Sawdust Recycling in the Development of Permeable Clay Paving Bricks: Optimizing Mixing Ratio and Particle Size

Abstract

1. Introduction

2. Materials and Methods

2.1. Clay Soil and Sawdust

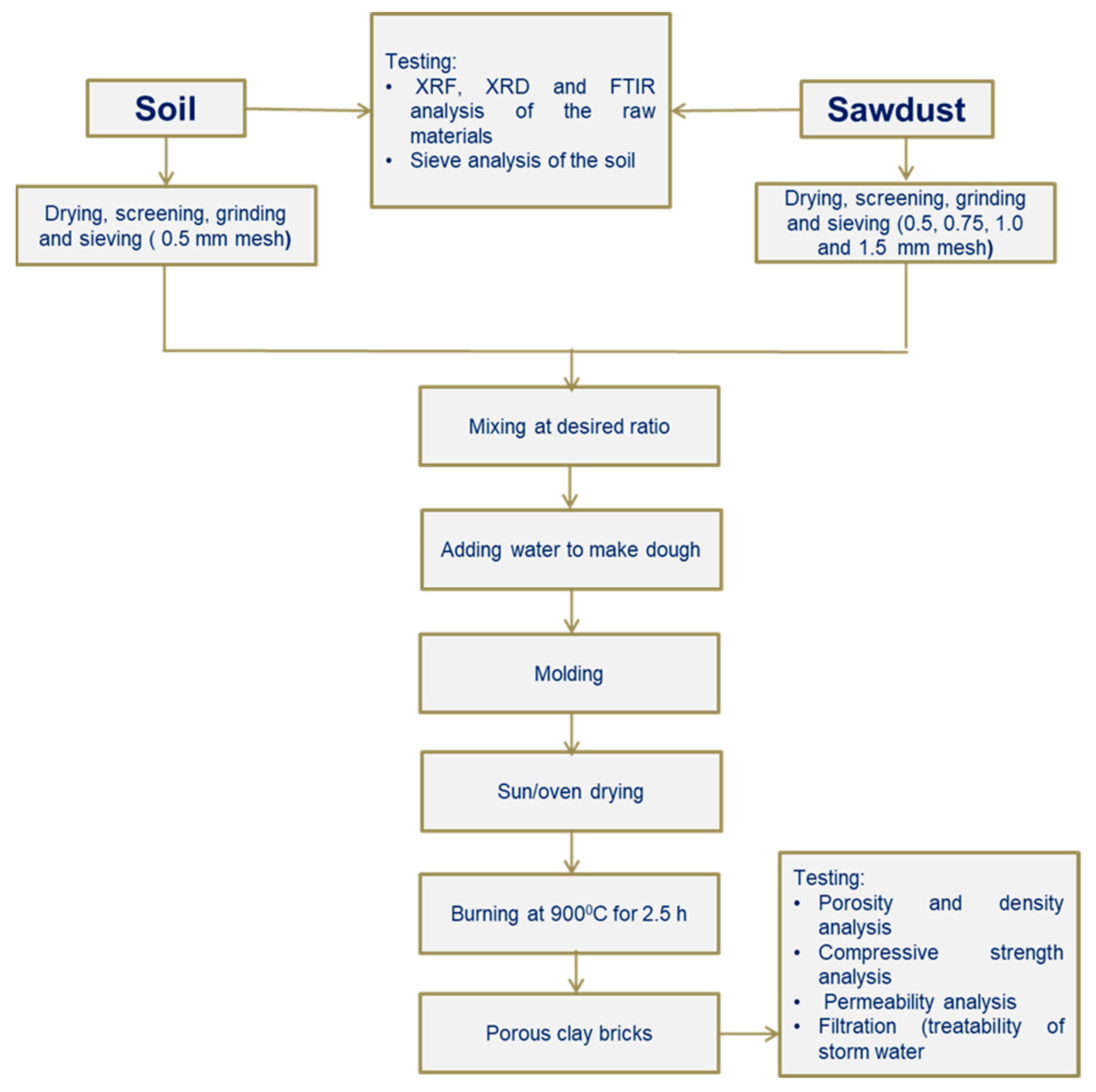

2.2. Porous Clay Bricks Manufacturing Process

2.3. Characterization of Raw Soil and Sawdust

2.3.1. Sieve Analysis of Soil

2.3.2. Chemical and Morphological Characterization of Soil and Sawdust

2.4. Characterization of Raw Soil and Sawdust

2.4.1. Apparent Porosity, Water Adsorption, and Bulk Density

2.4.2. Compressive Strength Tests

2.4.3. Permeability Test

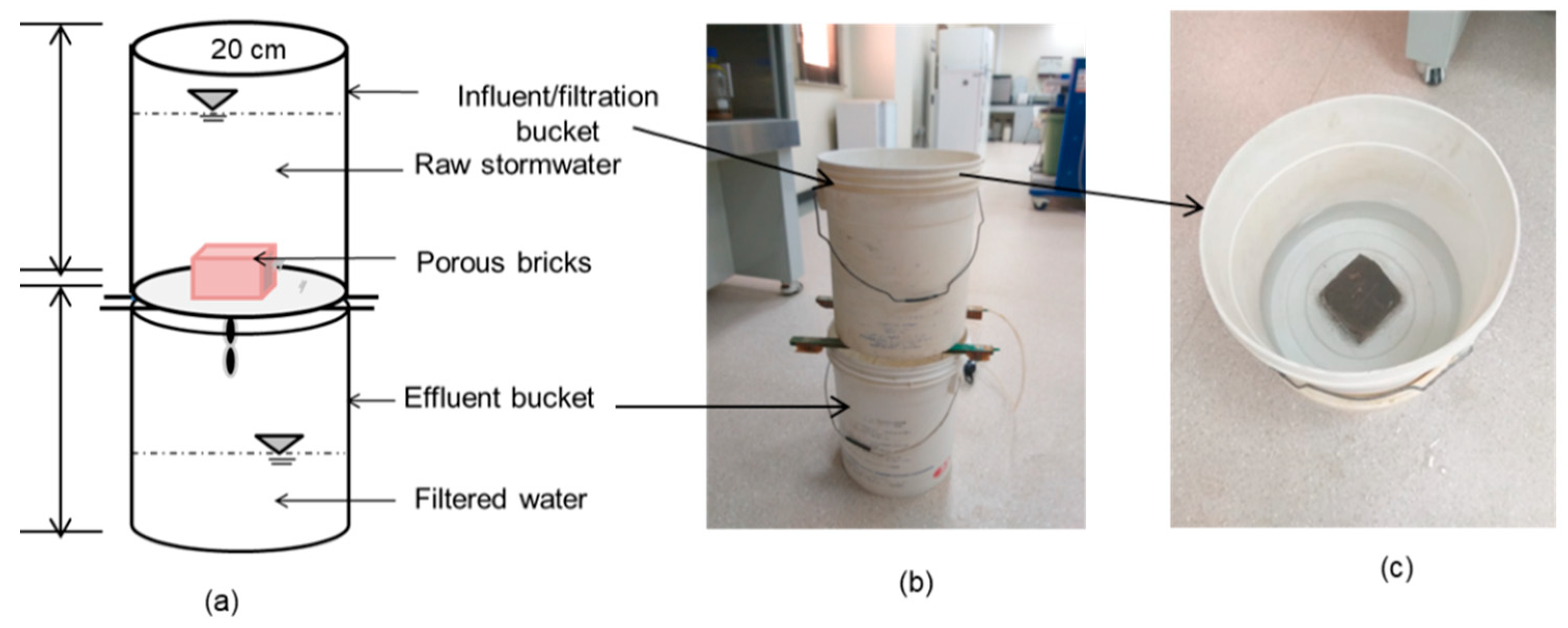

2.4.4. Stormwater (Runoff) Filtration Experiments

2.5. Water Quality Analysis

2.6. Statistical Analysis

3. Results and Discussions

3.1. Grain Size Distributions of Soil

3.2. Elemental Compositions of Soil and SD Samples

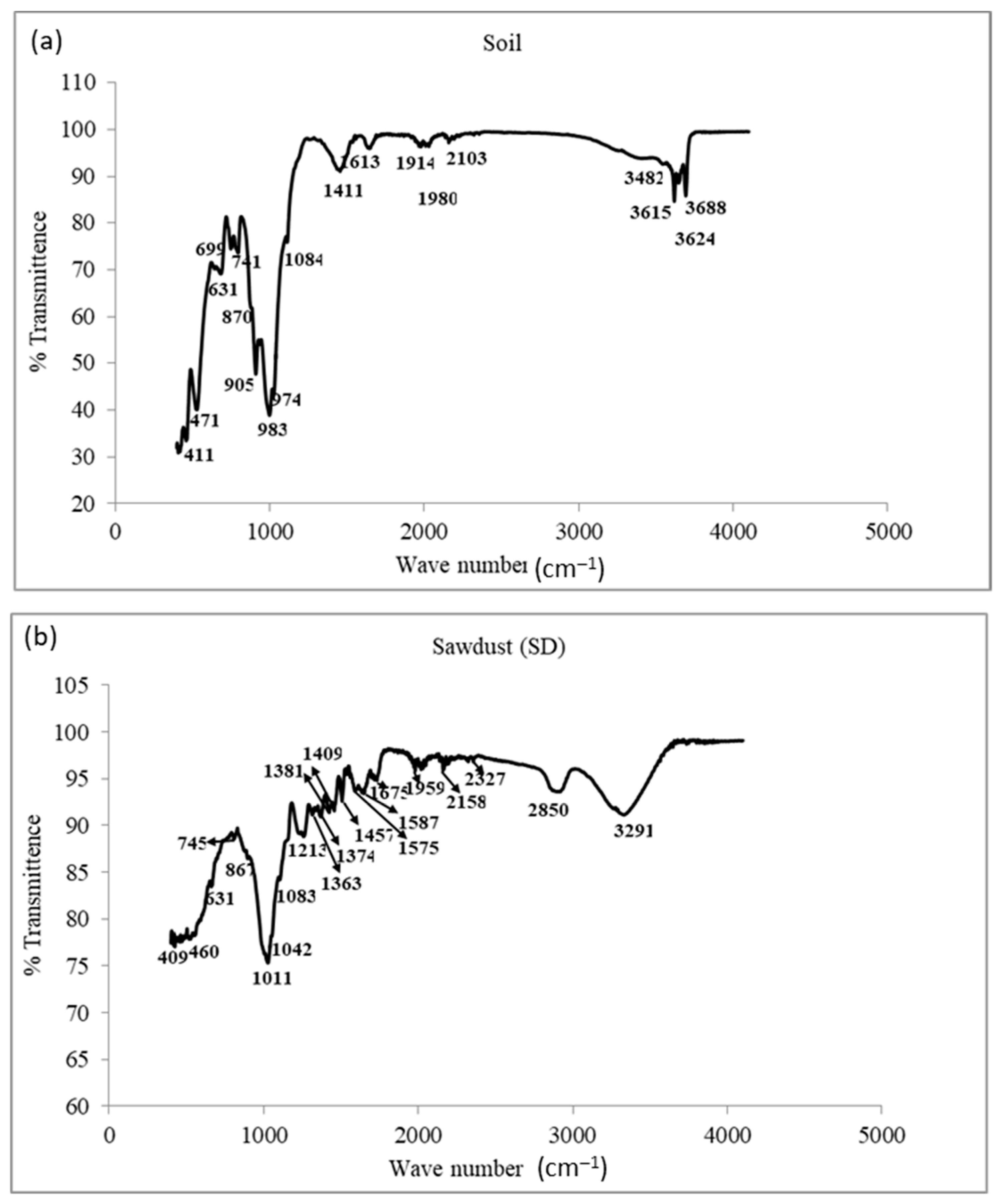

3.3. FTIR Analysis of Raw Soil and SD Samples

3.4. XRD Analysis of Raw Soil and SD Samples

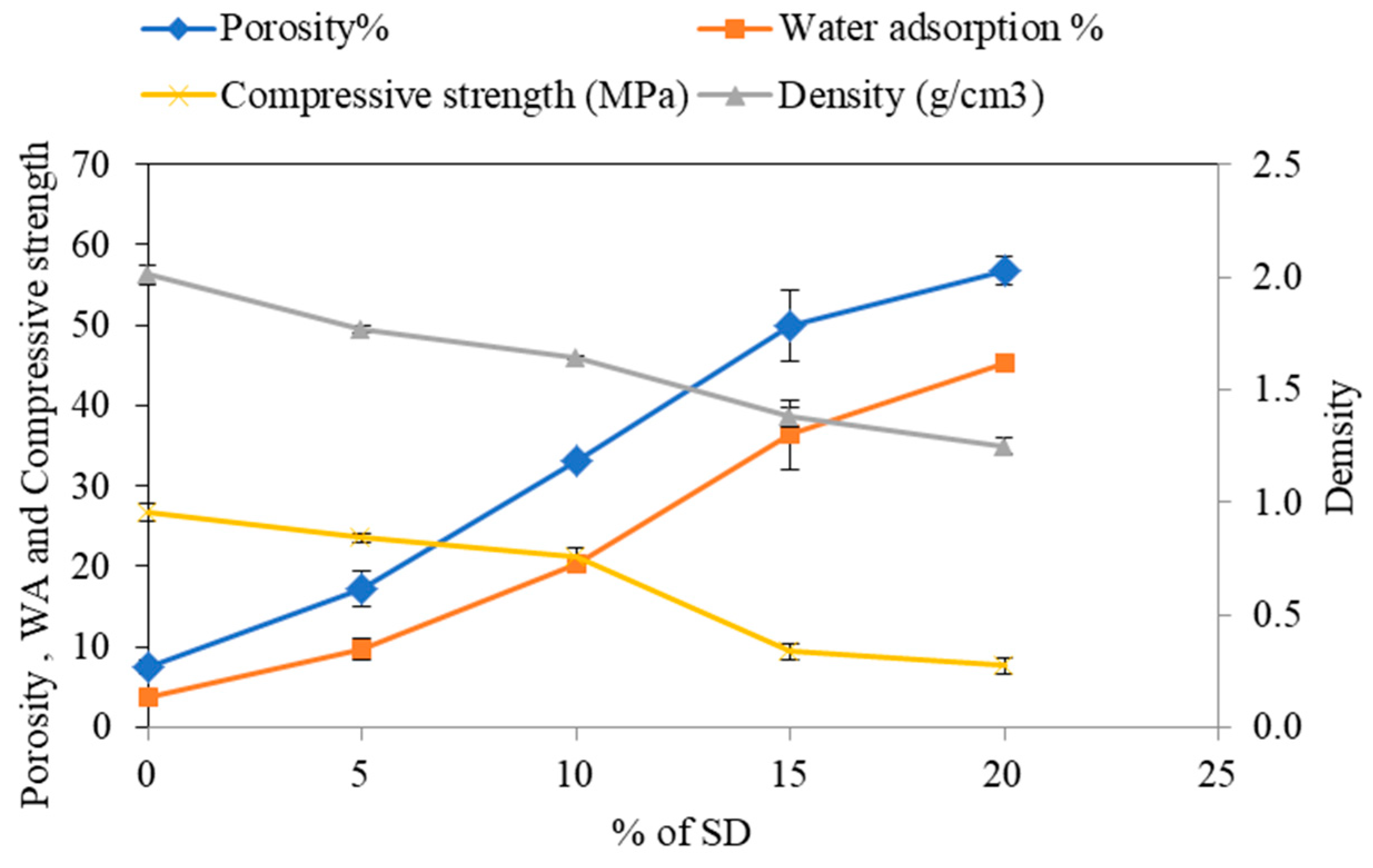

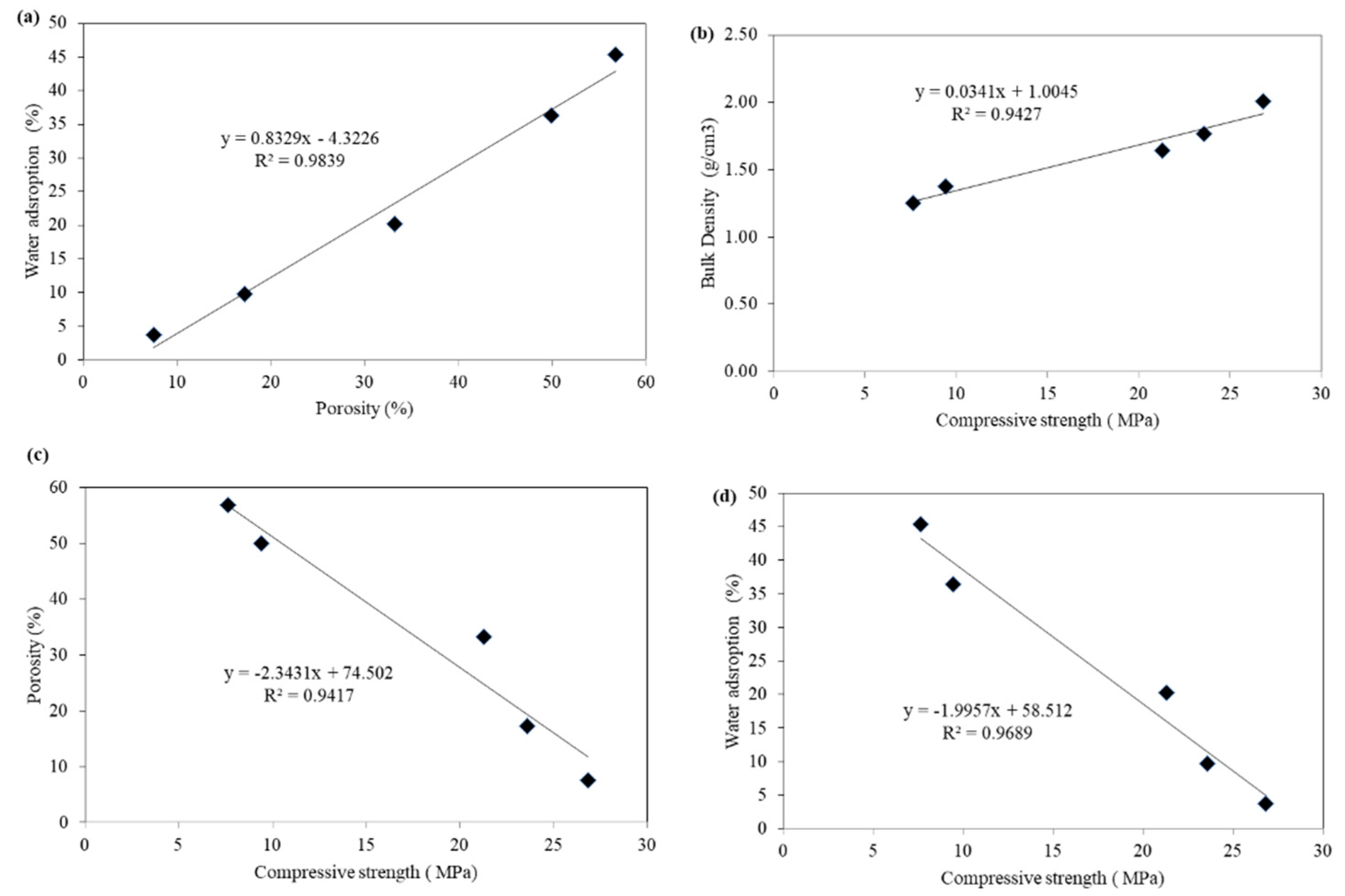

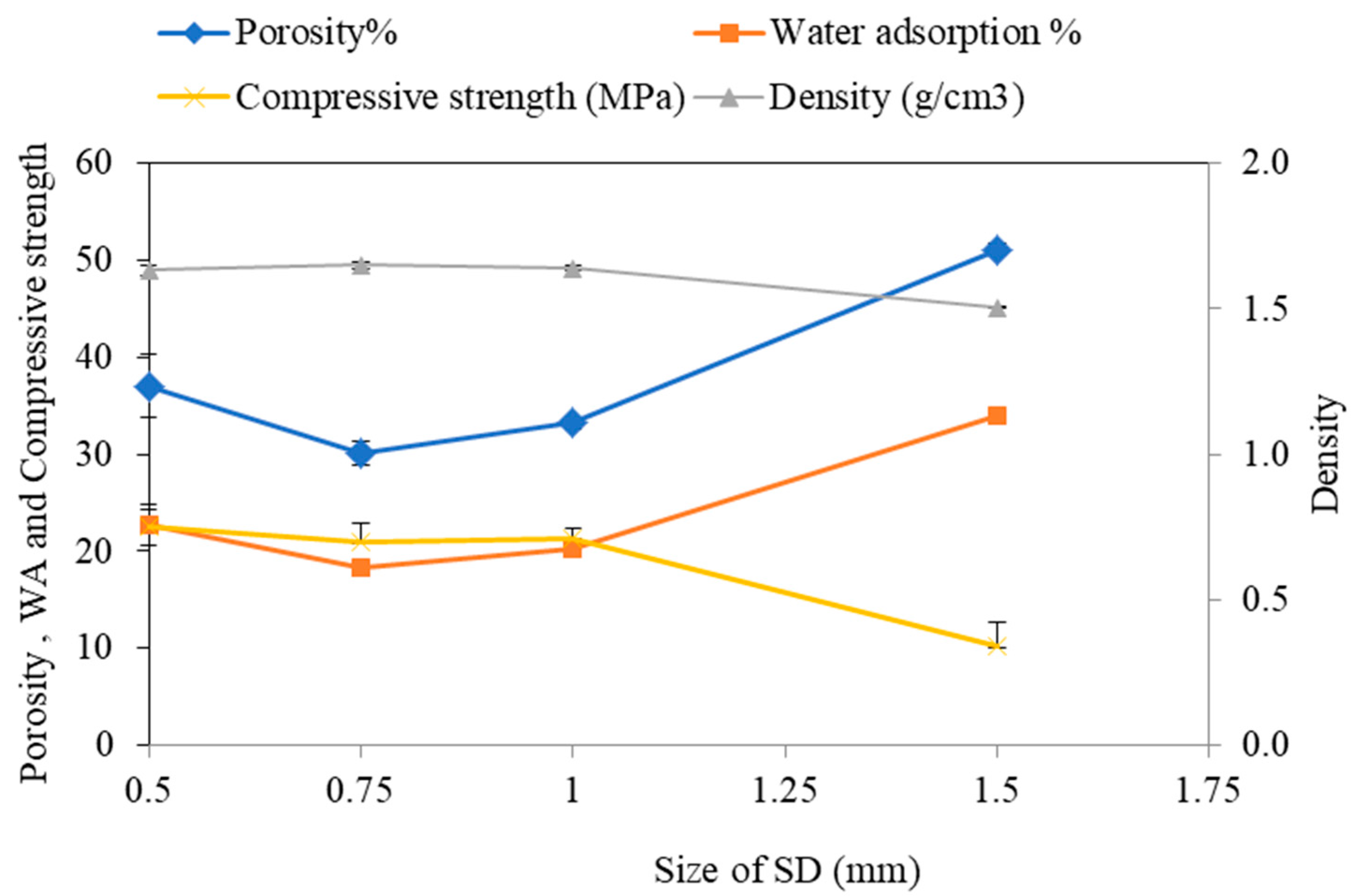

3.5. Properties of Bricks with Varying Percentages of Sawdust

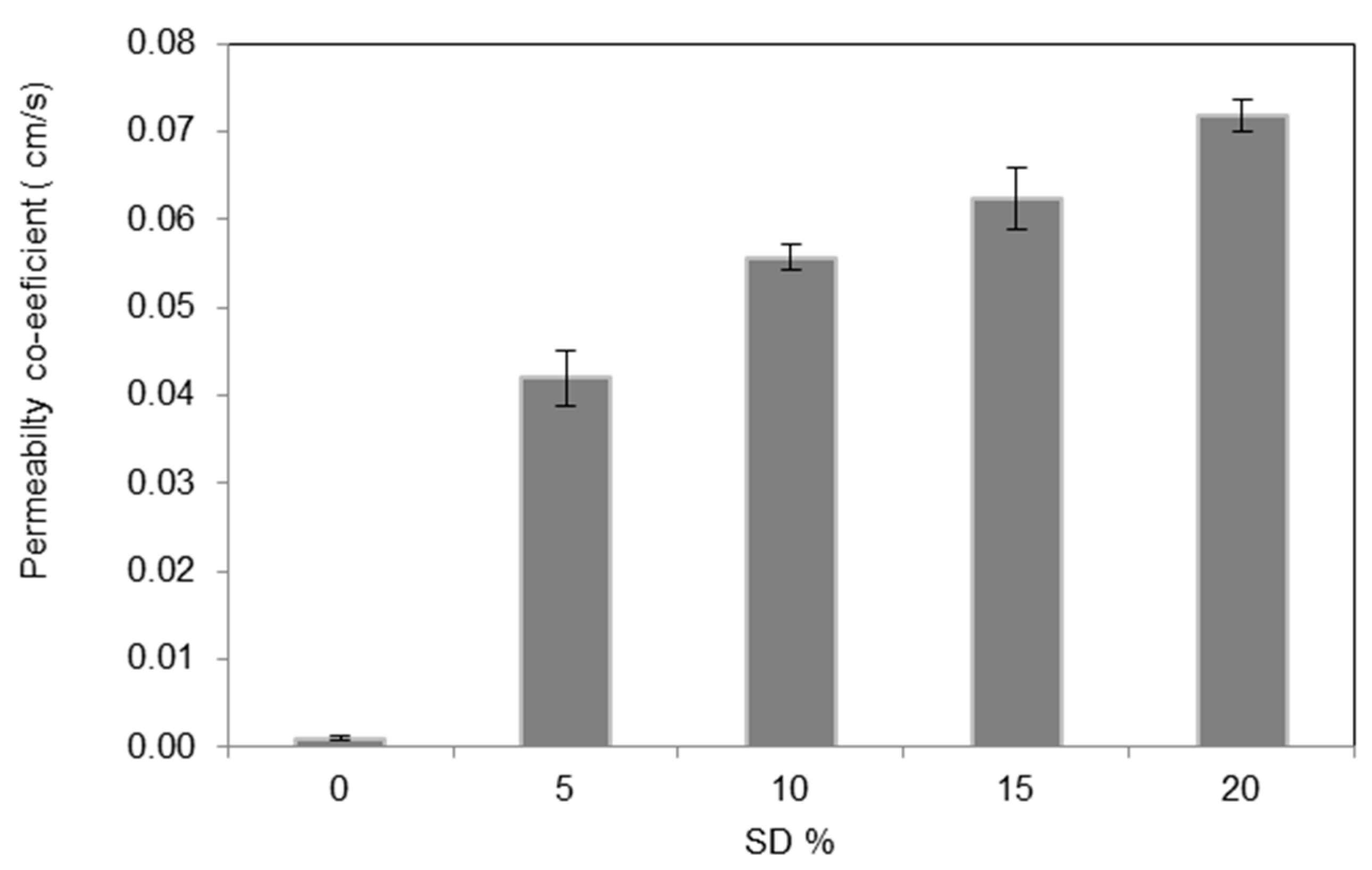

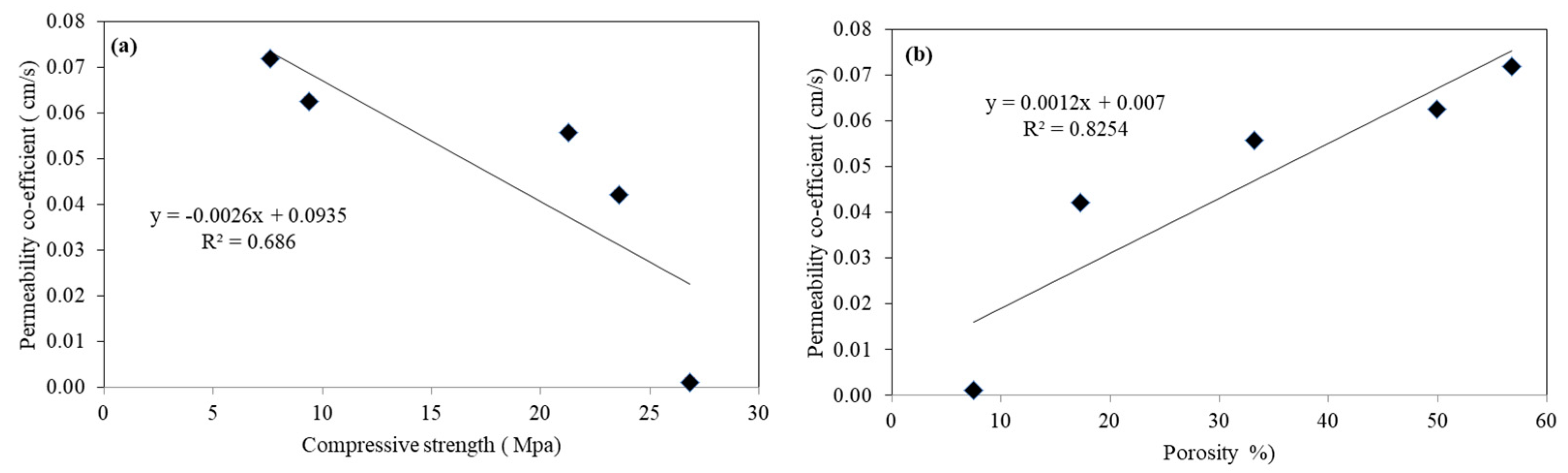

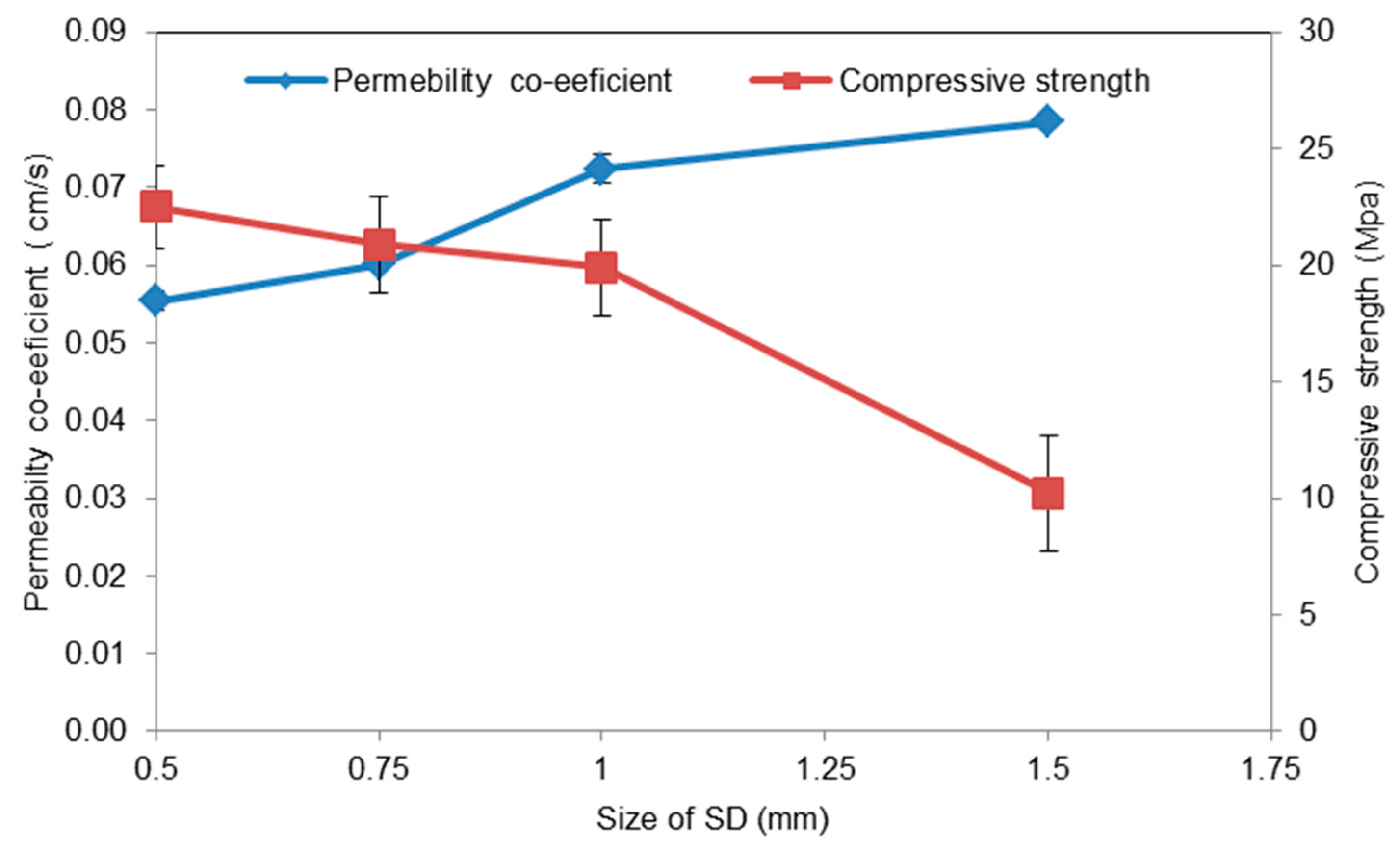

3.6. The Permeability Coefficient of Bricks Made of Soil with Varying % and Size of SD

3.7. Stormwater Treatment Efficiency of Selected Bricks

3.8. Comparison of the Key Properties of the Bricks between This Research and the Previous Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghumman, A.R.; Ghazaw, Y.M.; Alodah, A.; Rauf, A.U.; Shafiquzzaman, M.; Haider, H. Identification of Parameters of Evaporation Equations Using an Optimization Technique Based on Pan Evaporation. Water 2020, 12, 228. [Google Scholar] [CrossRef]

- Brabec, E.; Schulte, S.; Richards, P.L. Impervious surfaces and water quality: A review of current literature and its implications for watershed planning. J. Plan. Lit. 2002, 16, 499–514. [Google Scholar] [CrossRef]

- Newman, A.P.; Aitken, D.; Antizar-Ladislao, B. Stormwater quality performance of a macro-pervious pavement car park installation equipped with channel drain based oil and silt retention devices. Water Res. 2013, 47, 7327–7336. [Google Scholar] [CrossRef] [PubMed]

- Brattebo, B.O.; Booth, D.B. Long-term stormwater quantity and quality performance of permeable pavement systems. Water Res. 2003, 37, 4369–4376. [Google Scholar] [CrossRef]

- Haider, H.; Ghumman, A.R.; Al-Salamah, I.S.; Ghazaw, Y.; Abdel-Maguid, R.H. Sustainability evaluation of rainwater harvesting based flood risk management strategies: A multilevel decision-making framework for arid environments. Arab. J. Sci. Eng. 2019, 10, 8465–8488. [Google Scholar] [CrossRef]

- Mugume, S.N.; Gomez, D.E.; Fu, G.; Farmani, R.; Butler, D. A global analysis approach for investigating structural resilience in urban drainage systems. Water Res. 2015, 81, 15–26. [Google Scholar] [CrossRef]

- Bhatt, A.; Bradford, A.; Abbassi, B.E. Cradle to- grave life cycle assessment (LCA) of low-impact development (LID) technologies in southern Ontario. J. Environ. Manag. 2019, 231, 98–109. [Google Scholar] [CrossRef]

- Qin, Y. Urban flooding mitigation techniques: A systematic review and future studies. Water 2020, 12, 3579. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, L.; Hou, X.; Wei, G.; Zhang, X.; Shen, Z. Detailed quantification of the reduction effect of roof runoff by low impact development practices. Water 2020, 12, 795. [Google Scholar] [CrossRef]

- Hunt, W.F.; Traver, R.G.; Davis, A.P.; Emerson, C.H.; Collins, K.A.; Stagge, J.H. Low impact development practices: Designing to infiltrate in urban environments. In Effects of Urbanization on Groundwater: An Engineering Case-Based Approach for Sustainable Development; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 308–343. [Google Scholar]

- Locatelli, L.; Mark, O.; Mikkelsen, P.S.; Arnbjerg-Nielsen, K.; Deletic, A.; Roldin, M.; Binning, P.J. Hydrologicimpact of urbanization with extensive storm water infiltration. J. Hydrol. 2017, 544, 524–537. [Google Scholar] [CrossRef]

- USEPA. Green Infrastructure in the Semi-Arid West, Low-Impact Development and Green Infrastructure in the Semi-Arid West. Available online: https://www.epa.gov/green-infrastructure/green-infrastructure-semi-arid-west#6 (accessed on 20 November 2020).

- Antunes, L.N.; Ghisi, E.; Thives, L.P. Permeable pavements life cycle assessment: A literature review. Water 2018, 10, 1575. [Google Scholar] [CrossRef]

- Mullaney, J.; Lucke, T. Practical Review of Pervious Pavement Designs. CLEAN Soil Air Water 2013, 42, 111–124. [Google Scholar] [CrossRef]

- Zhang, K.; Yong, F.; McCarthy, D.T.; Deletic, A. Predicting long term removal of heavy metals from porous pavements for stormwater treatment. Water Res. 2018, 142, 236–245. [Google Scholar] [CrossRef]

- Pagotto, C.; Legret, M.; Le Cloirec, P. Comparison of the hydraulic behaviour and the quality of highway runoff water according to the type of pavement. Water Res. 2000, 34, 4446–4454. [Google Scholar] [CrossRef]

- Rushton, B. Low-impact parking lot design reduces runoff and pollutant loads. J. Water Resour. Plan. Manag. 2000, 127, 172–179. [Google Scholar] [CrossRef]

- Shafiquzzaman, M.; Alqarawi, S.M.A.; Haider, H.; Rafiquzzaman, M.; Almoshaogeh, M.; Alharbi, F.; El-Ghoul, Y. Evaluating Permeable Clay Brick Pavement for Pollutant Removal from Varying Strength Stormwaters in Arid Regions. Water 2022, 14, 491. [Google Scholar] [CrossRef]

- Han, S.; Yang, Y.; Liu, S.; Lu, M. Decontamination performance and cleaning characteristics of three common used paved permeable bricks. Environ. Sci. Pollut. Res. 2020, 28, 15114–15122. [Google Scholar] [CrossRef]

- Fwa, T.F.; Lim, E.; Tan, K.H. Comparison of permeability and clogging characteristics of porous asphalt and pervious concrete pavement materials. Transp. Res. Rec. J. Transp. Res. Board 2015, 2511, 72–80. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material—Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Drake, J.A.P.; Bradford, A.; Marsalek, J. Reviewof environmental performance of permeable pavementsystems: State of the knowledge. Water Qual. Res. J. 2013, 48, 203–222. [Google Scholar] [CrossRef]

- Li, F.; Liu, Y.; Engel, B.A.; Chen, J.; Sun, H. Green infrastructure practices simulation of the impacts of landuse on surface runoff: Case study in Ecorse River watershed, Michigan. J. Environ. Manag. 2019, 233, 603–611. [Google Scholar] [CrossRef] [PubMed]

- Dondi, M.; Guarini, G.; Raimondo, M.; Zanelli, C.; Fabbriche, D.D.; Agostini, A. Recycling the insoluble residue from titania slag dissolution (tionite) in clay bricks. Ceram. Int. 2010, 36, 2461–2467. [Google Scholar] [CrossRef][Green Version]

- Faria, K.C.P.; Gurgel, R.F.; Holanda, J.N.F. Recycling of sugarcane bagasse ash waste in the production of clay bricks. J. Environ. Manag. 2012, 101, 7–12. [Google Scholar] [CrossRef]

- Bories, C.; Borredon, M.E.; Vedrenne, E.; Vilarem, G. Development of eco-friendly porous fired clay bricks using pore-forming agents: A review. J. Environ. Manag. 2014, 143, 186–196. [Google Scholar] [CrossRef]

- Thalmaiera, G.; Cobîrzana, N.; Baloga, A.A.; Constantinescua, H.; Strezab, M.; Nasuia, M.; Neamtua, B.V. Influence of sawdust particle size on fired clay brick properties. Mater. Constr. 2020, 70, 338. [Google Scholar] [CrossRef]

- Beal, B.; Selby, A.; Atwater, C.; James, C.; Viens, C.; Almquist, C. A Comparison of thermal and mechanical properties of clay bricks prepared with three different pore-forming additives: Vermiculite, wood ash, and sawdust. Environ. Prog. Sustain. Energy 2019, 38, 13150. [Google Scholar] [CrossRef]

- Maza-Ignacio, O.T.; Jiménez-Quero, V.G.; Guerrero-Paz, J.; Montes-García, P. Recycling untreated sugarcane bagasse ash and industrial wastes for the preparation of resistant, lightweight and ecological fired bricks. Constr. Build. Mater. 2020, 234, 117314. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Yu, C.; Qi, J.; Yang, C.; Cheng, B.; Liang, S. Global timber harvest footprints of nations and virtual timber trade flows. J. Clean. Prod. 2020, 250, 119503. [Google Scholar] [CrossRef]

- Penna, I. Understanding the FAO’s Wood Supply from Planted Forests Projections, 1st ed.; Centre for Environmental Management, University of Ballarat: Ballarat, Australia, 2010; Volume 2010. [Google Scholar]

- Rominiyi, O.L.; Adaramola, B.A.; Ikumapayi, O.M.; Oginni, O.T.; Akinola, S.A. Potential Utilization of Sawdust in Energy, Manufacturing and Agricultural Industry; Waste to Wealth. World J. Eng. Technol. 2017, 5, 526–539. [Google Scholar] [CrossRef]

- Mwango, A.; Kambole, C. Engineering Characteristics and Potential Increased Utilisation of Sawdust Composites in Construction—A Review. J. Build. Constr. Plan. Res. 2019, 7, 59–88. [Google Scholar] [CrossRef]

- Chemani, B.; Chemani, H. Effect of adding sawdust on mechanical-physical properties of ceramic bricks to obtain lightweight building material. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2012, 6, 2521–2525. [Google Scholar]

- Chemani, H.; Chemani, B. Valorization of wood sawdust in making porous clay brick. Sci. Res. Essays 2013, 8, 609–614. [Google Scholar]

- Herek, L.C.S.; Hori, C.E.; Reis, M.H.M.; Mora, N.D.; Tavares, C.R.G.; Bergamasco, R. Characterization of ceramic bricks incorporated with textile laundry sludge. Ceram. Int. 2012, 38, 951–959. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, C.; Xu, B.; Ruan, X.; Wei, Z. The use of urban river sediments as a primary raw material in the production of highly insulating brick. Ceram. Int. 2014, 40, 8833–8840. [Google Scholar] [CrossRef]

- Velasco, P.M.; Morales Ortíz, M.P.; Mendívil Giró, M.A.; Muñoz Velasco, L. Fired clay bricks manufactured by adding wastes as sustainable construction material—A review. Constr. Build. Mater. 2014, 63, 97–107. [Google Scholar] [CrossRef]

- ASTM D422-63; Standard Test Method for Particle-Size Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- ASTM C20-00; Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM C67-05; Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile. ASTM International: West Conshohocken, PA, USA, 2005.

- ASTM D2434-68; Standard Test Method for Permeability of Granular Soils (Constant Head). ASTM International: West Conshohocken, PA, USA, 2006.

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater, 21st ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Farmer, V.C. Transverse and Longitudinal Crystal Modes Associated with OH Stretching Vibrations in Single Crystals of Kaolinite and Dickite. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2000, 56, 927–930. [Google Scholar] [CrossRef]

- Jozanikohan, G.; Abarghooei, M.N. The Fourier transform infrared spectroscopy (FTIR) analysis for the clay mineralogy studies in a clastic reservoir. J. Pet. Explor. Prod. Technol. 2022, 12, 2093–2106. [Google Scholar] [CrossRef]

- Ji, J.; Ge, Y.; Balsam, W.; Damuth, J.E.; Chen, J. Rapid identification of dolomite using a Fourier transform infrared spectrophotometer (FTIR): A fast method for identifying Heinrich events in IODP Site U1308. Mar. Geol. 2009, 258, 60–68. [Google Scholar] [CrossRef]

- Akhouairi, S.; Ouachtak, H.; Addi, A.A.; Jada, A.; Douch, J. Natural Sawdust as Adsorbent for the Eriochrome Black T Dye Removal from Aqueous Solution. Water Air Soil Pollut. 2019, 230, 181. [Google Scholar] [CrossRef]

- Rahman, N.U.; Ullah, I.; Alam, S.; Khan, M.S.; Shah, L.A.; Zekker, I.; Burlakovs, J.; Kallistova, A.; Pimenov, N.; Vincevica-Gaile, Z.; et al. Activated Ailanthus altissima Sawdust as Adsorbent for Removal of Acid Yellow 29 from wastewater: Kinetics Approach. Water 2021, 13, 2136. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, S.; Chen, Z.; Wang, M.; Cao, J.; Wang, R. Preparation and Characterization of Superabsorbent Polymers Based on Sawdust. Polymers 2019, 11, 1891. [Google Scholar] [CrossRef] [PubMed]

- Alharbi, F.; Almoshaogeh, M.; Shafiquzzaman, M.; Haider, H.; Rafiquzzaman, M.; Al-Ragi, A.; ElKholy, S.; Bayoumi, E.-S.A.; El-Ghoul, Y. Development of rice bran mixed porous clay bricks for permeable pavements: A sustainable LID technique for Arid Regions. Sustainability 2021, 13, 1443. [Google Scholar] [CrossRef]

- Khoo, Y.C.; Johari, I.; Ahmad, Z.A. Influence of Rice Husk Ash on the Engineering Properties of Fired-Clay Brick. Adv. Mater. Res. 2013, 795, 14–18. [Google Scholar] [CrossRef]

- ASTM C902-15; Standard Specification for Pedestrian and Light Traffic Paving Brick. ASTM International: West Conshohocken, PA, USA, 2015.

- Mayne, P.W.; Christopher, B.R.; DeJong, J. Manual on Subsurface Investigations; Publication No. FHWA NHI-01-031; National Highway Institute, Federal Highway Administration: Washington, DC, USA, 2001; p. 305. [Google Scholar]

- World Health Organization (WHO). Excreta and Greywater Use in Agriculture. In Guidelines for the Safe Use of Wastewater Excreta and Greywater; WHO: Geneva, Switzerland, 2006; Volume 4. [Google Scholar]

- Ministry of Water and Electricity (MWE). Technical Guidelines for the Use of Treated Sanitary Wastewater in Irrigation for Landscaping and Agricultural Irrigationl; Ministry of Water and Electricity: Riyadh, Saudi Arabia, 2006. [Google Scholar]

- Ogunmodede, O.T.; Adebayo, O.L.; Ojo, A.A. Enhancing adsorption capacity of clay and application in dye removal from wastewater. Int. Lett. Chem. Phys. Astron. 2014, 39, 35–51. [Google Scholar] [CrossRef]

- Zhang, Z.; Wong, Y.C.; Arulrajah, A.; Horpibulsuk, S. A review of studies on bricks using alternative materials and approaches. Constr. Build. Mater. 2018, 188, 1101–1118. [Google Scholar] [CrossRef]

- Yang, C.; Cui, C.; Qin, J.; Cui, X. Characteristics of the fired bricks with low-silicon iron tailings. Constr. Build. Mater. 2014, 70, 36–42. [Google Scholar] [CrossRef]

- Zhou, W.; Yang, F.; Zhu, R.; Dai, G.; Wang, W.; Wang, W.; Guo, X.; Jiang, J.; Wang, Z. Mechanism analysis of pore structure and crystalline phase of thermal insulation bricks with high municipal sewage sludge content. Constr. Build. Mater. 2020, 263, 120021. [Google Scholar] [CrossRef]

- Muñoz, P.; Letelier, V.; Zamora, D.; Morales, M.P. Feasibility of using paper pulp residues into fired clay bricks. J. Clean. Prod. 2020, 262, 121464. [Google Scholar] [CrossRef]

- Gorhan, G.; Simsek, O. Porous clay bricks manufactured with rice husks. Constr. Build. Mater. 2013, 40, 390–396. [Google Scholar] [CrossRef]

- Tang, C.W. Properties of fired bricks incorporating TFT-LCD waste glass powder with reservoir sediments. Sustainability 2018, 10, 2503. [Google Scholar] [CrossRef]

- Lin, K.L.; Chang, J.C.; Shie, J.L.; Chen, H.J.; Ma, C.M. Characteristics of porous ceramics produced from waste diatomite and water purification sludge. Environ. Eng. Sci. 2012, 29, 436–446. [Google Scholar] [CrossRef]

| Brick Name | SD Size (mm) | Soil (% by wt.) | SD (% by wt.) | |

|---|---|---|---|---|

| SD0 | 1.0 | 100 | 0 | |

| SD5 | 95 | 5 | ||

| Series 1 | SD10 | 90 | 10 | |

| SD15 | 85 | 15 | ||

| SD20 | 80 | 20 | ||

| SD-S0.5 | 0.5 | 90 | 10 | |

| Series 2 | SD-S0.75 | 0.75 | 90 | |

| SD-S1.0 | 1.0 | 90 | ||

| SD-S1.5 | 1.5 | 90 |

| Soil Characteristics | Values |

|---|---|

| D10 | 0.06 |

| D30 | 0.14 |

| D60 | 0.22 |

| Cu | 3.67 |

| Cc | 1.48 |

| Gravel (%) | 0.0 |

| Medium sand (%) | 18.8 |

| Fine sand (%) | 63.7 |

| Clay/silt (%) | 17.5 |

| Compositions (%) | Soil | SD |

|---|---|---|

| Silica (SiO2) | 50.47 | 33.11 |

| Alumina (Al2O3) | 19.14 | 16.38 |

| Iron oxide (Fe2O3) | 8.87 | 9.56 |

| Calcium oxide (CaO) | 3.2 | 28.08 |

| Magnesium oxide (MgO) | 3.27 | 0 |

| Others | 11.05 | 12.87 |

| Brick Specimens | Soil (%) | SD (%) | SD SIZE (mm) | Permeability Coefficient (cm/s) | Compressive Strength (MPa) | Meet the Standards (Y/N) |

|---|---|---|---|---|---|---|

| SD0 | 100 | 0 | 1.00 | 0.0010 | 26.8 | N |

| SD5 | 95 | 5 | 1.00 | 0.0420 | 23.6 | Y |

| SD10 | 90 | 10 | 1.00 | 0.0556 | 21.2 | Y |

| SD15 | 85 | 15 | 1.00 | 0.0624 | 9.4 | N |

| SD20 | 80 | 20 | 1.00 | 0.0718 | 7.6 | N |

| SD-S0.5 | 90 | 10 | 0.50 | 0.0554 | 22.5 | Y |

| SD-S0.75 | 90 | 10 | 0.75 | 0.0601 | 20.8 | Y |

| SD-S1.0 | 90 | 10 | 1.00 | 0.0724 | 19.8 | Y |

| SD-S1.5 | 90 | 10 | 1.50 | 0.0785 | 10.2 | N |

| Parameters | Unit | Observed Values | After Filtration | Removal Efficiency (%) | Wastewater Reuse Standard of KSA [55] | Wastewater Reuse Standard of WHO [54] |

|---|---|---|---|---|---|---|

| pH | - | 8.1 | 7.9 | - | 6.0–8.4 | 6.0–9.0 |

| TSS | mg/L | 549.7 | 7.9 | 98.6 | 10 | - |

| EC | us/cm | 595.7 | 548.0 | 8.1 | - | |

| DO | mg/L | 6.7 | 6.2 | 7.2 | - | |

| Turbidity | NTU | 34.5 | 1.1 | 96.8 | 5 | 5 |

| TDS | mg/L | 416.2 | 407.7 | 2.0 | 2500 | 2500 |

| BOD5 | mg/L | 44 | 9.8 | 77.7 | 10 | - |

| TN | mg/L | 7.0 | 5.0 | 28.2 | 40 | - |

| TP | mg/L | 2.1 | 1.4 | 33.6 | - | - |

| Waste Materials | Ratio (%) | Key Properties of the Bricks | References | |||

|---|---|---|---|---|---|---|

| Density (g/cm3) | Water Adsorption (%) | Porosity (%) | Compressive Strength (MPa) | |||

| Sawdust | 0–10 | 1.4–1.88 | 9.02–27.2 | 15.7–39.6 | 4.1–36.63 | [57] |

| Fly ash | 0–20 | 1.85–2.07 | 15.2–17.5 | 28–32.5 | 16–26 | [58] |

| Sewage sludge | 35–50 | 0.22–0.29 | 6–13.8 | - | 8.5–12.5 | [59] |

| Residual Pulp | 0–20 | 1.21–1.7 | 13–27 | - | 3–11.5 | [60] |

| Rice husk | 10 | - | 22–27 | - | 7–8 | [61] |

| Glass waste | 0–30 | 2.21–2.24 | 12.9–14.5 | - | 35.2–48.2 | [62] |

| Water treatment sludge | 0–20 | 0.74–0.97 | 51–91 | 50–67 | 3–18 | [63] |

| Rice Bran | 0–20 | 1.3–1.9 | 10.5–39.3 | 10.1–59.1 | 6.98–29.7 | [50] |

| Sawdust | 0–20 | 1.25–2.01 | 3.71–45 | 7.47–56 | 6.5–27.5 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shafiquzzaman, M.; Alqarawi, S.M.A.; Haider, H.; Rafiquzzaman, M.; Almoshaogeh, M.; Alharbi, F.; EL-Ghoul, Y. Sawdust Recycling in the Development of Permeable Clay Paving Bricks: Optimizing Mixing Ratio and Particle Size. Sustainability 2022, 14, 11115. https://doi.org/10.3390/su141811115

Shafiquzzaman M, Alqarawi SMA, Haider H, Rafiquzzaman M, Almoshaogeh M, Alharbi F, EL-Ghoul Y. Sawdust Recycling in the Development of Permeable Clay Paving Bricks: Optimizing Mixing Ratio and Particle Size. Sustainability. 2022; 14(18):11115. https://doi.org/10.3390/su141811115

Chicago/Turabian StyleShafiquzzaman, Md., Saad Mohammed A. Alqarawi, Husnain Haider, Md. Rafiquzzaman, Meshal Almoshaogeh, Fawaz Alharbi, and Yassine EL-Ghoul. 2022. "Sawdust Recycling in the Development of Permeable Clay Paving Bricks: Optimizing Mixing Ratio and Particle Size" Sustainability 14, no. 18: 11115. https://doi.org/10.3390/su141811115

APA StyleShafiquzzaman, M., Alqarawi, S. M. A., Haider, H., Rafiquzzaman, M., Almoshaogeh, M., Alharbi, F., & EL-Ghoul, Y. (2022). Sawdust Recycling in the Development of Permeable Clay Paving Bricks: Optimizing Mixing Ratio and Particle Size. Sustainability, 14(18), 11115. https://doi.org/10.3390/su141811115