Experimental Study on the Mechanics and Impact Resistance of Multiphase Lightweight Aggregate Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Materials and Mix Design

2.2. Test Methods

3. Experimental Design and Results

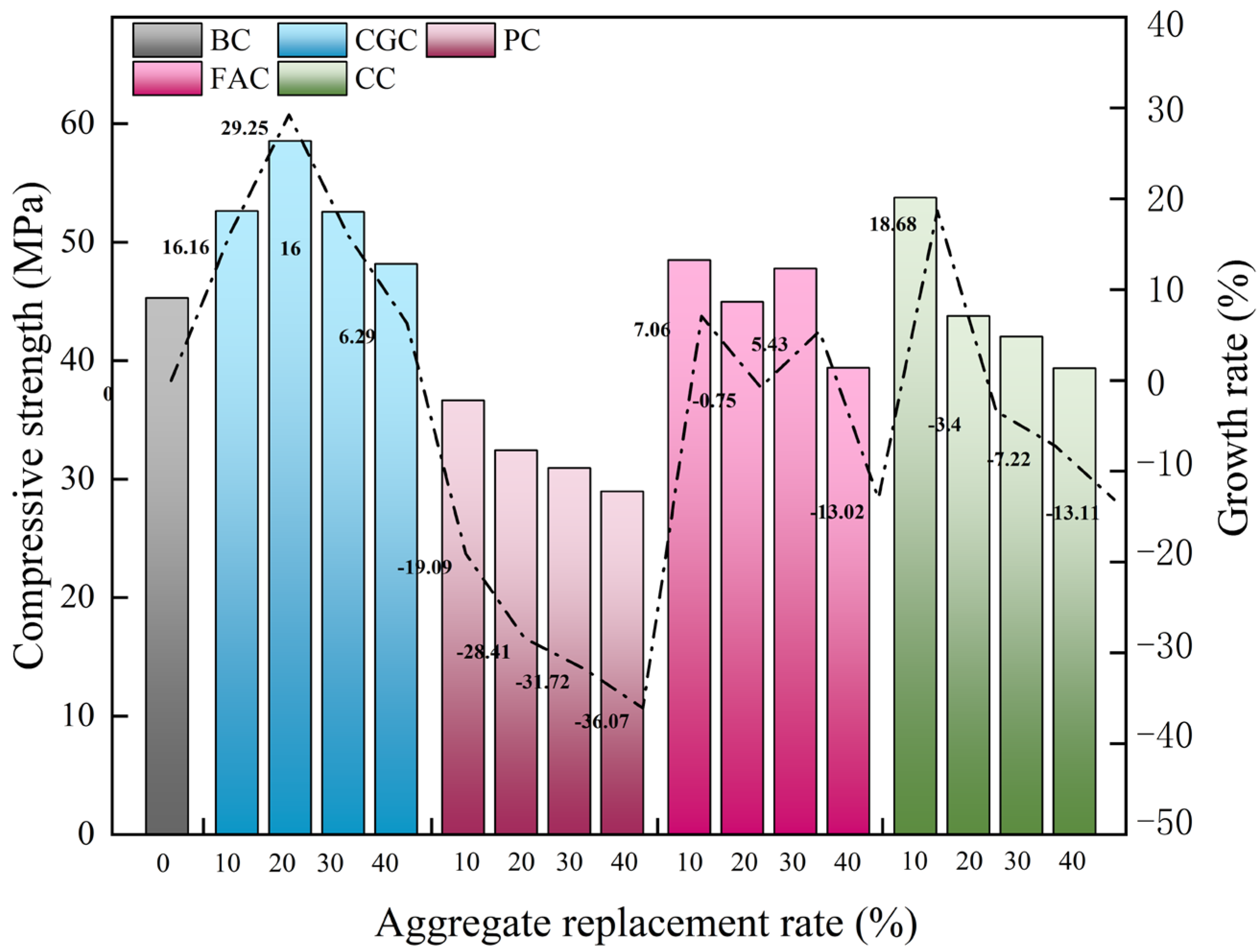

3.1. Cubic Compressive Strength Test

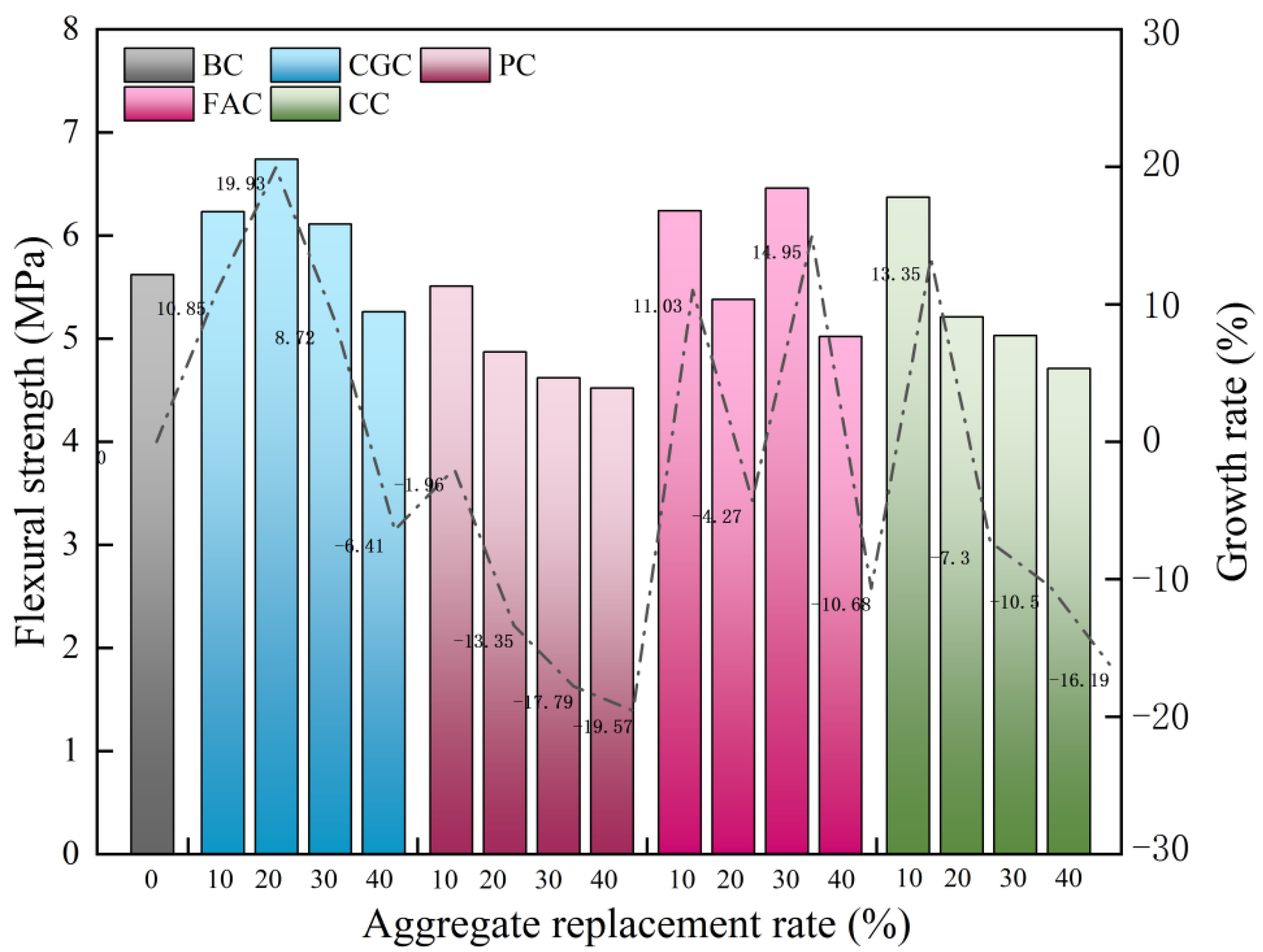

3.2. Flexural Strength Test

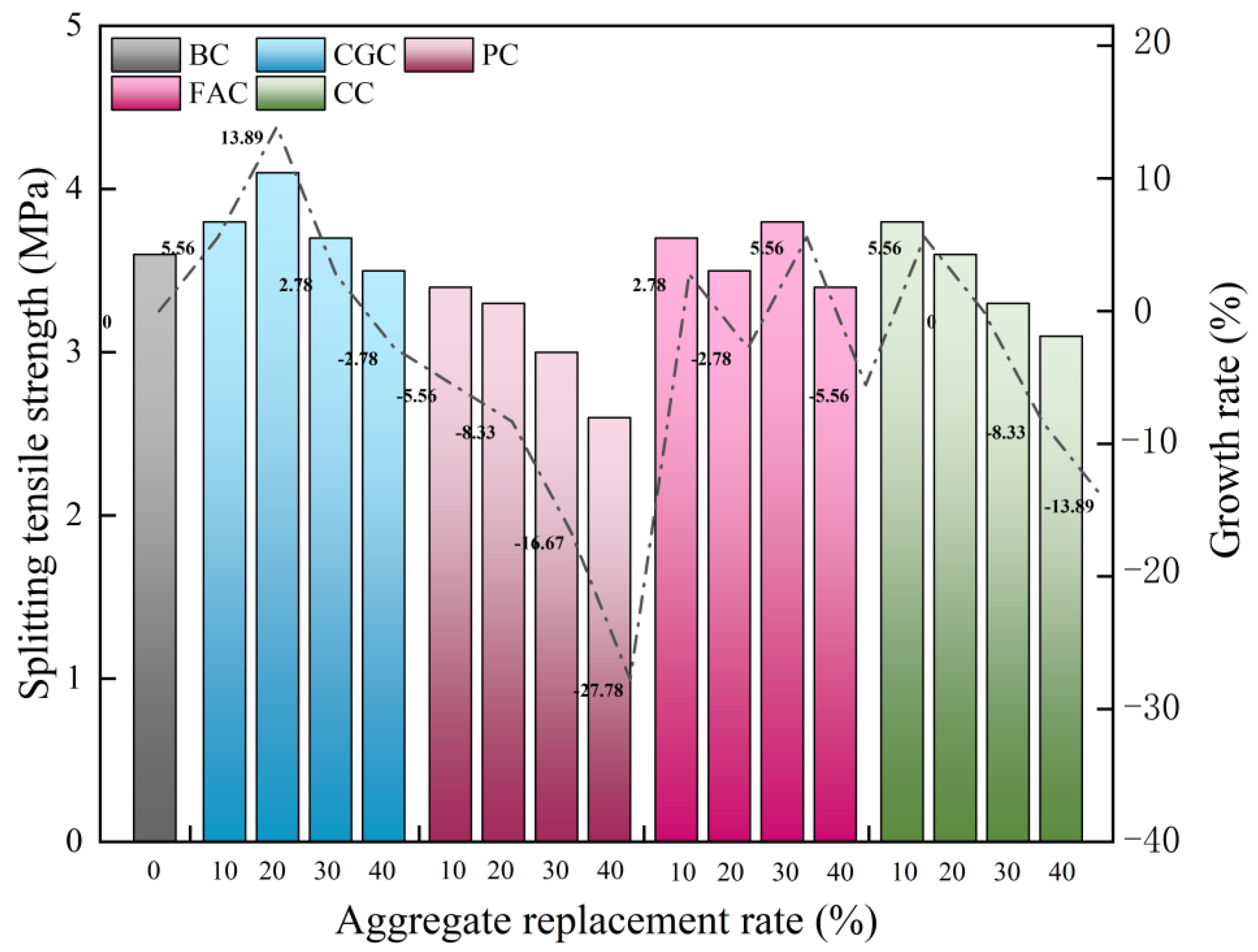

3.3. Splitting Tensile Strength

3.4. Internal Mechanism Analysis of MLAC

4. Impact Resistance Test

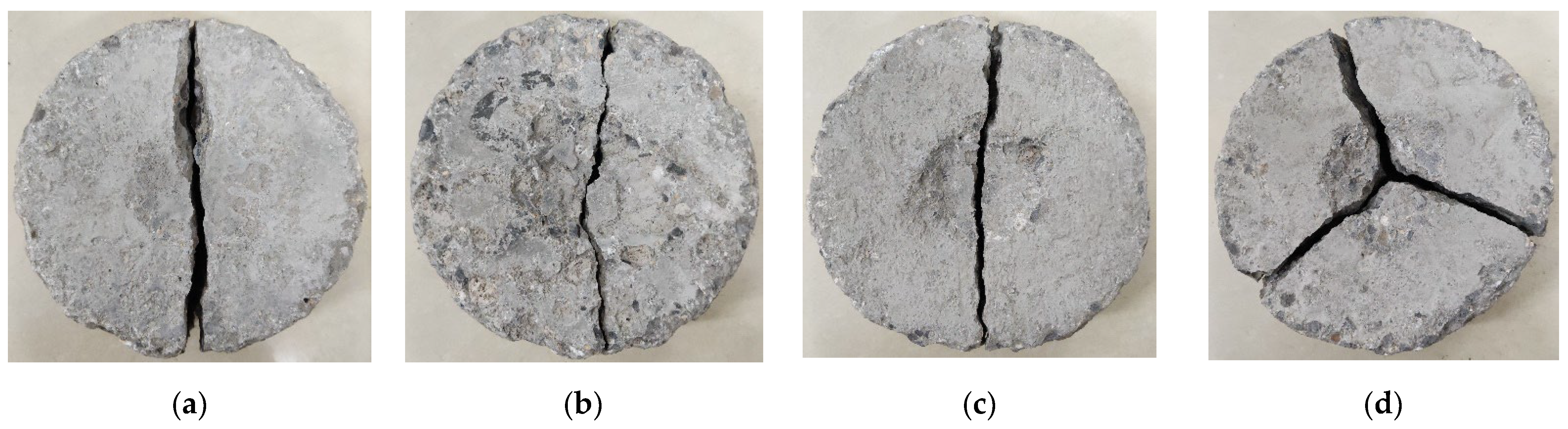

4.1. Impact Specimen Damage Pattern

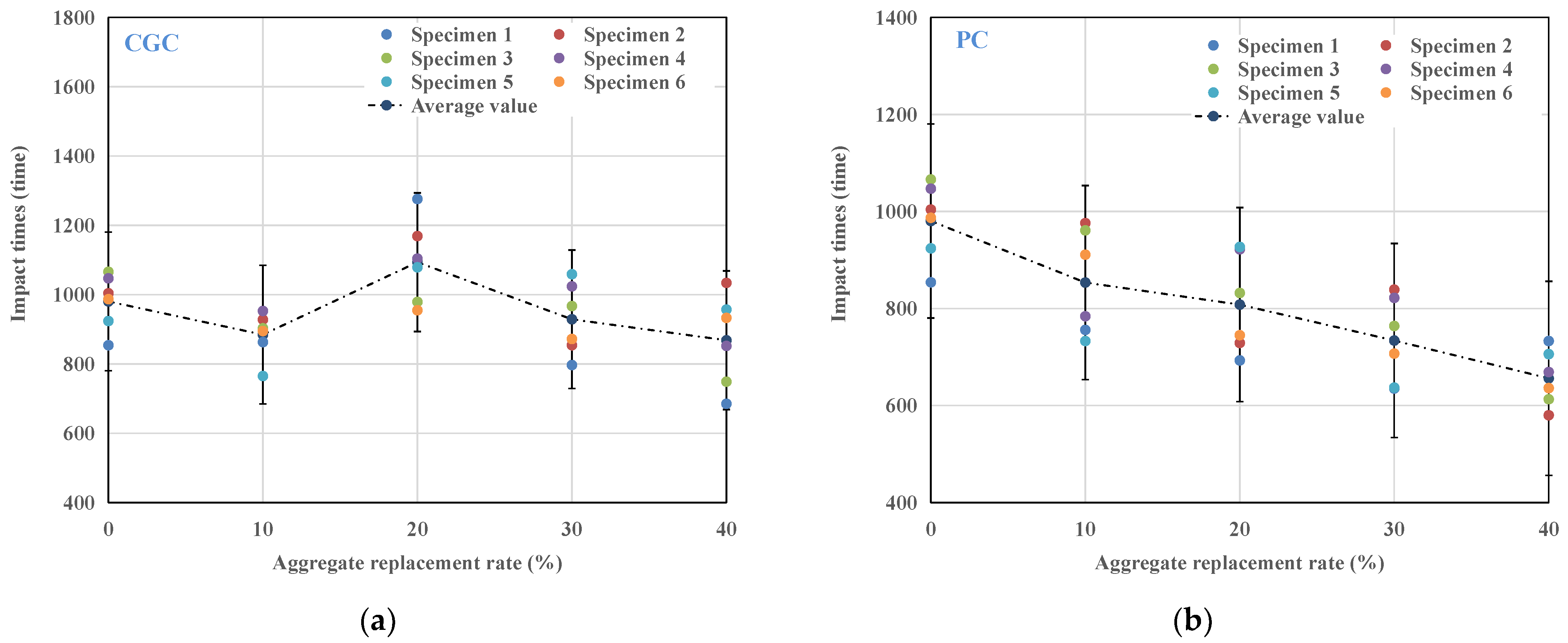

4.2. Impact Performance

4.3. Impact Resistance Analysis of MLAC Based on Two-Parameter Weibull Distribution Model

4.3.1. Parameter Determination of Two-Parameter Weibull Distribution Model

4.3.2. Impact Life Analysis of MLAC under Multiple Factors

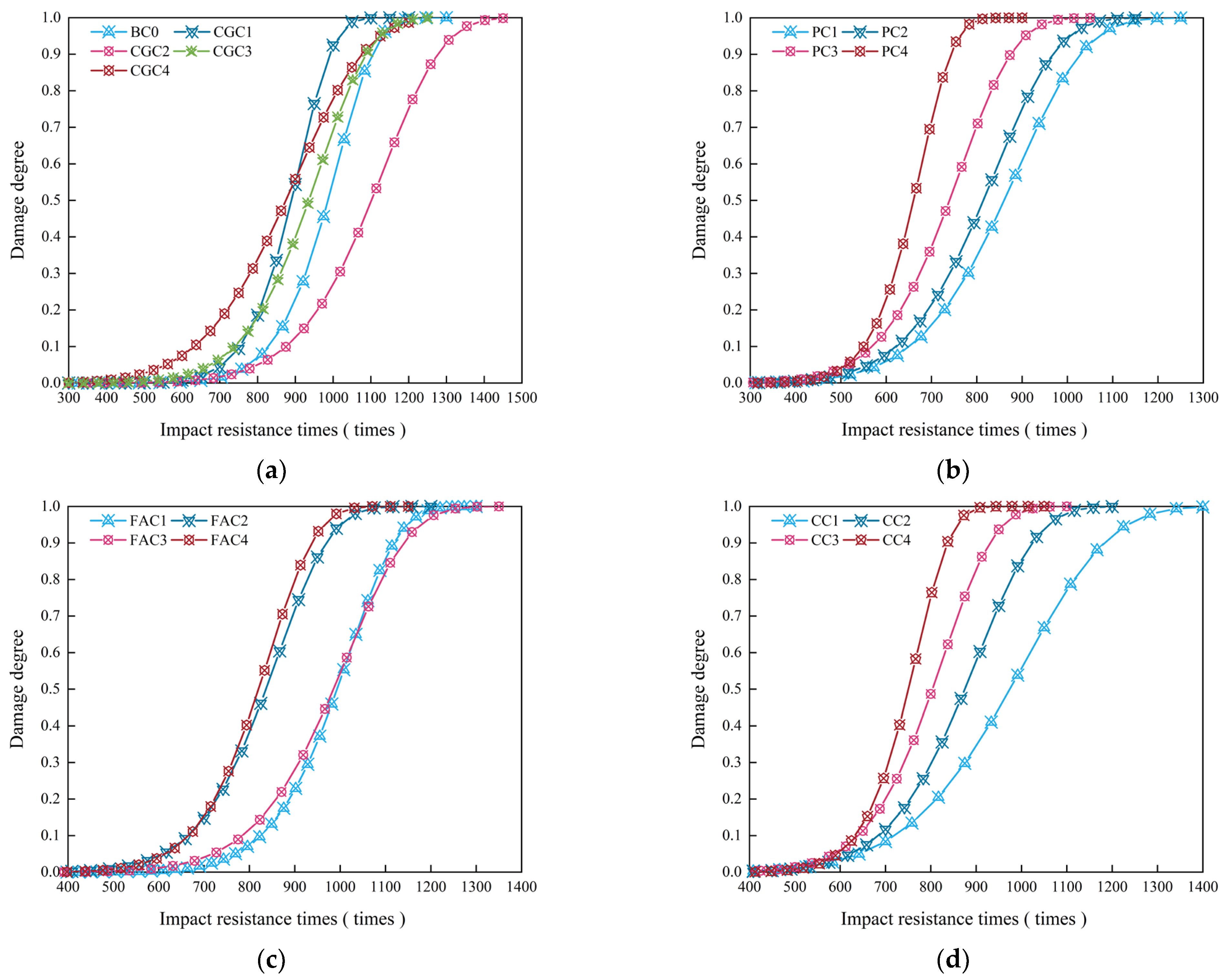

4.3.3. Impact Damage Analysis of MLAC

5. Conclusions

- With the increase in coal gangue ceramsite, the mechanical properties of CGC first increased and then decreased. With the increase in fly ash ceramsite, the mechanical properties of FAC increased, decreased, increased again and finally decreased. With the increase in coral aggregate content, the CC increased then decreased. With the increase in pumice aggregate, the PC decreased. The comprehensive performance was CGC > FAC > CC > PC.

- When coal gangue ceramsite was 20%, the mechanical properties and impact resistance of concrete were the best. The compressive, flexural and splitting tensile strength and the impact energy consumption increased by 29.25%, 19.93%, 13.89% and 8.2%, respectively, compared with the reference concrete.

- The impact test results of MLAC obeyed the distribution law of the two-parameter Weibull distribution model, which can be used to predict and describe the impact life of multi-phase lightweight aggregate concrete under different failure probabilities.

- The impact resistance of MLAC under multiple factors was analyzed in depth. The analysis showed that the influence of the aggregate replacement rate on the impact resistance of multi-phase lightweight aggregate concrete was higher than the probability of failure or the failure of the concrete specimens.

- Through the establishment of the impact damage evolution equation, the damage degradation of each specimen under drop hammer impact was studied in depth. The variation law of the data derived from the equation was highly consistent with the experimental results. The damage degradation of MLAC under dynamic load can be reasonably described by the equation.

6. Prospect

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Global ABC/IEA/UNEP (Global Alliance for Buildings and Construction, International Energy Agency, and the U.N.E.P.). Global ABC Roadmap for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; Global ABC/IEA/UNEP: Paris, France, 2020. [Google Scholar]

- Jabłońska, B.; Kityk, A.V.; Busch, M.; Huber, P. The structural and surface properties of natural and modified coal gangue. J. Environ. Manag. 2017, 190, 80–90. [Google Scholar] [CrossRef] [PubMed]

- Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste. A review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Cristelo, N.; Castro, F.; Miranda, T.; Abdollahnejad, Z.; Fernández-Jiménez, A. Iron and aluminium production wastes as exclusive components of alkali activated binders—Towards a sustainable alternative. Sustainability 2021, 13, 9938. [Google Scholar] [CrossRef]

- Bilir, T.; Aygun, B.F.; Shi, J.; Gencel, O.; Ozbakkaloglu, T. Influence of Different Types of Wastes on Mechanical and Durability Properties of Interlocking Concrete Block Paving (ICBP): A Review. Sustainability 2022, 14, 3733. [Google Scholar] [CrossRef]

- Nicoara, A.I.; Stoica, A.E.; Vrabec, M.; Šmuc Rogan, N.; Sturm, S.; Ow-Yang, C.; Gulgun, M.A.; Bundur, Z.B.; Ciuca, I.; Vasile, B.S. End-of-life materials used as supplementary cementitious materials in the concrete industry. Materials 2020, 13, 1954. [Google Scholar] [CrossRef] [Green Version]

- Ashfaq, M.; Heera Lal, M.; Moghal, A.A.B. Utilization of coal gangue for earthworks: Sustainability perspective. In Advances in Sustainable Construction and Resource Management; Springer: Berlin/Heidelberg, Germany, 2021; pp. 203–218. [Google Scholar]

- Gao, S.; Zhang, S.; Guo, L. Application of Coal Gangue as a Coarse Aggregate in Green Concrete Production: A Review. Materials 2021, 14, 6803. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Durability of lightweight concretes with lightweight fly ash aggregates. Constr. Build. Mater. 2011, 25, 1430–1438. [Google Scholar] [CrossRef]

- Jayabharath, P.; Kesavan, G. Study on Impact Strength of Fly Ash Aggregate Concrete. IOSR J. Mech. Civ. Eng. 2017, 14, 75–82. [Google Scholar] [CrossRef]

- Dahim, M.; Abuaddous, M.; Al-Mattarneh, H.; Rawashdeh, A.; Ismail, R. Enhancement of road pavement material using conventional and nano-crude oil fly ash. App. Nanosci. 2021, 11, 2517–2524. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics–Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Yıldırım, H.; Özturan, T. Impact resistance of concrete produced with plain and reinforced cold-bonded fly ash aggregates. J. Build. Eng. 2021, 42, 102875. [Google Scholar] [CrossRef]

- Kurt, M.; Gül, M.S.; Gül, R.; Aydin, A.C.; Kotan, T. The effect of pumice powder on the self-compactability of pumice aggregate lightweight concrete. Constr. Build. Mater. 2016, 103, 36–46. [Google Scholar] [CrossRef]

- Kotan, T.; Gül, R. Effect of atmospheric pressure steam curing to mechanical properties of lightweight concrete produced with Erzurum–Pasinler pumice. Mach. Technol. Mater. Int. Virtual J. 2010, 43, 4–5. [Google Scholar]

- Öz, H.Ö. Properties of pervious concretes partially incorporating acidic pumice as coarse aggregate. Constr. Build. Mater. 2018, 166, 601–609. [Google Scholar] [CrossRef]

- Hossain, K.; Ahmed, S.; Lachemi, M. Lightweight concrete incorporating pumice based blended cement and aggregate: Mechanical and durability characteristics. Constr. Build. Mater. 2011, 25, 1186–1195. [Google Scholar] [CrossRef]

- Kurt, M.; Aydin, A.C.; Gül, M.S.; Gül, R.; Kotan, T. The effect of fly ash to self-compactability of pumice aggregate lightweight concrete. Sadhana 2015, 40, 1343–1359. [Google Scholar] [CrossRef]

- Amel, C.L.; Kadri, E.-H.; Sebaibi, Y.; Soualhi, H. Dune sand and pumice impact on mechanical and thermal lightweight concrete properties. Constr. Build. Mater. 2017, 133, 209–218. [Google Scholar] [CrossRef]

- Bakis, A. The usability of pumice powder as a binding additive in the aspect of selected mechanical parameters for concrete road pavement. Materials 2019, 12, 2743. [Google Scholar] [CrossRef] [Green Version]

- Johra, H.; Margheritini, L.; Antonov, Y.I.; Frandsen, K.M.; Simonsen, M.E.; Møldrup, P.; Jensen, R.L. Thermal, moisture and mechanical properties of Seacrete: A sustainable sea-grown building material. Constr. Build. Mater. 2021, 266, 121025. [Google Scholar] [CrossRef]

- Arumugam, R.; Ramamurthy, K. Study of compressive strength characteristics of coral aggregate concrete. Mag. Concr. Res. 1996, 48, 141–148. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Niu, D.; Su, L.; Luo, Y.; Huang, D.; Luo, D. Experimental study on mechanical properties and durability of basalt fiber reinforced coral aggregate concrete. Constr. Build. Mater. 2020, 237, 117628. [Google Scholar] [CrossRef]

- Rao, L.; Wang, L.; Zheng, Y. Experimental Research on Mechanical Properties and Compression Constitutive Relationship of PVA Fiber-Reinforced Coral Concrete. Materials 2022, 15, 1762. [Google Scholar] [CrossRef]

- Cheng, S.; Shui, Z.; Sun, T.; Yu, R.; Zhang, G. Durability and microstructure of coral sand concrete incorporating supplementary cementitious materials. Constr. Build. Mater. 2018, 171, 44–53. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, J.; Deng, W.; Xing, J.; Liang, J. Factors affecting brittleness behavior of coal-gangue ceramsite lightweight aggregate concrete. Front. Mater. 2020, 7, 554718. [Google Scholar] [CrossRef]

- Shafigh, P.; Nomeli, M.A.; Alengaram, U.J.; Mahmud, H.B.; Jumaat, M.Z. Engineering properties of lightweight aggregate concrete containing limestone powder and high volume fly ash. J. Clean. Prod. 2016, 135, 148–157. [Google Scholar] [CrossRef]

- ACI Committee 544. Measurement of Properties of Fiber Reinforced Concrete. ACI Mater. J. 1998, 85, 83–93. [Google Scholar]

- Yoo, D.-Y.; Banthia, N. Impact resistance of fiber-reinforced concrete–A review. Cement Concr. Compos. 2019, 104, 103389. [Google Scholar] [CrossRef]

- Ding, Q.; Xiang, W.; Zhang, G.; Hu, C. Effect of Pre-wetting Lightweight Aggregates on the Mechanical Performances and Microstructure of Cement Pastes. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2020, 35, 140–146. [Google Scholar] [CrossRef]

- Rahmani, T.; Kiani, B.; Shekarchi, M.; Safari, A. Statistical and experimental analysis on the behavior of fiber reinforced concretes subjected to drop weight test. Constr. Build. Mater. 2012, 37, 360–369. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Kaushik, S. Flexural fatigue-life distributions of plain and fibrous concrete at various stress levels. J. Mater. Civil Eng. 2005, 17, 650–658. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, Y.M.; Abdelgader, H.S.; Fediuk, R.; Susrutha, A.; Poonguzhali, K. Impact performance of novel multi-layered prepacked aggregate fibrous composites under compression and bending. Structures 2020, 28, 1502–1515. [Google Scholar] [CrossRef]

| No. | Bulk Density (kg/m3) | Apparent Density (kg/m3) | Water Absorption (%) | Tube Compressive Strength (MPa) | |

|---|---|---|---|---|---|

| 1 h | 24 h | ||||

| Coal gangue ceramsite | 975 | 1730 | 5.07 | 7.43 | 6.8 |

| Pumice aggregate | 690 | 1593 | 16.44 | 17.32 | 2.98 |

| Fly ash ceramsite | 650 | 1323 | 12.51 | 12.98 | 6.5 |

| Coral aggregate | 915 | 1841 | 8.5 | 11.0 | 3.1 |

| No. | Substitution Rate (kg/m3) | Water (kg/m3) | Cement (kg/m3) | Fly Ash (kg/m3) | Gravel (kg/m3) | Lightweight Aggregate (kg/m3) | Sand (kg/m3) | Water Reducing Agent (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| BC0 | 0 | 180 | 366.4 | 91.6 | 1070 | 0 | 656 | 2 |

| CGC1 | 10 | 180 | 366.4 | 91.6 | 963 | 107 | 656 | 2 |

| CGC2 | 20 | 180 | 366.4 | 91.6 | 856 | 214 | 656 | 2 |

| CGC3 | 30 | 180 | 366.4 | 91.6 | 749 | 321 | 656 | 2 |

| CGC4 | 40 | 180 | 366.4 | 91.6 | 642 | 428 | 656 | 2 |

| PC1 | 10 | 180 | 366.4 | 91.6 | 963 | 107 | 656 | 2 |

| PC2 | 20 | 180 | 366.4 | 91.6 | 856 | 214 | 656 | 2 |

| PC3 | 30 | 180 | 366.4 | 91.6 | 749 | 321 | 656 | 2 |

| PC4 | 40 | 180 | 366.4 | 91.6 | 642 | 428 | 656 | 2 |

| FAC1 | 10 | 180 | 366.4 | 91.6 | 963 | 107 | 656 | 2 |

| FAC2 | 20 | 180 | 366.4 | 91.6 | 856 | 214 | 656 | 2 |

| FAC3 | 30 | 180 | 366.4 | 91.6 | 749 | 321 | 656 | 2 |

| FAC4 | 40 | 180 | 366.4 | 91.6 | 642 | 428 | 656 | 2 |

| CC1 | 10 | 180 | 366.4 | 91.6 | 963 | 107 | 656 | 2 |

| CC2 | 20 | 180 | 366.4 | 91.6 | 856 | 214 | 656 | 2 |

| CC3 | 30 | 180 | 366.4 | 91.6 | 749 | 321 | 656 | 2 |

| CC4 | 40 | 180 | 366.4 | 91.6 | 642 | 428 | 656 | 2 |

| No. | N1/N2 | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| BC0 | 853/854 | 1003/1004 | 1065/1066 | 1046/1047 | 923/924 | 986/987 |

| CGC1 | 861/863 | 927/928 | 902/903 | 952/953 | 763/765 | 894/895 |

| CGC2 | 1274/1276 | 1167/1169 | 976/979 | 1102/1104 | 1077/1079 | 953/955 |

| CGC3 | 796/797 | 853/854 | 965/967 | 1023/1024 | 1058/1059 | 871/872 |

| CGC4 | 684/685 | 1034/1034 | 749/749 | 852/852 | 957/957 | 932/933 |

| PC1 | 755/756 | 975/976 | 959/961 | 783/784 | 732/733 | 910/911 |

| PC2 | 692/693 | 728/729 | 831/832 | 921/922 | 925/927 | 744/745 |

| PC3 | 635/635 | 838/839 | 764/764 | 822/822 | 637/637 | 706/707 |

| PC4 | 732/733 | 580/580 | 613/613 | 669/669 | 706/706 | 636/636 |

| FAC1 | 954/955 | 891/892 | 933/935 | 967/968 | 1131/1132 | 1035/1036 |

| FAC2 | 740/741 | 713/714 | 948/949 | 885/886 | 821/822 | 869/870 |

| FAC3 | 1107/1108 | 1065/1066 | 1009/1010 | 853/854 | 864/865 | 965/966 |

| FAC4 | 715/715 | 736/737 | 834/834 | 872/872 | 928/928 | 800/800 |

| CC1 | 823/825 | 835/836 | 891/892 | 1084/1085 | 1102/1103 | 1054/1055 |

| CC2 | 742/744 | 756/757 | 872/873 | 971/972 | 915/916 | 946/947 |

| CC3 | 685/686 | 718/719 | 783/784 | 813/814 | 868/869 | 914/915 |

| CC4 | 670/671 | 754/754 | 836/837 | 765/766 | 825/825 | 703/703 |

| No. | Average of the Number of Impacts | Impact Energy Consumption/(w/J) | ||

|---|---|---|---|---|

| N1 | N2 | N2 − N1 | ||

| BC0 | 976 | 977 | 1 | 21,564.833 |

| CGC1 | 913 | 914 | 1 | 20,174.265 |

| CGC2 | 1055 | 1057 | 2 | 23,330.633 |

| CGC3 | 928 | 929 | 1 | 20,505.353 |

| CGC4 | 873 | 873 | 0 | 19,269.293 |

| PC1 | 852 | 853 | 1 | 18,827.843 |

| PC2 | 807 | 808 | 1 | 17,834.58 |

| PC3 | 734 | 734 | 0 | 16,201.215 |

| PC4 | 656 | 656 | 0 | 14,479.56 |

| FAC1 | 985 | 986 | 1 | 21,763.485 |

| FAC2 | 829 | 930 | 1 | 20,527.425 |

| FAC3 | 977 | 978 | 1 | 21,586.905 |

| FAC4 | 814 | 814 | 0 | 17,967.015 |

| CC1 | 965 | 966 | 1 | 21,322.035 |

| CC2 | 867 | 868 | 1 | 19,158.93 |

| CC3 | 797 | 798 | 1 | 17,613.855 |

| CC4 | 759 | 759 | 0 | 16,753.028 |

| No. | Regression Parameters | Correlation Coefficient | |

|---|---|---|---|

| R2 | |||

| BC0 | 10.949 | −75.854 | 0.973 |

| CGC1 | 11.356 | −77.494 | 0.899 |

| CGC2 | 8.208 | −57.866 | 0.927 |

| CGC3 | 8.018 | −55.224 | 0.943 |

| CGC4 | 5.803 | −39.674 | 0.976 |

| PC1 | 6.807 | −46.364 | 0.863 |

| PC2 | 7.011 | −47.357 | 0.880 |

| PC3 | 7.21 | −47.997 | 0.898 |

| PC4 | 10.342 | −67.519 | 0.978 |

| FAC1 | 10.151 | −70.422 | 0.839 |

| FAC2 | 8.243 | −55.833 | 0.956 |

| FAC3 | 8.322 | −57.731 | 0.93 |

| FAC4 | 9.088 | −61.345 | 0.956 |

| CC1 | 6.249 | −43.373 | 0.798 |

| CC2 | 7.699 | −52.519 | 0.902 |

| CC3 | 8.279 | −55.746 | 0.973 |

| CC4 | 11.148 | −74.181 | 0.809 |

| No. | |||||

|---|---|---|---|---|---|

| BC0 | 831 | 929 | 987 | 1038 | 1101 |

| CGC1 | 754 | 840 | 890 | 935 | 990 |

| CGC2 | 876 | 1017 | 1102 | 1179 | 1276 |

| CGC3 | 740 | 862 | 936 | 1003 | 1087 |

| CGC4 | 632 | 780 | 874 | 962 | 1075 |

| PC1 | 652 | 780 | 860 | 933 | 1026 |

| PC2 | 622 | 741 | 814 | 881 | 966 |

| PC3 | 570 | 675 | 740 | 799 | 874 |

| PC4 | 551 | 620 | 661 | 697 | 742 |

| FAC1 | 825 | 931 | 994 | 1049 | 1118 |

| FAC2 | 665 | 771 | 836 | 894 | 967 |

| FAC3 | 786 | 910 | 985 | 1053 | 1138 |

| FAC4 | 667 | 763 | 820 | 872 | 936 |

| CC1 | 721 | 876 | 975 | 1065 | 1181 |

| CC2 | 685 | 802 | 875 | 940 | 1022 |

| CC3 | 640 | 742 | 804 | 859 | 929 |

| CC4 | 634 | 707 | 751 | 789 | 836 |

| — |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, J.; Xu, Z.; Liu, Z.; Chen, S.; Wang, C.; Zhao, B.; Zhou, A. Experimental Study on the Mechanics and Impact Resistance of Multiphase Lightweight Aggregate Concrete. Sustainability 2022, 14, 9606. https://doi.org/10.3390/su14159606

Meng J, Xu Z, Liu Z, Chen S, Wang C, Zhao B, Zhou A. Experimental Study on the Mechanics and Impact Resistance of Multiphase Lightweight Aggregate Concrete. Sustainability. 2022; 14(15):9606. https://doi.org/10.3390/su14159606

Chicago/Turabian StyleMeng, Jian, Ziling Xu, Zeli Liu, Song Chen, Chen Wang, Ben Zhao, and An Zhou. 2022. "Experimental Study on the Mechanics and Impact Resistance of Multiphase Lightweight Aggregate Concrete" Sustainability 14, no. 15: 9606. https://doi.org/10.3390/su14159606

APA StyleMeng, J., Xu, Z., Liu, Z., Chen, S., Wang, C., Zhao, B., & Zhou, A. (2022). Experimental Study on the Mechanics and Impact Resistance of Multiphase Lightweight Aggregate Concrete. Sustainability, 14(15), 9606. https://doi.org/10.3390/su14159606