Occupational Risk Assessment for Flight Schools: A 3,4-Quasirung Fuzzy Multi-Criteria Decision Making-Based Approach

Abstract

:1. Introduction

2. Research Background

3. Research Method

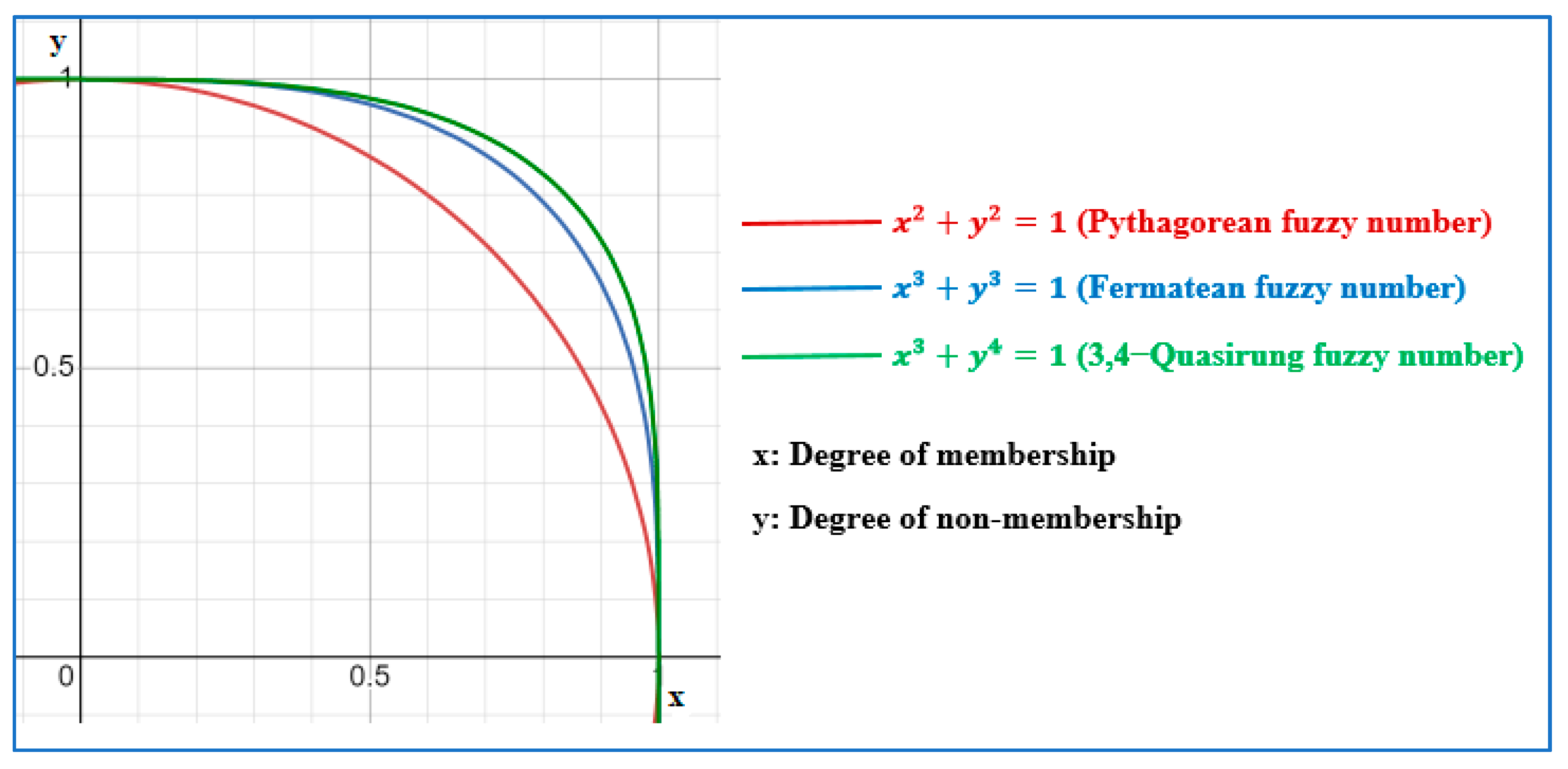

3.1. Preliminaries on 3,4-QFSs

3.2. Development of 3,4-QF MCDM-Based Occupational Risk Assessment Model

- If provides maximum value for one particular hazard, then this hazard has the highest priority and is the most serious/riskiest.

- If provides maximum value for more than one particular hazard, then the most serious/riskiest hazard is one which has the highest value.

- If the values are equal for two or more than two hazards, the decision maker is free to select one of them. Both are possible and have the same priority orders.

4. Method Implementation and Results

4.1. Case Study Description

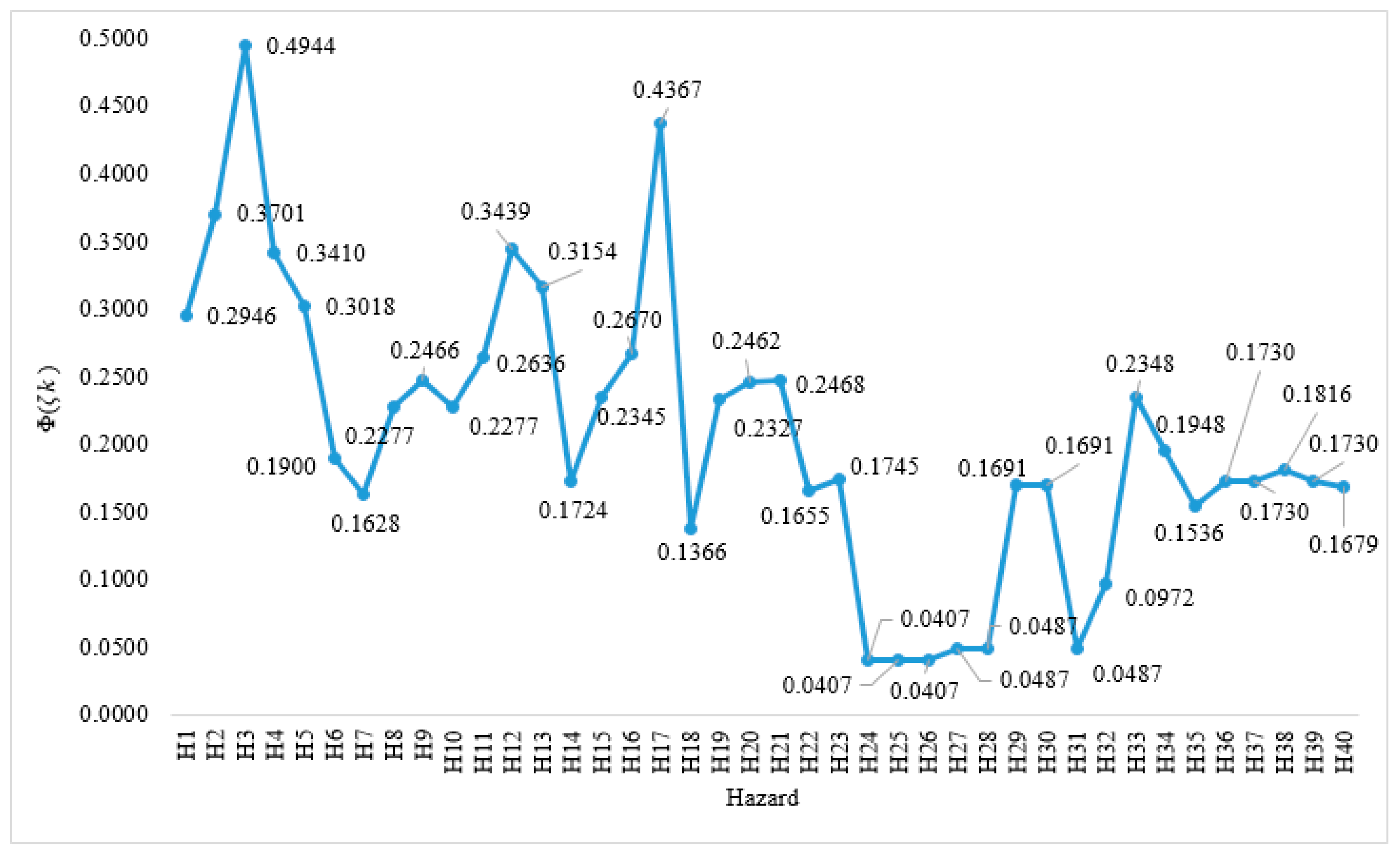

4.2. Results of 3,4-QF MCDM-Based Occupational Risk Assessment Model

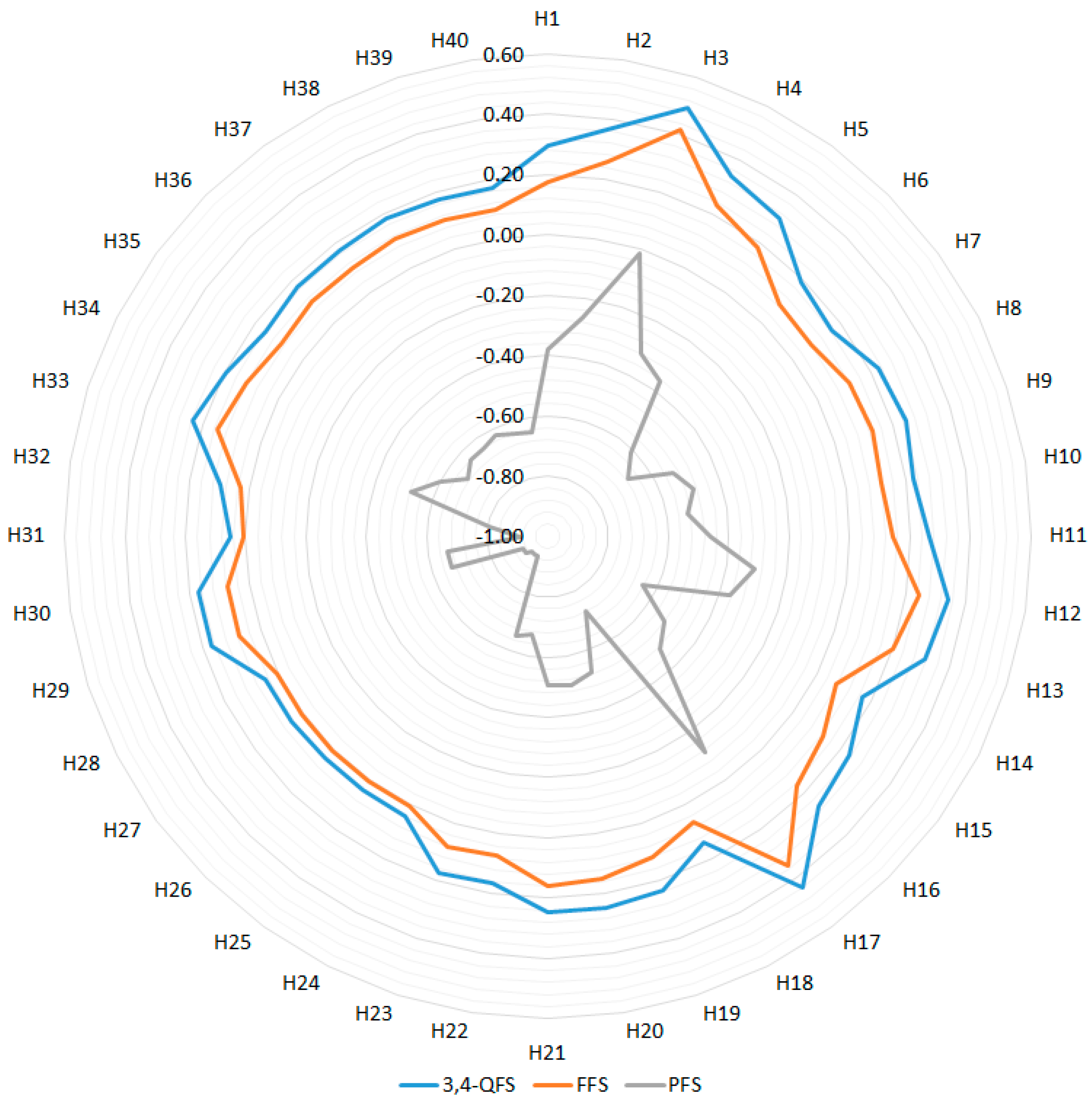

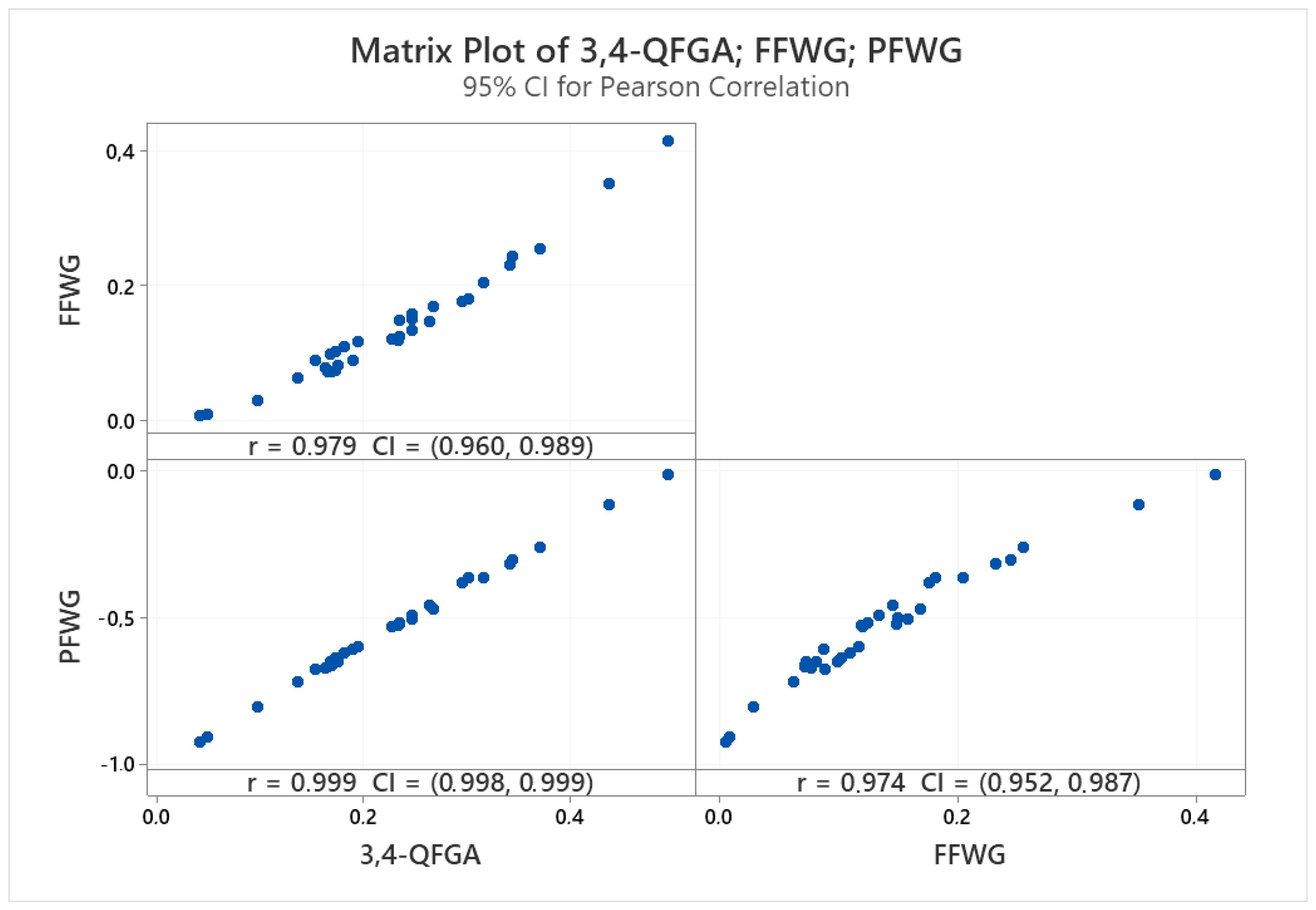

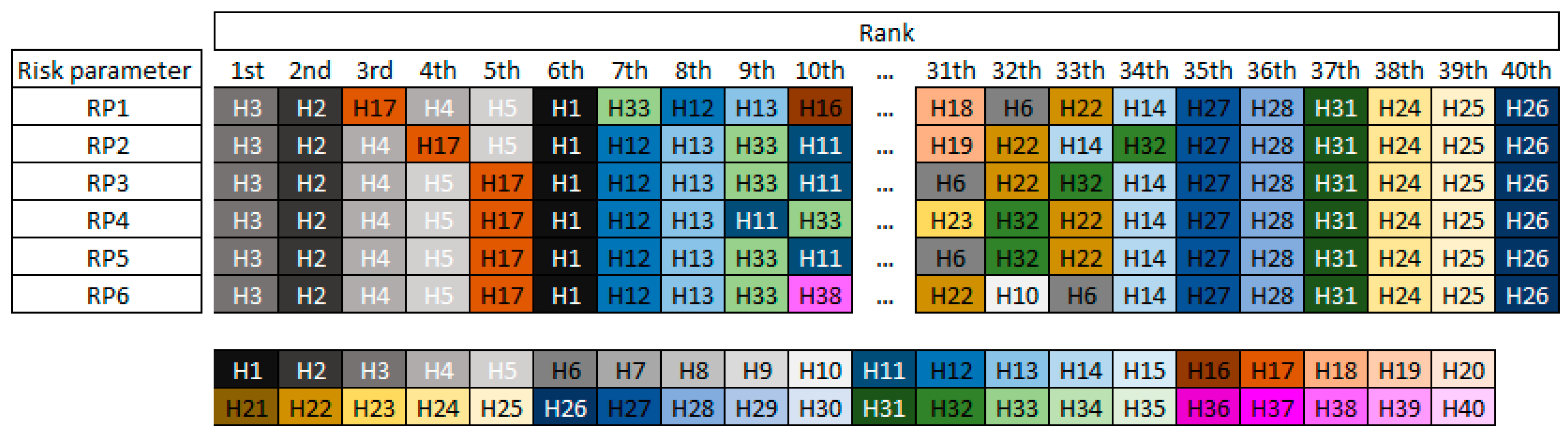

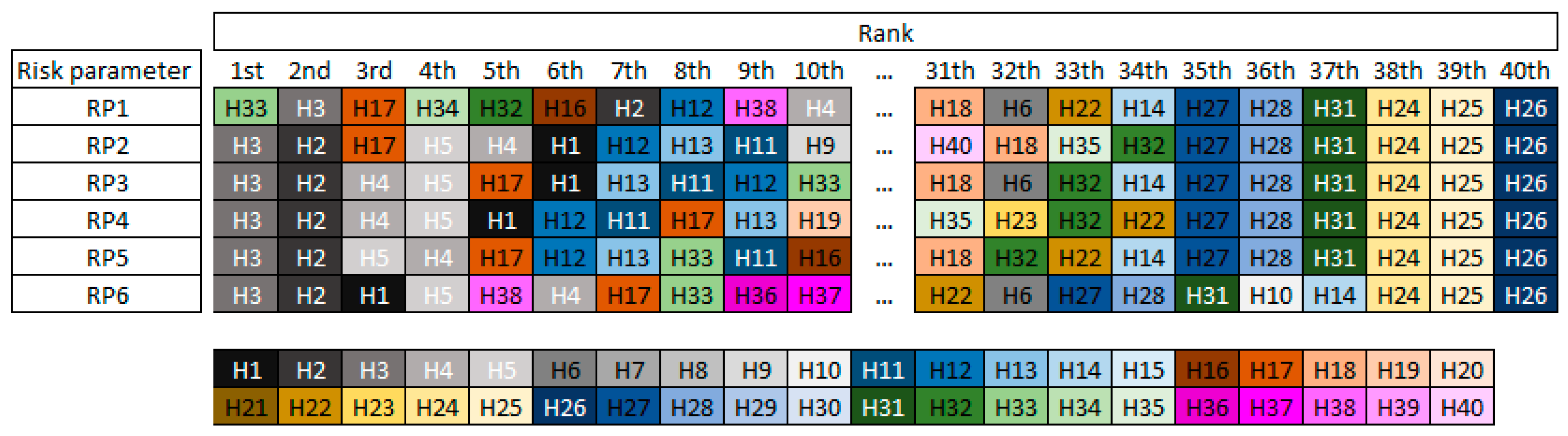

4.3. Comparative Study and Discussion

5. Conclusions

5.1. Summary of Findings

5.2. Research Contributions

- A new extension 3,4-QFS with a broader space than the Fermatean and Pythagorean fuzzy numbers has been adapted for the first time to an occupational risk assessment study. The proposed 3,4-QF-MCDM based approach uses more risk parameters than conventional risk assessments and calculates their weight values with Rezaei’s BWM method.

- In addition, with the developed 3,4-QF scale, each hazard can be evaluated according to the relevant risk parameter, and the subjective judgments given by all the experts participating in the evaluation are aggregated with the 3,4-QFGA operator.

- Experts with field experience and pilot training practice were included in the process of determining risk assessment parameters which allows for a more detailed and consistent evaluation of problems, hazards, and related risk situations in the flight school processes. It made model more sustainable and applicable model. An innovative sensitivity analysis was conducted to analyze how the change in the weights of the parameters used in the flight school occupational risk assessment affected the priority score and, of course, the order of each hazard. In this respect, it is considered to make an important methodological contribution.

- Risk assessment for flight schools, which constitute the education pillar of the aviation industry, is undoubtedly extremely important in terms of serious hazards it contains. In this context, the occupational risk assessment study carried out in a flight school in order to test the applicability of the model contributes to the application as it is an adaptable model.

5.3. Limitations and Future Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission; Directorate-General for Employment, Social Affairs and Inclusion. Guidance on Risk Assessment at Work; Publications Office: Luxembourg, 1996. [Google Scholar]

- Cox, L.A., Jr. Risk Analysis Foundations, Models, and Methods; Springer Science & Business Media: Berlin, Germany, 2012; Volume 45. [Google Scholar]

- European Agency for Safety and Health at Work. Directive 89/391/EEC—OSH “Framework Directive”; 1989; Available online: https://osha.europa.eu/en/legislation/directives/the-osh-framework-directive/1 (accessed on 30 July 2022).

- Pinto, A. QRAM a Qualitative Occupational Safety Risk Assessment Model for the construction industry that incorporate uncertainties by the use of fuzzy sets. Saf. Sci. 2014, 63, 57–76. [Google Scholar] [CrossRef]

- IEC 31010:2019; Risk Management—Risk Assessment Techniques, 2nd ed. International Organization for Standardization (ISO): Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/72140.html (accessed on 25 May 2022).

- Gul, M. A review of occupational health and safety risk assessment approaches based on multi-criteria decision-making methods and their fuzzy versions. Hum. Ecol. Risk Assess. Int. J. 2018, 24, 1723–1760. [Google Scholar] [CrossRef]

- Markowski, A.S.; Mannan, M.S. Fuzzy risk matrix. J. Hazard. Mater. 2008, 159, 152–157. [Google Scholar] [CrossRef] [PubMed]

- Markowski, A.S.; Siuta, D. Fuzzy logic approach for identifying representative accident scenarios. J. Loss Prev. Process Ind. 2018, 56, 414–423. [Google Scholar] [CrossRef]

- Markowski, A.S.; Mannan, M.S.; Bigoszewska, A. Fuzzy logic for process safety analysis. J. Loss Prev. Process Ind. 2009, 22, 695–702. [Google Scholar] [CrossRef]

- Kabir, S. An overview of fault tree analysis and its application in model based dependability analysis. Expert Syst. Appl. 2017, 77, 114–135. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.C. FMEA using uncertainty theories and MCDM methods. In FMEA Using Uncertainty Theories and MCDM Methods; Springer: Singapore, 2016; pp. 13–27. [Google Scholar]

- Dunjó, J.; Fthenakis, V.; Vílchez, J.A.; Arnaldos, J. Hazard and operability (HAZOP) analysis. A literature review. J. Hazard. Mater. 2010, 173, 19–32. [Google Scholar] [CrossRef]

- Marhavilas, P.K.; Filippidis, M.; Koulinas, G.K.; Koulouriotis, D.E. The integration of HAZOP study with risk-matrix and the analytical-hierarchy process for identifying critical control-points and prioritizing risks in industry—A case study. J. Loss Prev. Process Ind. 2019, 62, 103981. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef] [Green Version]

- Ozdemir, Y.; Basligil, H.; Ak, M.F. Airport safety risk evaluation based on fuzzy Anp and fuzzy ahp. In Airport Safety Risk Evaluation Based on Fuzzy Anp and Fuzzy Ahp; World Scientific: Singapore, 2016. [Google Scholar]

- Seikh, M.R.; Mandal, U. Multiple attribute decision-making based on 3, 4-quasirung fuzzy sets. Granular Computing 2022, 1–14. [Google Scholar] [CrossRef]

- Yager, R.R. Pythagorean membership grades in multicriteria decision making. IEEE Trans. Fuzzy Syst. 2014, 22, 958–965. [Google Scholar] [CrossRef]

- Senapati, T.; Yager, R.R. Fermatean fuzzy sets. J. Ambient Intell. Humaniz. Comput. 2020, 11, 663–674. [Google Scholar] [CrossRef]

- Gholamizadeh, K.; Zarei, E.; Omidvar, M.; Yazdi, M. Fuzzy Sets Theory and Human Reliability: Review, Applications, and Contributions. In Linguistic Methods under Fuzzy Information in System Safety and Reliability Analysis; Springer: Berlin/Heidelberg, Germany, 2022; pp. 91–137. [Google Scholar]

- Pouyakian, M.; Khatabakhsh, A.; Yazdi, M.; Zarei, E. Optimizing the Allocation of Risk Control Measures Using Fuzzy MCDM Approach: Review and Application. In Linguistic Methods under Fuzzy Information in System Safety and Reliability Analysis; Yazdi, M., Ed.; Studies in Fuzziness and Soft Computing; Springer: Cham, Switzerland, 2022; Volume 414. [Google Scholar]

- Turkey Directorate General of Civil Aviation (DGCA). 2020 Annual Bulletin of Safety İncidents. 2020. Available online: https://web.shgm.gov.tr/documents/sivilhavacilik/files/mevzuat/sektorel/bulten/2020/EOYB-2020.pdf (accessed on 30 July 2022).

- Delikhoon, M.; Zarei, E.; Banda, O.V.; Faridan, M.; Habibi, E. Systems Thinking Accident Analysis Models: A Systematic Review for Sustainable Safety Management. Sustainability 2022, 14, 5869. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. In Fuzzy Sets, Fuzzy Logic, and Fuzzy Systems; World Scientific: Singapore, 1996; pp. 394–432. [Google Scholar]

- Pedrycz, W. Why triangular membership functions? Fuzzy Sets Syst. 1994, 64, 21–30. [Google Scholar] [CrossRef]

- Atanassov, K.T. Intuitionistic fuzzy sets. In Intuitionistic Fuzzy Sets; Physica: Heidelberg, Germany, 1999; pp. 1–137. [Google Scholar]

- Karnik, N.N.; Mendel, J.M. Operations on type-2 fuzzy sets. Fuzzy Sets Syst. 2001, 122, 327–348. [Google Scholar] [CrossRef]

- Torra, V. Hesitant fuzzy sets. Int. J. Intell. Syst. 2010, 25, 529–539. [Google Scholar] [CrossRef]

- Cuong, B.C.; Kreinovich, V. Picture fuzzy sets. J. Comput. Sci. Cybern. 2014, 30, 409–420. [Google Scholar]

- Kutlu Gündoğdu, F.; Kahraman, C. Spherical fuzzy sets and spherical fuzzy TOPSIS method. J. Intell. Fuzzy Syst. 2019, 36, 337–352. [Google Scholar] [CrossRef]

- Yager, R.R. Generalized orthopair fuzzy sets. IEEE Trans. Fuzzy Syst. 2016, 25, 1222–1230. [Google Scholar] [CrossRef]

- Marhavilas, P.K.; Filippidis, M.; Koulinas, G.K.; Koulouriotis, D.E. An expanded HAZOP-study with fuzzy-AHP (XPA-HAZOP technique): Application in a sour crude-oil processing plant. Saf. Sci. 2020, 124, 104590. [Google Scholar] [CrossRef]

- Celik, E.; Gul, M. Hazard identification, risk assessment and control for dam construction safety using an integrated BWM and MARCOS approach under interval type-2 fuzzy sets environment. Autom. Constr. 2021, 127, 103699. [Google Scholar] [CrossRef]

- Gul, M.; Mete, S.; Serin, F.; Celik, E. Fine–Kinney-Based Fuzzy Multi-Criteria Occupational Risk Assessment; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Wang, W.; Ding, L.; Liu, X.; Liu, S. An interval 2-Tuple linguistic Fine-Kinney model for risk analysis based on extended ORESTE method with cumulative prospect theory. Inf. Fusion 2022, 78, 40–56. [Google Scholar] [CrossRef]

- Wang, W.; Jiang, W.; Han, X.; Liu, S. An extended gained and lost dominance score method based risk prioritization for Fine-Kinney model with interval type-2 fuzzy information. Hum. Ecol. Risk Assess. Int. J. 2022, 28, 154–183. [Google Scholar] [CrossRef]

- Çalış Boyacı, A.; Selim, A. Assessment of occupational health and safety risks in a Turkish public hospital using a two-stage hesitant fuzzy linguistic approach. Environ. Sci. Pollut. Res. 2022, 29, 36313–36325. [Google Scholar] [CrossRef] [PubMed]

- Can, G.F.; Toktas, P. An Advanced Stochastic Risk Assessment Approach Proposal Based on KEMIRA-M, QFD and Fine-Kinney Hybridization. Int. J. Inf. Technol. Decis. Mak. 2021, 20, 431–468. [Google Scholar] [CrossRef]

- Dagsuyu, C.; Oturakci, M.; Essiz, E.S. A New Fine-Kinney Method Based on Clustering Approach. Int. J. Uncertain. Fuzziness Knowl. Based Syst. 2020, 28, 497–512. [Google Scholar] [CrossRef]

- Tang, J.; Liu, X.; Wang, W. A hybrid risk prioritization method based on generalized TODIM and BWM for Fine-Kinney under interval type-2 fuzzy environment. Hum. Ecol. Risk Assess. Int. J. 2021, 27, 954–979. [Google Scholar] [CrossRef]

- Khalilzadeh, M.; Ghasemi, P.; Afrasiabi, A.; Shakeri, H. Hybrid fuzzy MCDM and FMEA integrating with linear programming approach for the health and safety executive risks: A case study. J. Model. Manag. 2021, 16, 1025–1053. [Google Scholar] [CrossRef]

- Shahri, M.M.; Jahromi, A.E.; Houshmand, M. Failure Mode and Effect Analysis using an integrated approach of clustering and MCDM under pythagorean fuzzy environment. J. Loss Prev. Process Ind. 2021, 72, 104591. [Google Scholar] [CrossRef]

- Jafarzadeh Ghoushchi, S.; Soleimani Nik, M.; Pourasad, Y. Health Safety and Environment Risk Assessment Using an Extended BWM-COPRAS Approach Based on G-Number Theory. Int. J. Fuzzy Syst. 2022, 24, 1888–1908. [Google Scholar] [CrossRef]

- Valipour, M.; Yousefi, S.; Jahangoshai Rezaee, M.; Saberi, M. A clustering-based approach for prioritizing health, safety and environment risks integrating fuzzy C-means and hybrid decision-making methods. Stoch. Environ. Res. Risk Assess. 2021, 36, 919–938. [Google Scholar] [CrossRef]

- La Fata, C.M.; Giallanza, A.; Micale, R.; La Scalia, G. Improved FMECA for effective risk management decision making by failure modes classification under uncertainty. Eng. Fail. Anal. 2022, 135, 106163. [Google Scholar] [CrossRef]

- Karamustafa, M.; Cebi, S. Extension of safety and critical effect analysis to neutrosophic sets for the evaluation of occupational risks. Appl. Soft Comput. 2021, 110, 107719. [Google Scholar] [CrossRef]

- Liu, R.; Liu, Z.; Liu, H.C.; Shi, H. An improved alternative queuing method for occupational health and safety risk assessment and its application to construction excavation. Autom. Constr. 2021, 126, 103672. [Google Scholar] [CrossRef]

- Liu, R.; Zhu, Y.J.; Chen, Y.; Liu, H.C. Occupational health and safety risk assessment using an integrated TODIM-PROMETHEE model under linguistic spherical fuzzy environment. Int. J. Intell. Syst. 2021, 36, 6814–6836. [Google Scholar] [CrossRef]

- Mohandes, S.R.; Durdyev, S.; Sadeghi, H.; Mahdiyar, A.; Hosseini, M.R.; Banihashemi, S.; Martek, I. Towards enhancement in reliability and safety of construction projects: Developing a hybrid multi-dimensional fuzzy-based approach. Eng. Constr. Archit. Manag. 2022. [Google Scholar] [CrossRef]

- Mohandes, S.R.; Sadeghi, H.; Fazeli, A.; Mahdiyar, A.; Hosseini, M.R.; Arashpour, M.; Zayed, T. Causal analysis of accidents on construction sites: A hybrid fuzzy Delphi and DEMATEL approach. Saf. Sci. 2022, 151, 105730. [Google Scholar] [CrossRef]

- La Fata, C.M.; Giallanza, A.; Micale, R.; La Scalia, G. Ranking of occupational health and safety risks by a multi-criteria perspective: Inclusion of human factors and application of VIKOR. Saf. Sci. 2021, 138, 105234. [Google Scholar] [CrossRef]

- Lolli, F.; Coruzzolo, A.M.; Alessandro, G.; Balugani, E.; Butturi, M.A.; Marinello, S.; Marinelli, S. The Dynamic, Individual and Integrated Risk Assessment: A Multi-criteria Approach Using Big Data. In Proceedings of the International Conference on Applied Human Factors and Ergonomics, New York, NY, USA, 25–29 July 2021; Springer: Cham, Switzerland, 2021; pp. 207–215. [Google Scholar]

- Zarei, E.; Ramavandi, B.; Darabi, A.H.; Omidvar, M. A framework for resilience assessment in process systems using a fuzzy hybrid MCDM model. J. Loss Prev. Process Ind. 2021, 69, 104375. [Google Scholar] [CrossRef]

- Gul, M.; Lo, H.W.; Yucesan, M. Fermatean fuzzy TOPSIS-based approach for occupational risk assessment in manufacturing. Complex Intell. Syst. 2021, 7, 2635–2653. [Google Scholar] [CrossRef]

- Ak, M.F.; Yucesan, M.; Gul, M. Occupational health, safety and environmental risk assessment in textile production industry through a Bayesian BWM-VIKOR approach. Stoch. Environ. Res. Risk Assess. 2022, 36, 629–642. [Google Scholar] [CrossRef]

- Di Bona, G.; Silvestri, A.; Forcina, A.; Petrillo, A. Total efficient risk priority number (TERPN): A new method for risk assessment. J. Risk Res. 2018, 21, 1384–1408. [Google Scholar] [CrossRef]

- Grassi, A.; Gamberini, R.; Mora, C.; Rimini, B. A fuzzy multi-attribute model for risk evaluation in workplaces. Saf. Sci. 2009, 47, 707–716. [Google Scholar] [CrossRef]

- Chen, J.K. Prioritization of corrective actions from utility viewpoint in FMEA application. Qual. Reliab. Eng. Int. 2017, 33, 883–894. [Google Scholar] [CrossRef]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- European Aviation Safety Agency. Annual Safety Review 2020; Publications Office: Luxembourg, 2020. [Google Scholar]

- ICAO. International Civil Aviation Organization. Global Aviation Safety Plan 2020–2022. Available online: https://www.icao.int/Meetings/anconf13/Documents/Doc_10004_GASP_2020_2022_Edition.pdf (accessed on 13 October 2021).

- Senapati, T.; Yager, R.R. Fermatean fuzzy weighted averaging/geometric operators and its application in multi-criteria decision-making methods. Eng. Appl. Artif. Intell. 2019, 85, 112–121. [Google Scholar] [CrossRef]

- Zhou, L.P.; Wan, S.P.; Dong, J.Y. A Fermatean Fuzzy ELECTRE Method for Multi-Criteria Group Decision-Making. Informatica 2022, 33, 181–224. [Google Scholar] [CrossRef]

- Yager, R.R. Pythagorean fuzzy subsets. In Proceedings of the 2013 Joint IFSA World Congress and NAFIPS Annual Meeting (IFSA/NAFIPS), Edmonton, AB, Canada, 24–28 June 2013; pp. 57–61. [Google Scholar]

- Peng, X.; Selvachandran, G. Pythagorean fuzzy set: State of the art and future directions. Artif. Intell. Rev. 2019, 52, 1873–1927. [Google Scholar] [CrossRef]

- Peng, X.D.; Yang, Y.; Song, J.; Jiang, Y. Pythagorean fuzzy soft set and its application. Comput. Eng. 2015, 41, 224–229. [Google Scholar]

| Linguistic Term of Risk Parameter | Corresponding 3,4-QF Number | ||||||

|---|---|---|---|---|---|---|---|

| RP1 | RP2 | RP3 | RP4 | RP5 | RP6 | Membership Degree | Non-Membership Degree |

| Very Low | Needs first aid | Easy | Very low cost | Negligible | Totally possible | 0.11 | 0.99 |

| Low | Minor injury | Highly possible | Lower costs | Low | Highly possible | 0.44 | 0.95 |

| Medium | Serious injury | Sometimes possible | Moderate cost | Medium | Medium | 0.69 | 0.82 |

| High | Fatality | Highly difficult | High cost | High | Low possibility | 0.92 | 0.51 |

| Very High | Many fatalities | Extremely difficult | Very high cost | Maximum | Not possible at all | 1.00 | 0.00 |

| Quantitative Value | Qualitative Value | Description of Parameter |

|---|---|---|

| 1 | Very low | Hardly ever |

| 2 | Low | Once a year |

| 3 | Medium | Once in a month |

| 4 | High | Once a week |

| 5 | Very high | Every day (very often) |

| Quantitative Value | Qualitativevalue | Description of Parameter |

|---|---|---|

| 1 | Very Light | No loss of working hours, first aid required |

| 2 | Light | No lost workdays, outpatient treatment |

| 3 | Serious | Minor injury, treatment in bed |

| 4 | Very serious | Serious injury, loss of limb, occupational disease |

| 5 | Disaster | One or more deaths |

| Quantitative Value | Qualitative Value | Description of Parameter |

|---|---|---|

| 1 | Very high | Risk can be detected very quickly and easily. |

| 2 | High | Risk can be detected quickly and easily. |

| 3 | Medium | Risk can be detected with reasonable time and experience. |

| 4 | Low | Determining the risk is very time-consuming and difficult. |

| 5 | Very low | Identifying the risk is almost impossible. |

| Quantitative Value | Qualitative Value | Description of Parameter |

|---|---|---|

| 1 | Very low cost | Between 0% and 20% of the total annual budget is allocated to OHS measures. |

| 2 | Lower costs | Between 21% and 40% of the total annual budget is allocated to OHS measures. |

| 3 | Moderate cost | Between 41% and 60% of the total annual budget is allocated to OHS measures. |

| 4 | High cost | Between 61% and 80% of the total annual budget is allocated to OHS measures. |

| 5 | Very high cost | Between 81% and 100% of the total annual budget is allocated to OHS measures. |

| Quantitative Value | Qualitative Value | Description of Parameter |

|---|---|---|

| 1 | Negligible | Risk can be avoided without using PPE. |

| 2 | Low | The use of PPE can reasonably reduce the risk. |

| 3 | Moderate | The use of PPE reduces the risk. |

| 4 | High | It is necessary to use PPE to reduce the risk. |

| 5 | Maximum | PPE must be used. |

| Quantitative Value | Qualitative Value | Description of Parameter |

|---|---|---|

| 1 | Quite possible | Opportunities for preventive measures and their applicability are entirely possible. |

| 2 | High | Opportunities for preventive measures and their feasibility are high. |

| 3 | Moderate | Opportunities for preventive measures and their applicability are moderate. |

| 4 | High | Opportunities for preventive measures and their viability are low. |

| 5 | Practically impossible | Opportunities for preventive measures and their applicability are not possible. |

| Hazard ID | Hazard | Related Risk | Process |

|---|---|---|---|

| H1 | Lack of flight safety | Mid-air collusion | Flight Training |

| H2 | Mechanical: Engine | Engine fails in flight | Flight Training |

| H3 | Mechanical: Control Mechanism | Flight Control Mechanism Malfunction | Flight Training |

| H4 | Mechanical: Landing Gear | Landing gear not deployed | Flight Training |

| H5 | Inadequate preflight planning | Smoke, fire, and fumes | Flight Training |

| H6 | Mismanagement of fuel | Critical level of fuel | Flight Training |

| H7 | Mechanical: Control Mechanism | System malfunction | Flight Training |

| H8 | Misjudgment of distance and speed | Excursion | Flight Training |

| H9 | Misjudgment of distance and speed | Incursion | Flight Training |

| H10 | Improper in-flight decision | Abandoned take-off | Flight Training |

| H11 | Improper in-flight decision | Emergency declaration | Flight Training |

| H12 | Lack of flight safety | Forced landing off track | Flight Training |

| H13 | Improper in-flight decisions | Hard landing | Flight Training |

| H14 | Failure to maintain directional control | Landing on the wrong runway | Flight Training |

| H15 | Inadequate preflight planning | Tire damage and blowouts | Flight Training |

| H16 | Lack of flight safety | Runway Crossing Incursion | Flight Training |

| H17 | Failure to see and avoid objects or obstructions. | Bird Strike | Flight Training |

| H18 | Improper in-flight decision | Getting lost in flight (individual flight) | Flight Training |

| H19 | Physiological factors | Pilot Incapacitation | Flight Training |

| H20 | Violation of aviation safety rules | NOTAM | Flight Training |

| H21 | Violation of aviation safety rules | Worksite Violation | Flight Training |

| H22 | Lack of flight safety | Disobey ATC instructions | Flight Training |

| H23 | Work environment factors | FOD on runway | Flight Training |

| H24 | Inadequate preflight controls | Planning with a lack of Instructor Authorization: Ground training | Ground Training |

| H25 | Inadequate preflight controls | Lack of training of trainers certificate: Ground training | Ground Training |

| H26 | Inadequate preflight controls | Availability of staff/teachers who were recruited without registration | Administrative Process |

| H27 | Insufficient practical training | Ensuring the integration of theoretical training and flight training | Training Management |

| H28 | Improper in-flight decisions | Uncertainty of communication in emergency situations, course of action in incidents or accidents | Flight Training |

| H29 | Mechanical | Injury in the candidate selection process | Facilities |

| H30 | Human error | Injury in the candidate selection process | Facilities |

| H31 | Violation of aviation safety rules | Candidate restricted area entry and simulator use | Flight Training |

| H32 | Weakness of communication in education | Distrust between candidate and instructor | Administrative Process |

| H33 | COVID-19 virus | COVID-19 transmission risk | Administrative Process |

| H34 | COVID-19 virus | Online course due to pandemic risk | Training Management |

| H35 | COVID-19 virus | Continuation of flight activity in the pandemic | Flight Training |

| H36 | COVID-19 virus | Delay of the normalization process due to the pandemic | Administrative Process |

| H37 | COVID-19 virus | The risk of mass transmission in theoretical trainings made face-to-face due to the pandemic | Training Management |

| H38 | COVID-19 virus | Risk of virus transmission from headphones | Training Management |

| H39 | COVID-19 virus | The need to give online lessons to students during the full closure of the pandemic | Training Management |

| H40 | COVID-19 virus | Continuation of flight activity during the full closure of the pandemic | Flight Training |

| Hazard | Aggregated Value in 3,4-QF Number | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RP1 | RP2 | RP3 | RP4 | RP5 | RP6 | |||||||

| H1 | 0.11 | 0.99 | 1.00 | 0.00 | 0.77 | 0.78 | 0.83 | 0.71 | 0.55 | 0.91 | 0.69 | 0.82 |

| H2 | 0.22 | 0.98 | 0.92 | 0.51 | 0.86 | 0.65 | 0.89 | 0.63 | 0.55 | 0.91 | 0.62 | 0.87 |

| H3 | 0.44 | 0.95 | 1.00 | 0.00 | 0.86 | 0.65 | 0.83 | 0.71 | 0.55 | 0.91 | 0.62 | 0.87 |

| H4 | 0.22 | 0.98 | 0.92 | 0.51 | 0.86 | 0.65 | 0.83 | 0.71 | 0.55 | 0.91 | 0.49 | 0.93 |

| H5 | 0.11 | 0.99 | 1.00 | 0.00 | 0.86 | 0.65 | 0.83 | 0.71 | 0.62 | 0.87 | 0.62 | 0.87 |

| H6 | 0.11 | 0.99 | 0.92 | 0.51 | 0.77 | 0.78 | 0.66 | 0.87 | 0.39 | 0.94 | 0.16 | 0.99 |

| H7 | 0.11 | 0.99 | 0.55 | 0.91 | 0.86 | 0.65 | 0.83 | 0.71 | 0.28 | 0.96 | 0.49 | 0.93 |

| H8 | 0.11 | 0.99 | 0.92 | 0.51 | 0.86 | 0.65 | 0.66 | 0.87 | 0.28 | 0.96 | 0.44 | 0.95 |

| H9 | 0.11 | 0.99 | 0.94 | 0.48 | 0.86 | 0.65 | 0.74 | 0.81 | 0.28 | 0.96 | 0.49 | 0.93 |

| H10 | 0.22 | 0.98 | 0.92 | 0.51 | 0.86 | 0.65 | 0.66 | 0.87 | 0.28 | 0.96 | 0.11 | 0.99 |

| H11 | 0.11 | 0.99 | 0.92 | 0.51 | 0.92 | 0.51 | 0.98 | 0.36 | 0.28 | 0.96 | 0.44 | 0.95 |

| H12 | 0.31 | 0.97 | 0.94 | 0.48 | 0.77 | 0.78 | 0.83 | 0.71 | 0.28 | 0.96 | 0.44 | 0.95 |

| H13 | 0.25 | 0.97 | 0.92 | 0.51 | 0.86 | 0.65 | 0.66 | 0.87 | 0.28 | 0.96 | 0.49 | 0.93 |

| H14 | 0.11 | 0.99 | 0.86 | 0.65 | 0.86 | 0.65 | 0.66 | 0.87 | 0.28 | 0.96 | 0.11 | 0.99 |

| H15 | 0.11 | 0.99 | 0.92 | 0.51 | 0.86 | 0.65 | 0.66 | 0.87 | 0.28 | 0.96 | 0.49 | 0.93 |

| H16 | 0.55 | 0.91 | 0.69 | 0.82 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.44 | 0.95 |

| H17 | 0.55 | 0.91 | 1.00 | 0.00 | 0.77 | 0.78 | 0.66 | 0.87 | 0.28 | 0.96 | 0.49 | 0.93 |

| H18 | 0.11 | 0.99 | 0.49 | 0.93 | 0.77 | 0.78 | 0.83 | 0.71 | 0.28 | 0.96 | 0.44 | 0.95 |

| H19 | 0.11 | 0.99 | 0.92 | 0.51 | 0.86 | 0.65 | 0.83 | 0.71 | 0.28 | 0.96 | 0.31 | 0.97 |

| H20 | 0.22 | 0.98 | 0.80 | 0.73 | 0.77 | 0.78 | 0.66 | 0.87 | 0.28 | 0.96 | 0.44 | 0.95 |

| H21 | 0.31 | 0.97 | 0.69 | 0.82 | 0.77 | 0.78 | 0.66 | 0.87 | 0.28 | 0.96 | 0.44 | 0.95 |

| H22 | 0.11 | 0.99 | 0.74 | 0.78 | 0.86 | 0.65 | 0.33 | 0.95 | 0.28 | 0.96 | 0.44 | 0.95 |

| H23 | 0.16 | 0.99 | 0.69 | 0.82 | 0.86 | 0.65 | 0.33 | 0.95 | 0.28 | 0.96 | 0.44 | 0.95 |

| H24 | 0.11 | 0.99 | 0.11 | 0.99 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.11 | 0.99 |

| H25 | 0.11 | 0.99 | 0.11 | 0.99 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.11 | 0.99 |

| H26 | 0.11 | 0.99 | 0.11 | 0.99 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.11 | 0.99 |

| H27 | 0.11 | 0.99 | 0.11 | 0.99 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.44 | 0.95 |

| H28 | 0.11 | 0.99 | 0.11 | 0.99 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.44 | 0.95 |

| H29 | 0.11 | 0.99 | 0.69 | 0.82 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.69 | 0.82 |

| H30 | 0.11 | 0.99 | 0.69 | 0.82 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.69 | 0.82 |

| H31 | 0.11 | 0.99 | 0.11 | 0.99 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.44 | 0.95 |

| H32 | 0.86 | 0.65 | 0.11 | 0.99 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.44 | 0.95 |

| H33 | 0.86 | 0.65 | 0.44 | 0.95 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.62 | 0.87 |

| H34 | 0.69 | 0.82 | 0.44 | 0.95 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.44 | 0.95 |

| H35 | 0.44 | 0.95 | 0.44 | 0.95 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.44 | 0.95 |

| H36 | 0.44 | 0.95 | 0.44 | 0.95 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.69 | 0.82 |

| H37 | 0.44 | 0.95 | 0.44 | 0.95 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.69 | 0.82 |

| H38 | 0.44 | 0.95 | 0.44 | 0.95 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.86 | 0.65 |

| H39 | 0.44 | 0.95 | 0.44 | 0.95 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.69 | 0.82 |

| H40 | 0.44 | 0.95 | 0.44 | 0.95 | 0.77 | 0.78 | 0.33 | 0.95 | 0.28 | 0.96 | 0.62 | 0.87 |

| Ranking Order | Hazard | Ranking Order | Hazard |

|---|---|---|---|

| 1 | H3 | 17 | H8; H10 |

| 2 | H17 | 18 | H34 |

| 3 | H2 | 19 | H6 |

| 4 | H12 | 20 | H38 |

| 5 | H4 | 21 | H23 |

| 6 | H13 | 22 | H36; H37; H39 |

| 7 | H5 | 23 | H14 |

| 8 | H1 | 24 | H29; H30 |

| 9 | H16 | 25 | H40 |

| 10 | H11 | 26 | H22 |

| 11 | H21 | 27 | H7 |

| 12 | H9 | 28 | H35 |

| 13 | H20 | 29 | H18 |

| 14 | H33 | 30 | H32 |

| 15 | H15 | 31 | H27; H28; H31 |

| 16 | H19 | 32 | H24; H25; H26 |

| Scenario # | Weight of Major Risk Parameter | Weight of Minor Risk Parameter |

|---|---|---|

| Scenario 1 | 0.20 | 0.16 |

| Scenario 2 | 0.40 | 0.12 |

| Scenario 3 | 0.60 | 0.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gul, M.; Ak, M.F. Occupational Risk Assessment for Flight Schools: A 3,4-Quasirung Fuzzy Multi-Criteria Decision Making-Based Approach. Sustainability 2022, 14, 9373. https://doi.org/10.3390/su14159373

Gul M, Ak MF. Occupational Risk Assessment for Flight Schools: A 3,4-Quasirung Fuzzy Multi-Criteria Decision Making-Based Approach. Sustainability. 2022; 14(15):9373. https://doi.org/10.3390/su14159373

Chicago/Turabian StyleGul, Muhammet, and Muhammet Fatih Ak. 2022. "Occupational Risk Assessment for Flight Schools: A 3,4-Quasirung Fuzzy Multi-Criteria Decision Making-Based Approach" Sustainability 14, no. 15: 9373. https://doi.org/10.3390/su14159373

APA StyleGul, M., & Ak, M. F. (2022). Occupational Risk Assessment for Flight Schools: A 3,4-Quasirung Fuzzy Multi-Criteria Decision Making-Based Approach. Sustainability, 14(15), 9373. https://doi.org/10.3390/su14159373