A Tree-Planting Vehicle for Promoting the Sustainable Development of Desert Greening

Abstract

:1. Introduction

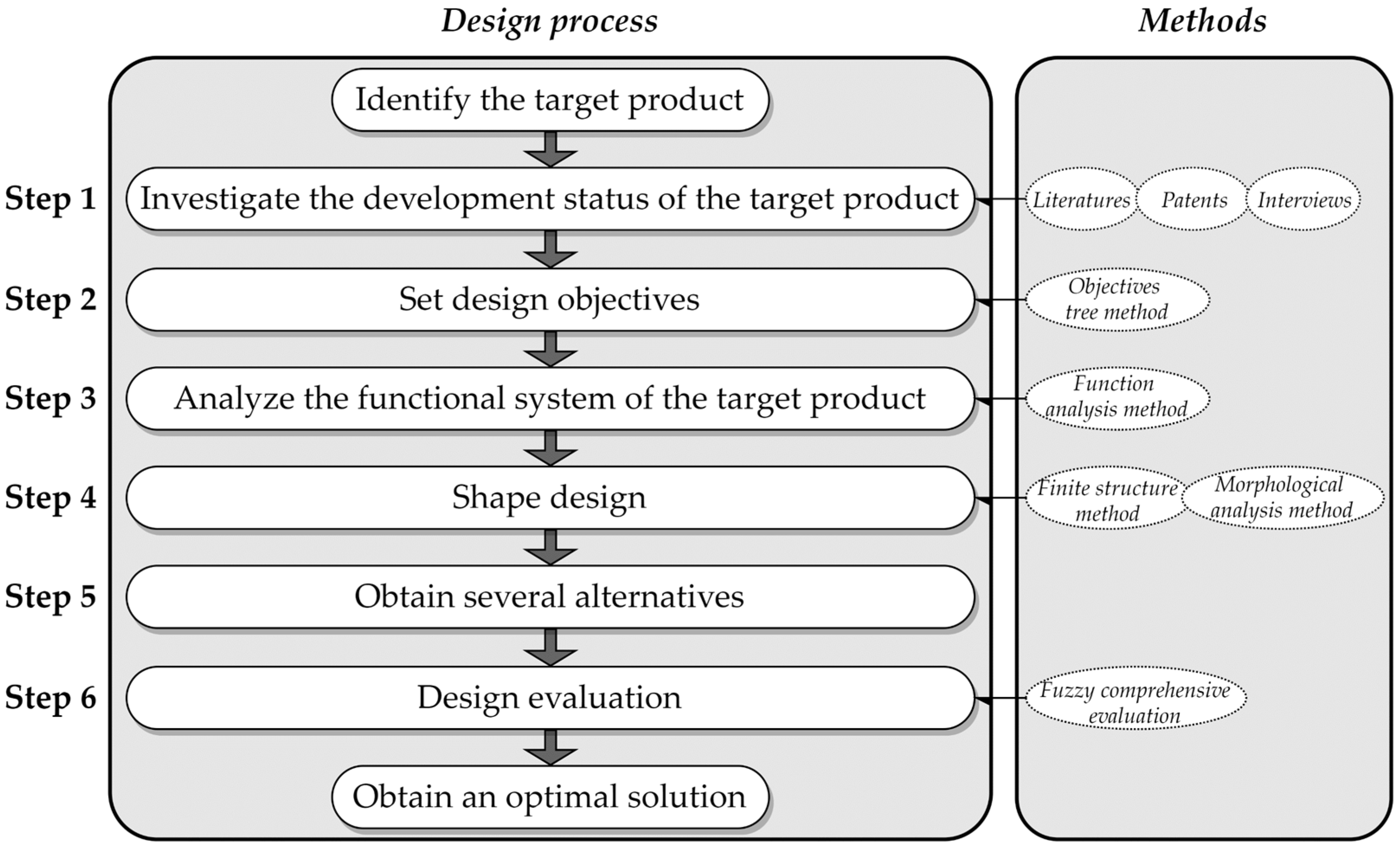

2. Theoretical Foundations and Methods

2.1. Objectives Tree Method

- List the design objectives through investigations, interviews, and discussions and expand the design objectives as much as possible;

- According to the primary and secondary relationship between the design objectives, all design objectives are grouped;

- Draw an objective tree diagram to present the relationship between design targets.

2.2. Function Analysis Method

- Define the functional system of the target product based on “input” and “output” (i.e., black box);

- Decompose the overall function of the target product into a series of necessary secondary functions;

- In the “black box”, from left to right, use a block diagram to represent the relationship between secondary functions;

- Plan out several reasonable functional system boundaries;

- Search for appropriate elements to realize the association between secondary functions.

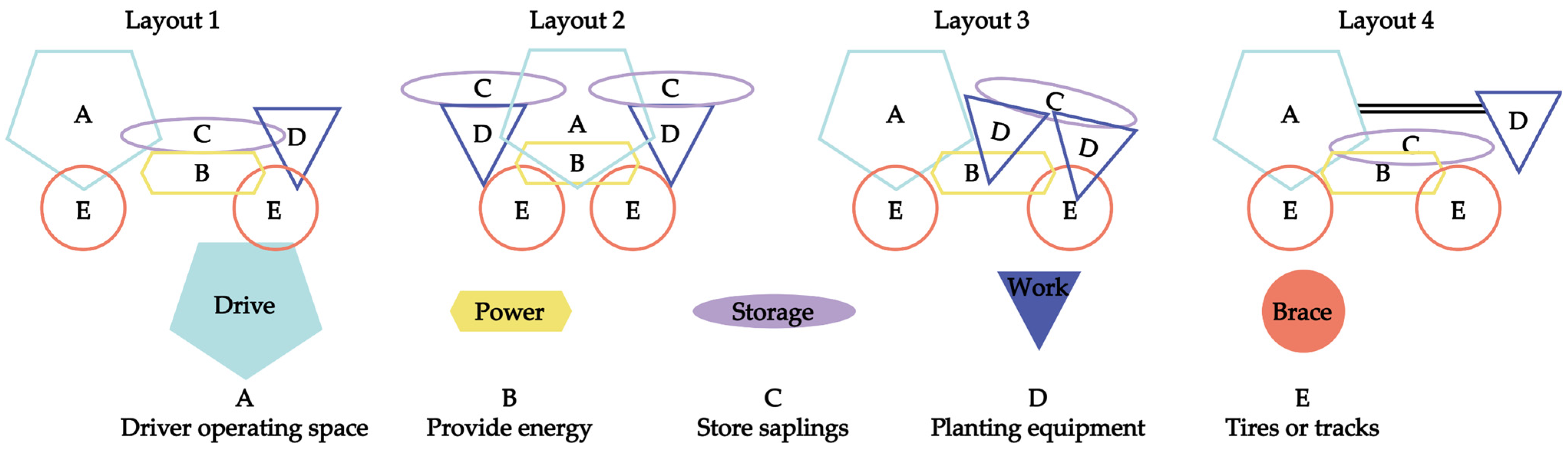

2.3. Finite Structure Method (FSM)

- Determine the primary functions of the target product;

- Disassemble the primary function into a combination of several secondary functional units;

- Use geometric figures to represent secondary functional units and analyze various possible layouts in two-dimensional space;

- Reflect on the feasibility of various layouts according to the design objectives and then obtain several reasonable spatial layouts.

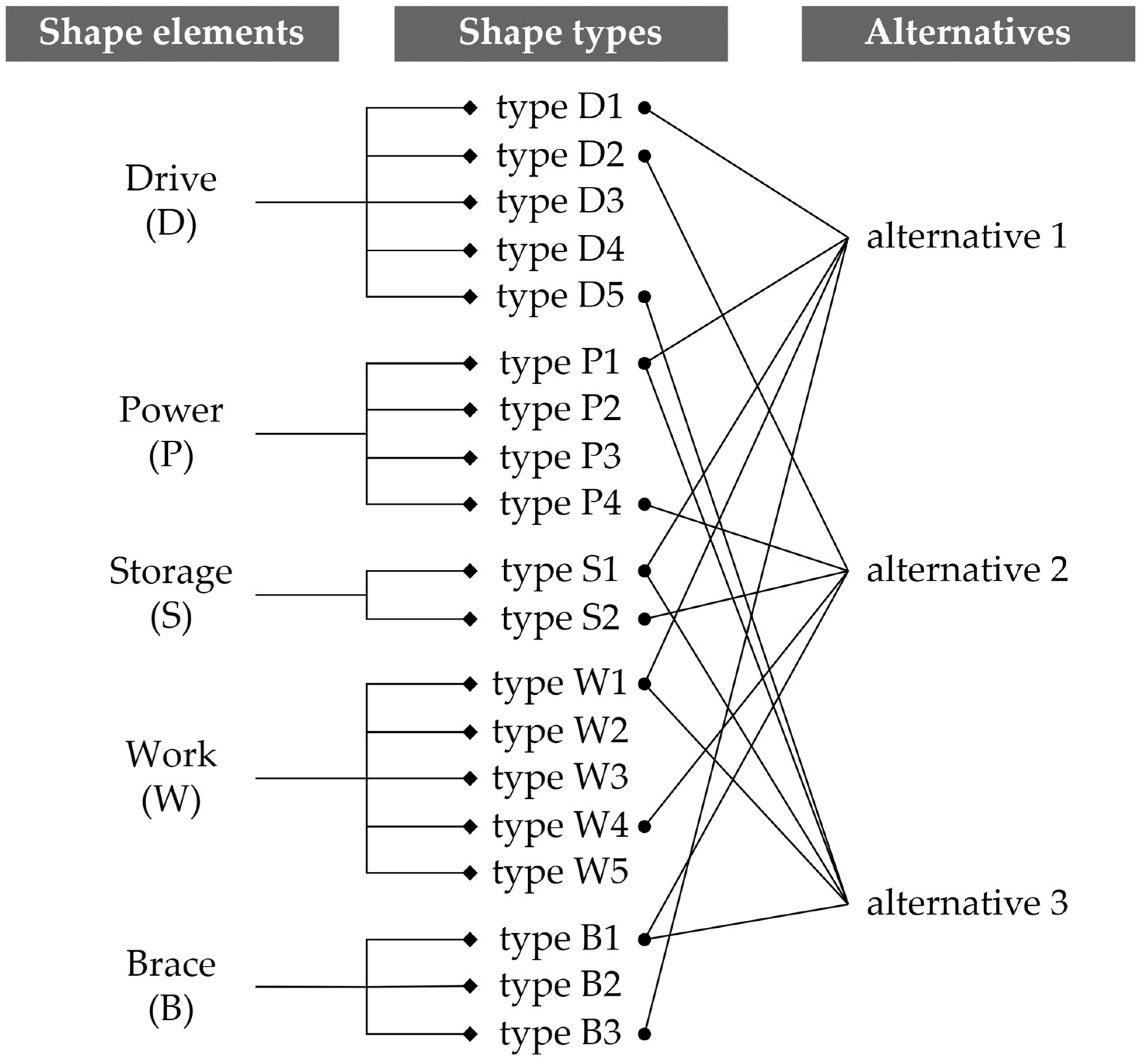

2.4. Morphological Analysis Method

- List the shape elements of the target product;

- Present various types of each shape element;

- Establish a morphological chart;

- Obtain several alternatives through rational screening.

2.5. Fuzzy Comprehensive Evaluation

- (1)

- Establish a factor set:

- (2)

- Establish a weight set:

- (3)

- Establish an evaluation set:

- (4)

- Single-factor fuzzy evaluation:

- (5)

- Fuzzy comprehensive evaluation:

3. Empirical Study

3.1. Step 1: Gather Information about the Tree-Planting Vehicle

3.2. Step 2: Clarify the Design Objectives of the Desert Tree-Planting Vehicle

3.3. Step 3: Analyze the Functional System of the Desert Tree-Planting Vehicle

3.4. Step 4: Deduce the Shape of the Desert Tree-Planting Vehicle

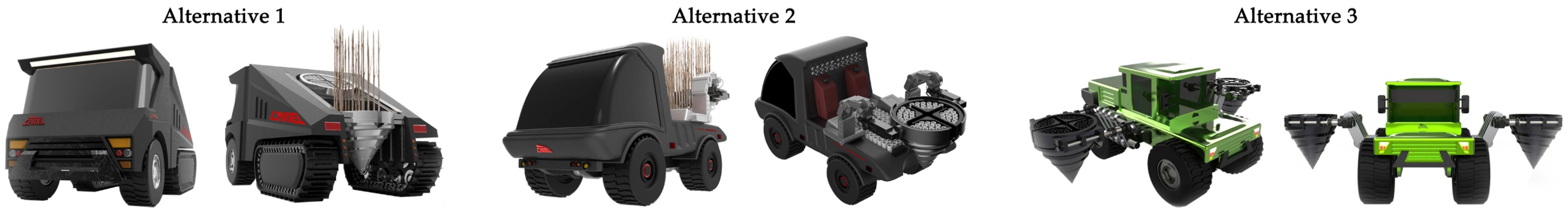

3.5. Step 5: Generate Several Alternatives

3.6. Step 6: Design Evaluation of Several Alternatives

3.6.1. Establish the Factor Set of the Desert Tree-Planting Vehicle

3.6.2. Establish the Weight Set of the Desert Tree-Planting Vehicle

3.6.3. Establish an Evaluation Set for the Desert Tree-Planting Vehicle

3.6.4. Single-Factor Fuzzy Evaluation for the Desert Tree-Planting Vehicle

3.6.5. Fuzzy Comprehensive Evaluation for the Desert Tree-Planting Vehicle

4. Results and Discussion

- Since the storage unit and the work unit are independent of each other, the storage unit could store more saplings, saving time when transporting and replenishing saplings;

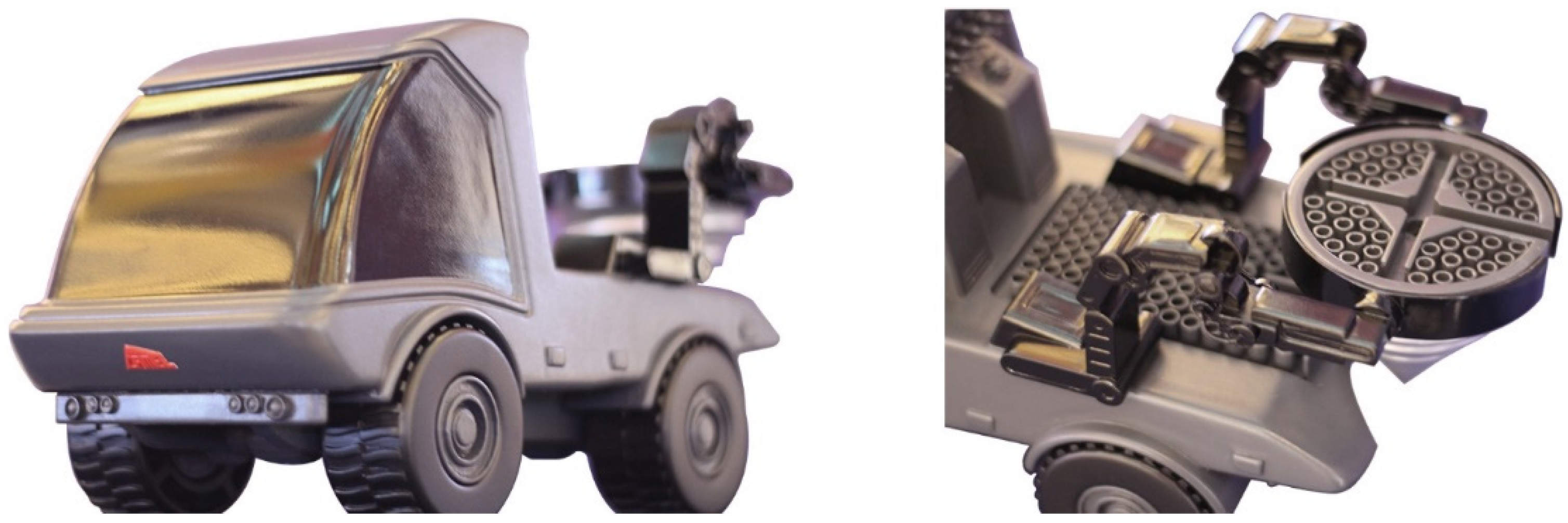

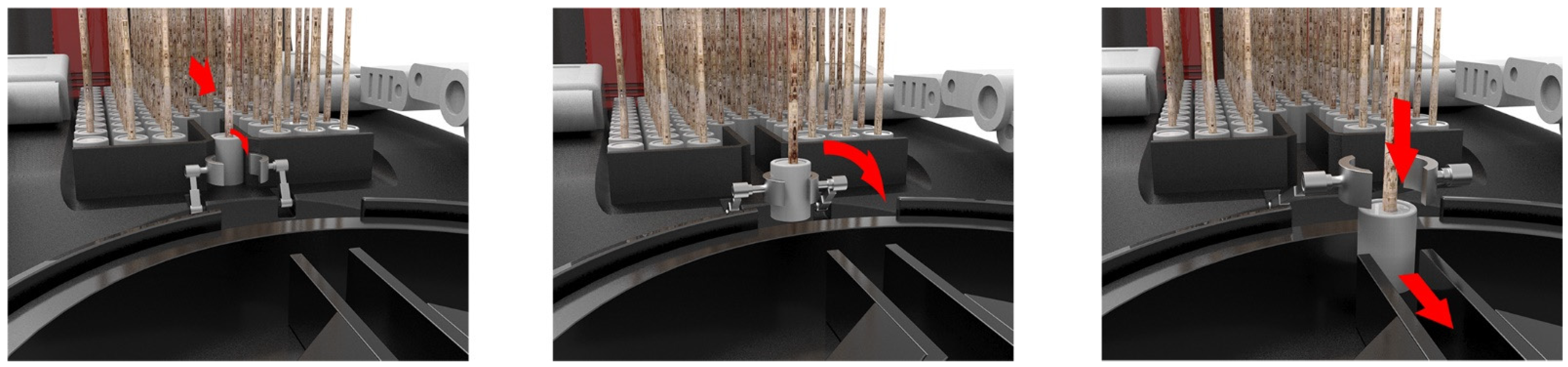

- The storage unit adopts an integrated storage method for storing saplings (see Table 1). This method can not only carry more saplings at one time, but also, the saplings can be transferred from the storage unit to the work unit through the automatic transfer system. The detailed transfer process is shown in Figure 9;

- The drive unit adopts a round-head cockpit. In contrast to other cockpits, the round cockpit has a rounded shape, and there are no extra recessed edges to collect dust.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Paola, F.; Ducci, D.; Giugni, M. Desertification and erosion sensitivity. A case study in southern Italy: The Tusciano River catchment. Environ. Earth Sci. 2013, 70, 2179–2190. [Google Scholar] [CrossRef]

- Fernández, R.J. Do humans create deserts? Trends Ecol. Evol. 2002, 17, 6–7. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Deserts and Drylands. Tunza 2006, 4, 24. [Google Scholar]

- Chang, I.; Prasidhi, A.K.; Im, J.; Shin, H.D.; Cho, G.C. Soil treatment using microbial biopolymers for anti–desertification purposes. Geoderma 2015, 253, 39–47. [Google Scholar] [CrossRef]

- Mainguet, M. What is Desertification? Definitions and Evolution of the Concept, Desertification Natural Background and Human Mismanagement; Springer Press: Berlin, Germany, 1994. [Google Scholar]

- McDonald, M. Interactions of desertification and climate. Eos. Trans. AGU 1996, 77, 379. [Google Scholar] [CrossRef]

- Prince, S.D. Spatial and temporal scales for detection of desertification. In Global Desertification: Do Humans Cause Deserts? Reynolds, J.F., StaffordSmith, D.M., Eds.; Dahlem University Press: Berlin, Germany, 2002; pp. 23–40. [Google Scholar]

- Wang, W. When Maowusu became a desert?—View through new archaeological finds. Archaeol. Cult. Relics. 2002, 22, 80–85. [Google Scholar]

- Wang, T. Progress in sandy desertification research of China. J. Geogr. Sci. 2004, 14, 387–400. [Google Scholar] [CrossRef]

- Dawelbait, M.; Morari, F. Monitoring desertification in a Savannah region in Sudan using Landsat images and spectral mixture analysis. J. Arid. Environ. 2012, 80, 45–55. [Google Scholar] [CrossRef]

- D′Odorico, P.; Bhattachan, A.; Davis, K.F.; Ravi, S.; Runyan, C.W. Global desertification: Drivers and feedbacks. Adv. Water. Res. 2013, 51, 326–344. [Google Scholar] [CrossRef]

- Zhang, F.; Tiyip, T.; Johnson, V.C.; Kung, H.; Ding, J.; Zhou, M.; Fan, Y.; Kelimu, A.; Nurmuhammat, I. Evaluation of land desertification from 1990 to 2010 and its causes in Ebinur Lake region, Xinjiang China. Environ. Earth Sci. 2015, 73, 5731–5745. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, D.; Peng, D.; Zhang, Y. Quantifying the influences of natural and human factors on the water footprint of afforestation in desert regions of northern China. Sci. Total Environ. 2021, 780, 146577. [Google Scholar] [CrossRef] [PubMed]

- Tuo, F.; Gao, B.B.; Dong, Z.B. Technological Breakthrough for the Afforestation of Populus euphratica in the Mu Us Desert in China. Sustainability 2021, 13, 13900. [Google Scholar] [CrossRef]

- Tervonen, T.; Sepehr, A.; Kadziński, M. A multi-criteria inference approach for anti-desertification management. J. Environ. Manag. 2015, 162, 9–19. [Google Scholar] [CrossRef] [PubMed]

- Keram, A.; Halik, Ü.; Keyimu, M.; Aishan, T.; Mamat, Z.; Rouzi, A. Gap dynamics of natural Populus euphratica floodplain forests affected by hydrological alteration along the Tarim River: Implications for restoration of the riparian forests. For. Ecol. Manag. 2019, 438, 103–113. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Z.; Sun, G.; Chen, L.; Xu, H.; Chen, S. Biophysical controls on nocturnal sap flow in plantation forests in a semi–arid region of northern China. Agr. For. Meteorol. 2020, 284, 107904. [Google Scholar] [CrossRef]

- Ferreira, C.S.; Seifollahi–Aghmiuni, S.; Destouni, G.; Ghajarnia, N.; Kalantari, Z. Soil degradation in the European Mediterranean region: Processes, status and consequences. Sci. Total Environ. 2022, 805, 150106. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Zhu, J.; Yan, W.; Zhao, C. Projections of desertification trends in Central Asia under global warming scenarios. Sci. Total Environ. 2021, 781, 146777. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, W.; Wang, G.; Yang, S.; Pereira, P. Effects of long–term afforestation and natural grassland recovery on soil properties and quality in Loess Plateau (China). Sci. Total Environ. 2021, 770, 144833. [Google Scholar] [CrossRef]

- Zeng, F.J.; Zhang, W.J.; Liu, G.J.; Zhang, D.Y.; Li, X.Y.; Zhang, L.; Yuan, L.; Zhang, X. Stable restoration pattern and sustainable management technology of main dominant vegetation in typical desert areas of china. Bull. Chin. Acad. Sci. 2020, 6, 709–716. [Google Scholar] [CrossRef]

- Khamzina, A.; Lamers, J.; Martius, C. Above–and belowground litter stocks and decay at a multi–species afforestation site on arid, saline soil. Nutr. Cycl. Agroecosyst. 2016, 104, 187–199. [Google Scholar] [CrossRef]

- Zhou, J.W.; Liu, Y.Q.; Jie, J.X. Research on the use of modified "desert tree planter" to bury sand–proof columns. Highway 2017, 12, 57–59. [Google Scholar]

- Castro, J.; Leverkus, A.B.; Fuster, F. A new device to foster oak forest restoration via seed sowing. New For. 2015, 46, 919–929. [Google Scholar] [CrossRef]

- Guan, J.Z. Gobi desert tree–planting robot design. World For. Res. 2021, 34, 142. [Google Scholar]

- Dugdale, S.J.; Malcolm, I.A.; Hannah, D.M. Drone-based Structure-from-Motion provides accurate forest canopy data to assess shading effects in river temperature models. Sci. Total Environ. 2019, 678, 326–340. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D. A Tree Planter. C.H.N. Patent CN202496204U, 15 March 2012. [Google Scholar]

- Jia, C.Y. An Improved Tree Planting Vehicle. C.H.N. Patent CN105475087B, 14 July 2018. [Google Scholar]

- Xu, Y.D.; Zhao, Z.Y.; Xu, D.; Zhang, H.F.; Chou, S.; Wu, Y.X.; Zhao, Y.; Xu, M.H. A Tree Planting Device Suitable for Desert and Dry Sandy Land. C.H.N. Patent CN105794588B, 26 February 2019. [Google Scholar]

- Cross, N. Engineering Design Methods: Strategies for Product Design, 3rd ed.; John Wiley & Sons Press: New York, NY, USA, 1994. [Google Scholar]

- Lu, P.; Li, Z.; Li, J.; Hsiao, S.W. A consumer–oriented design thinking model for product design education. Interact. Learn. Environ. 2021, 1–19. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, P. Research on product modeling design program based on finite structure method. In Proceedings of the International Joint Conference on Information, Media and Engineering, Osaka, Japan, 17–19 December 2019; pp. 311–315. [Google Scholar]

- Zwicky, F. Morphological astronomy. Observatory 1948, 68, 121–143. [Google Scholar]

- Lu, P.; Hsiao, S.W.; Wu, F. A product shape design and evaluation model based on morphology preference and macroscopic shape information. Entropy 2021, 23, 639. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.J.; Fu, Y.T.; Korvenmaa, P. A preliminary study of perceptual matching for the evaluation of beverage bottle design. Int. J. Ind. Ergon. 2012, 42, 219–232. [Google Scholar] [CrossRef]

- Chang, C.C.; Wu, J.C. The underlying factors dominating categorical perception of product form of mobile phones. Int. J. Ind. Ergon. 2009, 39, 667–680. [Google Scholar] [CrossRef]

- Chuang, M.C.; Ma, Y.C. Expressing the expected product images in product design of micro–electronic products. Int. J. Ind. Ergon. 2001, 27, 233–245. [Google Scholar] [CrossRef] [Green Version]

- Tian, Q.M. The result analysis of fuzzy comprehensive evaluation. J. Dalian Fish. Coll. 1990, 5, 61–65. [Google Scholar]

- Cheng, H.; Zhu, L.; Meng, J. Fuzzy evaluation of the ecological security of land resources in mainland China based on the Pressure–State–Response framework. Sci. Total Environ. 2022, 804, 150053. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Xu, K.; Lian, J.; Bin, L.; Ma, C. Multiple flood vulnerability assessment approach based on fuzzy comprehensive evaluation method and coordinated development degree model. J. Environ. Manag. 2018, 213, 440–450. [Google Scholar] [CrossRef]

- Zheng, Z.; Mo, J.; Xu, Y. Research on public fitness equipment experience based on satisfaction. Healthcare 2021, 9, 501. [Google Scholar] [CrossRef]

- Hsiao, S.W.; Ko, Y.C. A study on bicycle appearance preference by using FCE and FAHP. Int. J. Ind. Ergon. 2013, 43, 264–273. [Google Scholar] [CrossRef]

| Sub-Functions | Type 1 | Type 2 | Type 3 | Type 4 | Type 5 |

|---|---|---|---|---|---|

| Drive (D) |  (D1) Wrapped Cockpit |  (D2) Round head cockpit |  (D3) Flat-headed cockpit |  (D4) Reversible cockpit |  (D5) Extended cockpit |

| Power (P) |  (P1) Fuel oil |  (P2) Solar energy |  (P3) Electric energy |  (P4) Hybrid energy | |

| Storage (S) |  (S1) Separate storage |  (S2) Integrated storage | |||

| Work (W) |  (W1) Traditional drill |  (W2) Mechanical arm drill |  (W3) Retractable drill |  (W4) Split drill |  (W5) Flat drill |

| Brace (B) |  (B1) Traditional round wheel |  (B2) Triangular track |  (B3) Rounded rectangular track |

| Level 2 Evaluation Factors | Weight (W) | Evaluation Scores | ||

|---|---|---|---|---|

| Alternative 1 | Alternative 2 | Alternative 3 | ||

| Storage capacity | 0.54 | 0.285 | 0.885 | 0.465 |

| Planting speed | 0.46 | 0.240 | 0.285 | 0.840 |

| Degree of difficulty of replacement | 0.49 | 0.420 | 0.570 | 0.330 |

| Rationality of structure | 0.51 | 0.285 | 0.465 | 0.285 |

| Inclusiveness of operation errors | 0.31 | 0.285 | 0.420 | 0.420 |

| Sand-prevention performance | 0.36 | 0.615 | 0.375 | 0.420 |

| Heat-shielding performance | 0.33 | 0.375 | 0.330 | 0.420 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, P.; Wu, F.; Lin, Y.-C. A Tree-Planting Vehicle for Promoting the Sustainable Development of Desert Greening. Sustainability 2022, 14, 9171. https://doi.org/10.3390/su14159171

Lu P, Wu F, Lin Y-C. A Tree-Planting Vehicle for Promoting the Sustainable Development of Desert Greening. Sustainability. 2022; 14(15):9171. https://doi.org/10.3390/su14159171

Chicago/Turabian StyleLu, Peng, Fan Wu, and Yang-Cheng Lin. 2022. "A Tree-Planting Vehicle for Promoting the Sustainable Development of Desert Greening" Sustainability 14, no. 15: 9171. https://doi.org/10.3390/su14159171

APA StyleLu, P., Wu, F., & Lin, Y.-C. (2022). A Tree-Planting Vehicle for Promoting the Sustainable Development of Desert Greening. Sustainability, 14(15), 9171. https://doi.org/10.3390/su14159171