Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes

Abstract

:1. Introduction

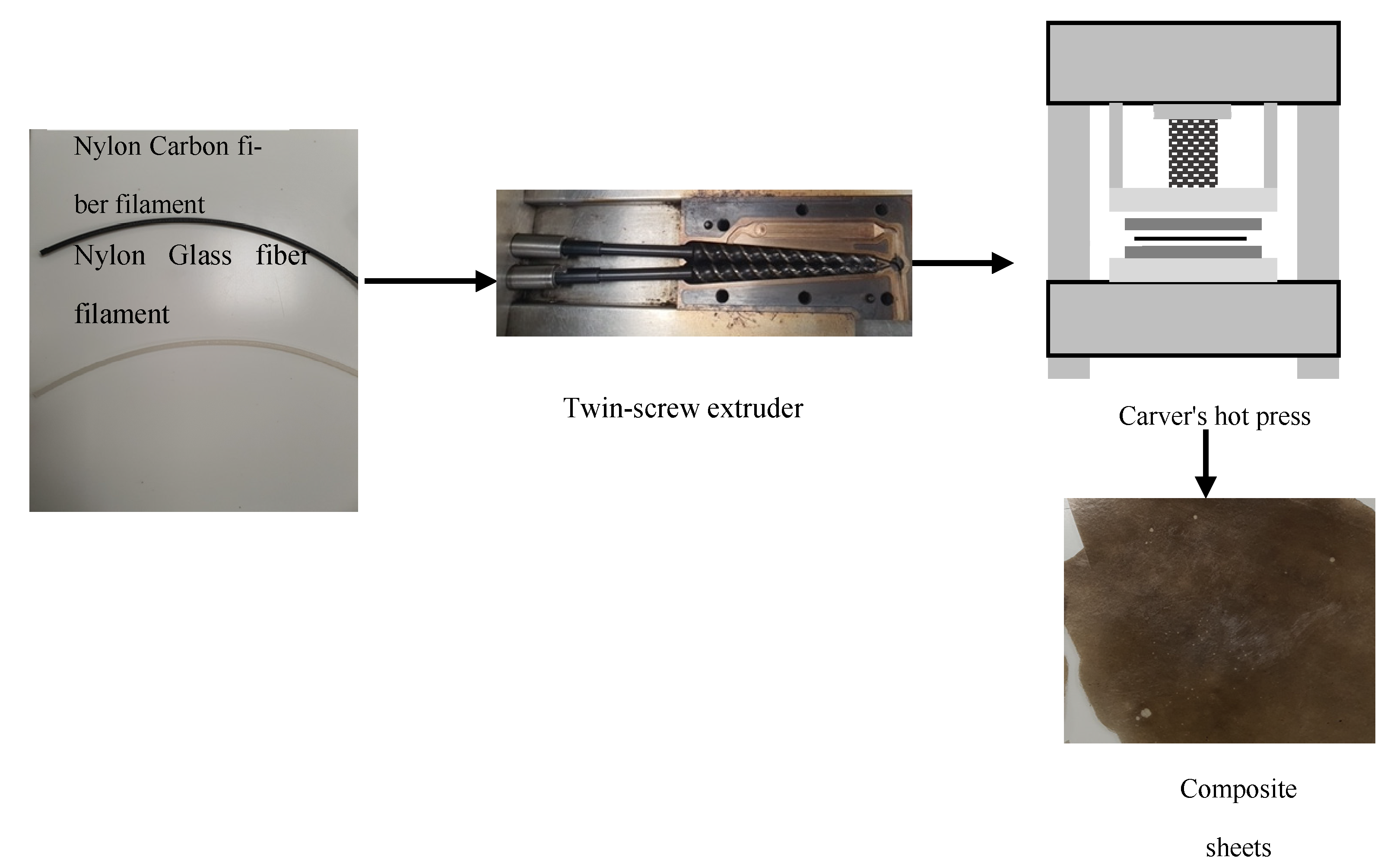

2. Material and Methods

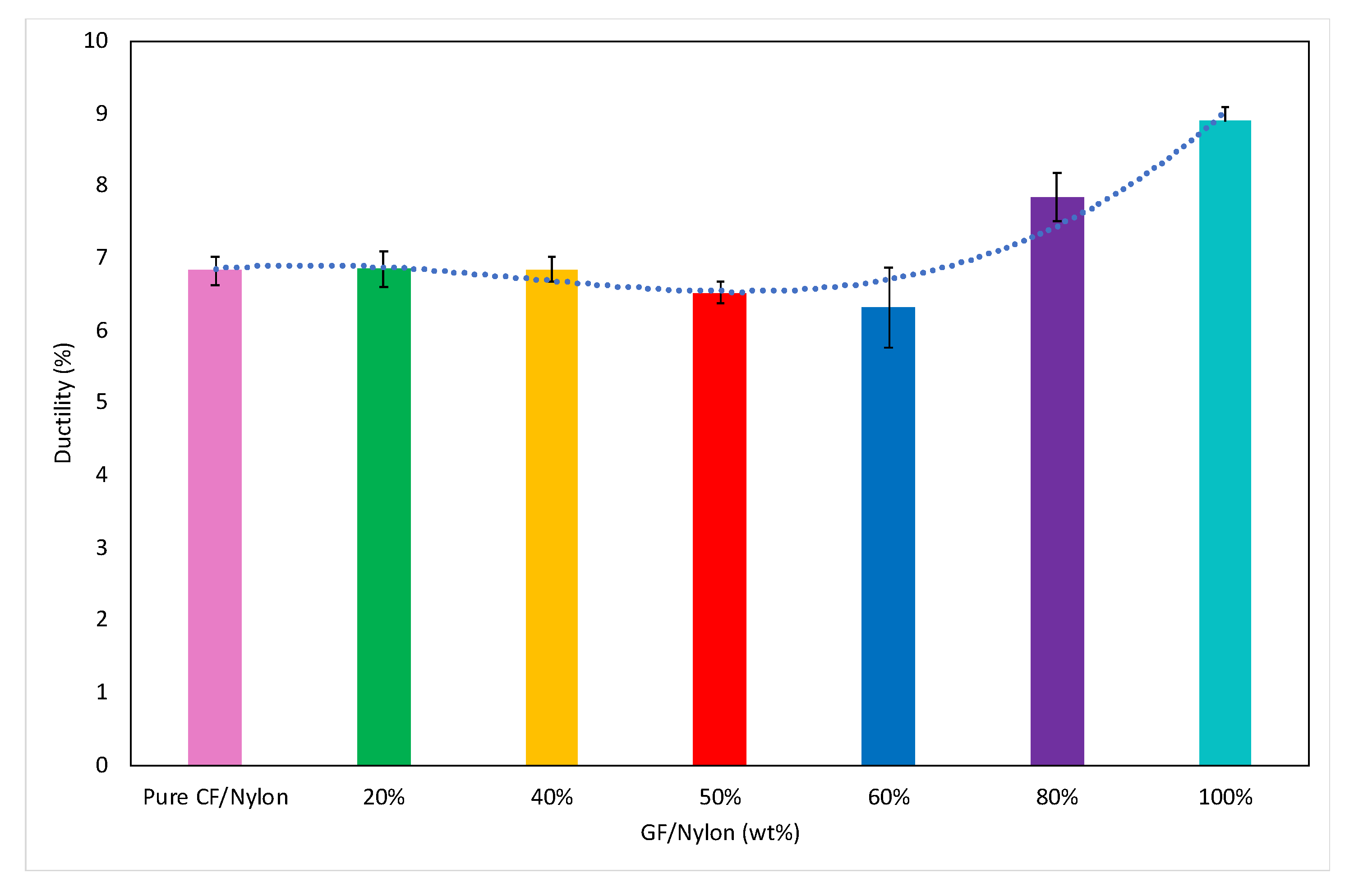

3. Results and Discussion

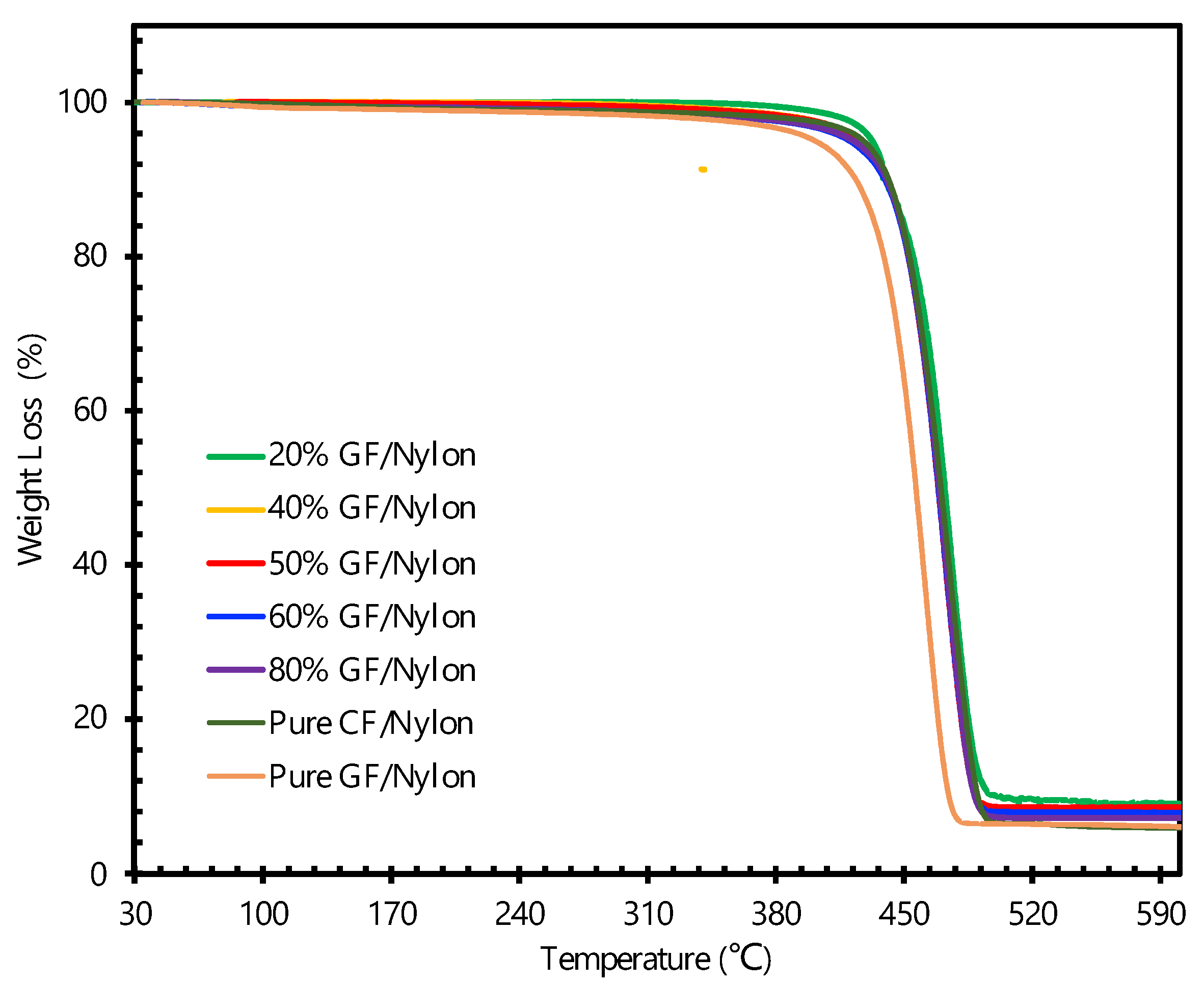

4. Thermogravimetric Analysis (TGA)

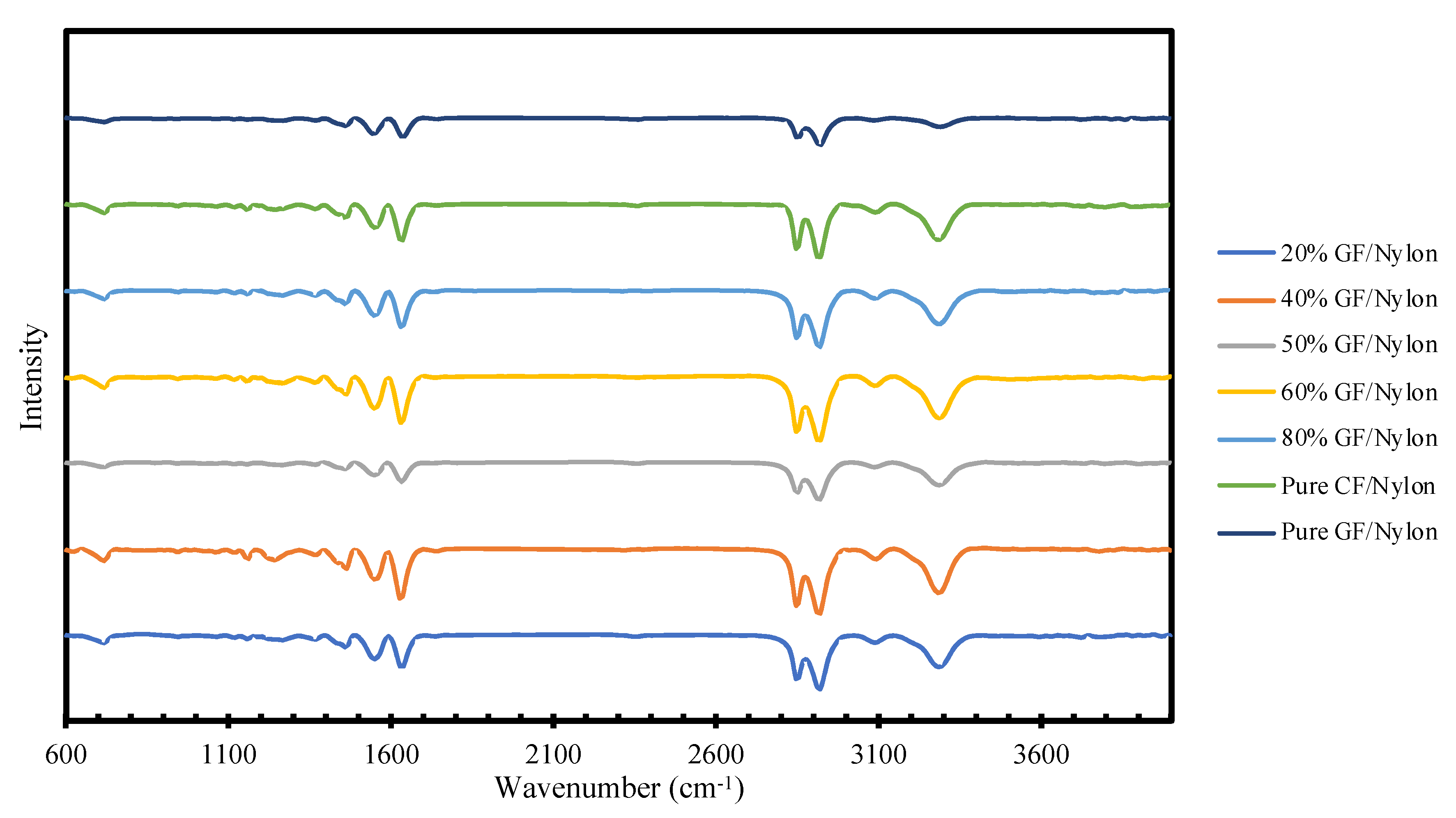

5. Fourier Transform Infrared (FTIR) Spectroscopy

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suksiripattanapong, C.; Phetprapai, T.; Singsang, W.; Phetchuay, C.; Thumrongvut, J.; Tabyang, W. Utilization of Recycled Plastic Waste in Fiber Reinforced Concrete for Eco-Friendly Footpath and Pavement Applications. Sustainability 2022, 14, 6839. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Boom, Y.J.; Giustozzi, F. Sustainable polymers from recycled waste plastics and their virgin counterparts as bitumen modifiers: A comprehensive review. Polymers 2021, 13, 3242. [Google Scholar] [CrossRef] [PubMed]

- Alhazmi, H.; Almansour, F.H.; Aldhafeeri, Z. Plastic waste management: A review of existing life cycle assessment studies. Sustainability 2021, 13, 5340. [Google Scholar] [CrossRef]

- Abdissa, G.; Ayalew, A.; Dunay, A.; Illés, C.B. Role of Reverse Logistics Activities in the Recycling of Used Plastic Bottled Water Waste Management. Sustainability 2022, 14, 7650. [Google Scholar] [CrossRef]

- Holmes, M. Recycled carbon fiber composites become a reality. Reinf. Plast. 2018, 62, 148–153. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 433. [Google Scholar] [CrossRef] [Green Version]

- Taylor, S. Waste Management Implications of 3D Printing; EcoMENA: Doha, Qatar, 2014. [Google Scholar]

- Epps, T.H., III; Korley, L.T.; Yan, T.; Beers, K.L.; Burt, T.M. Sustainability of Synthetic Plastics: Considerations in Materials Life-Cycle Management. JACS Au 2021, 2, 3–11. [Google Scholar] [CrossRef]

- Gebhardt, A. Understanding Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar] [CrossRef]

- Jang, G.-E.; Cho, G.-Y. Effects of Ag Current Collecting Layer Fabricated by Sputter for 3D-Printed Polymer Bipolar Plate of Ultra-Light Polymer Electrolyte Membrane Fuel Cells. Sustainability 2022, 14, 2997. [Google Scholar] [CrossRef]

- Wohlers, T.; Gornet, T. History of additive manufacturing. Wohlers Rep. 2014, 24, 118. [Google Scholar]

- Wong, K.; Hernandez, A. A Review of Additive Manufacturing. Int. Sch. Res. Netw. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Zheng, H.; Sun, X.; Li, W. Customized Investment Decisions for New and Remanufactured Products Supply Chain Based on 3D Printing Technology. Sustainability 2022, 14, 2502. [Google Scholar] [CrossRef]

- Stansbury, J.; Idacavage, M. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 24–64. [Google Scholar] [CrossRef] [PubMed]

- Love, L.; Kunc, V.; Rios, O.; Duty, C.; Elliott, A.; Post, B.; Smith, R.; Blue, C. The importance of carbon fiber to polymer additive manufacturing. J. Mater. Res. 2014, 29, 1893–1898. [Google Scholar] [CrossRef] [Green Version]

- Guo, N.; Leu, M. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Pilipović, A.; Ilinčić, P.; Bakić, A.; Kodvanj, J. Influence of Atmospheric Conditions on Mechanical Properties of Polyamide with Different Content of Recycled Material in Selective Laser Sintering. Polymers 2022, 14, 2355. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, S.A.; Shatalov, M.; Murashkin, E.V.; Akinlabi, E.T. Additive Manufacturing/3D Printing Technology: A Review. Ann. Dunarea Jos Univ. Galati. Fascicle XII Weld. Equip. Technol. 2019, 30, 51–58. [Google Scholar] [CrossRef]

- Al-Sinan, M.A.; Bubshait, A.A. Using Plastic Sand as a Construction Material toward a Circular Economy: A Review. Sustainability 2022, 14, 6446. [Google Scholar] [CrossRef]

- Immonen, K.; Metsä-Kortelainen, S.; Nurmio, J.; Tribot, A.; Turpeinen, T.; Mikkelson, A.; Kalpio, T.; Kaukoniemi, O.-V.; Kangas, H. Recycling of 3D Printable Thermoplastic Cellulose-Composite. Sustainability 2022, 14, 2734. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, A.; Darmoul, S.; Ameen, W.; Abidi, M.; Al-ahmari, A. Rapid Prototyping for Assembly Training and Validation. Int. Fed. Autom. Control 2015, 48, 412–417. [Google Scholar] [CrossRef]

- Williams, C.; Mistree, F.; Rosen, D. A Functional Classification Framework for the Conceptual Design of Additive Manufacturing Technologies. J. Mech. Des. 2011, 133, 121002. [Google Scholar] [CrossRef]

- Karayannis, P.; Saliakas, S.; Kokkinopoulos, I.; Damilos, S.; Koumoulos, E.P.; Gkartzou, E.; Gomez, J.; Charitidis, C. Facilitating Safe FFF 3D Printing: A Prototype Material Case Study. Sustainability 2022, 14, 3046. [Google Scholar] [CrossRef]

- Lee, C.H.; Padzil, F.N.B.M.; Lee, S.H.; Ainun, Z.M.A.A.; Abdullah, L.C. Potential for natural fiber reinforcement in P.L.A. polymer filaments for fused deposition modeling (FDM) additive manufacturing: A review. Polymers 2021, 13, 1407. [Google Scholar] [CrossRef]

- Arefin, A.; Khatri, N.; Kulkarni, N.; Egan, P. Polymer 3D Printing Review: Materials, Process, and Design Strategies for Medical Applications. Appl. 3D Print. Polym. 2021, 13, 1499. [Google Scholar] [CrossRef]

- Khaki, S.; Rio, M.; Marin, P. Characterization of Emissions in Fab Labs: An Additive Manufacturing Environment Issue. Sustainability 2022, 14, 2900. [Google Scholar] [CrossRef]

- Connor, H.; Dowling, D. Comparison between the properties of polyamide 12 and glass bead filled polyamide 12 using the multi jet fusion printing process. Addit. Manuf. 2020, 31, 100961. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, N.; Yang, R.; Yang, C.; Wu, P. Effects of Extracellular Polymeric Substances and Specific Compositions on Enhancement of Copper Bioleaching Efficiency from Waste Printed Circuit Boards. Sustainability 2022, 14, 2503. [Google Scholar] [CrossRef]

- Song, X.; He, W.; Qin, H.; Yang, S.; Wen, S. Fused Deposition Modeling of Poly (lactic acid)/Macadamia Composites—Thermal, Mechanical Properties and Scaffolds. Materials 2020, 13, 258. [Google Scholar] [CrossRef] [Green Version]

- Shakiba, M.; Rezvani Ghomi, E.; Khosravi, F.; Jouybar, S.; Bigham, A.; Zare, M.; Ramakrishna, S. Nylon—A material introduction and overview for biomedical. Polym. Adv. Technol. 2021, 32, 3368–3383. [Google Scholar] [CrossRef]

- Mostafa, K.; Montemagno, C.; Qureshi, A. Strength to cost ratio analysis of FDM Nylon 12 3D Printed Parts. Procedia Manuf. 2018, 26, 753–762. [Google Scholar] [CrossRef]

- Thomas, D. 3D printing durable patient specific knee implants. J. Orthop. 2017, 14, 182–183. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jacobs, C.; Soulliere, K.; Sawyer-Beaulieu, S.; Sabzwari, A.; Tam, E. Challenges to the Circular Economy: Recovering Wastes from Simple versus Complex Products. Sustainability 2022, 14, 2576. [Google Scholar] [CrossRef]

- Wang, X.; Wu, G.; Xie, P.; Gao, X.; Yang, W. Microstructure and properties of glass fiber-reinforced polyamide/nylon microcellular foamed composites. Polymers 2020, 12, 2368. [Google Scholar] [CrossRef] [PubMed]

- Pizzorni, M.; Parmiggiani, A.; Prato, M. Adhesive bonding of a mixed short and continuous carbon-fiber-reinforced Nylon-6 composite made via fused filament fabrication. Int. J. Adhes. Adhes. 2021, 107, 102856. [Google Scholar] [CrossRef]

- F Calignano, F.; Lorusso, M.; Roppolo, I.; Minetola, P. Investigation of the mechanical properties of a carbon fibre-reinforced nylon filament for 3D printing. Machines 2020, 8, 52. [Google Scholar] [CrossRef]

- Kikuchi, B.C.; Bussamra, F.L.D.S.; Donadon, M.V.; Ferreira, R.T.L.; Sales, R.D.C.M. Moisture effect on the mechanical properties of additively manufactured continuous carbon fiber-reinforced Nylon-based thermoplastic. Polym. Compos. 2020, 41, 5227–5245. [Google Scholar] [CrossRef]

- Giannakis, E.; Koidis, C.; Kyratsis, P.; Tzetzis, D. Static and fatigue properties of 3D printed continuous carbon fiber nylon composites. Int. J. Mod. Manuf. Technol. 2019, 11, 69–76. [Google Scholar]

- Anton, H.; Florin, B.; Andrei-Daniel, V.; Daniel, V.; Daniela-Ioana, T.; Cătălin, A. Mechanical Characteristics Evaluation of a Single Ply and Multi-Ply Carbon Fiber-Reinforced Plastic Subjected to Tensile and Bending Loads. Polymers 2022, 14, 3213. [Google Scholar] [CrossRef]

- Yoo, Y.; Spencer, M.W.; Paul, D.R. Morphology and mechanical properties of glass fiber reinforced Nylon 6 nanocomposites. Polymer 2011, 52, 180–190. [Google Scholar] [CrossRef]

- Tomiak, F.; Schoeffel, A.; Rathberger, K.; Drummer, D. Expandable Graphite, Aluminum Diethylphospinate and Melamine Polyphosphate as Flame Retarding System in Glass Fiber-Reinforced PA6. Polymers 2022, 14, 1263. [Google Scholar] [CrossRef]

- Etcheverry, M.; Barbosa, S.E. Glass fiber reinforced polypropylene mechanical properties enhancement by adhesion improvement. Materials 2012, 5, 1084–1113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sodeifian, G.; Ghaseminejad, S.; Yousefi, A.A. Preparation of polypropylene/short glass fiber composite as Fused Deposition Modeling (FDM) filament. Results Phys. 2019, 12, 205–222. [Google Scholar] [CrossRef]

- Salahuddin, B.; Mutlu, R.; Baigh, T.A.; Alghamdi, M.N.; Aziz, S. Self-Reinforced Nylon 6 Composite for Smart Vibration Damping. Polymers 2021, 13, 1235. [Google Scholar] [CrossRef] [PubMed]

- Fiber Force Italy. Nylforce Carbon Fiber. Available online: https://marketplace.ultimaker.com/app/cura/materials/AliGhandour/fiberforce_NylonCarbon_2020 (accessed on 21 April 2022).

- Fiber Force Italy. Nylforce Glass Fiber. Available online: https://marketplace.ultimaker.com/app/cura/materials/AliGhandour/Fiberforce_NylonGlass_2020 (accessed on 21 April 2022).

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. American Society of Testing and Materials: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D883-20b; Standard Terminology Relating to Plastics. American Society of Testing and Materials: West Conshohocken, PA, USA, 2020. [CrossRef]

- Genena, F.A.; Jamal, D.A.; Ahmed, W.K.; Almarzooqi, L.A.; Almazrouei, A.S.; Al-Naqbi, A.H. Implementing green solutions to recycle U.A.E. domestic waste: Aircraft composite materials. In Proceedings of the 2018 5th International Conference on Renewable Energy: Generation and Applications (I.C.R.E.G.A.), Al Ain, United Arab Emirates, 25–28 February 2018; pp. 30–33. [Google Scholar] [CrossRef]

- Mansour, A.; Alabdouli, H.; Almehairi, A.R.; Alhammadi, M.; Alqaidy, H.; Ahmed, W.K.; Alnaqbi, A.H. Investigating the Compressive Strength of CFRP Pre-Preg Scrap from Aerospace Indu stries: Compression Molding. In Proceedings of the Advances in Science and Engineering Technology International Conferences (A.S.E.T.), Dubai, United Arab Emirates, 26 March–10 April 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Ahmed, W.K.; Alnaqbi, A.H.; Almazrouei, A.S.S.; Almarzooqi, L.A.A.M.; Al Jamal, D.; Genena, F.A.A. Method of Recycling Carbon Fiber Prepreg Waste. U.S. Patent No. 10,328,610B2, 25 June 2019. [Google Scholar]

- Ahmed, W.K. Method of Recycling Carbon Fiber Prepreg Waste and Transparent Thermoplastic Waste. U.S. Patent No. 10,507,598B2, 17 December 2019. [Google Scholar]

- Singh, B.; Kumar, K.; Chohan, J.C. Polymer matrix composites in 3D printing: A state of art review. Mater. Today Proc. 2020, 33, 1562–1567. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Effect of printing temperature on microstructure, thermal behavior and tensile properties of 3D printed Nylon using fused deposition modeling. J. Appl. Polym. Sci. 2020, 138, 50162. [Google Scholar] [CrossRef]

- Gu, G.X.; Wettermark, S.; Buehler, M.J. Algorithm-driven design of fracture resistant composite materials realized through additive manufacturing. Addit. Manuf. 2017, 17, 47–54. [Google Scholar] [CrossRef]

- FiberForce Italy. Nylforce Carbon Fiber Data Sheet. 2019. Available online: http://www.fiberforce.it/wp-content/uploads/2019/07/TDS_NY-CARBON_REV-2.1.pdf (accessed on 23 July 2022).

- FiberForce Italy. Nylforce Glass Fiber Data Sheet. 2019. Available online: http://www.fiberforce.it/wp-content/uploads/2019/07/TDS_NY-GLASS_REV-2.0.pdf (accessed on 23 July 2022).

- D20 Committee. Guide for Determination of Thickness of Plastic Film Test Specimens; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Mohammadizadeh, M.; Gupta, A.; Fidan, I. Mechanical benchmarking of additively manufactured continuous and short carbon fiber reinforced Nylon. J. Compos. Mater. 2021, 55, 3629–3638. [Google Scholar] [CrossRef]

- Kumar Jain, P.A.; Sattar, S.; Mulqueen, D.; Pedrazzoli, D.; Kravchenko, S.G.; Kravchenko, O.G. Role of annealing and isostatic compaction on mechanical properties of 3D printed short glass fiber nylon composites. Addit. Manuf. 2022, 51, 102599. [Google Scholar] [CrossRef]

- Nuruzzaman, D.M.; Asif Iqbal, A.K.M.; Oumer, A.N.; Ismail, N.M.; Basri, S. Experimental investigation on the mechanical properties of glass fiber reinforced Nylon. Mater. Sci. Eng. 2016, 114, 012118. [Google Scholar] [CrossRef]

- Gensamer, M. Strength and Ductility. Metallogr. Microstruct. Anal. 2017, 6, 171–185. [Google Scholar] [CrossRef]

- Dey, D.; Srinivas, D.; Panda, B.; Suraneni, P.; Sitharam, T.G. Use of industrial waste materials for 3D printing of sustainable concrete: A review. J. Clean. Prod. 2022, 340, 130749. [Google Scholar] [CrossRef]

- Chong, S.; Yang, T.C.K.; Lee, K.C.; Chen, Y.F.; Juan, J.C.; Tiong, T.J.; Huang, C.M.; Pan, G.T. Evaluation of the physico-mechanical properties of activated-carbon enhanced recycled polyethylene/polypropylene 3D printing filament. Sādhanā 2020, 45, 57. [Google Scholar] [CrossRef]

- Patti, A.; Cicala, G.; Acierno, D. Eco-sustainability of the textile production: Waste recovery and current recycling in the composites world. Polymers 2020, 13, 134. [Google Scholar] [CrossRef] [PubMed]

- Rafiq, R.; Cai, D.; Jin, J.; Song, M. Increasing the toughness of nylon 12 by the incorporation of functionalized graphene. Carbon 2010, 48, 4309–4314. [Google Scholar] [CrossRef]

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the use of recycled or biodegradable filaments for sustainability of 3D printing. In Proceedings of the International Conference on Sustainable Design and Manufacturing, Bologna, Italy, 26–28 April 2017; Springer: Cham, Switzerland, 2017; pp. 776–785. [Google Scholar]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Kechagias, J.D. Sustainable additive manufacturing: Mechanical response of polyamide 12 over multiple recycling processes. Materials 2021, 14, 466. [Google Scholar] [CrossRef]

- Saadatkhah, N.; Carillo Garcia, A.; Ackermann, S.; Leclerc, P.; Latifi, M.; Samih, S.; Patience, G.S.; Chaouki, J. Experimental methods in chemical engineering: Thermogravimetric analysis—TGA. Can. J. Chem. Eng. 2020, 98, 34–43. [Google Scholar] [CrossRef]

- Liu, X.; Yu, W. Evaluating the thermal stability of high-performance fibers by TGA. J. Appl. Polym. Sci. 2006, 99, 937–944. [Google Scholar] [CrossRef]

- Aljarrah, M.T.; Abdelal, N.R. Improvement of the mode I interlaminar fracture toughness of carbon fiber composite reinforced with electrospun nylon nanofiber. Compos. Part B Eng. 2019, 165, 379–385. [Google Scholar] [CrossRef]

- Feng, N.; Wang, X.; Wu, D. Surface modification of recycled carbon fiber and its reinforcement effect on nylon 6 composites: Mechanical properties, morphology and crystallization behaviors. Curr. Appl. Phys. 2013, 13, 2038–2050. [Google Scholar] [CrossRef]

- Prajapati, A.R.; Dave, H.K.; Raval, H.K. An Experimental Study on Mechanical, Thermal and Flame-Retardant Properties of 3D-Printed Glass-Fiber-Reinforced Polymer Composites. J. Mater. Eng. Perform. 2021, 30, 5266–5277. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Jaafar, J.; Ismail, A.F.; Othman, M.H.D.; Rahman, M.A. Fourier transform infrared (FTIR) spectroscopy. In Membrane Characterization; Elsevier: Amsterdam, The Netherlands, 2017; pp. 3–29. [Google Scholar] [CrossRef]

- Petit, T.; Puskar, L. FTIR spectroscopy of nanodiamonds: Methods and interpretation. Diam. Relat. Mater. 2018, 89, 52–66. [Google Scholar] [CrossRef]

- Charles, J.; Ramkumaar, G.R.; Azhagiri, S.; Gunasekaran, S. FTIR and Thermal Studies on Nylon-66 and 30% Glass Fibre Reinforced Nylon-66. J. Chem. 2009, 6, 909017. [Google Scholar] [CrossRef] [Green Version]

- An, T.; Pant, B.; Kim, S.Y.; Park, M.; Park, S.J.; Kim, H.Y. Mechanical and optical properties of electrospun nylon-6, 6 nanofiber reinforced cyclic butylene terephthalate composites. J. Ind. Eng. Chem. 2017, 55, 35–39. [Google Scholar] [CrossRef]

- Nadagouda, M.N.; Ginn, M.; Rastogi, V. A review of 3D printing techniques for environmental applications. Curr. Opin. Chem. Eng. 2020, 28, 173–178. [Google Scholar] [CrossRef]

- Al-Mazrouei, N.; Ismail, A.; Ahmed, W.; Al-Marzouqi, A.H. ABS/Silicon Dioxide Micro Particulate Composite from 3D Printing Polymeric Waste. Polymers 2022, 14, 509. [Google Scholar] [CrossRef]

| Samples | CF/nylon, wt% | GF/nylon, wt% |

|---|---|---|

| CF/nylon | 100 | 0 |

| Blend 1 | 80 | 20 |

| Blend 2 | 60 | 40 |

| Blend 3 | 50 | 50 |

| Blend 4 | 40 | 60 |

| Blend 5 | 20 | 80 |

| GF/nylon | 0 | 100 |

| GF/Nylon (%) | Tensile Strength (MPa) | SD | Ductility (%) | SD | Elastic Modulus (MPa) | SD | Toughness (MPa) | SD |

|---|---|---|---|---|---|---|---|---|

| Pure CF/Nylon | 64.20 | ±4.07 | 6.83 | ±0.20 | 2740.23 | ±170.81 | 11.50 | ±0.88 |

| 20% | 64.90 | ±3.35 | 6.86 | ±0.25 | 2850.70 | ±113.99 | 12.76 | ±0.93 |

| 40% | 65.90 | ±1.63 | 6.85 | ±0.17 | 3050.67 | ±97.11 | 13.24 | ±0.39 |

| 50% | 66.40 | ±2.10 | 6.53 | ±0.15 | 3360.84 | ±148.13 | 13.35 | ±0.54 |

| 60% | 67.40 | ±3.69 | 6.33 | ±0.55 | 3430.08 | ±32.77 | 14.08 | ±0.69 |

| 80% | 62.20 | ±4.62 | 7.86 | ±0.34 | 3240.50 | ±81.63 | 14.97 | ±1.45 |

| 100% | 59.30 | ±2.27 | 8.90 | ±0.20 | 2520.01 | ±23.26 | 16.54 | ±0.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Mazrouei, N.; Al-Marzouqi, A.H.; Ahmed, W. Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes. Sustainability 2022, 14, 10458. https://doi.org/10.3390/su141710458

Al-Mazrouei N, Al-Marzouqi AH, Ahmed W. Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes. Sustainability. 2022; 14(17):10458. https://doi.org/10.3390/su141710458

Chicago/Turabian StyleAl-Mazrouei, Noura, Ali H. Al-Marzouqi, and Waleed Ahmed. 2022. "Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes" Sustainability 14, no. 17: 10458. https://doi.org/10.3390/su141710458

APA StyleAl-Mazrouei, N., Al-Marzouqi, A. H., & Ahmed, W. (2022). Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes. Sustainability, 14(17), 10458. https://doi.org/10.3390/su141710458