Experimental Study and Theoretical Analysis of Side-Pressure Laminated Bamboo Lumber Columns under Axial Compression

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Material and Fabrication of Specimens

2.2. Loading Regime and Arrangement of Measurement Points

3. Experimental Results and Discussion

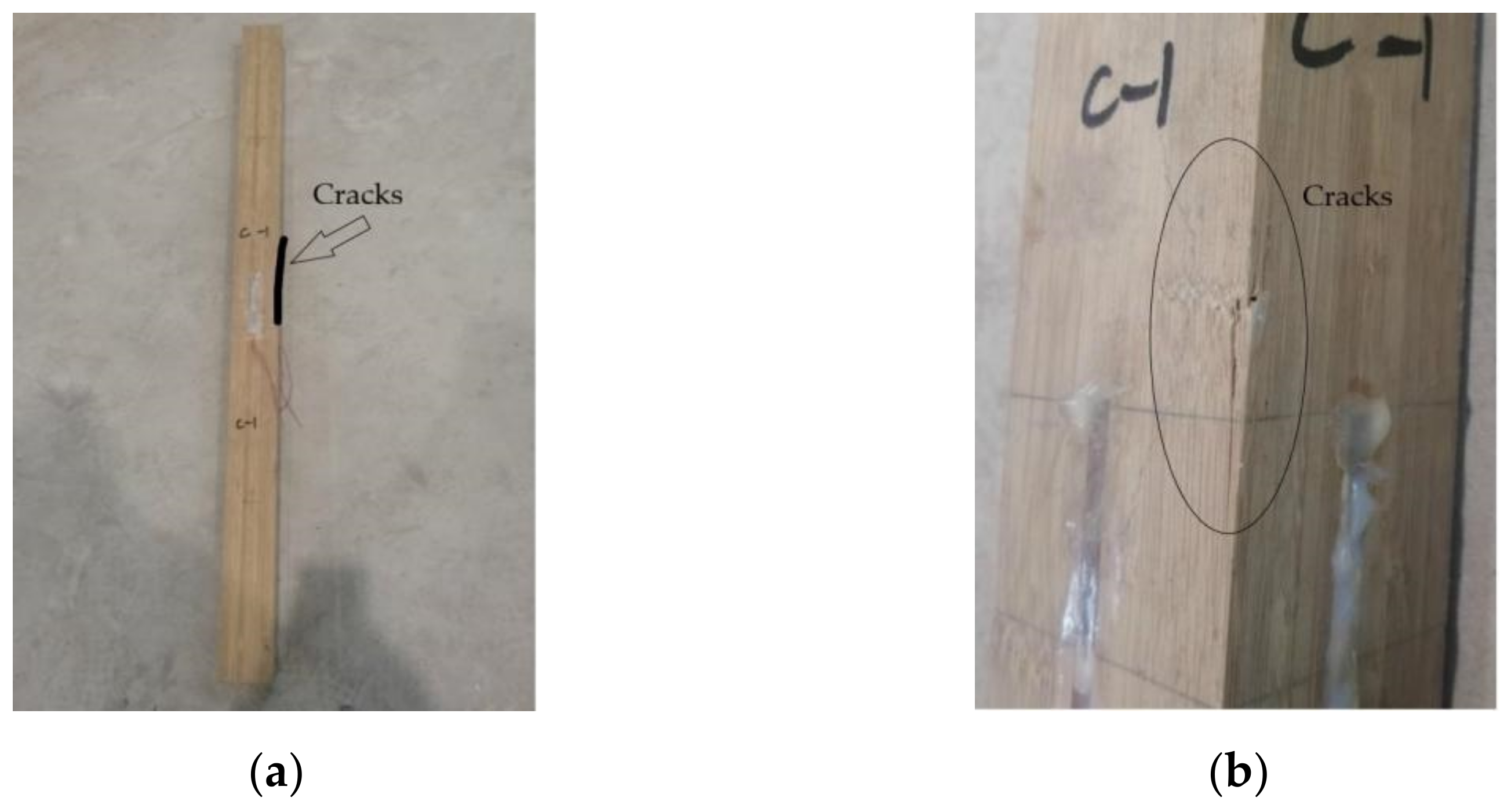

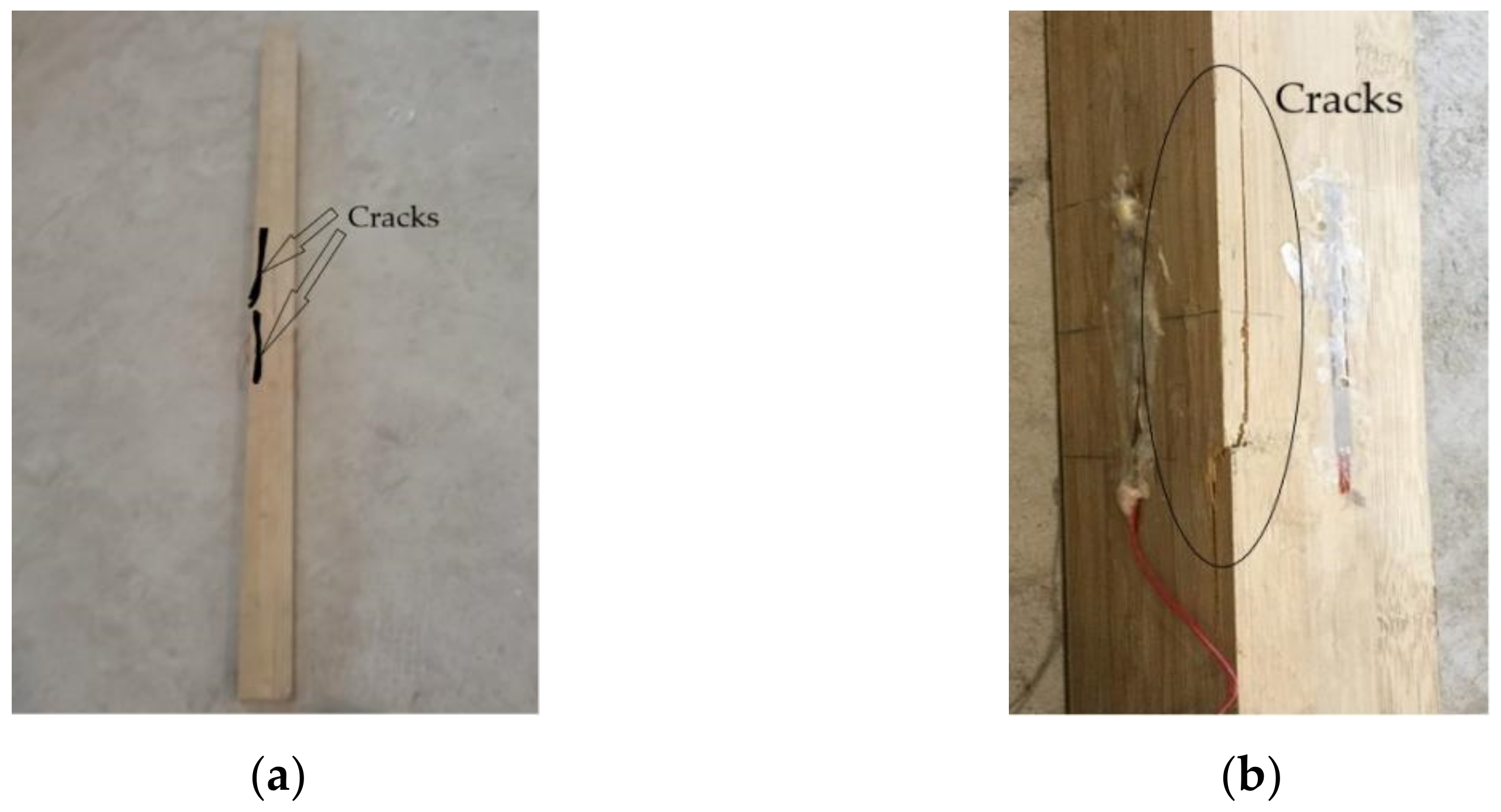

3.1. Experimental Result and Failure Characteristics

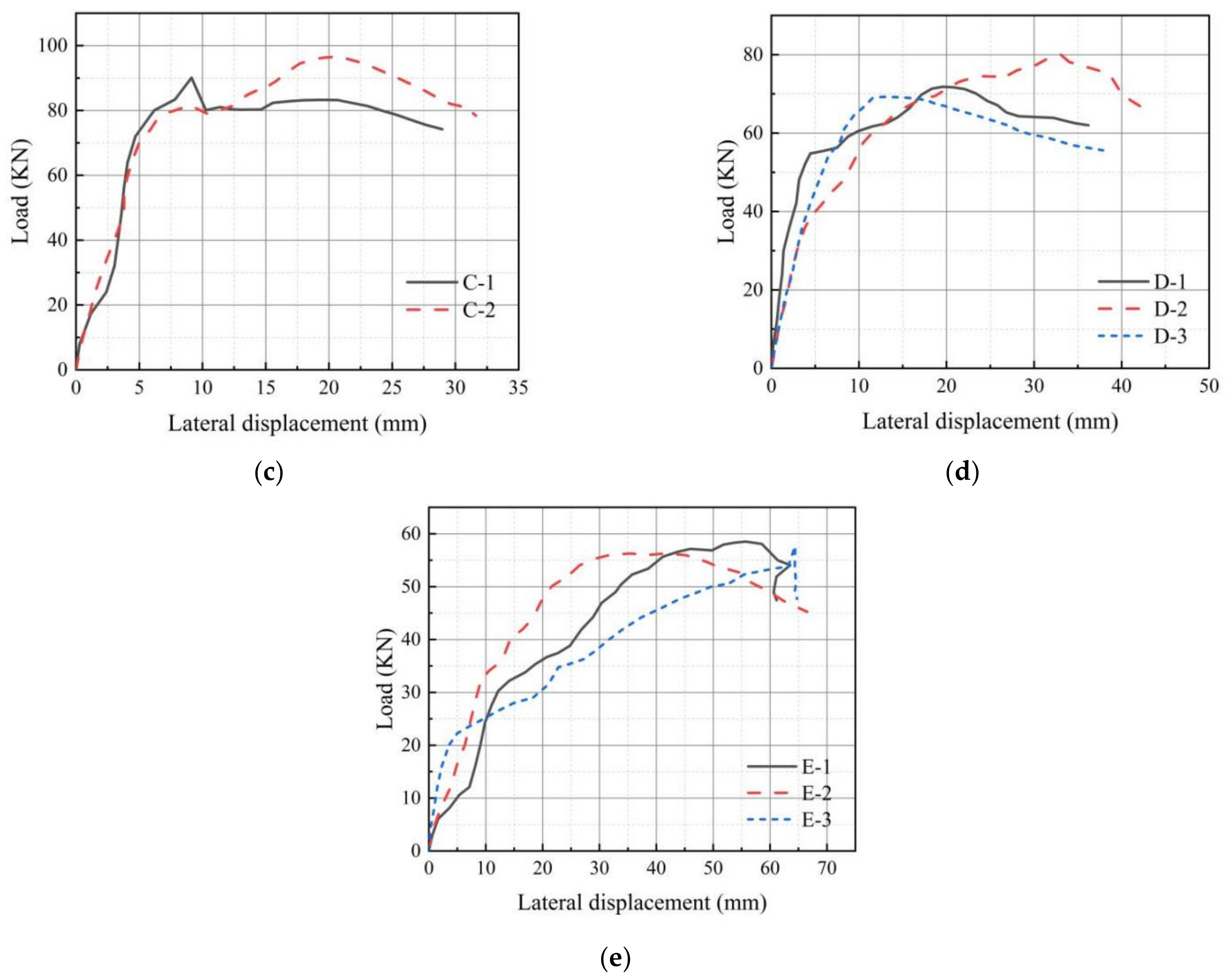

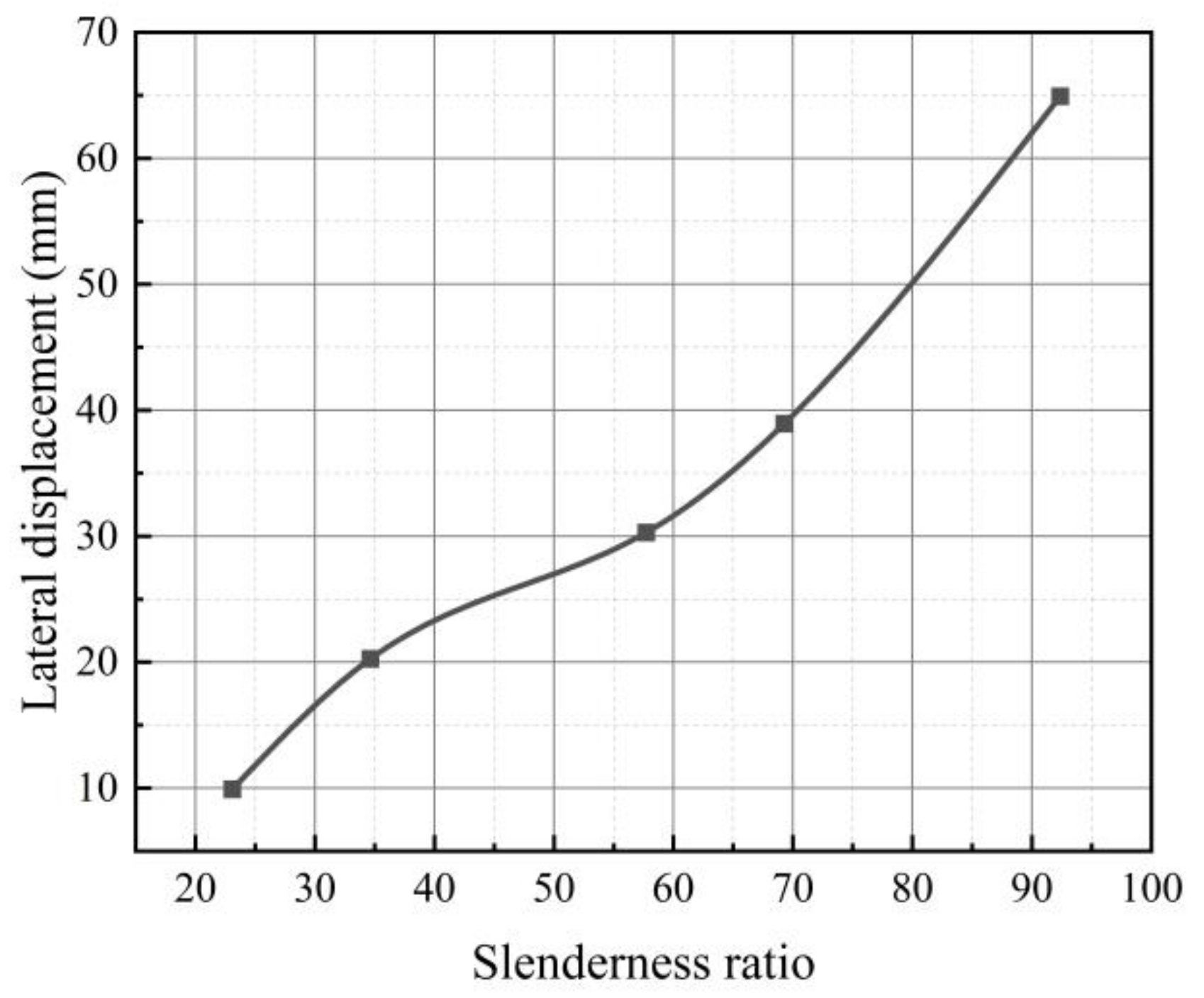

3.2. Load-Lateral Displacement Curve

4. Analysis of Column Load and Lateral Displacement under Axial Compression

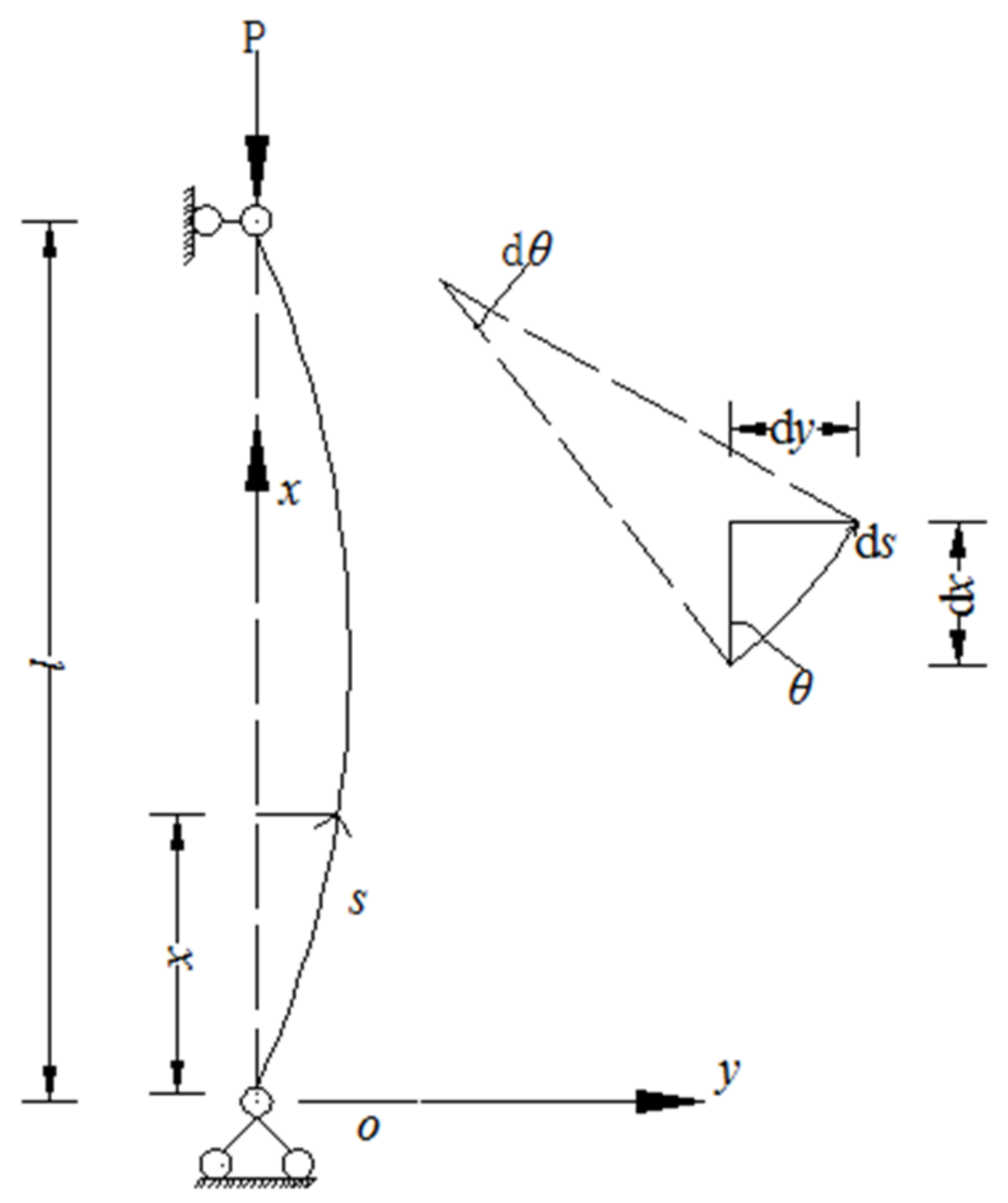

4.1. Analysis of Rod Stability under Axial Compression

4.2. Stable Differential Equation

4.3. Lateral Displacement Solution

4.4. Comparison between Theoretical Value and Experimental Value

5. Conclusions

- (1)

- The mechanical property of side-pressure laminated bamboo lumber under axial compression is studied with reference to the Standard for Test Methods of Timber Structures (GB/T 50329-2012). The study shows that short-column specimens in group A and group B are subjected to strength failure because the bamboo fibers on the tensile side are pulled off and those on the compressive side are flexed. The long-column specimens in group C to group E undergo buckling failure due to excessive lateral displacement during the experiment.

- (2)

- The side-pressure laminated bamboo lumber column undergoes an elastic stage, elastic-plastic stage, and failure stage under axial compression in that order. The damage is characterized by obvious ductility. With the increase of the slenderness ratio, the elastic stage is gradually shortened, while the elastic-plastic stage is prolonged.

- (3)

- As an anisotropic material, the side-pressure laminated bamboo lumber has prominent nonlinearity in terms of the mechanical properties. The material is subjected to deformation under compression. Thus, large deflection theory should be used as the reference to analyze the rod under axial compression.

- (4)

- The stable differential equation is used to solve the established side-pressure laminated bamboo lumber column. The relationship between the ultimate bearing capacity of the compressed column and the lateral displacement in the middle of the column is derived. The error between the theoretical and experimental values is not greater than 1%, with high goodness of fit. It is hoped that this research can provide an effective reference for future engineering applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ren, H.; Jiang, Z.; Fei, B. Future development path of modern wood frame housing in China. China Wood Ind. 2006, 20, 45–47. [Google Scholar] [CrossRef]

- Tian, L.; Jin, B.; Hao, J. Research and application of modern bamboo structures. Eng. Mech. 2019, 36, 1–18+27. [Google Scholar]

- Van der Lugt, P.; Van den Dobbelsteen, A.A.J.F.; Janssen, J.J.A. An Environmental, Economic and Practical Assessment of Bamboo as a Building Material for Supporting Structures. Constr. Build. Mater. 2006, 20, 648–656. [Google Scholar] [CrossRef]

- Liu, K.; Oliver, F. An overview of global bamboo architecture: Trends and Challenges. World Archit. 2013, 12, 27–34. [Google Scholar] [CrossRef]

- Hao, J.; Qin, M.; Tian, L. Experimental study on mechanical properties of bamboo parallel to the grain. J. Xi’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2017, 49, 777–783. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, J. The state of the art of modern bamboo structures. Ind. Constr. 2015, 45, 1–6. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, R.Z.; Shan, B. Production, Environmental Impact and Mechanical Properties of Glubam. Constr. Build. Mater. 2013, 44, 765–773. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, R.; Shan, B. Experimental research on mechanical properties of glubam. J. Build. Struct. 2012, 33, 150–157. [Google Scholar] [CrossRef]

- Huang, D.; Zhou, A.; Bian, Y. Experimental and Analytical Study on the Nonlinear Bending of Parallel Strand Bamboo Beams. Constr. Build. Mater. 2013, 44, 585–592. [Google Scholar] [CrossRef]

- Chen, G.; Yu, Y.; Li, X.; He, B. Mechanical Behavior of Laminated Bamboo Lumber for Structural Application: An Experimental Investigation. Eur. J. Wood Prod. 2020, 78, 53–63. [Google Scholar] [CrossRef]

- Sun, X.; He, M.; Li, Z. Novel Engineered Wood and Bamboo Composites for Structural Applications: State-of-Art of Manufacturing Technology and Mechanical Performance Evaluation. Constr. Build. Mater. 2020, 249, 118751. [Google Scholar] [CrossRef]

- Jiang, Z.; Chang, L.; Wang, Z.; Gao, L. Physical and mechanical properties of glued structural laminated bamboo. China Wood Ind. 2005, 19, 22–24+30. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Wu, G.; Xiong, X.; Li, Y. A review on development of laminated bamboo lumber. J. For. Eng. 2016, 1, 10–16. [Google Scholar] [CrossRef]

- Liu, Y. The Experimental Study on Axial Compression of Reconsolidated Bamboo Columns. Master’s Thesis, Central South University of Forestry and Technology, Changsha, China, 2019. [Google Scholar]

- Wang, X. Study on the Compression Performance and Load Carrying Capacity of Bamboo/Wood Columns. Ph.D. Thesis, Nanjing Forestry University, Nanjing, China, 2020. [Google Scholar]

- Tan, C.; Li, H.; Ashraf, M.; Corbi, I.; Corbi, O.; Lorenzo, R. Evaluation of Axial Capacity of Engineered Bamboo Columns. J. Build. Eng. 2021, 34, 102039. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Wu, G. Stress-strain model of side pressure laminated bamboo under compression. J. Southeast Univ. (Nat. Sci. Ed.) 2015, 45, 1130–1134. [Google Scholar]

- Li, H.; Wu, G.; Zhang, Q.; Chen, G. Experimental study on side pressure LBL under tangential eccentric compression. J. Hunan Univ. (Nat. Sci. Ed.) 2016, 43, 90–96. [Google Scholar] [CrossRef]

- Su, J.; Li, H.; Yang, P.; Zhang, Q.; Huang, D. Compressive strength of laminated bamboo square column. J. For. Eng. 2015, 29, 89–93. [Google Scholar] [CrossRef]

- Xiao, Y.; Feng, L.; Lv, X.; She, L.; Shen, Y. Experimental Studies of Glubam Columns under Axial Loads. Ind. Constr. 2015, 45, 13–17. [Google Scholar] [CrossRef]

- Lv, X. Experimental Rasearch and Finite Element Analysis of GluBam Columns under Axial Compression. Master’s Thesis, Hunan University, Changsha, China, 2011. [Google Scholar]

- Tang, C.; Chen, B. Experimental study on the long-term compression performance of glue-laminated bamboo under lateral pressure. J. Hunan City Univ. (Nat. Sci. Ed.) 2020, 29, 11–13. [Google Scholar]

- GB/T 50329-2012; Standard for Test Methods of Timber Structures. China Building Industry Press: Beijing, China, 2012.

- GB 50005-2017; Standard for Design of Timber Structures. China Building Industry Press: Beijing, China, 2017.

- Li, C. Structural Stability and Internal Force, 1st ed.; China Communications Press: Beijing, China, 1979; Volume 1979, p. 294. [Google Scholar]

- Elliptic Integral Writing Group. Elliptic Integral Table, 1st ed.; China Machine Press: Beijing, China, 1979; Volume 19–48. [Google Scholar]

| Property Index | Air-Dry Density | Moisture Content | Parallel-to-Grain Compression Strength |

|---|---|---|---|

| Result | 0.640 g/cm3 | 6.3% | 84.9 MPa |

| Number of specimens | 32 | 32 | 32 |

| Standard Deviation | 0.04 | 0.003 | 3.04 |

| Coefficient of Variation | 0.06 | 0.04 | 0.04 |

| Specimen No. | l/mm | l0/mm | λ | Size of Cross-Section (mm × mm) |

|---|---|---|---|---|

| A | 400 | 400 | 23.1 | 60 × 60 |

| B | 600 | 600 | 34.6 | 60 × 60 |

| C | 1000 | 1000 | 57.7 | 60 × 60 |

| D | 1200 | 1200 | 69.3 | 60 × 60 |

| E | 1600 | 1600 | 92.4 | 60 × 60 |

| Specimen No. | λ | NPeak,i/kN | NPeak/kN | ymax,i/mm | ymax/mm |

|---|---|---|---|---|---|

| A-1 | 23.1 | 244.4 | 245.8 | 10.04 | 9.92 |

| A-2 | 23.1 | 245.7 | 9.65 | ||

| A-3 | 23.1 | 247.3 | 10.07 | ||

| B-1 | 34.6 | 144.1 | 188.9 | 23.84 | 20.27 |

| B-2 | 34.6 | 221.9 | 16.7 | ||

| B-3 | 34.6 | 200.9 | — | ||

| C-1 | 57.7 | 92.7 | 91.7 | 28.95 | 30.28 |

| C-2 | 57.7 | 96.6 | 31.61 | ||

| C-3 | 57.7 | 86.0 | — | ||

| D-1 | 69.3 | 71.9 | 73.8 | 36.19 | 38.93 |

| D-2 | 69.3 | 80.0 | 42.74 | ||

| D-3 | 69.3 | 69.5 | 37.86 | ||

| E-1 | 92.4 | 58.6 | 57.6 | 61.16 | 64.14 |

| E-2 | 92.4 | 56.4 | 66.51 | ||

| E-3 | 92.4 | 57.8 | 64.74 |

| Specimen No. | l/mm | λ | αl/2 | ymax, real | ymax, theory | Error (%) |

|---|---|---|---|---|---|---|

| A | 400 | 23.1 | 1.5718 | 9.92 | 9.94 | 0.20% |

| B | 600 | 34.6 | 1.5726 | 20.27 | 20.30 | 0.14% |

| C | 1000 | 57.7 | 1.5722 | 30.28 | 30.33 | 0.17% |

| D | 1200 | 69.3 | 1.5725 | 38.93 | 38.99 | 0.15% |

| E | 1600 | 92.4 | 1.5733 | 64.14 | 64.20 | 0.10% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Gao, D.; Xie, Y.; Chen, B. Experimental Study and Theoretical Analysis of Side-Pressure Laminated Bamboo Lumber Columns under Axial Compression. Sustainability 2022, 14, 11360. https://doi.org/10.3390/su141811360

Liu S, Gao D, Xie Y, Chen B. Experimental Study and Theoretical Analysis of Side-Pressure Laminated Bamboo Lumber Columns under Axial Compression. Sustainability. 2022; 14(18):11360. https://doi.org/10.3390/su141811360

Chicago/Turabian StyleLiu, Shuai, Danping Gao, Yazi Xie, and Bowang Chen. 2022. "Experimental Study and Theoretical Analysis of Side-Pressure Laminated Bamboo Lumber Columns under Axial Compression" Sustainability 14, no. 18: 11360. https://doi.org/10.3390/su141811360