Deformation Characteristics and Damage Assessment of Prefabricated Frame Tunnels after Central and External Explosions

Abstract

:1. Introduction

2. Structural Design and Numerical Model of a Prefabricated Frame Tunnel

2.1. Structural Design of the Frame Tunnel

2.2. Constitutive Model

2.2.1. Concrete and Steel Components

2.2.2. Air

2.2.3. TNT

2.2.4. Soil

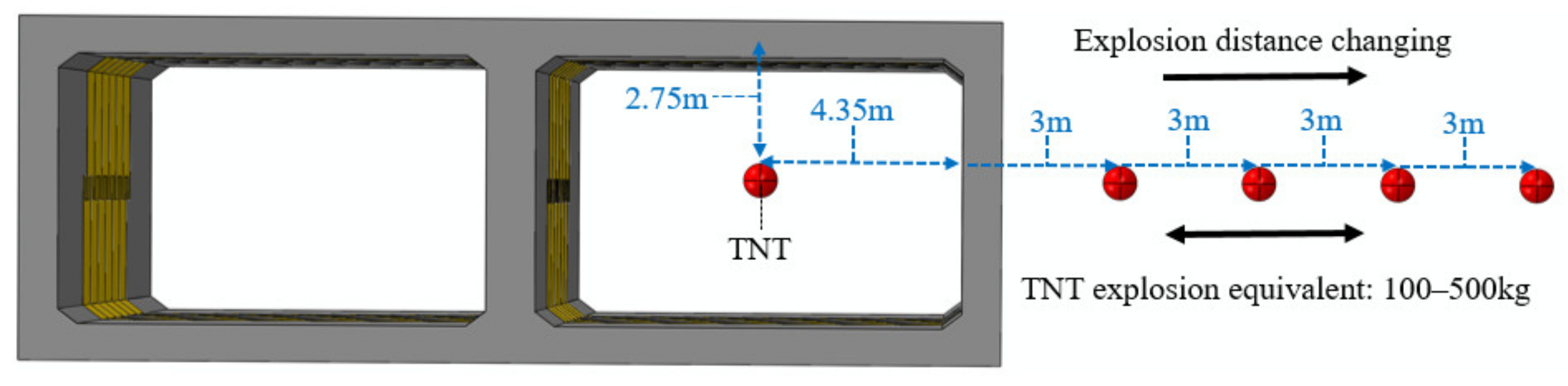

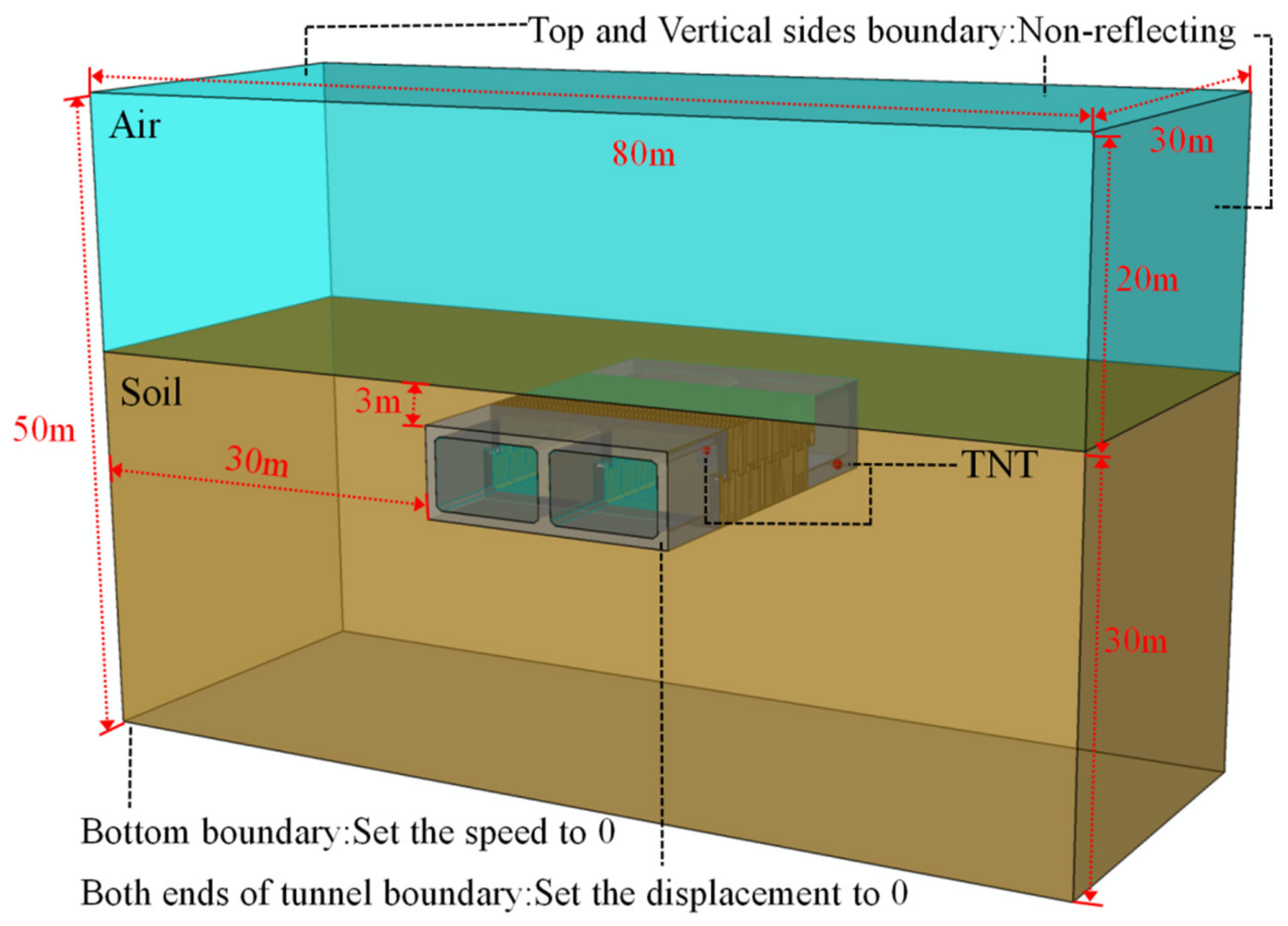

2.3. Boundary Conditions and Explosion Modes

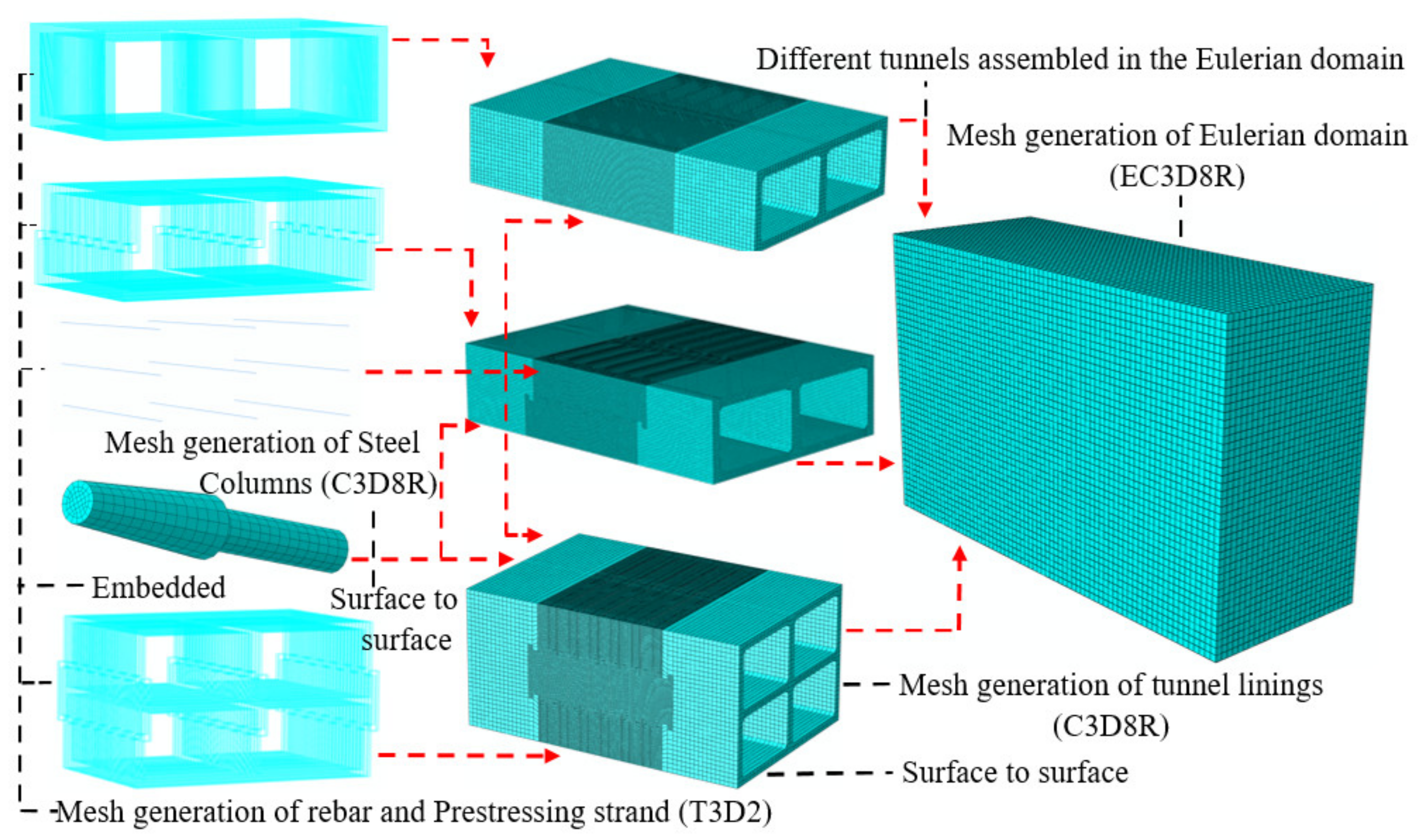

2.4. Contact Relationship and Mesh Generation

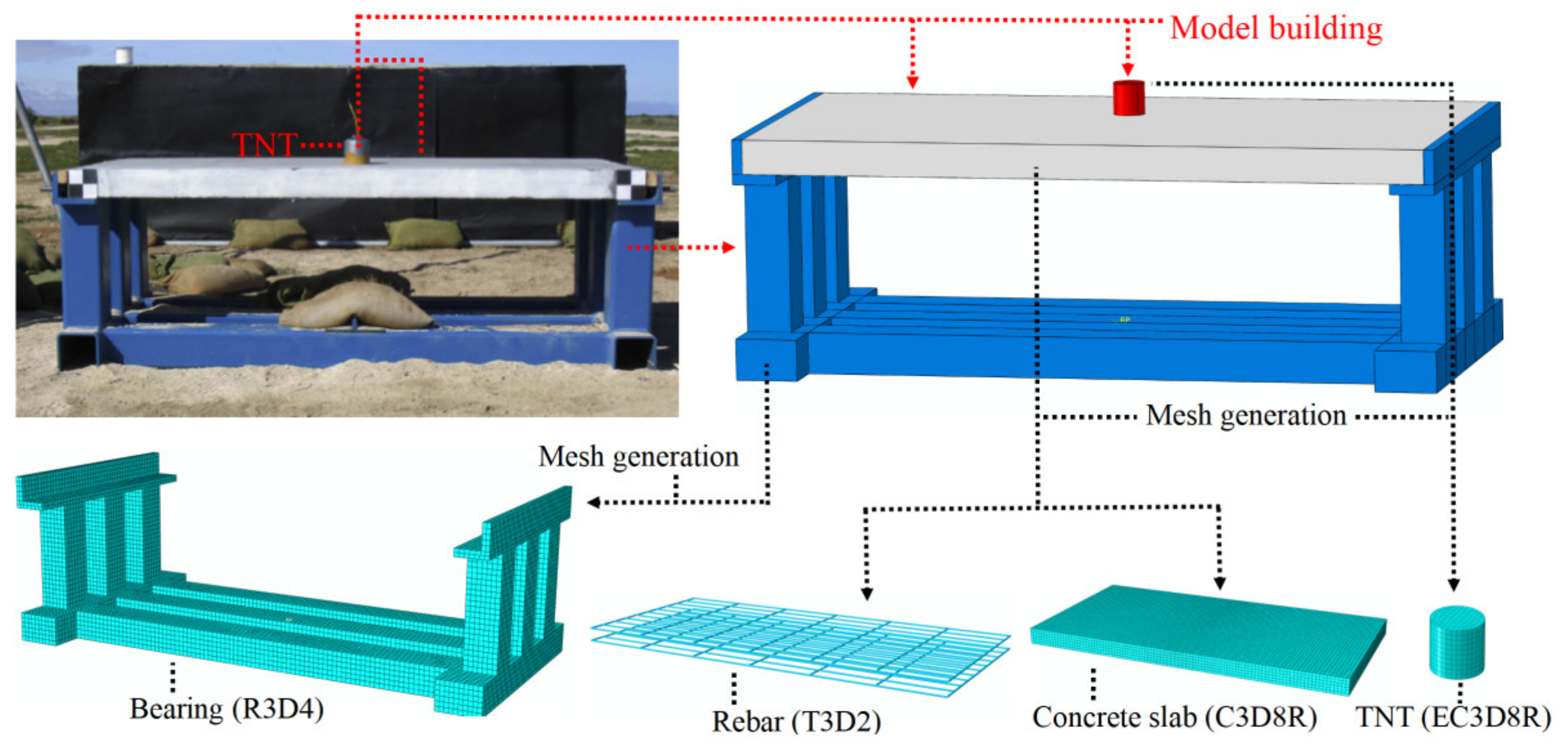

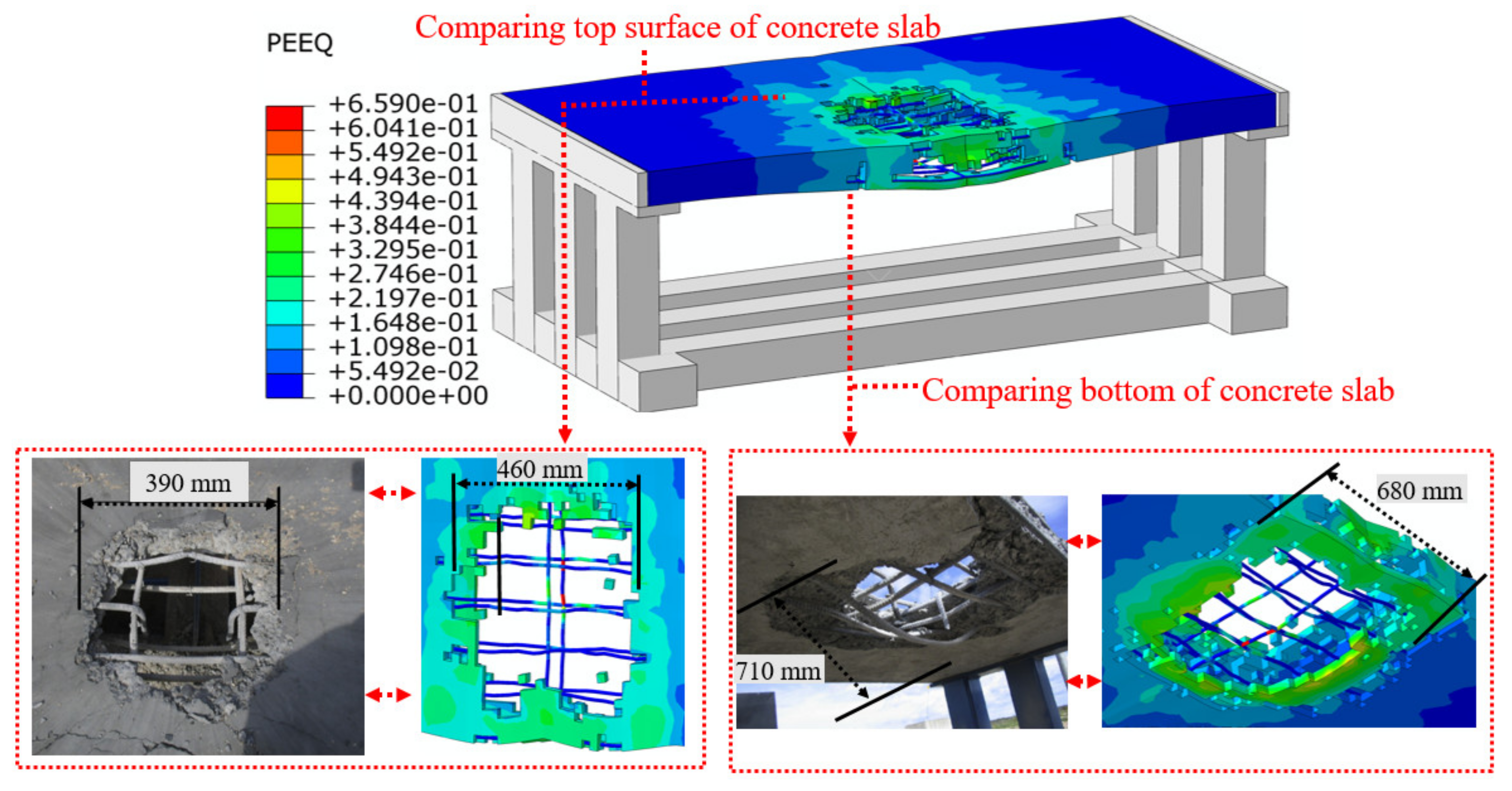

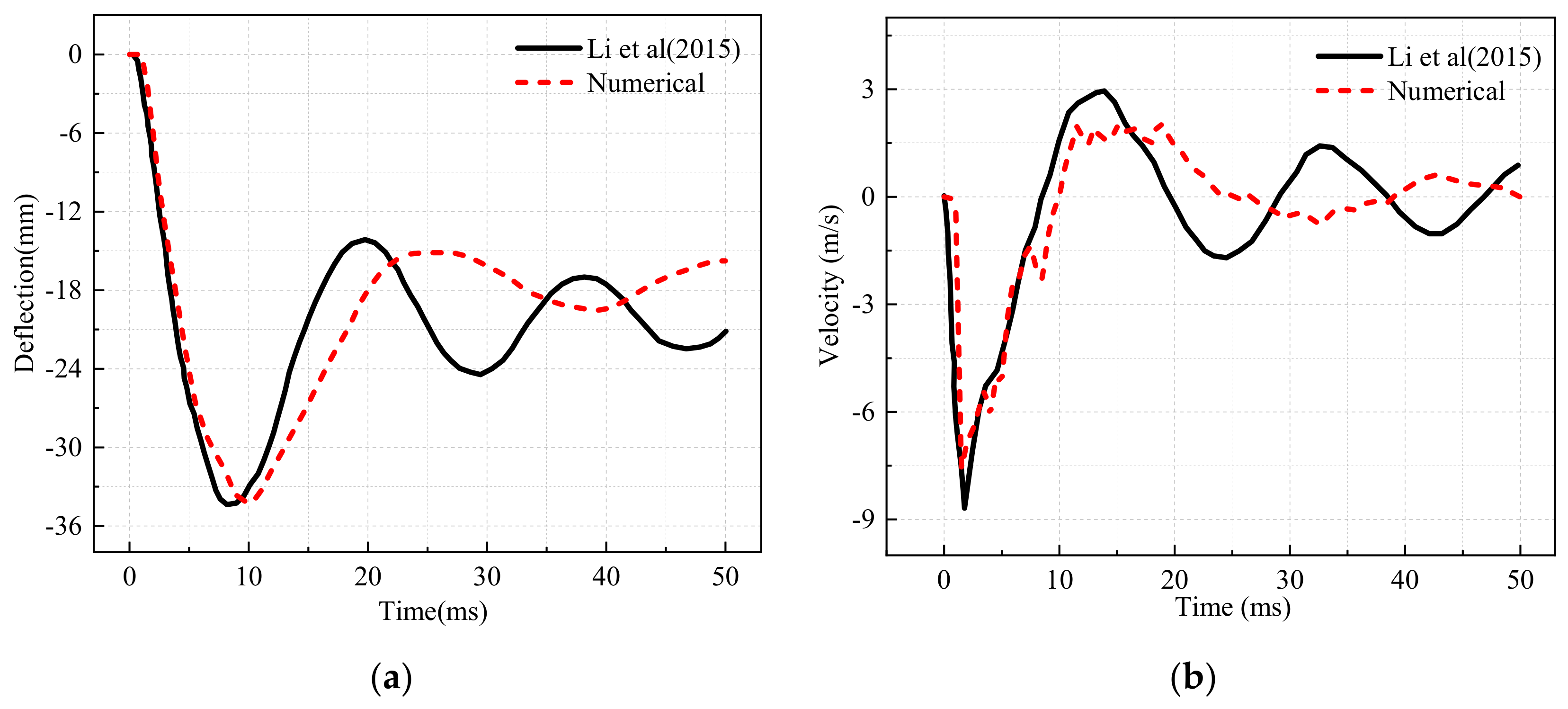

3. Model Validation

4. Deformation Characteristics of a Prefabricated Frame Tunnel

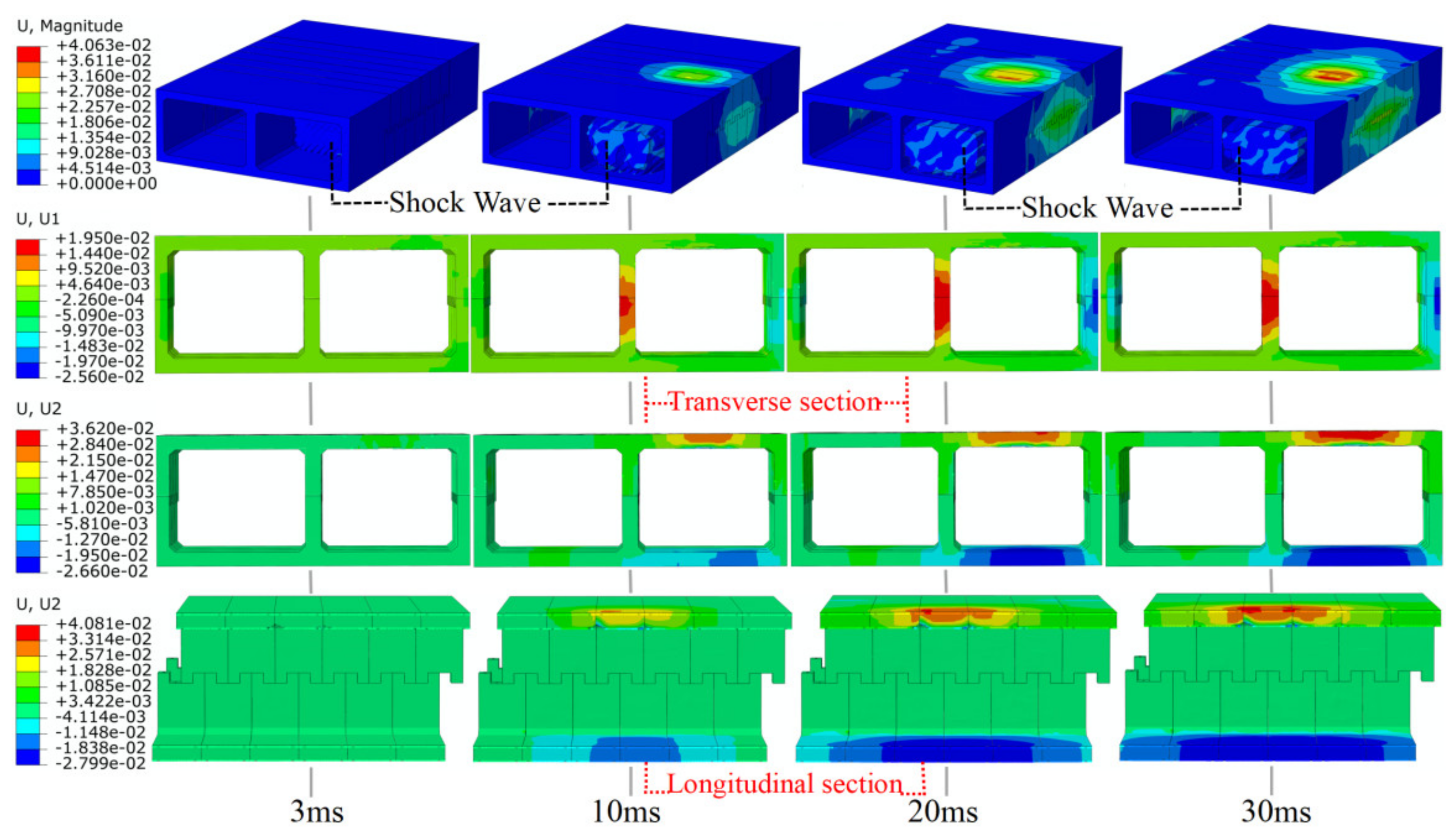

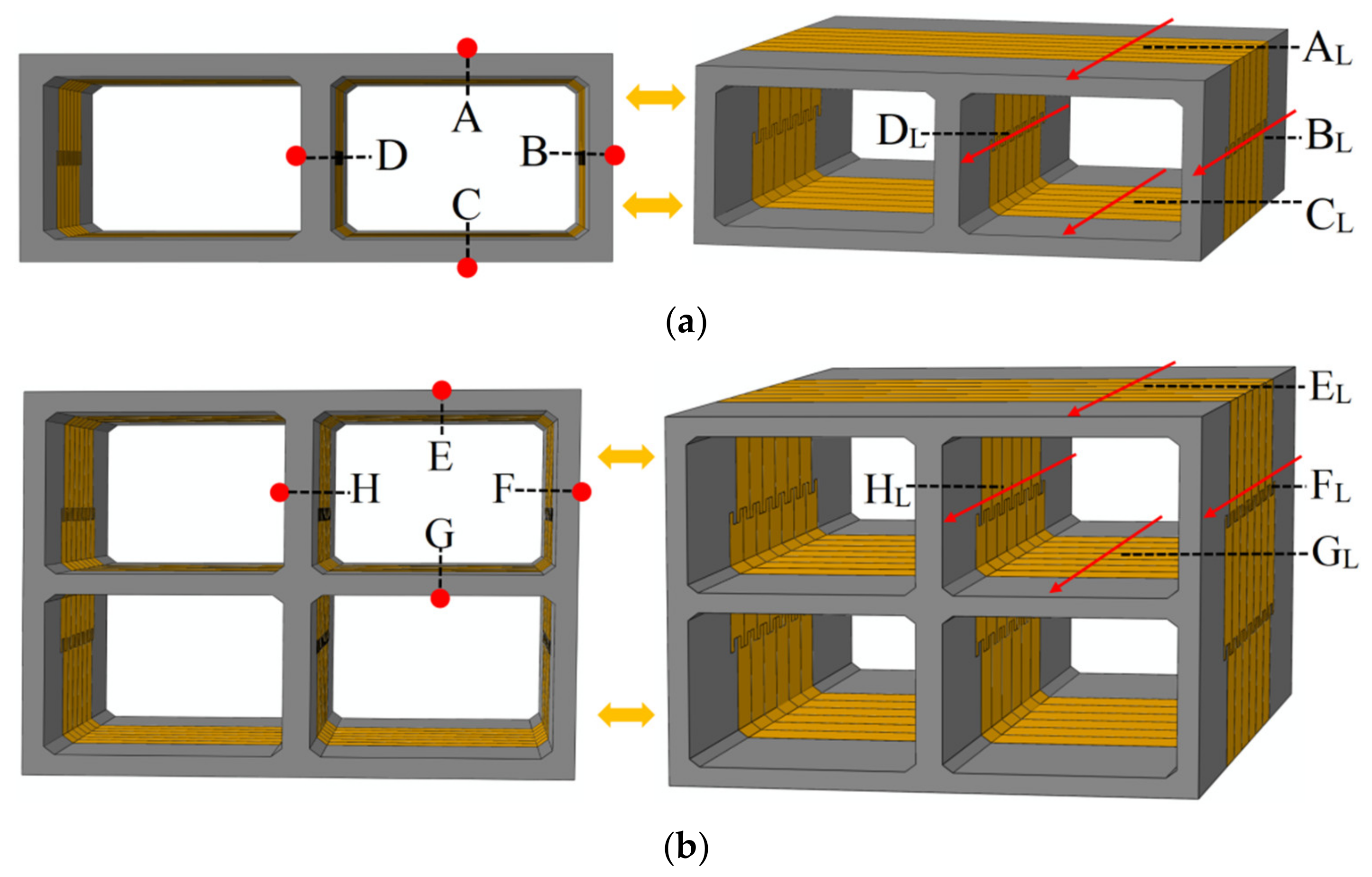

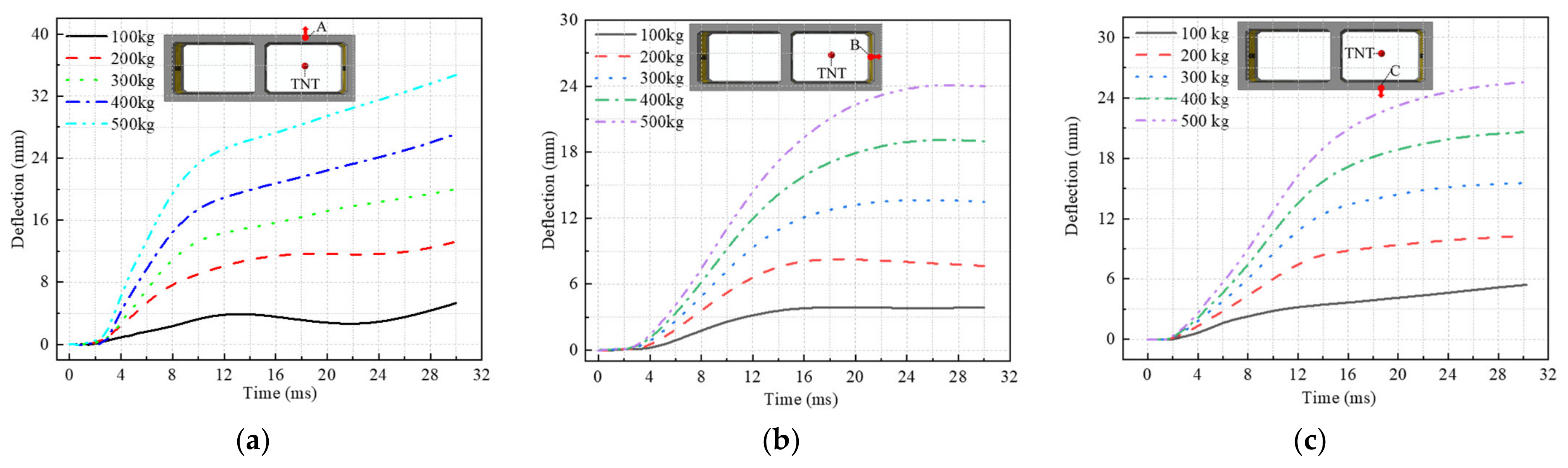

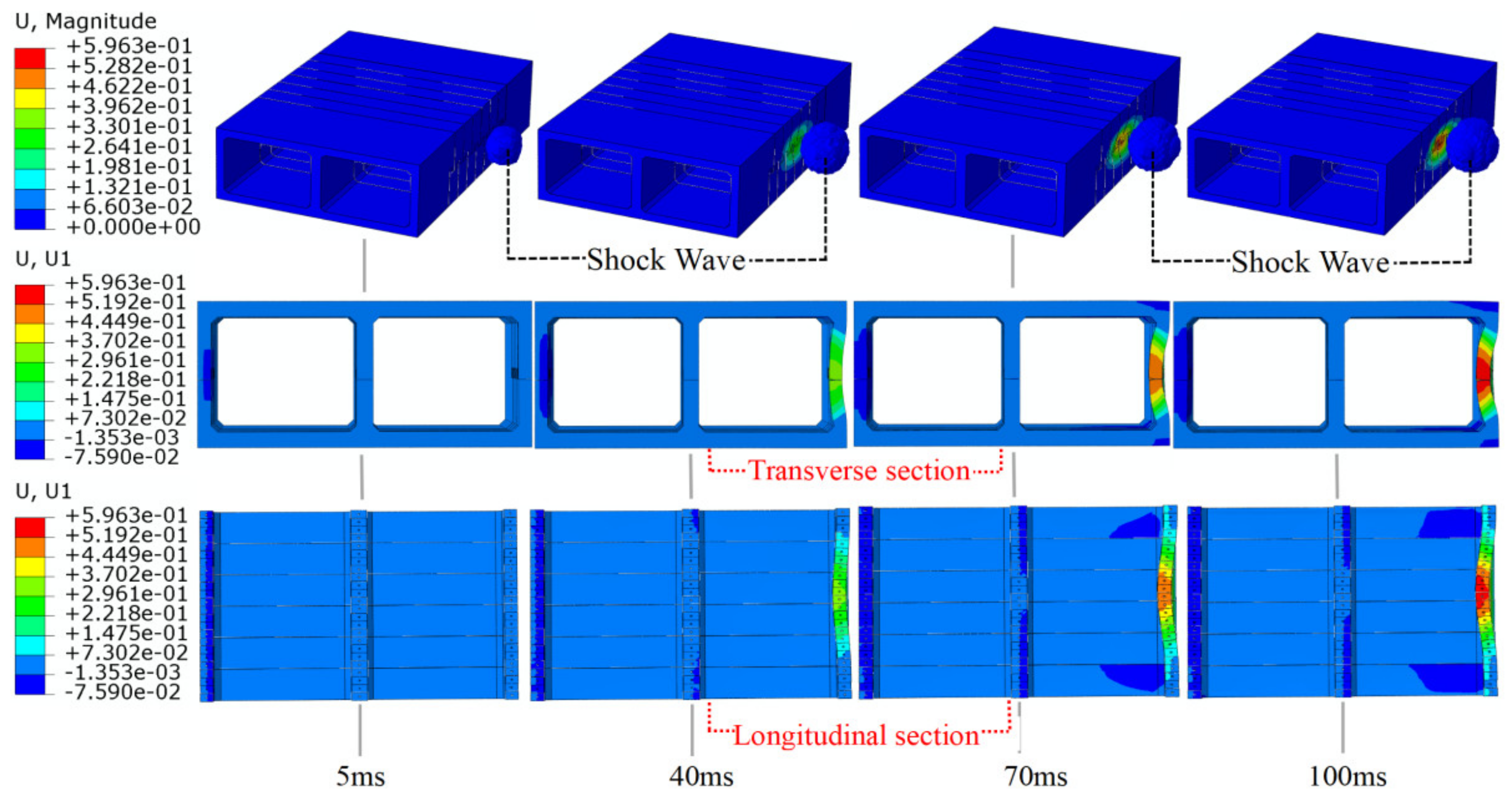

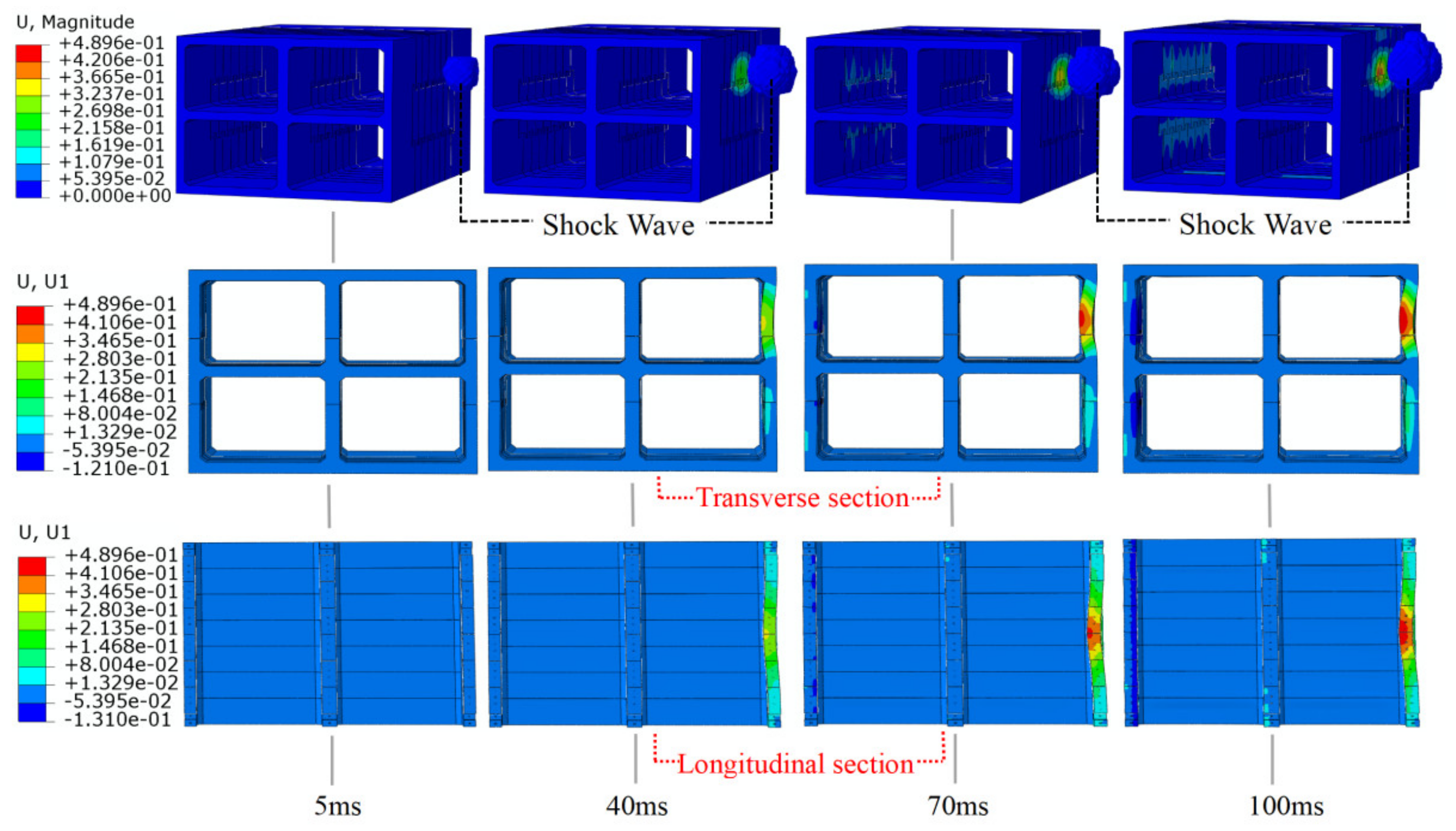

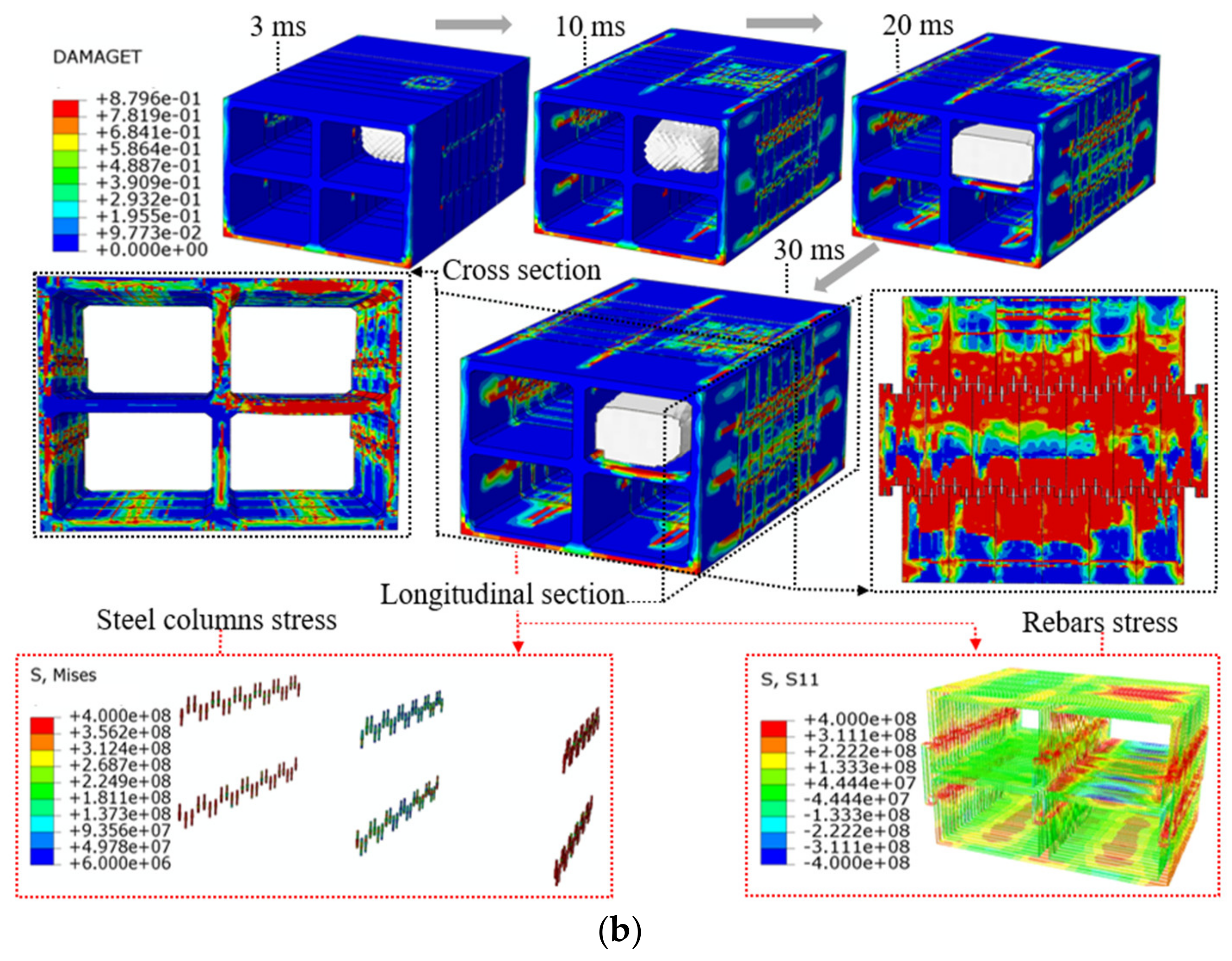

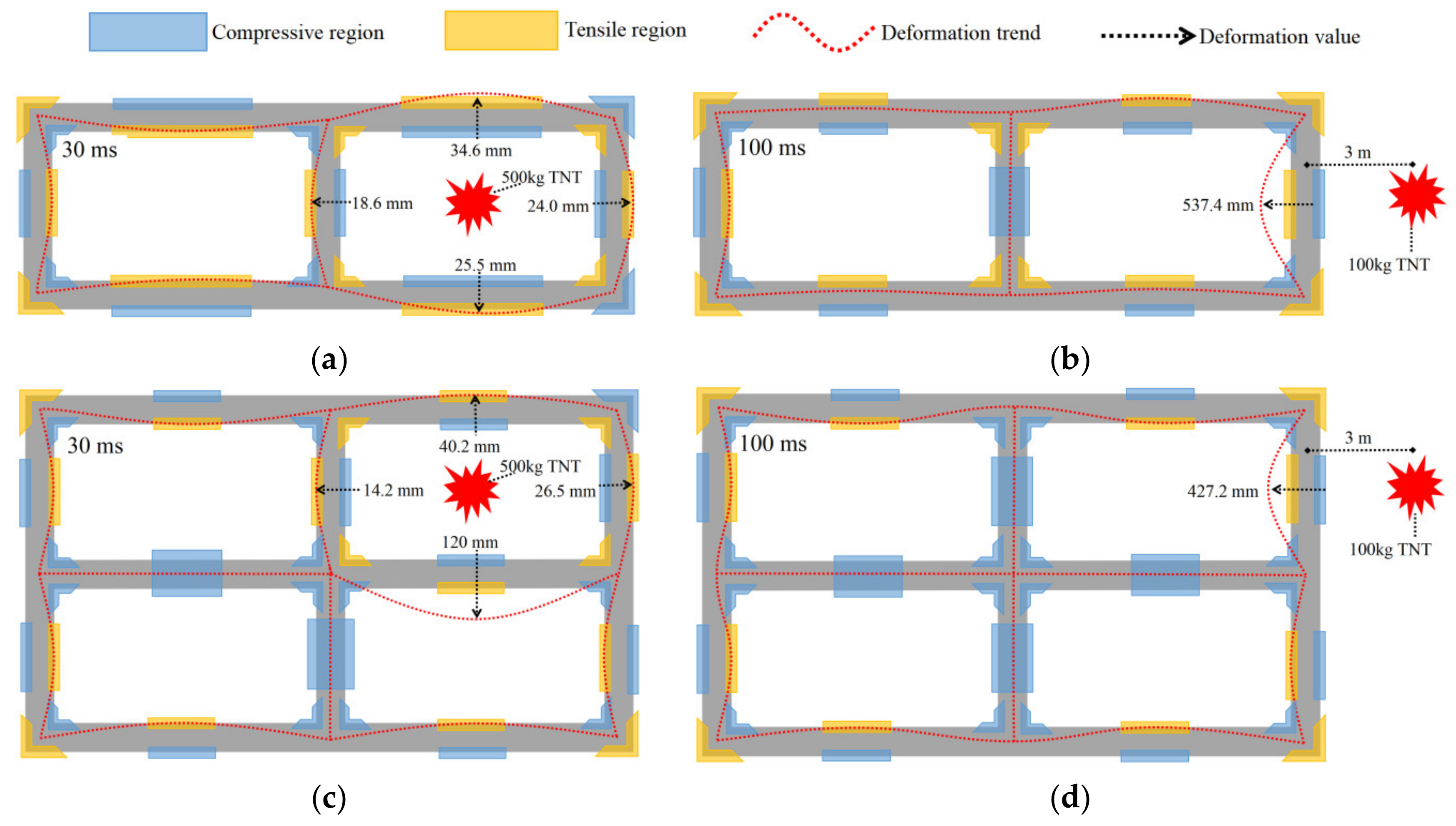

4.1. Central Explosion

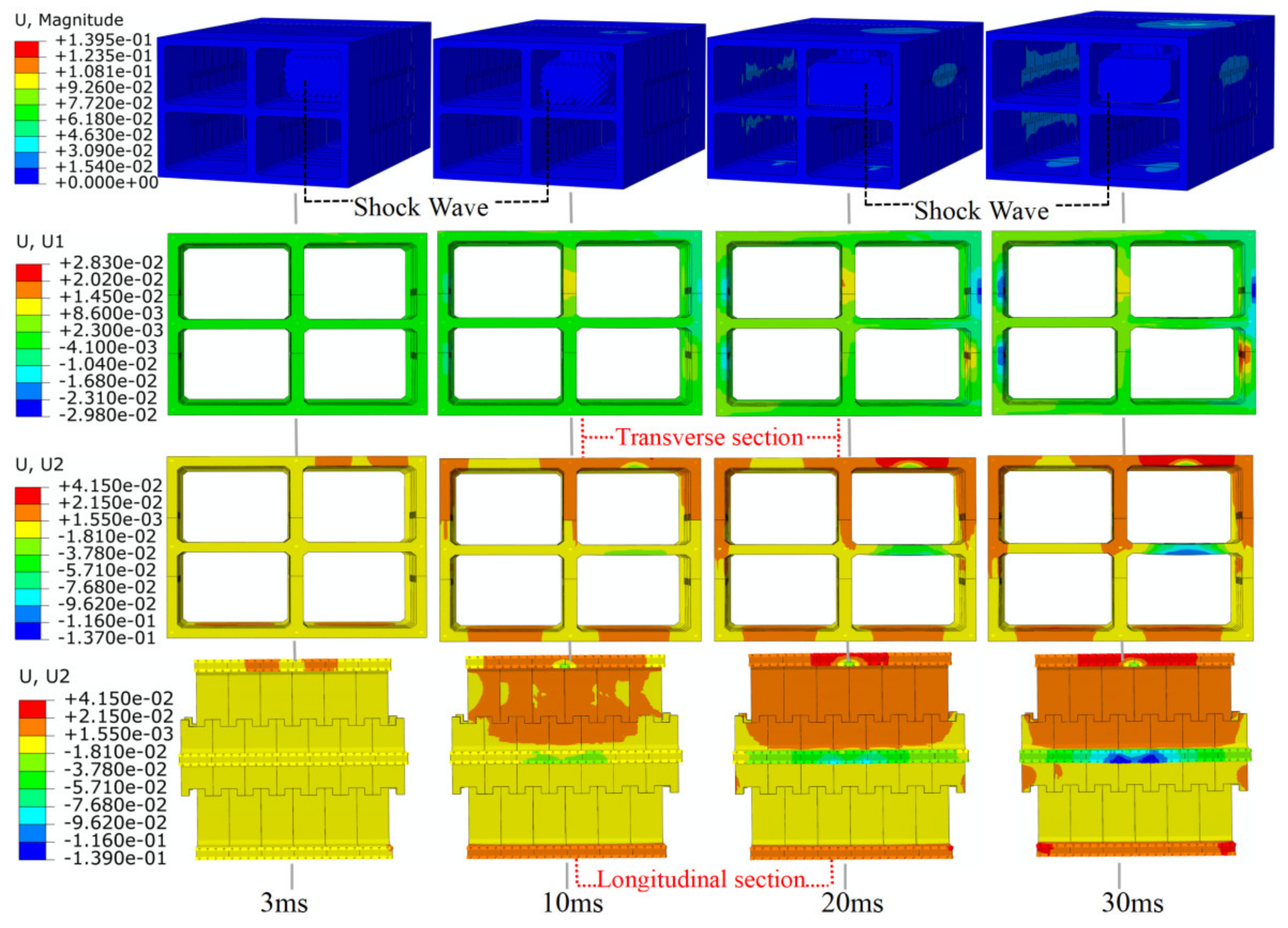

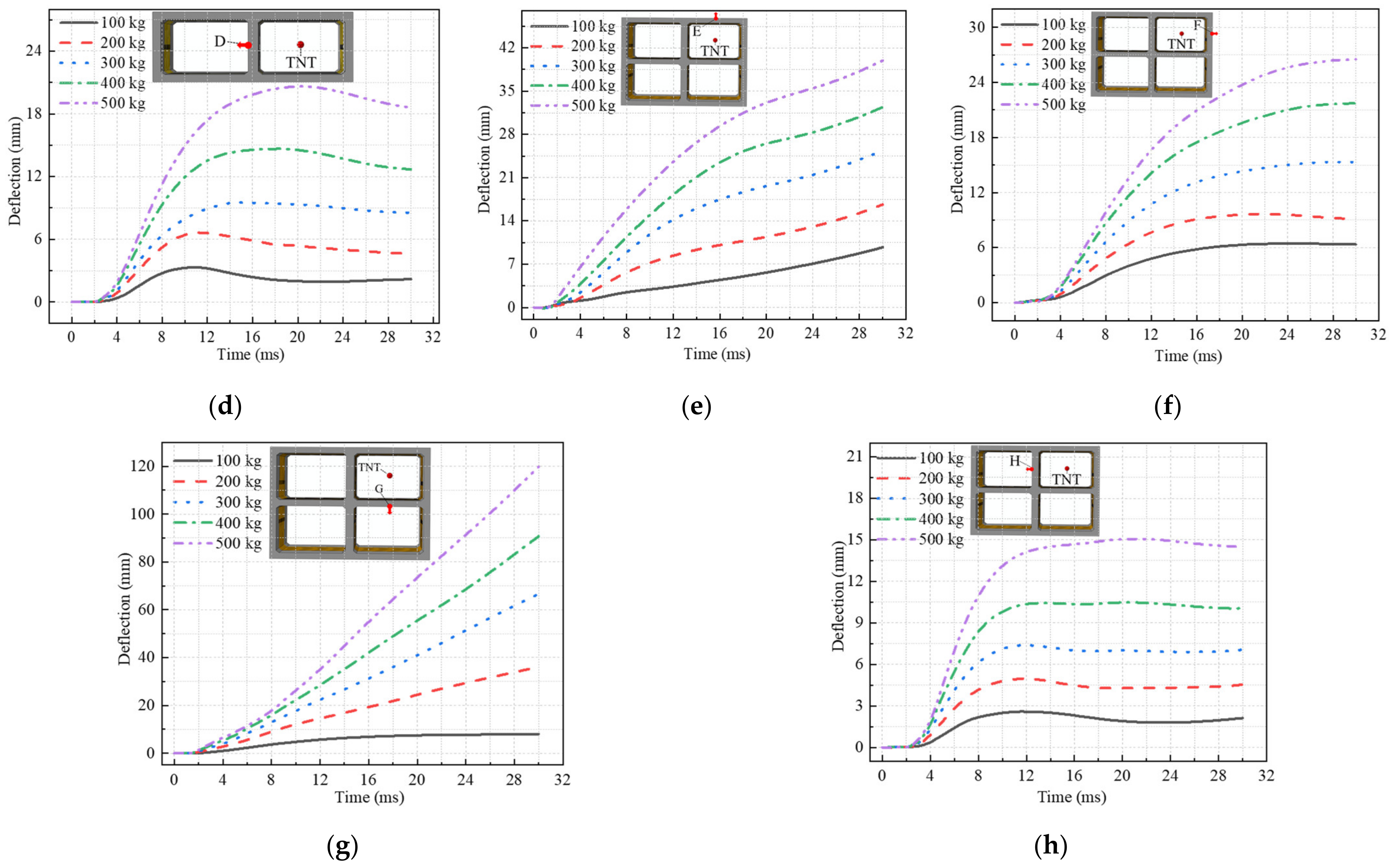

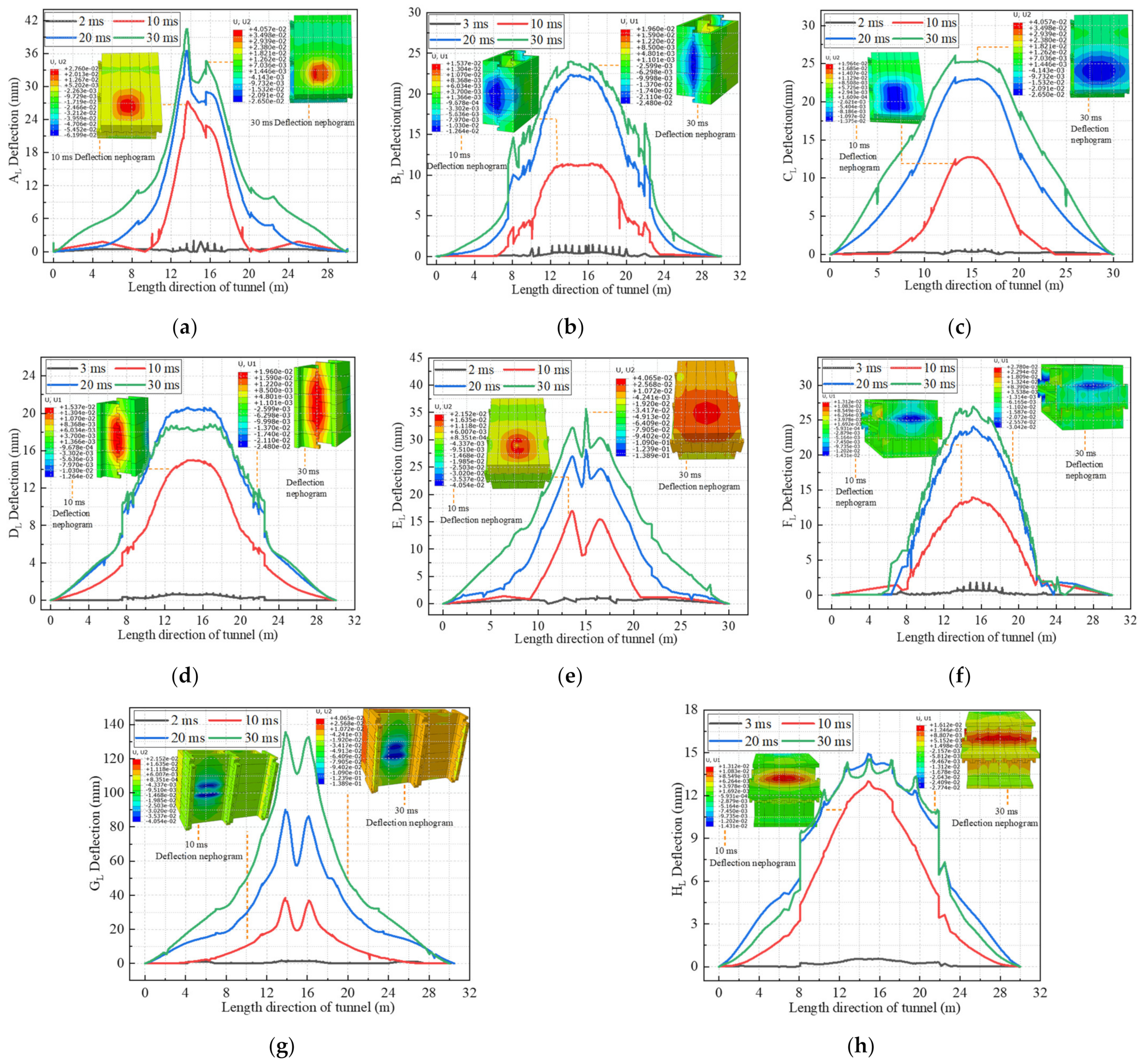

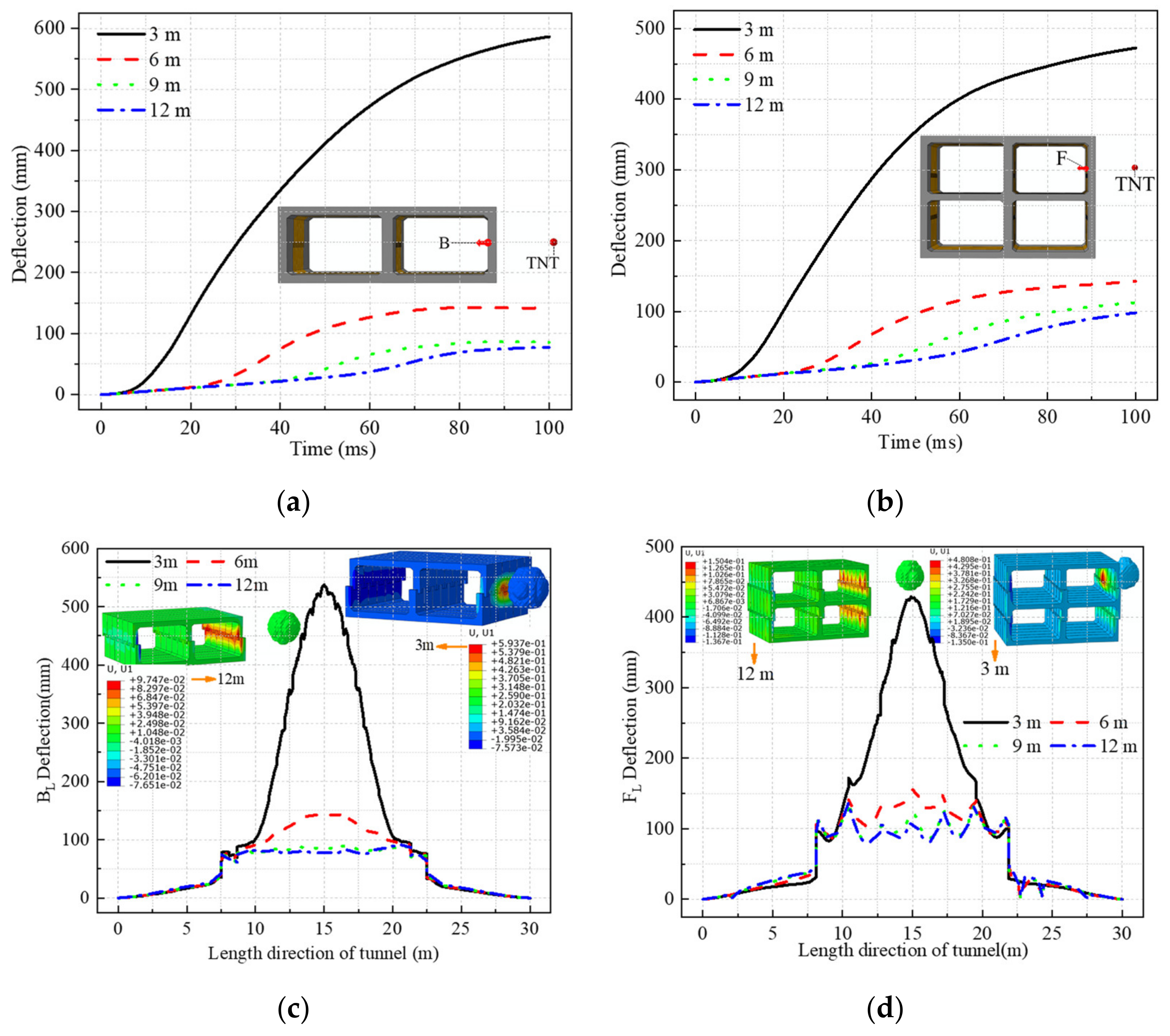

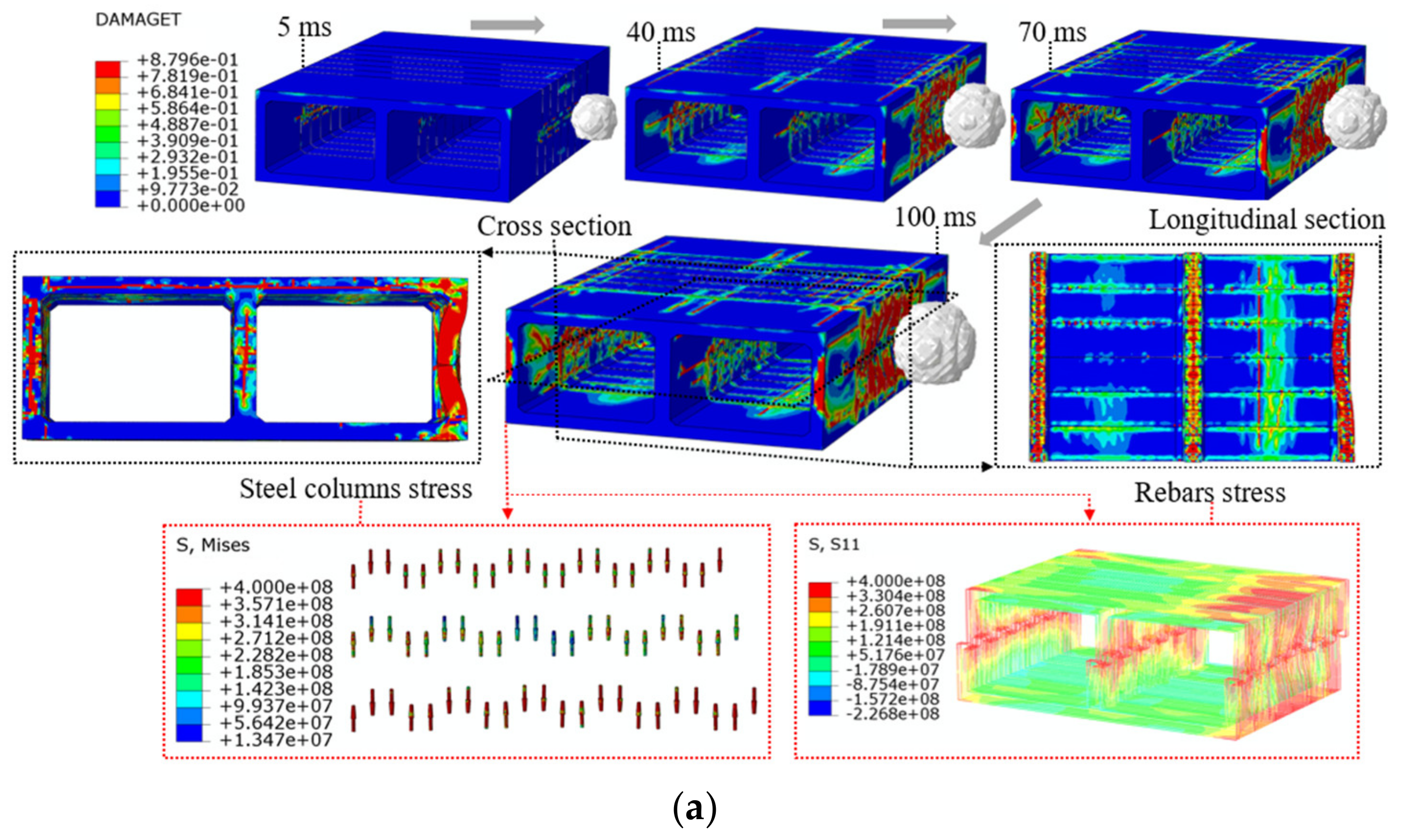

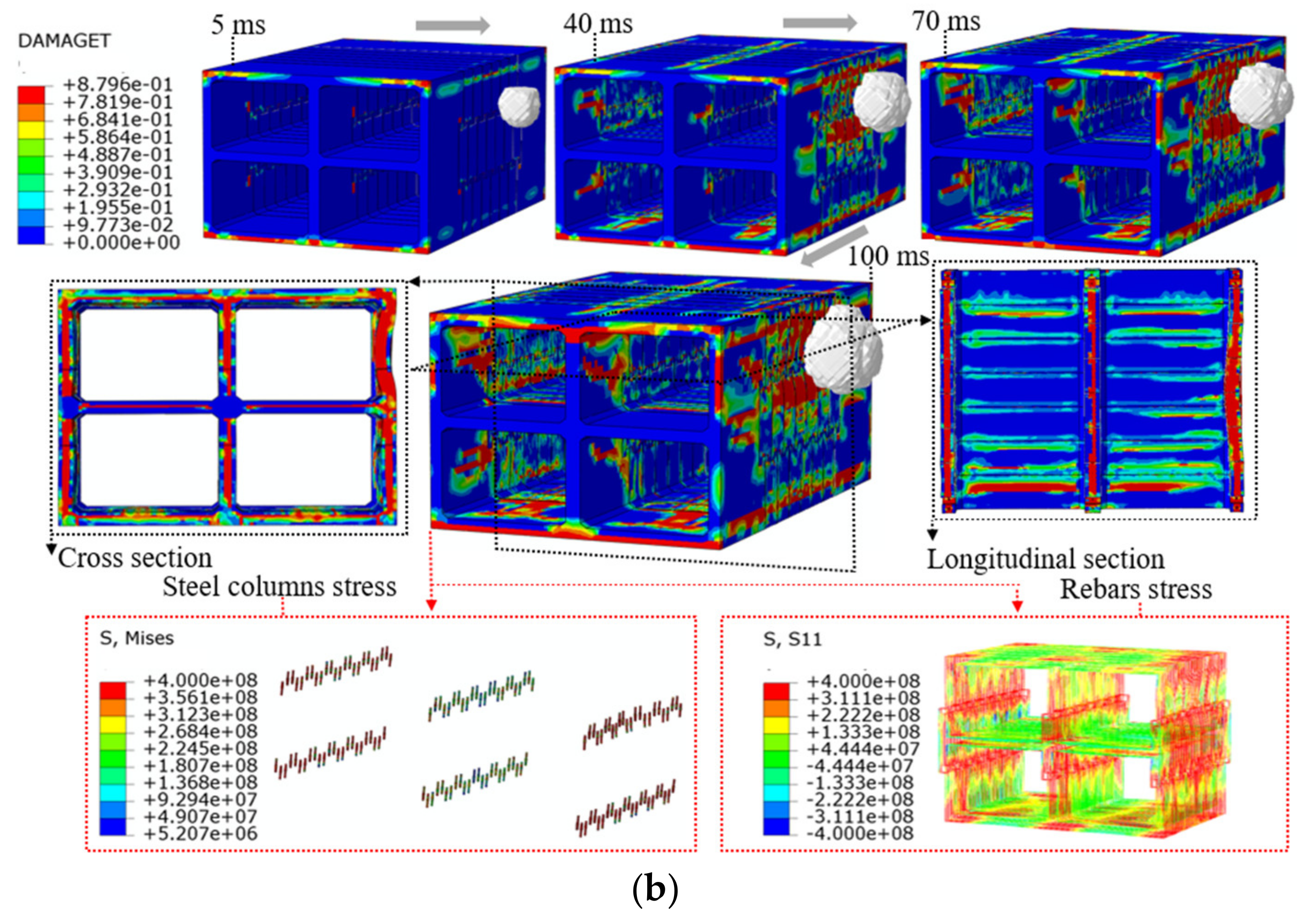

4.2. External Explosion

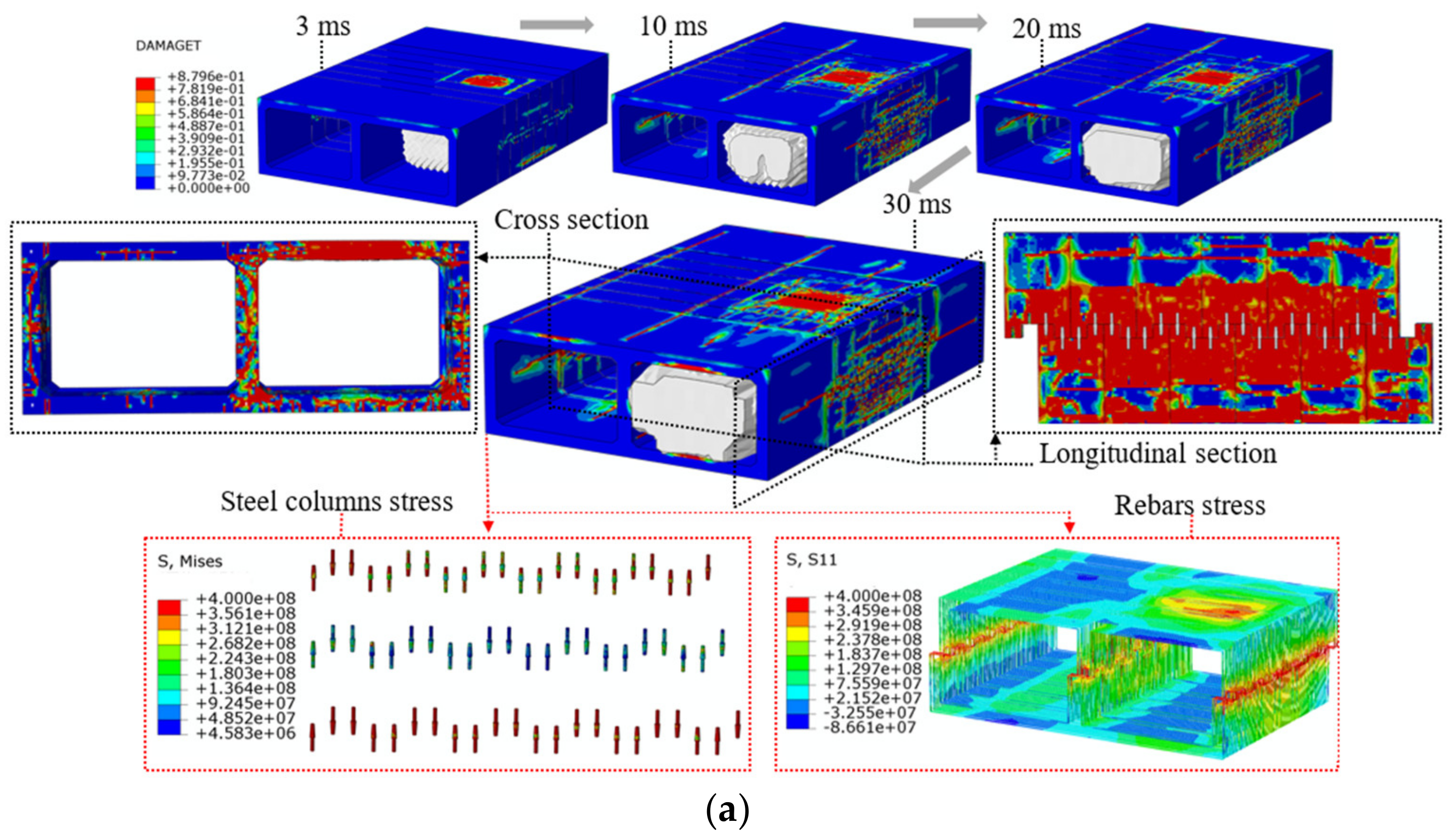

4.3. Damage Characteristics of the Prefabricated Frame Tunnel

4.4. Failure Mode of the Fabricated Frame Tunnel

5. Conclusions

- (1)

- Under the central explosion load, the shock wave energy is continuously consumed by the tunnel and the surrounding soil, and the reflected wave continuously propagates inside the tunnel, causing large-area concrete spalling of the prefabricated frame tunnel lining. The lining deforms outward towards the tunnel in the direction of the explosion wave, the inner side of the tunnel is compressed, and the outer side is pulled. The deformation and damage at the structural joints of the single-layer and the double-layer frame are significantly higher than those at other parts, while the deformation and damage of the mid-partition in the double-layer frame are more serious. The mid-partition of the tunnel can be strengthened, and flexible damping material can be added at the joint to improve the explosion resistance of the prefabricated frame tunnel.

- (2)

- Under an external explosive load, part of the explosion shock wave is absorbed by the deformation of the tunnel lining, and the other part is reflected into the soil. External blasts are more damaging to the tunnel due to the low compressibility of the soil and the hollow interior of the frame. The close-range explosion not only causes local concrete collapse and spalling but also causes serious bending deformation of the tunnel lining. The tunnel deformation is localized. The tunnel side wall deforms inwardly towards the tunnel along the direction of the explosion wave, the outer side region of the tunnel is compressed, and the inner side region exhibits tensile stress. With increasing explosion distance, tunnel lining damage no longer shows a high degree of locality but is gradually dominated by bending deformation. Therefore, it is recommended to set a safe distance around the tunnel.

- (3)

- The disadvantage of this study is that the CEL algorithm can observe the process of air compression caused by the expansion of TNT, but the computational resource consumption is very large. Thus, the seed arrangement of the Euler grid needs to be carefully considered. At the same time, the M–C constitutive cannot reflect the yield caused by the compression characteristics during the simulation process, which may have an impact on the accuracy of the calculation results of the external explosion. Subsequent research can be aimed at the establishment of the soil constitutive model under the explosion load in terms of calculation accuracy and calculation efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, R.S.; Chen, W.S.; Hao, H.; Li, J.D. A state-of-the-art review of road tunnel subjected to blast loads. Tunn. Undergr. Space Technol. 2021, 112, 103911. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, C.L.; Ma, S.K.; Zhang, J.B.; Zhu, Q.X. Study of the mechanical behaviour and damage characteristics of three new types of joints for fabricated rectangular tunnels using a numerical approach. Tunn. Undergr. Space Technol. 2021, 118, 104184. [Google Scholar] [CrossRef]

- Wang, P.Y.; Wang, S.H.; Khan, M.I.; Zhu, C.J. Bending mechanics model and value of transverse joints in precast prestressed utility tunnel. J. Asian Archit. Build. Eng. 2020, 19, 203–219. [Google Scholar] [CrossRef]

- Zhou, R.; Fang, W.P.; Wu, J.S. A risk assessment model of a sewer pipeline in an underground utility tunnel based on a Bayesian network. Tunn. Undergr. Space Technol. 2020, 103, 103473. [Google Scholar] [CrossRef]

- Wu, X.G.; Chen, X.K.; Yu, S.Y.; Hong, S.; Kang, T.H.K. Experimental study on waterproofing properties of putty-based composite rubber strip for underground post-tensioned precast concrete structures. Int. J. Concr. Struct. Mater. 2019, 13, 8. [Google Scholar] [CrossRef]

- He, S.Y.; Su, L.J.; Fan, H.B.; Ren, R. Methane explosion accidents of tunnels in SW China. Geomat. Nat. Hazards Risk 2019, 10, 667–677. [Google Scholar] [CrossRef]

- Xue, Y.Z.; Chen, G.H.; Zhang, Q.; Xie, M.L.; Ma, J.J. Simulation of the dynamic response of an urban utility tunnel under a natural gas explosion. Tunn. Undergr. Space Technol. 2021, 108, 103713. [Google Scholar] [CrossRef]

- Lin, Y.X.; Yin, Z.Y.; Wang, X.; Huang, L.C. A systematic 3D simulation method for geomaterials with block inclusions from image recognition to fracturing modelling. Theor. Appl. Fract. Mech. 2022, 117, 103194. [Google Scholar] [CrossRef]

- Lin, Y.X.; Wang, X.; Ma, J.J.; Huang, L.C. A finite-discrete element based appoach for modelling the hydraulic fracturing of rocks with irregular inclusions. Eng. Fract. Mech. 2022, 261, 108209. [Google Scholar] [CrossRef]

- Qian, H.M.; Zong, Z.H.; Wu, C.Q.; Li, J.; Gan, L. Numerical study on the behavior of utility tunnel subjected to ground surface explosion. Thin-Walled Struct. 2021, 161, 107422. [Google Scholar] [CrossRef]

- Tiwari, R.; Chakraborty, T.; Matsagar, V. Dynamic analysis of tunnel in weathered rock subjected to internal blast loading. Rock Mech. Rock Eng. 2016, 49, 4441–4458. [Google Scholar] [CrossRef]

- Mussa, M.H.; Mutalib, A.A.; Hamid, R.; Naidu, S.R.; Radzi, N.A.M.; Abedini, M. Assessment of damage to an underground box tunnel by a surface explosion. Tunn. Undergr. Space Technol. 2017, 66, 64–76. [Google Scholar] [CrossRef]

- Ge, J.J.; Xu, Y.; Huang, W.; Wang, H.B.; Yang, R.Z.; Zhang, Z.Y. Experimental Study on Crack Propagation of Rock by Blasting under Bidirectional Equal Confining Pressure Load. Sustainability 2021, 13, 12093. [Google Scholar] [CrossRef]

- Zhou, Q.; He, H.G.; Liu, S.F.; Chen, X.S.; Tang, Z.X.; Liu, Y.; Qiu, Z.Y.; Li, S.S.; Wang, H.; Zhou, Y.Z.; et al. Blast resistance evaluation of urban utility tunnel reinforced with BFRP bars. Def. Technol. 2021, 17, 512–530. [Google Scholar] [CrossRef]

- Zhao, Y.T.; Chu, C.; Yi, Y.J. Study on an engineering measure to improve internal explosion resistance capacity of segmental tunnel lining structures. J. Vibroeng. 2016, 18, 2997–3009. [Google Scholar]

- Hanifehzadeh, M.; Aryan, H.; Gencturk, B.; Akyniyazov, D. Structural response of steel jacket-uhpc retrofitted reinforced concrete columns under blast loading. Materials 2021, 14, 1521. [Google Scholar] [CrossRef]

- Williamson, E.B.; Bayrak, O.; Davis, C.; Williams, G.D. Performance of bridge columns subjected to blast loads. I: Experimental program. J. Bridge Eng. 2011, 16, 693–702. [Google Scholar] [CrossRef]

- Huang, Z.K.; Zhang, D.M.; Pitilakis, K.; Tsinidis, G.; Huang, H.W.; Zhang, D.M.; Argyroudis, S. Resilience assessment of tunnels: Framework and application for tunnels in alluvial deposits exposed to seismic hazard. Soil Dyn. Earthq. Eng. 2022, 162, 107456. [Google Scholar] [CrossRef]

- Dassault Systèmes Simulia. Abaqus 6.18; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2016. [Google Scholar]

- Shi, C.H.; Cao, C.Y.; Lei, M.F.; Peng, L.M.; Ai, H.J. Effects of lateral unloading on the mechanical and deformation performance of shield tunnel segment joints. Tunn. Undergr. Space Technol. 2016, 51, 175–188. [Google Scholar] [CrossRef]

- Mandal, J.; Agarwal, A.K.; Goel, M.D. Numerical modeling of shallow buried tunnel subject to surface blast loading. J. Perform. Constr. Facil. 2020, 34, 04020106. [Google Scholar] [CrossRef]

- Yu, T.; Teng, J.G.; Wong, Y.L.; Dong, S.L. Finite element modeling of confined concrete-I: Drucker-Prager type plasticity model. Eng. Struct. 2010, 32, 665–679. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture and Building Press: Beijing, China, 2015.

- Sabagh, M.; Ghalandarzadeh, A. Numerical modelings of continuous shallow tunnels subject to reverse faulting and its verification through a centrifuge. Comput. Geotech. 2020, 128, 103813. [Google Scholar] [CrossRef]

- Deng, X.F.; Zhu, J.B.; Chen, S.G.; Zhao, Z.Y.; Zhou, Y.X.; Zhao, J. Numerical study on tunnel damage subject to blast-induced shock wave in jointed rock masses. Tunn. Undergr. Space Technol. 2014, 43, 88–100. [Google Scholar] [CrossRef]

- Li, Z.L.; Soga, K.; Wang, F.; Wright, P.; Tsuno, K. Behaviour of cast-iron tunnel segmental joint from the 3D FE analyses and development of a new bolt-spring model. Tunn. Undergr. Space Technol. 2014, 41, 176–192. [Google Scholar] [CrossRef]

- Liu, X.; Dong, Z.B.; Song, W.; Bai, Y. Investigation of the structural effect induced by stagger joints in segmental tunnel linings: Direct insight from mechanical behaviors of longitudinal and circumferential joints. Tunn. Undergr. Space Technol. 2018, 71, 271–291. [Google Scholar] [CrossRef]

- Do, T.V.; Pham, T.M.; Hao, H. Numerical investigation of the behavior of precast concrete segmental columns subjected to vehicle collision. Eng. Struct. 2018, 156, 375–393. [Google Scholar] [CrossRef]

- Luccioni, B.; Ambrosini, D.; Nurick, G.; Snyman, I. Craters produced by underground explosions. Comput. Struct. 2009, 87, 1366–1373. [Google Scholar] [CrossRef]

- Yu, L.; Lyu, C.; Wang, M.N.; Xu, T.Y. Three-dimensional upper bound limit analysis of a deep soil-tunnel subjected to pore pressure based on the nonlinear Mohr-Coulomb criterion. Comput. Geotech. 2019, 112, 293–301. [Google Scholar] [CrossRef]

- Li, X. Finite element analysis of slope stability using a nonlinear failure criterion. Comput. Geotech. 2007, 34, 127–136. [Google Scholar] [CrossRef]

- Keskin, İ.; Ahmed, M.Y.; Taher, N.R.; Gör, M.; Abdulsamad, B.Z. An evaluation on effects of surface explosion on underground tunnel; availability of ABAQUS Finite element method. Tunn. Undergr. Space Technol. 2022, 120, 104306. [Google Scholar] [CrossRef]

- Liu, X.P.; Bradford, M.A.; Chen, Q.J.; Ban, H.Y. Finite element modelling of steel-concrete composite beams with high-strength friction-grip bolt shear connectors. Finite Elem. Anal. Des. 2016, 108, 54–65. [Google Scholar] [CrossRef]

- Ferreira, F.P.V.; Martins, C.H.; De Nardin, S. A parametric study of steel-concrete composite beams with hollow core slabs and concrete topping. Structures 2020, 28, 276–296. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. JTG 3370.1-2018 Highway Tunnel Design Code; China Communications Press: Beijing, China, 2019. [Google Scholar]

- Li, J.; Wu, C.Q.; Hao, H. Investigation of ultra-high performance concrete slab and normal strength concrete slab under contact explosion. Eng. Struct. 2015, 102, 395–408. [Google Scholar] [CrossRef]

- Yang, G.D.; Wang, G.H.; Lu, W.B.; Yan, P.; Chen, M. Damage assessment and mitigation measures of underwater tunnel subjected to blast loads. Tunn. Undergr. Space Technol. 2019, 94, 103131. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Mass density | 2440 kg/m3 | Expansion angle-Ψ (°) | 38 |

| Elastic modulus | 36 MPa | Eccentricity-ξ | 0.1 |

| Poisson’s ratio | 0.2 | σb0/σc0 | 1.16 |

| Viscosity coefficient-µ (s−1) | 1 × 10−5 | Kc | 2/3 |

| Steel columns and rebar | Parameter | Value | Prestressing strand | Parameter | Value |

| Mass density | 7850 kg/m3 | Mass density | 7850 kg/m3 | ||

| Elastic modulus | 210 GPa | Elastic modulus | 210 MPa | ||

| Poisson’s ratio | 0.28 | Poisson’s ratio | 0.3 | ||

| Yield stress | 400 MPa | Yield stress | 1860 MPa | ||

| Thermal expansion coefficient | 0.0001 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Reference density | 1.225 kg/m3 | 1.4 | |

| Reference temperature | 288.2 K | Specific heat | 717.3 J/kg K |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Reference density | 1658 kg/m3 | ω | 0.35 |

| A | 3.7377 × 108 kPa | R1 | 4.15 |

| B | 3.73471 × 106 kPa | R2 | 0.9 |

| Detonation velocity | 6.93 × 103 m/s | Energy/unit volume | 6 × 106 kJ/m3 |

| Pressure | 2.1 × 107 kPa | / | / |

| Elastic | Mohr-Coulomb Plasticity | |||||

|---|---|---|---|---|---|---|

| Young’s Modulus (kPa) | Passion’s Ratio | Friction Angle (°) | Dilation Angle | Cohesion Yield Stress (kPa) | Abs Plastic Strain | Density (kg/m3) |

| 5.0 × 107 | 0.3 | 24 | 0 | 1.0 × 105 | 0.0 | 2200 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Hu, Z.; Zhang, C.; Pan, Z.; Hu, J.; Chen, X. Deformation Characteristics and Damage Assessment of Prefabricated Frame Tunnels after Central and External Explosions. Sustainability 2022, 14, 9942. https://doi.org/10.3390/su14169942

Huang Z, Hu Z, Zhang C, Pan Z, Hu J, Chen X. Deformation Characteristics and Damage Assessment of Prefabricated Frame Tunnels after Central and External Explosions. Sustainability. 2022; 14(16):9942. https://doi.org/10.3390/su14169942

Chicago/Turabian StyleHuang, Zhen, Zhaojian Hu, Chenlong Zhang, Zhijun Pan, Jie Hu, and Xinpeng Chen. 2022. "Deformation Characteristics and Damage Assessment of Prefabricated Frame Tunnels after Central and External Explosions" Sustainability 14, no. 16: 9942. https://doi.org/10.3390/su14169942

APA StyleHuang, Z., Hu, Z., Zhang, C., Pan, Z., Hu, J., & Chen, X. (2022). Deformation Characteristics and Damage Assessment of Prefabricated Frame Tunnels after Central and External Explosions. Sustainability, 14(16), 9942. https://doi.org/10.3390/su14169942