Active Power Control of Retrofit LED Tube Lamps for Achieving Entitled Energy Savings in View of the EU Ban on Mercury

Abstract

:1. Introduction

1.1. Background

1.2. Environmental Policy and the “Mercury Ban”

1.3. LED Replacement: Luminaire vs. Lamps

- High initial costs of LED luminaires (compared to LED lamps [13]);

- High downtime for installations (especially when lighting for 24 h per day);

- High cost of labor (removing old luminaires and replacing them with new);

- Cannibalization of prior investments in fluorescent troffer electronic ballasts;

- Low fluorescent lamp replacement costs (the mercury ban is not yet enforced).

2. Materials and Methods

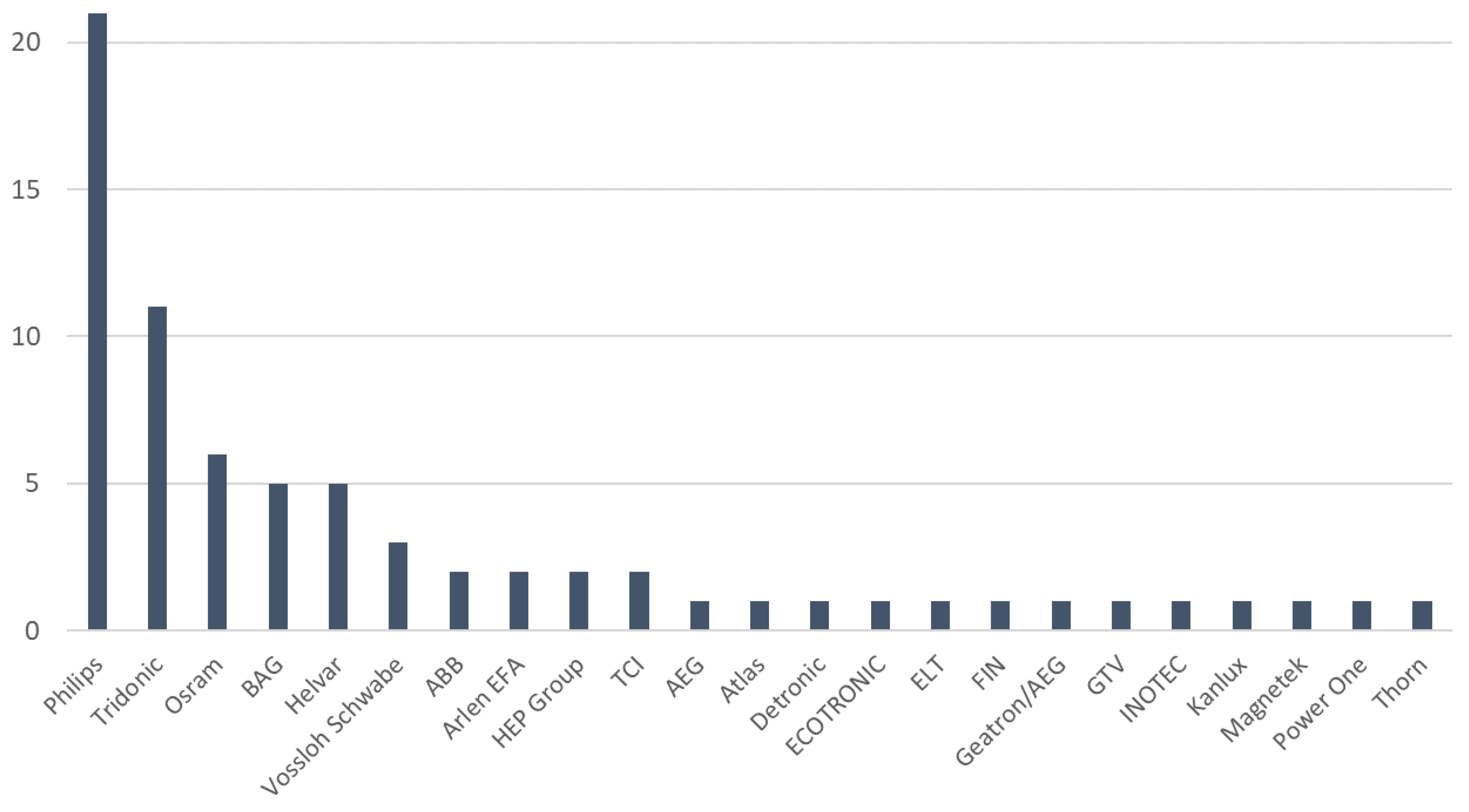

2.1. Field-Recovered Ballasts

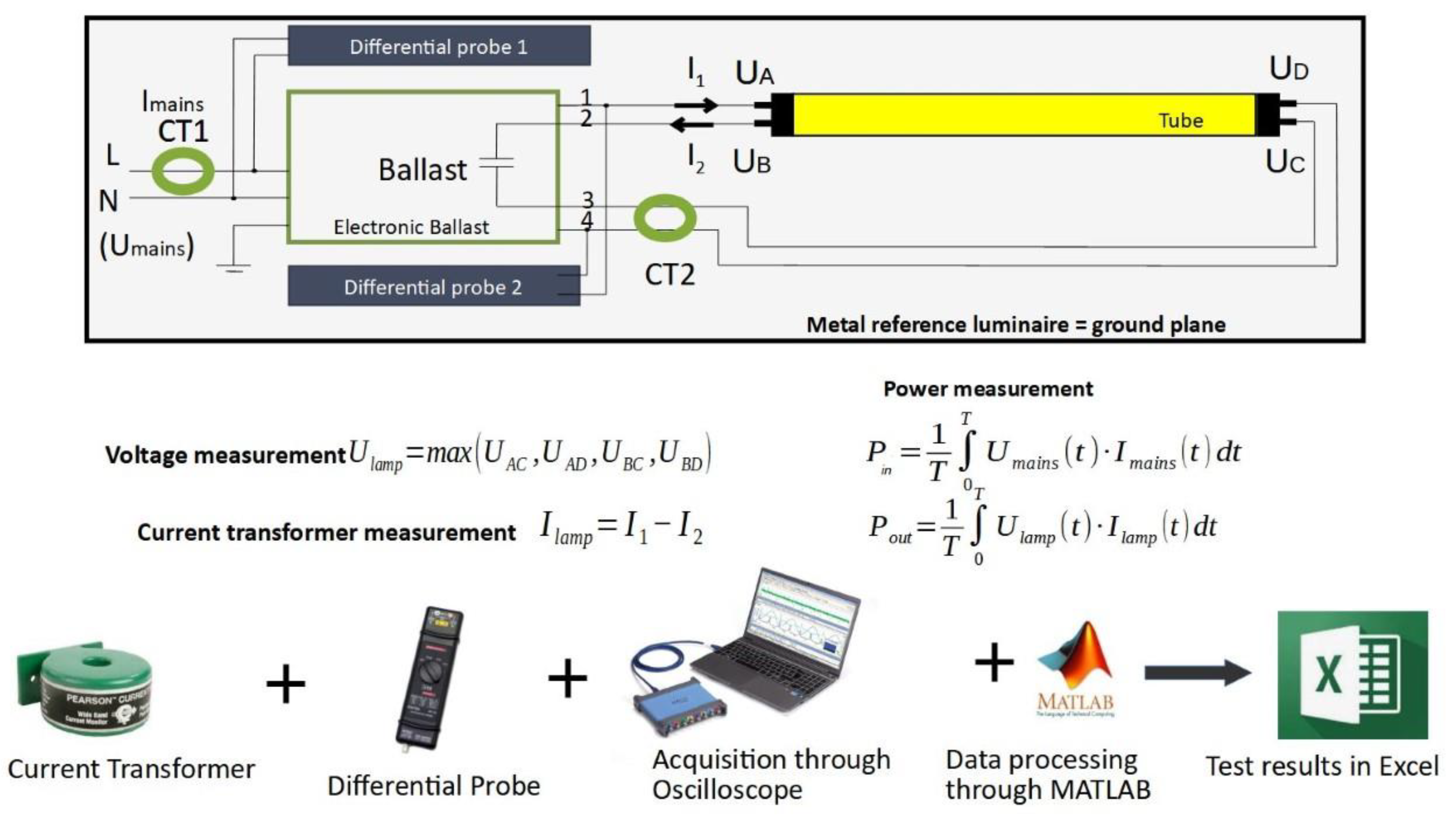

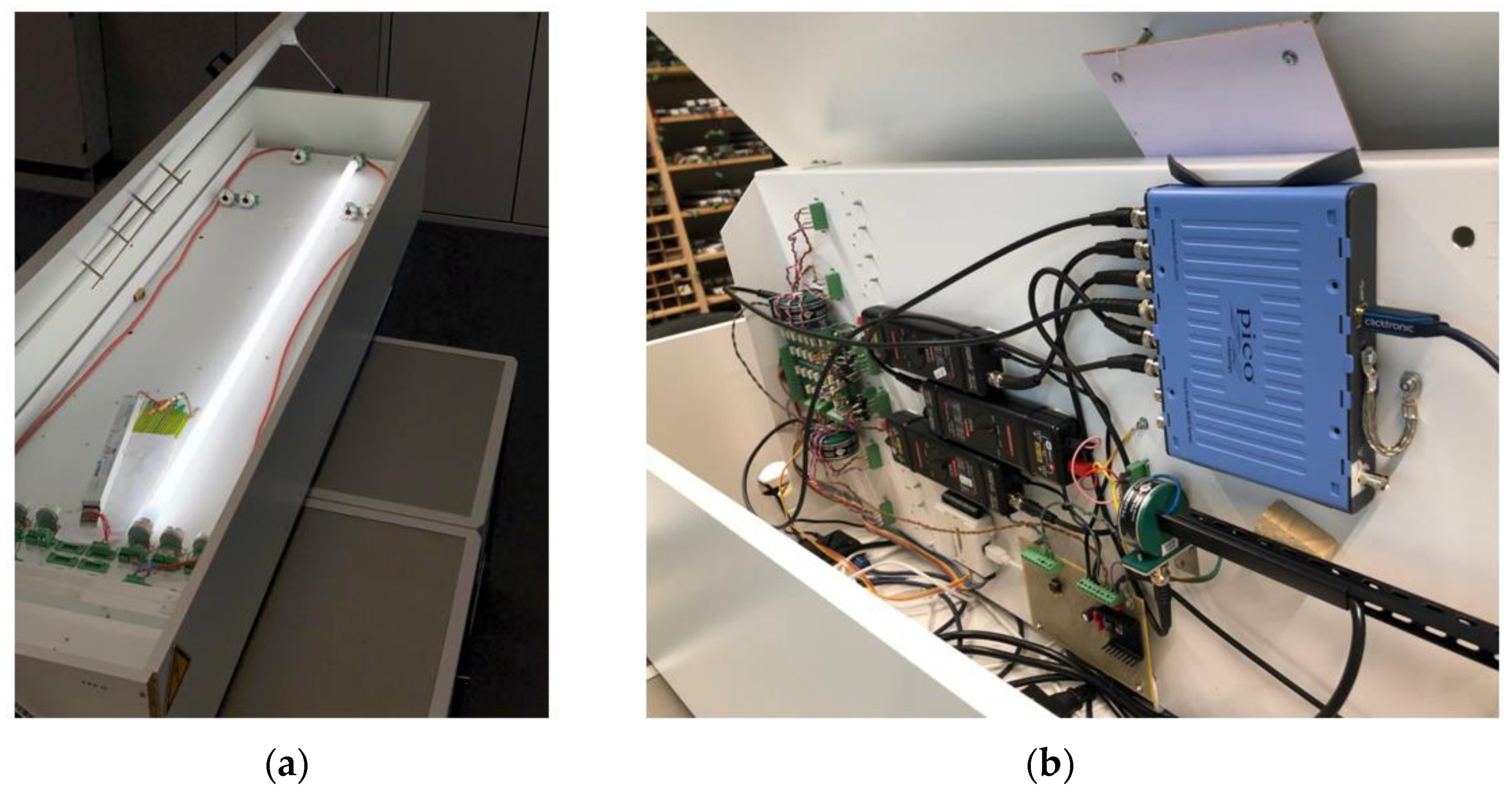

2.2. Lamp Test Apparatus

- CT1 (Current Transformer 1) is used for ballast input current measurement;

- CT2 (Current Transformer 2) is used for ballast output current measurement;

- Differential probe 1 is used for input voltage measurement;

- Differential probe 2 is used for output voltage measurement;

- According to measurement standards, the highest voltage over the 4 outputs of an electronic ballast should be used. “Voltage swapping” between ballast outputs 1, 2, 3, and 4 is automated using a relay board and the measurement software;

- An oscilloscope is used to receive the signals from the transducers;

- The voltage and current values are collected and, thereafter, the MATLAB code is used to calculate the RMS power for both input and output measurements.

- Ballast Input: U_rms, I_rms, P (system power), PF (power factor), frequency;

- Ballast Output/Lamp input: U_rms, I_rms, P (lamp power), frequency, PF (power factor);

- Thermal: ambient temperature.

- Localized voltage and current acquisition to minimize the common-mode rejection ratio (CMRR) and crosstalk;

- Metal reference luminaire, to provide a ground connection for interference and leakage currents from ballasts;

- Tightly wired luminaire, to enable accurate high-frequency measurements with leakage capacitances within electronic ballast specifications.

3. Results

3.1. Commercially Available Retrofit LED Tubes: Selection

3.2. Commercially Available Retrofit LED Tubes: Test Results

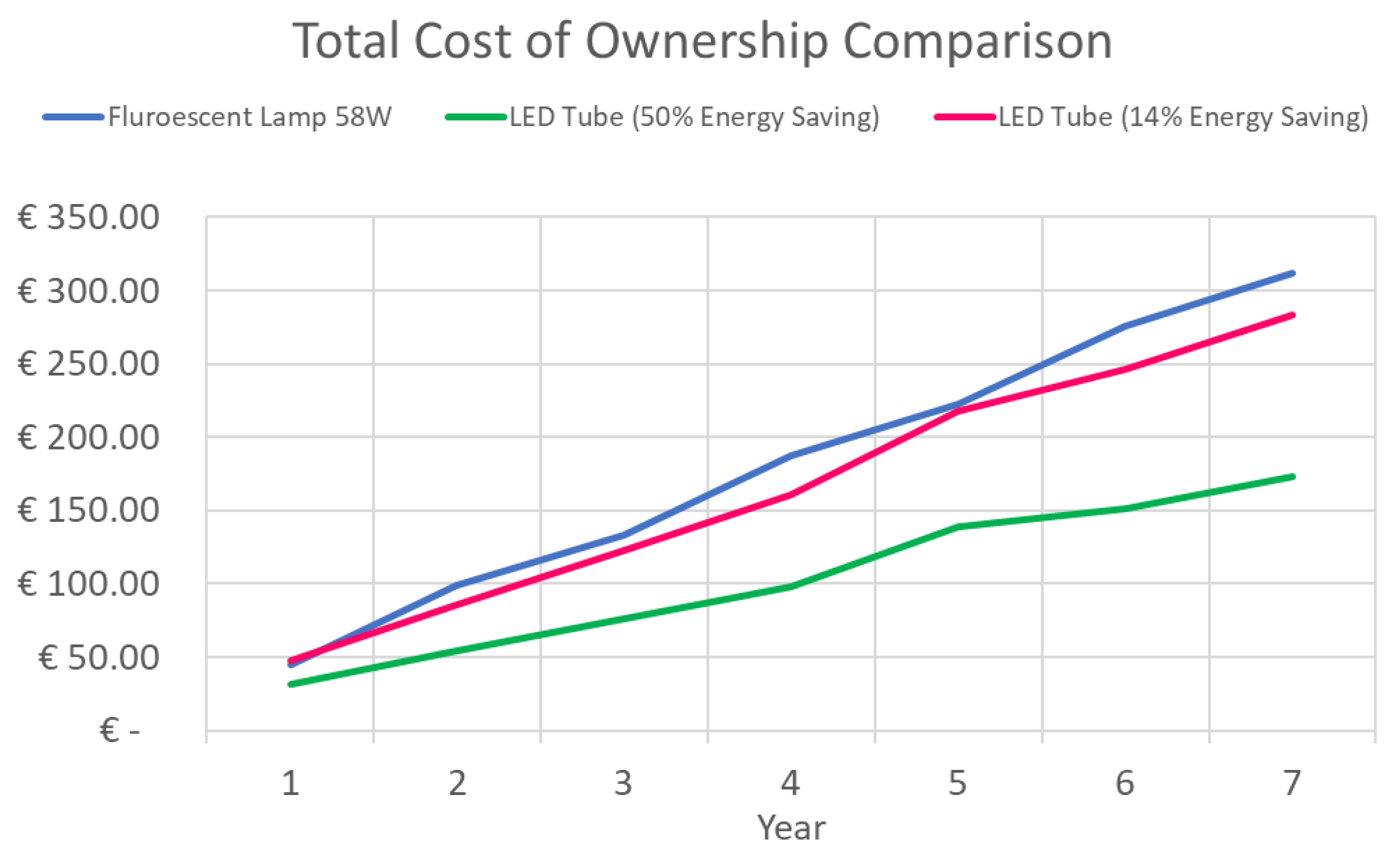

4. Discussion

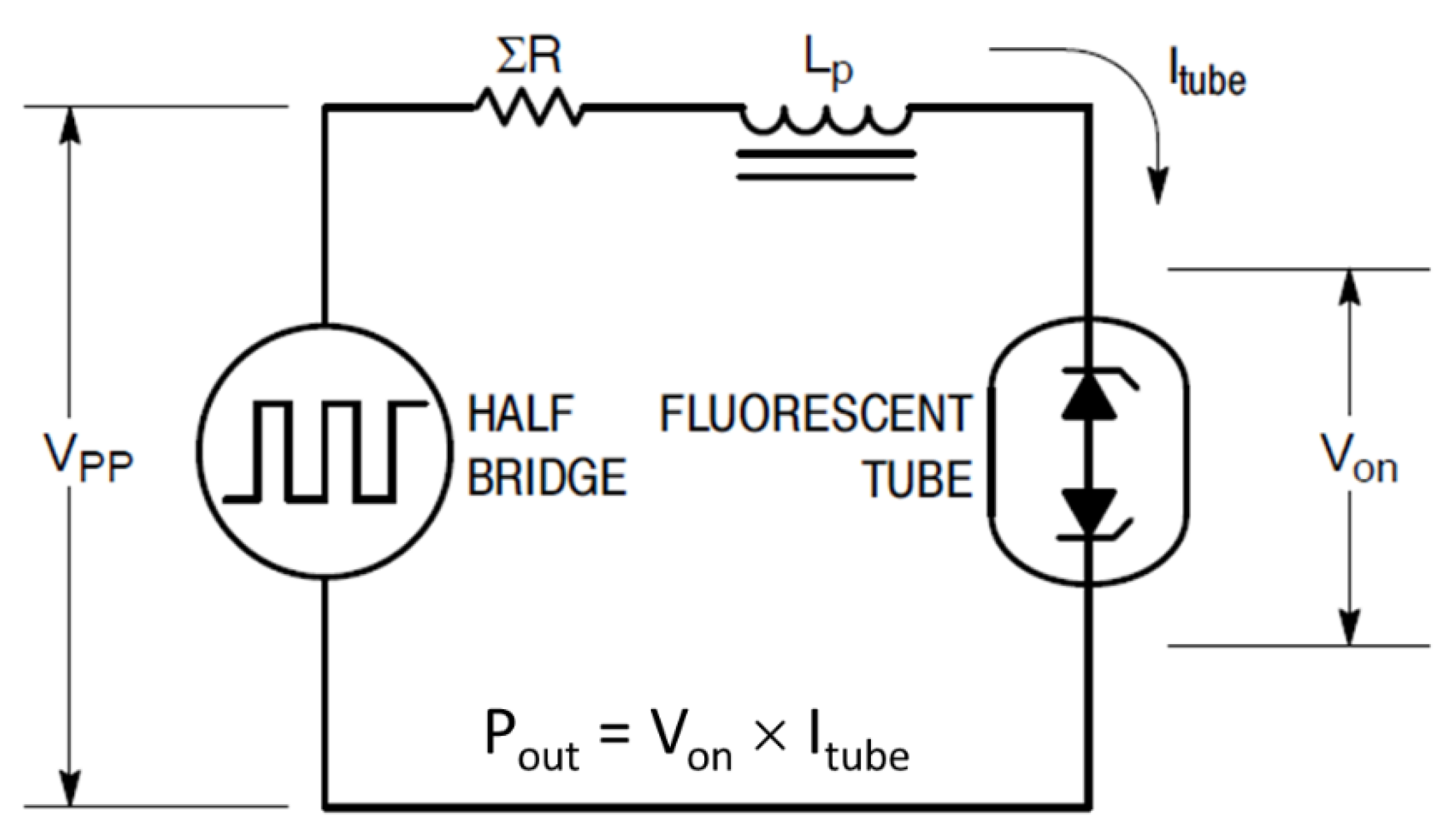

4.1. Constant-Current Electronic Ballasts

4.2. Constant-Power Electronic Ballasts

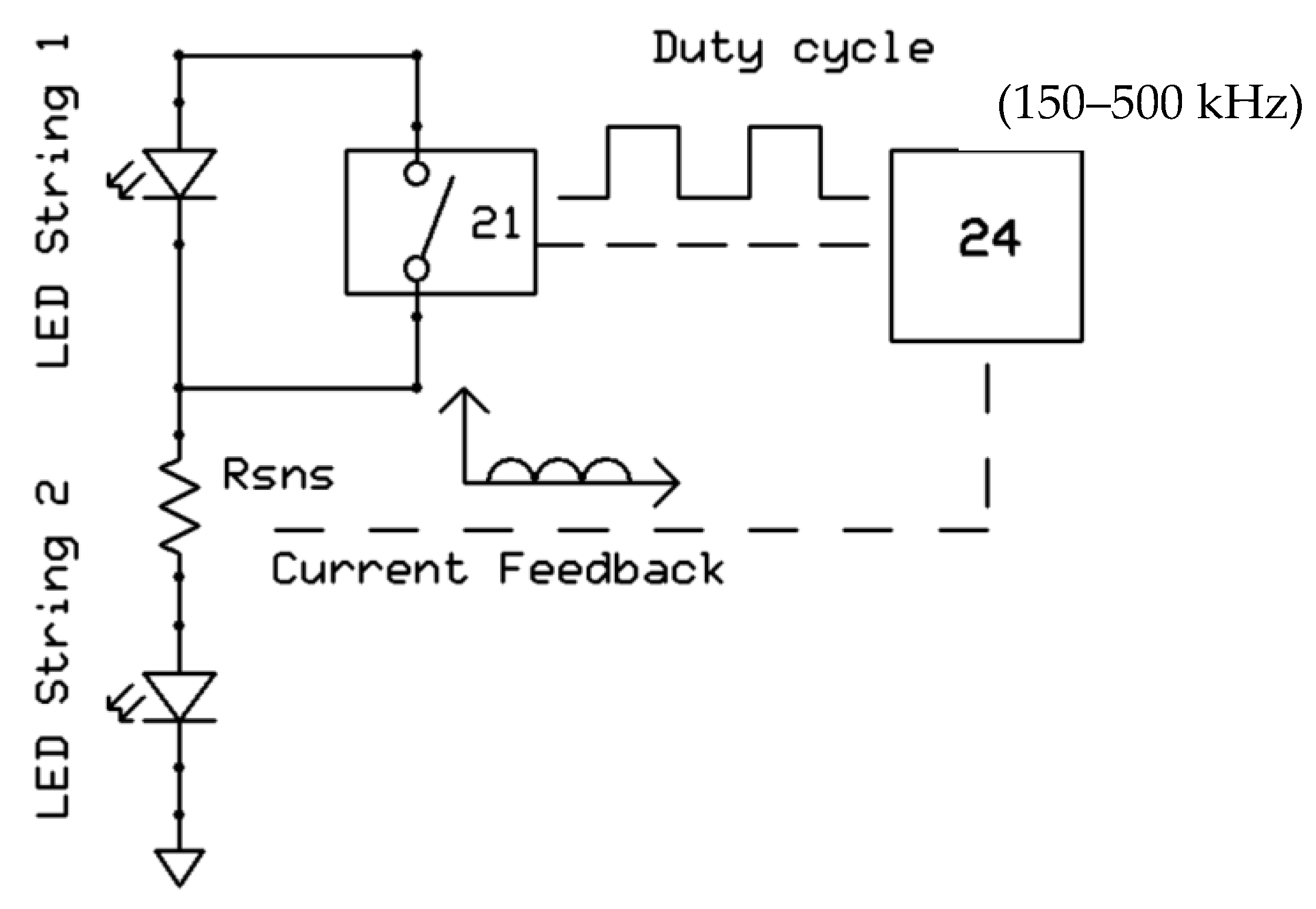

4.3. Active Power Control (APC)

- Determining the LED tube power needed to meet lumen and energy-saving requirements and choosing a total LED string size;

- The total LED string is split into two strings, string 1 and string 2, in an empirically determined ratio. This ratio is determined using the following steps:

- LED string 2. The number of LEDs in string 2, when used as a load, should give an LED tube power equal to the rated LED tube lamp power with the highest output current electronic ballasts;

- LED string 1. The total number of LEDs in string 1 and string 2, when used as a load together, should give an LED tube power equal to the rated LED tube lamp power with the lowest output-current electronic ballasts. (The string ratio is crucial and should ideally consider all electronic ballasts available for measurement).

- A semiconductor switch (transistor, MOSFET, or IGBT) is placed in parallel to string 1 (see Figure 11).

5. Conclusions

6. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zissis, G.; Bertoldi, P.; Serrenho, T. Update on the Status of LED-Lighting World Market since 2018; EUR 30500 EN; Publications Office of the European Union: Luxembourg, 2021; ISBN 978-92-76-27244-1. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Adoption of Light-Emitting Diodes in Common Lighting Applications. 2020. Available online: https://www.energy.gov/eere/ssl/downloads/2020-led-adoption-report (accessed on 16 July 2022).

- Dillon, H.E.; Ross, C.; Rachel Dzombak, R. Environmental and Energy Improvements of LED Lamps over Time: A Comparative Life Cycle Assessment. LEUKOS 2020, 16, 229–237. [Google Scholar] [CrossRef]

- Bennich, P.; Scholand, M. Evidence of the Availability of Mercury-Free Alternative Products to Certain Fluorescent Lamps; Report to the Committee on the Regulation of Hazardous Substances; CLASP: Washington, DC, USA, 12 December 2019; Revision v.2. [Google Scholar]

- VHK. Model for European Light Source Analysis (MELISA); Version 0; Prepared for the European Commission; VHK: Delft, The Netherlands, 31 January 2015. [Google Scholar]

- U.S. Department of Energy. 2015 U.S. Lighting Market Characterization. 2017. Available online: https://www.energy.gov/sites/default/files/2017/12/f46/lmc2015_nov17.pdf (accessed on 16 July 2022).

- Pattison, P.M.; Hansen, M.; Tsao, J.Y. LED lighting efficacy: Status and directions. Comptes Rendus Phys. 2018, 19, 134–145. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Minamata Convention on Mercury: Text and Annexes. 2013. Available online: https://wedocs.unep.org/20.500.11822/8541 (accessed on 16 July 2022).

- Kohler, P.; Morgera, E.; Ripley, K.; Schabus, N.; Tsioumani, E. Summary of the Fifth Meeting of the Inter-Governmental Negotiating Committee to Prepare a Global Legally Binding Instrument on Mercury; International Institute for Sustainable Development: Winnipeg, MB, Canada, 21 January 2013. [Google Scholar]

- Bergesen, J.D.; Tähkämö, L.; Gibon, T.; Suh, S. Potential Long-Term Global Environmental Implications of Efficient Light-Source Technologies. J. Ind. Ecol. 2016, 20, 263–275. [Google Scholar] [CrossRef]

- European Council for an Energy Efficiency Economy, EU Bans Inefficient Toxic Lighting at Home, Proposes to Manufacture & Export Abroad. 1 September 2021. Available online: https://www.eceee.org/all-news/news/eu-bans-toxic-lighting-at-home-proposes-to-manufacture-export-abroad/ (accessed on 16 July 2022).

- Amann, J.T.; Fadie, B.; Mauer, J.; Swaroop, K.; Tolentino, C. Farewell to Fluorescent Lighting: How a Phaseout Can Cut Mercury Pollution, Protect the Climate, and Save Money; American Council for an Energy-Efficient Economy: Washington, DC, USA, 2022; Available online: https://www.aceee.org/research-report/b2202 (accessed on 17 July 2022).

- U.S. Department of Energy. Energy Savings Forecast of Solid-State Lighting in General Illumination Applications. December 2019. Available online: https://www.energy.gov/sites/default/files/2020/02/f72/2019_ssl-energy-savings-forecast.pdf (accessed on 16 July 2022).

- European Commission. Commission Regulation (EU) 2019/2020 of 1 October 2019 Laying Down Ecodesign Requirements for Light Sources and Separate Control Gears Pursuant to Directive 2009/125/EC of the European Parliament and of the Council and Repealing Commission Regulations (EC) No 244/2009, (EC) No 245/2009 and (EU) No 1194/2012, 12 May 2019; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Electricity Price Statistics. April 2022. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics (accessed on 16 July 2022).

- Shen, Y.C.; Mueller, G.O.; Watanabe, S.; Gardner, N.F.; Munkholm, A.; Krames, M.R. Auger recombination in InGaN measured by photoluminescence. Appl. Phys. Lett. 2007, 91, 141101. [Google Scholar] [CrossRef]

- Ho, W.Y.; Chow, Y.C.; Myers, D.J.; Wu, F.; Peretti, J.; Weisbuch, C.; Speck, J.S. Quantitative correlation of hot electron emission to Auger recombination in the active region of c-plane blue III-N LEDs. Appl. Phys. Lett. 2021, 119, 051105. [Google Scholar] [CrossRef]

- Meneghini, M.; de Santi, C.; Tibaldi, A.; Vallone, M.; Bertazzi, F.; Meneghesso, G.; Zanoni, E.; Goano, M. Thermal droop in III-nitride based light-emitting diodes: Physical origin and perspectives. J. Appl. Phys. 2020, 127, 211102. [Google Scholar] [CrossRef]

- Van Driel, W.D.; Schuld, M.; Jacobs, B.; Commissaris, F.; van der Eyden, J.; Hamon, B. Lumen maintenance predictions for LED packages. Microelectron. Reliab. 2016, 62, 39–44. [Google Scholar] [CrossRef]

- Vitanza, A.; Scollo, R.; Hayes, A. Electronic Fluorescent Lamp Ballast, ST Microelectronics AN527/1294. Available online: https://www.st.com/resource/en/application_note/an527-electronic-fluorescent-lamp-ballast-stmicroelectronics.pdf (accessed on 16 July 2022).

| Equipment | Manufacturer | Part No. | Function |

|---|---|---|---|

| Oscilloscope | Pico Technology Ltd. (St. Neots, UK) | 4824A | Capture input and output voltage and current signals from electronic ballasts. |

| Differential probe (3) | Pintek Electronics Co., Ltd. (Shulin City, Taiwan) | DP-25 | Measure ballast input and output voltage. |

| Current monitor (3) | Pearson Electronics, Inc. (Palo Alto, CA, USA) | 411 | Measure ballast input and output current. |

| AC power source | Keysight Technologies, Inc. (Santa Rosa, CA, USA) | AC6801A | Provide stable 50 Hz power to the ballast. |

| Parameter | Specification |

|---|---|

| Bandwidth | DC–20 MHz (−3 dB) Picoscope |

| voltage | DC–25 MHz (−3 dB) |

| current | 1 Hz–20 MHz (−3 dB) |

| Max sample rate | 80 MS/s |

| A/D resolution | 12-bit—(16-bit software-enhanced) |

| Buffer memory | 256 MS (shared between active channels) |

| DC accuracy | ±1% range ±300 μV Picoscope |

| Voltage | ±2% Diff. probe |

| Current | +1%/−0% Current transformer |

| 100 kHz accuracy | ±1% range ±300 μV Picoscope |

| Voltage | ±2% Diff. probe |

| Current | + 1%/−0% Current transformer |

| 1 MHz accuracy | ±1% range ±300 μV Picoscope |

| Voltage | ±2% Diff. probe |

| Current | +1%/−0% Current transformer |

| LED Lamp Manufacturer | Declared Value (W) | Mean Power (W) | Stdev (W) | Stdev (%) | Fractionwithin +5/−10% of Declared Value |

|---|---|---|---|---|---|

| Company A | 24 | 27.1 | 6.0 | 22% | 42% |

| Company B | 24 | 26.6 | 6.1 | 23% | 44% |

| Company C (#1) | 23 | 26.2 | 5.5 | 21% | 29% |

| Company C (#2) | 24 | 27.2 | 4.2 | 17% | 37% |

| Active Power Control (APC)—this paper | n/a * | 28.6 | 3.8 | 13% | 82% |

| Type | Application No. | Filing Date | Status |

|---|---|---|---|

| PCT | WO2020084087A1 | 24 October 2018 | Published. In National Phase |

| Nationalized PCT (USA) | US20210385921A1 | 24 October 2019 | Publication Date: 9 December 2021 |

| Nationalized PCT (China) | CN112913328A | 24 October 2019 | Publication Date: 4 June 2021 |

| Nationalized PCT (Europe) | EP3871471A1 | 24 October 2019 | Publication Date: 1 September 2021 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roy, S.; Krames, M. Active Power Control of Retrofit LED Tube Lamps for Achieving Entitled Energy Savings in View of the EU Ban on Mercury. Sustainability 2022, 14, 10062. https://doi.org/10.3390/su141610062

Roy S, Krames M. Active Power Control of Retrofit LED Tube Lamps for Achieving Entitled Energy Savings in View of the EU Ban on Mercury. Sustainability. 2022; 14(16):10062. https://doi.org/10.3390/su141610062

Chicago/Turabian StyleRoy, Shounak, and Michael Krames. 2022. "Active Power Control of Retrofit LED Tube Lamps for Achieving Entitled Energy Savings in View of the EU Ban on Mercury" Sustainability 14, no. 16: 10062. https://doi.org/10.3390/su141610062

APA StyleRoy, S., & Krames, M. (2022). Active Power Control of Retrofit LED Tube Lamps for Achieving Entitled Energy Savings in View of the EU Ban on Mercury. Sustainability, 14(16), 10062. https://doi.org/10.3390/su141610062