Improved Neural Network Algorithm Based Flow Characteristic Curve Fitting for Hydraulic Turbines

Abstract

:1. Introduction

2. Theoretical Foundation

- (1)

- Data pre-processing: Normalization of the collected unit operation data to eliminate the influence of different characteristic parameters with different magnitudes on the learning ability of the network.

- (2)

- Network parameter search for optimization: According to the established deep learning network model, using the improved particle swarm algorithm to optimize the important network parameters and determine the key parameters.

- (3)

- Model training and prediction: After the network parameters are determined, the deep learning network is trained using the training set data, and its prediction performance is evaluated on the test set.

2.1. Data Pre-Processing

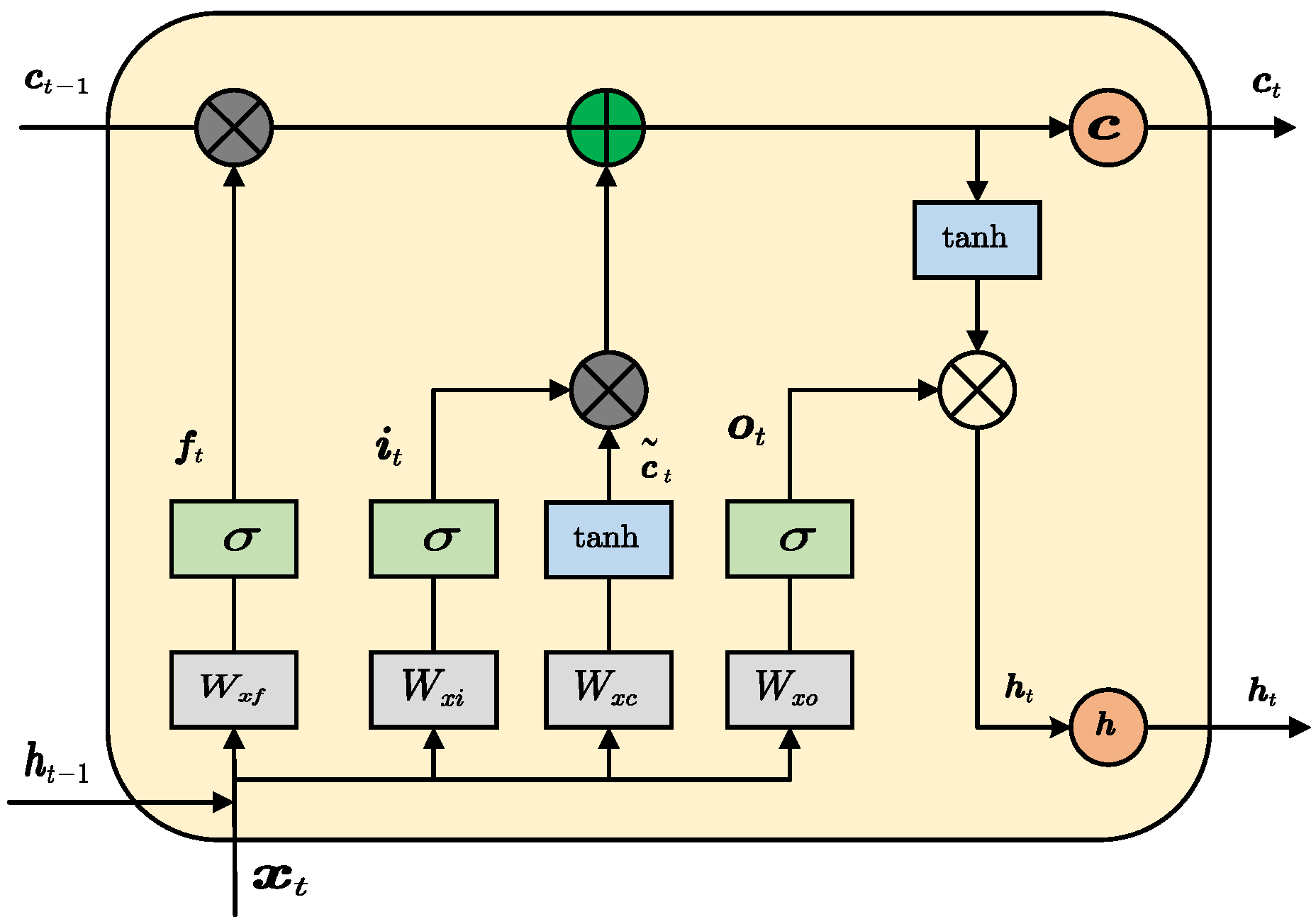

2.2. LSTM Neural Network

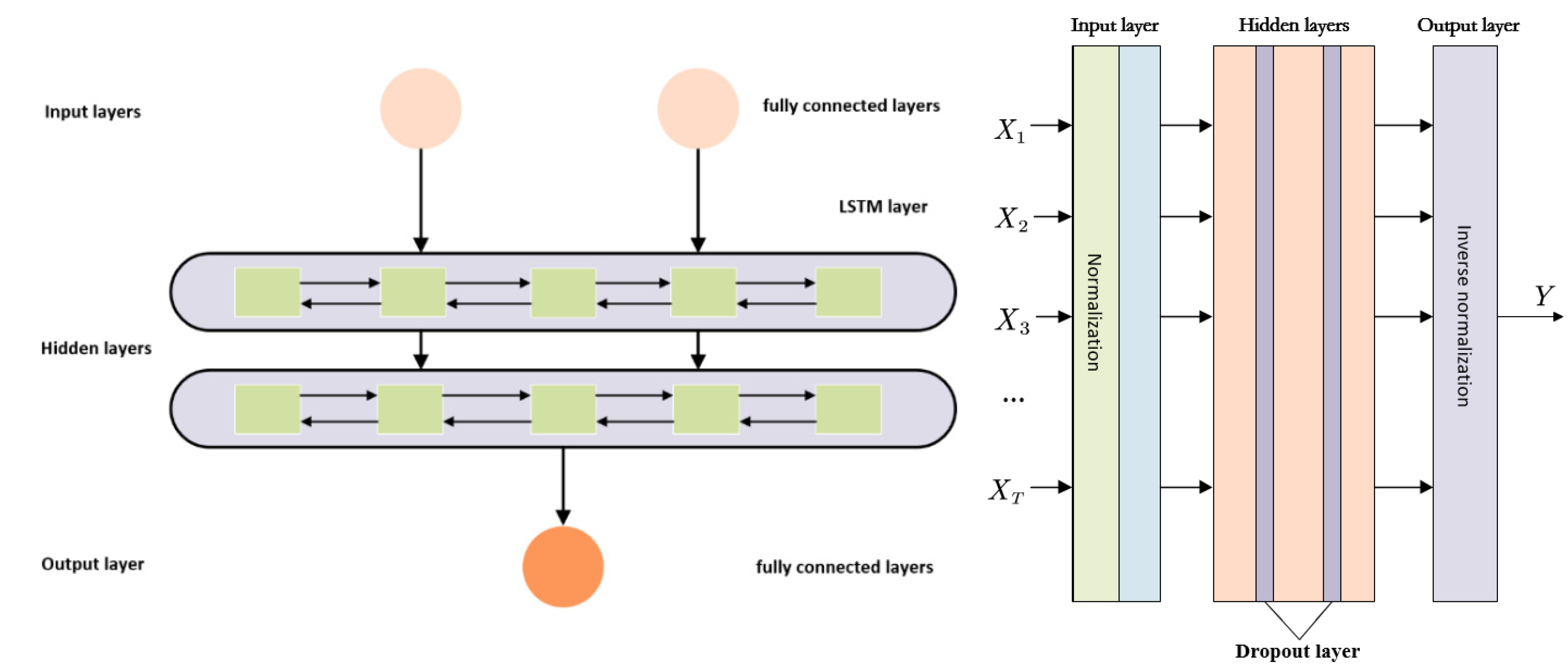

2.3. Network Modeling

3. IPSO-Based Neural Network Parameter Optimization

3.1. IPSO Algorithm

3.2. Network Parameter Optimization

- (1)

- Initialize each individual’s parameters. Determine the population size, the number of iterations, the learning factor and the range of intervals in which the velocity and position of the particles are taken.

- (2)

- Initialize the position and velocity information of the particles. Randomly generate a certain number of population particles , i = 1, 2, …, n, with the values of the particles in each dimension within a limited interval.

- (3)

- Calculate the fitness value corresponding to each particle according to the established objective function equation, determine the global extremes and individual extremes of the initial population, and use the best position of each particle as its historical best value.

- (4)

- In each iteration, update the velocity and position information of the particles according to Equations (9) and (10), calculate the fitness value of each particle of the new population after the update, and determine the individual extreme value and global extreme value of the current population.

- (5)

- Repeat steps (3) and (4) until the maximum number of iterations or accuracy is satisfied, output the optimal network parameters and train the network model.

3.3. Evaluation Indicators

4. Case Analysis

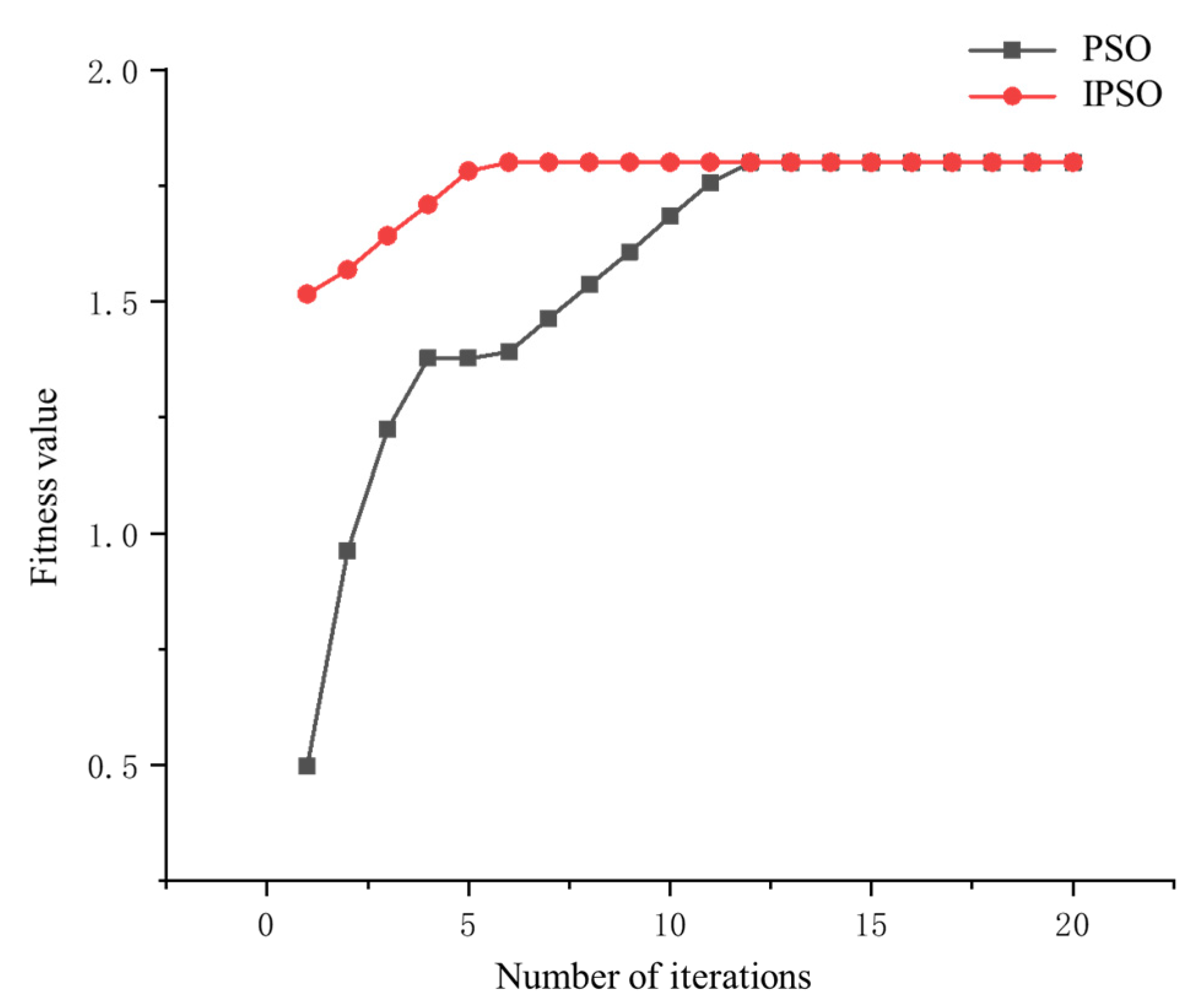

4.1. Parametric Optimization

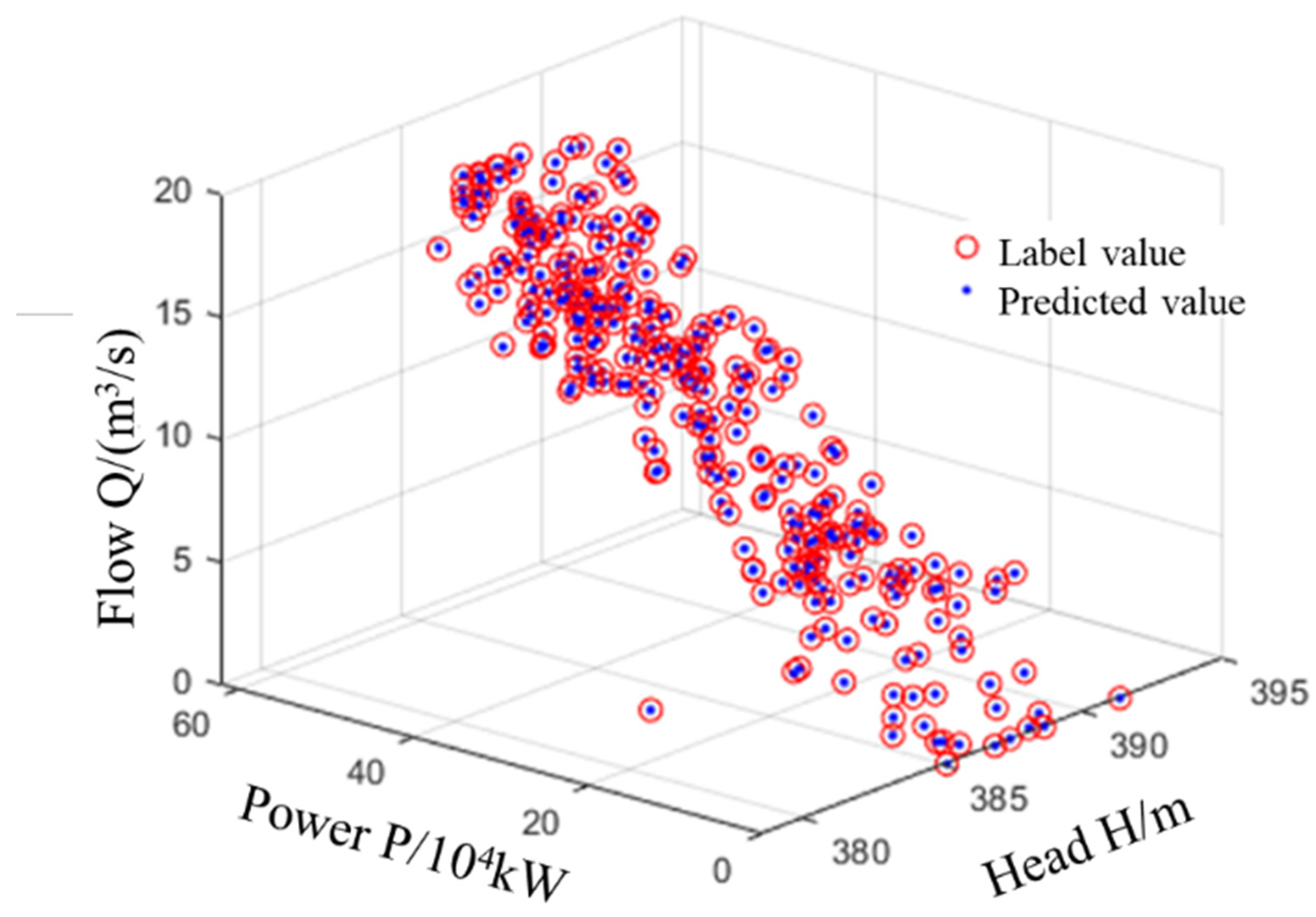

4.2. Model Training and Prediction

5. Conclusions

- (1)

- The deep learning-based hydraulic turbine flow characteristic curve fitting method can continuously train and correct the model by continuously accumulating historical data, and its fitting accuracy will improve with the accumulation of the number of training sets, so the method has the characteristics of self-learning and self-correction.

- (2)

- The training process of the IPSO-LSTM-based deep learning model for fitting the flow characteristics of hydraulic turbines is closely related to the number of training sets; the more samples in the training set, the faster the model training converges and the smaller the error.

- (3)

- Since the deep learning-based hydraulic turbine flow characteristic curve fitting method uses a large amount of real machine operation data to train the model and construct a mapping relationship between input and output quantities, compared with traditional mathematical fitting methods and machine learning methods, it can effectively discover the laws in a large amount of historical operation data, use the connection between historical data and future operating conditions, and make accurate calculations of future unit operating conditions characteristics and parameters. It can also make reasonable predictions for certain unknown operating conditions and has good adaptability.

- (4)

- The hydraulic turbine flow characteristics curve fitting method combining hydraulic turbine model test data and real machine operation data proposed in this article, i.e., considering the full working condition operation characteristics of the hydraulic turbine in the model test and combining the vibration avoidance operation characteristics of the real machine data. Compared with the traditional fitting method, the fitting model learns the operating characteristics of the hydraulic turbine in each working condition and the actual operating characteristics at the same time. Therefore, the results of the fitting calculations using the method proposed in this article are accurate and economical at the same time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.; Yang, K.; Su, L.; Hu, H. The short-term economical operation problem for hydropower station using chaotic normal cloud model based discrete shuffled frog leaping algorithm. Water Resour. Manag. 2020, 34, 905–927. [Google Scholar] [CrossRef]

- Chen, S.; Liang, B.; Lu, H. Derivation of the aggregation-decomposition principle for optimal load distribution of hydropower station. J. Hydraul. Eng. 2017, 48, 1185–1194. [Google Scholar]

- Zhao, W. The Study of the Economic Operation of Hydropower Station Based on APSO-SA Algorithm; Huazhong University of Science and Technology: Wuhan, China, 2016. [Google Scholar]

- Zhang, Y.; Zang, W.; Zheng, J.; Cappietti, L.; Zhang, J.; Zheng, Y.; Fernandez-Rodriguez, E. The influence of waves propagating with the current on the wake of a tidal stream turbine. J. Appl. Energy. 2021, 290, 116729. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, D. Water Turbine; China WaterPower Press: Beijing, China, 2011. [Google Scholar]

- Zhang, R.; Liu, Z.; Wang, L.; Zhang, Y. Data interpolation by Delaunay triangulation for the combined characteristic curve of a turbine. J. Hydroelectr. Eng. 2011, 30, 197–201+221. [Google Scholar]

- Liu, D.; Hu, X.; Zeng, Q.; Zhou, H.K.; Xiao, Z.H. Refined hydro-turbine characteristic curve model based on input-output correction. J. Hydraul. Eng. 2019, 50, 555–564. [Google Scholar]

- Li, J.; Chen, Q.; Chen, G. Study on synthetic characteristic curve processing of Francis turbine conbined with BP neural network. J. Hydroelectr. Eng. 2015, 34, 182–188. [Google Scholar]

- Huang, X.; Liu, D. The treatment of hydroturbine synthetic characteristic curve by radial basis networks. J. Hydroelectr. Eng. 2007, 26, 114–118. [Google Scholar]

- Kilinc, H.C.; Yurtsever, A. Short-Term Streamflow Forecasting Using Hybrid Deep Learning Model Based on Grey Wolf Algorithm for Hydrological Time Series. Sustainability 2022, 14, 3352. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, H.; Wang, Z.; Chen, J. Short-Term Wind Power Forecasting Based on LSTM. Power Syst. Technol. 2017, 41, 3797–3802. [Google Scholar]

- Dai, J.; Song, H.; Sheng, G. Prediction Method for Power Transformer Running State Based on LSTM Network. High Volt. Eng. 2018, 44, 1099–1106. [Google Scholar]

- Zhou, D.; Zhuang, X.; Zuo, H. A hybrid deep neural network based on multi-time window convolutional bidirectional LSTM for civil aircraft APU hazard identification. Chin. J. Aeronaut. 2022, 35, 344–361. [Google Scholar] [CrossRef]

- Nitish, S.; Geoffrey, E.; Hinton, A.K.; Ilya, S.; Ruslan, S. Dropout: A simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Wang, X.; Wu, J.; Liu, C.; Yang, H.; Du, Y.; Niu, W. Exploring LSTM based recurrent neural network for failure time series prediction. J. Beijing Univ. Aeronaut. Astronaut. 2018, 44, 772–784. [Google Scholar]

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

- Xue, L.; Dezhi, H.; Letian, D.; Qiuting, T. Intrusion detection of wireless sensor networks based on IPSO algorithm and BP neural network. Int. J. Comput. Sci. Eng. 2020, 22, 221–232. [Google Scholar]

- Li, W.; Feng, F.; Jiang, Q. Prediction for railway passenger volume based on modified PSO optimized LSTM neural network. J. Railw. Sci. Eng. 2018, 15, 3274–3280. [Google Scholar]

- Wang, Q.; Li, J.; Chen, S.; Wang, X. SVM-based Implicit Stochastic Scheduling Mode for Cascade Hydropower Stations. MATEC Web Conf. 2018, 246, 2046. [Google Scholar] [CrossRef]

- Zhou, J.; Yu, X.; Jin, B. Short-Term Wind Power Forecasting: A New Hybrid Model Combined Extreme-Point Symmetric Mode Decomposition, Extreme Learning Machine and Particle Swarm Optimization. Sustainability 2018, 10, 3202. [Google Scholar] [CrossRef] [Green Version]

| MAE | MSE | RMSE | |

|---|---|---|---|

| Single-layer | 1.09440 | 0.00076 | 0.06373 |

| Double-layer | 0.59028 | 0.00041 | 0.02752 |

| Network Layer (type) | Output Dimension |

|---|---|

| dense1 (FC) | 2 |

| lstm1 (LSTM) | |

| dropout1 (Dropout) | |

| lstm2 (LSTM) | |

| dropout2 (Dropout) | |

| dense2 (FC) | 1 |

| Indicators | MSE | MAE | RMSE | |

|---|---|---|---|---|

| Methods | ||||

| SVM | 0.57100 | 0.5916 | 0.7556 | |

| ELM | 0.00160 | 0.0347 | 0.0400 | |

| IPSO-LSTM | 0.00086 | 0.0259 | 0.0293 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, H.; Hang, C.; Feng, F.; Zheng, Y.; Li, F. Improved Neural Network Algorithm Based Flow Characteristic Curve Fitting for Hydraulic Turbines. Sustainability 2022, 14, 10757. https://doi.org/10.3390/su141710757

Pan H, Hang C, Feng F, Zheng Y, Li F. Improved Neural Network Algorithm Based Flow Characteristic Curve Fitting for Hydraulic Turbines. Sustainability. 2022; 14(17):10757. https://doi.org/10.3390/su141710757

Chicago/Turabian StylePan, Hong, Chenyang Hang, Fang Feng, Yuan Zheng, and Fang Li. 2022. "Improved Neural Network Algorithm Based Flow Characteristic Curve Fitting for Hydraulic Turbines" Sustainability 14, no. 17: 10757. https://doi.org/10.3390/su141710757

APA StylePan, H., Hang, C., Feng, F., Zheng, Y., & Li, F. (2022). Improved Neural Network Algorithm Based Flow Characteristic Curve Fitting for Hydraulic Turbines. Sustainability, 14(17), 10757. https://doi.org/10.3390/su141710757