1. Introduction

The annual energy consumption of all pumps (constant- and variable-flow applications) was 225 TWh in 2015 [

1]. Drinking-water processes and wastewater activities account for 3–4% of energy consumption in the U.S. [

2]. The energy consumption of the water sector is about 3.5% of the total EU budget [

3]. The estimated total energy consumption of the water sector is projected to be 253 TWh/year in 2025 [

1], with an increase of 12.5% over a decade.

The above data clearly show that the activities associated with the water treatment processes and drinking-water supply activities require high energy consumption. Based on market research and data from the industry for constant- and variable-flow applications, it has been determined that a significant part of clean-water-pump application is for variable flow. However, the number of pumps installed in the water sector with variable-speed drive (VSD) is still limited [

1]. Therefore, there would be a large energy-saving potential if VSD pumps were implemented in applications with variable flow.

Drinking-water supply systems (DWSSs) are adapted to the geographic conditions and the requirements of each city. Therefore, DWSSs are uniquely developed and implemented in each city. Commonly, DWSSs include water treatment stations (WTSs), booster pumping stations, storage tanks/reservoirs, and drinking-water distribution systems (e.g., tunnels, aqueducts or pipelines, siphons, valves) [

4]. A few researchers have developed methods for optimizing municipal drinking-water distribution networks considering different criteria, but they applied them to hypothetical cases [

5]. A literature survey revealed several investigations that have analyzed drinking-water distribution systems, taking into account the specific features of each case [

6,

7,

8]. The application of multiple criteria (e.g., the financial constraints associated with operational and maintenance costs, the minimization of water residence time, maintaining positive water pressure to avoid contamination, and controlling the pressure in the water distribution network to maintain the hydraulic integrity) for the optimization of municipal drinking-water distribution networks requires taking into account the specific constraints for each case [

9,

10]. Mathematical models and numerical simulations deliver effective and feasible results to investigate the hydraulic integrity and water quality conditions of DWSSs [

11,

12,

13]. These predictive capabilities are useful for detecting the integrity loss of DWSSs [

4].

WTSs deliver drinking water to the community through supply systems. The major energy consumption of WTSs is associated with the operation of pumping units in the water supply system (WSS). The pumping units installed in the WSS consume up to 90% of the total energy [

14,

15]. The energy consumption depends upon the pumping-unit type (e.g., constant-speed pumping units (CSPUs) and variable-speed pumping units (VSPUs)) and the selected operation strategy [

16]. A significant reduction in energy consumption can be achieved by combining variable-speed pumping units (VSPUs) and constant-speed pumping units (CSPUs) in the operation strategy of WSSs. A remarkable reduction in energy consumption through the pumping units installed in the WSS of Milan city has been reported by Castro-Gama et al. (2017) [

17].

The purpose of the investigation conducted in our research study is to select a strategy with reduced operating and maintenance costs for installed pumping units in the water sector. An improved operation strategy for pumping units is developed based on an in-depth analysis of the available infrastructure and water treatment processes conducted in 2019 and then implemented in September 2020 in an infrastructure with four pumping units (two VSPUs and two CSPUs) available in Timisoara pumping station No. 1 (TPS1) in the Bega municipal water treatment station (MWTS). The analyzed data collected in 2021 from the pumping units installed in TPS1 highlight a decrease in operating and maintenance costs.

An overview of the drinking-water supply system and the water treatment stations available in Timisoara city is detailed in

Section 2. The layout of TPS1 is presented, highlighting its contribution to the Bega MWTS. The specific energy consumption associated with the operation of the pumping units installed in TSP1 is detailed. Two specific energy consumption indicators (ECIs) are determined to assess the performance of TSP1. Both old and new operating strategies for the four pumping units selected in TPS1 are examined in

Section 3. The old operation scenario of the pumping units installed in TSP1 is investigated, revealing its limitations. Then, a new strategy is developed and implemented for the operation of the pumping units installed in TPS1 to better adapt to the operating conditions, improving the specific energy consumption as well as diminishing the failure incidents. The new operation strategy is assessed based on the data acquired from TPS1. The number of hours in service in the last six years for each pumping unit and the total time for all pumping units are analyzed in

Section 4. The failure incidents of the pumping units counted in service are enumerated and correlated with the operating conditions of the pumping units. The conclusions and the lessons learned in this case study are drawn in the last section.

2. Drinking-Water Supply System (DWSS) of Timisoara City

At the beginning of the 20th century, the water source for Timisoara city was groundwater captured from deep drilled wells. The water supply infrastructure of Timisoara city was designed and developed by the technical service of the mayor’s office under the coordination of engineer Stan Vidrighin. The groundwater source was supplemented with treated water from the Bega River starting with the industrial development of Timisoara city in the second part of the last century [

18]. The first development of the surface water treatment station (denoted WTS2), which took water from the Bega River with a designed capacity of 0.12 m

3/s, was carried out at the end of 1959. Several extensions of the WTS2 capacity have been successively implemented: 0.3 m

3/s in 1965 and 0.48 m

3/s in 1976. A new surface-water treatment station (denoted WTS4) with a capacity of 0.9 m

3/s was put into operation in 1982 in the same location as WTS2 [

18]. The WTS4 capacity was expanded to 1.24 m

3/s in 1994. As a result, a maximum capacity for both surface-water treatment plants (WTS2 + WTS4) of 1.72 m

3/s was reached.

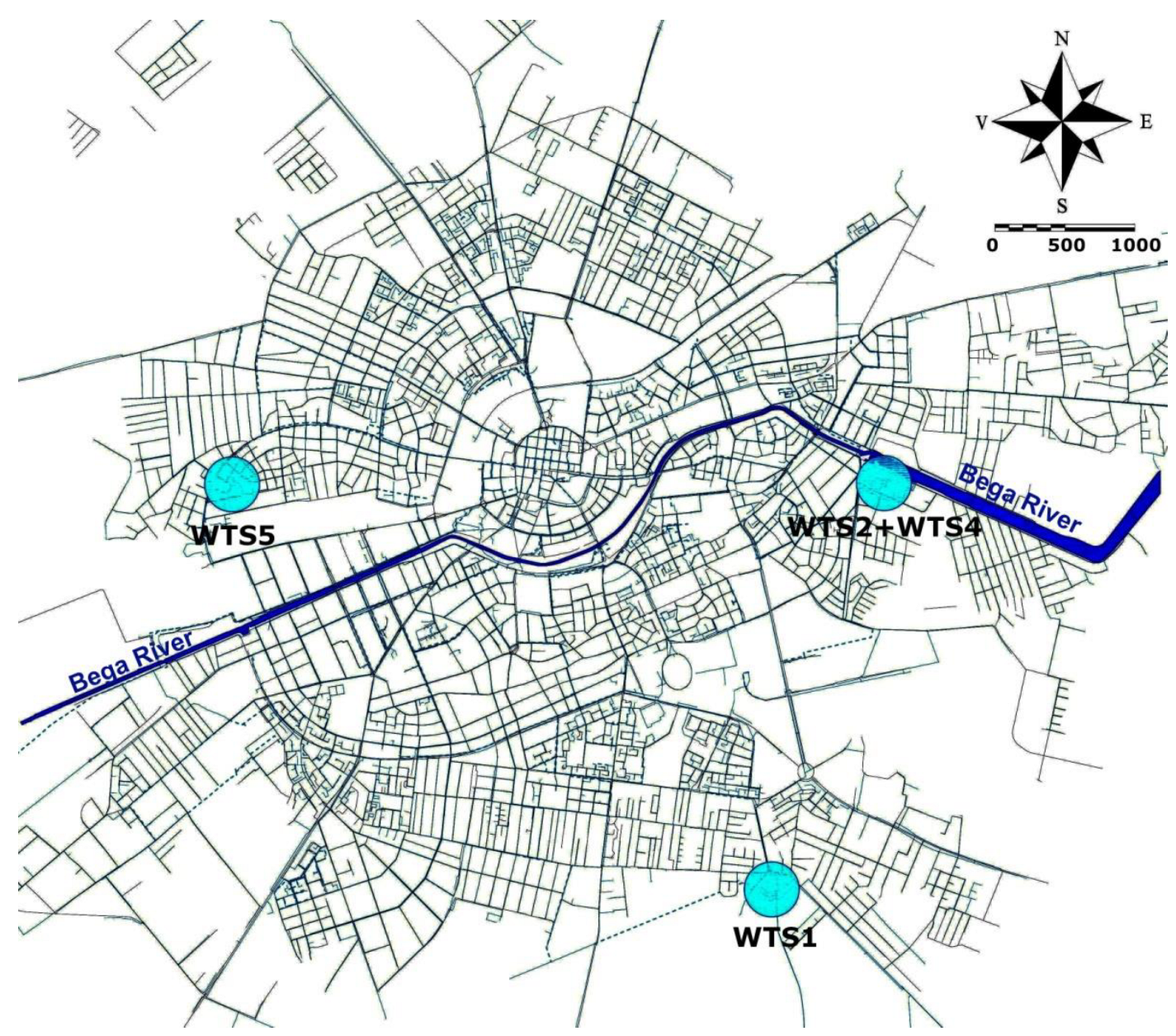

Nowadays, the drinking-water supply system in Timisoara city is a combination of two sources: WTS2 and WTS4 deliver up to 72% of surface water from the Bega River and the rest from groundwater is provided by WTS1 (called Urseni WTS) and WTS5 (called Ronaţ WTS), as shown in

Figure 1. Thus, the groundwater is an alternative and complementary source to the primary water surface source for Timisoara city. The water supply infrastructure of Timisoara city has been managed by the municipal company AQUATIM S.A. since 1991 [

18].

The layout of the Bega MWTS (WTS2 + WTS4) of Timisoara city for surface water from the Bega River is given in

Figure 2.

The water flow into the Bega MWTS is gravitational along the passage from the river intake to the TSP1 pumping station because it is installed below the Bega River water level (see

Figure 2). The water settling stage takes place along this passage to the underground suction tank of the hydraulic pumping units installed in TPS1. Four hydraulic pumping units installed in TPS1 deliver water to the WTS2 and WTS4. Then, the water processed in WTSs is pumped into the DWSS of Timisoara city, as presented in

Figure 1.

The energy consumption in the water treatment process of Bega MWTS (WTS2 and WTS4) for three years is shown in

Figure 3. One can remark in this figure that around 50% of the energy is consumed in the water distribution pumping process and 33% of energy consumption is associated with the pumping process in TSP1. The energy consumption from 4% to 7% is accounted for by the sludge treatment process, while around 11% is related to other processes (e.g., household reagents, chlorination station, thermal power plant, workshop, and so on). In contrast, the energy consumption in the filtering processes is less than 2% of the total budget.

The volume of water pumped by TSP1 and treated by WTS2 and WTS4 from 2016 to 2021 is shown in

Figure 4a. There was an increase in the volume of water pumped by TSP1 from 25.45 million m

3 in 2016 to 28.18 million m

3 in 2019. We would like to point out that this increase equates to 10% of the volume of pumped water. Moreover, the volume of water pumped by TSP1 in 2020 and 2021 was practically the same as in 2019. The energy consumption of the pumping units installed in TSP1 for the treatment of water volumes by WTS2 and WTS4 from 2016 to 2021 is shown in

Figure 4b. As expected, the energy consumption of the pumping units installed in TSP1 increased with the volume of water processed. The energy consumption of the pumping units increased from 1.3 million kWh in 2016 to 1.51 million kWh in 2019, an increase of 16.3%. In 2020 and 2021 there was a 1% and 2% decrease in energy consumption compared to 2019.

The annual population equivalents (PE) for Bega MWTS (WST2 + WST4) are given in

Figure 5 from 2016 to 2021. There is a monotonous increase in the population equivalents that is served by Bega MWTS every year. An average value of 290,000 population equivalents (PE) can be estimated for Bega MWTS.

Two specific energy consumption indicators (ECIs) are determined to assess the performances of TSP1. The first indicator is the specific energy consumption in relation to the volume of water pumped. The indicator ECI

m3 is defined as the ratio between the annual energy consumption and the annual volume pumped by units installed in TSP1.

The second indicator ECI

PE is defined as the ratio between the annual energy consumption and population equivalents (PE) served by pumping units installed in TSP1 [

19]:

The ECI

m3 indicator was calculated for each year from 2016 to 2021 using Equation (1) with the data included in

Figure 4. The data obtained for the pumping units installed in TSP1 for the ECI

m3 indicator are plotted in

Figure 6. The minimum value of 0.0509 kWh/m

3 of the ECI

m3 indicator was reached in 2016, while the maximum value of 0.0548 kWh/m

3 was reached in 2018. We noticed an improvement in the ECI

m3 indicator of the specific energy consumption of the pumping process in TSP1 after 2018 by decreasing the indicator to 0.0535 kWh/m

3 in 2019 and 2021, respectively to 0.0544 kWh/m

3 in 2020. There was an improvement of up to 2% in specific energy consumption.

It is shown in

Figure 3 that the energy consumption in TSP1 represents 33% of the energy consumption of the full process of Bega MWTS (WTS2 + WTS4). As a result, a range from 0.154 kWh/m

3 to 0.166 kWh/m

3 was obtained for the six years taken into account for the ECI

m3 specific energy consumption indicator of the full water treatment process in the Bega MWTS. Benchmarking the energy consumption undertaken for selected regions in Europe shows that electricity consumption for water supply is in the range of 0.5–0.7 kWh/m

3 in Germany, 0.2–0.6 kWh/m

3 in Denmark, and 0.7–0.93 kWh/m

3 in Sweden, with a median value of 0.76 kWh/m

3 [

20]. The range of the specific energy consumption indicator ECI

m3 obtained for the Bega MWTS (WST2 + WST4) is near to the lower limit of the range 0.14 ÷ 0.71 kWh/m

3 indicated by Vaccari et al. (2018) [

19] for water treatment plants available in Italy with population equivalents larger than 100,000.

The ECI

PE indicator is calculated using Equation (2) with the data included in

Figure 4b and

Figure 5 from 2016 to 2021. The data for the ECI

PE indicator corresponding to the pumping units installed in TSP1 is shown in

Figure 7. The minimum value of 4.57 kWh/PE/year of the ECI

PE indicator was reached in 2016 while the maximum value of 5.19 kWh/PE/year was reached in 2019. We noticed an improvement in the ECI

PE indicator of the specific energy consumption of the pumping process in TSP1 after 2019 with a decrease in the indicator to 5.11 kWh/PE/year in 2020 and 5.03 kWh/PE/year in 2021. There was an improvement in this specific energy consumption indicator in 2021 of over 3% compared to 2019.

The specific energy consumption indicator ECI

PE of the full water treatment process in the Bega MWTS (WTS2 + WTS4) covers a range from 13.85 kWh/PE/year to 15.73 kWh/PE/year over the six years taken into account in our investigation. The range limits of the ECI

PE indicator are determined based on the fact that the energy consumption in TSP1 represents 33% of the energy consumption of the whole process (see

Figure 3). A literature survey led to a reference value for the ECI

PE indicator corresponding to large water treatment stations (>100,000 PE), as follows: 18 kWh/PE/year for German water treatment stations [

21], 20 ÷ 22.5 kWh/PE/year for northwest European water treatment stations [

22], and 23 kWh/PE/year for Italian water treatment stations [

19]. The maximum value of 15.73 kWh/PE/year determined for the full water treatment process in Bega MWTS (WTS2 + WTS4) was lower than the reference values specified in the literature. It can be concluded based on the specific indicators determined above that the energy consumption in Bega MWTS is in line with the international recommendations for large WTSs.

An in-depth analysis of the pumping process in TSP1 performed in 2019 led to the identification of limitations in the operation of the pumping units. A new operating strategy for TP1 pumping units was implemented in September 2020. The improvements in the reduced operating and maintenance costs due to the new operating strategy were quantified in 2021. The next section presents the two operating strategies (old and new) of the pumping units installed in TSP1.

5. Conclusions

The paper focuses on the issues associated with the drinking-water infrastructure of large cities. The key elements of the water infrastructure corresponding to the drinking-water supply system and water treatment stations (MWTSs) of Timisoara city are presented. The Bega municipal water treatment station (MWTS) is considered as a case study for our investigation. The main components of the water treatment process included in the Bega MWTS are shown.

Two specific energy consumption indicators (ECIs) associated with water treatment processes from the Bega MWTS are determined. Both the ECIm3 and ECIPE indicators are determined for the Bega MWTS from 2016 to 2021, covering the pandemic period. The ECIm3 indicator corresponded to a range of 0.154 kWh/m3 to 0.166 kWh/m3 over the six years taken into account for the full process of the Bega MWTS. The maximum value of the ECIm3 specific energy consumption indicator for Bega MWTS corresponded to the reference value for water treatment plants with population equivalents larger than 100,000 available in Europe (e.g., Italy, Germany, Scandinavian countries).

It has been identified, based on recorded data from the Bega MWTS, that 83% of the energy consumption corresponds to the pumping activities (50% of the energy is consumed in the water distribution pumping process and 33% of the energy consumption is associated with the pumping process in TSP1). As a result, the ECIm3 indicator associated with the energy consumption in the pumping process in TSP1 is improved up to 2% in the last three years. The ECIPE indicator corresponding to the pumping units installed in TSP1 showed an improvement in 2021 of over 3% compared to 2019. This slight reduction in energy consumption was also due to the implementation of the new operating strategy of the pumping units installed in TSP1.

The number of hours in service for each pumping unit and the total time for all pumping units were examined for the last six years. It was determined that the cumulative operating time per year for all pumping units, computed as a percentage from total available time, has increased from 41.2% to 49.2%. It is emphasized that this 8% represents the increase in the number of operating hours in the last six years of the pumps installed in TSP1. The mean operating time over the last six years for all pumping units installed in TSP1 is 44%. This percentage value of 44% is slightly lower than the 50% taken into account at the design stage. It is noticed that there has been an increasing trend in drinking-water consumption since May 2020 due to the SARS-CoV-2 pandemic.

The layout of the TPS1 has been detailed, and its contribution to the Bega MWTS has been highlighted. A technical solution with four pumping units (two VSPUs and two CSPUs) is implemented in TPS1. This old operating strategy, labeled scenario no. 1, has been implemented in TSP1 since 2011. This operating procedure involves only one group in service, while the second group is in reserve. The selection of pumping operation in TPS1 implies that the butterfly valve (BV1) located between pumping groups G1 and G2 is always open and both water treatment plants (WTS2 + WTS4) are supplied by a single pumping group (with one or two pumping units). The failure incidents of the pumping units counted in service were enumerated and correlated with operating conditions. The main drawback of this operating scenario, identified over time, is the high maintenance and repair cost of the pumping units. It was identified that the high maintenance and repair costs of the pump units in this scenario are associated with their operation beyond the limit set by the manufacturer.

A new operating strategy, labeled scenario no. 2, was developed based on in situ investigations conducted in 2019. The new operating strategy was implemented in TSP1 in September 2020 to better adapt to in situ operating conditions, improving the specific power consumption as well as diminishing the failure incidents. The new operating strategy for TSP1 pumping units involves operation with the butterfly valve (BV1) closed. As a result, the pumping group G1 serves the WTS4 and the pumping group G2 supplies water to the WTS2. One pumping unit corresponding to the G1 pumping group operates with variable-speed drive to supply water to WTS4 and one pumping unit with variable-speed drive is available in the G2 pumping group to deliver water to WTS2. Each pumping unit independently adjusts its volumetric flow rate according to the requirements of each water treatment station it supplies. One pumping unit from each pumping group is in reserve in scenario no. 2. The energy losses from adjusting the butterfly valves in scenario no. 1 are not found in scenario no. 2. Therefore, it is expected that part of this energy recovered through the implementation of scenario no. 2 in TSP1 is found in the improved values of the specific energy consumption indicators (ECIm3 and ECIPE) for 2021. It is certain that the operating and maintenance costs due to failure incidents in the operation of the pumping units were decreased, as no incidents were reported in 2021. The lessons learned in this case study are useful for other cases in the water sector.

The AQUATIM Company operates a fleet of hundreds of hydraulic pumping units that cover a quite wide range of powers, from a few kilowatts to megawatts, installed in dozens of water treatment stations. Further work will focus on investigating the operating conditions of pumping systems available in the water treatment plants administrated by AQUATIM in order to reduce operating and maintenance costs using the lessons learned in this case study.