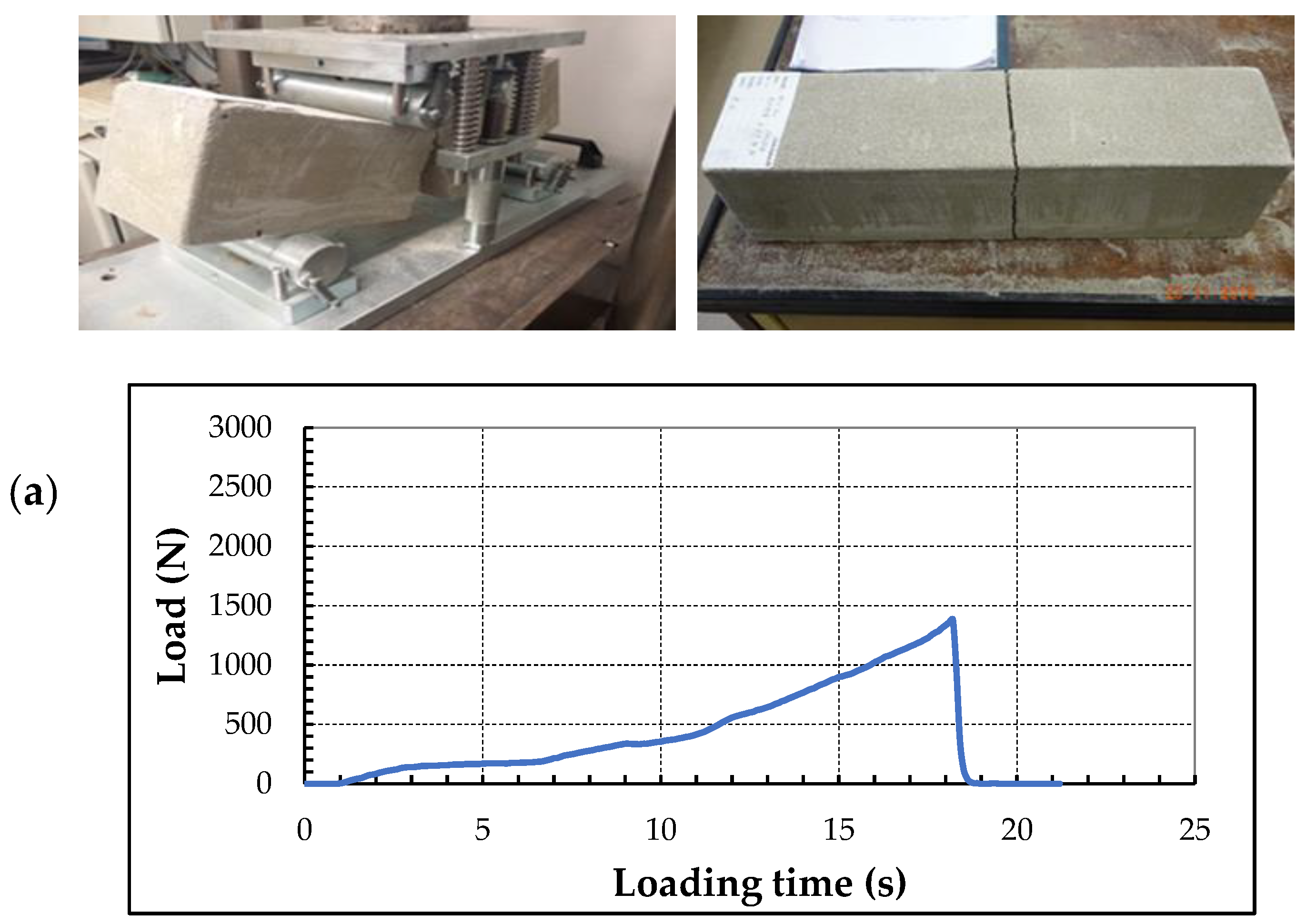

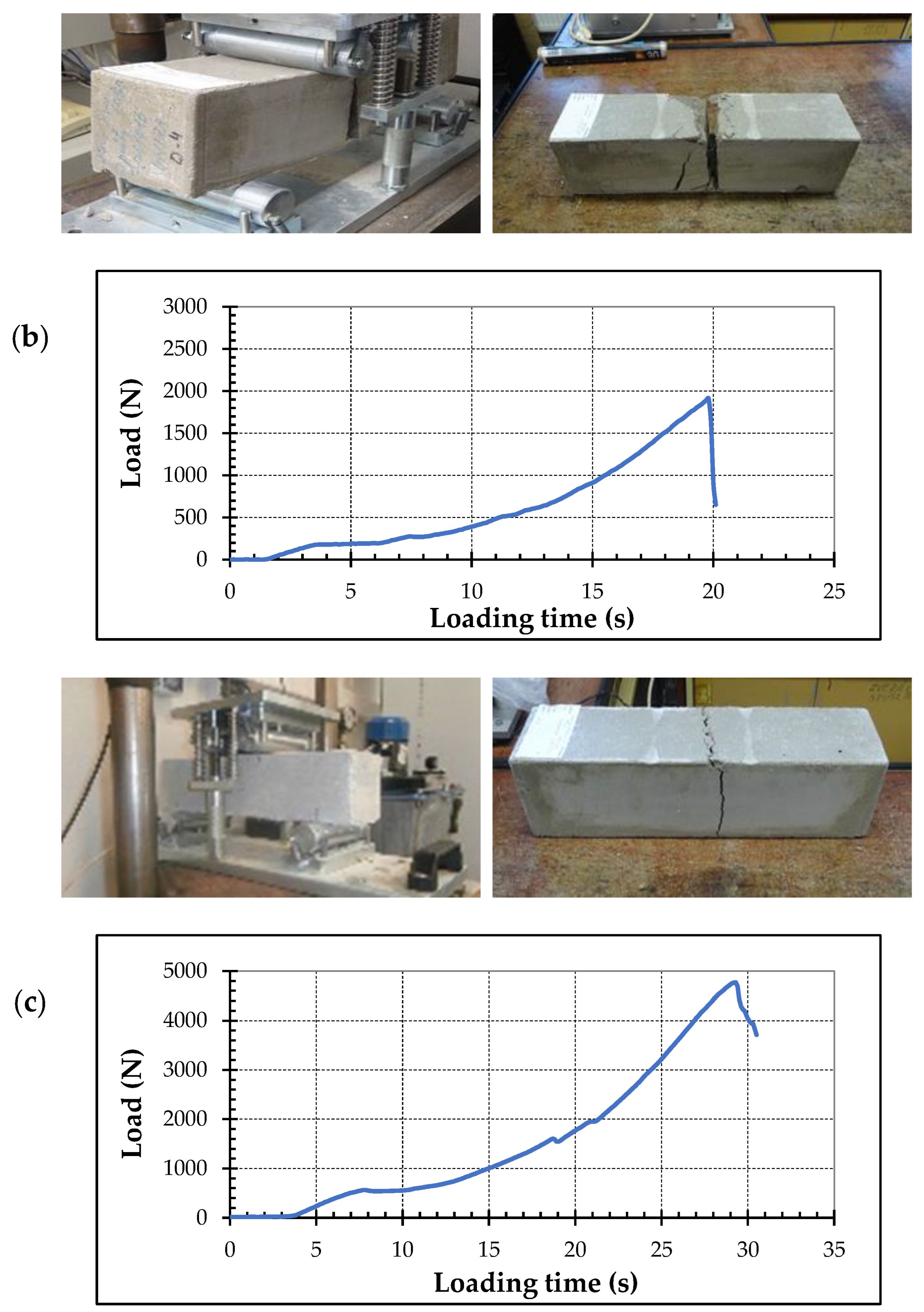

- Determination of flexural strength of isomorphic models with foam concrete according to STN EN 12390-5:2020 Testing hardened concrete. Part 5: Flexural strength of test specimens [55];

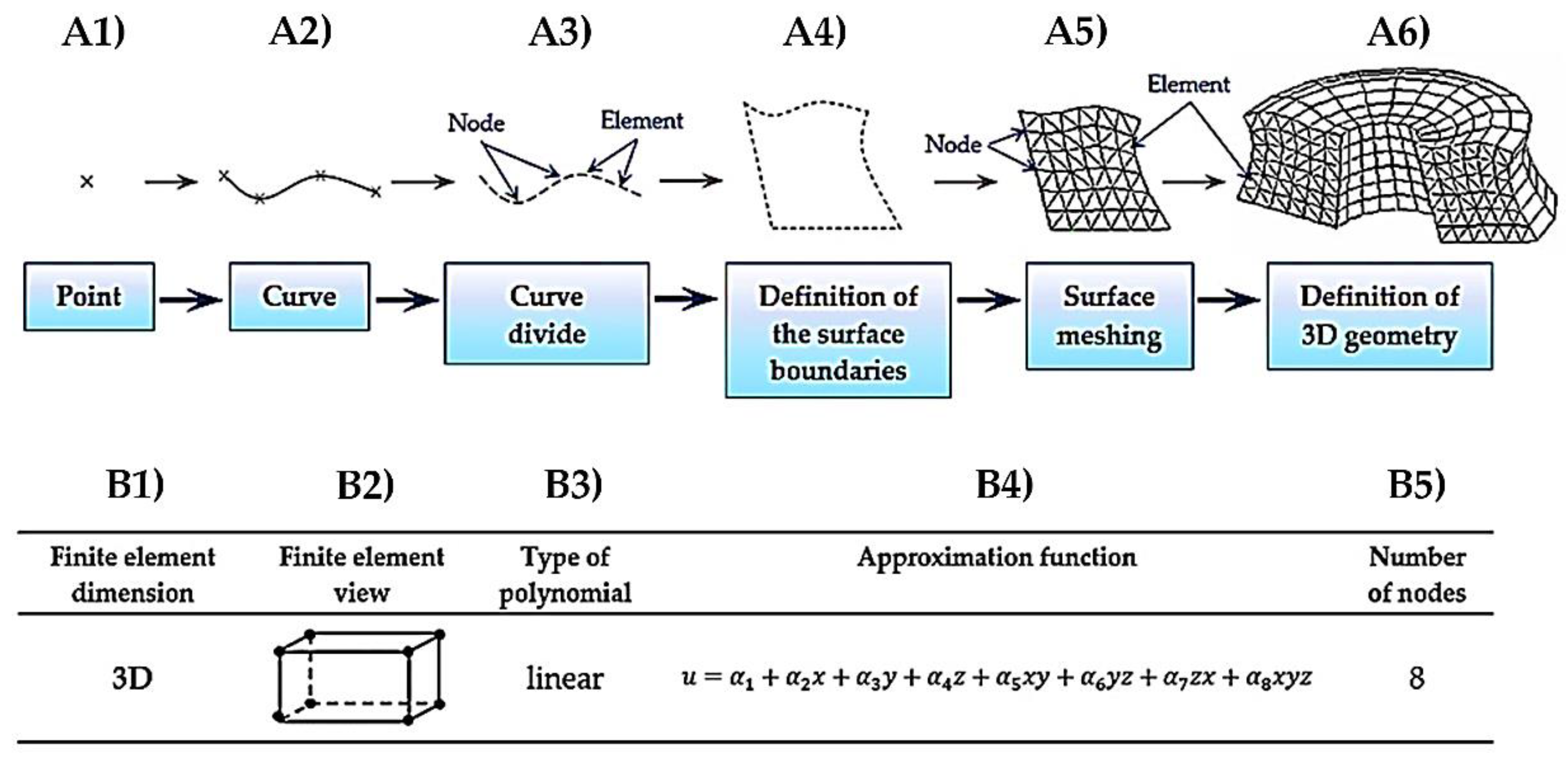

- FEM models are used to validate the modeling methodology and to create a FEM model of the pavements of interest;

- Analytical models in Central European conditions binding for design of asphalt and cement concrete (CC) pavements with reinforces FC 500 base course.

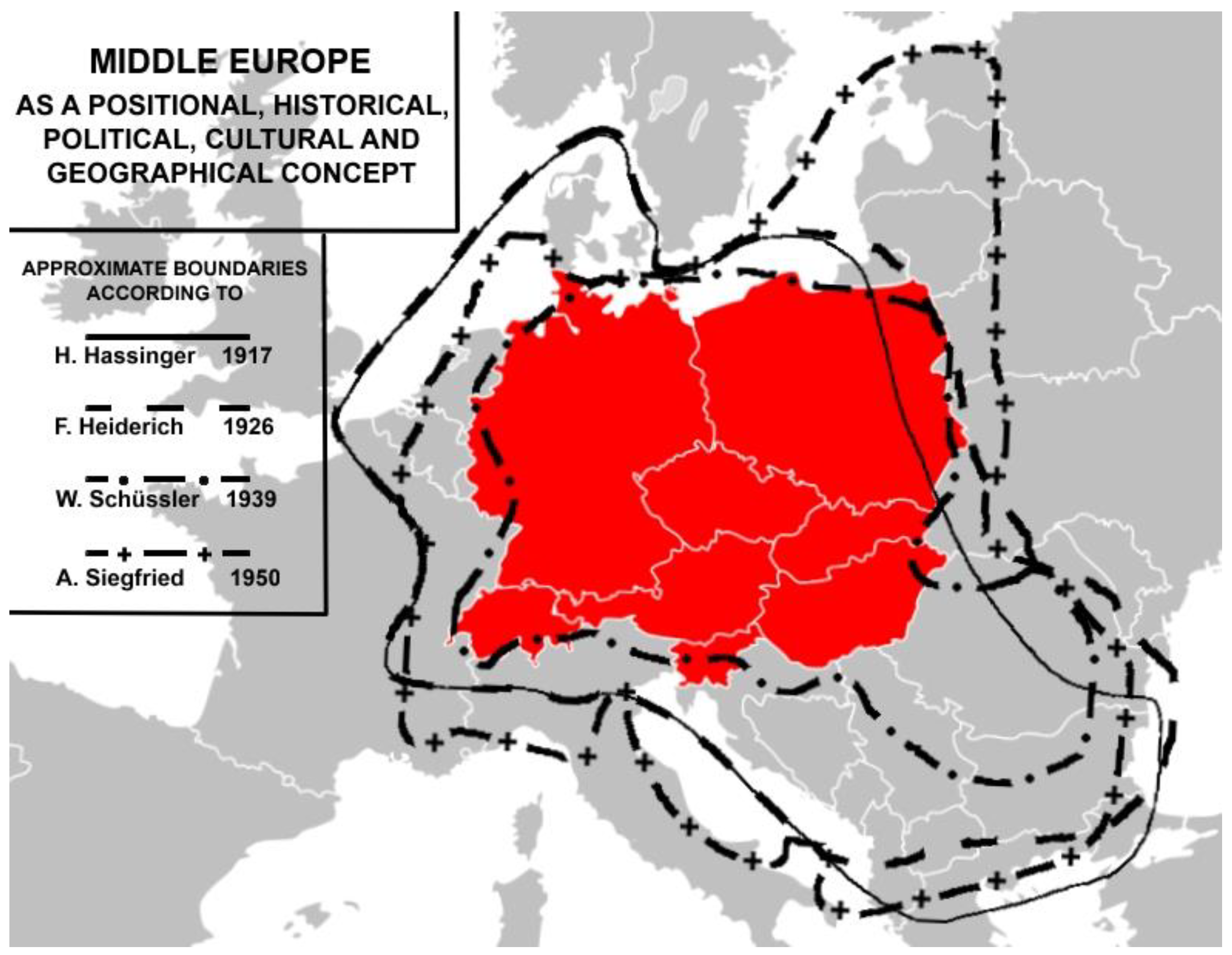

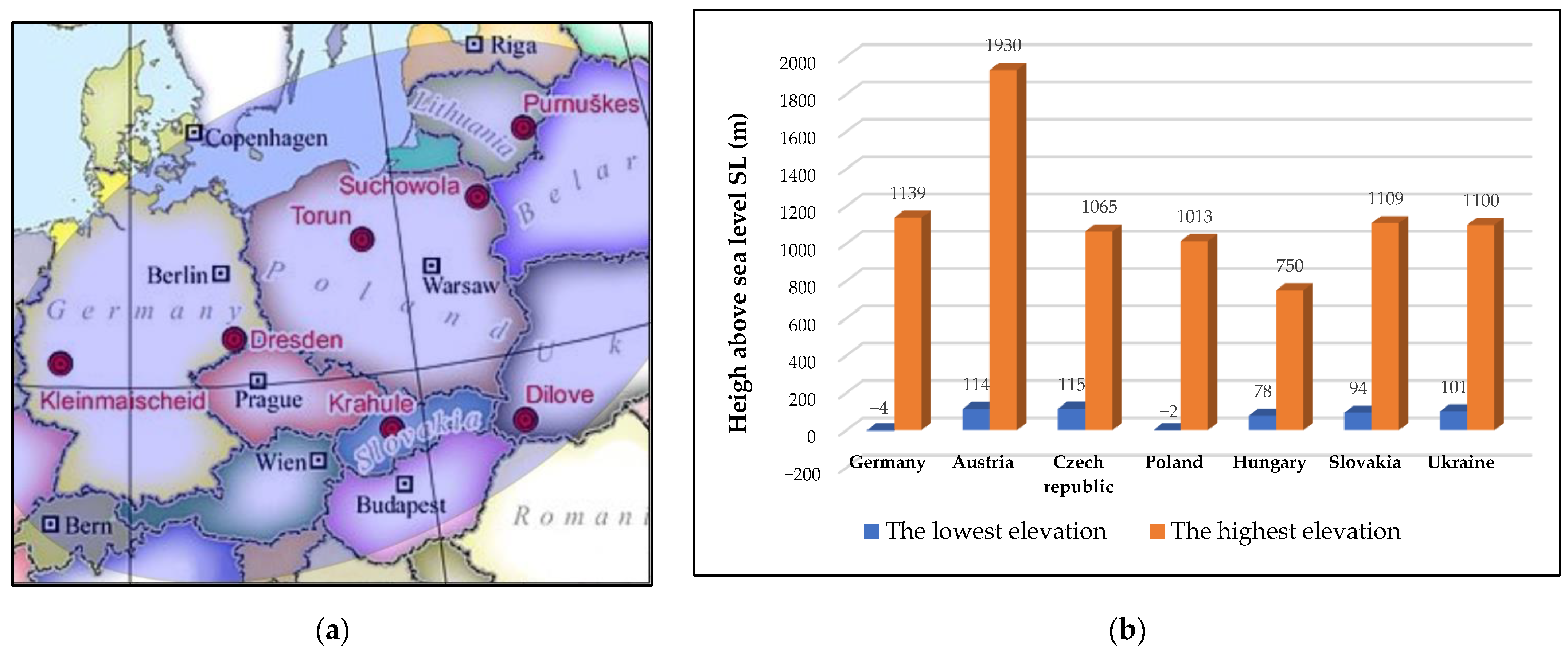

2.1. Territorial Definition of the Central European Area and the Range of Heights

2.2. Basic Criteria for the Structural Pavement Design Assessment

- A. Road protection against the adverse effects of subsoil freezing;

- B. Ratio of flexure tensile strength and critical bending stress in asphalt or cement-bound pavements layers.

| FIn | frost index determined for the respective periodicity n | (°C) |

| hpf | permissible thickness of pavement freezing | (m) |

| λ | thermal conductivity coefficient of subgrade soil. | (W·m−1·K−1) |

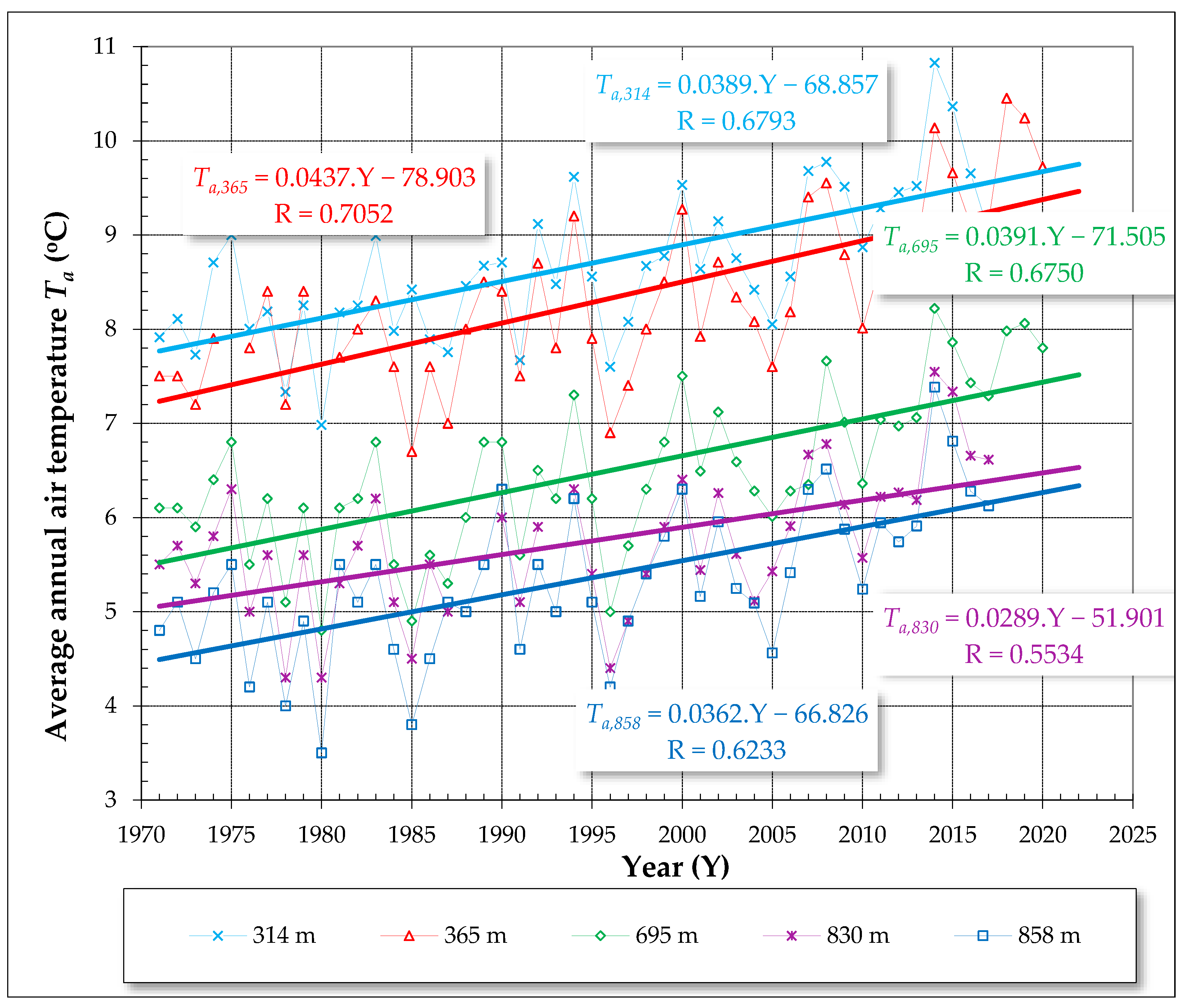

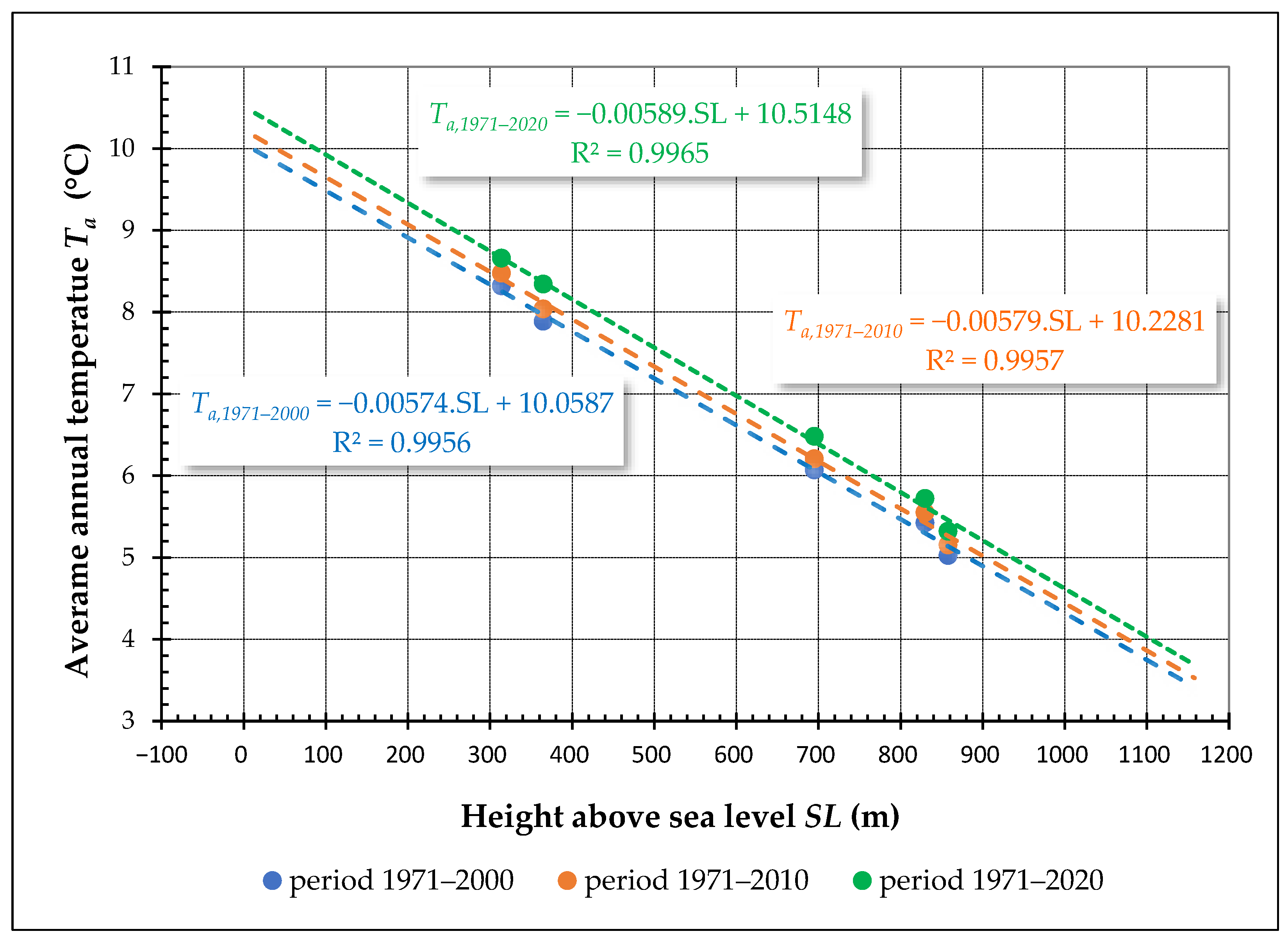

2.3. Dependence of Climatic Characteristics of Central Europe on Altitude

- Average annual air temperature-design of concrete pavements;

- Frost index (FI)-design of asphalt and concrete pavements.

- Average annual temperature 1971–2000;

- Average annual temperature 1971–2010;

- Average annual temperature 1971–2020;

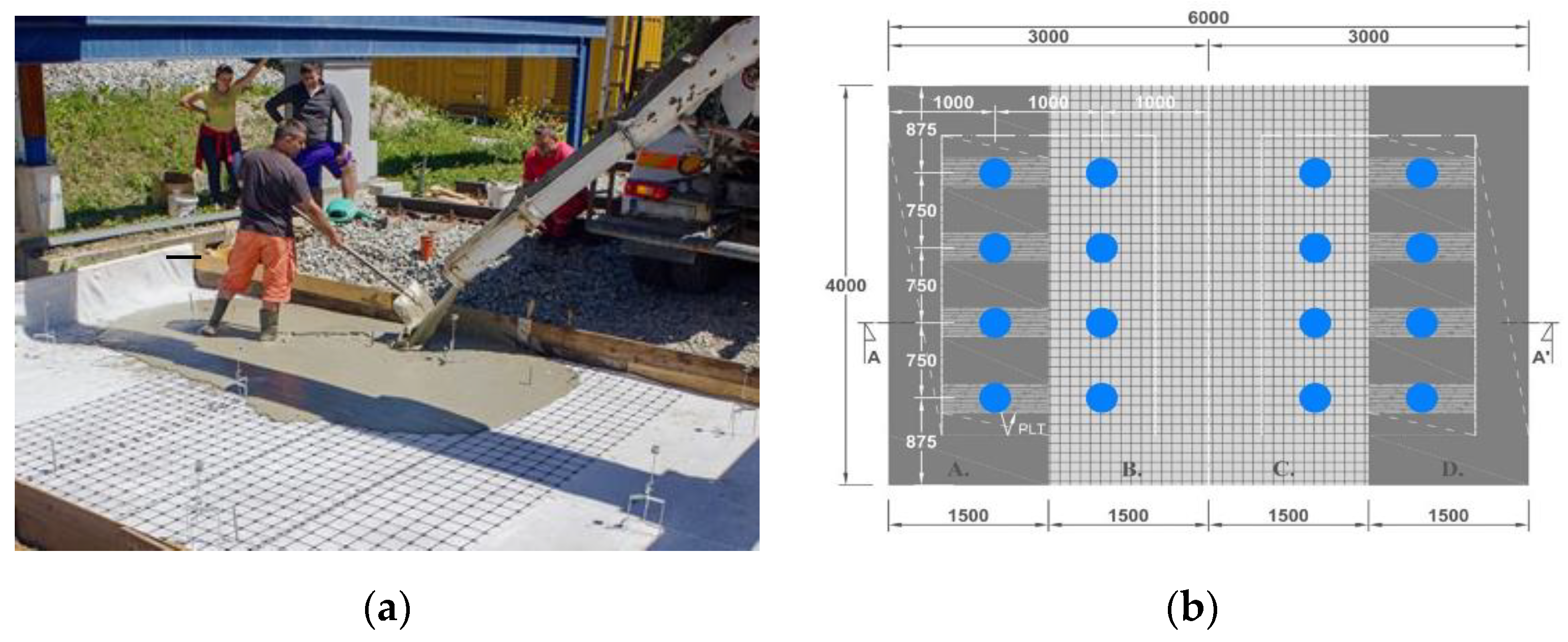

2.4. Flexural Strength of Isomorphic Models of Foam Concrete FC 500 Construction Layer

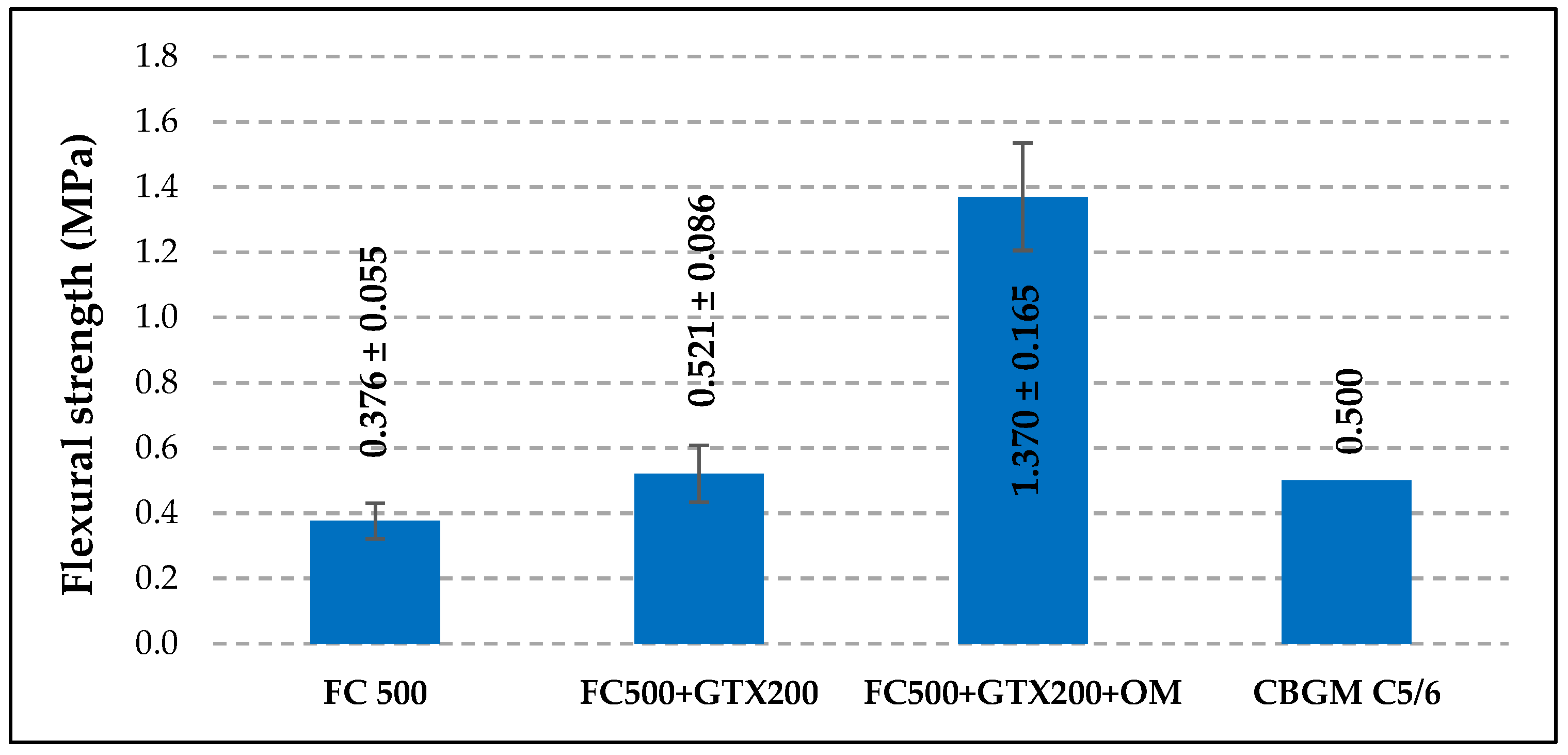

3. Three-Dimensional Model of a Cycle Pavement with a Layer of FC Reinforced with a Basalt Mesh

4. Discussion

- Average annual temperature 1971–2000 8.34 °C (300 m) and 3.75 °C (1100 m);

- Average annual temperature 1971–2010 8.49 °C (300 m) and 3.86 °C (1100 m);

- Average annual temperature 1971–2020 8.75 °C (300 m) and 4.03 °C (1100 m).

- Average value of the frost index in the period 1971–2000 for:

- n = 0.10

- 392.8 (300 m) and 839.5 (1100 m);

- n = 0.15

- 348.2 (300 m) and 762.6 (1100 m);

- n = 0.25

- 305.6 (300 m) and 668.7 (1100 m);

- Average value of the frost index in the period 1971–2011 for:

- n = 0.10

- 384.5 (300 m) and 839.4 (1100 m);

- n = 0.15

- 335.0 (300 m) and 750.0 (1100 m);

- n = 0.25

- 305.5 (300 m) and 664.8 (1100 m).

5. Conclusions

| TS4.5 = 2.26 MPa | TS11.5 = 1.64 MPa; |

| TS4.5 = 2.63 MPa | TS11.5 = 1.91 MPa; |

| TS4.5 = 2.72 MPa | TS11.5 = 1.92 MPa. |

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ruiz-Mallén, I.; Heras, M. What Sustainability? Higher Education Institutions’ Pathways to Reach the Agenda 2030 Goals. Sustainability 2020, 12, 1290. [Google Scholar] [CrossRef] [Green Version]

- Dodds, F.; Donoghue, A.D.; Roesch, J.L. Negotiating the Sustainable Development Goals: A Transformational Agenda for an Insecure World, 1st ed.; Routledge: Abingdon-on-Thames, UK, 2016; ISBN 978-1138695085. [Google Scholar]

- Colglazier, W. Sustainable Development Agenda: 2030. Science 2015, 349, 1048–1050. [Google Scholar] [CrossRef] [PubMed]

- Švajlenka, J.; Kozlovská, M. Modern Method of Construction Based on Wood in the Context of Sustainability. Civ. Eng. Environ. Syst. 2017, 34, 127–143. [Google Scholar] [CrossRef]

- Kibert, C.J. Establishing Principles and a Model for Sustainable Construction. In Proceedings of the First International Conference of CIB TG 16 on Sustainable Construction, Tampa, FL, USA, 6–9 November 1994. [Google Scholar]

- Vanegas, J.A.; Pearce, A.R. Drivers for Change: An Organizational Perspective on Sustainable Construction. In Proceedings of the Construction Congress VI: Building Together for a Better Tomorrow in an Increasingly Complex World, Orlando, FL, USA, 20–22 February 2000; Volume 278, pp. 406–415. [Google Scholar]

- McDonough, W.; Braungart, M. Cradle to Cradle: Remaking the Way We Make Things, 1st ed.; North Point Press: Albany, CA, USA, 2002; ISBN 978-0865475878. [Google Scholar]

- Pulaski, M.H.; Horman, M.J.; Riley, D.R.; Dahl, P.; Hickey, A.; Lapinski, A.R.; Magent, C.; Shaltes, N. Field Guide for Sustainable Construction; The Pennsylvania State University: State College, PA, USA, 2004. [Google Scholar]

- Mallick, R.B.; El-Korchi, T. Pavement Engineering: Principles and Practice, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008; ISBN 978-1420060294. [Google Scholar]

- Jandačka, D.; Ďurčanská, D. Particulate Matter Assessment in the Air Based on the Heavy Metals Presence. Civil. Environ. Eng. 2014, 10, 26–39. [Google Scholar] [CrossRef] [Green Version]

- Drliciak, M.; Celko, J.; Cingel, M.; Jandacka, D. Traffic Volumes as a Modal Split Parameter. Sustainability 2020, 12, 10252. [Google Scholar] [CrossRef]

- Koglin, T.; Rye, T. The Marginalisation of Bicycling in Modernist Urban Transport Planning. J. Transp. Health 2014, 1, 214–222. [Google Scholar] [CrossRef] [Green Version]

- Hunkin, S.; Krell, K. Promoting Active Modes of Transport: A Policy Brief from the Policy Learning Platform on Low-Carbon Economy. Interreg Europe 2019. Available online: https://www.interregeurope.eu/sites/default/files/inline/TO4_PolicyBrief_Active_Modes.pdf (accessed on 7 June 2022).

- Georgiou, A.; Skoufas, A.; Basbas, S. Perceived Pedestrian Level of Service in an Urban Central Network: The Case of a Medium Size Greek City. Case Stud. Transp. Policy 2021, 9, 889–905. [Google Scholar] [CrossRef]

- Mésároš, P.; Spišáková, M.; Mandičák, T.; Čabala, J.; Oravec, M.M. Adaptive Design of Formworks for Building Renovation Considering the Sustainability of Construction in BIM Environment-Case Study. Sustainability 2021, 13, 799. [Google Scholar] [CrossRef]

- Dolnikova, E.; Katunsky, D.; Darula, S. Assessment of Overcast Sky Daylight Conditions in the Premises of Engineering Operations Considering Two Types of Skylights. Build. Environ. 2020, 180, 106976. [Google Scholar] [CrossRef]

- Trojanová, M.; Decký, M.; Remišová, E. The Implication of Climatic Changes to Asphalt Pavement Design. Procedia Eng. 2015, 111, 770–776. [Google Scholar] [CrossRef] [Green Version]

- Remišová, E.; Decký, M.; Podolka, L.; Kováč, M.; Vondráčková, T.; Bartuška, L. Frost Index from Aspect of Design of Pavement Construction in Slovakia. Procedia Earth Planet. Sci. 2015, 15, 3–10. [Google Scholar] [CrossRef] [Green Version]

- Remišová, E.; Decký, M.; Mikolaš, M.; Hájek, M.; Kovalčík, L.; Mečár, M. Design of Road Pavement Using Recycled Aggregate. IOP Conf. Ser. Earth Environ. Sci. 2016, 44, 022016. [Google Scholar] [CrossRef] [Green Version]

- Hajek, M. Environmental Optimization of Road Design. Ph.D. Thesis, University of Zilina, Zilina, Slovakia. in progress.

- Komačka, J.; Remišová, E.; Liu, G.; Leegwater, G.; Nielsen, E. Influence of Reclaimed Asphalt with Polymer Modified Bitumen on Properties of Different Asphalts for a Wearing Course. In Sustainability, Eco-Efficiency and Conservation in Transportation Infrastructure Asset Management, Proceedings of the 3rd International Conference on Tranportation Infrastructure, Pisa, Italy, 22–25 April 2014; Taylor & Francis Group: London, UK, 2014; pp. 179–185. [Google Scholar]

- Lima, M.S.S.; Hajibabaei, M.; Hesarkazzazi, S.; Sitzenfrei, R.; Buttgereit, A.; Queiroz, C.; Tautschnig, A.; Gschösser, F. Environmental Potentials of Asphalt Materials Applied to Urban Roads: Case Study of the City of Münster. Sustainability 2020, 12, 6113. [Google Scholar] [CrossRef]

- Varma, S.; Jamrah, A.; Kutay, M.E.; Korkmaz, K.A.; Haider, S.W.; Buch, N. A Framework Based on Engineering Performance and Sustainability to Assess the Use of New and Recycled Materials in Pavements. Road Mater. Pavement Des. 2019, 20, 1844–1863. [Google Scholar] [CrossRef]

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of Recycled and Waste Materials in Various Construction Applications. Am. J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Maciejewski, K.; Ramiaczek, P.; Remisova, E. Effects of Short-Term Ageing Temperature on Conventional and High-Temperature Properties of Paving-Grade Bitumen with Anti-Stripping and Wma Additives. Materials 2021, 14, 6229. [Google Scholar] [CrossRef]

- D’Angelo, J.; Harm, E.; Bartoszek, J.; Baumgardner, G.; Corrigan, M.; Cowsert, J.; Harman, T.; Jamshidi, M.; Jones, W.; Newcomb, D.; et al. Warm-Mix Asphalt: European Practice; U.S. Department of Transportation: Washington, DC, USA, 2008.

- Falliano, D.; de Domenico, D.; Ricciardi, G.; Gugliandolo, E. Compressive and Flexural Strength of Fiber-Reinforced Foamed Concrete: Effect of Fiber Content, Curing Conditions and Dry Density. Constr. Build. Mater. 2019, 198, 479–493. [Google Scholar] [CrossRef]

- Van Dijk, S. Foamed Concrete: A Dutch View; British Cement Association: Camberley, UK, 1991. [Google Scholar]

- Amran, Y.H.M.; Farzadnia, N.; Ali, A.A.A. Properties and Applications of Foamed Concrete; a Review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Yang, K.H.; Lee, K.H.; Song, J.K.; Gong, M.H. Properties and Sustainability of Alkali-Activated Slag Foamed Concrete. J. Clean. Prod. 2014, 68, 226–233. [Google Scholar] [CrossRef]

- Wei, S.; Yiqiang, C.; Yunsheng, Z.; Jones, M.R. Characterization and Simulation of Microstructure and Thermal Properties of Foamed Concrete. Constr. Build. Mater. 2013, 47, 1278–1291. [Google Scholar] [CrossRef]

- Kim, H.K.; Jeon, J.H.; Lee, H.K. Workability, and Mechanical, Acoustic and Thermal Properties of Lightweight Aggregate Concrete with a High Volume of Entrained Air. Constr. Build. Mater. 2012, 29, 193–200. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, X.; Wang, L.; Li, Y. Foam Concrete: A State-of-the-Art and State-of-the-Practice Review. Adv. Mater. Sci. Eng. 2020, 2020, 6153602. [Google Scholar] [CrossRef] [Green Version]

- Falliano, D.; de Domenico, D.; Ricciardi, G.; Gugliandolo, E. Improving the Flexural Capacity of Extrudable Foamed Concrete with Glass-Fiber Bi-Directional Grid Reinforcement: An Experimental Study. Compos. Struct. 2019, 209, 45–59. [Google Scholar] [CrossRef]

- Vlcek, J.; Drusa, M.; Scherfel, W.; Sedlar, B. Experimental Investigation of Properties of Foam Concrete for Industrial Floors in Testing Field. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 022049. [Google Scholar] [CrossRef] [Green Version]

- Kadela, M.; Kozłowski, M.; Kukiełka, A. Application of Foamed Concrete in Road Pavement—Weak Soil System. Procedia Eng. 2017, 193, 439–446. [Google Scholar] [CrossRef]

- Hulimka, J.; Krzywoń, R.; Jȩdrzejewska, A. Laboratory Tests of Foam Concrete Slabs Reinforced with Composite Grid. Procedia Eng. 2017, 193, 337–344. [Google Scholar] [CrossRef]

- Izvolt, L.; Dobes, P.; Drusa, M.; Kadela, M.; Holesova, M. Experimental and Numerical Verification of the Railway Track Substructure with Innovative Thermal Insulation Materials. Materials 2022, 15, 160. [Google Scholar] [CrossRef]

- Act No. 135/1961, Act on Roads (Road Law), Slovak Government, Bratislava, Slovakia, 1961, Coll. on Roads (Road Act). Available online: https://www.zakonypreludi.sk/zz/1961-135 (accessed on 7 June 2022).

- Keeling, R.C. Design of Flexible Pavements Using the Triaxial Compression Test; Highway Research Board Bulletin: Washington, DC, USA, 1947. [Google Scholar]

- Barber, E.S. Application of Triaxial Compression Test Results to the Calculation of Flexible Pavement Thickness. In Proceedings of the Twenty-Sixth Annual Meeting of the Highway Research Board, Washington, DC, USA, 5–8 December 1946; Volume 26, pp. 26–39. [Google Scholar]

- McLeod, N.W. Flexible Pavement Thickness Requirements; Proceedings; AAPT: Cleveland, OH, USA, 1956; Volume 25. [Google Scholar]

- Ullidtz, P. Pavement Analysis. Developments in Civil Engineering; Elsevier Science Ltd.: Amsterdam, The Netherlands, 1987; Volume 19, ISBN 0444428178. [Google Scholar]

- Duncan, J.M.; Monismith, C.L.; Wilson, E.L. Finite Element Analysis of Pavements. Highw. Res. Rec. 1968, 228, 157. [Google Scholar]

- Cho, Y.H.; Mccullough, B.F.; Weissmann, J. Considerations on Finite-Element Method Application in Pavement Structural Analysis. Transp. Res. Rec. 1996, 1539, 96–101. [Google Scholar] [CrossRef]

- Yin, H.; Stoffels, S.; Solaimanian, M. Optimization of Asphalt Pavement Modeling Based on the Global-Local 3D FEM Approach. Road Mater. Pavement Des. 2008, 9, 345–355. [Google Scholar] [CrossRef]

- Jiang, X.; Zeng, C.; Gao, X.; Liu, Z.; Qiu, Y. 3D FEM Analysis of Flexible Base Asphalt Pavement Structure under Non-Uniform Tyre Contact Pressure. Int. J. Pavement Eng. 2019, 20, 999–1011. [Google Scholar] [CrossRef]

- Hájek, M.; Decký, M.; Scherfel, W. Objectification of Modulus Elasticity of Foam Concrete Poroflow 17-5 on the Subbase Layer. Civ. Environ. Eng. 2016, 12, 55–62. [Google Scholar] [CrossRef] [Green Version]

- Hajek, M.; Decky, M.; Drusa, M.; Orininová, L.; Scherfel, W. Elasticity Modulus and Flexural Strength Assessment of Foam Concrete Layer of Poroflow. IOP Conf. Ser. Earth Environ. Sci. 2016, 44, 022021. [Google Scholar] [CrossRef] [Green Version]

- Decky, M.; Scherfel, W.; Remisova, E.; Sramek, J.; Zgutova, K.; Vangel, J.; Plesnik, J. Sustainable Materials and Technologies for the Pavement Construction and Reinforcement of Traffic Areas; University of Zilina, EDIS—Publishing Center: Zilina, Slovakia, 2021. [Google Scholar]

- Sinnhuber, K.A. Central Europe: Mitteleuropa: Europe Centrale: An Analysis of a Geographical Term. Trans. Pap. (Inst. Br. Geogr.) 1954, 29, 15–39. [Google Scholar] [CrossRef]

- Pynsent, R.B. Tinkering with the Ferkos: A Kind of Slovakness. Slavon. East Eur. Rev. 1998, 76, 279–295. [Google Scholar]

- Petritsch, W. Culture in Central Europe: Possibilities and Preconditions. Anal.-Cent. East. Eur. Rev.-Engl. Ed. 2008, 1, 131–140. [Google Scholar]

- Wikipedia. Available online: https://En.Wikipedia.Org/Wiki/Central_Europe (accessed on 6 June 2022).

- STN EN 12390-5:2020; Testing Hardened Concrete. Part 5: Flexural Strength of Test Specimens. Slovak Standard; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2020. (In Slovak)

- Wikipedia. Available online: https://En.Wikipedia.Org/Wiki/Geographical_midpoint_of_Europe (accessed on 6 June 2022).

- Decky, M.; Papanova, Z.; Juhas, M.; Kudelcikova, M. Evaluation of the Effect of Average Annual Temperatures in Slovakia between 1971 and 2020 on Stresses in Rigid Pavements. Land 2022, 11, 764. [Google Scholar] [CrossRef]

- Zuzulova, A. TP 098 Cement Concrete Pavement Design on Road Network; Technological Standard of Ministry of Transport; Construction and Regional Development of the Slovak Republic, Section for Road Transport and Roads, Slovak Road Administration: Bratislava, Slovakia, 2015. [Google Scholar]

- STN 73 6114; Pavement of Roads; Basic Provision for Structural Design. Slovak Standard; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 1997. (In Slovak)

- Decký, M.; Drusa, M.; Pepucha, L.; Zgútová, K. Earth Structures of Transport Constructions, 1st ed.; Pearson Educ. Ltd.: Harlow, UK, 2013; ISBN 978-1-78399-925-5. [Google Scholar]

- De Normalisation, C.E. EN 12390–5: Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens; CEN: Brussels, Belgium, 2009. [Google Scholar]

- Ramamurthy, K.; Kunhanandan Nambiar, E.K.; Indu Siva Ranjani, G. A Classification of Studies on Properties of Foam Concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Raj, A.; Sathyan, D.; Mini, K.M. Physical and Functional Characteristics of Foam Concrete: A Review. Constr. Build. Mater. 2019, 221, 787–799. [Google Scholar] [CrossRef]

- Rahman, M.T.; Mahmud, K.; Ahsan, S. Stress-Strain Characteristics of Flexible Pavement Using Finite Element Analysis. Int. J. Civ. Struct. Eng. 2011, 2, 233–240. [Google Scholar]

- Reiterman, P.; Davidová, V.; Machovec, J.; Šulc, R. Freeze-Thaw Resistance of the Pavement with High Replacement of Portland Cement. AIP Conf. Proc. 2021, 2322, 020027. [Google Scholar]

- Webster, K. The Circular Economy a Wealth of Flows; Ellen MacArthur Foundation Publishing: Cowes, UK, 2017. [Google Scholar]

- Spišáková, M.; Mandičák, T.; Mésároš, P.; Špak, M. Waste Management in a Sustainable Circular Economy as a Part of Design of Construction. Appl. Sci. 2022, 12, 4553. [Google Scholar] [CrossRef]

- Pohoryles, D.A.; Bournas, D.A. A Unified Macro-Modelling Approach for Masonry-Infilled RC Frames Strengthened with Composite Materials. Eng. Struct. 2020, 223, 111161. [Google Scholar] [CrossRef]

- Vaitkus, A.; Gražulyte, J.; Skrodenis, E.; Kravcovas, I. Design of Frost Resistant Pavement Structure Based on Road Weather Stations (RWSs) Data. Sustainability 2016, 8, 1328. [Google Scholar] [CrossRef] [Green Version]

- Nazarko, J.; Radziszewski, P.; Dȩbkowska, K.; Ejdys, J.; Gudanowska, A.; Halicka, K.; Kilon, J.; Kononiuk, A.; Kowalski, K.J.; Król, J.B.; et al. Foresight Study of Road Pavement Technologies. Procedia Eng. 2015, 122, 129–136. [Google Scholar] [CrossRef] [Green Version]

- Schnecke, H.; Albrecht, W.; Eisenmann, J.; Jacobs, J.; Kloss, E.W.; Melior, H.; Schneider, W.; Schuster, F.O.; Wehner, B. CONCRETE PAVEMENTS, WEST GERMANY. In Proceedings of the XIVth World Road Congress, Prague, Czechoslovakia; 1971. Available online: https://trid.trb.org/view/137360 (accessed on 7 June 2022).

- Weninger-Vycudil, A.; Simanek, P.; Molzer, C.; Litzka, J. Actual Researches on the Austrian PMS-Sector. In Proceedings of the 6th International Conference on Managing Pavements, Brisbane, Australia, 19–24 October 2004. [Google Scholar]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.J.; Hui, D. A Short Review on Basalt Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Jiang, J.; Jiang, C.; Li, B.; Feng, P. Bond Behavior of Basalt Textile Meshes in Ultra-High Ductility Cementitious Composites. Compos. Part B Eng. 2019, 174, 107022. [Google Scholar] [CrossRef]

- Bieliatynskyi, A.; Krayushkina, K.; Breskich, V.; Lunyakov, M. Basalt Fiber Geomats—Modern Material for Reinforcing the Motor Road Embankment Slopes. Transp. Res. Procedia 2021, 54, 744–757. [Google Scholar] [CrossRef]

- Sarkar, A.; Hajihosseini, M. The Effect of Basalt Fibre on the Mechanical Performance of Concrete Pavement. Road Mater. Pavement Des. 2020, 21, 1726–1737. [Google Scholar] [CrossRef]

- Krzywoń, R.; Hulimka, J.; Jędrzejewska, A.; Górski, M. Application of Fibre Composite Grids as Reinforcement of Foamed PC and GP Concrete. MATEC Web Conf. 2019, 274, 05002. [Google Scholar] [CrossRef] [Green Version]

- Hájek, M.; Decký, M. Homomorphic Model Pavement with Sub Base Layer of Foam Concrete. Procedia Eng. 2017, 192, 283–288. [Google Scholar] [CrossRef]

- Decký, M.; Drusa, M.; Zgútová, K.; Blaško, M.; Hájek, M.; Scherfel, W. Foam Concrete as New Material in Road Constructions. Procedia Eng. 2016, 161, 428–433. [Google Scholar] [CrossRef] [Green Version]

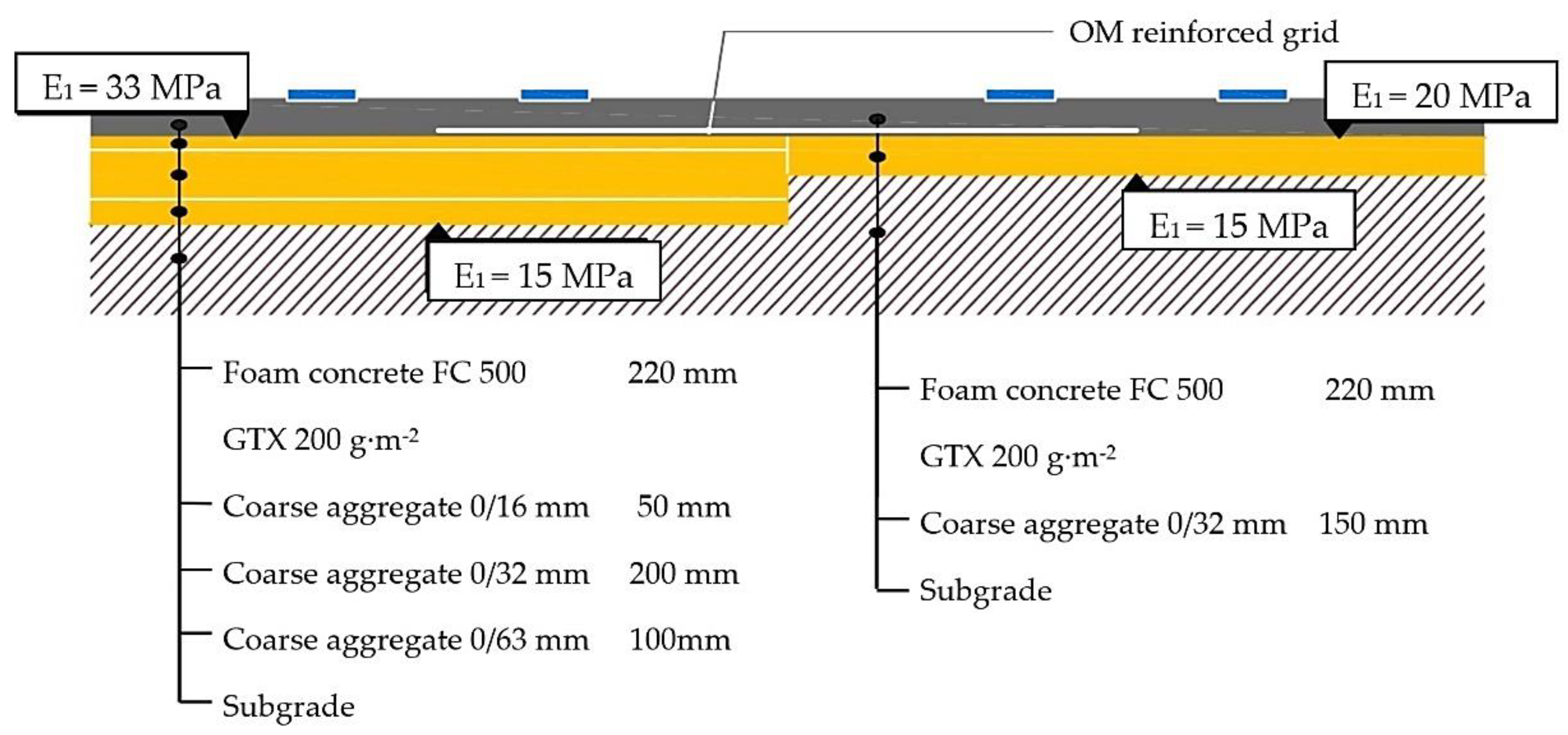

| Density Average Value (kg·m−3) | Flexural Strength (N·mm−2) | ||||

|---|---|---|---|---|---|

| Average Value | Standard Dev. | Student’s Distribution t0.05 | Design Value | ||

| FC 500 | 522 | 0.376 | 0.055 | 2.080 | 0.36 |

| FC 500 + GTX 200 | 516 | 0.521 | 0.086 | 2.069 | 0.48 |

| FC 500 + GTX 200 + OM | 525 | 1.370 | 0.165 | 4.303 | 0.96 |

| Modulus of Elasticity (MPa) | |||

|---|---|---|---|

| Isomorphic Model | Sub-Base | Equivalent Modulus Ee | Back-Calculation E |

| FC 500 + GTX 200 | 19.6 | 82.50 | 1412.5 |

| 33.3 | 130.75 | 2062.5 | |

| FC 500 + GTX 200 + OM | 19.6 | 107.75 | 3675.0 |

| 33.3 | 155.00 | 3575.0 | |

| Cycle Pavement Construction | Thickness | Modulus of Elasticity | Poisson’s Ratio | Flexural Tensile Strength | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (MPa) | (MPa) | (MPa) | |||||||

| 0 °C | 11 °C | 27 °C | 0 °C | 11 °C | 27 °C | 0 °C | 11 °C | 27 °C | ||

| Single-layer cement concrete pavement CC III; PE (polyethylene) geotextile | 180 | 35.103 | 0.2 | 4.0 | ||||||

| Foam concrete with reinforcing mesh FC 500 + OM, base layer | 100 | 1800 | 0.23 | 1.0 | ||||||

| Gravel crushed stone Unbound gravel materials (UGM), sub-base layer | 150 | 350 | 0.3 | - | ||||||

| Numerical Results-Stresses (Obtained by Different Methods) | Model of Cycle Pavement 3 | Single Load |

|---|---|---|

| Westergaard | (WEST) | 3.113 MPa |

| Pickett and Ray | (PICRA) | 3.298 MPa |

| Elastic multilayered half-space | (LAYMED) | 2.965 MPa |

| Finite element method | (FEM) | 2.583 MPa |

| Thermal Stresses | (THERM) | 1.083 MPa |

| Criterial Limit value according to standard TP 098 | CC III | 4.0 MPa |

| Pavement Construction Layer | Pavement 1 | Pavement 2 | Pavement 3 | Pavement 4 | Pavement 5 |

|---|---|---|---|---|---|

| Cement concrete for surface CC III; EN 13877 | 190 | 190 | 180 | - | - |

| Asphalt concrete for base course AC 11; EN 13108-1 | 40 | - | - | - | - |

| Asphalt concrete for wearing course AC 8; EN 13108-1 | - | - | - | 30 | 30 |

| Asphalt concrete for binder course AC 16; EN 13108-1 | - | - | - | 50 | 50 |

| Asphalt concrete for road base AC 16; EN 13108-1 | - | - | - | 50 | 50 |

| Cement bound granular mixture CBGM C5/6; EN 14227-1 | 150 | - | - | 150 | - |

| Foam concrete + reinforcing basalt mesh FC 500 + OM | - | - | 100 | - | 100 |

| Unbound mixtures (UM) for sub-base layer UM 0/31.5; EN 13285 | - | 180 | - | - | - |

| Unbound mixtures (UM), for sub-base layer UM 0/31.5; EN 13285 | 180 | 180 | 150 | 200 | 150 |

| Elasticity modulus of subgrade E (MPa) | min. 30 | ||||

| Pavement service life (years) | min. 30 | ||||

| Total pavement thickness (mm) | 560 | 550 | 430 | 480 | 380 |

| The required thermal resistance of the pavement (m2·K·W−1) | 0.260 for altitude 300 m according to TP 098 [58] 0.412 for altitude 1100 m according to TP 098 [58] | ||||

| The real thermal resistance of the pavement (m2·K·W−1) | 0.263 | 0.285 | 0.650 | 0.286 | 0.676 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Decky, M.; Hodasova, K.; Papanova, Z.; Remisova, E. Sustainable Adaptive Cycle Pavements Using Composite Foam Concrete at High Altitudes in Central Europe. Sustainability 2022, 14, 9034. https://doi.org/10.3390/su14159034

Decky M, Hodasova K, Papanova Z, Remisova E. Sustainable Adaptive Cycle Pavements Using Composite Foam Concrete at High Altitudes in Central Europe. Sustainability. 2022; 14(15):9034. https://doi.org/10.3390/su14159034

Chicago/Turabian StyleDecky, Martin, Katarina Hodasova, Zuzana Papanova, and Eva Remisova. 2022. "Sustainable Adaptive Cycle Pavements Using Composite Foam Concrete at High Altitudes in Central Europe" Sustainability 14, no. 15: 9034. https://doi.org/10.3390/su14159034