Experimental Study on Strength Weakening of Gypsum Rock with Effect of Long-Term Overlying Strata Pressure

Abstract

:1. Introduction

2. Coring from the Gypsum Rock Pillar

2.1. Situation of Gypsum Mine Gob

2.2. Coring from Gypsum Rock Pillars

3. Uniaxial Compression Strength Test of Gypsum Rock

3.1. Experimental Equipment

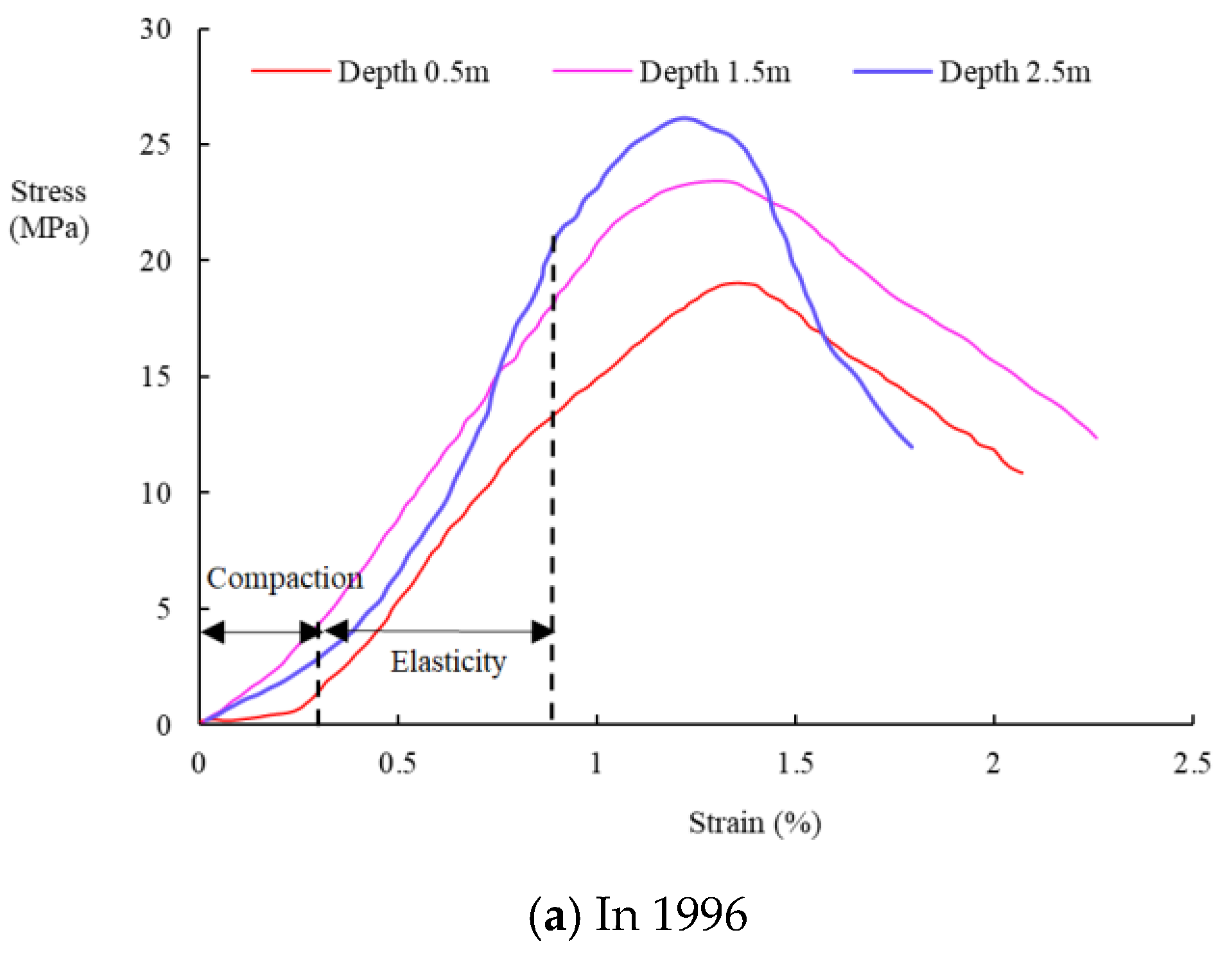

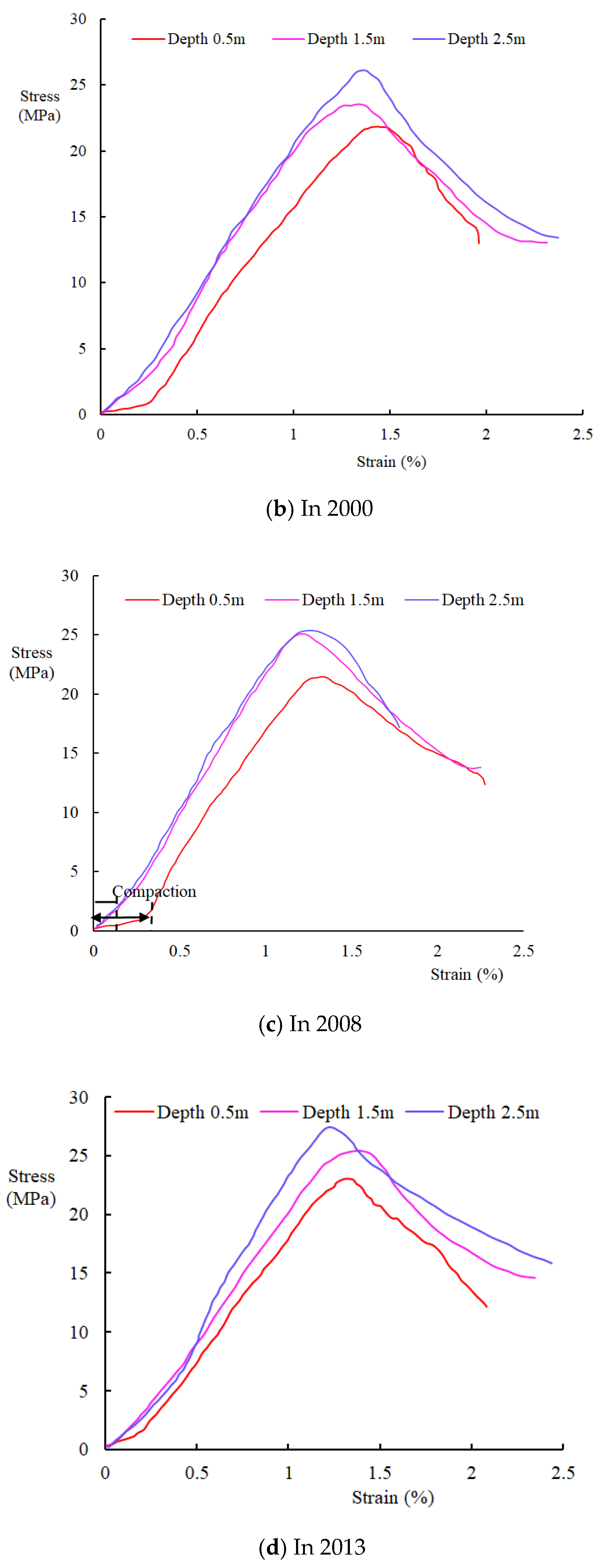

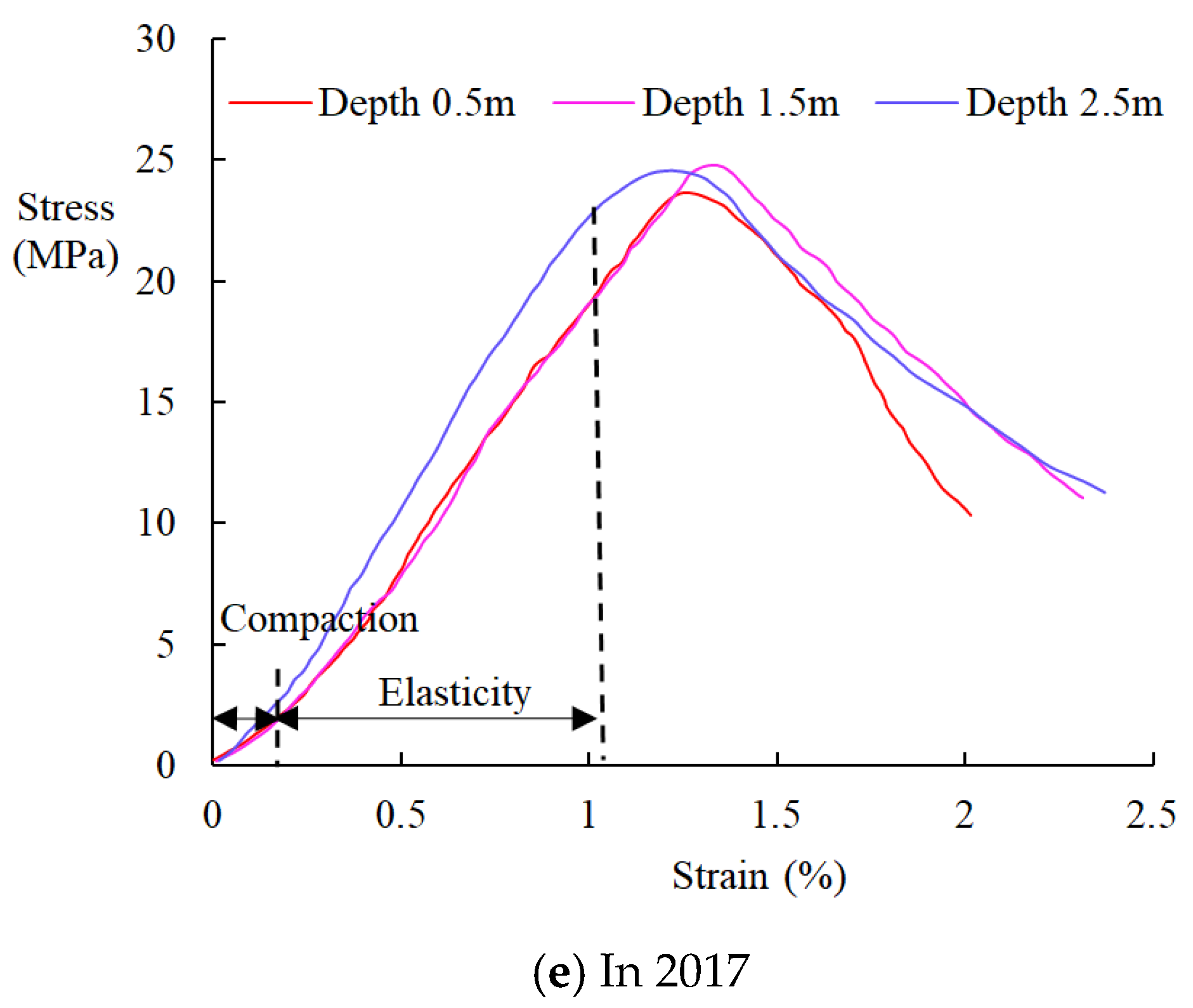

3.2. Uniaxial Compression Strength Curve

3.3. Evolution Law of Strength Curve

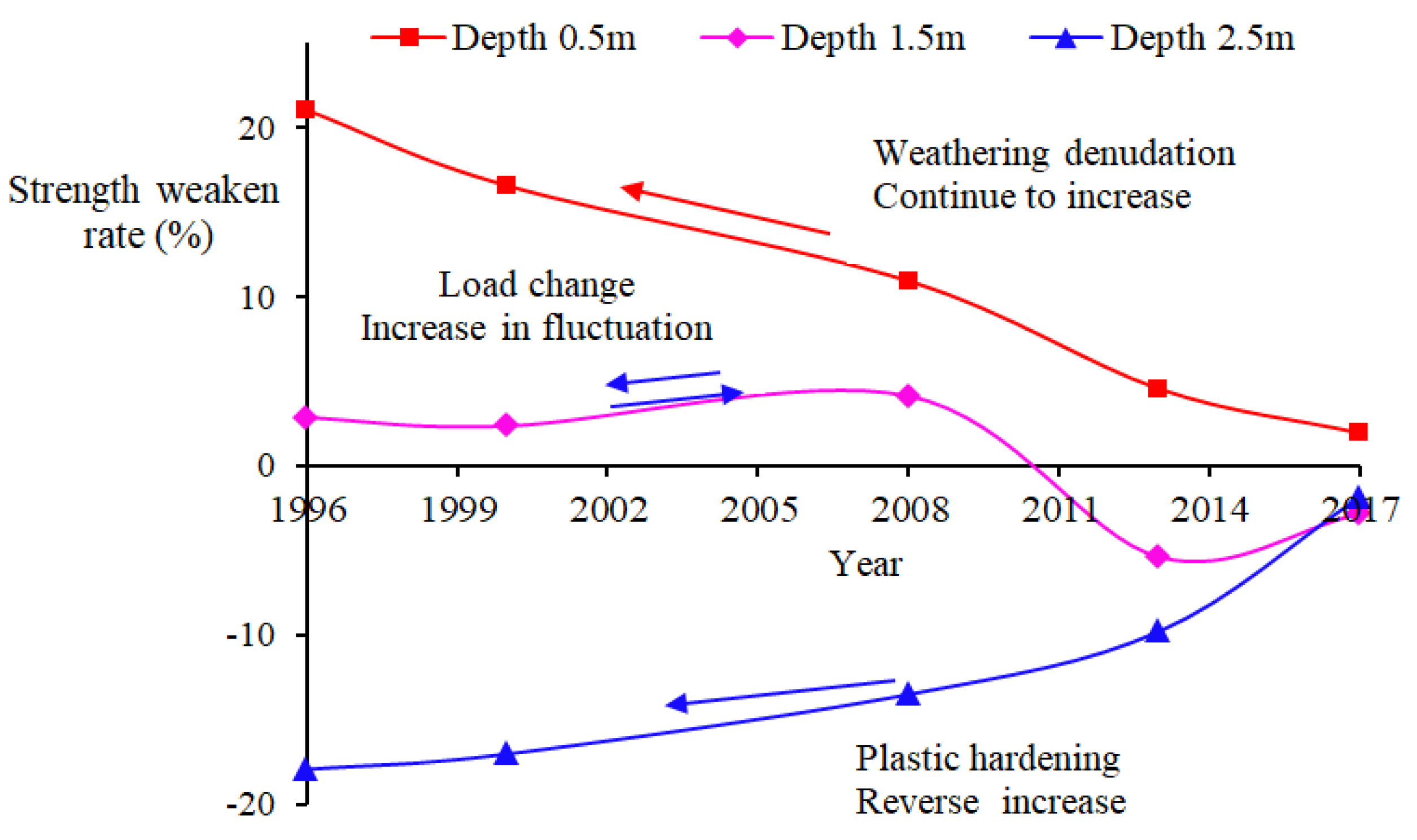

4. Strength Weakening of Gypsum Rock

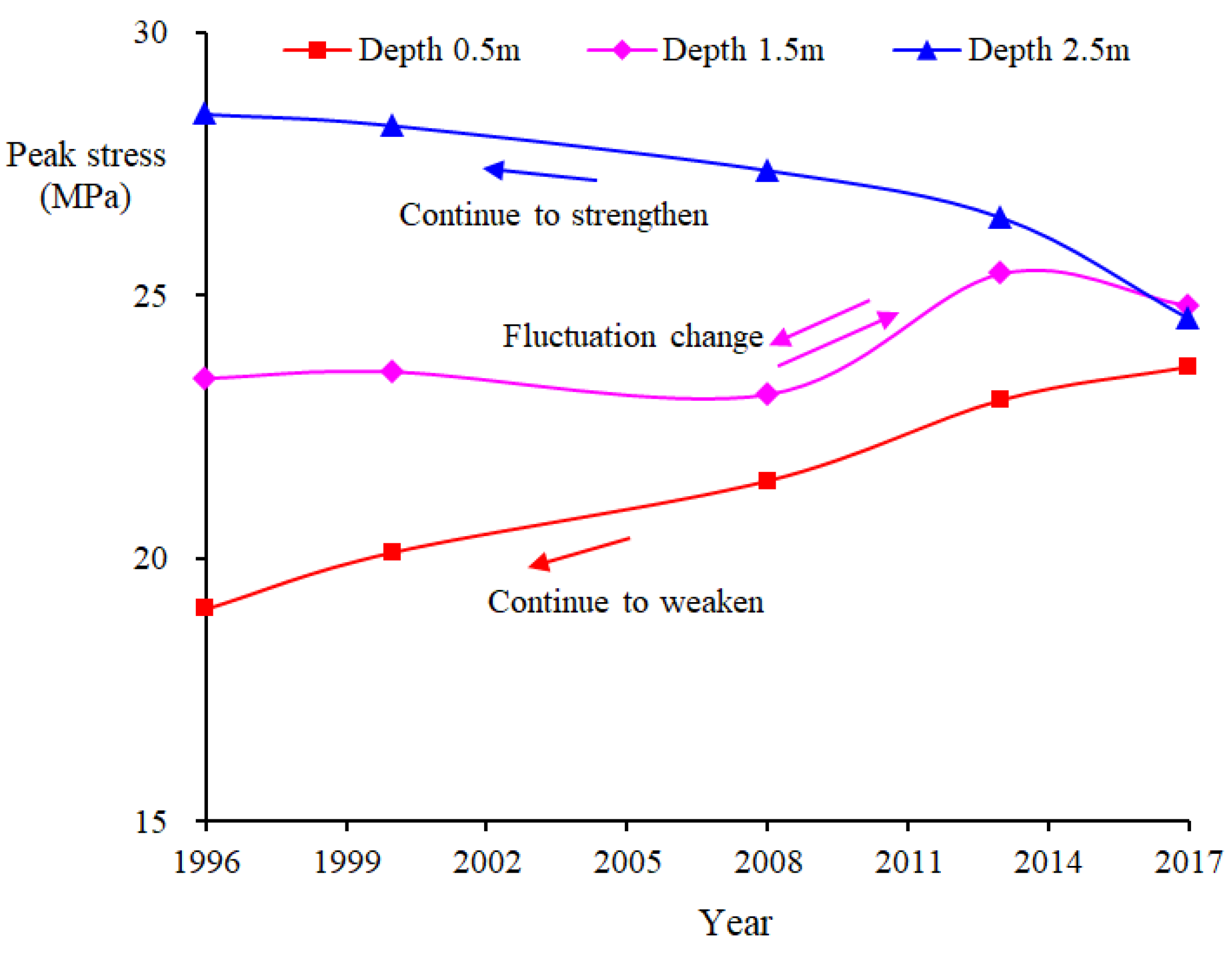

4.1. Evolution Law of Peak Strength

4.2. Strength Weakening of Gypsum Rock

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, R.; Han, Z.; Zhou, Y.; Liu, H.; Liu, Y. Analysis on disaster characteristics and preventive measures of goaf in metal and non-metal mines. Min. Res. Dev. 2020, 40, 33–38. [Google Scholar]

- Luo, G.; Chen, L.; Jia, Q.; Song, S.; Liu, G. Gob area No. 1 subsidence mechanism and development trend prediction in Dangyang gypsum mine, Hubei Province. Coal Geo. Chin. 2019, 31, 62–65. [Google Scholar]

- Xu, X.; Zhou, Y.; Pang, S. Analysis of catastrophic instability of plastic supporting system in old goaf of gypsum mine. Chin. J. Rock Mech. Eng. 2018, 37, 2548–2555. [Google Scholar]

- Zhu, Y.; Huang, X.; Liu, Y.; Liu, Z.; Lan, H.; Tian, W. Nonlinear viscoelastoplastic fatigue model for natural gypsum rock subjected to various cyclic loading conditions. Int. J. Geomech. 2021, 21, 1004. [Google Scholar] [CrossRef]

- Xia, K.; Chen, C.; Liu, X.; Zhou, Y.; Jiang, X. Study of the failure of pillar-roof system in gypsum mines based on catastrophe theory. Chin. J. Rock Mech. Eng. 2016, 35, 3837–3845. [Google Scholar]

- Xia, K.; Chen, C.; Yang, K.; Sun, C.; Liu, X.; Zhou, Y. Influence of relative humidity on the non-linear failure and stability of gypsum mines. Eur. J. Environ. Civ. Eng. 2020, 3, 1518–1543. [Google Scholar] [CrossRef]

- Zheng, H.; Hou, X.; Liu, Z.; Li, B.; Li, H. Disturbance mechanism of rock deformation based on energy accumulation. Ind. Miner. Process. 2017, 46, 44–49. [Google Scholar]

- Caselle, C.; Bonetto, S.; Comina, C. Comparison of laboratory and field electrical resistivity measurements of a gypsum rock for mining prospection applications. Int. J. Min. Sci. Technol. 2019, 29, 841–849. [Google Scholar] [CrossRef]

- Li, M.; Liu, Z.; Miao, Q.; Zheng, H.; Zhang, J. Analysis of major influence factors to stability of mined-out area. Ind. Miner. Process. 2013, 42, 20–24. [Google Scholar]

- Liu, X.; Jiang, X.; Chen, C.; Xia, K.; Zhou, Y. Study of creep characteristics of gypsum rock in natural and saturated state. Rock Soil Mech. 2017, 38, 277–283. [Google Scholar] [CrossRef]

- Ma, H.; Song, Y.; Chen, S.; Yin, D.; Zheng, J.; Shen, F.; Li, X.; Ma, Q. Experimental investigation on the mechanical behavior and damage evolution mechanism of water-immersed gypsum rock. Rock Mech. Rock Eng. 2021, 54, 4929–4948. [Google Scholar] [CrossRef]

- Li, W.; Einstein, H.H. Theoretical and numerical investigation of the cavity evolution in gypsum rock. Water Resour. Res. 2017, 53, 9988–10001. [Google Scholar] [CrossRef]

- Liu, Z.; Zheng, H.; Li, M. Experimental research on creep failure characteristics of gypsum rock based on rock longitudinal wave velocity. Geotech. Geol. Eng. 2019, 37, 1515–1522. [Google Scholar] [CrossRef]

- Wang, S.; Lv, W.; Liu, Z.; Zheng, H. Lagging collapse mechanism of gypsum-mined gob with rock creep. Geotech. Geol. Eng. 2022, 40, 2489–2499. [Google Scholar] [CrossRef]

- Lyu, C.; Liu, J.; Wu, Z.; Liu, H.; Xiao, F.; Zeng, Y. Experimental study on mechanical properties, permeability and acoustic emission characteristics of gypsum rock under THM Coupling. Rock Mech. Rock Eng. 2021, 54, 5761–5779. [Google Scholar] [CrossRef]

- Xu, X.; Cui, X.; Liu, X.; Tang, Q.; Zhang, X.; Sun, Y. Damage analysis of soaking gypsum and safety evaluation of goaf: Based on energy dissipation theory. Geotech. Geol. Eng. 2020, 38, 6177–6188. [Google Scholar] [CrossRef]

- Heidari, M.; Khanlari, G.R.; Torabi Kaveh, M.; Kargarian, S. Predicting the uniaxial compressive and tensile strengths of gypsum rock by point load testing. Rock Mech. Rock Eng. 2012, 45, 265–273. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, Y.; Liu, H. Time-dependent theoretical model of rock strength evolution. Rock Soil Mech. 2014, 35, 1521–1527. [Google Scholar]

- Hogan, J.D.; Boonsue, S.; Spray, J.G.; Rogers, R.J. Micro-scale deformation of gypsum during micro-indentation loading. Int. J. Rock Mech. Min. 2012, 54, 140–149. [Google Scholar] [CrossRef]

- Liu, N.; Zhang, C.; Chu, W. Experimental research on time-dependent behavior of crack propagation in Jinping deep marble. Rock Soil Mech. 2012, 33, 2437–2443. [Google Scholar]

- Jin, J.; Xu, Y.; Li, J.; Wan, L.; Wang, L. Influencing factors analysis on rock mass strength considering time and depth effect. Chin. J. Under Sp. Eng. 2016, 12, 475–480. [Google Scholar]

- Li, X.; Zhang, X.; Zhao, Z.; Liu, G. Non-probabilistic reliability prediction on aging stability of ore pillar in gypsum mine. Ind. Miner. Process. 2018, 47, 37–41. [Google Scholar]

- Wang, J.; Zhang, C.; Zheng, D.; Song, W.; Ji, X. Stability analysis of roof in goaf considering time effect. J. Min. Strat. Control. Eng. 2020, 2, 013011. [Google Scholar]

- Meng, T.; Hu, Y.; Fang, R.; Kok, J.; Fu, Q.; Feng, G. Study of fracture toughness and weakening mechanisms in gypsum interlayers in corrosive environments. J. Nat. Gas Sci. Eng. 2015, 26, 356–366. [Google Scholar] [CrossRef]

- Gómez, S.; Sanchidrián, J.A.; Segarra, P. Near-field vibration from blasting and rock damage prediction with a full-field solution. Int. J. Rock Mech. Min. 2020, 134, 104357. [Google Scholar] [CrossRef]

- Ji, S.; Zhang, J.; Pan, R.; Karlovšek, J. Local acceleration monitoring and its application in physical modelling of underground mining. Int. J. Rock Mech. Min. 2020, 128, 104282. [Google Scholar] [CrossRef]

- Huang, F.; Yan, S.; Wang, X.; Jiang, P.; Zhan, S. Experimental study on infrared radiation characteristics of gneiss under uniaxial compression. J. Min. Strat. Control. Eng. 2021, 3, 013011. [Google Scholar]

- Li, W.; Li, S.; Feng, X.; Li, S.; Yuan, C. Study of post-peak strain softening mechanical properties of rock based on Mohr-Coulomb criterion. Chin. J. Rock Mech. Eng. 2011, 30, 1460–1466. [Google Scholar]

- Ji, S.; Karlovšek, J. Calibration and uniqueness analysis of micro parameters for DEM cohesive granular material. Int. J. Min. Sci. Techno. 2022, 32, 121–136. [Google Scholar] [CrossRef]

- Li, L.; Zhang, X.; Deng, H.; Han, L. Mechanical properties and energy evolution of sandstone subjected to uniaxial compression with different loading rates. J. Min. Strat. Control. Eng. 2020, 2, 043037. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Liu, Z.; Zhang, K.; Zhu, G.; Zheng, H. Experimental Study on Strength Weakening of Gypsum Rock with Effect of Long-Term Overlying Strata Pressure. Sustainability 2022, 14, 11442. https://doi.org/10.3390/su141811442

Wang S, Liu Z, Zhang K, Zhu G, Zheng H. Experimental Study on Strength Weakening of Gypsum Rock with Effect of Long-Term Overlying Strata Pressure. Sustainability. 2022; 14(18):11442. https://doi.org/10.3390/su141811442

Chicago/Turabian StyleWang, Shuli, Zhihe Liu, Kaizhi Zhang, Guangli Zhu, and Huaichang Zheng. 2022. "Experimental Study on Strength Weakening of Gypsum Rock with Effect of Long-Term Overlying Strata Pressure" Sustainability 14, no. 18: 11442. https://doi.org/10.3390/su141811442