Parameters Affecting the Efficiency of Solar Stills—Recent Review

Abstract

:1. Introduction

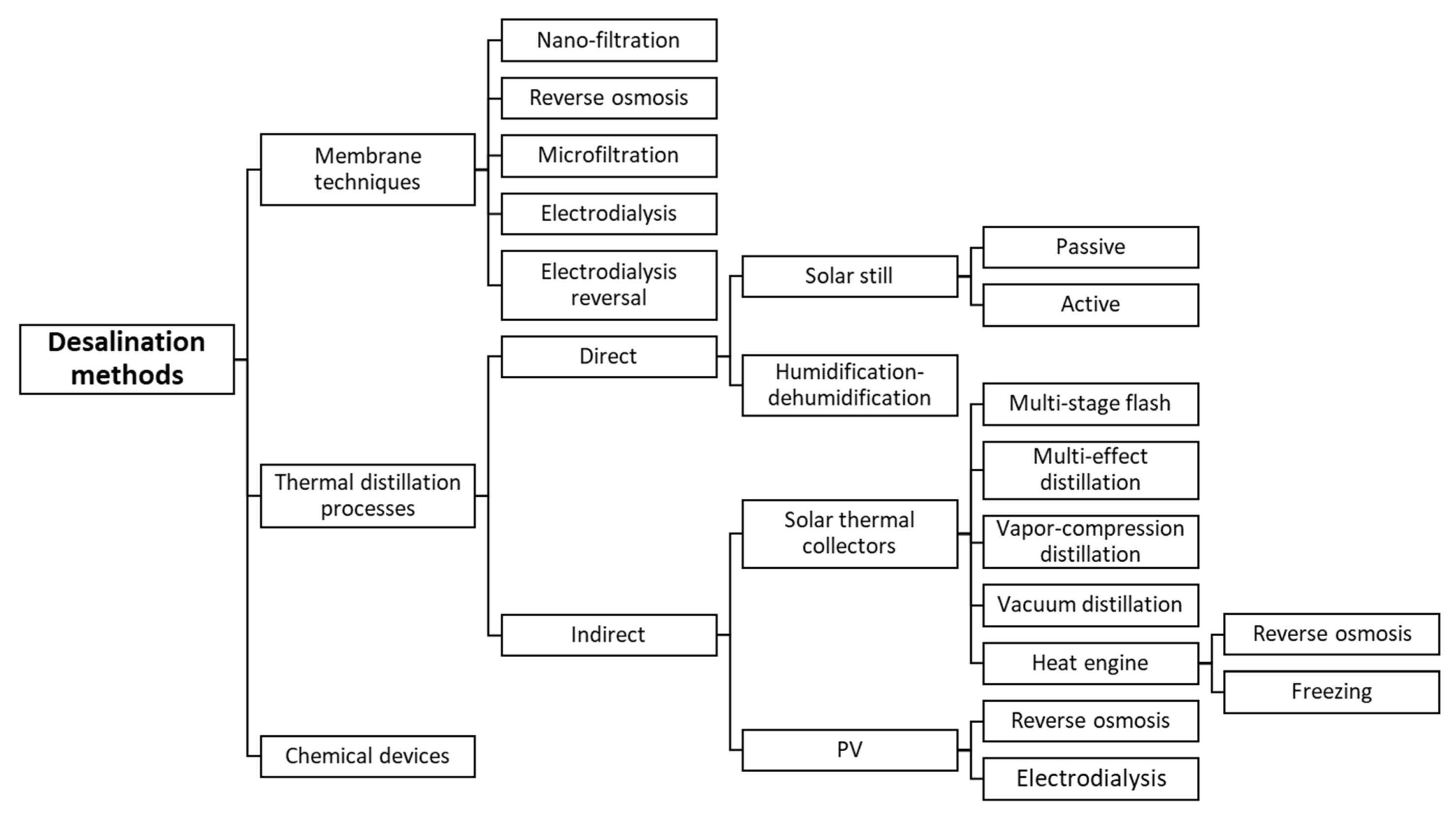

2. Desalination as a Solution for Potable Water Shortage Problem

2.1. Membrane Techniques (Single Phase Processes)

2.1.1. Reverse Osmosis

2.1.2. Nano-Filtration

2.1.3. Electrodialysis

2.2. Thermal Distillation Processes (Phase Change Processes)

2.2.1. Multi-Stage Flash

2.2.2. Multi-Effect Distillation

2.2.3. Vapor-Compression Distillation

2.2.4. Vacuum Distillation

2.2.5. Freezing

2.2.6. Humidification—Dehumidification Process

2.2.7. Solar Still Distillation (SSD)

3. Performance of Solar Stills

4. Factors Affecting Distiller Performance

4.1. Climatic Factors

4.1.1. Effect of Solar Radiation

4.1.2. Effect of Air Temperature

4.1.3. Effect of Air Speed

4.1.4. Effect of Dusty and Cloudy Weather

4.2. Design Factors

4.2.1. Effect of Evaporative and Exposure Surface Areas

4.2.2. Effect of Glazing Cover Material, Inclination, and Thickness

4.2.3. Effect of Solar Still Materials

4.2.4. Effect of Solar Still Volumetric Isometry

4.2.5. Effect of Insulating Material and Thickness

4.3. Operating Factors

4.3.1. Basin Water Temperature

4.3.2. Feed/Supply Water Temperature

4.3.3. Applying Vacuum inside the Solar Distiller

4.3.4. Heat Absorbing and Thermal Storage Materials

4.3.5. Difference between the Glass and Basin Water Temperatures

4.3.6. Capability of Hybrid Systems

5. Conclusions

- The main strongest affecting parameter on the solar distiller performance is the solar radiation. It has been verified in countless studies and publications that the higher the radiation intensity, the higher the productivity of solar stills. As a result, several amendments were introduced to increase the incident solar radiation on the basin water;

- Lowering the basin water depth improved the freshwater productivity of the solar distiller. It was concluded that the best water depth inside the solar distillers should be around 1–3 cm. In addition, it can be concluded that the daytime productivity of the distiller is inversely proportional to the basin water depth, while the nighttime productivity is proportional to the basin water depth;

- The ambient temperature affects slightly the solar distiller performance. The efficiency of the solar still is marginally improved with increasing the surrounding air temperature;

- Additionally, the surrounding air speed influences on the thermal performance of the solar distiller. Some publications state that the distillate of the solar distiller is augmented with increasing the air speed until a certain value, and it declines after that critical value;

- Raising the feed water temperature improves the solar distiller yield. Numerous techniques such as the solar water heater, mini solar pond, shallow solar pond, and solar collectors were developed to achieve this goal. Moreover, this can be achieved by linking two desalination systems together such as the solar stills and HDH, and the reject water of the HDH is used to warm the feed water of the solar stills;

- The second most significant parameter that affects the performance of solar stills, after solar radiation, is the difference between the water and glass temperatures. The greater this difference is, the higher the solar still productivity is, and the better the distiller performance is. This can be achieved by raising the basin water temperature, decreasing the glass temperature, or both;

- Furthermore, the evaporative and exposure surface areas have a vital role on determining how much the solar distiller performance can be improved. The larger the evaporative and exposure surface areas, the better the distiller performance;

- The glass cover tilt angle is also a significant factor that influences the solar still productivity up to great extent. Many papers have stated that the tilt angle must be ±10° of the latitude of the place of experiments;

- Applying vacuum inside the solar is still able to increase the output distillate and thermal efficiency of the solar still remarkably;

- Using the heat storage materials, dyes, and phase change materials is a good choice to improve the thermal performance of the solar distiller. The literature reported that the paraffin wax and stearic acid have superior matching properties that enhance the soar still performance significantly. The solar distiller can still work during the nighttime and sun absent when using these materials;

- Finally, the shape of the solar still is chosen based on the latitude of the experiments’ place, where the single slope distiller is preferable when the latitude is more than 20°, and the double slope distiller is preferable when the latitude is lower than 20°. This configuration eliminates the energy loss from the glazing of the distiller and increases its productivity.

6. Recommendations

- Fabricating an automatic mechanism to clean the dust accrued over the glass cover surface of the solar distiller. This will help increase the incident solar radiation on the solar still liner. The performance of the solar distiller should be tested when installing this cleaning mechanism.

- Similar to the sun tracking systems, a tracking system for the optimum tilt angle of the glass cover shall be proposed and investigated. This will help make the glass cover normal to the direct solar beams, which increases the solar energy input to the solar still basin. Hence, the evaporation and condensation rates will be increased. As a result, the solar still productivity is thought to be improved.

- New materials for the basin solar still shall be introduced, taking into consideration the heat transfer characteristics of these materials. This will lead to improving the heat transfer between the basin water and basin liner, hence the water temperature is thought to be increased. Therefore, the solar distiller distillate would be improved.

- Providing air conditioning to the glass cover with an integrated air conditioning system. This will avoid the loss of the incident solar radiation due to the cooling of glass cover by water because of the film created on the glass surface. Additionally, this mechanism will increase the temperature difference between the basin water and glass cover. As a result, the evaporation and condensation quantities will be augmented. Hence, the solar still productivity will be enhanced.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Description |

| ED | Electrodialysis |

| EDR | Electrodialysis reversal |

| HDH | Humidification-dehumidification |

| HF | Hyperfiltration |

| MED | Multi-effect distillation |

| MF | Microfiltration |

| MSF | Multi-stage flash |

| NF | Nanofiltration |

| PCM | Phase change material |

| ppm | Particle per million |

| RO | Reverse osmosis |

| SS | Solar still |

| SSD | Solar still distillation |

| TDS | Total dissolved solids |

| UF | Ultrafiltration |

| VCD | Vapor-compression distillation |

| VD | Vacuum distillation |

Nomenclatures

| Symbol | Description |

| Ag | Glass area |

| Exoutput | Daily overall exergy gain |

| Pg | Partial pressure of glass |

| Pw | Partial pressure of water |

| Ta | Air temperature |

| Tg | Glass temperature |

| Asun | Sun temperature |

| Tw | Water temperature |

| hc.w−g | Water-glass convective heat transfer coefficient |

| he,w−g | Water-glass evaporative heat transfer coefficient |

| hfg | Vaporization latent heat |

| Hourly distillate | |

| ηex | Exergy efficiency |

| ηd | Daily thermal efficiency |

| A | System area |

| I | Daily average solar radiation |

References

- Tiwari, G.N.; Sahota, L. Advanced Solar-Distillation Systems: Basic Principles, Thermal Modeling, and Its Application; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Essa, F.A. Thermal Desalination Systems: From Traditionality to Modernity and Development; Distillation Processes—From Conventional to Reactive Distillation Modeling, Simulation and Optimization; Steffen, D., Ed.; IntechOpen: London, UK, 2022; p. 23. [Google Scholar]

- Kumar, M.; Puri, A. A review of permissible limits of drinking water. Indian J. Occup. Environ. Med. 2012, 16, 40. [Google Scholar] [PubMed]

- Zhou, J.-Q.; Li, L.; Fu, C.; Wang, J.; Fu, P.; Kong, C.-P.; Bai, F.-Q.; Eglitis, R.I.; Zhang, H.-X.; Jia, R. A novel TC 3 N and seawater desalination. Nanoscale 2020, 12, 5055–5066. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, A.; Essa, F.; Omara, Z.; Rashid, Y.; Hadj-Taieb, L.; Abdelaziz, G.; Kabeel, A. Rotating-drum solar still with enhanced evaporation and condensation techniques: Comprehensive study. Energy Convers. Manag. 2019, 199, 112024. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Omara, Z.M.; Essa, F.A. Numerical investigation of modified solar still using nanofluids and external condenser. J. Taiwan Inst. Chem. Eng. 2017, 75, 77–86. [Google Scholar] [CrossRef]

- Malaeb, L.; Aboughali, K.; Ayoub, G.M. Modeling of a modified solar still system with enhanced productivity. Sol. Energy 2016, 125, 360–372. [Google Scholar] [CrossRef]

- Elango, C.; Gunasekaran, N.; Sampathkumar, K. Thermal models of solar still—A comprehensive review. Renew. Sustain. Energy Rev. 2015, 47, 856–911. [Google Scholar] [CrossRef]

- Tiwari, G.N.; Mishra, A.K.; Meraj, M.; Ahmad, A.; Khan, M.E. Effect of shape of condensing cover on energy and exergy analysis of a PVT-CPC active solar distillation system. Sol. Energy 2020, 205, 113–125. [Google Scholar] [CrossRef]

- Abdelkader, M.; Nafy, A.S.; Abdelmotalip, A.; Mabrouk, A. Experimental evaluation of solar still mathematical models. In Proceedings of the Fourth International Water Technology Conference, Alexandria, Egypt, 23–25 April 1999. [Google Scholar]

- Nafey, A.S.; Abdelkader, M.; Abdelmotalip, A.; Mabrouk, A. Parameters affecting solar still productivity. Energy Convers. Manag. 2000, 41, 1797–1809. [Google Scholar] [CrossRef]

- Almuhanna, E.A. Evaluation of Single Slop Solar Still Integrated with Evaporative Cooling System for Brackish Water Desalination. J. Agric. Sci. 2014, 6, 48. [Google Scholar] [CrossRef]

- Aburideh, H.; Deliou, A.; Abbad, B.; Alaoui, F.; Tassalit, D.; Tigrine, Z. An Experimental Study of a Solar Still: Application on the sea water desalination of Fouka. Procedia Eng. 2012, 33, 475–484. [Google Scholar] [CrossRef] [Green Version]

- Morse, R.; Read, W. A rational basis for the engineering development of a solar still. Sol. Energy 1968, 12, 5–17. [Google Scholar] [CrossRef]

- Rahbar, N.; Esfahani, J.A. Experimental study of a novel portable solar still by utilizing the heatpipe and thermoelectric module. Desalination 2012, 284, 55–61. [Google Scholar] [CrossRef]

- Okeke, C.; Egarievwe, S.; Animalu, A. Effects of coal and charcoal on solar-still performance. Energy 1990, 15, 1071–1073. [Google Scholar] [CrossRef]

- Kamal, W. A theoretical and experimental study of the basin-type solar still under the arabian gulf climatic conditions. Sol. Wind Technol. 1988, 5, 147–157. [Google Scholar] [CrossRef]

- Al-Hinai, H.; Al-Nassri, M.; Jubran, B. Effect of climatic, design and operational parameters on the yield of a simple solar still. Energy Convers. Manag. 2002, 43, 1639–1650. [Google Scholar] [CrossRef]

- Malik, M.A.; Tiwari, G.N.; Kumar, A.; Sodha, M. Solar Distillation: A Practical Study of a Wide Range of Stills and Their Optimum Design, Construction, and Performance; Pergamon Press: Oxford, UK, 1982. [Google Scholar]

- Alheefi, T. Experimental and Analytical Study of Water Production of Solar Still; Brunel University London: Uxbridge, UK, 2019. [Google Scholar]

- Essa, F.A.; Abdullah, A.S.; Omara, Z.M. Rotating discs solar still: New mechanism of desalination. J. Clean. Prod. 2020, 275, 123200. [Google Scholar] [CrossRef]

- Soliman, S. Effect of wind on solar distillation. Sol. Energy 1972, 13, 403–415. [Google Scholar] [CrossRef]

- El-Sebaii, A. Effect of wind speed on active and passive solar stills. Energy Convers. Manag. 2004, 45, 1187–1204. [Google Scholar] [CrossRef]

- El-Sebaii, A. On effect of wind speed on passive solar still performance based on inner/outer surface temperatures of the glass cover. Energy 2011, 36, 4943–4949. [Google Scholar] [CrossRef]

- Reddy, R.; Reddy, K. Upward heat flow analysis in basin type solar still. J. Min. Metall. B Metall. 2009, 45, 121–126. [Google Scholar]

- Muftah, A.F.; Alghoul, M.; Fudholi, A.; Abdul-Majeed, M.; Sopian, K. Factors affecting basin type solar still productivity: A detailed review. Renew. Sustain. Energy Rev. 2014, 32, 430–447. [Google Scholar] [CrossRef]

- Hegazy, A.A. Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew. Energy 2001, 22, 525–540. [Google Scholar] [CrossRef]

- Hottel, H.; Woertz, B. The Performance of Flat-Plate Solar Heat Collectors; Routledge: London, UK, 2018. [Google Scholar]

- El-Nashar, A.M. The effect of dust accumulation on the performance of evacuated tube collectors. Sol. Energy 1994, 53, 105–115. [Google Scholar] [CrossRef]

- El-Nashar, A.M. Seasonal effect of dust deposition on a field of evacuated tube collectors on the performance of a solar desalination plant. Desalination 2009, 239, 66–81. [Google Scholar] [CrossRef]

- Omara, Z.; Hamed, M.H.; Kabeel, A. Performance of finned and corrugated absorbers solar stills under Egyptian conditions. Desalination 2011, 277, 281–287. [Google Scholar] [CrossRef]

- Abdullah, A.S.; Omara, Z.M.; Alarjani, A.; Essa, F.A. Experimental investigation of a new design of drum solar still with reflectors under different conditions. Case Stud. Therm. Eng. 2021, 24, 100850. [Google Scholar] [CrossRef]

- Velmurugan, V.; Gopalakrishnan, M.; Raghu, R.; Srithar, K. Single basin solar still with fin for enhancing productivity. Energy Convers. Manag. 2008, 49, 2602–2608. [Google Scholar] [CrossRef]

- Sakthivel, M.; Shanmugasundaram, S.; Alwarsamy, T. An experimental study on a regenerative solar still with energy storage medium—Jute cloth. Desalination 2010, 264, 24–31. [Google Scholar] [CrossRef]

- Velmurugan, V.; Kumaran, S.S.; Prabhu, N.V.; Srithar, K. Productivity enhancement of stepped solar still: Performance analysis. Therm. Sci. 2008, 12, 153–163. [Google Scholar] [CrossRef]

- Minasian, A.; Al-Karaghouli, A. An improved solar still: The wick-basin type. Energy Convers. Manag. 1995, 36, 213–217. [Google Scholar] [CrossRef]

- Tiwari, A.K.; Tiwari, G. Effect of water depths on heat and mass transfer in a passive solar still: In summer climatic condition. Desalination 2006, 195, 78–94. [Google Scholar] [CrossRef]

- Elango, T.; Murugavel, K.K. The effect of the water depth on the productivity for single and double basin double slope glass solar stills. Desalination 2015, 359, 82–91. [Google Scholar] [CrossRef]

- Khalifa, A.J.N.; Hamood, A.M. On the verification of the effect of water depth on the performance of basin type solar stills. Sol. Energy 2009, 83, 1312–1321. [Google Scholar] [CrossRef]

- Lindblom, J. Solar Thermal Technologies for Seawater Desalination: State of the Art. 2003. Available online: https://www.researchgate.net/publication/228401141_Solar_thermal_technologies_for_seawater_desalination_state_of_the_art (accessed on 6 April 2022).

- Ghoneyem, A.; Ileri, A. Software to analyze solar stills and an experimental study on the effects of the cover. Desalination 1997, 114, 37–44. [Google Scholar] [CrossRef]

- Akash, B.A.; Mohsen, M.S.; Nayfeh, W. Experimental study of the basin type solar still under local climate conditions. Energy Convers. Manag. 2000, 41, 883–890. [Google Scholar] [CrossRef]

- Singh, H.; Tiwari, G. Monthly performance of passive and active solar stills for different Indian climatic conditions. Desalination 2004, 168, 145–150. [Google Scholar] [CrossRef]

- Panchal, H.; Shah, P.K. Investigation on solar stills having floating plates. Int. J. Energy Environ. Eng. 2012, 3, 8. [Google Scholar] [CrossRef]

- Nassef, E.M.; El-Abd, M.Z.; El-Tawil, Y.A. Study of the performance of solar still. In Proceedings of the 2nd International Conference on Energy Systems and Technologies, Cairo, Egypt, 18–21 February 2013. [Google Scholar]

- Essa, F.A.; Abd Elaziz, M.; Elsheikh, A.H. An enhanced productivity prediction model of active solar still using artificial neural network and Harris Hawks optimizer. Appl. Therm. Eng. 2020, 170, 115020. [Google Scholar] [CrossRef]

- Abdullah, A.S.; Essa, F.A.; Omara, Z.M. Effect of different wick materials on solar still performance—A review. Int. J. Ambient Energy 2019, 42, 1055–1082. [Google Scholar] [CrossRef]

- Al-Hassan, G.A.; Algarni, S.A. Exploring of Water Distillation by Single Solar Still Basins. Am. J. Clim. Chang. 2013, 2, 57–61. [Google Scholar] [CrossRef]

- Fath, H.E.S.; El-Samanoudy, M.; Fahmy, K.; Hassabou, A. Thermal-economic analysis and comparison between pyramid-shaped and single-slope solar still configurations. Desalination 2003, 159, 69–79. [Google Scholar] [CrossRef]

- Murugavel, K.K.; Chockalingam, K.K.; Srithar, K. Progresses in improving the effectiveness of the single basin passive solar still. Desalination 2008, 220, 677–686. [Google Scholar] [CrossRef]

- Tiwari, G.; Dimri, V.; Chel, A. Parametric study of an active and passive solar distillation system: Energy and exergy analysis. Desalination 2009, 242, 1–18. [Google Scholar] [CrossRef]

- Martin, C.L.; Goswami, D.Y. Solar Energy Pocket Reference; Earthscan: London, UK, 2005; ISBN 978-1-84407-306-1. [Google Scholar]

- Manokar, A.M.; Murugavel, K.K.; Esakkimuthu, G. Different parameters affecting the rate of evaporation and condensation on passive solar still—A review. Renew. Sustain. Energy Rev. 2014, 38, 309–322. [Google Scholar] [CrossRef]

- Kabeel, A.; Omara, Z.M.; Essa, F.; Abdullah, A.; Arunkumar, T.; Sathyamurthy, R. Augmentation of a solar still distillate yield via absorber plate coated with black nanoparticles. Alex. Eng. J. 2017, 56, 433–438. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Sathyamurthy, R.; Sharshir, S.W.; Muthumanokar, A.; Panchal, H.; Prakash, N.; Prasad, C.; Nandakumar, S.; El Kady, M. Effect of water depth on a novel absorber plate of pyramid solar still coated with TiO2 nano black paint. J. Clean. Prod. 2019, 213, 185–191. [Google Scholar] [CrossRef]

- Sathyamurthy, R.; Balasubramanian, M.; Devarajan, M.; Sharshir, S.W.; Manokar, A.M. Experimental study on enhancing the yield from stepped solar still coated using fumed silica nanoparticle in black paint. Mater. Lett. 2020, 272, 127873. [Google Scholar] [CrossRef]

- Essa, F.A.; Abdullah, A.S.; Omara, Z.M. Improving the performance of tubular solar still using rotating drum—Experimental and theoretical investigation. Process Saf. Environ. Prot. 2021, 148, 579–589. [Google Scholar] [CrossRef]

- Abdullah, A.; Alarjani, A.; Al-Sood, M.A.; Omara, Z.; Kabeel, A.; Essa, F. Rotating-wick solar still with mended evaporation technics: Experimental approach. Alex. Eng. J. 2019, 58, 1449–1459. [Google Scholar] [CrossRef]

- Abdullah, A.S.; Omara, Z.M.; Essa, F.A.; Alarjani, A.; Mansir, I.B.; Amro, M.I. Enhancing the solar still performance using reflectors and sliding-wick belt. Sol. Energy 2021, 214, 268–279. [Google Scholar] [CrossRef]

- Abdullah, A.S.; Essa, F.A.; Bacha, H.B.; Omara, Z.M. Improving the trays solar still performance using reflectors and phase change material with nanoparticles. J. Energy Storage 2020, 31, 101744. [Google Scholar] [CrossRef]

- Essa, F.; Alawee, W.H.; Mohammed, S.A.; Abdullah, A.; Omara, Z. Enhancement of pyramid solar distiller performance using reflectors, cooling cycle, and dangled cords of wicks. Desalination 2021, 506, 115019. [Google Scholar] [CrossRef]

- Alawee, W.H.; Mohammed, S.A.; Dhahad, H.A.; Abdullah, A.; Omara, Z.; Essa, F. Improving the performance of pyramid solar still using rotating four cylinders and three electric heaters. Process Saf. Environ. Prot. 2021, 148, 950–958. [Google Scholar] [CrossRef]

- Rai, S.; Tiwari, G. Single basin solar still coupled with flat plate collector. Energy Convers. Manag. 1983, 23, 145–149. [Google Scholar] [CrossRef]

- Morad, M.; El-Maghawry, H.A.; Wasfy, K.I. Improving the double slope solar still performance by using flat-plate solar collector and cooling glass cover. Desalination 2015, 373, 1–9. [Google Scholar] [CrossRef]

- Khalifa, A.J.N.; Hamood, A.M. Effect of insulation thickness on the productivity of basin type solar stills: An experimental verification under local climate. Energy Convers. Manag. 2009, 50, 2457–2461. [Google Scholar] [CrossRef]

- Tiwari, G.N.; Dimri, V.; Singh, U.; Chel, A.; Sarkar, B. Comparative thermal performance evaluation of an active solar distillation system. Int. J. Energy Res. 2007, 31, 1465–1482. [Google Scholar] [CrossRef]

- Sahoo, B.; Sahoo, N.; Mahanta, P.; Borbora, L.; Kalita, P.; Saha, U. Performance assessment of a solar still using blackened surface and thermocol insulation. Renew. Energy 2008, 33, 1703–1708. [Google Scholar] [CrossRef]

- Ford, E.C.; Ribeiro, F.; Lima, R.; Souza, E. Solar distiller in a pyramidal covering and isolation with composite material. Rev. Eng. Térmica 2008, 7, 37–40. [Google Scholar] [CrossRef]

- Tiris, C.; Tiris, M.; Erdalli, Y.; Sohmen, M. Experimental studies on a solar still coupled with a flat-plate collector and a single basin still. Energy Convers. Manag. 1998, 39, 853–856. [Google Scholar]

- Abdel-Rehim, Z.S.; Lasheen, A. Experimental and theoretical study of a solar desalination system located in Cairo, Egypt. Desalination 2007, 217, 52–64. [Google Scholar] [CrossRef]

- MohanRai, M.; Kumaresan, S.; Mathiyazhagan, S.; Kirubakaran, Y. Performance Analysis of Passive Solar Still Combined with Flat Plate Collector. In Proceedings of the 2018 4th International Conference on Electrical Energy Systems (ICEES), Chennai, India, 7–9 February 2018; pp. 402–406. [Google Scholar]

- Tanaka, H. Monthly optimum inclination of glass cover and external reflector of a basin type solar still with internal and external reflector. Sol. Energy 2010, 84, 1959–1966. [Google Scholar] [CrossRef]

- Eltawil, M.A.; Omara, Z. Enhancing the solar still performance using solar photovoltaic, flat plate collector and hot air. Desalination 2014, 349, 1–9. [Google Scholar] [CrossRef]

- Boubekri, M.; Chaker, A. Yield of an improved solar still: Numerical approach. Energy Procedia 2011, 6, 610–617. [Google Scholar] [CrossRef]

- Jedidiah, S.S.; Lawrence, I.D. Enhance the Productivity of the Solar Still by Improving the Operational Parameters. Int. J. Mod. Eng. Res. 2014, 4, 73–78. [Google Scholar]

- El-Sebaii, A.; Aboul-Enein, S.; Ramadan, M.; Khallaf, A. Thermal performance of an active single basin solar still (ASBS) coupled to shallow solar pond (SSP). Desalination 2011, 280, 183–190. [Google Scholar] [CrossRef]

- El-Sebaii, A.; Ramadan, M.; Aboul-Enein, S.; Salem, N. Thermal performance of a single-basin solar still integrated with a shallow solar pond. Energy Convers. Manag. 2008, 49, 2839–2848. [Google Scholar] [CrossRef]

- Panchal, H.N. Enhancement of distillate output of double basin solar still with vacuum tubes. J. King Saud Univ.-Eng. Sci. 2015, 27, 170–175. [Google Scholar] [CrossRef]

- Ahmed, M.; Hrairi, M.; Ismail, A. On the characteristics of multistage evacuated solar distillation. Renew. Energy 2009, 34, 1471–1478. [Google Scholar] [CrossRef]

- Al-Kharabsheh, S.; Yogi, D. Analysis of an innovative water desalination system using low-grade solar heat. Desalination 2003, 156, 323–332. [Google Scholar] [CrossRef]

- Al-Hussaini, H.; Smith, I. Enhancing of solar still productivity using vacuum technology. Energy Convers. Manag. 1995, 36, 1047–1051. [Google Scholar] [CrossRef]

- Nassar, Y.F.; Yousif, S.A.; Salem, A.A. The second generation of the solar desalination systems. Desalination 2007, 209, 177–181. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Omara, Z.; Essa, F. Improving the performance of solar still by using nanofluids and providing vacuum. Energy Convers. Manag. 2014, 86, 268–274. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Omara, Z.; Essa, F. Enhancement of modified solar still integrated with external condenser using nanofluids: An experimental approach. Energy Convers. Manag. 2014, 78, 493–498. [Google Scholar] [CrossRef]

- Omara, Z.M.; Kabeel, A.E.; Essa, F.A. Effect of using nanofluids and providing vacuum on the yield of corrugated wick solar still. Energy Convers. Manag. 2015, 103, 965–972. [Google Scholar] [CrossRef]

- Naim, M.M.; Abd El Kawi, M.A. Non-conventional solar stills Part 1. Non-conventional solar stills with charcoal particles as absorber medium. Desalination 2003, 153, 55–64. [Google Scholar] [CrossRef]

- Ayoub, G.M.; Malaeb, L. Developments in Solar Still Desalination Systems: A Critical Review. Crit. Rev. Environ. Sci. Technol. 2012, 42, 2078–2112. [Google Scholar] [CrossRef]

- Abdallah, S.; Abu-Khader, M.M.; Badran, O. Effect of various absorbing materials on the thermal performance of solar stills. Desalination 2009, 242, 128–137. [Google Scholar] [CrossRef]

- Garg, H.; Mann, H. Effect of climatic, operational, and design parameters on the year round performance of single-sloped and double-sloped solar still under Indian arid zone conditions. Sol. Energy 1976, 18, 159–163. [Google Scholar] [CrossRef]

- Rajvanshi, A.K. Effect of various dyes on solar distillation. Sol. Energy 1981, 27, 51–65. [Google Scholar] [CrossRef]

- Akash, B.A.; Mohsen, M.S.; Osta, O.; Elayan, Y. Experimental evaluation of a single-basin solar still using different absorbing materials. Renew. Energy 1998, 14, 307–310. [Google Scholar] [CrossRef]

- Nijmeh, S.; Odeh, S.; Akash, B. Experimental and theoretical study of a single-basin solar sill in Jordan. Int. Commun. Heat Mass Transf. 2005, 32, 565–572. [Google Scholar] [CrossRef]

- Tabrizi, F.F.; Sharak, A.Z. Experimental study of an integrated basin solar still with a sandy heat reservoir. Desalination 2010, 253, 195–199. [Google Scholar] [CrossRef]

- Srithar, K. Performance Analysis of Vapour AdsorptionSolar Still Integrated with Mini-solar Pond for Effluent Treatment. Int. J. Chem. Eng. Appl. 2010, 1, 336–341. [Google Scholar] [CrossRef]

- Omara, Z.M.; Kabeel, A. The Performance of Different Sand Beds Solar Stills. Int. J. Green Energy 2013, 11, 240–254. [Google Scholar] [CrossRef]

- Pandey, A.; Hossain, M.; Tyagi, V.; Abd Rahim, N.; Jeyraj, A.; Selvaraj, L.; Sari, A. Novel approaches and recent developments on potential applications of phase change materials in solar energy. Renew. Sustain. Energy Rev. 2018, 82, 281–323. [Google Scholar] [CrossRef]

- Safaei, M.R.; Goshayeshi, H.R.; Chaer, I. Solar Still Efficiency Enhancement by Using Graphene Oxide/Paraffin Nano-PCM. Energies 2019, 12, 2002. [Google Scholar] [CrossRef]

- Arunkumar, T.; Denkenberger, D.; Ahsan, A.; Jayaprakash, R. The augmentation of distillate yield by using concentrator coupled solar still with phase change material. Desalination 2013, 314, 189–192. [Google Scholar] [CrossRef]

- Radhwan, A.M. Transient performance of a stepped solar still withbuilt-in latent heat thermal energy storage. Desalination 2005, 171, 61–76. [Google Scholar] [CrossRef]

- El-Sebaii, A.; Al-Ghamdi, A.; Al-Hazmi, F.; Faidah, A.S. Thermal performance of a single basin solar still with PCM as a storage medium. Appl. Energy 2009, 86, 1187–1195. [Google Scholar] [CrossRef]

- Ansari, O.; Asbik, M.; Bah, A.; Arbaoui, A.; Khmou, A. Desalination of the brackish water using a passive solar still with a heat energy storage system. Desalination 2013, 324, 10–20. [Google Scholar] [CrossRef]

- Murugavel, K.K.; Chockalingam, K.K.; Srithar, K. An experimental study on single basin double slope simulation solar still with thin layer of water in the basin. Desalination 2008, 220, 687–693. [Google Scholar] [CrossRef]

- Patel, R.V.P.; Kumar, A. Experimental Investigation of Double Slope Solar Still for the Climatic Condition of Sultanpur. Int. J. Eng. Technol. 2018, 9, 4019–4033. [Google Scholar] [CrossRef] [Green Version]

- Abu-Arabi, M.; Zurigat, Y.; Al-Hinai, H.; Al-Hiddabi, S. Modeling and performance analysis of a solar desalination unit with double-glass cover cooling. Desalination 2002, 143, 173–182. [Google Scholar] [CrossRef]

- Janarthanan, B.; Chandrasekaran, J.; Kumar, S. Performance of floating cum tilted-wick type solar still with the effect of water flowing over the glass cover. Desalination 2006, 190, 51–62. [Google Scholar] [CrossRef]

- Abdullah, A.S.; Omara, Z.M.; Bek, M.A.; Essa, F.A. An augmented productivity of solar distillers integrated to HDH unit: Experimental implementation. Appl. Therm. Eng. 2020, 167, 114723. [Google Scholar] [CrossRef]

| No. | Property | World Health Organization (WHO) | Institute for Sustainable Infrastructure (ISI) | United States Environmental Protection Agency (US EPA) | Central Pollution Control Board (CPCB) |

|---|---|---|---|---|---|

| 1 | pH (mg/L) | 6.5–8.5 | 6.5–8.5 | 6.5–8.5 | 6.5–8.5 |

| 2 | Turbidity (NTU) | – | 10 | – | 10 |

| 3 | Conductivity (mg/L) | – | – | – | 2000 |

| 4 | Fluoride (mg/L) | 1.5 | 0.6–1.2 | 4 | 1.5 |

| 5 | Alkalinity (mg/L) | – | – | – | 600 |

| 6 | Total hardness (mg/L) | 500 | 300 | – | 600 |

| 7 | Chlorides (mg/L) | 200 | 250 | 250 | 1000 |

| 8 | Lead (mg/L) | 0.05 | 0.10 | – | No relaxation |

| 9 | Iron (mg/L) | 0.1 | 0. 3 | – | 1 |

| 10 | Nitrate (mg/L) | – | 45 | – | 100 |

| 11 | Copper (mg/L) | 1 | 0.05 | 1.3 | 1.5 |

| 12 | Zinc (mg/L) | 5 | 5 | – | 15 |

| 13 | Chromium (mg/L) | – | 0.05 | 0.1 | No relaxation |

| 14 | Sulfate (mg/L) | – | 150 | – | 400 |

| 15 | Residual (mg/L) free | – | 0.2 | – | – |

| 16 | Calcium (mg/L) | 75 | 75 | – | 200 |

| 17 | Magnesium (mg/L) | 50 | 30 | – | 100 |

| 18 | Mercury (mg/L) | 0.001 | 0.001 | 0.002 | No relaxation |

| 19 | Cadmium (mg/L) | 0.005 | 0.01 | 0.005 | No relaxation |

| 20 | Arsenic (mg/L) | 0.05 | 0.05 | 0.05 | No relaxation |

| 21 | Selenium (mg/L) | 001 | – | 0.05 | No relaxation |

| Daily Air Temperature | 33.71 | 34.51 | 34.8 | 36.11 | 38.15 |

|---|---|---|---|---|---|

| Daily total productivity (mL/m2) | 1900 | 1750 | 1800 | 2300 | 3200 |

| No. | Material/Absorber | Daily Productivity Rise, % |

|---|---|---|

| 1 | Black granite gravel | 17–20% |

| 2 | Sponge cubes | 14–18% |

| 3 | Sponges and fins in a stepped still | 96% |

| 4 | Potassium dichromate | 26% |

| 5 | Charcoal | 15% more than wick-type stills 11–18% more than black-paint 23–92% more than blackened rock-bed |

| 6 | Black gravel | 19% |

| 7 | Baffle suspended absorber | 20% |

| 8 | Absorbing black-rubber mat | 38% |

| 9 | Black ink | 45% |

| 10 | Black dye | 60% |

| 11 | Rubber material | 38% |

| 12 | Soot powder | 13–17% |

| 13 | Dyes | 10–20% |

| 14 | Black napthylamine (172.5 mg/L) | 17–28.8% |

| 15 | Black napthylamine (50 mg/L) | 15.9% |

| 16 | Red carmoisine (50 mg/L) | 7.4% |

| 17 | Red carmoisine (100 mg/L) | 19.9% |

| 18 | Dark green dyes (50 mg/L) | 14.8% |

| 19 | Dark green dyes (100 mg/L) | 12% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Essa, F.A.; Abdullah, A.; Majdi, H.S.; Basem, A.; Dhahad, H.A.; Omara, Z.M.; Mohammed, S.A.; Alawee, W.H.; Ezzi, A.A.; Yusaf, T. Parameters Affecting the Efficiency of Solar Stills—Recent Review. Sustainability 2022, 14, 10668. https://doi.org/10.3390/su141710668

Essa FA, Abdullah A, Majdi HS, Basem A, Dhahad HA, Omara ZM, Mohammed SA, Alawee WH, Ezzi AA, Yusaf T. Parameters Affecting the Efficiency of Solar Stills—Recent Review. Sustainability. 2022; 14(17):10668. https://doi.org/10.3390/su141710668

Chicago/Turabian StyleEssa, Fadl A., AbdelKader Abdullah, Hasan Sh. Majdi, Ali Basem, Hayder A. Dhahad, Zakaria M. Omara, Suha A. Mohammed, Wissam H. Alawee, Amged Al Ezzi, and Talal Yusaf. 2022. "Parameters Affecting the Efficiency of Solar Stills—Recent Review" Sustainability 14, no. 17: 10668. https://doi.org/10.3390/su141710668

APA StyleEssa, F. A., Abdullah, A., Majdi, H. S., Basem, A., Dhahad, H. A., Omara, Z. M., Mohammed, S. A., Alawee, W. H., Ezzi, A. A., & Yusaf, T. (2022). Parameters Affecting the Efficiency of Solar Stills—Recent Review. Sustainability, 14(17), 10668. https://doi.org/10.3390/su141710668