Bio-Degradable Wax to Modify Asphalt Binder for Warm Mix Asphalt

Abstract

:1. Introduction

2. Background

2.1. Polymer

2.2. Polymers in Asphalt Pavements

2.3. Microplastic

- 1.

- Made of synthetic materials with a high polymer content,

- 2.

- Solid particles,

- 3.

- With a size of <5 mm,

- 4.

- Insoluble in water,

- 5.

- Non-degradable.

2.4. Waxes in Asphalt Pavements

3. Materials and Methods

3.1. Materials

3.2. Testing Program

3.3. Rheological Tests

4. Results

4.1. Conventional Tests

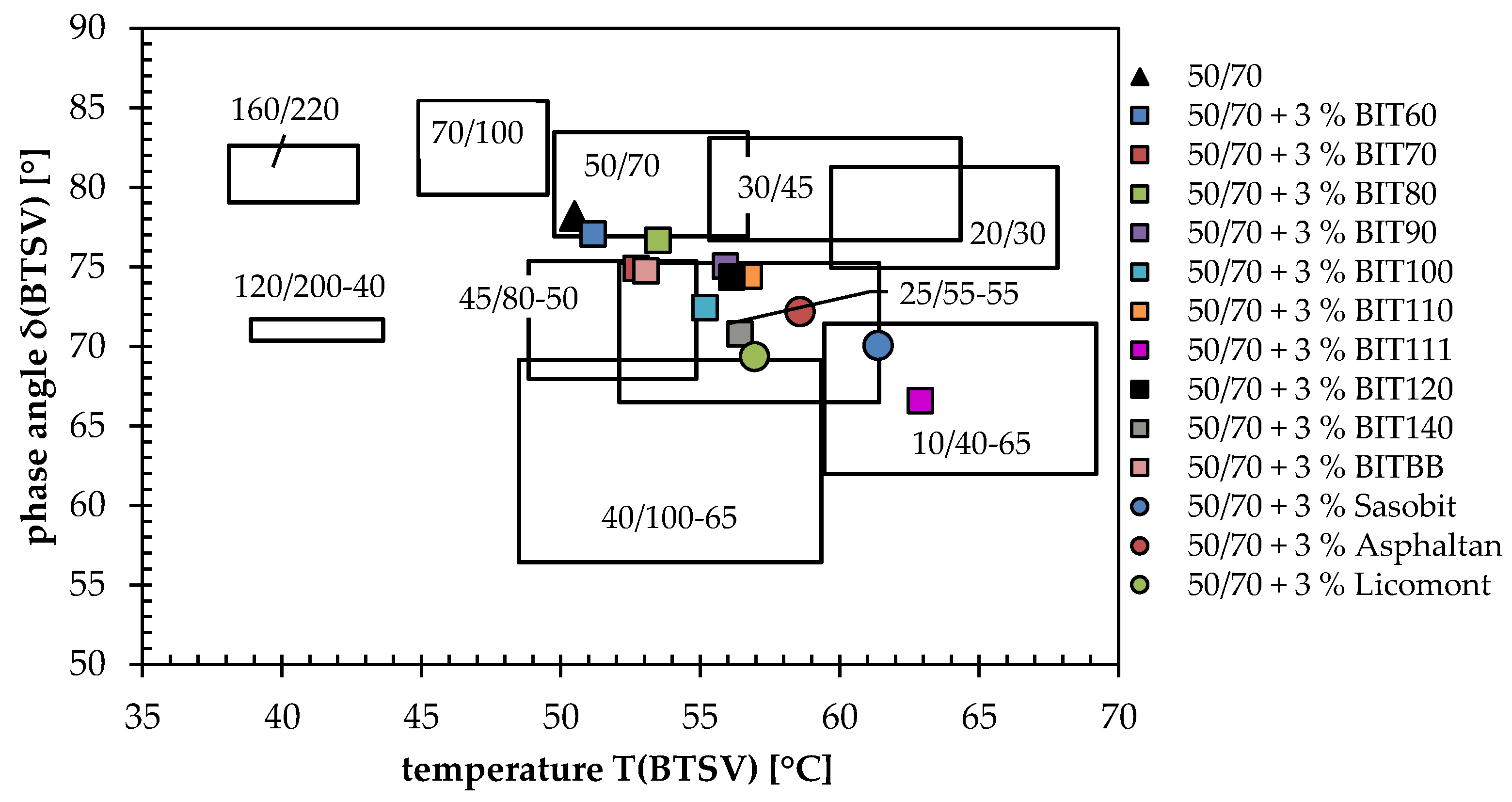

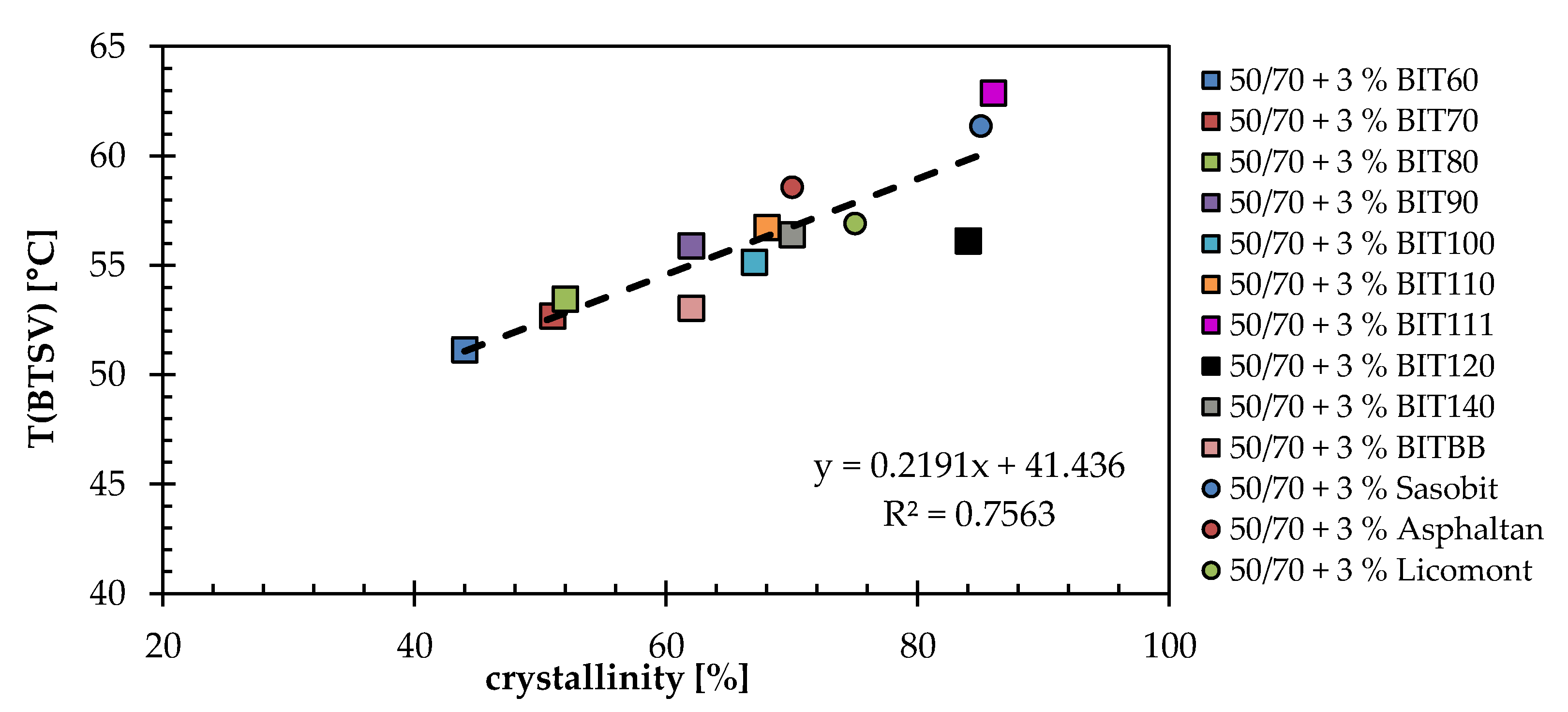

4.2. BTSV

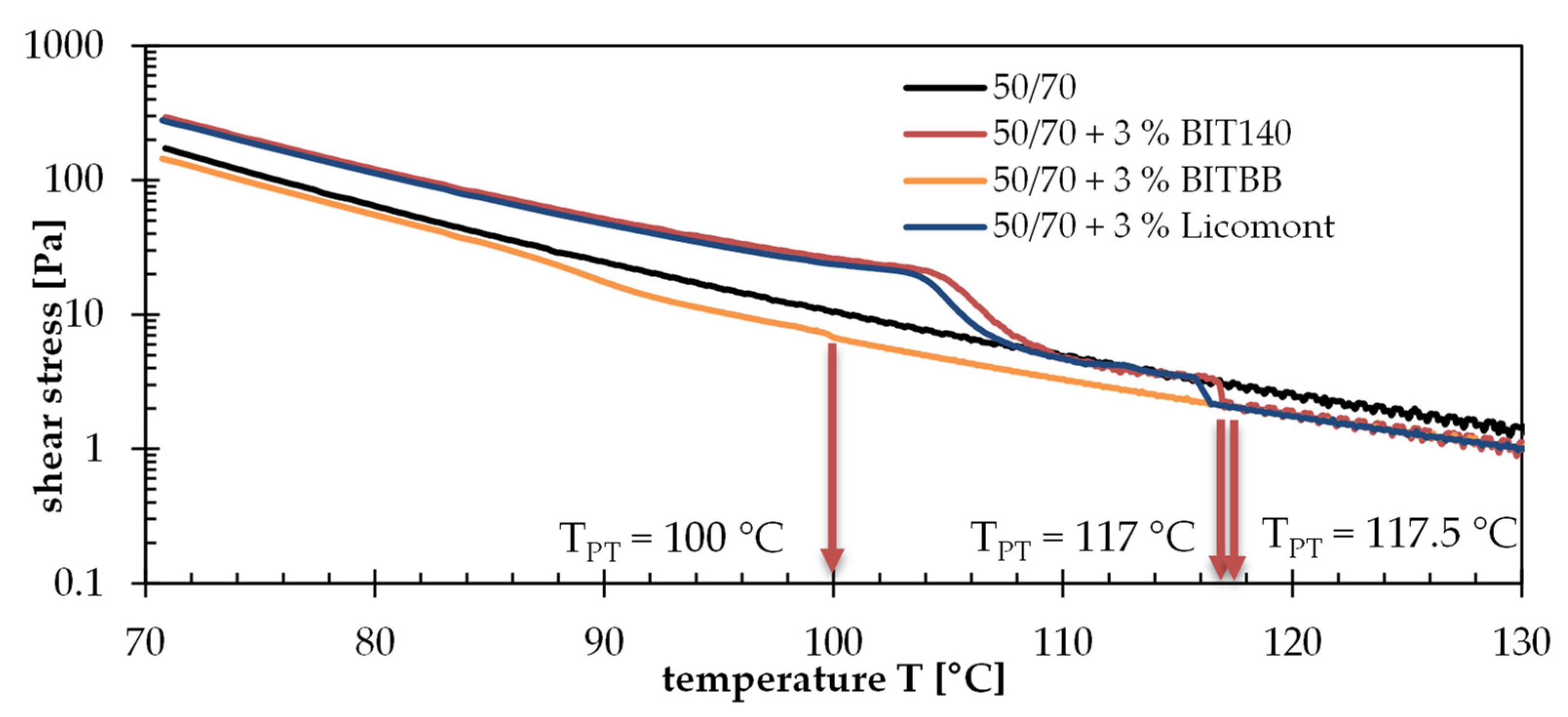

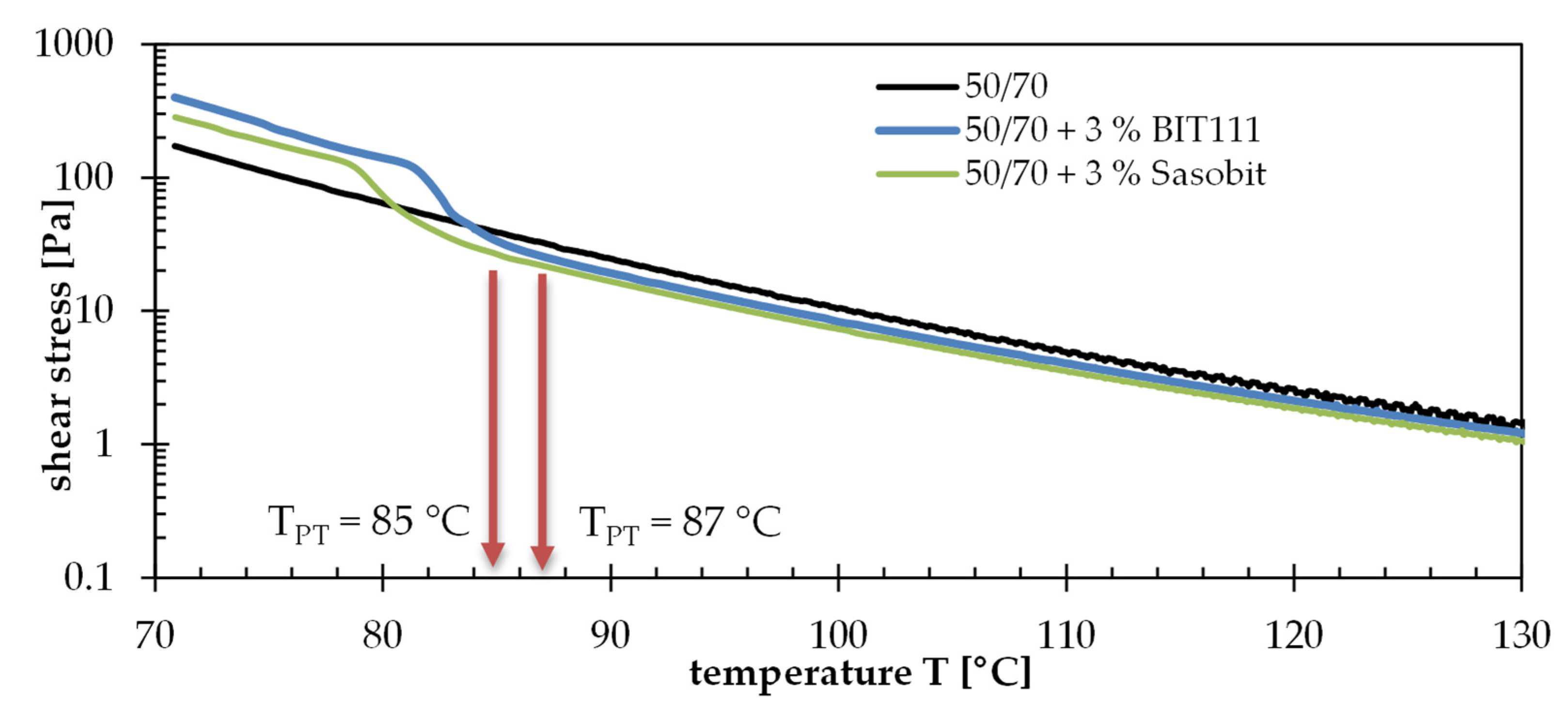

4.3. Phase Transition Temperature

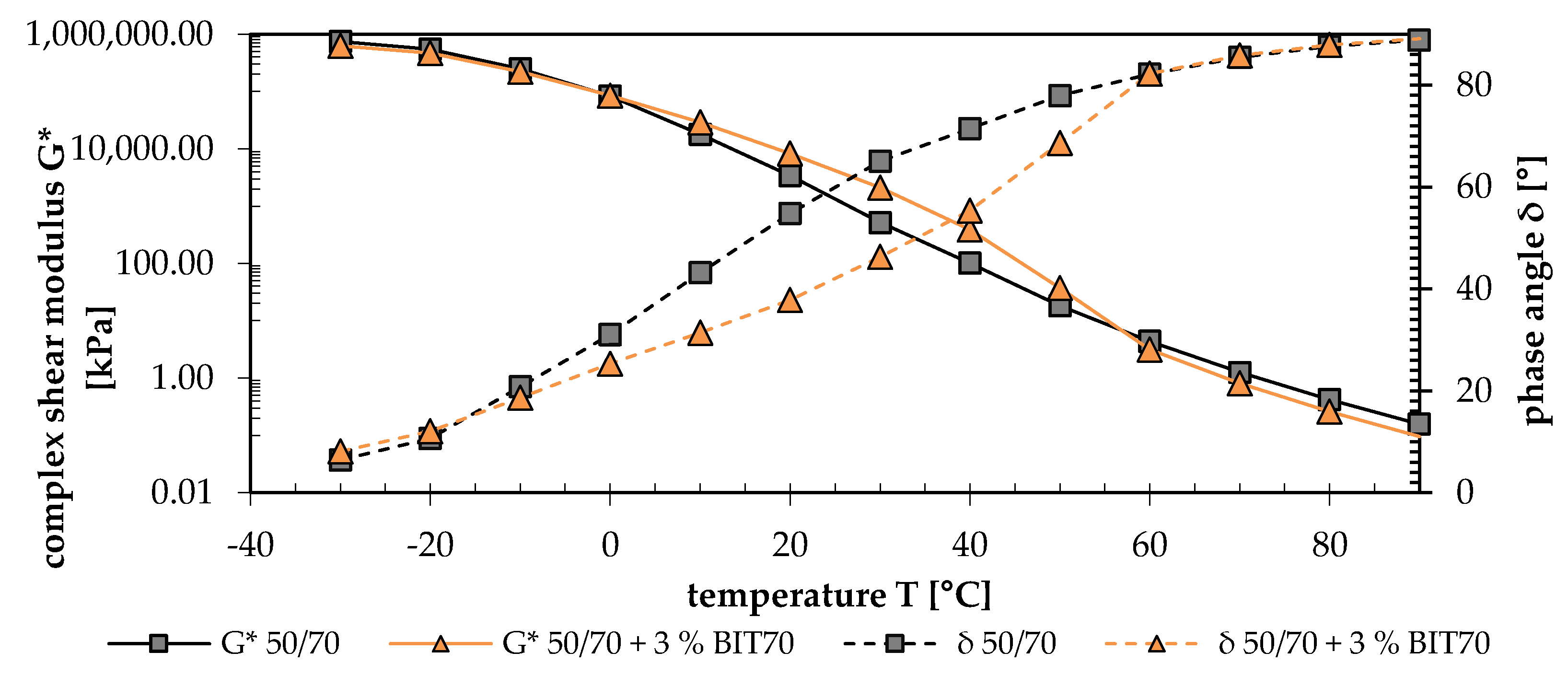

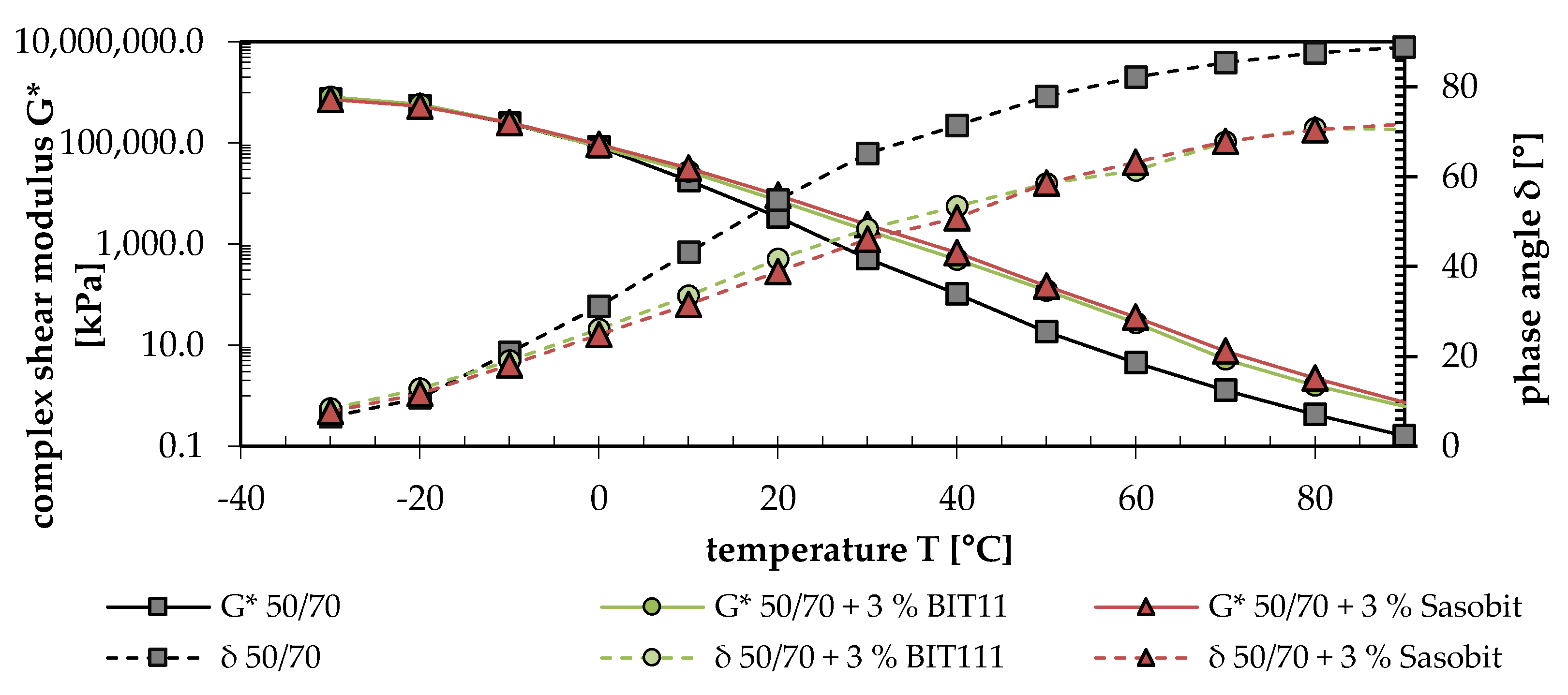

4.4. T-f-Sweep Tests

4.5. Relaxation Tests

5. Discussion

Microplastic in Asphalt Pavements

6. Conclusions

- The effect of Biomer waxes on bitumen properties was significantly affected by the composition and origin of the wax, and by the specific melting point of the Biomer. Below its melting point temperature, the Biomer increased stiffness and elasticity of the bitumen, while above the melting point temperature the Biomer decreased stiffness (viscosity-reducing effect) and increased viscosity. However, for many of the Biomer products considered in this study, no phase transition temperature was identified for the viscosity-modified binder, indicating that the effect of the Biomer is superimposed by the temperature dependent bitumen properties;

- Biomer BIT111 and Biomer BIT140 were identified as promising candidates to replace synthetic waxes Sasobit® and Licomont®, respectively, since the resulting properties of the viscosity-modified binders were quite similar. Additionally, the two types of Biomer waxes could also be used to create viscosity-modified binders, according to standard specifications. Based on the binder properties investigated in this study, selected bio-degradable waxes have the potential to completely replace conventionally refined waxes with no disadvantages regarding the binder properties;

- Replacing conventional FT waxes with Biomer waxes seems to have a negligible effect with regard to the reduction of microplastic. Instead, it is supposed to focus on the development of substitutes for polymer-modified bitumen, or on massively reducing tire abrasion. However, the application of Biomer as an alternative to FT waxes provides advantages in terms of environmental protection and resource conservation, since they are bio-degradable. Moreover, they are partly manufactured from renewable resources, as the raw material for Biomer is a waste product of sugar production. Hence, the use of Biomer supports the goal of an enhanced circular economy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rathore, M.; Haritonovs, V.; Zaumanis, M. Performance Evaluation of Warm Asphalt Mixtures Containing Chemical Additive and Effect of Incorporating High Reclaimed Asphalt Content. Materials 2021, 14, 3793. [Google Scholar] [CrossRef] [PubMed]

- Eurobitume. Eurobitume Statistik Bitumenverbrauch in Deutschland 2019. Available online: https://www.eurobitume.eu/de/nc/media/pressemitteilungen/?tx_pitsdownloadcenter_pitsdownloadcenter%5Bcontroller%5D=Download&tx_pitsdownloadcenter_pitsdownloadcenter%5Baction%5D=forceDownload&tx_pitsdownloadcenter_pitsdownloadcenter%5Bfileid%5D=8wphwz2dC5Ad61vS1vjUmw%3D%3D (accessed on 29 June 2022).

- Bertling, J.; Bertling, R.; Hamann, L. Kunststoffe in der Umwelt: Mikro- und Makroplastik: Ursachen, Mengen, Umweltschicksale, Wirkungen, Lösungsansätze, Empfehlungen; Kurzfassung der Konsortialstudie; Fraunhofer-Institut für Umwelt-, Sicherheits- und Energietechnik (UMSICHT): Oberhausen, Germany, 2018. [Google Scholar]

- Domininghaus, H.; Elsner, P.; Eyerer, P.; Hirth, T. Kunststoffe: Eigenschaften und Anwendungen; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-72400-1. [Google Scholar]

- European Commission. A European Strategy for Plastics in a Circular Economy: Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:2df5d1d2-fac7-11e7-b8f5-01aa75ed71a1.0001.02/DOC_1&format=PDF (accessed on 29 June 2022).

- Wistuba, M.P. Straßenbaustoff Asphalt; Erste Auflage; Technische Universität Braunschweig Inst. f. Straßenwesen: Braunschweig, Germany, 2019; ISBN 978-3-932164-16-3. [Google Scholar]

- Bonemazzi, F.; Braga, V.; Corrieri, R.; Giavarini, C.; Sartori, F. Characteristics of Polymers and Polymer-Modified Binders. Transp. Res. Rec. 1996, 1535, 36–47. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Oliviero Rossi, C. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- D’Angelo, J.A.; Dongré, R.N. Practical Use of Multiple Stress Creep and Recovery Test. TRR 2009, 2126, 73–82. [Google Scholar] [CrossRef]

- Herzog, R. Einsatz von BIOMEREN als viskositätsverändernde Zusätze im Bitumen; Masterarbeit; Technische Universität Braunschweig, Institut für Straßenwesen: Braunschweig, Germany, 2021. [Google Scholar]

- Wagner, M.; Lambert, S. Freshwater Microplastics: Emerging Environmental Contaminants? Springer International Publishing: Berlin/Heidelberg, Germany, 2018; ISBN 978-3-319-61614-8. [Google Scholar]

- Cowger, W.; Booth, A.M.; Hamilton, B.M.; Thaysen, C.; Primpke, S.; Munno, K.; Lusher, A.L.; Dehaut, A.; Vaz, V.P.; Liboiron, M.; et al. Reporting Guidelines to Increase the Reproducibility and Comparability of Research on Microplastics. Appl. Spectrosc. 2020, 74, 1066–1077. [Google Scholar] [CrossRef] [PubMed]

- EFSA Panel on Contaminants in the Food Chain. Statement on the presence of microplastics and nanoplastics in food, with particular focus on seafood. EFS2 2016, 14, e04501. [Google Scholar] [CrossRef]

- Kole, P.J.; Löhr, A.J.; van Belleghem, F.G.A.J.; Ragas, A.M.J. Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment. Int. J. Environ. Res. Public Health 2017, 14, 1265. [Google Scholar] [CrossRef] [PubMed]

- Soenen, H.; Tanghe, T.; Redelius, P.; de Visscher, J.; Vervacke, F.; Vanelstraete, A. A laboratory study on the use of waxes to reduce paving temperatures. In Proceedings of the 4th Eurasphalt & Eurobitume Congress, Copenhagen, Denmark, 21–23 May 2008. [Google Scholar]

- Wagner, M.; Wistuba, M.P.; Blab, R. Low viscous asphalt mixes—A critical review of FT paraffin modified mix properties using performance-based test methods. In Proceedings of the Transport Research Arena (TRA), Ljubljana, Slovenia, 21–24 April 2008. [Google Scholar]

- Edwards, Y.; Tasdemir, Y.; Butt Ali Azhar. Energy saving and environmental friendly wax concept for polymer modified mastic asphalt. Mat. Struct. 2010, 43, 123–131. [Google Scholar] [CrossRef]

- Edwards, Y. Influence of Waxes on Bitumen and Asphalt Concrete Mixture Performance. Ph.D. Dissertation, Royal Institut of Technology, Stockholm, Sweden, 2005. [Google Scholar]

- Wagner, M. Gebrauchsverhalten von mit Fischer-Tropsch Paraffinen Modifizierten, Niederviskosen Bitumen und Asphaltbetonen; Diplomarbeit; Technische Universität Wien, Institut für Straßenbau und Straßenerhaltung: Wien, Austria, 2006. [Google Scholar]

- Suaria, G.; Aliani, S.; Merlino, S.; Abbate, M. The Occurrence of Paraffin and Other Petroleum Waxes in the Marine Environment: A Review of the Current Legislative Framework and Shipping Operational Practices. Front. Mar. Sci. 2018, 5, 94. [Google Scholar] [CrossRef]

- European Chemicals Agency. How to Decide Whether a Substance Is a Polymer or Not and How to Proceed with the Relevant Registration; ECHA: Helsinki, Finland, 2017. [Google Scholar]

- Wollrab, A. Organische Chemie: Eine Einführung für Lehramts- und Nebenfachstudenten; 4. Auflage; Springer Spektrum: Berlin/Heidelberg, Germany, 2014; ISBN 978-3-642-45143-0. [Google Scholar]

- Forschungsgesellschaft für Straßen- und Verkehrswesen (FGSV). Empfehlungen zur Klassifikation von Viskositätsveränderten Bindemitteln; FGSV Verlag: Köln, Germany, 2016; (E KvB). [Google Scholar]

- European Committee for Standardization. Bitumen and Bituminous Binders—Determination of Needle Penetration; European Committee for Standardization: Brussels, Belgium, 2015; (EN 1426). [Google Scholar]

- European Committee for Standardization. Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method; European Committee for Standardization: Brussels, Belgium, 2015; (EN 1427). [Google Scholar]

- European Committee for Standardization. Bitumen and Bituminous Binders—Determination of Equi-Shear Modulus Temperature Using a Dynamic Shear Rheometer (DSR)—BTSV Test; European Committee for Standardization: Brussels, Belgium, 2021; (prEN 17643). [Google Scholar]

- German Road and Transportation Research Association. Test Description for Determining the Phase Transition Temperature of Viscosity Modified Binders Using a Dynamic Shear Rheometer (DSR)—Part 3: Testing with Constant Shear Rate; FGSV Verlag: Cologne, Germany, 2016. [Google Scholar]

- European Committee for Standardization. Bitumen and Bituminous Binders—Determination of Complex Shear Modulus and Phase Angle Using a Dynamic Shear Rheometer (DSR); European Committee for Standardization: Brussels, Belgium, 2012; (EN 14770). [Google Scholar]

- Wistuba, M.P.; Büchner, J. Prüfung von Rejuvenatoren mit dem Dynamischen Scherrheometer. Straße und Autobahn 2021, 72, 621–631. [Google Scholar]

- Büchner, J. Prüfung von Asphaltmastix im Dynamischen Scherrheometer. Doctocal Dissertation, Technische Universität Braunschweig, Institut für Straßenwesen, Braunschweig, Germany, 2021. [Google Scholar]

- Büchner, J.; Wistuba, M.P. Relating Asphalt Mixture Performance to Asphalt Mastic Rheology. In Proceedings of the 9th International Conference on Maintenance and Rehabilitation of Pavements—Mairepav9, Dübendorf, Switzerland, 1–3 July 2020; Raab, C., Ed.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 639–649, ISBN 978-3-030-48678-5. [Google Scholar]

- Radenberg, M.; Staschkiewicz, M. Development of a test method to determine the low temperature performance of Bitumen. In Proceedings of the 7th E&E Congress Proceedings, online, Spain, 16–18 June 2021; p. 159. [Google Scholar]

- Büchner, J.; Wistuba, M.P. Entwicklung einer Methodik zur Bewertung der Bindemittel- und Mastixeigenschaften im Asphaltstraßenbau: Schlussbericht zum Forschungsprojekt Bit-Q, finanziert durch die Arbeitsgemeinschaft, "ARGE Bit-Q“ bestehend aus Eiffage Infra-Südwest, Kemna, Leonhard Weiß, Matthäi, TPA/Strabag, Winkler; Strabag: Braunschweig, Germany, 2021. [Google Scholar]

- Büchner, J.; Wistuba, M.P. Analysis of Low Temperature Relaxation Properties of Asphalt Binder and Asphalt Mastic Using a Dynamic Shear Rheometer. In Proceedings of the Eleventh International Conference on the Bearing Capacity of Roads, Railways and Airfields, Trondheim, Norway, 28–30 June 2022; Hoff, I., Mork, H., Saba, R., Eds.; CRC Press: Boca Raton, FL, USA, 2022; pp. 508–516, ISBN 978-1-032-12049-2. [Google Scholar]

- European Committee for Standardization. Bitumen and Bituminous Binders—Specifications for Paving Grade Bitumen; European Committee for Standardization: Brussels, Belgium, 2016; (EN 12591). [Google Scholar]

- Alisov, A.; Riccardi, C.; Schrader, J.; Cannone Falchetto, A.; Wistuba, M.P. A Novel Method to Characterize Asphalt Binder at High Temperature. RMPD 2018, 21, 143–155. [Google Scholar] [CrossRef]

- Schrader, J.; Wistuba, M.P.; Cannone Falchetto, A.; Riccardi, C.; Alisov, A. A new Binder-Fast-Characterization-Test using DSR and its Application for Rejuvenating Reclaimed Asphalt Binder. J. Test. Eval. 2019, 48, 52–59. [Google Scholar] [CrossRef]

- NETZSCH Analyzing & Testing. Crystallinity/Degree of Crystallinity. Available online: https://www.netzsch-thermal-analysis.com/us/industries-branches/glossary/crystallinity-degree-of-crystallinity/ (accessed on 29 June 2022).

- Ait-Langomazino, N.; Sellier, R.; Jouquet, G.; Trescinski, M. Microbial degradation of bitumen. Experientia 1991, 47, 533–539. [Google Scholar] [CrossRef]

- European Chemicals Agency. Guidance for monomers and polymers: Guidance for the Implementation of REACH; Version 2.0; ECHA: Helsinki, Finland, 2012. [Google Scholar]

- Panchal, S.S.; Vasava, D.V. Biodegradable Polymeric Materials: Synthetic Approach. ACS Omega 2020, 5, 4370–4379. [Google Scholar] [CrossRef] [PubMed]

- Yin, G.-Z.; Yang, X.-M. Biodegradable polymers: A cure for the planet, but a long way to go. J. Polym. Res. 2020, 27, 38. [Google Scholar] [CrossRef]

- DEUREX AG. MATERIAL SAFETY DATA SHEET DEUREX® T—Series. Available online: https://www.deurex.com/files/15C201F6512/DEUREX-T-Series_MSDS_EN.pdf (accessed on 29 June 2022).

- Sasol. Sicherheitsdatenblatt Sasolwax 0587. Available online: https://shop.engelbrecht.de/WebRoot/SageSMB/Shops/Engelbrecht46754134/MediaGallery/Sicherheitsdatenblaetter/MSDS_SASOLWAX_0587_DE.PDF (accessed on 29 June 2022).

- Organisation for Economic Co-Operation and Development. Test No. 301: Ready Biodegradability; OECD Publishing: Paris, France, 1992; ISBN 9789264070349. [Google Scholar]

- Baensch-Baltruschat, B.; Kocher, B.; Stock, F.; Reifferscheid, G. Tyre and road wear particles (TRWP)—A review of generation, properties, emissions, human health risk, ecotoxicity, and fate in the environment. Sci. Total Environ. 2020, 733, 137823. [Google Scholar] [CrossRef] [PubMed]

- Amato, F.; Pandolfi, M.; Moreno, T.; Furger, M.; Pey, J.; Alastuey, A.; Bukowiecki, N.; Prevot, A.; Baltensperger, U.; Querol, X. Sources and variability of inhalable road dust particles in three European cities. Atmos. Environ. 2011, 45, 6777–6787. [Google Scholar] [CrossRef]

| Type of Modifier | Polymer | Abbreviation |

|---|---|---|

| elastomer | styrene–butadiene elastomer | SBE |

| styrene-butadiene-styrene (linear or radial) | SBS | |

| styrene–isopropene-styrene | SIS | |

| styrene–ethylene–butadiene–styrene | SEBS | |

| polyisobutene | PIB | |

| polybutadiene | PBD | |

| ethylene propylene rubber | EPR | |

| ethylene propylene diene rubber | EDPM | |

| thermoplastic | ethylene vinyl acetate | EVA |

| ethylene methyl acrylate | EMA | |

| atactic polypropylene | APP | |

| polyethylene | PE | |

| polypropylene | PP | |

| thermoset | epoxy resin | |

| polyurethane resin | PU |

| Designation | Size |

|---|---|

| Macroplastic | >5 mm |

| Mesoplastic | ≤5 mm to >1 mm |

| Microplastic | ≤1 mm to 0.1 μm |

| Nanoplastic | <0.1 μm |

| Wax | Melting Range [°C] | Crystallinity [%] | Color | Delivery Form |

|---|---|---|---|---|

| BIT60 | 60 | 44 | Brown | Granulate |

| BIT70 | 70 | 51 | White | Granulate |

| BIT80 | 80 | 52 | Brown | Granulate |

| BIT90 | 90 | 62 | White | Granulate |

| BIT100 | 100 | 67 | White | Granulate |

| BIT110 | 110 | 68 | White | Granulate |

| BIT111 | 110 | 86 | White | Powder |

| BIT120 | 120 | 84 | Yellow | Granulate |

| BIT140 | 140 | 70 | White | Granulate |

| BITBB | 60–140 | 62 | Brown | Granulate |

| Asphaltan A | 125 | 75 | Brown | Granulate |

| Licomont® | 140 | 70 | White | Granulate |

| Sasobit® | 100 | 85 | White | Granulate |

| Conventional Tests | Rheological Tests Using DSR | |||||

|---|---|---|---|---|---|---|

| Material Variant | Needle-Penetration | Softening Point Ring and Ball | BTSV Values | Phase Transition Temperature TPT | T-f-Sweep Test | Relaxation Test |

| 50/70 | X | X | X | X | X | X |

| 50/70 + 3% BIT60 | X | X | X | X | ||

| 50/70 + 3% BIT70 | X | X | X | X | X | X |

| 50/70 + 3% BIT80 | X | X | X | X | ||

| 50/70 + 3% BIT90 | X | X | X | X | X | X |

| 50/70 + 3% BIT100 | X | X | X | X | ||

| 50/70 + 3% BIT110 | X | X | X | X | X | X |

| 50/70 + 3% BIT111 | X | X | X | X | X | X |

| 50/70 + 3% BIT120 | X | X | X | X | ||

| 50/70 + 3% BIT140 | X | X | X | X | X | |

| 50/70 + 3% BITBB | X | X | X | X | ||

| 50/70 + 3% Asphaltan A | X | X | X | X | ||

| 50/70 + 3% Licomont® | X | X | X | X | X | |

| 50/70 + 3% Sasobit® | X | X | X | X | X | X |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sigwarth, T.; Büchner, J.; Wistuba, M.P. Bio-Degradable Wax to Modify Asphalt Binder for Warm Mix Asphalt. Sustainability 2022, 14, 10219. https://doi.org/10.3390/su141610219

Sigwarth T, Büchner J, Wistuba MP. Bio-Degradable Wax to Modify Asphalt Binder for Warm Mix Asphalt. Sustainability. 2022; 14(16):10219. https://doi.org/10.3390/su141610219

Chicago/Turabian StyleSigwarth, Tess, Johannes Büchner, and Michael P. Wistuba. 2022. "Bio-Degradable Wax to Modify Asphalt Binder for Warm Mix Asphalt" Sustainability 14, no. 16: 10219. https://doi.org/10.3390/su141610219

APA StyleSigwarth, T., Büchner, J., & Wistuba, M. P. (2022). Bio-Degradable Wax to Modify Asphalt Binder for Warm Mix Asphalt. Sustainability, 14(16), 10219. https://doi.org/10.3390/su141610219