Sustainable PV Module Design—Review of State-of-the-Art Encapsulation Methods

Abstract

:1. Introduction

2. Relevance of Sustainability in Photovoltaic Research

- Download abstracts and titles from the web of science with the search results of ‘photovoltaic’ (142,162 results). We proceeded using the 100,000 most recent publications.

- Create map based on text data (term map).

- Read data from bibliographic database files.

- Select web of science data.

- Title and abstract.

- Binary counting (only the presence or absence of a word matters not the number of the occurrences).

- Minimum number of occurrences (15).

3. Conventional Structure of c-Si Photovoltaic Modules

4. State-of-the-Art Production, Recycling and Reuse of c-Si Photovoltaic Modules

4.1. Production

4.2. Recycling

4.3. Reuse and Repair

5. Standard Encapsulation Material Ethylene Vinyl Acetate

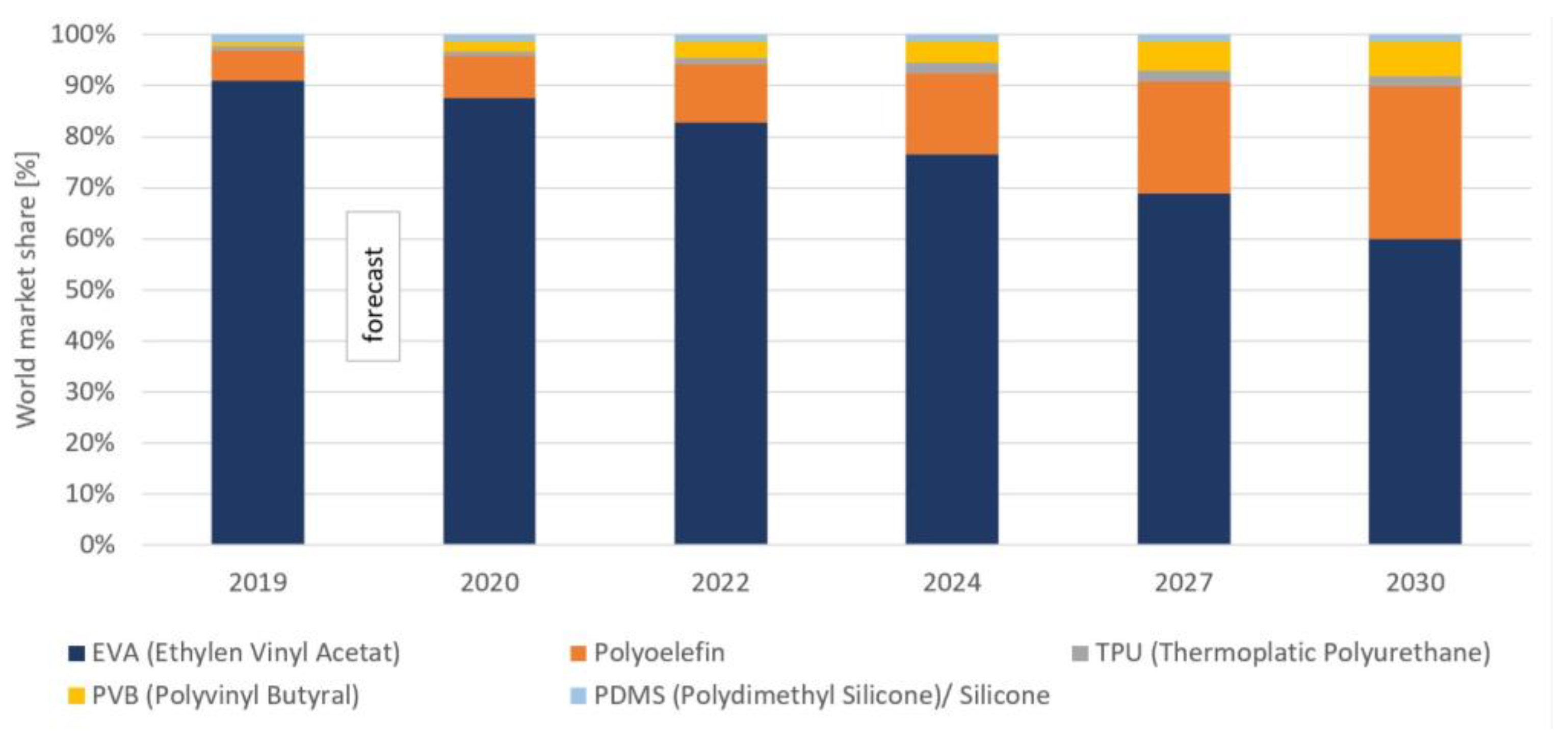

6. Opportunities to Replace EVA Encapsulation

6.1. Alternative Materials

- Thermoplastic polyolefin (TPO);

- Polyvinyl butyral (PVB);

- Polyolefin elastomer (POE);

- Polyurethane (PU) casting resins;

- Thermoplastic polyurethane (TPU);

- Polyacrylate casting resins;

- Two-component silicones;

- Ionoplasts.

6.1.1. Polyolefin

6.1.2. Polyvinyl Butyral

6.1.3. Silicones

6.1.4. Polyurethane

6.1.5. Ionoplasts

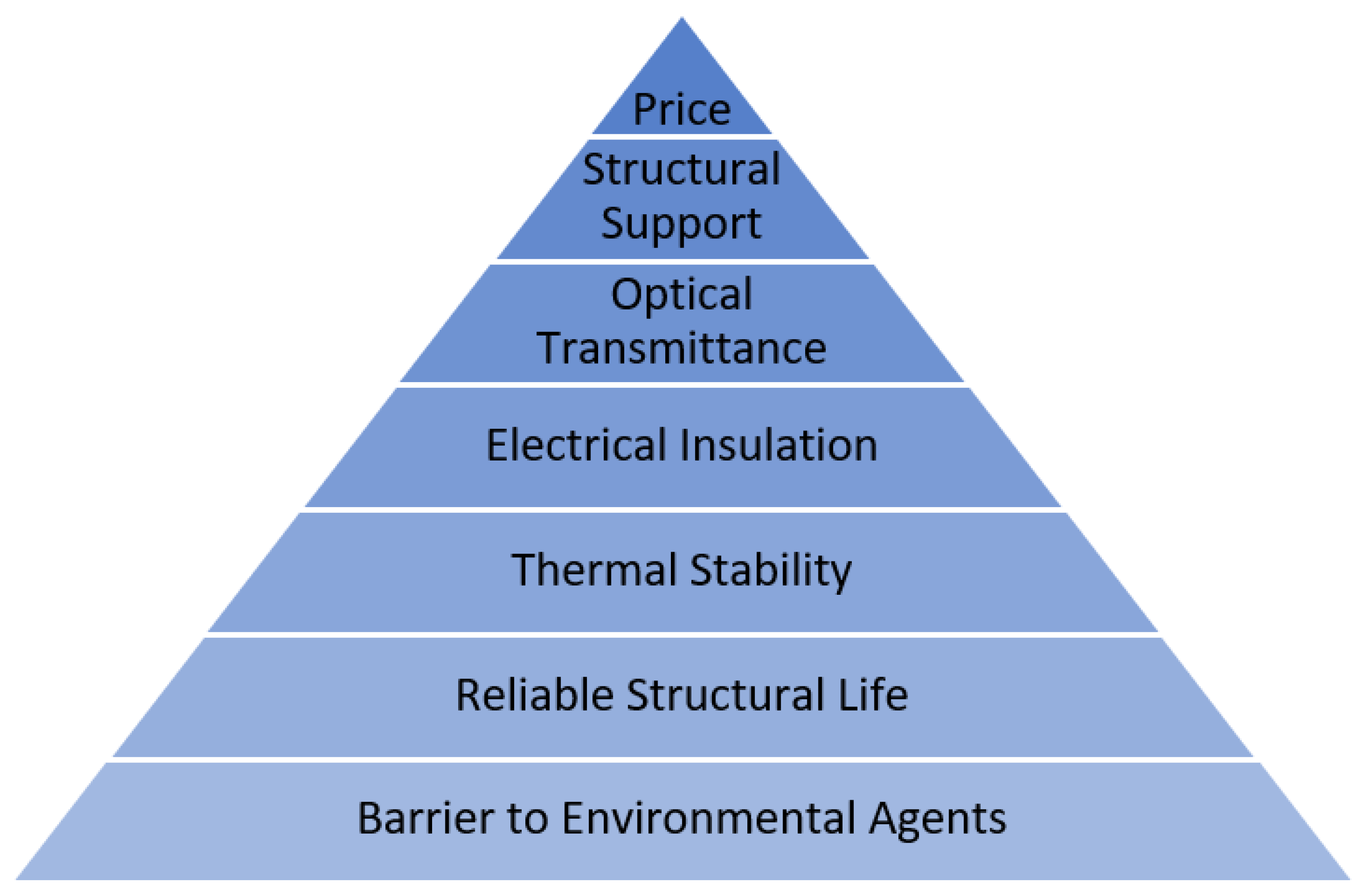

6.1.6. Comparison of the Alternative Materials

6.2. Alternative Module Structure

6.2.1. Double Encapsulated Modules with a Release Layer

6.2.2. NICE Technology

6.2.3. Comparison of the Alternative Module Structures

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baruch-Mordo, S.; Kiesecker, J.; Kennedy, C.M.; Oakleaf, J.R.; Opperman, J.J. Corrigendum: From Paris to practice: Sustainable implementation of renewable energy goals. Environ. Res. Lett. 2019, 14. [Google Scholar] [CrossRef]

- Mertens, K. Photovoltaik: Lehrbuch zu Grundlagen Technologie und Praxis. In Aktualisierte Auflage, 5th ed.; Carl Hanser Verlag: Munich, Germany, 2020. [Google Scholar] [CrossRef]

- Tsanakas, J.A.; Heide, A.; Radavičius, T.; Denafas, J.; Lemaire, E.; Wang, K.; Poortmans, J.; Voroshazi, E. Towards a circular supply chain for PV modules: Review of today’s challenges in PV recycling, refurbishment and re-certification. Prog. Photovolt. Res. Appl. 2020, 28, 454–464. [Google Scholar] [CrossRef]

- Ellen-MacArthur-Foundation. Towards the Circular Economy Vol.1: Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2013. [Google Scholar]

- Bressanelli, G.; Pigosso, D.C.; Saccani, N.; Perona, M. Enablers, levers and benefits of Circular Economy in the Electrical and Electronic Equipment supply chain: A literature review. J. Clean. Prod. 2021, 298, 126819. [Google Scholar] [CrossRef]

- Rebitzer, G. Integrating Life Cycle Costing and Life Cycle Assessment for Managing Costs and Environmental Impacts in Supply Chains. In Cost Management in Supply Chains; Seuring, S., Goldbach, M., Eds.; Physica-Verlag HD: Heidelberg, Germany, 2002; pp. 127–146. [Google Scholar] [CrossRef]

- European Commission. Ecodesign—European Commission to Examine Need for New Rules on Environmental Impact of Photovoltaics. Available online: https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/12819-Ecodesign-European-Commission-to-examine-need-for-new-rules-on-environmental-impact-of-photovoltaics_en (accessed on 10 July 2022).

- European Commission. About the Energy Label and Ecodesign. Available online: https://ec.europa.eu/info/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/energy-label-and-ecodesign/about_en (accessed on 10 July 2022).

- Michael, B. Cradle to Cradle®-Certification|Braungart.com. Available online: http://braungart.epea-hamburg.org/en/content/cradle-cradle%C2%AE-certification (accessed on 10 July 2022).

- Ostfalia—Fakultät Fahrzeugtechnik Institut für Recycling. Richtlinie zur Recycling- und Umweltgerechten Konstruktion von Photovoltaikmodulen; Ostfalia—Fakultät Fahrzeugtechnik Institut für Recycling: Wolfsburg, Germany, 2014. [Google Scholar]

- Hayati Soloot, H.E.; Hayati Soloot, A.; Moghadam, S. Multi-Criteria Analysis Method to Evaluate Different Encapsulation Materials for PV Modules and Proposing a Suitable Candidate. 8 pages. In Proceedings of the 38th European Photovoltaic Solar Energy Conference and Exhibition, Lisbon, Portugal, 6–10 September 2021; pp. 852–859. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Heath, G.A.; Silverman, T.J.; Kempe, M.; Deceglie, M.; Ravikumar, D.; Remo, T.; Cui, H.; Sinha, P.; Libby, C.; Shaw, S.; et al. Research and development priorities for silicon photovoltaic module recycling to support a circular economy. Nat. Energy 2020, 5, 502–510. [Google Scholar] [CrossRef]

- Padoan, F.C.; Altimari, P.; Pagnanelli, F. Recycling of end of life photovoltaic panels: A chemical prospective on process development. Sol. Energy 2019, 177, 746–761. [Google Scholar] [CrossRef]

- Ghosh, S.; Yadav, R. Future of photovoltaic technologies: A comprehensive review. Sustain. Energy Technol. Assess. 2021, 47, 101410. [Google Scholar] [CrossRef]

- Gerbinet, S.; Belboom, S.; Léonard, A. Life Cycle Analysis (LCA) of photovoltaic panels: A review. Renew. Sustain. Energy Rev. 2014, 38, 747–753. [Google Scholar] [CrossRef]

- Kim, B.; Azzaro-Pantel, C.; Pietrzak-David, M.; Maussion, P. Life cycle assessment for a solar energy system based on reuse components for developing countries. J. Clean. Prod. 2019, 208, 1459–1468. [Google Scholar] [CrossRef]

- Lange, R.F.M.; Luo, Y.; Polo, R.; Zahnd, J. The lamination of (multi)crystalline and thin film based photovoltaic modules. Prog. Photovolt. Res. Appl. 2011, 19, 127–133. [Google Scholar] [CrossRef]

- Deng, R.; Chang, N.L.; Ouyang, Z.; Chong, C.M. A techno-economic review of silicon photovoltaic module recycling. Renew. Sustain. Energy Rev. 2019, 109, 532–550. [Google Scholar] [CrossRef]

- Komoto, K.; Lee, J.S.; Wade, A.; Heath, G. Technology Trends in PV Module Recycling from Viewpoints of Patents and R&D Projects. 4 pages. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; pp. 1515–1518. [Google Scholar] [CrossRef]

- Pagnanelli, F.; Moscardini, E.; Granata, G.; Abo Atia, T.; Altimari, P.; Havlik, T.; Toro, L. Physical and chemical treatment of end of life panels: An integrated automatic approach viable for different photovoltaic technologies. Waste Manag. 2017, 59, 422–431. [Google Scholar] [CrossRef] [PubMed]

- Campana, G.; Howlett, R.J.; Setchi, R.; Cimatti, B. (Eds.) Sustainable Design and Manufacturing 2017. In Smart Innovation, Systems and Technologies; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Latunussa, C.E.; Ardente, F.; Blengini, G.A.; Mancini, L. Life Cycle Assessment of an innovative recycling process for crystalline silicon photovoltaic panels. Sol. Energy Mater. Sol. Cells 2016, 156, 101–111. [Google Scholar] [CrossRef]

- PV Panel Recycling Service|NPC Incorporated. Available online: https://www.npcgroup.net/eng/solarpower/reuse-recycle/recycle-service (accessed on 23 February 2022).

- Einhaus, R.; Madon, F.; Degoulange, J.; Wambach, K.; Denafas, J.; Lorenzo, F.R.; Abalde, S.C.; Garcia, T.D.; Bollar, A. Recycling and Reuse potential of NICE PV-Modules. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 561–564. [Google Scholar] [CrossRef]

- Rosi. ROSI|Return of Silicon. Available online: https://www.rosi-solar.com/ (accessed on 10 July 2022).

- Glatthaar, J.; Kamdje, E.; Barnikel, J.B.; Dax, M.; Schaub, V.; Stevens, H.G.; Jehle, B.; Ricklefs, U.; Stadlbauer, E.A.; Weigand, H. Development of a Modular Cradle to Cradle Process-Chain for c-Si-PV Panel Recycling. 5 pages. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; pp. 1528–1532. [Google Scholar] [CrossRef]

- 2ND LIFESOLAR. Qualitätsprüfung. Available online: https://2ndlifesolar.de/qualitaetspruefung (accessed on 6 July 2022).

- Ndzibah, E.; La Pinilla-De Cruz, G.A.; Shamsuzzoha, A. Collaboration towards value creation for end-of-life solar photovoltaic panel in Ghana. J. Clean. Prod. 2022, 333, 129969. [Google Scholar] [CrossRef]

- Solar Großhandel Photovoltaik Shop|pvXchange.com. Available online: https://www.pvxchange.com/ (accessed on 6 July 2022).

- SecondSol—The Photovoltaik Marketplace. Available online: https://www.secondsol.com/ (accessed on 6 July 2022).

- Schoden, F.; Detzmeier, J.; Schnatmann, A.K.; Blachowicz, T.; Schwenzfeier-Hellkamp, E. Investigating the Remanufacturing Potential of Dye-Sensitized Solar Cells. Sustainability 2022, 14, 5670. [Google Scholar] [CrossRef]

- Domininghaus, H.; Elsner, P.; Eyerer, P.; Hirth, T. Kunststoffe; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Grabmayer, K. Physikalische Charakterisierung des Vernetzungsgrades von EVA Einbettmaterialien für Solarzellen. Masterarbeit; Montanuniversität Leoben: Leoben, Austria, 2009. [Google Scholar]

- Koll, B. Alternativen zu Ethylen-Vinyl-Acetat (EVA). In Ep Photovoltaik—7/8-2009—Modultechnik für Die Praxis; HUSS-MEDIEN GmbH: Berlin, Germany, 2009. [Google Scholar]

- Ulicná, S.; Sinha, A.; Miller, D.C.; Schelhas, L.T.; Owen-Bellini, M. Accelerating Aging of Encapsulants for Application in Glass/Glass PV Modules. In Proceedings of the 38th European Photovoltaic Solar Energy Conference and Exhibition, EU PVSEC, Lisbon, Portugal, 6–10 September 2021. [Google Scholar]

- Adothu, B.; Costa, F.R.; Mallick, S. Degradation Evaluation of Thermoplastic Polyolefin Encapsulant Used in c-Si PV Modules and Laminates. 9 pages. In Proceedings of the 38th European Photovoltaic Solar Energy Conference and Exhibition, Lisbon, Portugal, 6–10 September 2021; pp. 631–639. [Google Scholar] [CrossRef]

- Sommeling, P.M.; Liu, J.; Kroon, J.M. Post Mortem Analysis of Bifacial PV Modules Based on n-Type Crystalline-Si Cells Using Three Different Types of Encapsulants. 4 pages. In Proceedings of the 37th European Photovoltaic Solar Energy Conference and Exhibition, Lisbon, Portugal, 7–11 September 2020; pp. 1082–1085. [Google Scholar] [CrossRef]

- Adothu, B.; Bhatt, P.; Chattopadhyay, S.; Zele, S.; Oderkerk, J.; Sagar, H.P.; Costa, F.R.; Mallick, S. Newly developed thermoplastic polyolefin encapsulant—A potential candidate for crystalline silicon photovoltaic modules encapsulation. Sol. Energy 2019, 194, 581–588. [Google Scholar] [CrossRef]

- Feldbacher, S.; Dobra, T.; Mühlbacher, I.; Oreski, G.; Aarnio-Winterhof, M. Solubility of Solar Encapsulants—Improvement of Recycling Processes. In Proceedings of the 38th European Photovoltaic Solar Energy Conference and Exhibition, Lisbon, Portugal, 6–10 September 2021. [Google Scholar]

- Adothu, B.; Pugstaller, R.; Tiefenthaler, M.; Costa, F.R.; Mallick, S.; Wallner, G.M. Crosslinking Kinetics of Photovoltaic Module Encapsulants—Investigation of Selected EVA and POE Grades. 4 pages. In Proceedings of the 38th European Photovoltaic Solar Energy Conference and Exhibition, Lisbon, Portugal, 6–10 September 2021; pp. 779–782. [Google Scholar] [CrossRef]

- Thornton, P.; Tracy, J.; Roraff, P.; Roy Choudhury, K.; Dauskardt, R.H. Durability of Polyolefin Encapsulation in Photovoltaic Modules with SmartWire Technology. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021; pp. 1170–1172. [Google Scholar] [CrossRef]

- Allak, S.A.; Chabane, F.; Agroui, K.; Zabat, M.; Khen, A.; Arfi, W. Optical and thermal analysis of PVB encapsulant polymer doped with yellow 083 and orange 240 organic dyes for photovoltaic application. In Proceedings of the 2018 International Conference on Communications and Electrical Engineering (ICCEE), El Oued, Algeria, 17–18 December 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Tupy, M.; Mokrejs, P.; Merinska, D.; Svoboda, P.; Zvonicek, J. Windshield recycling focused on effective separation of PVB sheet. J. Appl. Polym. Sci. 2014, 131, 39879. [Google Scholar] [CrossRef]

- Šooš, Ľ.; Matúš, M.; Pokusová, M.; Čačko, V.; Bábics, J. The Recycling of Waste Laminated Glass through Decomposition Technologies. Recycling 2021, 6, 26. [Google Scholar] [CrossRef]

- Khouri, S.; Behun, M.; Knapcikova, L.; Behunova, A.; Sofranko, M.; Rosova, A. Characterization of Customized Encapsulant Polyvinyl Butyral Used in the Solar Industry and Its Impact on the Environment. Energies 2020, 13, 5391. [Google Scholar] [CrossRef]

- Poulek, V.; Strebkov, D.S.; Persic, I.S.; Libra, M. Towards 50years lifetime of PV panels laminated with silicone gel technology. Sol. Energy 2012, 86, 3103–3108. [Google Scholar] [CrossRef]

- Hara, K.; Ohwada, H.; Furihata, T.; Masuda, A. Durable crystalline Si photovoltaic modules based on silicone-sheet encapsulants. Jpn. J. Appl. Phys. 2018, 57, 27101. [Google Scholar] [CrossRef]

- Panchenko, V.; Izmailov, A.; Kharchenko, V.; Lobachevskiy, Y. Photovoltaic Solar Modules of Different Types and Designs for Energy Supply. Int. J. Energy Optim. Eng. 2020, 9, 74–94. [Google Scholar] [CrossRef]

- Beaucarne, G.; Dupont, A.; Puthenmadom, D.; Shephard, N.; Sample, T. Material study of photovoltaic modules with silicone encapsulation after long-term outdoor exposure. Sol. Energy Mater. Sol. Cells 2021, 230, 111298. [Google Scholar] [CrossRef]

- Si, P.; Zhao, B. Water-based polyurethanes for sustainable advanced manufacture. Can. J. Chem. Eng. 2021, 99, 1851–1869. [Google Scholar] [CrossRef]

- Xia, H.; Hashimoto, Y.; Ni, Q.-Q. Electrically Triggered Actuation of Plasticized Thermoplastic Polyurethane Gels. Macromol. Mater. Eng. 2016, 301, 864–869. [Google Scholar] [CrossRef]

- Harl-Heinz, D.; Hubert, E.; Christian, H.; Juergen, R.; Gunther, S.; Robert, E.; Michael, N.; Peter, S. Solarmodule mit Polyurethaneinbettung und ein Verfahren zu deren Herstellung. European Patent EP1225642A1, 24 July 2002. [Google Scholar]

- Sable, L.; Kinsella, D.; Kozłowski, M. Influence of EVA, PVB and Ionoplast Interlayers on the Structural Behaviour and Fracture Pattern of Laminated Glass. Int. J. Struct. Glass Adv. Mater. Res. 2019, 3, 62–78. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, Y.; Hao, H.; Cui, J. The mechanical properties of ionoplast interlayer material at high strain rates. Mater. Des. 2015, 83, 387–399. [Google Scholar] [CrossRef]

- Doi, T.; Tsuda, I.; Sakuta, K.; Matsui, G. Development of a recyclable PV-module: Trial manufacturing and evaluation. In Proceedings of the 3rd World Conference on Photovoltaic Energy Conversion, Osaka, Japan, 11–18 May 2003; pp. 1952–1955. [Google Scholar]

- Monsite. Apollon Solar/Photovoltaic/Solar Silicon/Hydrogen/Lyon. Available online: https://en.apollonsolar.com/home (accessed on 25 February 2022).

- Saint-Sernin, E.; Einhaus, R.; Bamberg, K.; Panno, P. Industrialisation of Apollon Solar’s Nice Module Technology. 4 pages. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, 1–5 September 2008; pp. 2825–2828. [Google Scholar] [CrossRef]

- Dupuis, J.; Saint-Sernin, E.; Nichiporuk, O.; Lefillastre, P.; Bussery, D.; Einhaus, R. NICE module technology—From the concept to mass production: A 10 years review. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 3183–3186. [Google Scholar] [CrossRef]

- Madon, F.; Nichiporuk, O.; Einhaus, R.; Crampette, L.; Semmache, B.; Valette, L.; Charrier, V.; Damiani, B. NICE Module Technology Using Industrial n-Type Solar Cells without Front and Rear Busbars. 5 pages. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, Villepinte, Frankreich, 1–3 October 2013; pp. 3149–3153. [Google Scholar] [CrossRef]

- Dupuis, J.; Saint-Sernin, E.; Bamberg, K.; Einhaus, R.; Pilat, E.; Vachez, A.; Bussery, D. IEC Certification and Extended Ageing Test of NICE Modules. 4 pages. In Proceedings of the 25th European Photovoltaic Solar Energy Conference and Exhibition/5th World Conference on Photovoltaic Energy Conversion, Valencia, Spain, 6–10 September 2010; pp. 4148–4151. [Google Scholar] [CrossRef]

- Madon, F.; Colin, H.; Sicot, L.; Lefillastre, P.; Degoulange, J.; Einhaus, R. Results from Extended Degradation and Outdoor Tests of NICE Modules. 4 pages. In Proceedings of the 31st European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 14–18 September 2015; pp. 2534–2537. [Google Scholar] [CrossRef]

- Reinwand, D.; Pysch, D.; Bay, N.; Burschik, J.; Kuehnlein, H.H.; Madon, F.; Einhaus, R.; Brand, A.; Arya, V.; Smith, B.; et al. All Copper NICE Modules. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 628–631. [Google Scholar] [CrossRef]

| Term | Occurrence |

|---|---|

| sustainable development goal | 36 |

| sustainable future | 34 |

| energy sustainability | 31 |

| sustainable energy supply | 21 |

| sustainable growth | 19 |

| sustainable option | 19 |

| Encapsulation Material | EVA | TPO | POE | PVB |

|---|---|---|---|---|

| Advantage | State of the art, a lot of experience, low cost, good processing, good transparency and flexibility, low weight, high resistance to external influences | Thermoplastic (no crosslinking reaction, saves additives, energy and time), good transparency, high volume resistance and low water vapour permeability, good stability at high temperatures, better adhesion than EVA, lower degradation than EVA modules, better delamination properties than EVA modules | Good transparency, better adhesion than EVA, lower degradation than EVA modules | Thermoplastic (no crosslinking reaction, saves additives, energy and time), good transparency, good temperature stability, better adhesion than EVA, lower degradation than EVA modules, better delamination properties than EVA modules, recycling experience from glass recycling |

| Disadvantage | Poor recycling properties, use of additives, degradation processes (e.g., formation of acetic acid) | Less processing experience than with EVA modules, lower stability at low temperatures | Elastomer/thermoset (additives for crosslinking necessary, energy- and time-consuming production), less processing experience than with EVA modules, comparably poor delamination properties as EVA modules | Less processing experience than with EVA modules, low volume resistance and high water vapour permeability |

| Encapsulation Material | EVA | TPO | POE | PVB |

|---|---|---|---|---|

| Price | +++ [11,36] | ++++ [36,37] | ++ [36] | ++++ [36,37] |

| Structural support | +++ [11,33] | +++ [11,39] | +++ [42] | +++ [43] |

| Optical transmission | +++ [11,33] | +++ [11] | +++ [41] | +++ [11,43] |

| Degradation | ++ [11,33,34,37] | +++ [11,37,38,39] | +++ [38] | +++ [11] |

| Recyclability | + [2,10,11,18,19,34] | ++ [2,37,40] | + [2,37,41] | ++ [2,37,44,45,46] |

| Encapsulation Technology | EVA | NICE | Released Layer |

|---|---|---|---|

| Advantage | State of the art, a lot of experience, low cost, good processing, good transparency and flexibility, low weight, high resistance to external influences | Enables more efficient and cost-effective recycling, lower degradation than EVA modules, high fill factor, enables production of silver- and solder-free modules without busbars, no UV cut, less mechanical stress | Easier delamination, comparable stability |

| Disadvantage | Poor recycling properties, use of additives, degradation processes (e.g., formation of acetic acid) | Not yet industrial scale, significantly changed manufacturing process compared to the state of the art | Poor optical properties, poor module efficiency |

| Encapsulation Technology | EVA | NICE | Released Layer |

|---|---|---|---|

| Price | +++ [11] | N/A | N/A |

| Structural support | +++ [11,33] | +++ [59] | ++ [56] |

| Optical transmission | +++ [11,33] | +++ [59] | + [56] |

| Degradation | ++ [11,33,34,37] | +++ [58,61,62] | +++ [56] |

| Recyclability | + [2,10,11,18,19,34] | +++ [25] | ++ [56] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schnatmann, A.K.; Schoden, F.; Schwenzfeier-Hellkamp, E. Sustainable PV Module Design—Review of State-of-the-Art Encapsulation Methods. Sustainability 2022, 14, 9971. https://doi.org/10.3390/su14169971

Schnatmann AK, Schoden F, Schwenzfeier-Hellkamp E. Sustainable PV Module Design—Review of State-of-the-Art Encapsulation Methods. Sustainability. 2022; 14(16):9971. https://doi.org/10.3390/su14169971

Chicago/Turabian StyleSchnatmann, Anna Katharina, Fabian Schoden, and Eva Schwenzfeier-Hellkamp. 2022. "Sustainable PV Module Design—Review of State-of-the-Art Encapsulation Methods" Sustainability 14, no. 16: 9971. https://doi.org/10.3390/su14169971

APA StyleSchnatmann, A. K., Schoden, F., & Schwenzfeier-Hellkamp, E. (2022). Sustainable PV Module Design—Review of State-of-the-Art Encapsulation Methods. Sustainability, 14(16), 9971. https://doi.org/10.3390/su14169971