Application of a 2k–p Fractional Experimental Design in Coagulation-Flocculation Processes in the Treatment of Wastewater from a Slaughterhouse

Abstract

:1. Introduction

2. Materials and Methods

2.1. Case Study

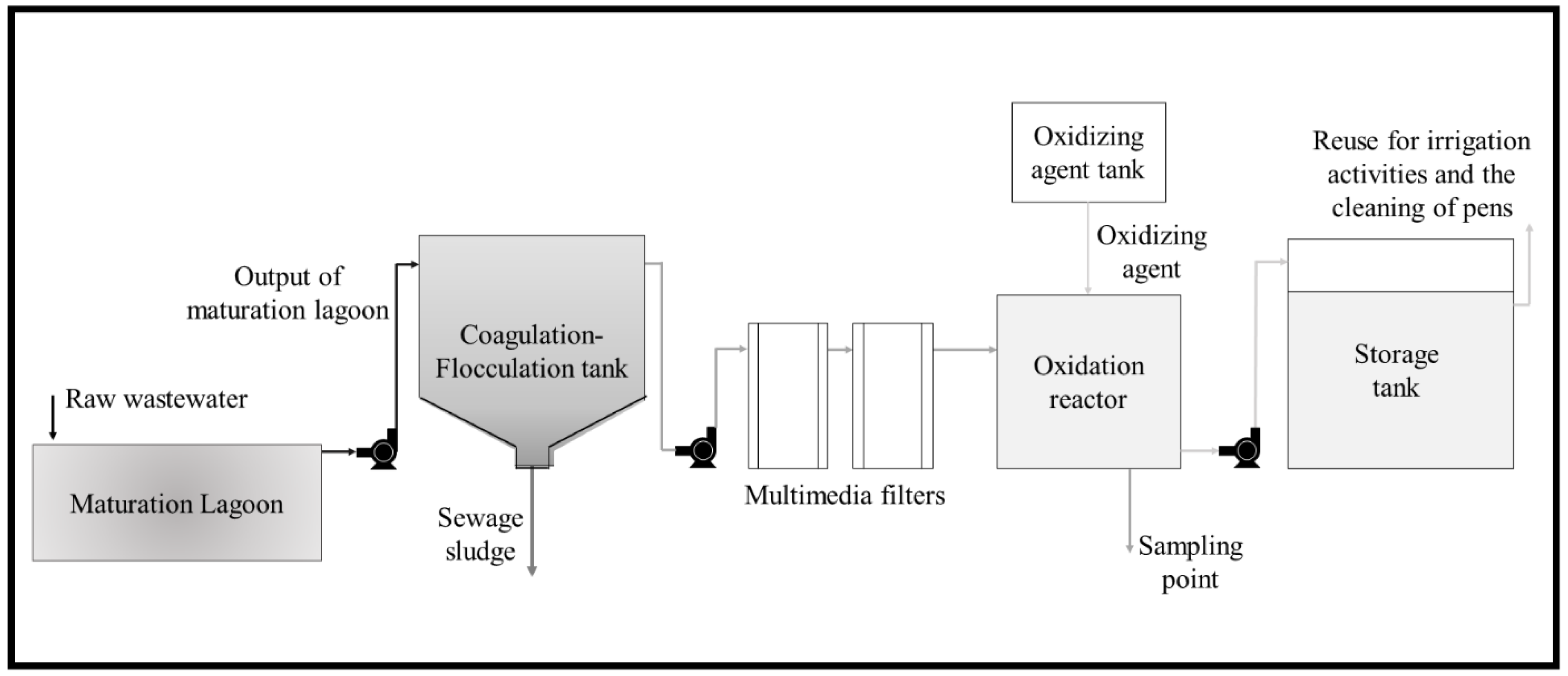

2.2. Sewage Treatment System

2.3. Experimental Factors Studied

2.3.1. Residence Time

2.3.2. Velocity Gradient

- G: Velocity gradient ,

- s: Rotor speed measured in revolutions per second (rev/s),

- T: Input torque on the rotor (N∙m),

- V: Fluid volume (m3),

- μ: Dynamic viscosity of the fluid (Pa∙s).

2.3.3. Primary Coagulant Concentration

2.3.4. Pre-Chlorination

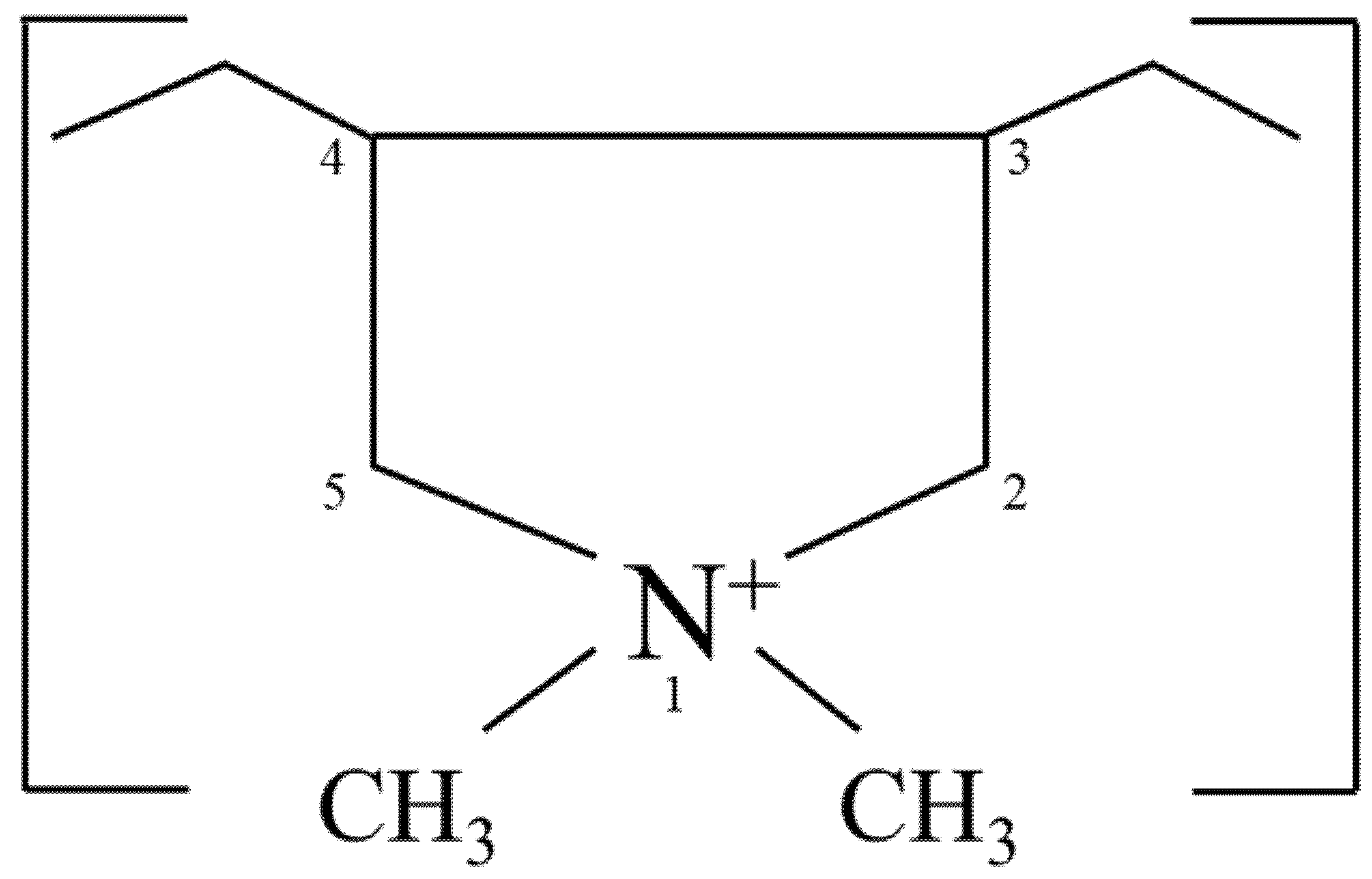

2.3.5. Coagulation Adjuvant

2.4. Experimental Design Planning

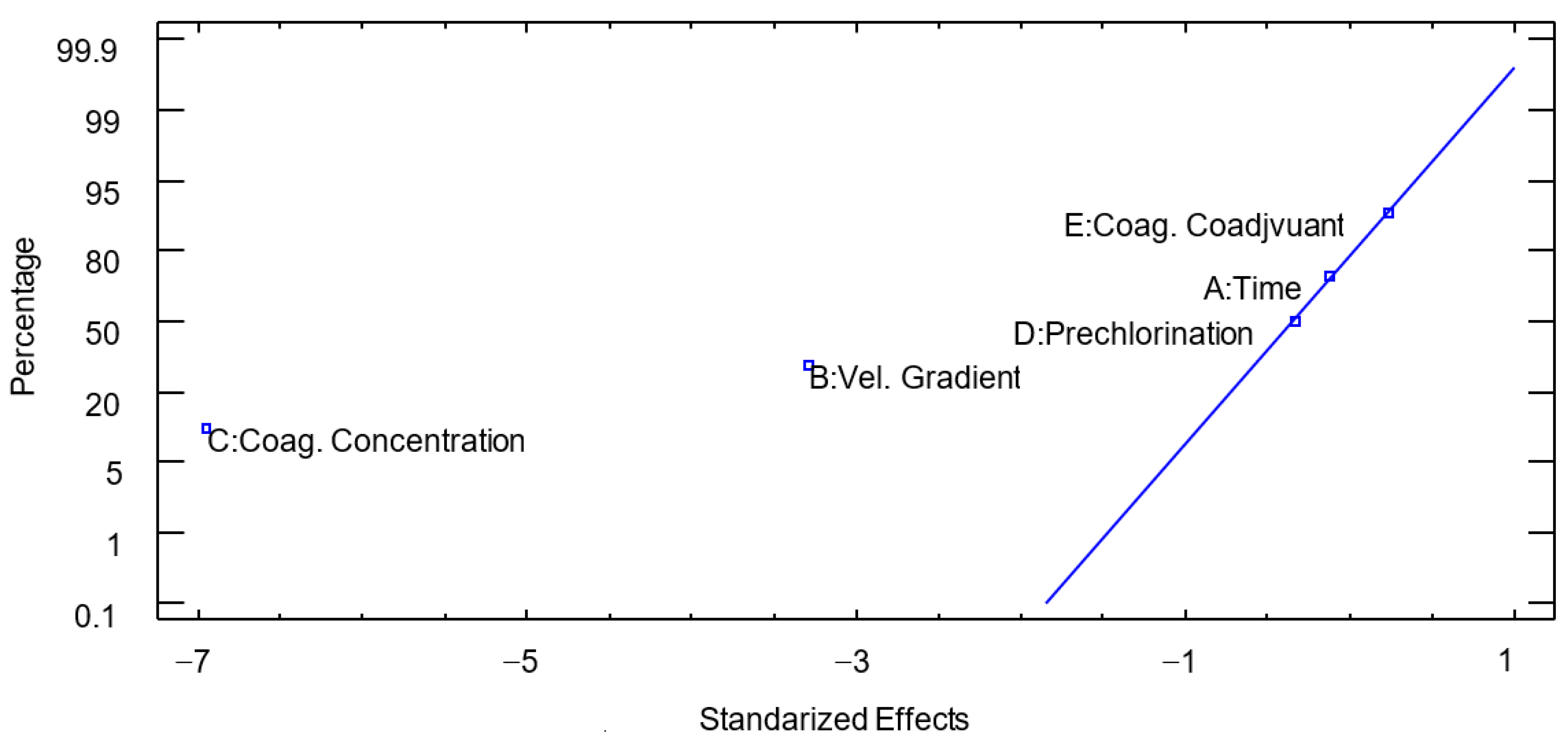

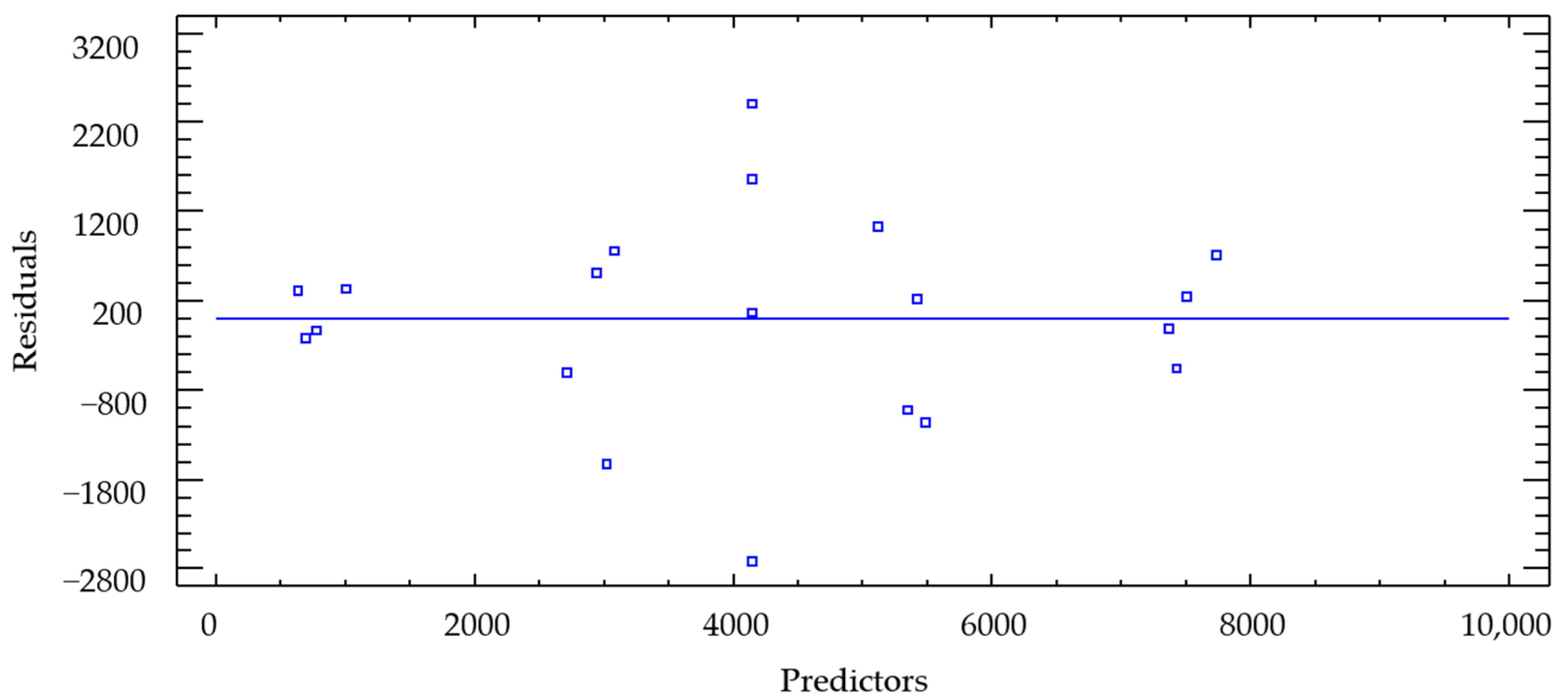

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ospina Zúñiga, O.E.; Cardona García, O.H. Evaluación de La Contaminación Por Aluminio Del Agua Para Consumo Humano, Región Central de Colombia. Inge CUC 2021, 17, 31–41. [Google Scholar] [CrossRef]

- Canales, F.A.; Plata-Solano, D.; Cantero-Rodelo, R.; Pereira, Y.Á.; Díaz-Martínez, K.; Carpintero, J.; Kaźmierczak, B.; Tavera-Quiroz, H. Assessment of Carwash Wastewater Reclamation Potential Based on Household Water Treatment Technologies. Water Resour. Ind. 2021, 26, 100164. [Google Scholar] [CrossRef]

- Al-Mutairi, N.Z.; Hamoda, M.F.; Al-Ghusain, I. Coagulant Selection and Sludge Conditioning in a Slaughterhouse Wastewater Treatment Plant. Bioresour. Technol. 2004, 95, 115–119. [Google Scholar] [CrossRef] [PubMed]

- Gökçek, Ö.B.; Özdemir, S. Optimization of the Coagulation–Flocculation Process for Slaughterhouse Wastewater Using Response Surface Methodology. CLEAN Soil Air Water 2020, 48, 2000033. [Google Scholar] [CrossRef]

- Hu, H.; Li, X.; Wu, S.; Yang, C. Sustainable Livestock Wastewater Treatment via Phytoremediation: Current Status and Future Perspectives. Bioresour. Technol. 2020, 315, 123809. [Google Scholar] [CrossRef]

- Słyś, D.; Pochwat, K.; Czarniecki, D. An Analysis of Waste Heat Recovery from Wastewater on Livestock and Agriculture Farms. Resources 2020, 9, 3. [Google Scholar] [CrossRef] [Green Version]

- Lahlou, F.Z.; Mackey, H.R.; Al-Ansari, T. Wastewater Reuse for Livestock Feed Irrigation as a Sustainable Practice: A Socio-Environmental-Economic Review. J. Clean. Prod. 2021, 294, 126331. [Google Scholar] [CrossRef]

- Bustillo-Lecompte, C.F.; Mehrvar, M. Slaughterhouse Wastewater Characteristics, Treatment, and Management in the Meat Processing Industry: A Review on Trends and Advances. J. Environ. Manag. 2015, 161, 287–302. [Google Scholar] [CrossRef]

- Orssatto, F.; Tavares, M.H.F.; da Silva, F.M.; Eyng, E.; Fleck, L.; Frare, L.M. Optimization of the Treatment of Wastewater from a Slaughterhouse and Packing Plant by the Combination of Electrocoagulation and Tannin-Based Coagulant. Desalinat. Water Treat. 2018, 102, 82–92. [Google Scholar] [CrossRef]

- Bui, H.M. Applying Response Surface Methodology to Optimize the Treatment of Swine Slaughterhouse Wastewater by Electrocoagulation. Pol. J. Environ. Stud. 2018, 27, 1975–1981. [Google Scholar] [CrossRef]

- Struk-Sokołowska, J.; Rodziewicz, J.; Mielcarek, A. Effect of Dairy Wastewater on Changes in COD Fractions in Technical-Scale SBR Type Reactors. Water Sci. Technol. 2018, 2017, 156–169. [Google Scholar] [CrossRef]

- Struk-Sokolowska, J.; Tkaczuk, J. Analysis of Bakery Sewage Treatment Process Options Based on COD Fraction Changes. J. Ecol. Eng. 2018, 19, 226–235. [Google Scholar] [CrossRef]

- Jiang, J.-Q. The Role of Coagulation in Water Treatment. Curr. Opin. Chem. Eng. 2015, 8, 36–44. [Google Scholar] [CrossRef]

- Guigui, C.; Rouch, J.C.; Durand-Bourlier, L.; Bonnelye, V.; Aptel, P. Impact of Coagulation Conditions on the In-Line Coagulation/UF Process for Drinking Water Production. Desalination 2002, 147, 95–100. [Google Scholar] [CrossRef]

- Suquet, J.; Godo-Pla, L.; Valentí, M.; Ferràndez, L.; Verdaguer, M.; Poch, M.; Martín, M.J.; Monclús, H. Assessing the Effect of Catchment Characteristics to Enhanced Coagulation in Drinking Water Treatment: RSM Models and Sensitivity Analysis. Sci. Total Environ. 2021, 799, 149398. [Google Scholar] [CrossRef] [PubMed]

- American Society for Testing and Materials. D2035-13 Standard Practice for Coagulation-Flocculation Jar Test of Water; American Society for Testing and Materials: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Mousa, K.M.; Hadi, H.J. Coagulation/Flocculation Process for Produced Water Treatment. Int. J. Curr. Eng. Technol. 2016, 6, 551–555. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 9th ed.; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2017; ISBN 9781119113478. [Google Scholar]

- Bobadilla, M.C.; Lorza, R.L.; García, R.E.; Gómez, F.S.; González, E.P.V. Coagulation: Determination of Key Operating Parameters by Multi-Response Surface Methodology Using Desirability Functions. Water 2019, 11, 398. [Google Scholar] [CrossRef] [Green Version]

- Carpintero, J.; Canales, F.A.; Fábregas, J.; Ávila, J. Factors and Interactions That Influence the Pressure Drop Across An Air Volume Reducing Device on Low-Pressure Water Distribution Networks. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 46, 1433–1443. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, Y.; Banks, C.; Heaven, S.; Longhurst, P. Investigation of the Impact of Trace Elements on Anaerobic Volatile Fatty Acid Degradation Using a Fractional Factorial Experimental Design. Water Res. 2017, 125, 458–465. [Google Scholar] [CrossRef] [Green Version]

- Stewardson, D.J.; Whitfield, R.I. A Demonstration of the Utility of Fractional Experimental Design for Finding Optimal Genetic Algorithm Parameter Settings. J. Oper. Res. Soc. 2004, 55, 132–138. [Google Scholar] [CrossRef] [Green Version]

- Haghiri, S.; Daghighi, A.; Moharramzadeh, S. Optimum Coagulant Forecasting by Modeling Jar Test Experiments Using ANNs. Drink. Water Eng. Sci. 2018, 11, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Bouyer, D.; Escudié, R.; Liné, A. Experimental Analysis of Hydrodynamics in a Jar-Test. Process Saf. Environ. Prot. 2005, 83, 22–30. [Google Scholar] [CrossRef]

- Griffith, J.D.; Williams, R.G. Application of Jar-Test Analysis at Phoenix, Ariz. J Am. Water Work. Assoc. 1972, 64, 825–830. [Google Scholar] [CrossRef]

- Bouyer, D.; Line, A.; Cockx, A.; Do-quang, Z. Experimental Analysis of Floc Size Distribution and Hydrodynamics in a Jar-Test. Chem. Eng. Res. Des. 2001, 79, 1017–1024. [Google Scholar] [CrossRef]

- Ministerio de Ambiente y Desarrollo Sostenible. Resolución 631 de 2015; Ministerio de Ambiente y Desarrollo Sostenible: Bogota, Colombia, 2015; Volume 2015. [Google Scholar]

- Ministerio de Ambiente y Desarrollo Sostenible. Resolución 1207 de 2014; Ministerio de Ambiente y Desarrollo Sostenible: Bogota, Colombia, 2014. [Google Scholar]

- Baird, R.B.; Eaton, A.D.; Rice, E.W. (Eds.) Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association, American Water Works Association & Water Environment Federation: Washington, DC, USA, 2017; ISBN 9780875532875. [Google Scholar]

- Daud, Z.; Nasir, N.; Kadir, A.A.; Aziz, A.; Latiff, A.; Ahmad, B.; Suhani, N.; Awang, H.; Halim, A.A. Treatment of Biodiesel Wastewater Using Ferric Chloride and Ferric Sulfate. Int. J. Integr. Eng. 2017, 9, 54–57. [Google Scholar]

- Kerneïs, A.; Nakache, F.; Deguin, A.; Feinberg, M. The Effects of Water Residence Time on the Biological Quality in a Distribution Network. Water Res. 1995, 29, 1719–1727. [Google Scholar] [CrossRef]

- Zhao, J.; Shi, H.; Liu, M.; Lu, J.; Li, W. Coagulation-Adsorption of Reactive Orange from Aqueous Solution by Freshly Formed Magnesium Hydroxide: Mixing Time and Mechanistic Study. Water Sci. Technol. 2017, 75, 1776–1783. [Google Scholar] [CrossRef] [PubMed]

- Kan, C.; Huang, C.; Pan, J.R. Time Requirement for Rapid-Mixing in Coagulation. Colloids Surf. A: Physicochem. Eng. Asp. 2002, 203, 1–9. [Google Scholar] [CrossRef]

- Som, A.M.; Ramlee, A.A.; Puasa, S.W.; Hamid, H.A.A. Optimisation of Operating Conditions during Coagulation-Flocculation Process in Industrial Wastewater Treatment Using Hylocereus Undatus Foliage through Response Surface Methodology. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef]

- Lai, R.J.; Hudson, H.E.; Singley, J.E. Velocity Gradient Calibration of Jar-Test Equipment. J. Am. Water Work. Assoc. 1975, 67, 553–557. [Google Scholar] [CrossRef]

- Zhan, X.; Gao, B.; Wang, Y.; Yue, Q. Influence of Velocity Gradient on Aluminum and Iron Floc Property for NOM Removal from Low Organic Matter Surfacewater by Coagulation. Chem. Eng. J. 2011, 166, 116–121. [Google Scholar] [CrossRef]

- TeKippe, R.J.; Ham, R.K. Velocity-Gradient Paths in Coagulation. J. Am. Water Work. Assoc. 1971, 63, 439–448. [Google Scholar] [CrossRef]

- Mhaisalkar, V.A.; Paramasivam, R.; Bhole, A.G. An Innovative Technique for Determining Velocity Gradient in Coagulation-Flocculation Process. Water Res. 1986, 20, 1307–1314. [Google Scholar] [CrossRef]

- Bratby, J. Coagulation and Flocculation in Water and Wastewater Treatment, 3rd ed.; IWA publishing: London, UK, 2016; ISBN 9781780407494. [Google Scholar]

- Teh, C.Y.; Wu, T.Y. The Potential Use of Natural Coagulants and Flocculants in the Treatment of Urban Waters. Chem. Eng. Trans. 2014, 39, 1603–1608. [Google Scholar] [CrossRef]

- Amirtharajah, A.; Dennett, K.E.; Studstill, A. Ferric Chloride Coagulation for Removal of Dissolved Organic Matter and Trihalomethane Precursors. Water Sci. Technol. 1993, 27, 113–121. [Google Scholar] [CrossRef]

- Domínguez, J.R.; De Heredia, J.B.; González, T.; Sanchez-Lavado, F. Evaluation of Ferric Chloride as a Coagulant for Cork Processing Wastewaters. Influence of the Operating Conditions on the Removal of Organic Matter and Settleability Parameters. Ind. Eng. Chem. Res. 2005, 44, 6539–6548. [Google Scholar] [CrossRef]

- Shi, X.; Bi, R.; Yuan, B.; Liao, X.; Zhou, Z.; Li, F.; Sun, W. A Comparison of Trichloromethane Formation from Two Algae Species during Two Pre-Oxidation-Coagulation-Chlorination Processes. Sci. Total Environ. 2019, 656, 1063–1070. [Google Scholar] [CrossRef]

- Lapsongpon, T.; Leungprasert, S.; Yoshimura, C. Pre-Chlorination Contact Time and the Removal and Control of Microcystis Aeroginosa in Coagulation. IOP Conf. Ser. Earth Environ. Sci. 2017, 67, 012011. [Google Scholar] [CrossRef]

- Ji, Q.; Liu, H.; Hu, C.; Qu, J.; Wang, D.; Li, J. Removal of Disinfection By-Products Precursors by Polyaluminum Chloride Coagulation Coupled with Chlorination. Sep. Purif. Technol. 2008, 62, 464–469. [Google Scholar] [CrossRef]

- Bruno, P.; Campo, R.; Giustra, M.G.; De Marchis, M.; Di Bella, G. Bench Scale Continuous Coagulation-Flocculation of Saline Industrial Wastewater Contaminated by Hydrocarbons. J. Water Process. Eng. 2020, 34, 101156. [Google Scholar] [CrossRef]

- Hazourli, S.; Ziati, M.; Benredjem, Z.; Delimi, R.; Boudiba, L. Analysis of Wastewater Loaded with Paint Before and After Treatment of Coagulation–Flocculation. Arab. J. Sci. Eng. 2012, 37, 897–903. [Google Scholar] [CrossRef]

- An, D.; Chen, Y.; Gu, B.; Westerhoff, P.; Hanigan, D.; Herckes, P.; Fischer, N.; Donovan, S.; Croue, J.P.; Atkinson, A. Lower Molecular Weight Fractions of PolyDADMAC Coagulants Disproportionately Contribute to N-Nitrosodimethylamine Formation during Water Treatment. Water Res. 2019, 150, 466–472. [Google Scholar] [CrossRef] [PubMed]

- Ariffin, A.; Razali, M.A.A.; Ahmad, Z. PolyDADMAC and Polyacrylamide as a Hybrid Flocculation System in the Treatment of Pulp and Paper Mills Waste Water. Chem. Eng. J. 2012, 179, 107–111. [Google Scholar] [CrossRef]

- Zahrim, A.Y.; Dexter, Z.D.; Joseph, C.G.; Hilal, N. Effective Coagulation-Flocculation Treatment of Highly Polluted Palm Oil Mill Biogas Plant Wastewater Using Dual Coagulants: Decolourisation, Kinetics and Phytotoxicity Studies. J. Water Process Eng. 2017, 16, 258–269. [Google Scholar] [CrossRef] [Green Version]

- Iuliani, P.; Carlucci, G.; Marrone, A. Investigation of the HPLC Response of NSAIDs by Fractional Experimental Design and Multivariate Regression Analysis. Response Optimization and New Retention Parameters. J. Pharm. Biomed. Anal. 2010, 51, 46–55. [Google Scholar] [CrossRef]

- Ofman, P.; Struk-Sokołowska, J. Artificial Neural Network (ANN) Approach to Modelling of Selected Nitrogen Forms Removal from Oily Wastewater in Anaerobic and Aerobic GSBR Process Phases. Water 2019, 11, 1594. [Google Scholar] [CrossRef] [Green Version]

- ICONTEC Norma Técnica Colombiana NTC 3903. Procedimiento Para El Ensayo de Coagulación-Floculación En Un Recipiente Con Agua o Método de Jarras. 2010. Available online: https://tienda.icontec.org/gp-procedimiento-para-el-ensayo-de-coagulacion-floculacion-en-un-recipiente-con-agua-o-metodo-de-jarras-ntc3903-2010.html (accessed on 15 June 2022).

- Tsaur, S.-L.; Fitch, R.M. Preparation and Properties of Polystyrene Model Colloids: II. Effect of Surface Charge Density on Coagulation Behavior. J. Colloid Interface Sci. 1987, 115, 463–471. [Google Scholar] [CrossRef]

- Oriekhova, O.; Stoll, S. Investigation of FeCl3 Induced Coagulation Processes Using Electrophoretic Measurement, Nanoparticle Tracking Analysis and Dynamic Light Scattering: Importance of PH and Colloid Surface Charge. Colloids Surf. A Physicochem. Eng. Asp. 2014, 461, 212–219. [Google Scholar] [CrossRef]

- de Paula, H.M.; de Oliveira Ilha, M.S.; Sarmento, A.P.; Andrade, L.S. Dosage Optimization of Moringa Oleifera Seed and Traditional Chemical Coagulants Solutions for Concrete Plant Wastewater Treatment. J. Clean. Prod. 2018, 174, 123–132. [Google Scholar] [CrossRef]

- Shihab, A.S.; Hamad, A.T. Effect of Inclination Angle, Dimensions of Impeller Blades, and Velocity Gradient on the Efficiency of Water Flocculation. Int. J. Civ. Eng. Technol. 2018, 9, 969–977. [Google Scholar]

- Mohammed, T.J.; Shakir, E. Effect of Settling Time, Velocity Gradient, and Camp Number on Turbidity Removal for Oilfield Produced Water. Egypt. J. Pet. 2018, 27, 31–36. [Google Scholar] [CrossRef]

- Yukselen, M.A.; Gregory, J. The Effect of Rapid Mixing on the Break-up and Re-Formation of Flocs. J. Chem. Technol. Biotechnol. 2004, 79, 782–788. [Google Scholar] [CrossRef]

- Choong Lek, B.L.; Peter, A.P.; Qi Chong, K.H.; Ragu, P.; Sethu, V.; Selvarajoo, A.; Arumugasamy, S.K. Treatment of Palm Oil Mill Effluent (POME) Using Chickpea (Cicer Arietinum) as a Natural Coagulant and Flocculant: Evaluation, Process Optimization and Characterization of Chickpea Powder. J. Environ. Chem. Eng. 2018, 6, 6243–6255. [Google Scholar] [CrossRef]

- Rossini, M.; Garrido, J.G.; Galluzzo, M. Optimization of the Coagulation-Flocculation Treatment: Influence of Rapid Mix Parameters. Water Res. 1999, 33, 1817–1826. [Google Scholar] [CrossRef]

- Kim, D.W.; Yu, S.I.; Im, K.; Shin, J.; Shin, S.G. Responses of Coagulant Type, Dosage and Process Conditions to Phosphate Removal Efficiency from Anaerobic Sludge. Int. J. Environ. Res. Public Health 2022, 19, 1693. [Google Scholar] [CrossRef] [PubMed]

- Shruthi Keerthi, D.; Mukunda Vani, M. Optimization Studies on Decolorization of Textile Wastewater Using Natural Coagulants. Mater. Today Proc. 2022, 57, 1546–1552. [Google Scholar] [CrossRef]

| Before the Treatment | After the Treatment | |||

|---|---|---|---|---|

| Parameter | Raw Wastewater, ppm | Output from Maturation Lagoon, ppm | Parameter | Sampling Point at the Oxidation Reactor, ppm |

| DBO5 | 2690 | 646 | DBO5 | 72 |

| DQO | 4201 | 813 | DQO | 178 |

| SST | 2070 | 233 | ||

| Grease and oils | 617 | 21 | ||

| DETERGENTS | 3.4 | 2.61 | ||

| Factor | Units | Low Level (−1) | Intermediate Level (0) | High Level (+1) |

|---|---|---|---|---|

| A: Residence time | minutes | 1 | 2 | 3 |

| B: Velocity gradient | rpm | 30 | 65 | 100 |

| C: Coagulant concentration | ppm | 100 | 350 | 600 |

| D: Pre-chlorination | ppm | 0 | 2.5 | 5 |

| E: Coagulation adjuvant | ppm | 1 | 3 | 5 |

| Run | BL | A | B | C | D | E | Color (Pt-Co) |

|---|---|---|---|---|---|---|---|

| 1 | 1 | −1 | −1 | −1 | −1 | +1 | 8460 |

| 2 | 1 | +1 | −1 | −1 | −1 | −1 | 7740 |

| 3 | 1 | −1 | +1 | −1 | −1 | −1 | 5640 |

| 4 | 1 | +1 | +1 | −1 | −1 | +1 | 4325 |

| 5 | 1 | −1 | −1 | +1 | −1 | −1 | 1400 |

| 6 | 1 | +1 | −1 | +1 | −1 | +1 | 3840 |

| 7 | 1 | −1 | +1 | +1 | −1 | +1 | 1340 |

| 8 | 1 | +1 | +1 | +1 | −1 | −1 | 640 |

| 9 | 1 | −1 | −1 | −1 | +1 | −1 | 7260 |

| 10 | 1 | +1 | −1 | −1 | +1 | +1 | 6875 |

| 11 | 1 | −1 | +1 | −1 | +1 | +1 | 4320 |

| 12 | 1 | +1 | +1 | −1 | +1 | −1 | 6140 |

| 13 | 1 | −1 | −1 | +1 | +1 | +1 | 3460 |

| 14 | 1 | +1 | −1 | +1 | +1 | −1 | 2120 |

| 15 | 1 | −1 | +1 | +1 | +1 | −1 | 950 |

| 16 | 1 | +1 | +1 | +1 | +1 | +1 | 487 |

| 17 | 1 | 0 | 0 | 0 | 0 | 0 | 6560 |

| 18 | 1 | 0 | 0 | 0 | 0 | 0 | 1420 |

| 19 | 1 | 0 | 0 | 0 | 0 | 0 | 5700 |

| 20 | 1 | 0 | 0 | 0 | 0 | 0 | 4200 |

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| A: Residence time | 27,473.1 | 1 | 27,473.1 | 0.02 | 0.9014 |

| B: Velocity gradient | 1.87337 × 107 | 1 | 1.87337 × 107 | 10.85 | 0.0053 |

| C: Coagulant concentration | 8.33706 × 107 | 1 | 8.33706 × 107 | 48.28 | 0.0000 |

| D: Pre-chlorination | 196,471.0 | 1 | 196,471.0 | 0.11 | 0.7409 |

| E: Coagulation adjuvant | 92,568.1 | 1 | 92,568.1 | 0.05 | 0.8203 |

| Total Error | 2.41754 × 107 | 14 | 1.72681 × 106 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carpintero, J.; Villa-Dominguez, J.; Tavera-Quiroz, M.J.; Tavera-Quiroz, H.C.; Kaźmierczak, B.; Fábregas-Villegas, J.; Canales, F.A. Application of a 2k–p Fractional Experimental Design in Coagulation-Flocculation Processes in the Treatment of Wastewater from a Slaughterhouse. Sustainability 2022, 14, 10402. https://doi.org/10.3390/su141610402

Carpintero J, Villa-Dominguez J, Tavera-Quiroz MJ, Tavera-Quiroz HC, Kaźmierczak B, Fábregas-Villegas J, Canales FA. Application of a 2k–p Fractional Experimental Design in Coagulation-Flocculation Processes in the Treatment of Wastewater from a Slaughterhouse. Sustainability. 2022; 14(16):10402. https://doi.org/10.3390/su141610402

Chicago/Turabian StyleCarpintero, Javier, Jennifer Villa-Dominguez, María José Tavera-Quiroz, Humberto Carlos Tavera-Quiroz, Bartosz Kaźmierczak, Jonathan Fábregas-Villegas, and Fausto A. Canales. 2022. "Application of a 2k–p Fractional Experimental Design in Coagulation-Flocculation Processes in the Treatment of Wastewater from a Slaughterhouse" Sustainability 14, no. 16: 10402. https://doi.org/10.3390/su141610402