Environmental Performance of Oxidized Kraft Lignin-Based Products

Abstract

:1. Introduction

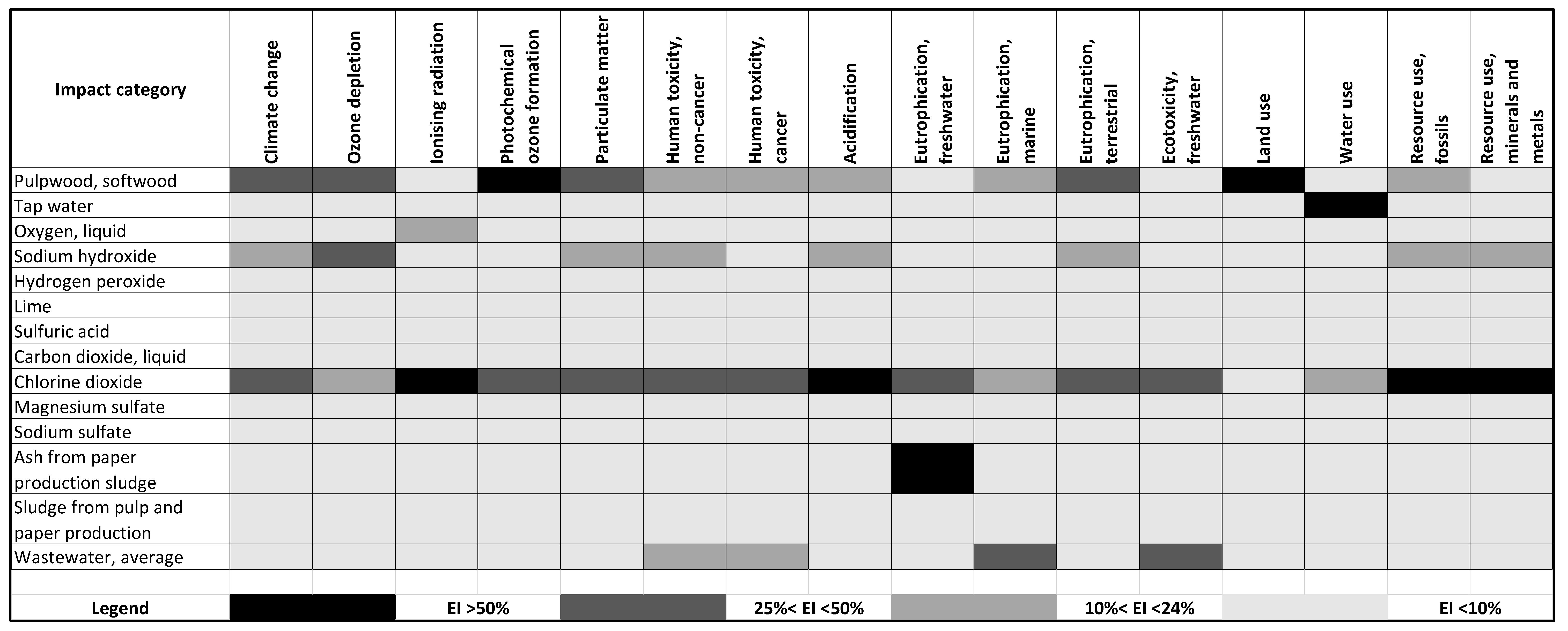

2. Materials and Methods

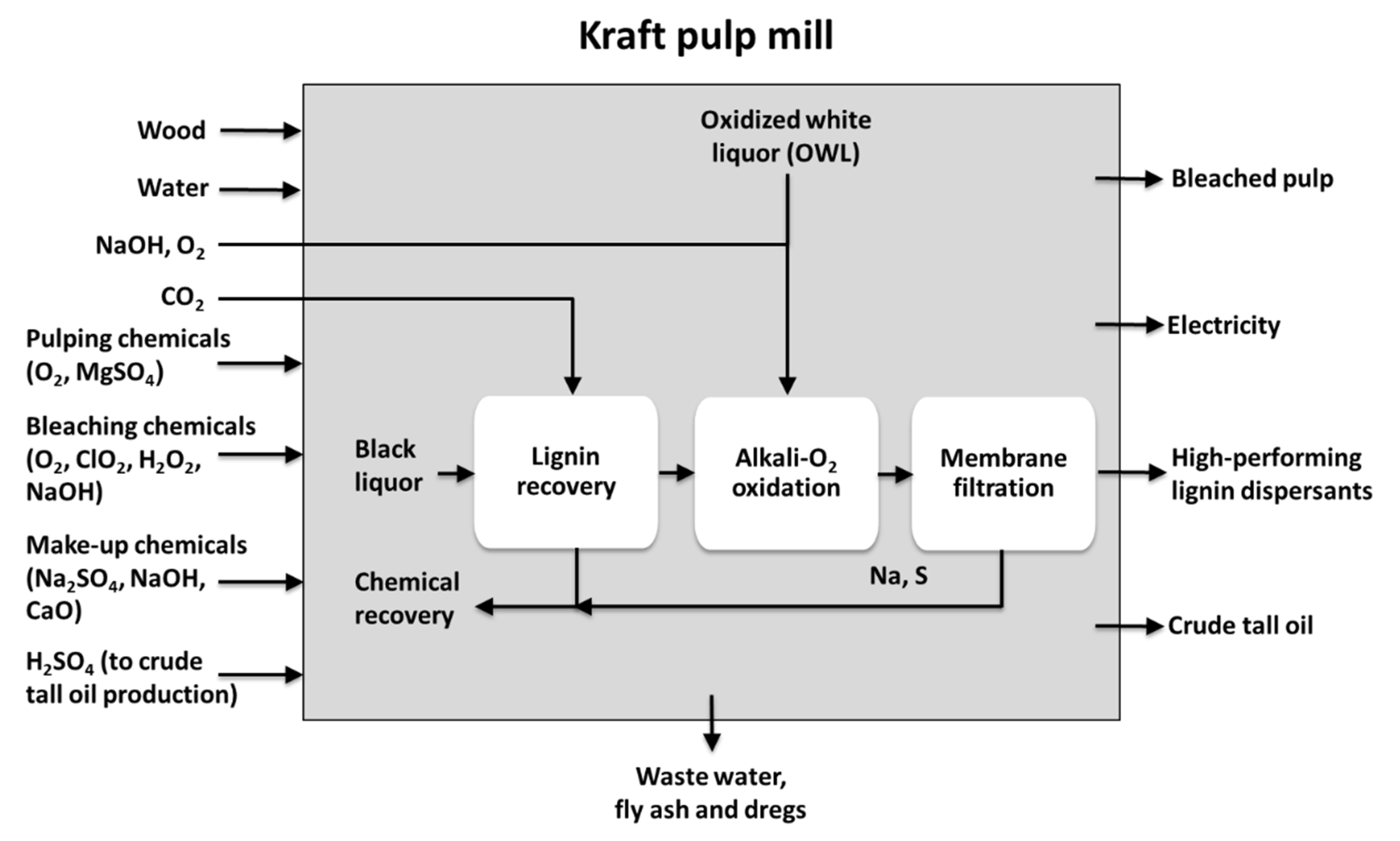

2.1. Lignin Recovery and Oxidation at a Kraft Pulp Mill

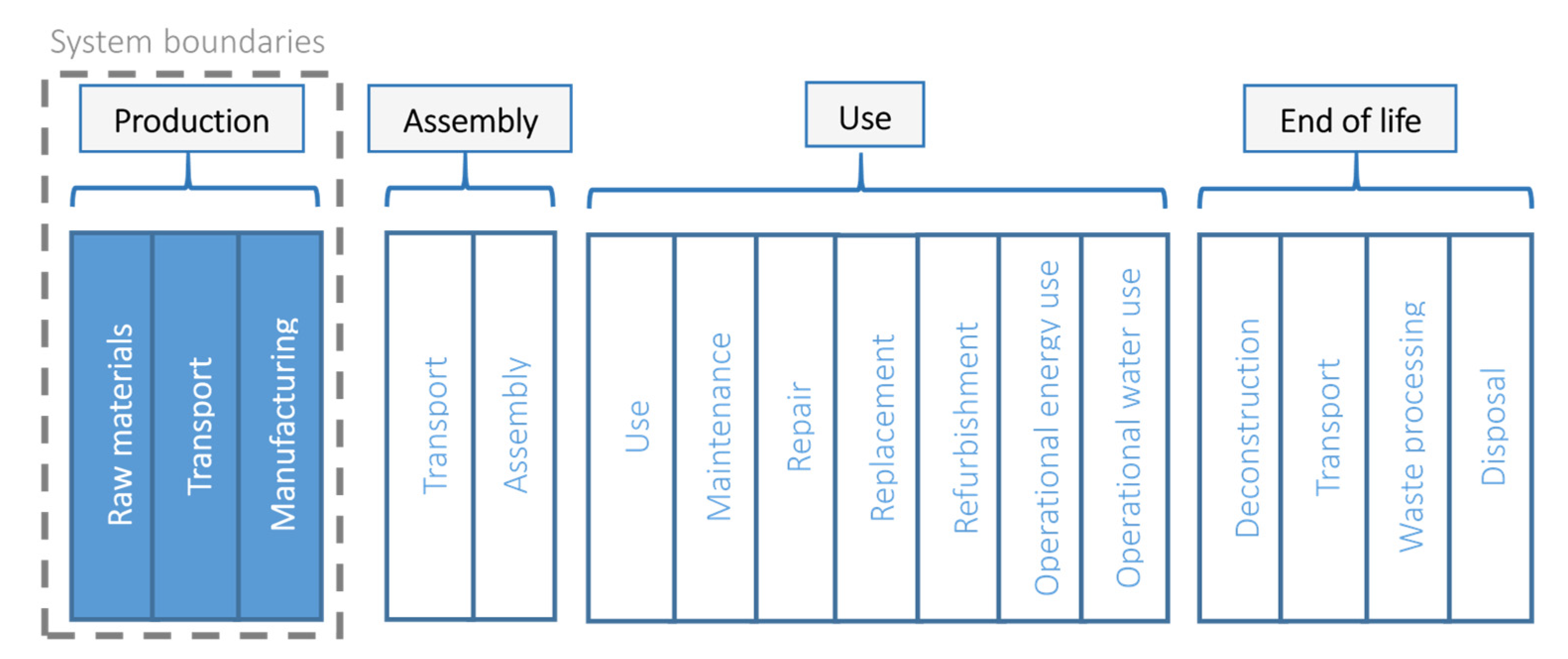

2.2. Life Cycle Assessment

- The raw material supplies (softwood).

- The transportation of raw materials to the production plant.

- The manufacturing of the product (including the provision of energy, production of auxiliaries and consumables and waste treatment).

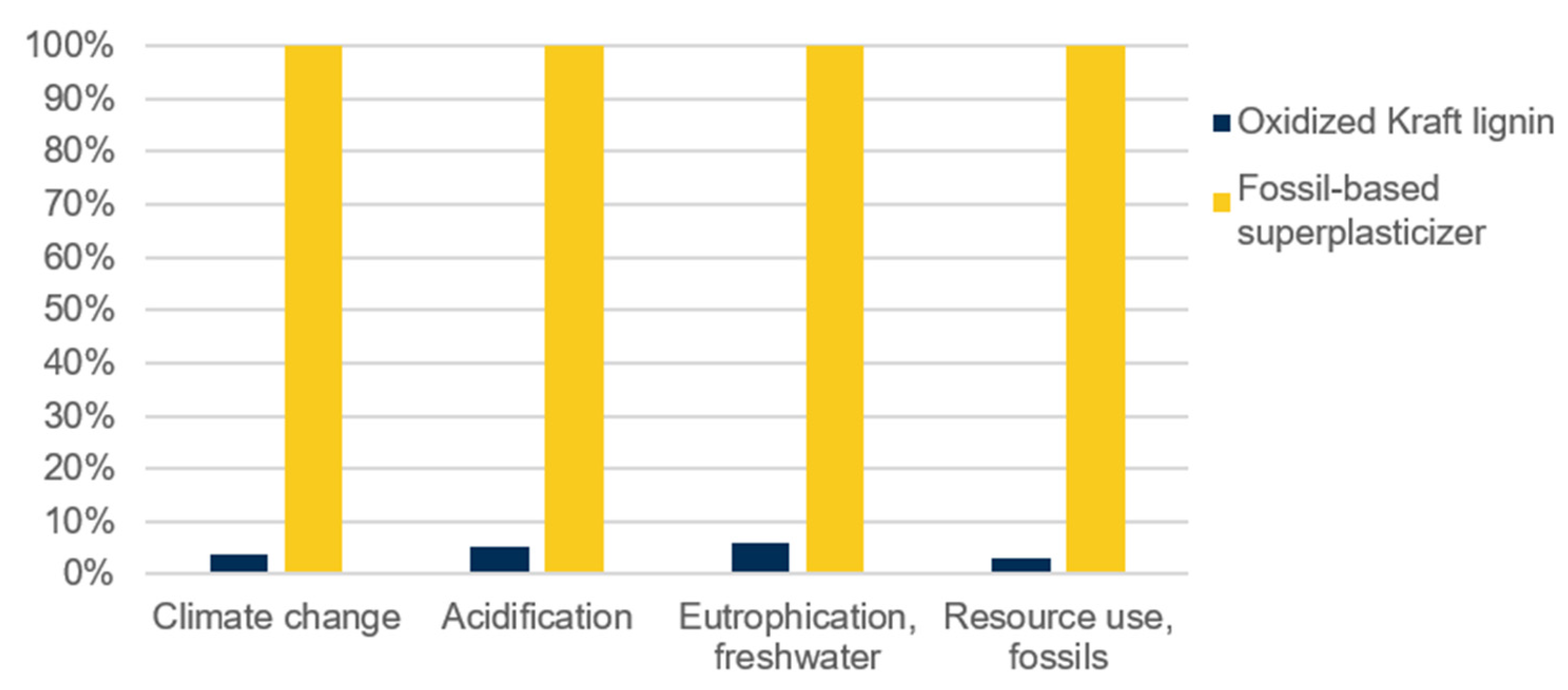

3. Results

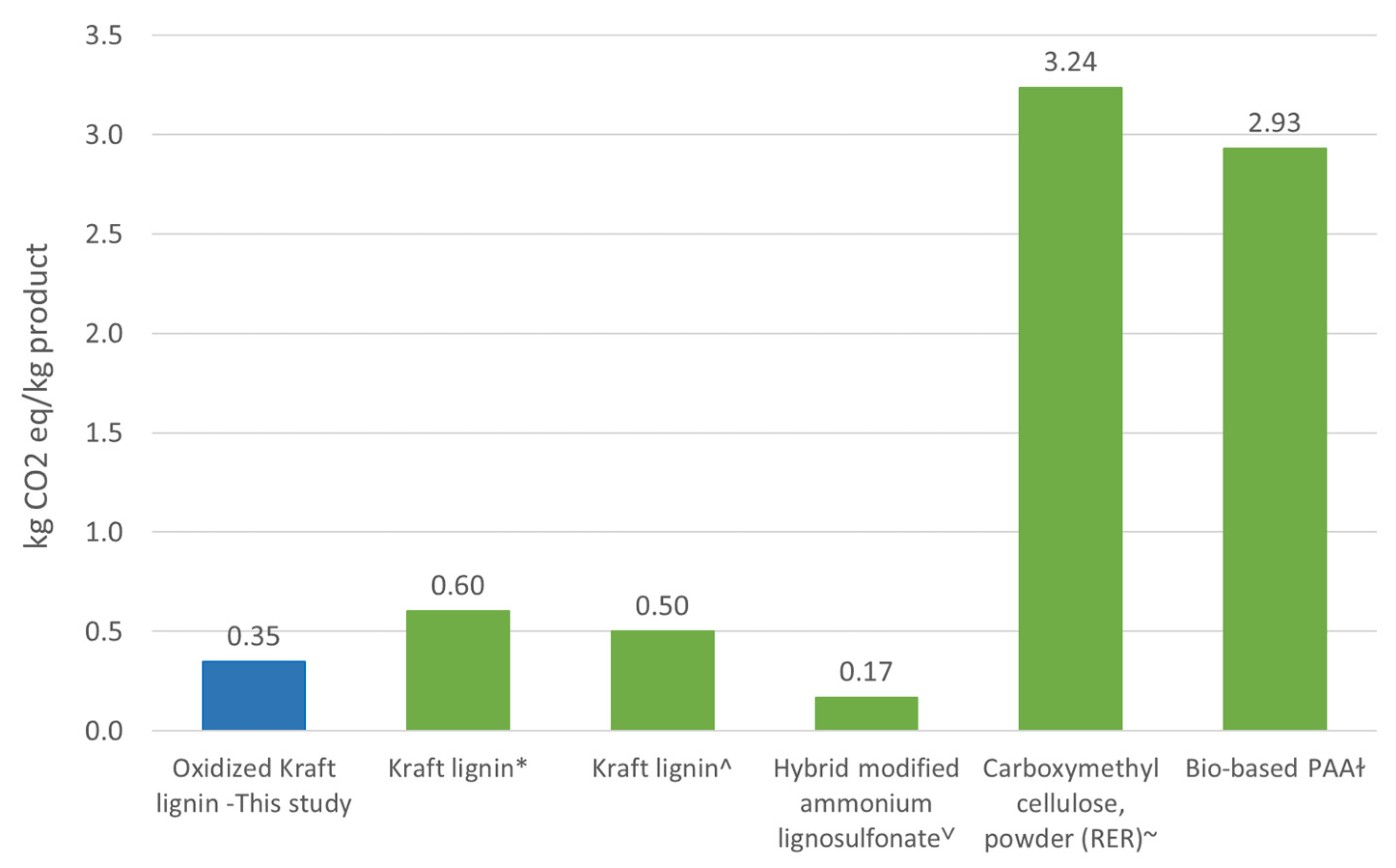

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Impact Category | Unit | Ligniox Lignin | Fossil-Based Superplasticizer | Fossil-Based Dispersant |

|---|---|---|---|---|

| Climate change | kg CO2 eq | 3.47 × 10−1 | 9.32 × 100 | 2.16 × 100 |

| Ozone depletion | kg CFC11 eq | 6.92 × 10−8 | 7.24 × 10−7 | 3.77 × 10−7 |

| Ionizing radiation | kBq U-235 eq | 2.08 × 10−2 | 1.28 × 100 | 1.66 × 10−1 |

| Photochemical ozone formation | kg NMVOC eq | 1.75 × 10−3 | 2.40 × 10−2 | 4.78 × 10−3 |

| Particulate matter | disease inc. | 1.95 × 10−8 | 2.15 × 10−7 | 6.53 × 10−8 |

| Human toxicity, non-cancer | CTUh | 8.89 × 10−9 | 5.76 × 10−8 | 2.09 × 10−8 |

| Human toxicity, cancer | CTUh | 5.48 × 10−10 | 1.61 × 10−9 | 7.13 × 10−10 |

| Acidification | mol H+ eq | 2.56 × 10−3 | 4.79 × 10−2 | 7.25 × 10−3 |

| Eutrophication, freshwater | kg P eq | 5.99 × 10−4 | 1.03 × 10−2 | 4.78 × 10−4 |

| Eutrophication, marine | kg N eq | 9.17 × 10−4 | 9.13 × 10−3 | 1.39 × 10−3 |

| Eutrophication, terrestrial | mol N eq | 4.75 × 10−3 | 8.07 × 10−2 | 1.37 × 10−2 |

| Ecotoxicity, freshwater | CTUe | 1.67 × 101 | 7.59 × 101 | 2.35 × 101 |

| Land use | Pt | 2.76 × 102 | 1.59 × 101 | 3.34 × 100 |

| Water use | m3 depriv. | 1.41 × 100 | 2.60 × 10−1 | 9.70 × 10−1 |

| Resource use, fossils | MJ | 4.32 × 100 | 1.41 × 102 | 4.31 × 101 |

| Resource use, minerals and metals | kg Sb eq | 4.67 × 10−6 | 1.41 × 10−5 | 1.91 × 10−5 |

References

- Weiss, M.; Haufe, J.; Carus, M.; Brandão, M.; Bringezu, S.; Hermann, B.; Patel, M.K. A Review of the Environmental Impacts of Biobased Materials. J. Ind. Ecol. 2012, 16, S169–S181. [Google Scholar] [CrossRef]

- Sixta, H. Handbook of Pulp; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- Dessbesell, L.; Paleologou, M.; Leitch, M.; Pulkki, R.; Xu, C. Global lignin supply overview and kraft lignin potential as an alternative for petroleum-based polymers. Renew. Sustain. Energy Rev. 2020, 123, 109768. [Google Scholar] [CrossRef]

- Bajwa, D.; Pourhashem, G.; Ullah, A.H.; Bajwa, S. A concise review of current lignin production, applications, products and their environmental impact. Ind. Crops Prod. 2019, 139, 111526. [Google Scholar] [CrossRef]

- Ekielski, A.; Mishra, P.K. Lignin for Bioeconomy: The Present and Future Role of Technical Lignin. Int. J. Mol. Sci. 2020, 22, 63. [Google Scholar] [CrossRef]

- Davidsdottir, B. Forest products and energy. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Li, T.; Takkellapati, S. The current and emerging sources of technical lignins and their applications. Biofuels Bioprod. Biorefining 2018, 12, 756–787. [Google Scholar] [CrossRef]

- Baral, N.R.; Kavvada, O.; Mendez-Perez, D.; Mukhopadhyay, A.; Lee, T.S.; Simmons, B.A.; Scown, C.D. Techno-economic analysis and life-cycle greenhouse gas mitigation cost of five routes to bio-jet fuel blendstocks. Energy Environ. Sci. 2019, 12, 807–824. [Google Scholar] [CrossRef]

- Aro, T.; Fatehi, P. Production and application of lignosulfonates and sulfonated lignin. ChemSusChem 2017, 10, 1861–1877. [Google Scholar] [CrossRef]

- Kalliola, A.; Kangas, P.; Winberg, I.; Vehmas, T.; Kyllönen, H.; Heikkinen, J.; Poukka, O.; Kemppainen, K.; Sjögård, P.; Pehu-Lehtonen, L. Oxidation process concept to produce lignin dispersants at a kraft pulp mill. Nord. Pulp Pap. Res. J. 2022, 37, 394–404. [Google Scholar] [CrossRef]

- Kalliola, A.; Vehmas, T.; Liitiä, T.; Tamminen, T. Alkali-O2 oxidized lignin–A bio-based concrete plasticizer. Ind. Crops Prod. 2015, 74, 150–157. [Google Scholar] [CrossRef]

- Kalliola, A.; Vehmas, T.; Liitiä, T.; Tamminen, T. Concrete Plasticizers and Versatile Dispersants from LigniOx Lignins. In Proceedings of the 7th Nordic Wood Biorefinery Conference, NWBC, Stockholm, Sweden, 28–30 March 2017. [Google Scholar]

- Jedrzejczak, P.; Collins, M.N.; Jesionowski, T.; Klapiszewski, L. The role of lignin and lignin-based materials in sustainable construction—A comprehensive review. Int. J. Biol. Macromol. 2021, 187, 624–650. [Google Scholar] [CrossRef]

- Ma, X.; Chen, J.; Zhu, J.; Yan, N. Lignin-Based Polyurethane: Recent Advances and Future Perspectives. Macromol. Rapid Commun. 2021, 42, e2000492. [Google Scholar] [CrossRef]

- Shu, F.; Jiang, B.; Yuan, Y.; Li, M.; Wu, W.; Jin, Y.; Xiao, H. Biological Activities and Emerging Roles of Lignin and Lignin-Based Products horizontal line A Review. Biomacromolecules 2021, 22, 4905–4918. [Google Scholar] [CrossRef]

- Tukker, A. Life cycle assessment as a tool in environmental impact assessment. Environ. Impact Assess. Rev. 2000, 20, 435–456. [Google Scholar] [CrossRef]

- Curran, M.A. Life Cycle Assessment: A review of the methodology and its application to sustainability. Curr. Opin. Chem. Eng. 2013, 2, 273–277. [Google Scholar] [CrossRef]

- Kirchain, R.E., Jr.; Gregory, J.R.; Olivetti, E.A. Environmental life-cycle assessment. Nat. Mater. 2017, 16, 693–697. [Google Scholar] [CrossRef]

- Benali, M.; Ajao, O.; Jeaidi, J.; Gilani, B.; Mansoornejad, B. Integrated lignin-Kraft pulp biorefinery for the production of lignin and its derivatives: Economic assessment and LCA-based environmental footprint. In Production of Biofuels and Chemicals from Lignin; Springer: Berlin/Heidelberg, Germany, 2016; pp. 379–418. [Google Scholar]

- Moretti, C.; Corona, B.; Hoefnagels, R.; van Veen, M.; Vural-Gürsel, I.; Strating, T.; Gosselink, R.; Junginger, M. Kraft lignin as a bio-based ingredient for Dutch asphalts: An attributional LCA. Sci. Total Environ. 2022, 806, 150316. [Google Scholar] [CrossRef]

- Moretti, C.; Hoefnagels, R.; van Veen, M.; Corona, B.; Obydenkova, S.; Russell, S.; Jongerius, A.; Vural-Gürsel, I.; Junginger, M. Using lignin from local biorefineries for asphalts: LCA case study for the Netherlands. J. Clean. Prod. 2022, 343, 131063. [Google Scholar] [CrossRef]

- Tokede, O.O.; Whittaker, A.; Mankaa, R.; Traverso, M. Life Cycle Assessment of Asphalt Variants in Infrastructures: The Case of Lignin in Australian road Pavements; Elsevier: Amsterdam, The Netherlands, 2020; pp. 190–199. [Google Scholar]

- Yuan, Y.; Guo, M. Do green wooden composites using lignin-based binder have environmentally benign alternatives? A preliminary LCA case study in China. Int. J. Life Cycle Assess. 2017, 22, 1318–1326. [Google Scholar] [CrossRef]

- Hermansson, F.; Janssen, M.; Svanström, M. Prospective study of lignin-based and recycled carbon fibers in composites through meta-analysis of life cycle assessments. J. Clean. Prod. 2019, 223, 946–956. [Google Scholar] [CrossRef]

- Bernier, E.; Lavigne, C.; Robidoux, P.Y. Life cycle assessment of kraft lignin for polymer applications. Int. J. Life Cycle Assess. 2013, 18, 520–528. [Google Scholar] [CrossRef]

- Culbertson, C.; Treasure, T.; Venditti, R.; Jameel, H.; Gonzalez, R. Life Cycle Assessment of lignin extraction in a softwood kraft pulp mill. Nord. Pulp Pap. Res. J. 2016, 31, 30-U247. [Google Scholar] [CrossRef]

- Moretti, C.; Corona, B.; Hoefnagels, R.; Vural-Gürsel, I.; Gosselink, R.; Junginger, M. Review of life cycle assessments of lignin and derived products: Lessons learned. Sci. Total Environ. 2021, 770, 144656. [Google Scholar] [CrossRef] [PubMed]

- Pawelzik, P.; Carus, M.; Hotchkiss, J.; Narayan, R.; Selke, S.; Wellisch, M.; Weiss, M.; Wicke, B.; Patel, M.K. Critical aspects in the life cycle assessment (LCA) of bio-based materials—Reviewing methodologies and deriving recommendations. Resour. Conserv. Recycl. 2013, 73, 211–228. [Google Scholar] [CrossRef]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Sustainability assessments of bio-based polymers. Polym. Degrad. Stab. 2013, 98, 1898–1907. [Google Scholar] [CrossRef]

- Montazeri, M.; Zaimes, G.G.; Khanna, V.; Eckelman, M.J. Meta-analysis of life cycle energy and greenhouse gas emissions for priority biobased chemicals. ACS Sustain. Chem. Eng. 2016, 4, 6443–6454. [Google Scholar] [CrossRef]

- Hermansson, F.; Janssen, M.; Svanström, M. Allocation in life cycle assessment of lignin. Int. J. Life Cycle Assess. 2020, 25, 1620–1632. [Google Scholar] [CrossRef]

- Broeren, M.L.; Zijp, M.C.; Waaijers-van der Loop, S.L.; Heugens, E.H.; Posthuma, L.; Worrell, E.; Shen, L. Environmental assessment of bio-based chemicals in early-stage development: A review of methods and indicators. Biofuels Bioprod. Biorefining 2017, 11, 701–718. [Google Scholar] [CrossRef]

- Valmet Valmet WinGEMS Process Simulator for Pulp and Paper Industries. Available online: https://www.valmet.com/pulp/automation-for-pulp/apc-advanced-process-controls/valmet-wingems/ (accessed on 19 January 2022).

- Kangas, P.; Kaijaluoto, S.; Määttänen, M. Evaluation of future pulp mill concepts–Reference model of a modern Nordic kraft pulp mill. Nord. Pulp Pap. Res. J. 2014, 29, 620–634. [Google Scholar] [CrossRef]

- Muralikrishna, I.V.; Manickam, V. Chapter Five—Life Cycle Assessment. In Environmental Management; Muralikrishna, I.V., Manickam, V., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 57–75. [Google Scholar]

- ISO14040; Environmental Management—Life Cycle Assessment: Principles and Framework. ISO: Geneva, Switzerland, 1997.

- ISO14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 1997.

- Goedkoop, M.; Oele, M.; de Schryver, A.; Vieira, M.; Hegger, S. SimaPro Database Manual Methods Library; PRé Consultants: Amersfoort, The Netherlands, 2008. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; et al. The ecoinvent Database: Overview and Methodological Framework (7 pp). Int. J. Life Cycle Assess. 2005, 10, 3–9. [Google Scholar] [CrossRef]

- Rouwette, R.a.S.A. LCI of Admixtures in Europe. Data Collection Process for LCAs of Concrete; EFCA: Brusseles, Belgium, 2002. [Google Scholar]

- Gontia, P.; Janssen, M. Life cycle assessment of bio-based sodium polyacrylate production from pulp mill side streams: Case study of thermo-mechanical and sulfite pulp mills. J. Clean. Prod. 2016, 131, 475–484. [Google Scholar] [CrossRef] [Green Version]

- Manfredi, S.; Allacker, K.; Chomkhamsri, K.; Pelletier, N.; Maia de Souze, D. Product Environmental Footprint (PEF) Guide; European Commission: Brussels, Belgium; Joint Research Centre: Ispra, Italy; Institute for Environment and Sustainability: Ispra, Italy, 2012. [Google Scholar]

- Nuss, P.; Gardner, K.H. Attributional life cycle assessment (ALCA) of polyitaconic acid production from northeast US softwood biomass. Int. J. Life Cycle Assess. 2013, 18, 603–612. [Google Scholar] [CrossRef]

- Cherian, C.; Siddiqua, S. Pulp and Paper Mill Fly Ash: A Review. Sustainability 2019, 11, 4394. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M.; Svanström, M. Life cycle assessment of construction materials: The influence of assumptions in end-of-life modelling. Int. J. Life Cycle Assess. 2014, 19, 723–731. [Google Scholar] [CrossRef]

- Fouquet, M.; Levasseur, A.; Margni, M.; Lebert, A.; Lasvaux, S.; Souyri, B.; Buhé, C.; Woloszyn, M. Methodological challenges and developments in LCA of low energy buildings: Application to biogenic carbon and global warming assessment. Build. Environ. 2015, 90, 51–59. [Google Scholar] [CrossRef]

- Levasseur, A.; Lesage, P.; Margni, M.; Samson, R. Biogenic carbon and temporary storage addressed with dynamic life cycle assessment. J. Ind. Ecol. 2013, 17, 117–128. [Google Scholar] [CrossRef]

- Taverna, R.; Hofer, P.; Werner, F.; Kaufmann, E.; Thürig, E. The CO2 effects of the Swiss forestry and timber industry: Scenarios of future potential for climate-change mitigation. Environ. Stud. 2007, 739, 102. [Google Scholar]

- Müller, D.B.; Bader, H.P.; Baccini, P. Long-term coordination of timber production and consumption using a dynamic material and energy flow analysis. J. Ind. Ecol. 2004, 8, 65–88. [Google Scholar] [CrossRef]

- Gaytán, I.; Burelo, M.; Loza-Tavera, H. Current status on the biodegradability of acrylic polymers: Microorganisms, enzymes and metabolic pathways involved. Appl. Microbiol. Biotechnol. 2021, 105, 991–1006. [Google Scholar] [CrossRef]

- Sodium Naphthalene-1-Sulphonate. Available online: https://echa.europa.eu/registration-dossier/-/registered-dossier/20000/5/3/1 (accessed on 7 June 2022).

- Vilkman, M.; Fearon, O.; Kalliola, A. Biodegradation of oxidized lignin dispersants. BioResources 2022, in press. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Lignin recovery | ||

| Amount of lignin | [%] | 20 |

| Black liquor dry content | [%] | 37 |

| CO2 charge | [kg/t lignin] | 275 |

| Lignin oxidation | ||

| OWL charge | [kg/t lignin] | 205 |

| NaOH charge | [kg/t lignin] | 220 |

| Lignin content | [%] | 15 |

| Lignin yield | [%] | 90 |

| Membrane filtration | ||

| Yield, ox. lignin | [%] | 89 |

| Na to retentate | [%] | 32 |

| S to retentate | [%] | 35 |

| Inputs | Unit | Kraft Mill Integrated Case | Related Dataset of Ecoinvent (v3.7.1) |

|---|---|---|---|

| Wood | m3 | 5.7 | Pulpwood, softwood, measured as solid wood under bark (Europe without Switzerland) |

| Water | m3 | 46.8 | Tap water (RER) |

| Oxygen | kg | 62.6 | Oxygen, liquid (RER) |

| Magnesium sulfate | kg | 3.77 | Magnesium oxide (RER) |

| Chlorine dioxide | kg | 39 | Chlorine dioxide (RER) |

| Sodium hydroxide | kg | 49.2 | Sodium hydroxide, without water, in 50% solution state (GLO) |

| Hydrogen peroxide | kg | 7.4 | Hydrogen peroxide, without water, in 50% solution state (GLO) |

| Lime | kg | 5.56 | Lime (GLO) |

| Sulfuric acid | kg | 4.9 | Sulfuric acid (RER) |

| Carbon dioxide | kg | 28.8 | Carbon dioxide, liquid (RER) |

| Sodium sulfate | kg | 12.4 | Sodium sulfate, anhydrite (RER) |

| Membrane | m3 | 0.06 | Polystyrene, general purpose (GLO); Thickness of membrane: 250 micron; density of PS: 50 kg/m3 |

| Electricity | kWh | 416 | Electricity, medium voltage (FI) |

| Fly ash | kg | 12 | Ash from paper production sludge (Europe without Switzerland) |

| Brine | kg | 1.6 | Sludge from pulp and paper production (Europe without Switzerland) |

| Wastewater | m3 | 19.1 | Wastewater, average (Europe without Switzerland) |

| Wastewater | m3 | 19.1 | Wastewater, average (Europe without Switzerland) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajagopalan, N.; Winberg, I.; Fearon, O.; Cardellini, G.; Liitia, T.; Kalliola, A. Environmental Performance of Oxidized Kraft Lignin-Based Products. Sustainability 2022, 14, 10897. https://doi.org/10.3390/su141710897

Rajagopalan N, Winberg I, Fearon O, Cardellini G, Liitia T, Kalliola A. Environmental Performance of Oxidized Kraft Lignin-Based Products. Sustainability. 2022; 14(17):10897. https://doi.org/10.3390/su141710897

Chicago/Turabian StyleRajagopalan, Neethi, Iris Winberg, Olesya Fearon, Giuseppe Cardellini, Tiina Liitia, and Anna Kalliola. 2022. "Environmental Performance of Oxidized Kraft Lignin-Based Products" Sustainability 14, no. 17: 10897. https://doi.org/10.3390/su141710897

APA StyleRajagopalan, N., Winberg, I., Fearon, O., Cardellini, G., Liitia, T., & Kalliola, A. (2022). Environmental Performance of Oxidized Kraft Lignin-Based Products. Sustainability, 14(17), 10897. https://doi.org/10.3390/su141710897