Economic and Environmental Assessment of Biomass Power Plants in Southern Italy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Energy Content of Biomass Sources

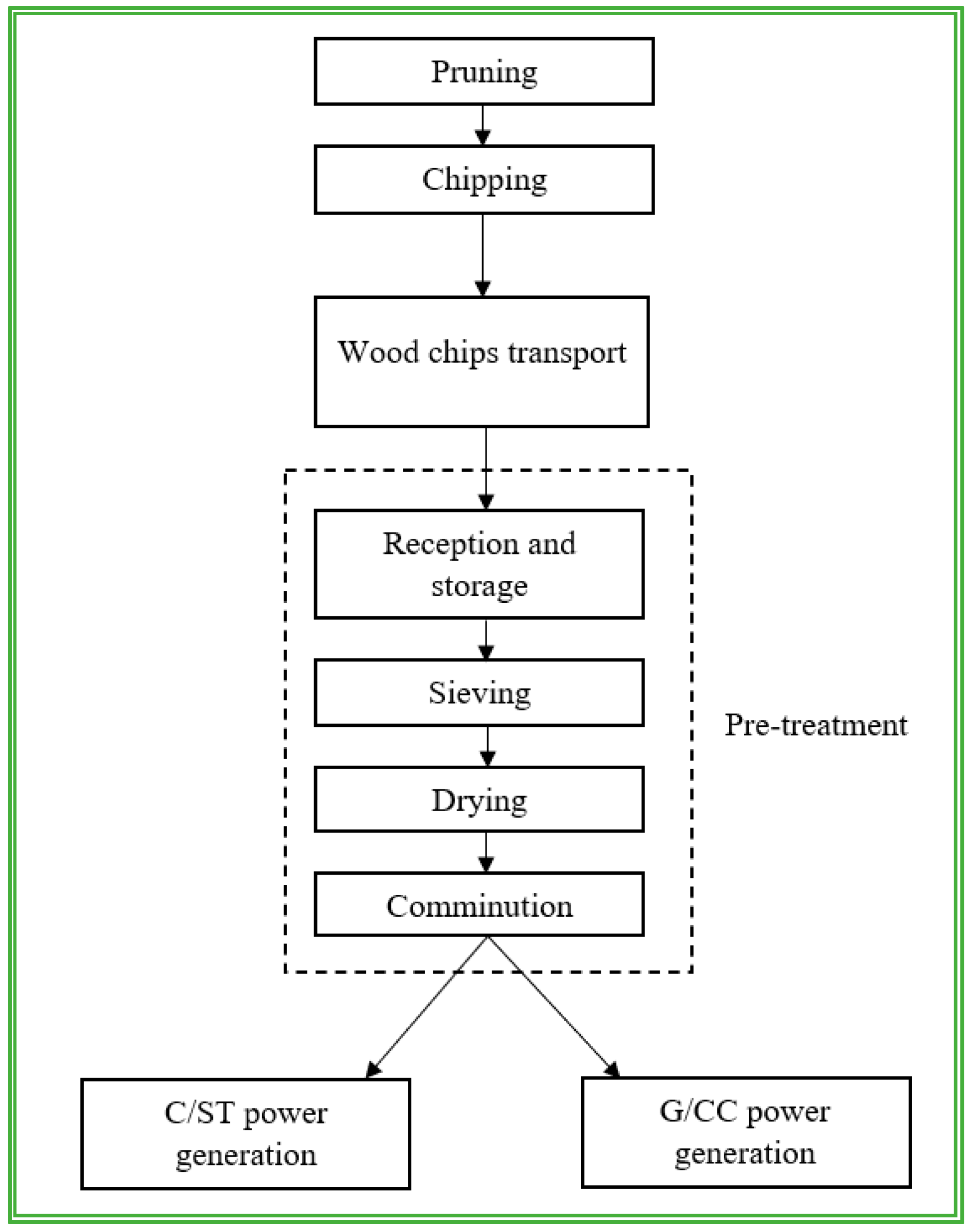

2.2. Biomass Power Plant Configurations

- Fluid bed combustion, followed by steam turbine cycle power generation (C/ST);

- Fluid bed gasification, followed by combined gas–steam cycle power generation (G/CC).

2.3. Economic Analysis

2.4. LCA Analysis

2.4.1. Goal and Scope Definition

2.4.2. Life Cycle Inventory

3. Results and Discussion

3.1. Economic Assessment

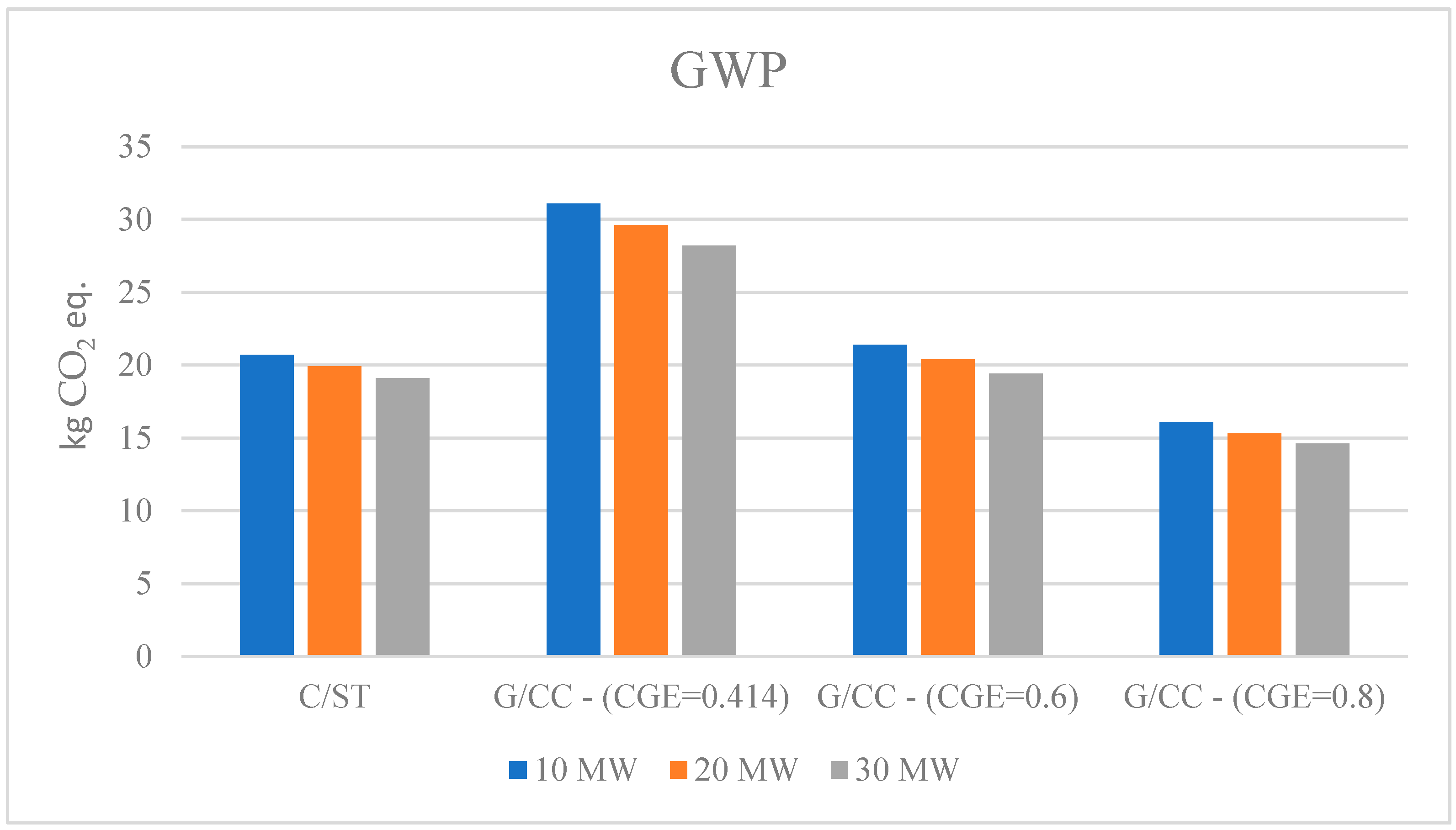

3.2. Life Cycle Impact Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- European Commission Clean Energy. The European Green Deal; European Commission Clean Energy: Brussels, Belgium, 2019. [Google Scholar]

- Robbins, A. How to understand the results of the climate change summit: Conference of Parties21 (COP21) Paris 2015. J. Public Health Policy 2016, 37, 129–132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- IEA. Renewable Electricity Capacity Additions, 2007–2021, Updated IEA Forecast. Available online: https://www.iea.org/data-and-statistics/charts/renewable-electricity-capacity-additions-2007-2021-updated-iea-forecast (accessed on 19 March 2021).

- Bharti, A.; Paritosh, K.; Mandla, V.R.; Chawade, A.; Vivekanand, V. GIS Application for the Estimation of Bioenergy Potential from Agriculture Residues: An Overview. Energies 2021, 14, 898. [Google Scholar] [CrossRef]

- Sciortino, R.; Micale, R.; Enea, M.; La Scalia, G. A webGIS-based system for real time shelf life prediction. Comput. Electron. Agric. 2016, 127, 451–459. [Google Scholar] [CrossRef]

- La Scalia, G.; Marra, F.P.; Rühl, J.; Sciortino, R.; Caruso, T. Fuzzy multi-criteria decision-making methodology to optimise olive agro-engineering processes based on geo-spatial technologies. Int. J. Manag. Decis. Mak. 2016, 15, 1–15. [Google Scholar]

- Miglietta, P.P.; Micale, R.; Sciortino, R.; Caruso, T.; Giallanza, A.; La Scalia, G. The sustainability of olive orchard planting management for different harvesting techniques: An integrated methodology. J. Clean. Prod. 2019, 238, 117989. [Google Scholar] [CrossRef]

- Haase, M.; Rösch, C.; Ketzer, D. GIS-based assessment of sustainable crop residue potentials in European regions. Biomass Bioenergy 2016, 86, 156–171. [Google Scholar] [CrossRef]

- Malico, I.; Carrajola, J.; Gomes, C.P.; Lima, J.C. Biomass residues for energy production and habitat preservation. Case study in a montado area in Southwestern Europe. J. Clean. Prod. 2016, 112, 3676–3683. [Google Scholar] [CrossRef] [Green Version]

- Garcia, D.A.; Sangiorgio, S.; Rosa, F. Estimating the potential biomasses energy source of forest and agricultural residues in the Cinque Terre Italian National Park. Energy Procedia 2015, 82, 674–680. [Google Scholar] [CrossRef] [Green Version]

- Lourinho, G.; Brito, P. Assessment of biomass energy potential in a region of Portugal (Alto Alentejo). Energy 2015, 81, 189–201. [Google Scholar] [CrossRef]

- Höhn, J.; Lehtonen, E.; Rasi, S.; Rintala, J. A Geographical Information System (GIS) based methodology for determination of potential biomasses and sites for biogas plants in southern Finland. Appl. Energy 2014, 113, 1–10. [Google Scholar] [CrossRef]

- Moliner, C.; Arato, E.; Marchelli, F. Current Status of Energy Production from Solid Biomass in Southern Italy. Energies 2021, 14, 2576. [Google Scholar] [CrossRef]

- Nandimandalam, H.; Gude, V.G.; Marufuzzaman, M. Environmental impact assessment of biomass supported electricity generation for sustainable rural energy systems—A case study of Grenada County, Mississippi, USA. Sci. Total Environ. 2022, 802, 149716. [Google Scholar] [CrossRef] [PubMed]

- Riva, G. Impianti a Biomasse per la Produzione di Energia Elettrica; Rapporto preparato dall’Ufficio Centrale del CTI: Milano, Italy, 2000. [Google Scholar]

- Qu, J.; Feng, Y.; Zhu, Y.; Zhou, S.; Zhang, W. Design and thermodynamic analysis of a combined system including steam Rankine cycle, organic Rankine cycle, and power turbine for marine low-speed diesel engine waste heat recovery. Energy Convers. Manag. 2021, 245, 114580. [Google Scholar] [CrossRef]

- Zhang, H.H.; Li, M.J.; Feng, Y.Q.; Xi, H.; Hung, T.C. Assessment and working fluid comparison of steam Rankine cycle-Organic Rankine cycle combined system for severe cold territories. Case Stud. Therm. Eng. 2021, 18, 101601. [Google Scholar] [CrossRef]

- Beagle, E.; Belmont, E. Comparative life cycle assessment of biomass utilization for electricity generation in the European Union and the United States. Energy Policy 2019, 128, 267–275. [Google Scholar] [CrossRef]

- Calì, G.; Deiana, P.; Bassano, C.; Meloni, S.; Maggio, E.; Mascia, M.; Pettinau, A. Syngas Production, Clean-Up and Wastewater Management in a Demo-Scale Fixed-Bed Updraft Biomass Gasification Unit. Energies 2020, 13, 2594. [Google Scholar] [CrossRef]

- Petrillo, A.; Travaglioni, M.; Di Fraia, S.; Vanoli, L.; Cirillo, D.; La Villetta, M. Experimental study and Life Cycle Assessment of biomass small-scale trigeneration plant. J. Clean. Prod. 2021, 326, 129234. [Google Scholar] [CrossRef]

- Maheshwari, M.; Singh, O. Thermodynamic study of different configurations of gas-steam combined cycles employing intercooling and different means of cooling in topping cycle. Appl. Therm. Eng. 2019, 162, 114249. [Google Scholar] [CrossRef]

- He, X.; Wang, H.; Li, R.; Sun, H.; Chen, H.; Li, C.; Ge, G.; Tao, F. Thermo-conversion of a physical energy storage system with high-energy density: Combination of thermal energy storage and gas-steam combined cycle. Energy 2022, 239, 122325. [Google Scholar] [CrossRef]

- Cardoso, J.; Silva, V.; Eusébio, D. Techno-economic analysis of a biomass gasification power plant dealing with forestry residues blends for electricity production in Portugal. J. Clean. Prod. 2019, 212, 741–753. [Google Scholar] [CrossRef]

- Malek, A.B.M.A.; Hasanuzzaman, M.; Rahim, N.A.; Turki, Y.A.A. Techno-economic analysis and environmental impact assessment of a 10 MW biomass-based power plant in Malaysia. J. Clean. Prod. 2017, 141, 502–513. [Google Scholar] [CrossRef]

- Caputo, A.; Palumbo, M.; Pelagagge, P.M.; Scacchia, F. Economics of biomass energy utilization in combustion and gasification plants: Effects of logistic variables. Biomass Bioenergy 2005, 28, 35–51. [Google Scholar] [CrossRef]

- Bridgwater, A.V.; Toft, A.J.; Brammer, J.G. A techno- economic comparison of power production by biomass fast pyrolysis with gasification and combustion. Renew. Sustain. Energy Rev. 2002, 6, 181–248. [Google Scholar] [CrossRef]

- La Scalia, G.; Micale, R.; Cannizzaro, L.; Marra, F.P. A sustainable phenolic compound extraction system from olive oil mill wastewater. J. Clean. Prod. 2017, 142, 3782–3788. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management Life Cycle Assessment–Principles and Framework. International Organization for Standardization (ISO), European Standard: Geneva, Switzerland, 2006.

- Gustavsson, L.; Börjesson, P.; Johansson, B.; Svenningsson, P. Reducing CO2 emissions by substituting biomass for fossil fuels. Energy 1995, 20, 1097–1113. [Google Scholar] [CrossRef]

- Nemecek, T.; Heil, A.; Huguenin, O.; Meier, S.; Erzinger, S.; Blaser, S.; Dux, D.; Zimmermann, A. Life Cycle Inventories of Agricultural Production Systems; Final Report Ecoinvent 2000 No. 15; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2003. [Google Scholar]

- Ente NAzionale per la Meccanizzazione Agricola (ENAMA). Progetto Biomasse ENAMA: Stato dell’arte degli Impianti di Produzione di Energia da Biomasse; Ente NAzionale per la Meccanizzazione Agricola (ENAMA): Lazio, Italy, 2012. [Google Scholar]

- Van Belle, J.F. A model to estimate fossil CO2 emission during the harvesting of forest residues for energy with an application on the case of chipping. Biomass Bioenergy 2006, 30, 1067–1075. [Google Scholar] [CrossRef]

- Whitty, K.J.; Eddings, E.G.; Zhang, H. Emissions from syngas combustion. Combust. Sci. Technol. 2008, 180, 1117–1136. [Google Scholar] [CrossRef]

| Biomass | (t/y) | LHV (MJ/kg) | Energy (MJ/kg) |

|---|---|---|---|

| Vineyard | 165,297 | 18.0 | 2,975,356,800 |

| Olive | 16,773 | 17.6 | 295,205,645 |

| Pomace | 15,724 | 15.5 | 243,726,650 |

| Plant Configuration | Plant Size (MW) | Energy Conversion Efficiency |

|---|---|---|

| C/ST | 10 | 0.25 |

| 20 | 0.26 | |

| 30 | 0.27 | |

| G/CC | 10 | 0.39 |

| 20 | 0.41 | |

| 30 | 0.43 |

| Plant Size (MW) | Biomass (t) | Catchment Area (km2) | Radius (km) | Average Round Trip (km) | Distance per Ton (km/t) |

|---|---|---|---|---|---|

| 10 | 56,629 | 768.3 | 15.63 | 20.85 | 1.04 |

| 20 | 113,258 | 1536.5 | 22.11 | 29.48 | 1.47 |

| 30 | 169,888 | 2304.8 | 27.08 | 36.11 | 1.80 |

| Life Cycle Step | Fuel Consumption (Diesel) (kg t−1 of Biomass) | Electricity Consumption/Transport (kWh/km t−1 of Biomass) | Emissions (g t−1 of Biomass) | |||

|---|---|---|---|---|---|---|

| HC | NOx | CO | ||||

| Pruning | Vineyards | 1.72 | 4.32 | 66.96 | 6.84 | |

| Olive groves | 2.27 | 5.68 | 88.10 | 9.00 | ||

| Chipping | Vineyards | 3.22 | 5.04 | 86.04 | 12.96 | |

| Olive groves | 3.22 | 6.63 | 113.21 | 17.05 | ||

| Transport | 10 MW | 1.04 km | ||||

| 20 MW | 1.47 km | |||||

| 30 MW | 1.80 km | |||||

| Pretreatment | Reception and storage | 1 kWh | ||||

| Sieving | 0.87 kWh | |||||

| Drying | 0.72 kWh of natural gas | 18.76 kWh | ||||

| Comminution | 37.71 kWh | |||||

| PM2.5 | NOx | CO | ||||

| C/ST | 198 | 1820 | 324 | |||

| G/CC | 167 | 2340 | 134 | |||

| C/ST | G/CC | |||||

|---|---|---|---|---|---|---|

| Power Size (MW) | 10 | 20 | 30 | 10 | 20 | 30 |

| Biomass storage/handling costs | 930,795 | 1,547,881 | 2,108,309 | 3,427,811 | 5,340,798 | 6,894,473 |

| Power generation costs | 10,136,918 | 15,472,668 | 19,891,613 | 11,921,571 | 19,416,493 | 25,559,681 |

| Air pollution costs | 1,682,789 | 2,496,475 | 3,156,707 | 1,682,789 | 2,496,475 | 3,156,707 |

| Piping costs | 1,152,687 | 1,810,832 | 2,381,543 | 1,152,687 | 1,810,832 | 2,381,543 |

| Electrical costs | 3,077,449 | 4,795,399 | 6,227,541 | 3,077,449 | 4,795,399 | 6,227,541 |

| Civil works costs | 3,825,158 | 5,010,492 | 5,875,564 | 3,825,158 | 5,010,492 | 5,875,564 |

| Direct installation costs | 8,287,826 | 12,686,066 | 16,351,809 | 11,070,911 | 17,714,948 | 23,147,060 |

| Indirect costs | 2,805,110 | 4,293,745 | 5,534,458 | 3,747,078 | 5,995,829 | 7,834,390 |

| Total TCI | 31,898,733 | 48,113,560 | 61,527,544 | 39,905,454 | 62,581,266 | 81,076,959 |

| C/ST | G/CC | |||||

|---|---|---|---|---|---|---|

| Power Size (MW) | 10 | 20 | 30 | 10 | 20 | 30 |

| Labor costs | 312,000 | 624,000 | 936,000 | 312,000 | 624,000 | 936,000 |

| Biomass cost | 1,685,790 | 3,241,904 | 4,682,750 | 1,080,635 | 2,055,841 | 2,940,331 |

| Biomass transport cost | 457,440 | 882,572 | 1,330,790 | 292,992 | 526,644 | 812,073 |

| Maintenance cost | 478,481 | 721,703 | 922,913 | 1,197,164 | 1,877,438 | 2,432,309 |

| Insurance cost | 318,987 | 481,136 | 615,275 | 399,055 | 625,813 | 810,770 |

| Total TOC | 3,252,698 | 5,951,315 | 8,487,728 | 3,281,845 | 5,709,736 | 7,931,482 |

| Power Size (MW) | 10 | 20 | 30 |

|---|---|---|---|

| Revenue | 14,586,480 | 29,172,960 | 43,759,440 |

| YEAR | C/ST | G/CC | ||||

|---|---|---|---|---|---|---|

| 10 MW | 20 MW | 30 MW | 10 MW | 20 MW | 30 MW | |

| 0 | −31,898,733 | −48,113,560 | −61,527,544 | −39,905,454 | −62,581,266 | −81,076,959 |

| 1 | 11,333,782 | 23,221,645 | 35,271,712 | 11,176,635 | 23,463,224 | 35,827,958 |

| 2 | 11,333,782 | 23,221,645 | 35,271,712 | 11,176,635 | 23,463,224 | 35,827,958 |

| … | … | … | … | … | … | … |

| 18 | 11,333,782 | 23,221,645 | 35,271,712 | 11,176,635 | 23,463,224 | 35,827,958 |

| 19 | 11,333,782 | 23,221,645 | 35,271,712 | 11,176,635 | 23,463,224 | 35,827,958 |

| 20 | 11,333,782 | 23,221,645 | 35,271,712 | 11,176,635 | 23,463,224 | 35,827,958 |

| Plant | Size (MW) | Electricity per Biomass Ton (MWhel t−1 of Biomass) |

|---|---|---|

| C/ST | 10 | 1.25 |

| 20 | 1.30 | |

| 30 | 1.35 | |

| G/CC—(ηCG = 0.414) | 10 | 0.81 |

| 20 | 0.85 | |

| 30 | 0.89 | |

| G/CC—(ηCG = 0.6) | 10 | 1.17 |

| 20 | 1.23 | |

| 30 | 1.29 | |

| G/CC—(ηCG = 0.8) | 10 | 1.56 |

| 20 | 1.64 | |

| 30 | 1.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

La Scalia, G.; Adelfio, L.; La Fata, C.M.; Micale, R. Economic and Environmental Assessment of Biomass Power Plants in Southern Italy. Sustainability 2022, 14, 9676. https://doi.org/10.3390/su14159676

La Scalia G, Adelfio L, La Fata CM, Micale R. Economic and Environmental Assessment of Biomass Power Plants in Southern Italy. Sustainability. 2022; 14(15):9676. https://doi.org/10.3390/su14159676

Chicago/Turabian StyleLa Scalia, Giada, Luca Adelfio, Concetta Manuela La Fata, and Rosa Micale. 2022. "Economic and Environmental Assessment of Biomass Power Plants in Southern Italy" Sustainability 14, no. 15: 9676. https://doi.org/10.3390/su14159676

APA StyleLa Scalia, G., Adelfio, L., La Fata, C. M., & Micale, R. (2022). Economic and Environmental Assessment of Biomass Power Plants in Southern Italy. Sustainability, 14(15), 9676. https://doi.org/10.3390/su14159676