Research on Mine Water Dispatching Mode Based on Maximization of Reuse Rate

Abstract

:1. Introduction

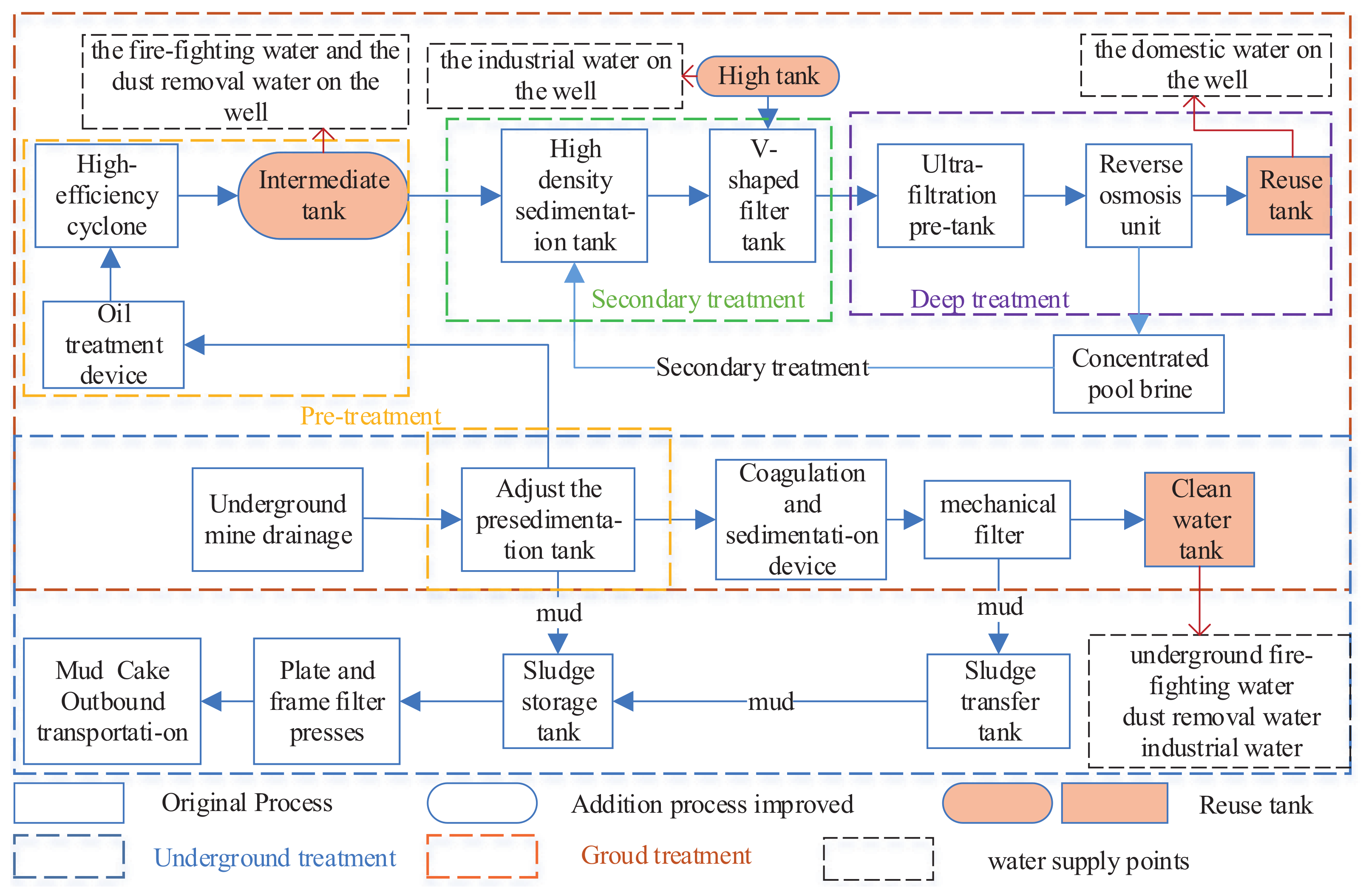

2. Mine Water Level Fractionation Utilization Pathway

2.1. Normal Water Supply Situation

2.2. Irregular Water Supply Situation

2.2.1. The Fire-Fighting Incidents on the Well Lead to Increased Water Consumption for the Fire-Fighting Water on the Well

2.2.2. Increased Water Consumption for Water Used for Dust Removal Underground and on the Well in the Non-Heating Season Compared to the Heating Season

2.2.3. Increased Production during the Transition Period from Non-Heating to Heating Season

3. Mine Water Dispatching Model

3.1. Proximity Utilization Dispatching Model

3.2. Dispatching Mode for the Industrial Chain of the Park

3.3. Dispatching Model to Achieve the Standard External Discharge

4. Na Lin River No. 2 Mine Water Supply Dispatching Model

4.1. Water Demand Model for Mining Sites

4.2. Dispatching Model for Reuse of Mine Water

4.3. Objective Function

4.4. Binding Conditions

5. Mine Water Dispatching Scheme and Model Analysis

5.1. Mine Water Dispatching and the Relationship with Spatial and Temporal Variation

5.2. Experimental and Test Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yajun, S.; Li, Z.; Zhimin, X.; Ge, C.; Xianming, Z.; Xin, L.; Yating, G.; Shangguo, Z.; Lulu, Z. Multi-field action mechanism and research progress of coal minewater quality formation and evolution. J. China Coal Soc. 2022, 47, 15. [Google Scholar]

- Guoxun, J.; Ruiqi, Q. Analysis on the Characteristics of Correlative Factors in Coal Mine Water Disasters from 2011 to 2020. J. Saf. Environ. 2021, 0707, 1–9. [Google Scholar] [CrossRef]

- Yun, Q.; Jun, L. Prediction of coal mine water hazards: A case study from the Huainan Coalfield. Arab. J. Geoences 2019, 12, 1–11. [Google Scholar]

- Weiyue, H.; Gan, T. Mine water disaster type and prevention and control countermeasures in China. Coal Sci. Technol. 2010, 38, 92–96. [Google Scholar]

- Pengcheng, Y.; Songhang, S.; Chaoyin, Z.; Xiaofei, Z. Classification of Coal Mine Water Sources by Improved BP Neural Network Algorithm. Spectrosc. Spectr. Anal. 2021, 41, 2288–2293. [Google Scholar]

- Qiang, W. Progress, problems and prospects of prevention and control technology of minewater and reutilization in China. J. China Coal Soc. 2014, 39, 11. [Google Scholar]

- Qiang, W.; Yi, Y.; Yingwang, Z.; Xiaoyan, Z.; Hua, X.; Yuanze, D.; Zhili, D. Numerical assessment of the water-flow hazard to workers in the water disaster of underground mine. J. Hydroinform. 2021, 23, 1325–1342. [Google Scholar]

- Lei, B.; Yang, L.; Zihang, Z.; Dongxu, Z.; Yiying, W. Research on an Online Monitoring System for Efficient and Accurate Monitoring of Mine Water. IEEE Access 2022, 10, 18743–18756. [Google Scholar]

- Qiang, G.; Xidong, S.; Xiaolong, H.; Jun, G.; Jingfeng, L. Treatment of high salinity mine water and storage of concentrated brine. Coal Eng. 2020, 52, 4. [Google Scholar]

- Wei, X.; Rodak, C.M.; Zhang, S.; Han, Y.; Wolfe, F.A. Mine Drainage Generation and Control Options. Water Environ. Res. 2016, 88, 1409–1432. [Google Scholar]

- Jingxin, S.; Wenping, H.; Hongjun, H.; Chunyan, X. Pollution control of wastewater from the coal chemical industry in China: Environmental management policy and technical standards. Renew. Sustain. Energy Rev. 2021, 143, 110883. [Google Scholar]

- Chao, G.; Huaiying, L.; Zhaorui, M.; Lin, S. Analysis and Application of Coal Mine Wastewater Treatment Process. Coal Eng. 2015, 47, 4. [Google Scholar]

- Xuwen, H.; Dayi, Q.; Yuanbing, T.; Dan, L.; Jing, C. Quality characteristics of mine drainage with high turbidity. Chin. J. Eng. 2008, 30, 844–847. [Google Scholar]

- Dazhao, G.; Ting, L.; Jingfeng, L.; Qiang, G.; Binbin, J.; Wei, B.; Yixiang, B. Current status and prospects of coal mine water treatment technology in China. Coal Sci. Technol. 2021, 49, 11–18. [Google Scholar]

- Siyu, Z.; Hao, W.; Xuwen, H.; Shaoqing, G.; Yu, X.; Yuexi, Z.; Kai, L.; Shipeng, Y. Research progress, problems and prospects of mine water treatment technology and resource utilization in China. Crit. Rev. Environ. Sci. Technol. 2019, 50, 331–383. [Google Scholar]

- Yong, L.; Yajun, S.; Meng, W. Characteristics and Pollution of Mine Water. Clean Coal Technol. 2007, 13, 83–86. [Google Scholar]

- Li, L.; Haixia, L.; Lan, M. The mine water resources and its utilization status in Ningdong coalfield. J. Arid Land Resour. Environ. 2021, 35, 6. [Google Scholar]

- Yabo, W.; Yaojun, H.; Zongjun, G.; Yuanyuan, M.; Jiutan, L. Characteristics and the origins of the main chemical components in mine water in the Xishan mining area, North China. Environ. Earth Sci. 2022, 81, 1–13. [Google Scholar]

- Ruixue, Z.; Pan, W.; Huijun, Y.; Xuexian, L. Hydrogeochemical Characteristics and Quality Assessment of Mine Water in Coalfield Area, Guizhou Province, Southwest China. Bull. Environ. Contam. Toxicol. 2021, 107, 1087–1094. [Google Scholar]

- Xuwen, H.; Jing, Y.; Linan, S.; Fuqin, L.; Xin, W. Problem and countermeasure of mine water resource regeneration in China. J. China Coal Soc. 2008, 33, 4. [Google Scholar]

- National Development and Reform Commission; National Energy Administration. Mine Water Utilization Development Plan; Issued Number 2; Resource Conservation and Environmental Protection Division: Beijing, China, 2013; p. 1.

- Ministry of Ecology and Environment. Action Plan of Prevention and Control of Water Pollution; People’s Publishing House: Beijing, China, 2015.

- Pin, H.; Shule, D.; Yecheng, F.; Yue, Y.; Xuwen, H.; Lei, B.; Zihang, Z. Efficient utilization and intelligent allocation technology of mine water based on underground-surface and classification and quality. Saf. Coal Mines 2021, 52, 9. [Google Scholar]

- Xuwen, H.; Fuqin, L. New Technology and Development Tendency of Mine Water Treatment. Coal Sci. Technol. 2010, 38, 7. [Google Scholar]

- Nan, Z.; Xinwei, G.; Shenhai, N.; Le, B.; Xiaohui, S. Study on Classification of Mine Water Development and Utilization Mode. Yellow River 2021, 43, 5. [Google Scholar]

- Jiawei, Y.; Hongrui, W.; Weijing, Z.; Meng, Z. Current status and prospect of mine water reutilization in China. Water Resour. Prot. 2021, 37, 7. [Google Scholar]

- Xiaoli, L.; Zhiguo, C.; Sushe, C.; Yantang, G. Seepage field analysis and optimal schedule of distributed underground reservoir in mining area. J. China Coal Soc. 2019, 44, 7. [Google Scholar]

- Zihang, Z.; Yang, L.; Lei, B.; Yuangan, Y.; Yiying, W. Economic Optimal Allocation of Mine Water Based on Two-Stage Adaptive Genetic Algorithm and Particle Swarm Optimization. Sensors 2022, 22, 883. [Google Scholar] [CrossRef]

- Maria, A.D. Turning Industrial Residues into Resources: An Environmental Impact Assessment of Goethite Valorization. Engineering 2018, 4, 421–429. [Google Scholar] [CrossRef]

- Dong, L.; Deng, S.; Wang, F. Some developments and new insights for environmental sustainability and disaster control of tailings dam. J. Clean. Prod. 2020, 269, 122270. [Google Scholar] [CrossRef]

- Yang, L.; Zihang, Z.; Lei, B.; Dongxu, Z. Multi-Objective Optimization of a Mine Water Reuse System Based on Improved Particle Swarm Optimization. Sensors 2021, 21, 4114. [Google Scholar]

- Shanshan, Z.; Qiaoling, W.; Haihong, J. Research on zero discharge treatment technology of mine wastewater. Energy Rep. 2022, 8, 275–280. [Google Scholar]

- Deblina, M.; Iqbal, A.; Ashraf, R.M.; Arukula, D. Comprehensive review on wastewater discharged from the coal-related industries—Characteristics and treatment strategies. Water Sci. Technol. 2019, 79, 2023–2035. [Google Scholar]

- Nikolaos, Y.; Alexandros, Y.; Georgios, G.; Vithleem, G. Evaluation of a pilot plant for a secondary treatment of mining effluen. Desalin. Water Treat. 2018, 127, 184–196. [Google Scholar]

- Chunming, H.; Ximeng, S.; Bing, X.; Shuanglin, H. Increase in fluoride concentration in mine water in Shendong mining area, Northwest China: Insights from isotopic and geochemical signatures. Ecotoxicol. Environ. Saf. 2022, 236, 113496. [Google Scholar]

- Zheng, Z.; Guoqing, L.; Xianbo, S.; Xinguo, Z.; Lei, W.; Haijiao, F.; Lin, L. Geochemical controls on the enrichment of fluoride in the mine water of the Shendong mining area, China. Chemosphere 2021, 284, 131388. [Google Scholar] [CrossRef]

- Shenhai, N.; Yuejin, P.; Nan, Z.; Chengyou, X.; Hengli, W. Study on industrial chain mode of coal mine water utilization to industrial zone. China Energy Environ. Prot. 2019, 41, 4. [Google Scholar]

| Water Points | Position | Water Volume (Heating Season) m³/m | Water Volume (Non-Heating Season) m³/m |

|---|---|---|---|

| Underground fire-fighting water | underground | 2880 | 2880 |

| Grouting water | underground | 17,280 | 17,280 |

| Underground dust removal water | underground | 4320 | 8640 |

| Cooling water | underground | 21,600 | 21,600 |

| Hydraulic support water | underground | 3456 | 3456 |

| The dust removal water | underground | 69,120 | 77,760 |

| Fire-fighting water | ground | 2880 | 2880 |

| Coal processing water | ground | 30,240 | 30,240 |

| Heat exchange stations water | ground | 25,920 | 38,880 |

| Cooling water | ground | 21,600 | 21,600 |

| Greening water | ground | 8640 | 8640 |

| Boiler water | ground | 51,840 | 8640 |

| Domestic water | ground | 1728 | 1728 |

| Other Water | ground | 43,200 | 51,840 |

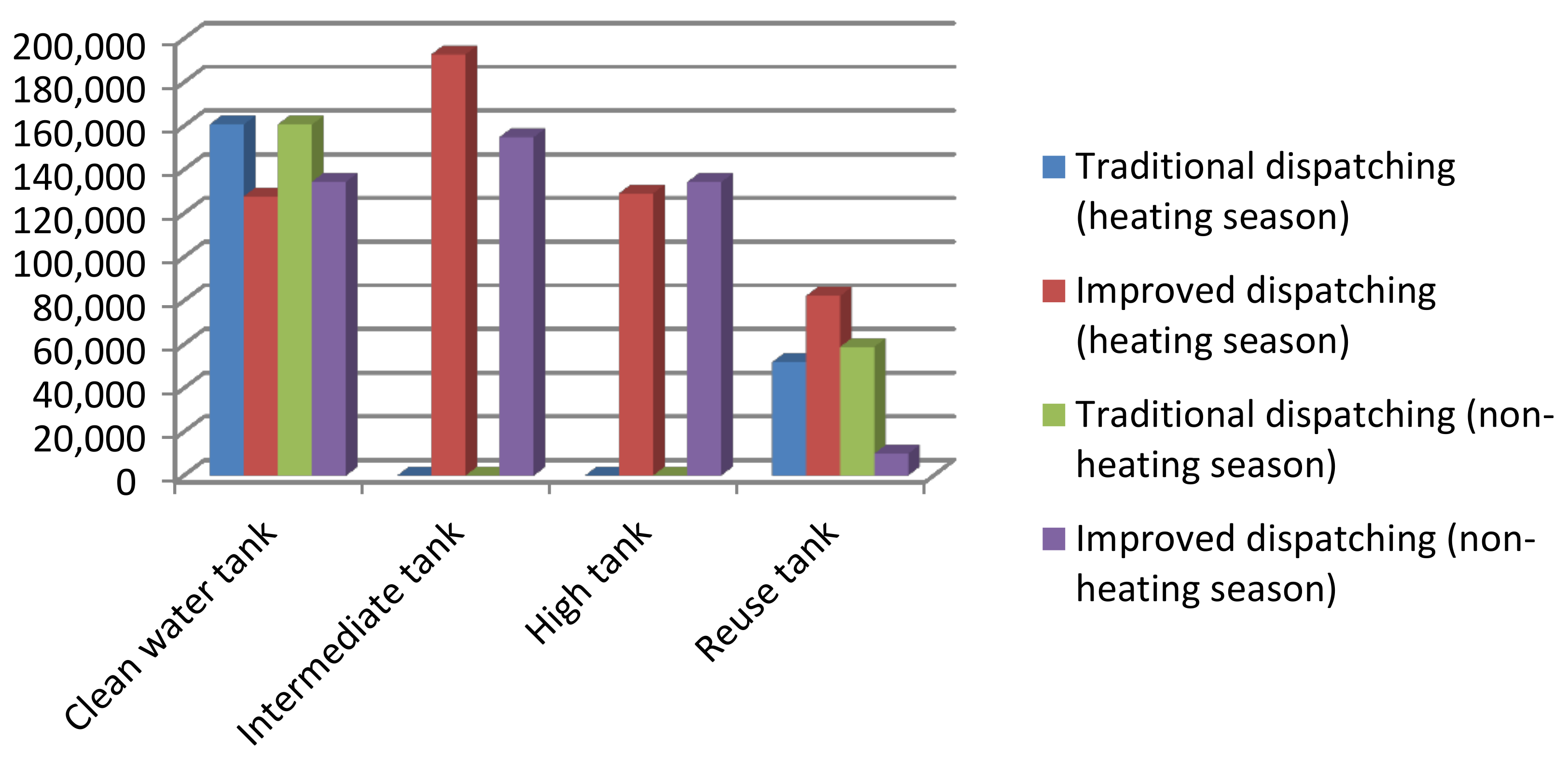

| Dispatching Model | Clean Water Tank | Intermediate Tank | High Tank | Reuse Tank |

|---|---|---|---|---|

| Traditional dispatching (heating season) | 160,700 | - | - | 51,840 |

| Traditional dispatching (non-heating season) | 160,700 | - | - | 58,875 |

| Improved dispatching (heating season) | 127,813.73 | 192,833.33 | 129,157.02 | 82,241.1 |

| Improved dispatching (non-heating season) | 134,530.75 | 154,986.77 | 134,246.52 | 9979.51 |

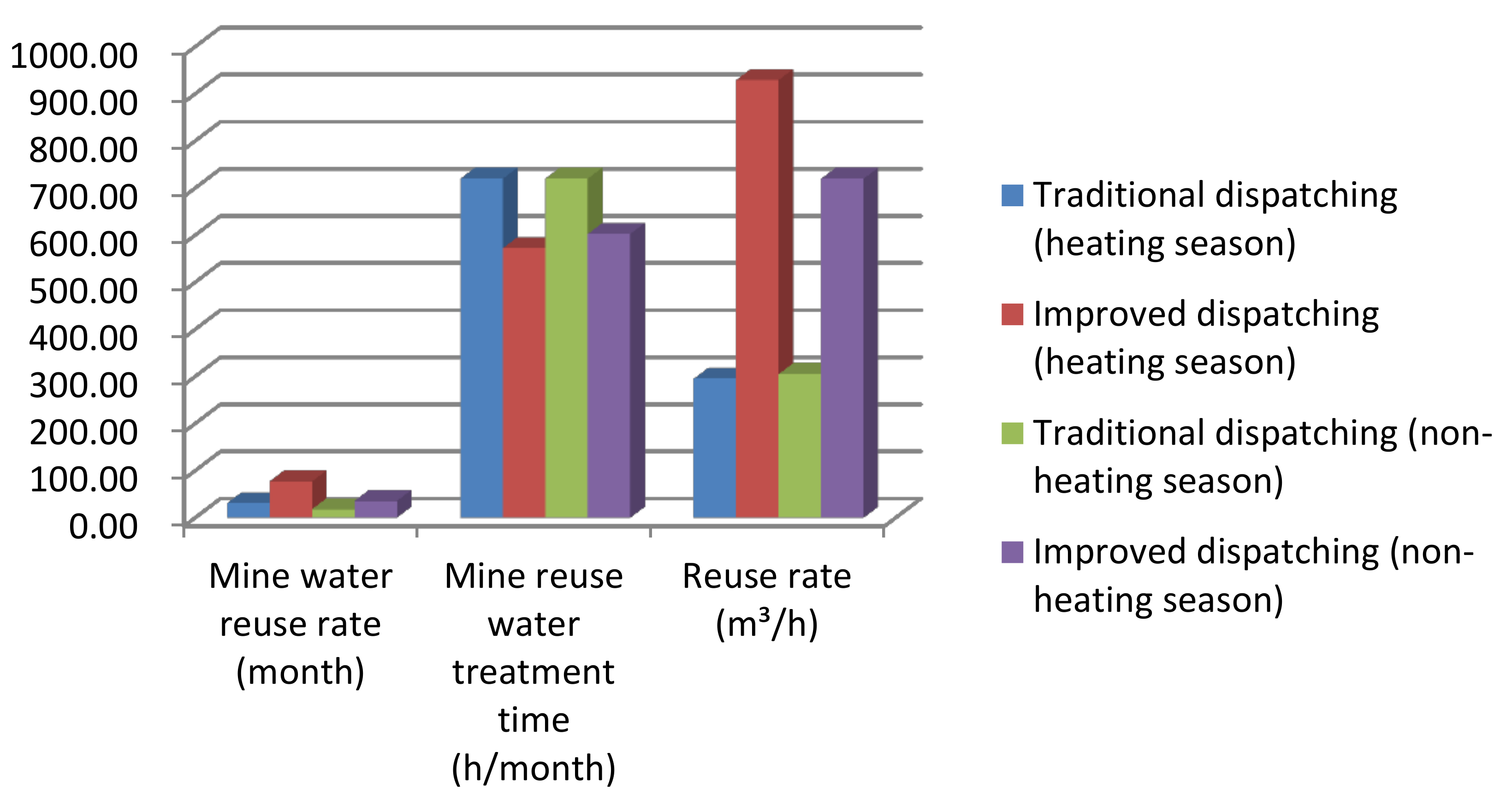

| Dispatching Model | Mine Water Reuse Rate (Month) | Mine Reuse Water Treatment Time | Reuse Rate (m³/h) |

|---|---|---|---|

| Traditional dispatching (heating season) | 30.75% | 720 h | 295.29 |

| Improved dispatching (heating season) | 76.95% | 572.41 h | 929.48 |

| Traditional dispatching (non-heating season) | 17.95% | 720 h | 305.06 |

| Improved dispatching (non-heating season) | 35.45% | 602.49 h | 719.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Liu, P.; Bo, L.; Li, Q.; Quan, G.; Zhuo, Y.; Han, Y.; Wang, Y. Research on Mine Water Dispatching Mode Based on Maximization of Reuse Rate. Sustainability 2022, 14, 9289. https://doi.org/10.3390/su14159289

Liu Y, Liu P, Bo L, Li Q, Quan G, Zhuo Y, Han Y, Wang Y. Research on Mine Water Dispatching Mode Based on Maximization of Reuse Rate. Sustainability. 2022; 14(15):9289. https://doi.org/10.3390/su14159289

Chicago/Turabian StyleLiu, Yang, Ping Liu, Lei Bo, Qingshan Li, Gefei Quan, Yuanjing Zhuo, Yuqi Han, and Yiying Wang. 2022. "Research on Mine Water Dispatching Mode Based on Maximization of Reuse Rate" Sustainability 14, no. 15: 9289. https://doi.org/10.3390/su14159289

APA StyleLiu, Y., Liu, P., Bo, L., Li, Q., Quan, G., Zhuo, Y., Han, Y., & Wang, Y. (2022). Research on Mine Water Dispatching Mode Based on Maximization of Reuse Rate. Sustainability, 14(15), 9289. https://doi.org/10.3390/su14159289