Structural Behavior of LC-GFRP Confined Waste Aggregate Concrete Square Columns with Sharp and Round Corners

Abstract

:1. Introduction

2. Experimental Program

2.1. Test Matrix

2.2. Material Properties

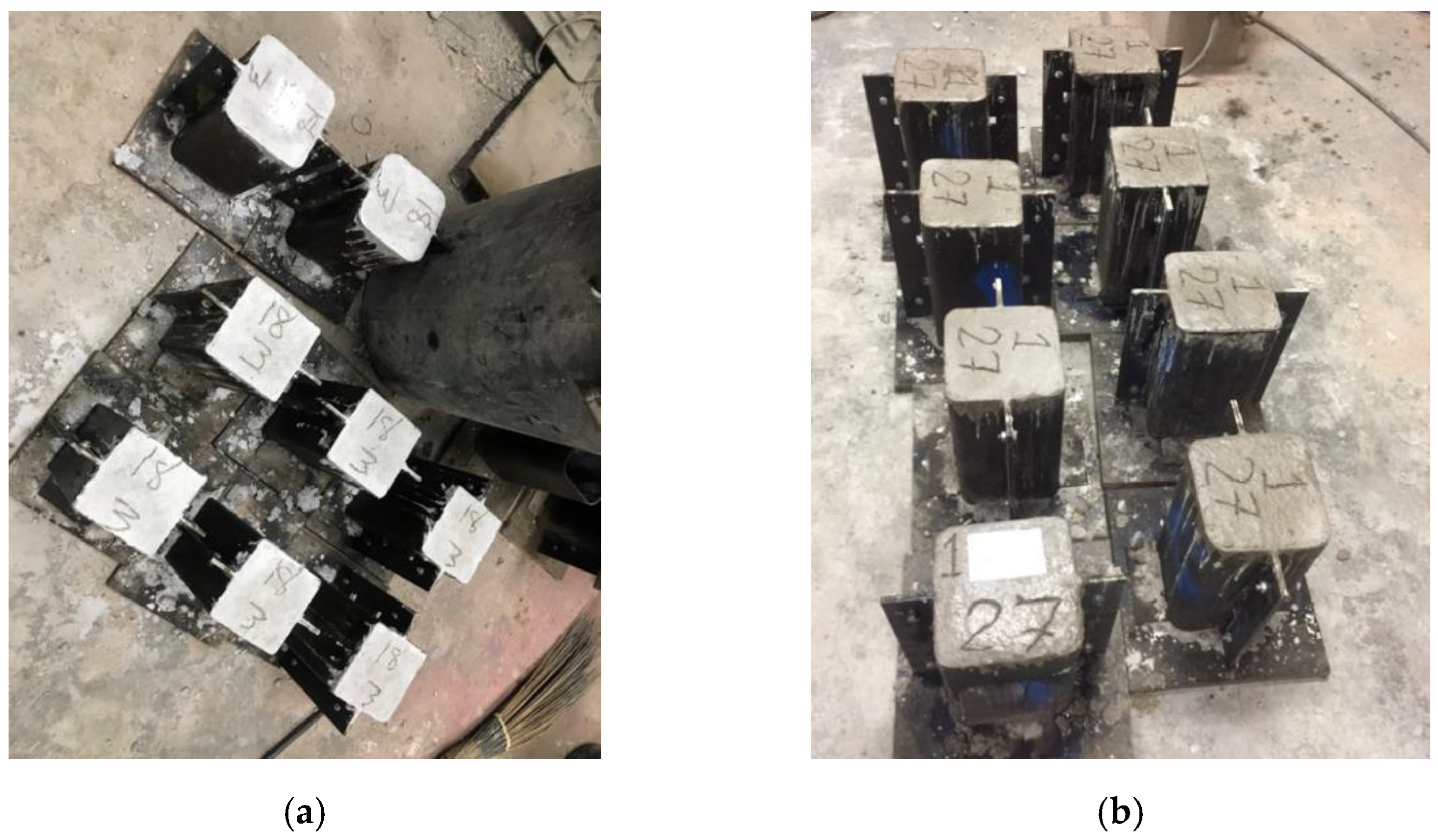

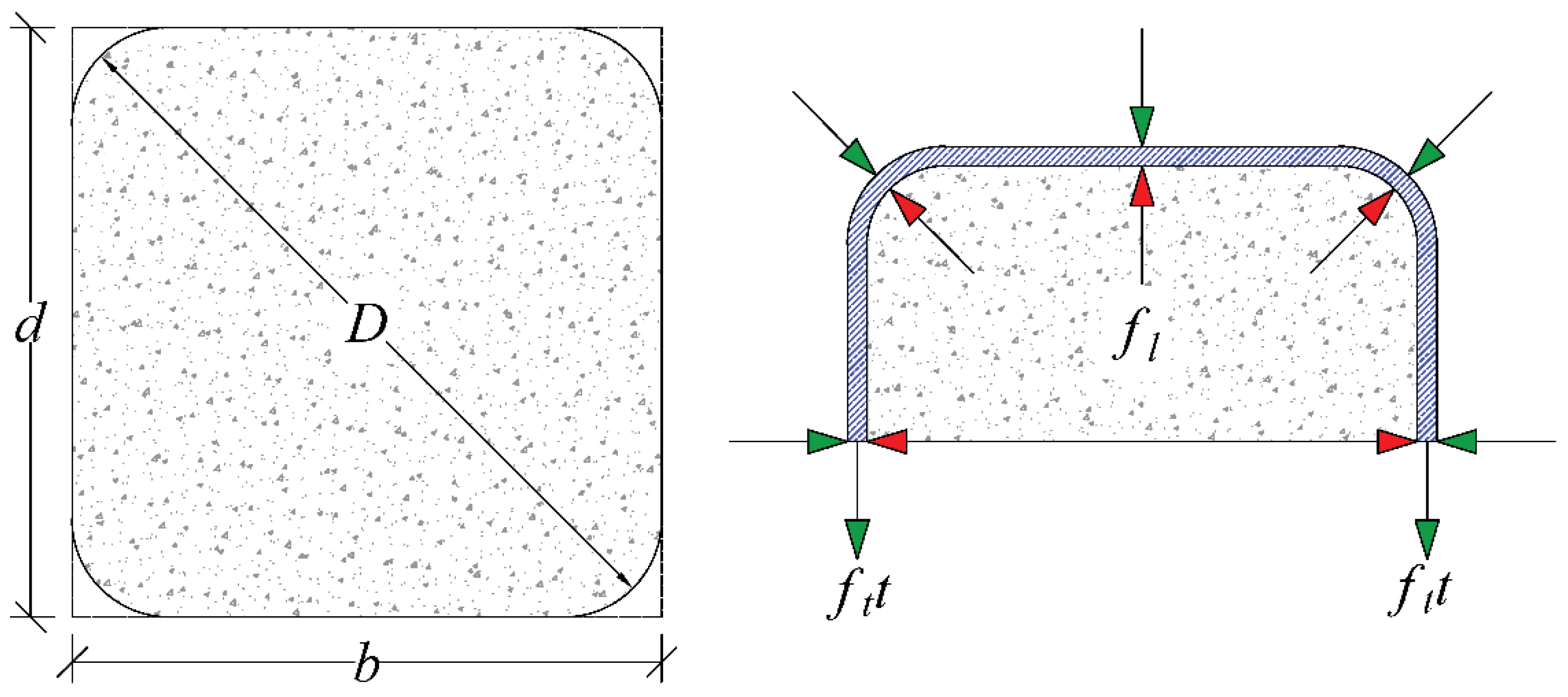

2.3. Details and Construction of Test Specimens

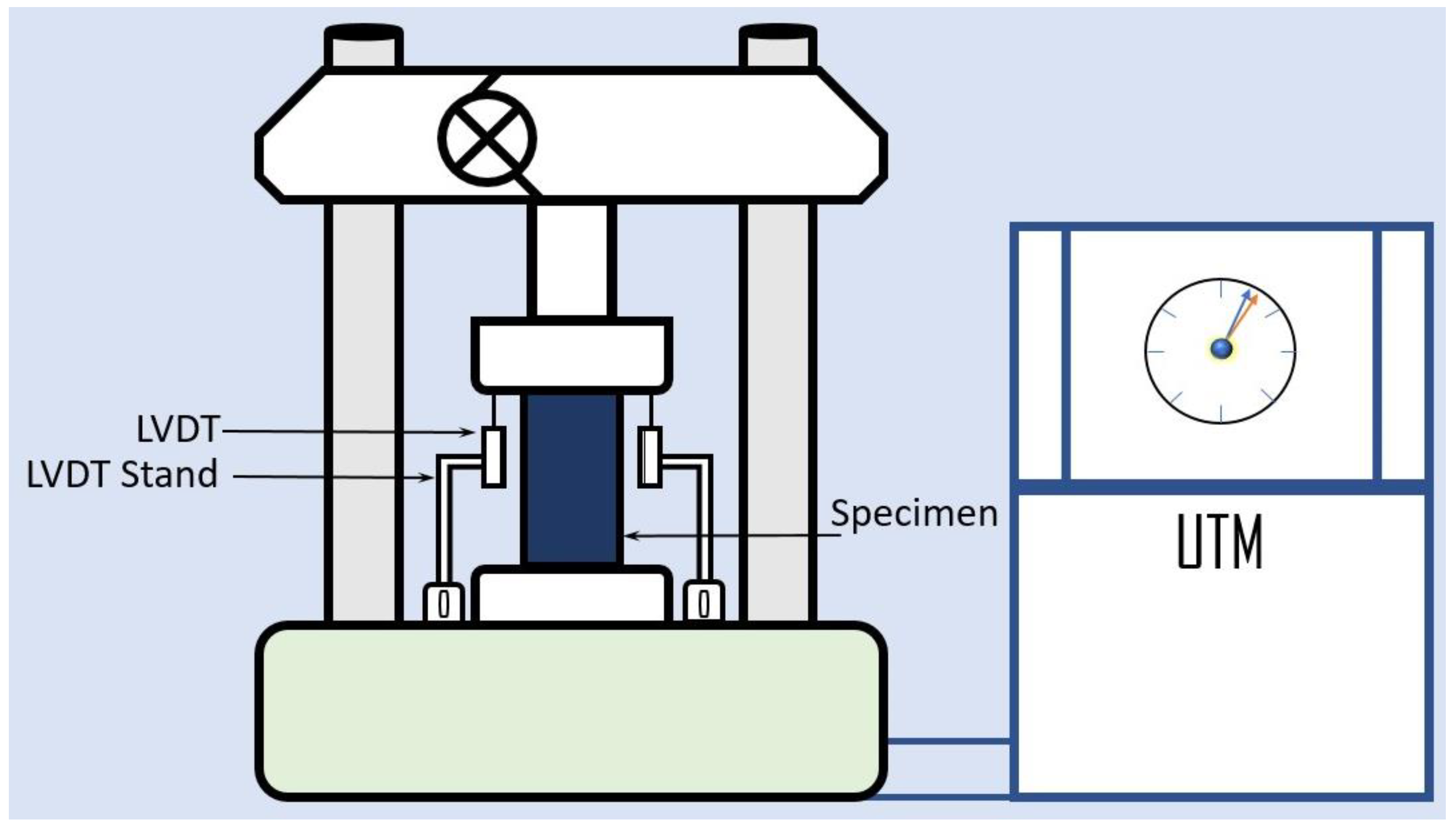

2.4. Test Setup and Instrumentation

3. Experimental Results

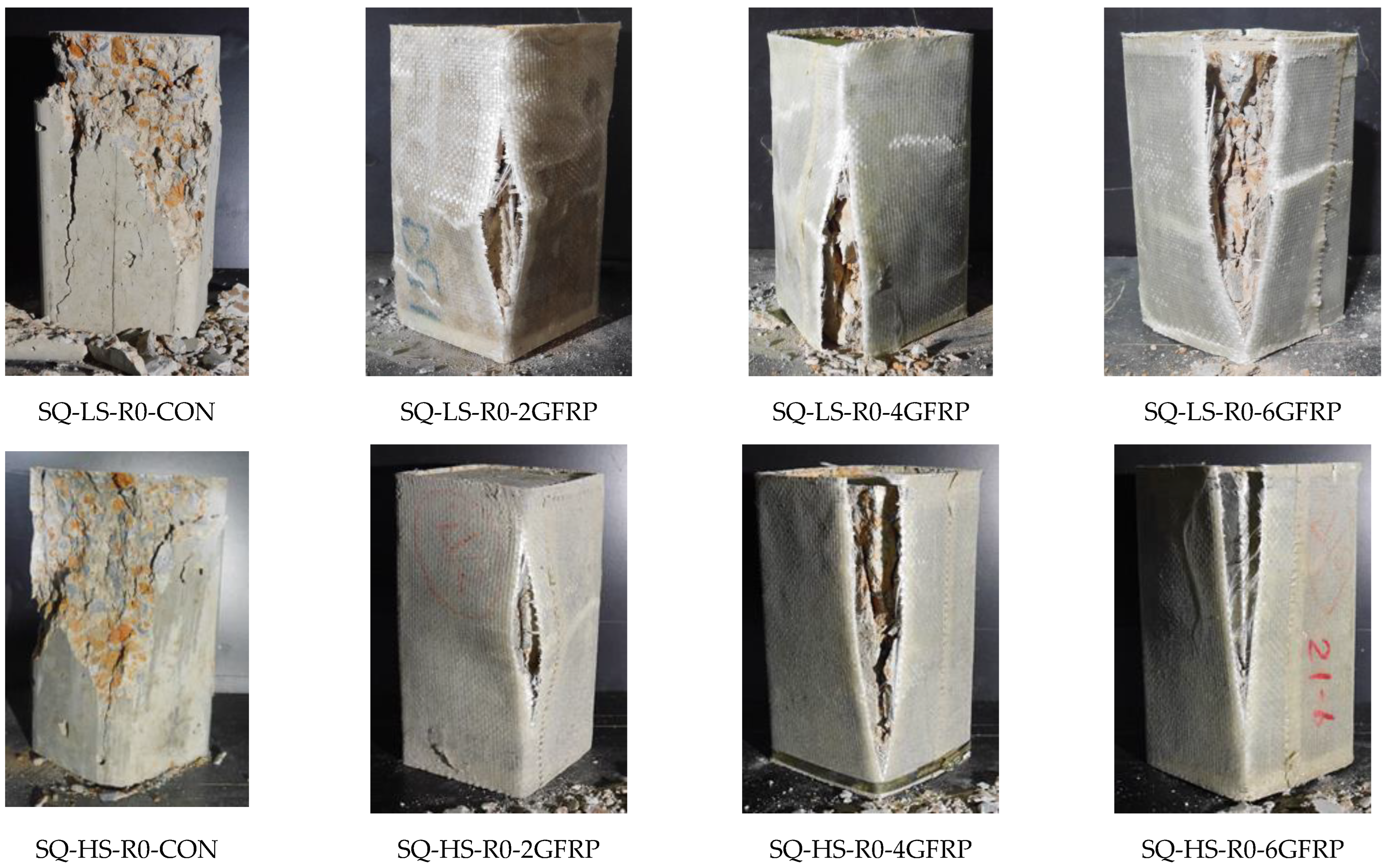

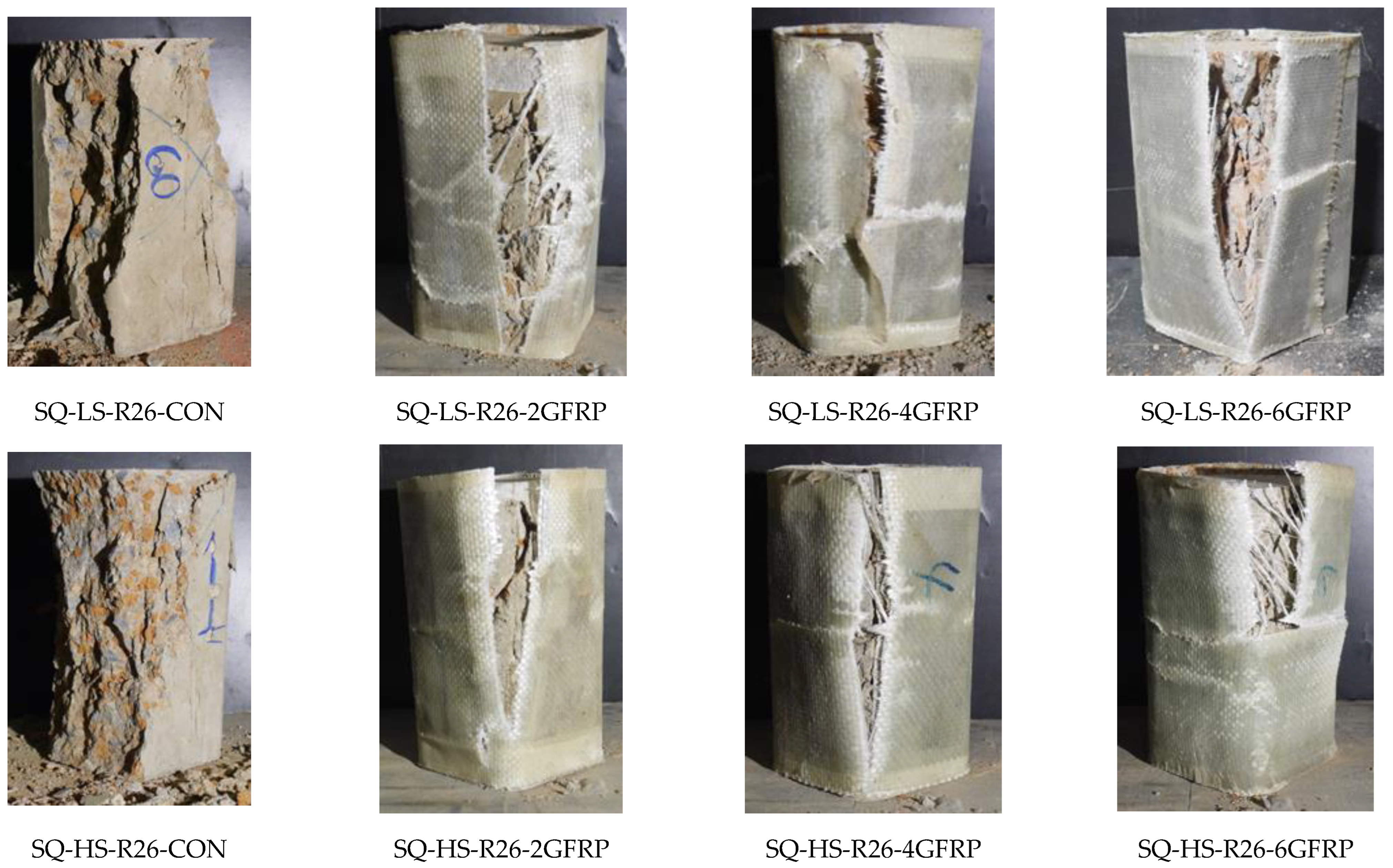

3.1. Ultimate Failure Modes

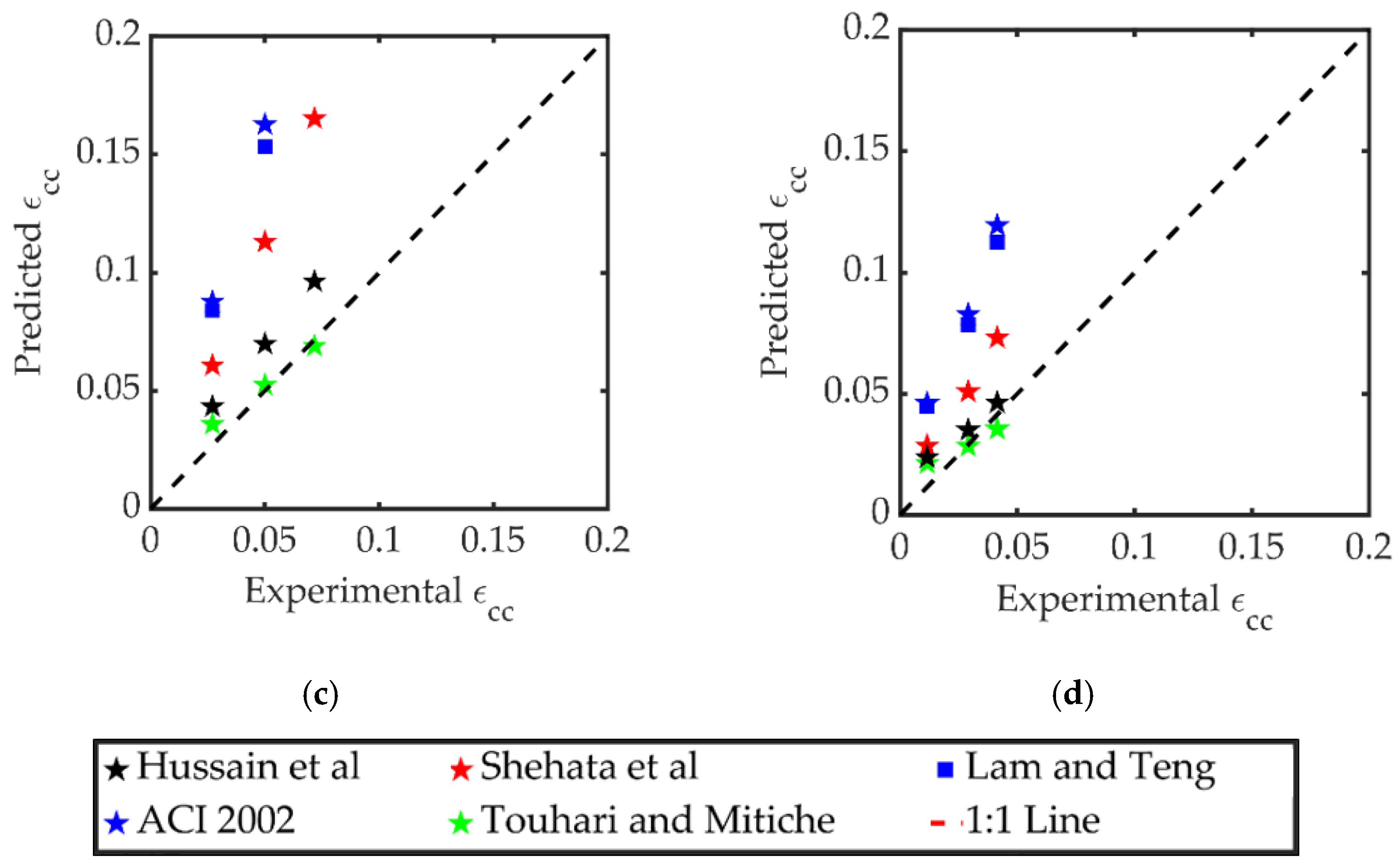

3.2. Peak Stress and Ultimate Strain

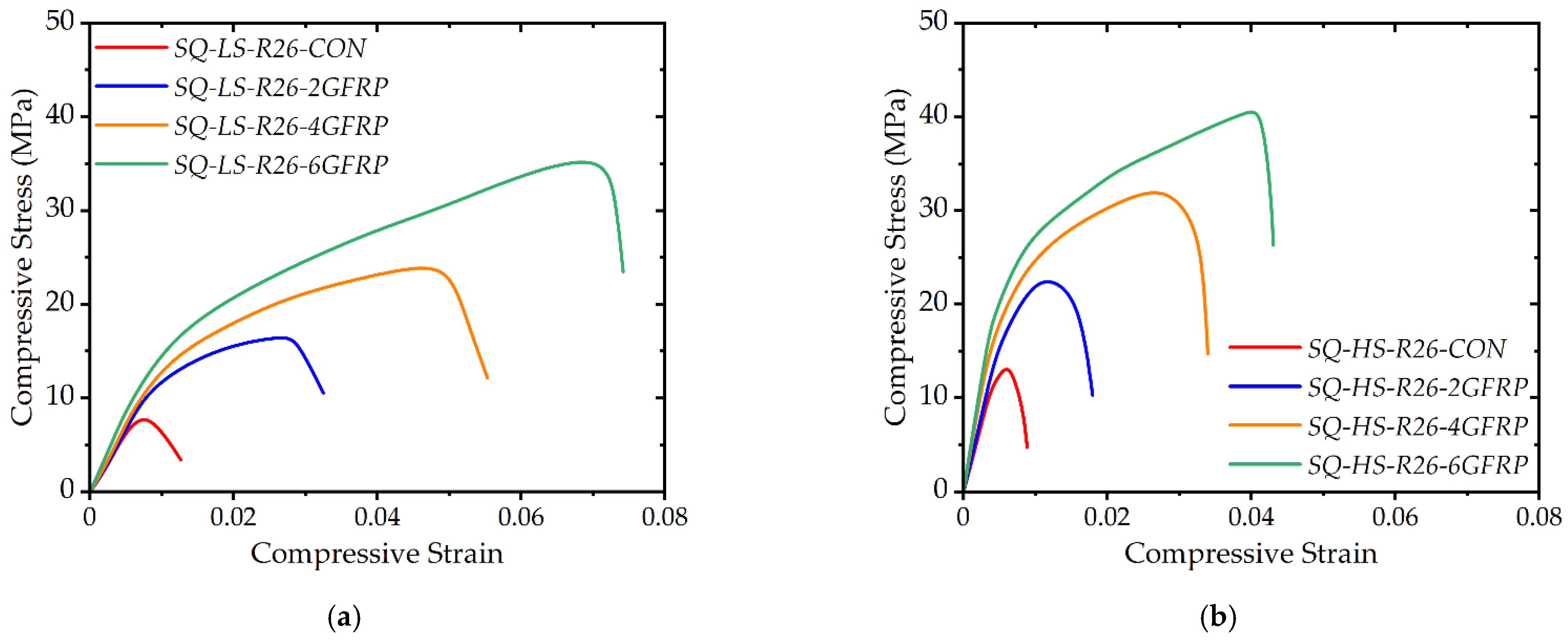

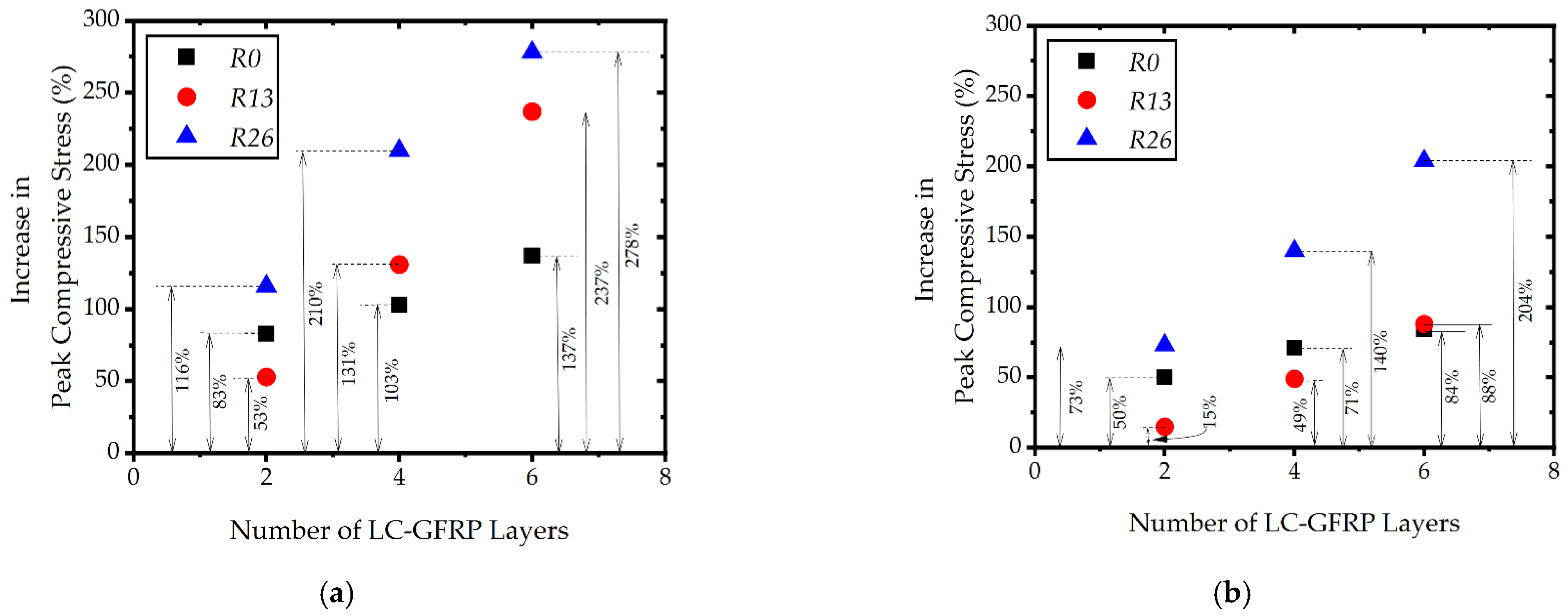

3.3. Compressive Stress-Strain Curves

3.4. Effect of Concrete Strength and Corner Radius

4. Analytical Investigations

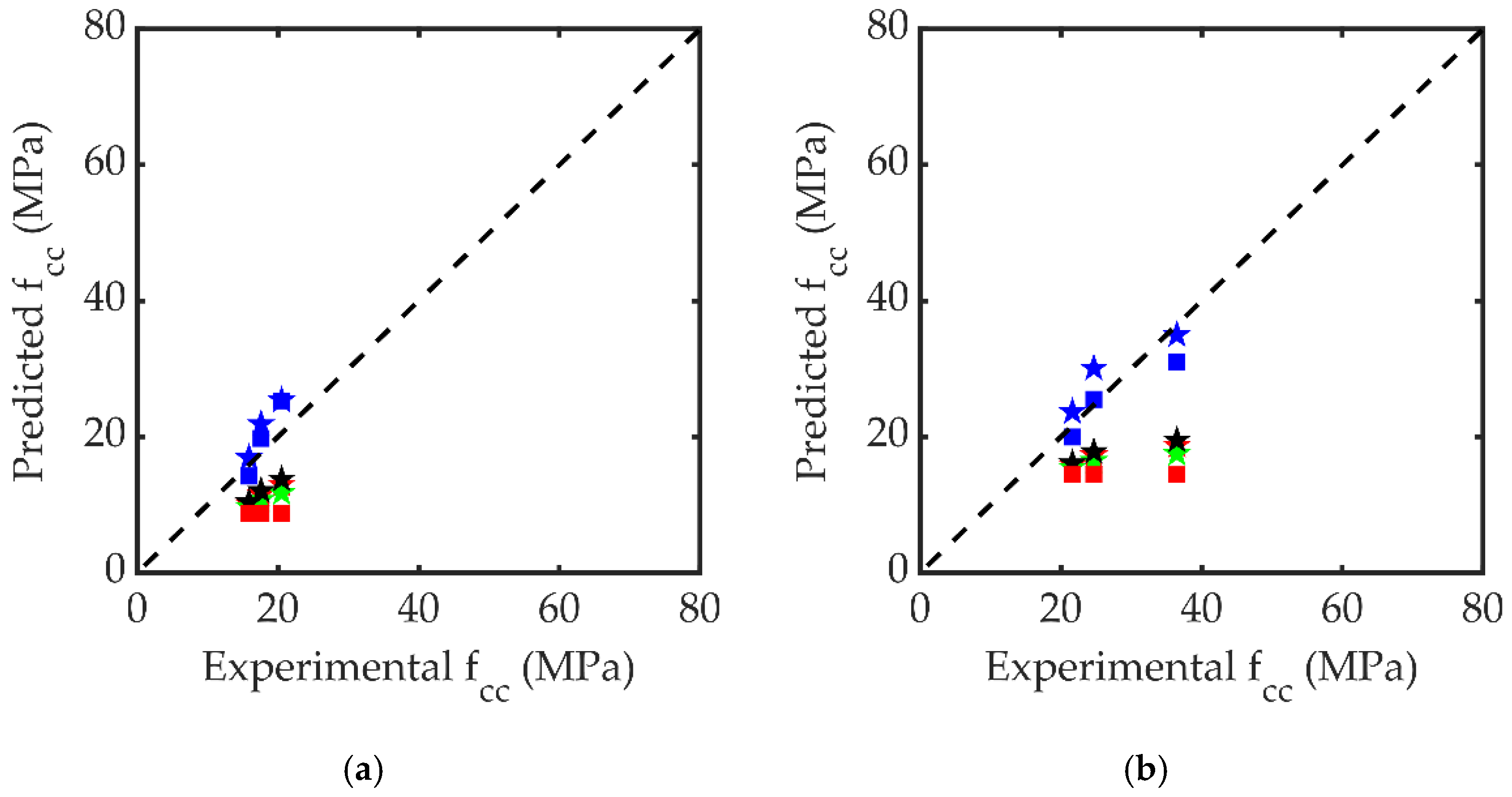

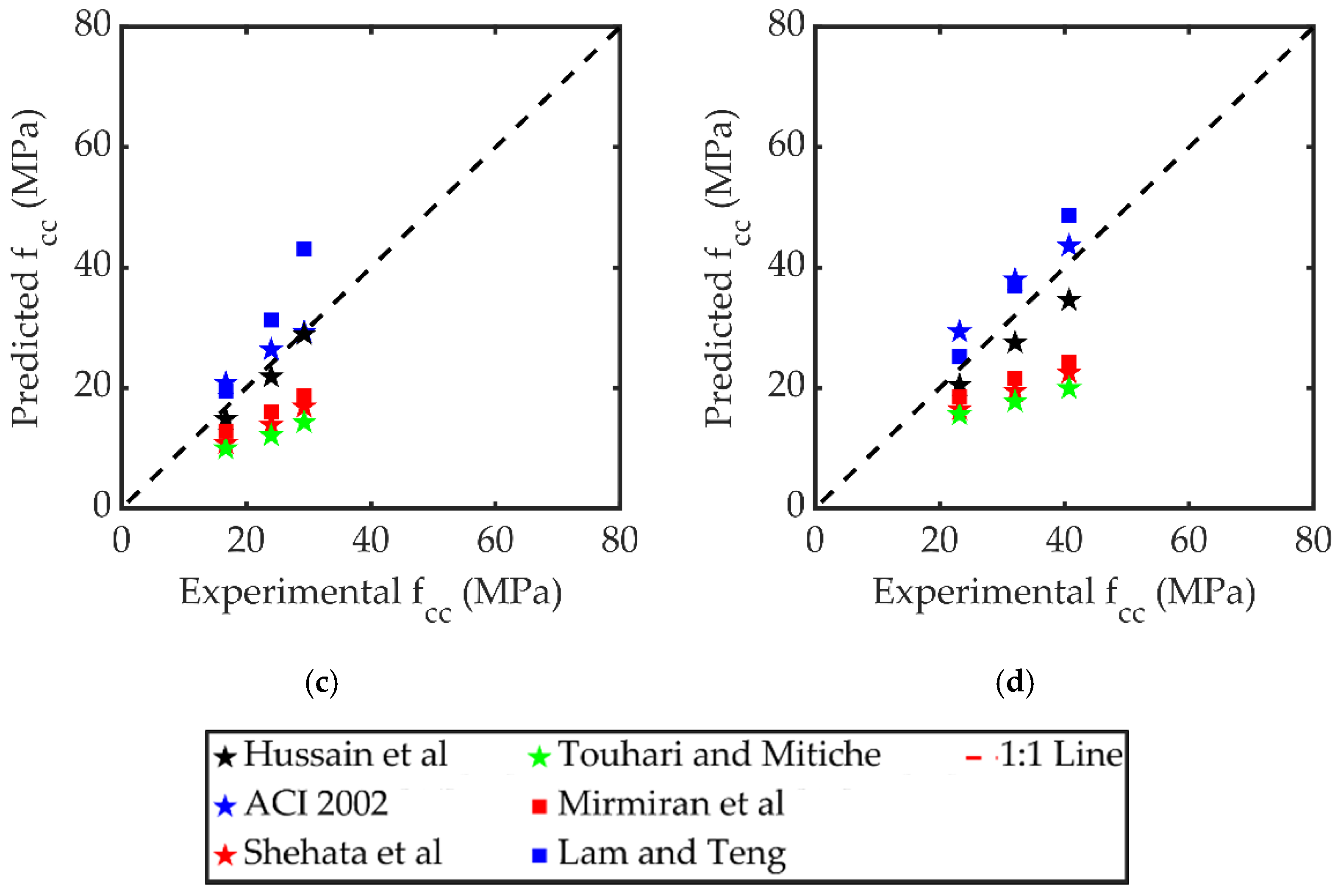

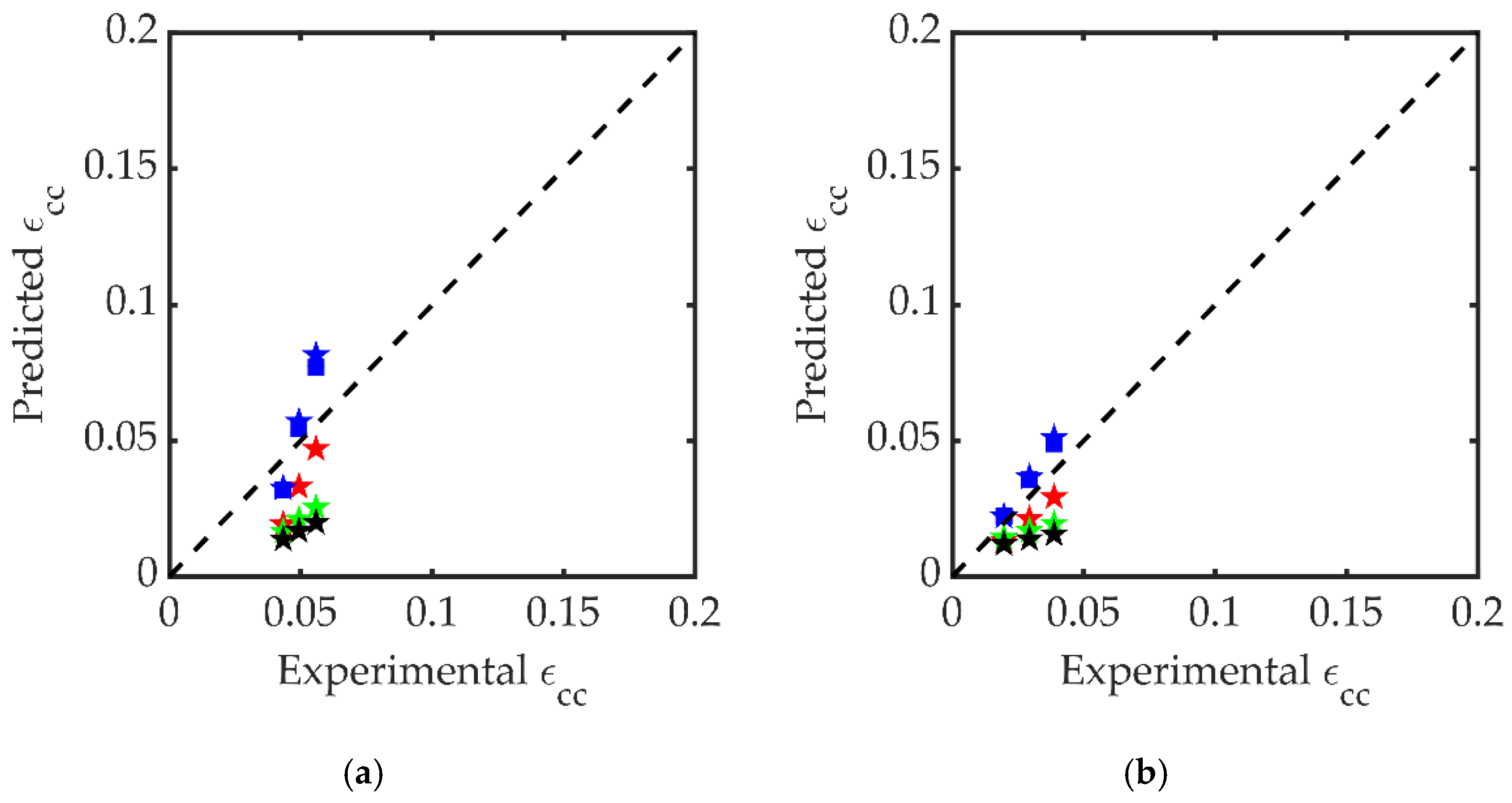

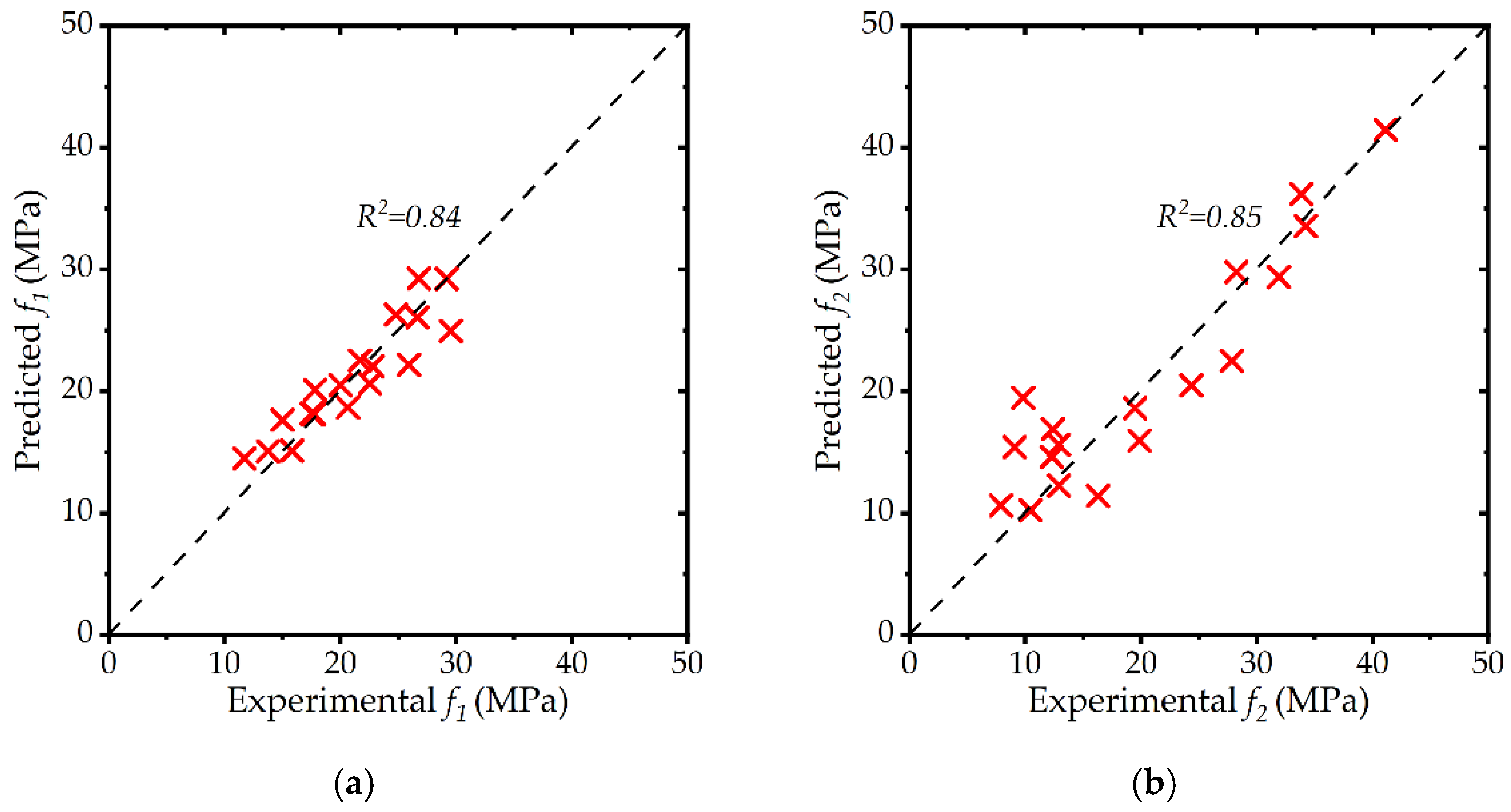

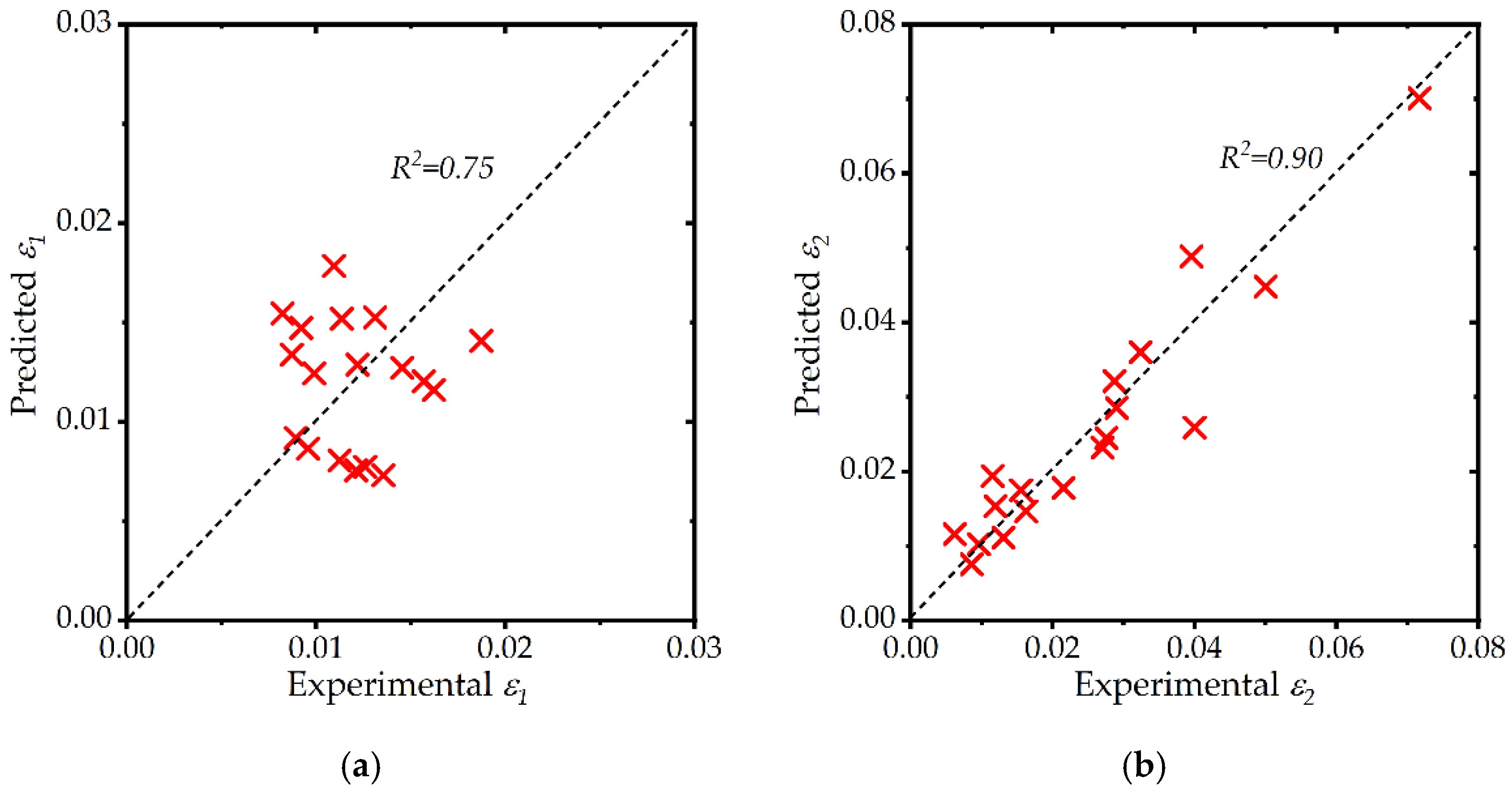

4.1. Existing Analytical Models

4.2. Proposed Model

5. Conclusions

- The peak compressive stress and ultimate strain were found to increase with the number of LC-GFRP wraps. The maximum increase in the peak compressive stress and the ultimate strain was observed for six LC-GFRP wraps;

- It was found that the provision of a 26 mm corner radius significantly improved the efficiency of LC-GFRP wraps. Premature failure due to stress concentrations near sharp corners in specimens with zero corner radius undermined the efficacy of LC-GFRP wraps. Therefore, it is suggested to provide a corner radius to prevent this premature failure;

- The shape of the compressive stress–strain curves of LC-GFRP-confined RBAC was bilinear. The initial stiff branch was identical in all of the strengthened specimens. The second branch was ascending and descending for the zero- and 26-mm corner radius, respectively. As a result, the ultimate stress of 26 mm corner radius specimens was higher;

- A comparison between the strengthened specimens based on the concrete strength revealed that low-strength specimens demonstrated a higher increase in the peak compressive stress and strain as compared to high-strength specimens;

- Existing FRP stress–strain models were found inconsistent in reproducing experimental results. Nonlinear regression analysis was conducted to propose equations for the key parameters in the stress–strain curves of LC-GFRP-confined RBAC.

6. Future Research Directions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Monteiro, P.J.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Noguchi, T.; Kitagaki, R.; Tsujion, M. Minimizing Environmental Impact and Maximizing Performance in Concrete Recycling. Struct. Concr. 2011, 12, 36–46. [Google Scholar] [CrossRef]

- Wong, C.L.; Mo, K.H.; Yap, S.P.; Alengaram, U.J.; Ling, T.C. Potential Use of Brick Waste as Alternate Concrete-Making Materials: A Review. J. Clean Prod. 2018, 195, 226–239. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The Utilization of Eco-Friendly Recycled Powder from Concrete and Brick Waste in New Concrete: A Critical Review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- He, Z.; Shen, A.; Wu, H.; Wang, W.; Wang, L.; Yao, C.; Wu, J. Research Progress on Recycled Clay Brick Waste as an Alternative to Cement for Sustainable Construction Materials. Constr. Build. Mater. 2021, 274, 122113. [Google Scholar] [CrossRef]

- Liu, Q.; Li, B.; Xiao, J.; Singh, A. Utilization Potential of Aerated Concrete Block Powder and Clay Brick Powder from C&D Waste. Constr. Build. Mater. 2020, 238, 117721. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, L.; Li, F.; Peng, J. Recycled Aggregates from Construction and Demolition Wastes as Alternative Filling Materials for Highway Subgrades in China. J. Clean Prod. 2020, 255, 120223. [Google Scholar] [CrossRef]

- Andrew, G.H.T.; Tay, Y.W.I.; Annapareddy, A.; Li, M.; Tan, M.J. Effect of Recycled Glass Gradation in 3D Cementitious Material Printing. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing, Nanyang Technological University, Singapore, 14–17 May 2018; pp. 50–55. [Google Scholar]

- Ting, G.H.A.; Quah, T.K.N.; Lim, J.H.; Tay, Y.W.D.; Tan, M.J. Extrudable Region Parametrical Study of 3D Printable Concrete Using Recycled Glass Concrete. J. Build. Eng. 2022, 50, 104091. [Google Scholar] [CrossRef]

- Zhu, L.; Zhu, Z. Reuse of Clay Brick Waste in Mortar and Concrete. Adv. Mater. Sci. Eng. 2020, 2020, 6326178. [Google Scholar] [CrossRef]

- Li, H.; Dong, L.; Jiang, Z.; Yang, X.; Yang, Z. Study on Utilization of Red Brick Waste Powder in the Production of Cement-Based Red Decorative Plaster for Walls. J. Clean Prod. 2016, 133, 1017–1026. [Google Scholar] [CrossRef]

- Mansur, M.A.; Wee, T.H.; Cheran, L.S. Crushed Bricks as Coarse Aggregate for Concrete. Mater. J. 1999, 96, 478–484. [Google Scholar] [CrossRef]

- Khalaf, F.M. Using Crushed Clay Brick as Coarse Aggregate in Concrete. J. Mater. Civ. Eng. 2006, 18, 518–526. [Google Scholar] [CrossRef]

- Khalaf, F.M.; DeVenny, A.S. Recycling of Demolished Masonry Rubble as Coarse Aggregate in Concrete: Review. J. Mater. Civ. Eng. 2004, 16, 331–340. [Google Scholar] [CrossRef]

- Vrijders, J.; Desmyter, J. Een Hoogwaardig Gebruik van Puingranulaten Stimuleren; OVAM: Mechelen, Belgium, 2008. [Google Scholar]

- Debieb, F.; Kenai, S. The Use of Coarse and Fine Crushed Bricks as Aggregate in Concrete. Constr Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; de Rojas, M.I.S.; Frías, M. Influence of Mixed Recycled Aggregate on the Physical—Mechanical Properties of Recycled Concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with Recycled Concrete Aggregate and Crushed Clay Bricks. Constr Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Nováková, I.; Mikulica, K. Properties of Concrete with Partial Replacement of Natural Aggregate by Recycled Concrete Aggregates from Precast Production. Procedia Eng. 2016, 151, 360–367. [Google Scholar] [CrossRef]

- Jiang, T.; Wang, X.M.; Zhang, W.P.; Chen, G.M.; Lin, Z.H. Behavior of FRP-Confined Recycled Brick Aggregate Concrete under Monotonic Compression. J. Compos. Constr. 2020, 24, 04020067. [Google Scholar] [CrossRef]

- Kox, S.; Vanroelen, G.; van Herck, J.; de Krem, H.; Vandoren, B. Experimental Evaluation of the High-Grade Properties of Recycled Concrete Aggregates and Their Application in Concrete Road Pavement Construction. Case Stud. Constr. Mater. 2019, 11, e00282. [Google Scholar] [CrossRef]

- Yang, Y.F.; Ma, G.L. Experimental Behaviour of Recycled Aggregate Concrete Filled Stainless Steel Tube Stub Columns and Beams. Thin-Walled Struct. 2013, 66, 62–75. [Google Scholar] [CrossRef]

- Ameli, M.; Ronagh, H.R.; Dux, P.F. Behavior of FRP Strengthened Reinforced Concrete Beams under Torsion. J. Compos. Constr. 2007, 11, 192–200. [Google Scholar] [CrossRef]

- Jiangfeng, D.; Shucheng, Y.; Qingyuan, W.; Wenyu, Z.; Jiangfeng, D.; Shucheng, Y.; Qingyuan, W.; Wenyu, Z. Flexural Behavior of RC Beams Made with Recycled Aggregate Concrete and Strengthened by CFRP Sheets. J. Build. Struct. 2019, 40, 71–78. [Google Scholar] [CrossRef]

- Smith, S.T.; Teng, J.G. FRP-Strengthened RC Beams. I: Review of Debonding Strength Models. Eng. Struct. 2002, 24, 385–395. [Google Scholar] [CrossRef]

- Harajli, M.H. Axial Stress–Strain Relationship for FRP Confined Circular and Rectangular Concrete Columns. Cem. Concr. Compos. 2006, 28, 938–948. [Google Scholar] [CrossRef]

- Spoelstra, M.R.; Monti, G. FRP-Confined Concrete Model. J. Compos. Constr. 1999, 3, 143–150. [Google Scholar] [CrossRef]

- Pimanmas, A.; Saleem, S. Dilation Characteristics of PET FRP–Confined Concrete. J. Compos. Constr. 2018, 22, 04018006. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A. Compressive Strength Models of FRP-Confined Concrete. In Proceedings of the 1st Asia-Pacific Conference on FRP in Structures, APFIS 2007, Hong Kong, China, 12–14 December 2007; Volume 1, pp. 175–180. [Google Scholar]

- Eid, R.; Paultre, P. Compressive Behavior of FRP-Confined Reinforced Concrete Columns. Eng. Struct. 2017, 132, 518–530. [Google Scholar] [CrossRef]

- Gao, C.; Huang, L.; Yan, L.; Kasal, B.; Li, W. Behavior of Glass and Carbon FRP Tube Encased Recycled Aggregate Concrete with Recycled Clay Brick Aggregate. Compos. Struct. 2016, 155, 245–254. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Tam, V.W.Y.; Yan, L. Mechanical Behaviors of CFRP-Confined Sustainable Geopolymeric Recycled Aggregate Concrete under Both Static and Cyclic Compressions. Compos. Struct. 2020, 252, 112750. [Google Scholar] [CrossRef]

- Han, Q.; Yuan, W.Y.; Ozbakkaloglu, T.; Bai, Y.L.; Du, X.L. Compressive Behavior for Recycled Aggregate Concrete Confined with Recycled Polyethylene Naphthalate/Terephthalate Composites. Constr. Build. Mater. 2020, 261, 120498. [Google Scholar] [CrossRef]

- Zeng, J.J.; Zhang, X.W.; Chen, G.M.; Wang, X.M.; Jiang, T. FRP-Confined Recycled Glass Aggregate Concrete: Concept and Axial Compressive Behavior. J. Build. Eng. 2020, 30, 101288. [Google Scholar] [CrossRef]

- Iskander, M.G.; Hassan, M. State of the Practice Review in FRP Composite Piling. J. Compos. Constr. 1998, 2, 116–120. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Z. Evaluation of FRP and Hybrid FRP Cables for Super Long-Span Cable-Stayed Bridges. Compos. Struct. 2010, 92, 2582–2590. [Google Scholar] [CrossRef]

- Chaiyasarn, K.; Hussain, Q.; Joyklad, P.; Rodsin, K. New Hybrid Basalt/E-Glass FRP Jacketing for Enhanced Confinement of Recycled Aggregate Concrete with Clay Brick Aggregate. Case Stud. Constr. Mater. 2021, 14, e00507. [Google Scholar] [CrossRef]

- Yoddumrong, P.; Rodsin, K.; Katawaethwarag, S. Seismic Strengthening of Low-Strength RC Concrete Columns Using Low-Cost Glass Fiber Reinforced Polymers (GFRPs). Case Stud. Constr. Mater. 2020, 13, e00383. [Google Scholar] [CrossRef]

- Rodsin, K.; Hussain, Q.; Suparp, S.; Nawaz, A. Compressive Behavior of Extremely Low Strength Concrete Confined with Low-Cost Glass FRP Composites. Case Stud. Constr. Mater. 2020, 13, e00452. [Google Scholar] [CrossRef]

- Rodsin, K. Confinement Effects of Glass FRP on Circular Concrete Columns Made with Crushed Fired Clay Bricks as Coarse Aggregates. Case Stud. Constr. Mater. 2021, 15, e00609. [Google Scholar] [CrossRef]

- Rodsin, K.; Ali, N.; Joyklad, P.; Chaiyasarn, K.; Zand, A.W.A.; Hussain, Q. Improving Stress-Strain Behavior of Waste Aggregate Concrete Using Affordable Glass Fiber Reinforced Polymer (GFRP) Composites. Sustainability 2022, 14, 6611. [Google Scholar] [CrossRef]

- Wang, L.M.; Wu, Y.F. Effect of Corner Radius on the Performance of CFRP-Confined Square Concrete Columns. Eng. Struct. 2008, 30, 493–505. [Google Scholar] [CrossRef]

- Hussain, Q.; Ruangrassamee, A.; Tangtermsirikul, S.; Joyklad, P.; Wijeyewickrema, A.C. Low-Cost Fiber Rope Reinforced Polymer (FRRP) Confinement of Square Columns with Different Corner Radii. Buildings 2021, 11, 355. [Google Scholar] [CrossRef]

- ASTM C1314-21; Standard Test Method for Compressive Strength of Masonry Prisms. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM C140/C140M-22a; Standard Test Methods for Sampling and Testing Concrete Masonry Units and Related Units. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2017.

- Soudki, K.; Alkhrdaji, T. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures (ACI 440.2R-02). In Proceedings of the Structures Congress and Exposition, New York, NY, USA, 20–24 April 2005; pp. 1–8. [Google Scholar] [CrossRef]

- Shehata, I.A.E.M.; Carneiro, L.A.V.; Shehata, L.C.D. Strength of Short Concrete Columns Confined with CFRP Sheets. Mater. Struct. 2002, 35, 50–58. [Google Scholar] [CrossRef]

- Touhari, M.; Mitiche, R.K. Strength Model of FRP Confined Concrete Columns Based on Analytical Analysis and Experimental Test. Int. J. Struct. Integr. 2020, 11, 82–106. [Google Scholar] [CrossRef]

- Mirmiran, A.; Shahawy, M.; Samaan, M.; Echary, H.E.; Mastrapa, J.C.; Pico, O. Effect of Column Parameters on FRP-Confined Concrete. J. Compos. Constr. 1998, 2, 175–185. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Strength Models for Fiber-Reinforced Plastic-Confined Concrete. J. Struct. Eng. 2002, 128, 612–623. [Google Scholar] [CrossRef]

| Group | Name | Strength | Corner Radius | GFRP | Number |

|---|---|---|---|---|---|

| SQ-LS-R0-CON | Low strength | R0 | - | 2 | |

| SQ-LS-R0-2GFRP | Low strength | R0 | 2 | 2 | |

| SQ-LS-R0-4GFRP | Low strength | R0 | 4 | 2 | |

| SQ-LS-R0-6GFRP | Low strength | R0 | 6 | 2 | |

| 1 | SQ-HS-R0-CON | High strength | R0 | - | 2 |

| SQ-HS-R0-2GFRP | High strength | R0 | 2 | 2 | |

| SQ-HS-R0-4GFRP | High strength | R0 | 4 | 2 | |

| SQ-HS-R0-6GFRP | High strength | R0 | 6 | 2 | |

| SQ-LS-R26-CON | Low strength | R26 | - | 2 | |

| SQ-LS-R26-2GFRP | Low strength | R26 | 2 | 2 | |

| SQ-LS-R26-4GFRP | Low strength | R26 | 4 | 2 | |

| 2 | SQ-LS-R26-6GFRP | Low strength | R26 | 6 | 2 |

| SQ-HS-R26-CON | High strength | R26 | - | 2 | |

| SQ-HS-R26-2GFRP | High strength | R26 | 2 | 2 | |

| SQ-HS-R26-4GFRP | High strength | R26 | 4 | 2 | |

| SQ-HS-R26-6GFRP | High strength | R26 | 6 | 2 |

| Property | Density | Compressive Strength (MPa) | Water Absorption (%) |

|---|---|---|---|

| Value | 120 | 3.14 | 23.27 |

| Constituent (kg/m3) | Cement | Sand | Natural Aggregates | Brick Aggregates | Water | |

|---|---|---|---|---|---|---|

| Strength | ||||||

| Low | 261 | 783 | 522 | 522 | 313 | |

| High | 627 | 806 | 358 | 358 | 251 | |

| Specimen ID | Peak Stress (MPa) | Standard Deviation | Increase in Peak Stress (%) | Ultimate Strain | Increase in (%) |

|---|---|---|---|---|---|

| SQ-LS-R0-CON | 8.66 | 0.707 | - | 0.0053 | - |

| SQ-LS-R0-2GFRP | 15.87 | 4.243 | 83 | 0.0096 | 82 |

| SQ-LS-R0-4GFRP | 17.59 | 0.000 | 103 | 0.0155 | 194 |

| SQ-LS-R0-6GFRP | 20.51 | 1.414 | 137 | 0.0400 | 658 |

| SQ-HS-R0-CON | 14.41 | 4.950 | - | 0.0051 | - |

| SQ-HS-R0-2GFRP | 21.62 | 4.243 | 50 | 0.0086 | 70 |

| SQ-HS-R0-4GFRP | 24.67 | 0.707 | 71 | 0.0131 | 159 |

| SQ-HS-R0-6GFRP | 26.48 | 2.121 | 84 | 0.0119 | 134 |

| SQ-LS-R26-CON | 7.74 | 0.707 | - | 0.0084 | - |

| SQ-LS-R26-2GFRP | 16.71 | 1.414 | 116 | 0.0270 | 222 |

| SQ-LS-R26-4GFRP | 23.99 | 1.414 | 210 | 0.0500 | 495 |

| SQ-LS-R26-6GFRP | 29.29 | 8.485 | 278 | 0.0717 | 752 |

| SQ-HS-R26-CON | 13.39 | 2.121 | - | 0.0062 | - |

| SQ-HS-R26-2GFRP | 23.16 | 1.414 | 73 | 0.0115 | 84 |

| SQ-HS-R26-4GFRP | 32.07 | 1.414 | 140 | 0.0290 | 364 |

| SQ-HS-R26-6GFRP | 40.73 | 6.364 | 204 | 0.0414 | 563 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parichatprecha, R.; Rodsin, K.; Chaiyasarn, K.; Ali, N.; Suthasupradit, S.; Hussain, Q.; Khan, K. Structural Behavior of LC-GFRP Confined Waste Aggregate Concrete Square Columns with Sharp and Round Corners. Sustainability 2022, 14, 11221. https://doi.org/10.3390/su141811221

Parichatprecha R, Rodsin K, Chaiyasarn K, Ali N, Suthasupradit S, Hussain Q, Khan K. Structural Behavior of LC-GFRP Confined Waste Aggregate Concrete Square Columns with Sharp and Round Corners. Sustainability. 2022; 14(18):11221. https://doi.org/10.3390/su141811221

Chicago/Turabian StyleParichatprecha, Rattapoohm, Kittipoom Rodsin, Krisada Chaiyasarn, Nazam Ali, Songsak Suthasupradit, Qudeer Hussain, and Kaffayatullah Khan. 2022. "Structural Behavior of LC-GFRP Confined Waste Aggregate Concrete Square Columns with Sharp and Round Corners" Sustainability 14, no. 18: 11221. https://doi.org/10.3390/su141811221

APA StyleParichatprecha, R., Rodsin, K., Chaiyasarn, K., Ali, N., Suthasupradit, S., Hussain, Q., & Khan, K. (2022). Structural Behavior of LC-GFRP Confined Waste Aggregate Concrete Square Columns with Sharp and Round Corners. Sustainability, 14(18), 11221. https://doi.org/10.3390/su141811221