A Novel AHP-PRISM Risk Assessment Method—An Empirical Case Study in a Nuclear Power Plant

Abstract

:1. Introduction

1.1. Contextual Background

1.2. The Aim of the Research

1.3. The Structure of This Study

- Which methodological problems of the initial PRISM method can be solved or reduced by combining pairwise comparison techniques like AHP?

- Why can AHP be suggested to improve the initial PRISM method’s weaknesses related to the case study’s characteristics?

- What are the limitations of this study, and what kind of future developments can be addressed?

- The main findings of the study are concluded in Section 5.

2. Methods and Materials

2.1. Methods

- The first step is to determine the MCDM problem, collect the comparable elements, and define the rating factors (rating factors are the dimensions in this case).

- The second step is executing the experts’ pairwise comparison of the elements. The comparison related to the occurrence, severity, and detection dimensions should be executed. After the comparisons are made, the consistency of the experts should be tested. Low consistency usually indicates that the decision-making problem definition was not precise enough. In the case of low consistency, the decision-making problem should be redefined, and the pairwise comparison should be executed again.

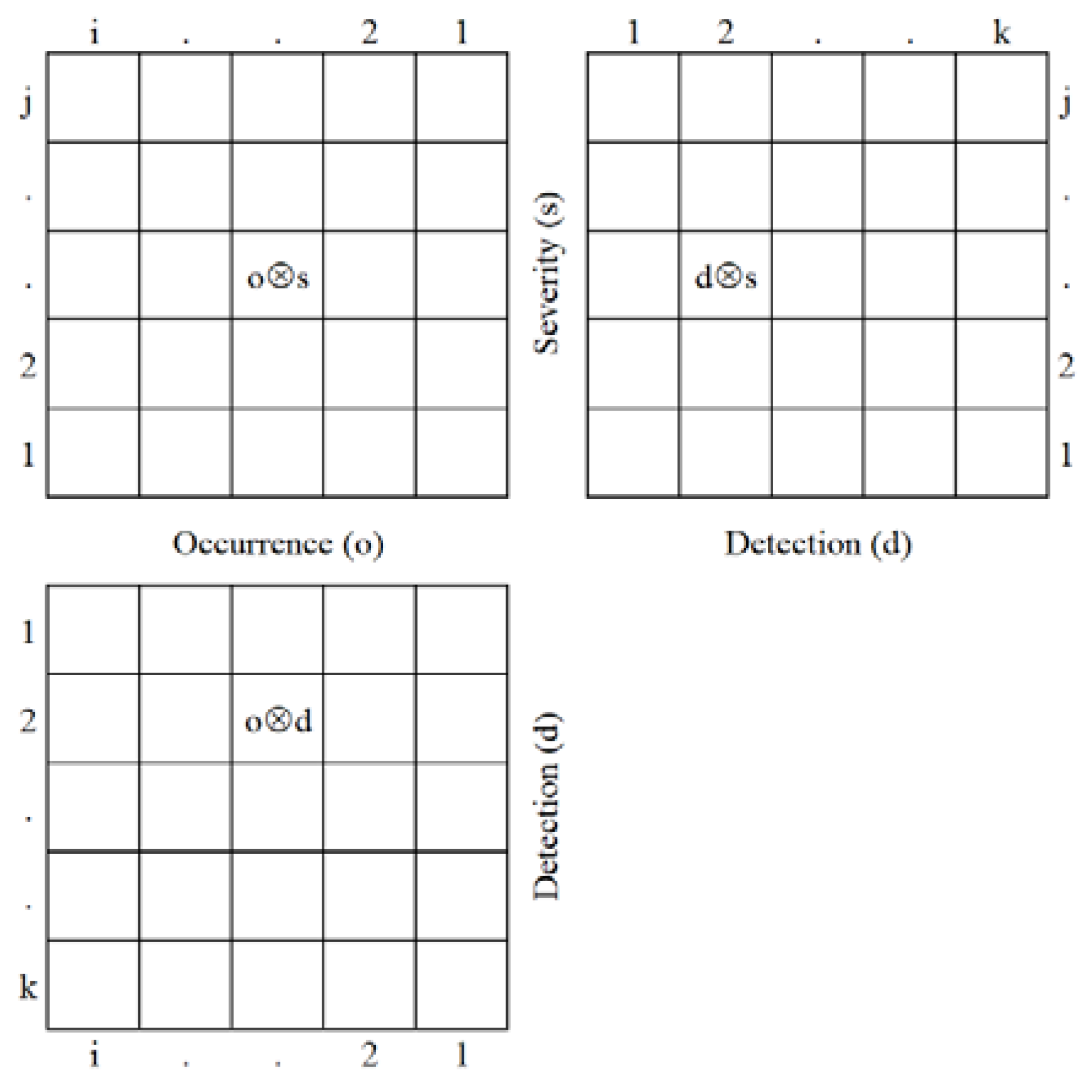

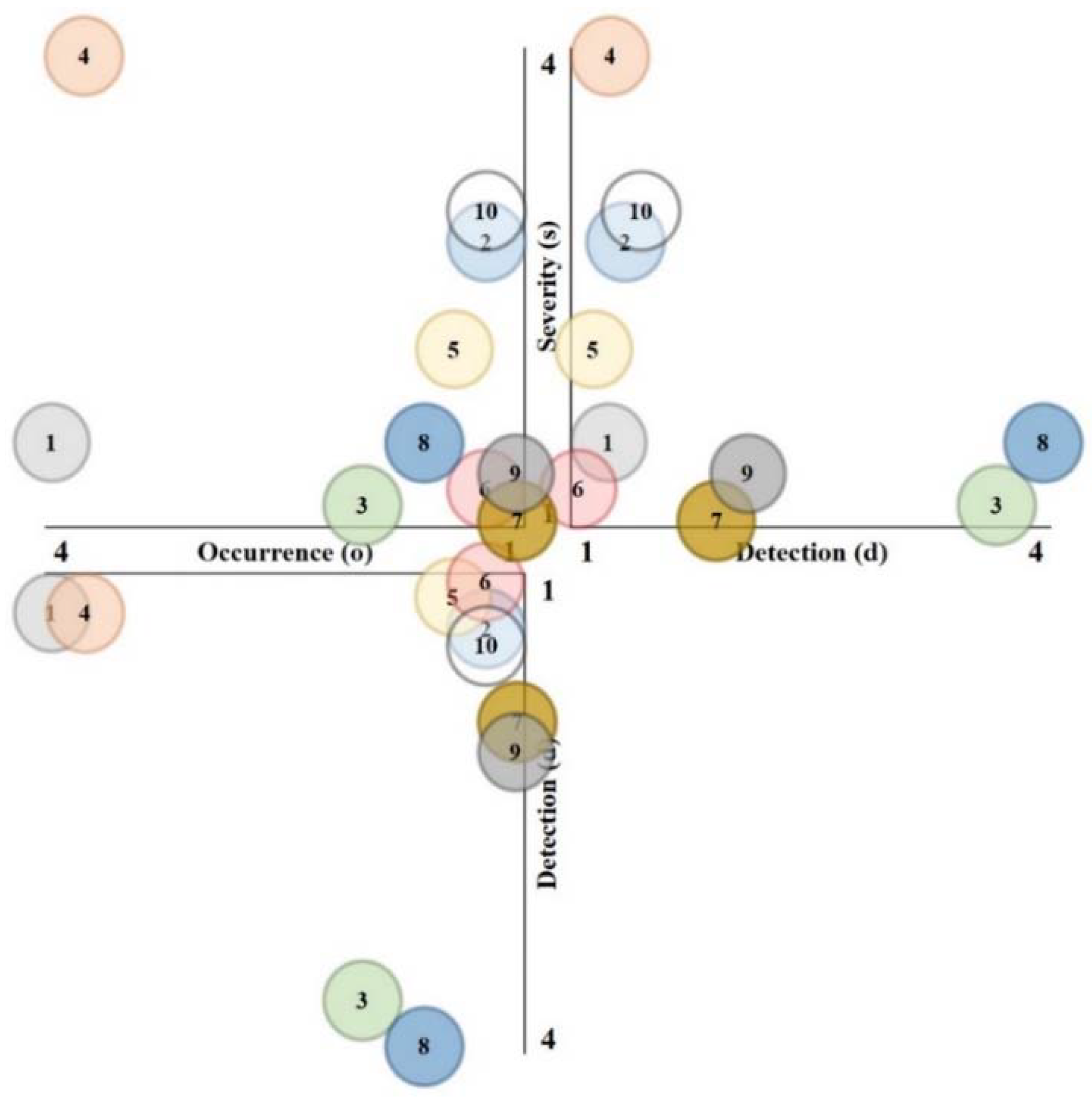

- Based on linear transformation, the AHP weights of the items are transformed to a traditional 1–4, 1–5, or 1–10 scale. In the case of and , the transformation is necessary since it is unreasonable to multiply the weights provided by the AHP. Although the function can be applied without the linear transformation, it is recommended to perform it.

- Based on the transformed o, s, and d values, the PRISM patterns can be determined, and by applying a PRISM function, the PRISM numbers of the incidents can be calculated. Thus, the orders of the elements by PRISM functions can be given. Next, the robustness test of the results can be performed by applying rank correlation coefficients (in the case of two rankings) or rank concordance coefficients (in the case of more than two rankings).

- In the case of the riskiest elements, risk mitigation actions can be planned and executed.

- Kendall’s tau approaches a normal distribution more rapidly than Spearman’s rho as the sample size increases;

- Kendall’s tau b handles the possible ties in the rankings (instead of Kendall’s tau a);

- Since the o, s, and d dimensions are measured on the same scale, Kendall’s tau c is not required.

2.2. Case Study

- Which incident group can occur more frequently?

- Which incident group has a more severe effect on the business processes?

- Which incident group is more difficult to detect?

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AHP | Analytic Hierarchy Process |

| BMW | Best Worst Method |

| CI | Consistency Index |

| CR | Consistency Ratio |

| DEMATEL | Decision-Making Trial and Evaluation Laboratory |

| ELECTRE | Elimination and Choice Translating Reality |

| FMEA | Failure Mode and Effects Analysis |

| FTA | Fault Tree Analysis |

| HAZOP | Hazard and Operability Analysis |

| HOF | Human and Organizational Factors |

| IRIDM | Integrated Risk-Informed Decision-Making |

| LOPA | Layers of Protection Analysis |

| MCDM | Multi-Criteria Decision-Making |

| NPP | Nuclear power plant |

| PRISM | Partial Risk Map |

| PSA | Probabilistic Safety Assessment |

| RI | Random Index |

| RM | Risk Matrix |

| TOPSIS | Technique for Order Preference by Similarity to Ideal Solution |

| VIKOR | VIsekriterijumska optimizacija i KOmpromisno Resenje |

| VTA | Value Tree Analysis |

Appendix A

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| E1 | 1 | 9 | 5 | 1 | 7 | 5 | 7 | 5 | 7 | 7 |

| E2 | 1/9 | 1 | 1 | 1/9 | 1 | 1 | 3 | 1/3 | 1 | 1 |

| E3 | 1/5 | 1 | 1 | 1/5 | 3 | 3 | 3 | 5 | 5 | 3 |

| E4 | 1 | 9 | 5 | 1 | 5 | 5 | 7 | 5 | 5 | 7 |

| E5 | 1/7 | 1 | 1/3 | 1/5 | 1 | 1 | 3 | 1/3 | 5 | 3 |

| E6 | 1/5 | 1 | 1/3 | 1/5 | 1 | 1 | 1 | 1/3 | 3 | 1 |

| E7 | 1/7 | 1/3 | 1/3 | 1/7 | 1/3 | 1 | 1 | 1 | 1 | 1/3 |

| E8 | 1/5 | 3 | 1/5 | 1/5 | 3 | 3 | 1 | 1 | 3 | 3 |

| E9 | 1/7 | 1 | 1/5 | 1/5 | 1/5 | 1/3 | 1 | 1/3 | 1 | 1/3 |

| E10 | 1/7 | 1 | 1/3 | 1/7 | 1/3 | 1 | 3 | 1/3 | 3 | 1 |

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| E1 | 1 | 1/7 | 3 | 1/7 | 1 | 3 | 3 | 1 | 1 | 1/5 |

| E2 | 7 | 1 | 5 | 1/3 | 1 | 5 | 3 | 5 | 7 | 1 |

| E3 | 1/3 | 1/5 | 1 | 1/7 | 1/5 | 1 | 3 | 1/3 | 1 | 1/5 |

| E4 | 7 | 3 | 7 | 1 | 5 | 5 | 7 | 5 | 7 | 1 |

| E5 | 1 | 1 | 5 | 1/5 | 1 | 3 | 7 | 3 | 5 | 1/3 |

| E6 | 1/3 | 1/5 | 1 | 1/5 | 1/3 | 1 | 3 | 1/3 | 1/3 | 1/3 |

| E7 | 1/3 | 1/3 | 1/3 | 1/7 | 1/7 | 1/3 | 1 | 1/3 | 1/3 | 1/7 |

| E8 | 1 | 1/5 | 3 | 1/5 | 1/3 | 3 | 3 | 1 | 3 | 1/3 |

| E9 | 1 | 1/7 | 1 | 1/7 | 1/5 | 3 | 3 | 1/3 | 1 | 1/5 |

| E10 | 5 | 1 | 5 | 1 | 3 | 3 | 7 | 3 | 5 | 1 |

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| E1 | 1 | 1 | 1/7 | 1 | 3 | 3 | 1/3 | 1/7 | 1/5 | 1/3 |

| E2 | 1 | 1 | 1/7 | 1 | 3 | 5 | 1/5 | 1/9 | 1/3 | 1/3 |

| E3 | 7 | 7 | 1 | 5 | 9 | 5 | 5 | 1 | 3 | 7 |

| E4 | 1 | 1 | 1/5 | 1 | 3 | 3 | 1/5 | 1/7 | 1/7 | 1/3 |

| E5 | 1/3 | 1/3 | 1/9 | 1/3 | 1 | 3 | 1/3 | 1/7 | 1/3 | 1 |

| E6 | 1/3 | 1/5 | 1/5 | 1/3 | 1/3 | 1 | 1/5 | 1/9 | 1/3 | 1/3 |

| E7 | 3 | 5 | 1/5 | 5 | 3 | 5 | 1 | 1/7 | 1 | 3 |

| E8 | 7 | 9 | 1 | 7 | 7 | 9 | 7 | 1 | 3 | 7 |

| E9 | 5 | 3 | 1/3 | 7 | 3 | 3 | 1 | 1/3 | 1 | 3 |

| E10 | 3 | 3 | 1/7 | 3 | 1 | 3 | 1/3 | 1/7 | 1/3 | 1 |

References

- Batyrshin, I.Z.; Tóth-Laufer, E. Bipolar Dissimilarity and Similarity Correlations of Numbers. Mathematics 2022, 10, 797. [Google Scholar] [CrossRef]

- Liu, H.C.; Liu, L.; Liu, N. Risk evaluation approaches in failure mode and effects analysis: A literature review. Expert Syst. Appl. 2013, 40, 828–838. [Google Scholar] [CrossRef]

- Huang, J.; You, J.X.; Liu, H.C.; Song, M.S. Failure mode and effect analysis improvement: A systematic literature review and future research agenda. Reliab. Eng. Syst. Saf. 2020, 199, 106885. [Google Scholar] [CrossRef]

- Liu, H.C.; Chen, X.Q.; Duan, C.Y.; Wang, Y.M. Failure mode and effect analysis using multi-criteria decision making methods: A systematic literature review. Comput. Ind. Eng. 2019, 135, 881–897. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications; Springer: New York, NY, USA, 1981. [Google Scholar]

- Roy, B. Classement et choix en présence de points de vue multiples (la méthode ELECTRE). La Rev. D’informatique Rech. Opérationelle 1968, 8, 57–75. [Google Scholar]

- Opricovic, S. Fuzzy VIKOR with an application to water resources planning. Expert Syst. Appl. 2011, 38, 12983–12990. [Google Scholar] [CrossRef]

- Fontela, E.; Gabus, A. The DEMATEL Observer. DEMATEL 1976 Report; Battelle Geneva Research Center: Geneva, Switzerland, 1976. [Google Scholar]

- Rezaei, J. Best-worst multi-criteria decision-making method. Omega 2015, 53, 49–57. [Google Scholar] [CrossRef]

- Cinelli, M.; Kadziński, M.; Gonzalez, M.; Słowiński, R. How to support the application of multiple criteria decision analysis? Let us start with a comprehensive taxonomy. Omega 2020, 96, 102261. [Google Scholar] [CrossRef]

- Cinelli, M.; Kadziński, M.; Miebs, G.; Gonzalez, M.; Słowiński, R. Recommending multiple criteria decision analysis methods with a new taxonomy-based decision support system. Eur. J. Oper. Res. 2022, 302, 633–651. [Google Scholar] [CrossRef]

- Vaidya, O.S.; Kumar, S. Analytic hierarchy process: An overview of applications. Eur. J. Oper. Res. 2006, 169, 1–29. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Marra, M. The state of the art development of AHP (1979–2017): A literature review with a social network analysis. Int. J. Prod. Res. 2017, 55, 6653–6675. [Google Scholar] [CrossRef] [Green Version]

- Vargas, L.G. An overview of the analytic hierarchy process and its applications. Eur. J. Oper. Res. 1990, 48, 2–8. [Google Scholar] [CrossRef]

- Russo, R.F.S.M.; Camanho, R. Criteria in AHP: A Systematic Review of Literature. Procedia Comput. Sci. 2015, 55, 1123–1132. [Google Scholar] [CrossRef]

- Dos Santos, P.H.; Neves, S.M.; Sant’Anna, D.O.; de Oliveira, C.H.; Carvalho, H.D. The analytic hierarchy process supporting decision making for sustainable development: An overview of applications. J. Clean. Prod. 2019, 212, 119–138. [Google Scholar] [CrossRef]

- Berényi, L.; Birkner, Z.; Deutsch, N. A Multidimensional Evaluation of Renewable and Nuclear Energy among Higher Education Students. Sustainability 2020, 12, 1449. [Google Scholar] [CrossRef]

- Buzási, A.; Jӓger, B.S. District-scale assessment of urban sustainability. Sustain. Cities Soc. 2020, 62, 102388. [Google Scholar] [CrossRef]

- Bargueño, D.R.; Salomon, V.A.P.; Marins, F.A.S.; Palominos, P.; Marrone, L.A. State of the Art Review on the Analytic Hierarchy Process and Urban Mobility. Mathematics 2021, 9, 3179. [Google Scholar] [CrossRef]

- Aszódi, A.; Biró, B.; Adorján, L.; Dobos, Á.C.; Illés, G.; Tóth, N.K.; Zagyi, D.; Zsiborás, Z.T. Comparative analysis of national energy strategies of 19 European countries in light of the green deal’s objectives. Energy Convers. Manag. X 2021, 12, 100136. [Google Scholar] [CrossRef]

- Toke, D. When safety is relative: Ecological modernisation theory and the nuclear safety regulatory regimes of France, the United Kingdom and United States. Energy Res. Soc. Sci. 2022, 86, 102447. [Google Scholar] [CrossRef]

- Bizet, R.; Bonev, P.; Lévêque, F. The effect of local monitoring on nuclear safety and compliance: Evidence from France. J. Environ. Econ. Manag. 2022, 113, 102651. [Google Scholar] [CrossRef]

- Schöbel, M.; Silla, I.; Teperi, A.M.; Gustafsson, R.; Piirto, A.; Rollenhagen, C.; Wahlström, B. Human and organizational factors in European nuclear safety: A fifty-year perspective on insights, implementations, and ways forward. Energy Res. Soc. Sci. 2022, 85, 102378. [Google Scholar] [CrossRef]

- Guang, Y.; Huang, W.J.; Lei, L.L. Using AHP and TOPSIS Approaches in Nuclear Power Plant Equipment Supplier Selection. Key Eng. Mater. 2009, 419–420, 761–764. [Google Scholar] [CrossRef]

- Kiser, L.; Otero, L.D. Using AHP to Choose Optimal Nuclear Power Plant Design. In Proceedings of the 2021 IEEE International Systems Conference (SysCon), Virtual Conference, 15 April–15 May 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Ok, C.I.; Kim, C.L.; Moon, S.R.; Koo, H.S.; Yun, K.H.; Lee, S.K. Prioritization of radiological accident scenarios during decommissioning of nuclear power plants by risk matrix and AHP method. Ann. Nucl. Energy 2022, 175, 109239. [Google Scholar] [CrossRef]

- Sun, M.; Li, T.; Yu, J.; Ge, D.; Bai, Y.; Tao, L. A New Reliability Allocation Method Based on PSA and AHP for Fusion Reactors. Energies 2022, 15, 4850. [Google Scholar] [CrossRef]

- Borysiewicz, M.; Kowal, K.; Potempski, S. An application of the value tree analysis methodology within the integrated risk informed decision making for the nuclear facilities. Reliab. Eng. Syst. Saf. 2015, 139, 113–119. [Google Scholar] [CrossRef]

- Jang, K.B.; Baek, C.H.; Woo, T.H. Assessment for nuclear security using Analytic Hierarchy Process (AHP) incorporated with Neural Networking Method in nuclear power plants (NPPs). Kerntechnik 2022, in press. [CrossRef]

- Woo, T.H.; Lee, U.C. Safeguard assessment in nuclear power plants (NPPs) operations using analytic hierarchy process (AHP) and production function. Energy Explor. Exploit. 2011, 29, 337–355. [Google Scholar] [CrossRef]

- He, S.; Xu, H.; Zhang, J.; Xue, P. Risk assessment of oil and gas pipelines hot work based on AHP-FCE. Petroleum 2022, in press. [CrossRef]

- Bathrinath, S.; Dhanasekar, M.; Dhanorvignesh, B.; Kamaldeen, Z.; Santhi, B.; Bhalaji, R.K.A.; Koppiahraj, K. Modeling sustainability risks in sugar industry using AHP-BWM. Mater. Today Proc. 2022, 50, 1397–1404. [Google Scholar] [CrossRef]

- Braglia, M. MAFMA: Multi-attribute failure mode analysis. Int. J. Qual. Reliab. Manag. 2000, 17, 1017–1033. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Díaz, H.; Soares, C.G. A failure analysis of floating offshore wind turbines using AHP-FMEA methodology. Ocean Eng. 2021, 234, 109261. [Google Scholar] [CrossRef]

- Golkhani, F.; Ghotbi, R.M.; Baesmat, S.; Abasi, B.F. The Use of Failure Mode Effects Analysis (FMEA) and Analytic Hierarchy Process (AHP) Methods to Determine the Most Important Safety Hazards. Health Educ. Health Promot. 2018, 6, 17–21. [Google Scholar] [CrossRef]

- Bognár, F.; Benedek, P. A Novel Risk Assessment Methodology: A Case Study of the PRISM Methodology in a Compliance Management Sensitive Sector. Acta Polytech. Hung. 2021, 18, 89–108. [Google Scholar] [CrossRef]

- Forgács, A.; Lukács, J.; Horváth, R. The Investigation of the Applicability of Fuzzy Rule-based Systems to Predict Economic Decision-Making. Acta Polytech. Hung. 2021, 18, 97–115. [Google Scholar] [CrossRef]

- Bognár, F.; Benedek, P. Multi-Method Risk Assessment Process for Sustainable Business—A compliance research Follow-up Case Study. Acta Polytech. Hung. 2022, Revised. [Google Scholar]

- Rosenberger, P.; Tick, J. Multivariate Optimization of PMBOK, Version 6 Project Process Relevance. Acta Polytech. Hung. 2021, 18, 9–28. [Google Scholar] [CrossRef]

- Babeshko, I.; Illiashenko, O.; Kharchenko, V.; Leontiev, K. Towards Trustworthy Safety Assessment by Providing Expert and Tool-Based XMECA Techniques. Mathematics 2022, 10, 2297. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Sneesl, R.; Jusoh, Y.Y.; Jabar, M.A.; Abdullah, S.; Bukar, U.A. Factors Affecting the Adoption of IoT-Based Smart Campus: An Investigation Using Analytical Hierarchical Process (AHP). Sustainability 2022, 14, 8359. [Google Scholar] [CrossRef]

- Bognár, F.; Hegedűs, C. Description and Consequences on some Aggregation functions of PRISM (Partial Risk Map) Risk Assessment Method. Mathematics 2022, 10, 676. [Google Scholar] [CrossRef]

- Gilpin, A.R. Table for Conversion of Kendall’s Tau to Spearman’s Rho Within the Context of Measures of Magnitude of Effect for Meta-Analysis. Educ. Psychol. Meas. 1993, 53, 87–92. [Google Scholar] [CrossRef]

- Kendall, M.G. Rank Correlation Methods; Griffin: London, UK, 1970. [Google Scholar]

- Gill, P.; Steward, K.F.; Treasure, E.; Chadwick, B.L. Methods of data collection in qualitative research: Interviews and focus groups. Br. Dent. J. 2008, 204, 291–295. [Google Scholar] [CrossRef] [PubMed]

- Bloor, M.; Frankland, J.; Thomas, M.; Robson, K. Focus Groups in Social Research; Sage Publications: London, UK, 2001. [Google Scholar] [CrossRef]

- Ross, R.T. Discussion: Optimal orders in the method of paired comparisons. J. Exp. Psychol. 1939, 25, 414–424. [Google Scholar] [CrossRef]

- Fleming, M.; Harvey, K.; Bowers, K.C. Development and testing of a nuclear regulator safety culture perception survey. Saf. Sci. 2022, 153, 105792. [Google Scholar] [CrossRef]

- Bognár, F.; Böcskei, E. A supportive model for reaching the corporate net-zero carbon emission goal. Public Financ. Q. 2022, 67. in press. [Google Scholar]

- Thurstone, L.L. A law of comparative judgment. Psychol. Rev. 1927, 34, 273–286. [Google Scholar] [CrossRef]

- Sjöberg, L. Thurstonian methods in the measurement of learning. Scand. J. Psychol. 1965, 6, 33–48. [Google Scholar] [CrossRef]

- Duleba, S.; Szádoczki, Z. Comparing aggregation methods in large-scale group AHP: Time for the shift to distance-based aggregation. Expert Syst. Appl. 2022, 196, 116667. [Google Scholar] [CrossRef]

- Kulcsár, E.; Csiszér, T.; Abonyi, J. Pairwise comparison based failure mode and effects analysis (FMEA). MethodsX 2020, 7, 101007. [Google Scholar] [CrossRef]

- Hegedűs, C.; Kosztyán, Z.T. The consideration of measurement uncertainty in forecast and maintenance related decisions. Probl. Manag. 21st Century 2011, 1, 46–69. [Google Scholar] [CrossRef]

- Kosztyán, Z.T.; Hegedűs, C. Computer Aided Diagnostic Methods to Forecast Condition-Based Maintenance Tasks. In Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2013; Volume 151, pp. 367–380. [Google Scholar] [CrossRef]

- Gavurova, B.; Kelemen, M.; Polishchuk, V. Expert model of risk assessment for the selected components of smart city concept: From safe time to pandemics as COVID-19. Socio-Econ. Plan. Sci. 2022, 82, 101253. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.J.; Huang, Z.R.; Zhao, F.Y.; Wang, Y. Mathematical modeling and evaluation of the safety culture for the operating nuclear power plants in China: Critical review and multi-criteria decision analysis. Ann. Nucl. Energy 2022, 168, 108871. [Google Scholar] [CrossRef]

- Abdulvahitoglu, A.; Kilic, M. A new approach for selecting the most suitable oilseed for biodiesel production; the integrated AHP-TOPSIS method. Ain Shams Eng. J. 2022, 13, 101604. [Google Scholar] [CrossRef]

- Nazim, M.; Mohammad, C.W.; Sadiq, M. A comparison between fuzzy AHP and fuzzy TOPSIS methods to software requirements selection. Alex. Eng. J. 2022, 61, 10851–10870. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R. Evaluating the circular supply chain implementation barriers using Pythagorean fuzzy AHP-DEMATEL approach. Clean. Logist. Supply Chain 2021, 2, 100014. [Google Scholar] [CrossRef]

| Judgment | Score |

|---|---|

| Equal importance | 1 |

| Slight importance | 2 |

| Moderate importance | 3 |

| Moderate plus importance | 4 |

| Strong importance | 5 |

| Strong plus importance | 6 |

| Demonstrated importance | 7 |

| Very strong importance | 8 |

| Extreme importance | 9 |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

| ID | Strategic Incident Group Name | Description |

|---|---|---|

| E1 | Late fulfillment | The supplier partner does not meet the agreed deadline but fulfills the agreed obligations. Late fulfillment can cause (further) slippage of processes built on it. |

| E2 | Non-fulfillment | The supplier partner cannot fulfill its commitments intentionally or for reasons beyond control. This risk will result in repeated work of the procurement units and hinder the plans’ feasibility. |

| E3 | Incorrect fulfillment | The supplier partner does not fulfill its agreed quantity/quality obligations. Incorrect fulfillment hinders the feasibility of the plans. |

| E4 | Environmental risks | External risks on which neither the supplier partner nor the nuclear power plant has a direct influence. |

| E5 | Cooperation gaps | Risks are inherent in the cooperation between the stakeholders of the logistics system. These can result from both intentional and unintentional acts. |

| E6 | Issues of responsible designation | Risk arises from the designation of the person responsible for specific stages of the procurement process, which may arise from the person’s knowledge/skills/skill deficiencies or from the impropriety of the authorization system that he/she received from the organization. It does not allow the completion of assigned tasks. |

| E7 | Stability issues in the supply chain | Risk arising from operational problems of the supplier partner, such as a legal risk that can be considered independent of the organization (e.g., embargo) or a risk arising from the economic stability of the organization. |

| E8 | Knowledge base issues | Risks are related to the knowledge base required to operate the procurement system. These may arise from the intellectual competencies of the contributors or the state of the serving information systems. |

| E9 | Server system non-availability | Risks arise from the functionality of the logistics system. These can also be risks of hardware or software origins. |

| E10 | Performance control issues | During the logistics processes, failure to check the actual implementation of material, information, and money flow according to plan. This results in documentation gaps and certifiability risks. |

| Occurrence | Severity | Detection | |

|---|---|---|---|

| λmax | 11.24 | 11.08 | 11.26 |

| CI | 0.14 | 0.12 | 0.14 |

| CR | 0.09 | 0.08 | 0.09 |

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Occurrence | 4.00 | 1.21 | 2.02 | 3.82 | 1.43 | 1.21 | 1.05 | 1.63 | 1.00 | 1.21 |

| Severity | 1.45 | 2.83 | 1.14 | 4.00 | 2.14 | 1.18 | 1.00 | 1.53 | 1.25 | 2.99 |

| Detection | 1.22 | 1.27 | 3.66 | 1.22 | 1.11 | 1.00 | 1.94 | 4.00 | 2.07 | 1.42 |

| MAX | MAX | MAX | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | 5.5 | 5.2 | 2.7 | 5.5 | 5.8 | 4.9 | 1.8 | 5.8 | 18.1 | 17.5 | 3.6 | 18.1 |

| E2 | 4.0 | 2.5 | 4.1 | 4.1 | 3.4 | 1.5 | 3.6 | 3.6 | 9.5 | 3.1 | 9.6 | 9.6 |

| E3 | 3.2 | 5.7 | 4.8 | 5.7 | 2.3 | 7.4 | 4.2 | 7.4 | 5.4 | 17.5 | 14.7 | 17.5 |

| E4 | 7.8 | 5.0 | 5.2 | 7.8 | 15.3 | 4.7 | 4.9 | 15.3 | 30.6 | 16.1 | 17.5 | 30.6 |

| E5 | 3.6 | 2.5 | 3.2 | 3.6 | 3.0 | 1.6 | 2.4 | 3.0 | 6.6 | 3.3 | 5.8 | 6.6 |

| E6 | 2.4 | 2.2 | 2.2 | 2.4 | 1.4 | 1.2 | 1.2 | 1.4 | 2.9 | 2.5 | 2.4 | 2.9 |

| E7 | 2.0 | 3.0 | 2.9 | 3.0 | 1.0 | 2.0 | 1.9 | 2.0 | 2.1 | 4.9 | 4.8 | 4.9 |

| E8 | 3.2 | 5.6 | 5.5 | 5.6 | 2.5 | 6.5 | 6.1 | 6.5 | 5.0 | 18.7 | 18.3 | 18.7 |

| E9 | 2.3 | 3.1 | 3.3 | 3.3 | 1.3 | 2.1 | 2.6 | 2.6 | 2.6 | 5.3 | 5.9 | 5.9 |

| E10 | 4.2 | 2.6 | 4.4 | 4.4 | 3.6 | 1.7 | 4.3 | 4.3 | 10.4 | 3.5 | 11.0 | 11.0 |

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | E9 | E10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 6 | 2 | 1 | 7 | 10 | 9 | 3 | 8 | 5 | |

| 4 | 6 | 2 | 1 | 7 | 10 | 9 | 3 | 8 | 5 | |

| 3 | 6 | 4 | 1 | 7 | 10 | 9 | 2 | 8 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bognár, F.; Benedek, P. A Novel AHP-PRISM Risk Assessment Method—An Empirical Case Study in a Nuclear Power Plant. Sustainability 2022, 14, 11023. https://doi.org/10.3390/su141711023

Bognár F, Benedek P. A Novel AHP-PRISM Risk Assessment Method—An Empirical Case Study in a Nuclear Power Plant. Sustainability. 2022; 14(17):11023. https://doi.org/10.3390/su141711023

Chicago/Turabian StyleBognár, Ferenc, and Petra Benedek. 2022. "A Novel AHP-PRISM Risk Assessment Method—An Empirical Case Study in a Nuclear Power Plant" Sustainability 14, no. 17: 11023. https://doi.org/10.3390/su141711023