Wastewater Treatment with Technical Intervention Inclination towards Smart Cities

Abstract

:1. Introduction

- To understand the role of Industry 4.0 (I4.0) in accomplishing the Sustainable Development Goal—2030 of safe and secure drinking water for everyone.

- To co-relate Sustainable Development Goals and Industry 4.0.

- To review use of prior work of Industry 4.0 in treatment of wastewater.

- To give advice for improving the positive aspects of wastewater treatment’s position in the SDGs with respect to various newly developed technologies.

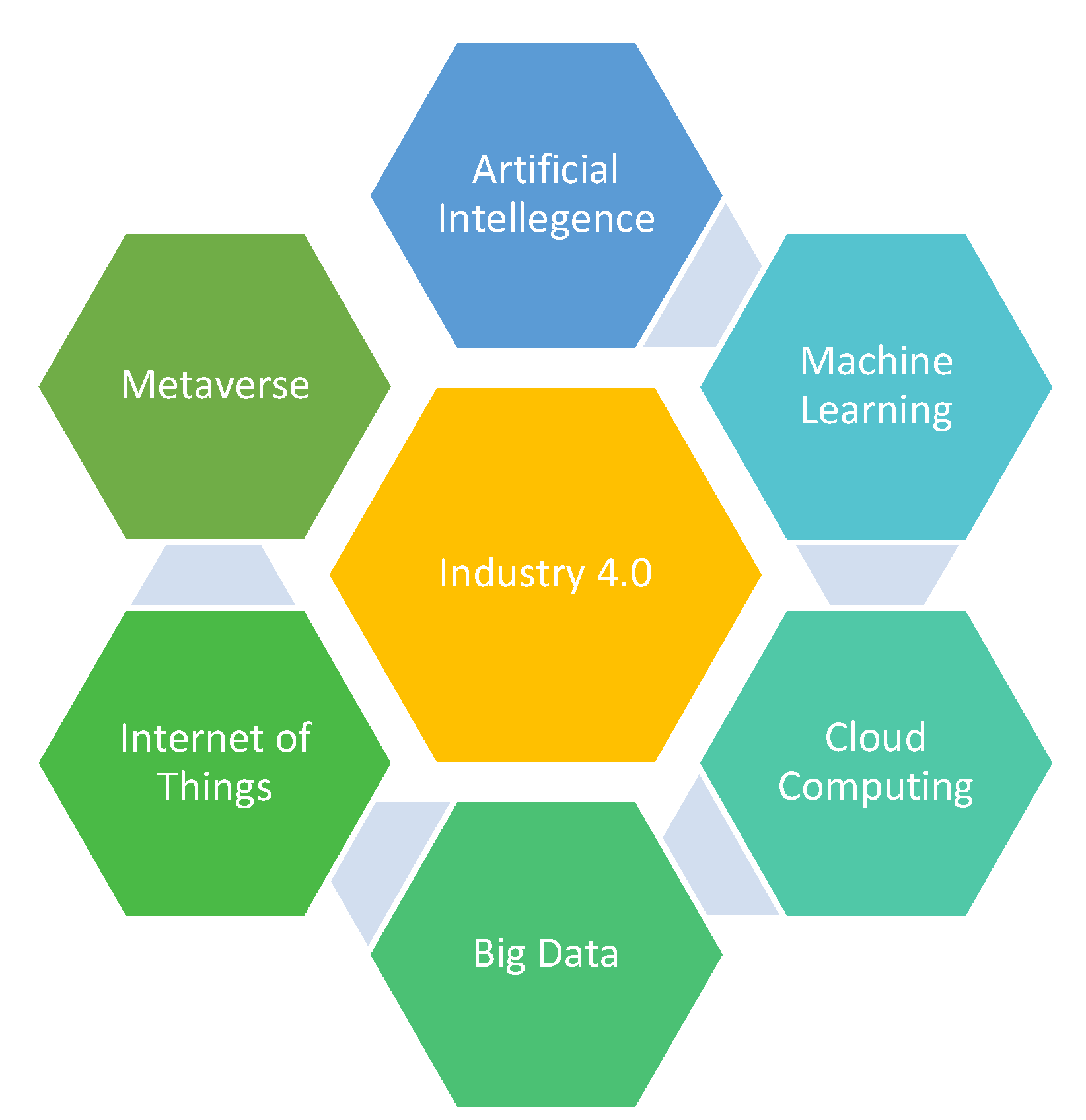

2. Overview of Sustainable Development Goals (SDGs) and Industry 4.0 (I4.0)

3. Wastewater Treatment or Processing

3.1. Effluent Treatment Plants (ETPs)

3.2. Septic/Sewage Treatment Plants (STPs)

3.3. Common and Combined Wastewater Treatment Facilities (CETP)

4. Treatment of Wastewater

5. Utilization of Industry 4.0 in Wastewater Treatment

5.1. IoT

5.2. Cloud Computing and Big Data

5.3. Artificial Intelligence (AI) and Machine Learning (ML)

5.4. Block Chain

5.5. Robotics and Drones

6. Discussion and Future Prospects

- Technologies such as the Internet of Things and automation make it feasible for organizations to play a larger role in the waste management arena by lowering or eliminating tasks that are “hazardous.” Artificial intelligence will make it possible to determine the composition of raw materials (trash) and to maintain constant mass balance throughout the selection process. It will also help in maintaining and controlling the temperature, pH and water sensors being used. Machine learning will offer increased traceability for all chosen commodities, improved stock and warehouse management, and overall logistics efficiency.

- Real-time conditions will be monitored by sensor networks established throughout supply, collection, treatment, and distribution activities and processes. Anywhere and at any time, data and information will be accessible through the cloud and mobile devices. The combination of data analytics and machine learning will make machines and gadgets intelligent, allowing for the autonomous execution of prescriptive actions based on data-driven predictions.

- Big data and Internet of Things (IoT), combined with artificial intelligence, will allow governments to construct individualized analytics dashboards, which can assist in achieving a deeper comprehension of waste streams and the development of more effective resource recovery initiatives. The combination of technologies might be simply used to automate the processes involved in recycling. Industries can use data from the Internet of Things (IoT) and other technologies to understand usage and disposal patterns better and to plan waste management with respect to environment.

- Within the next ten years, robotic recycling will enter the mainstream, bringing with it increased accuracy, improved flexibility, and faster market adaptation, as well as transforming the materials recovery facilities of the future. Drones outfitted with various sensors, such as vision or odor, and even integrating artificial intelligence, will enhance plant inspection, maintenance, anomaly detection, and health and safety. The use of robotics systems for maintenance and cleaning jobs will increase asset availability and enhance treatment capacity. Dual systems of modern robotics and artificial intelligence can also enhance capacity for trash selection, thus enhancing the working environment.

- Automation will replace mundane, manual operations with jobs that optimize performance and provide more value. In-situ monitoring devices will detect and send alerts about events such as water level rises, pressure spikes or dips, the presence of contaminants, loss of flow, out-of-specification water quality, etc., allowing preventive intervention and shifting the risk paradigm from consequence containment to prevention. The meter-to-cash payment procedure will be smooth.

- Application of virtual reality will help to learn and simulate for maintenance, breakdowns, and personnel training prior to operation. Augmented reality can help the allocation of equipment, as an interface for maintenance management, and as a self-protection and safety enhancement system for employees. It will ease onboarding and minimize the expense and time away from the office required for destination training events.

- However, just as every coin has two faces, these technologies possess some limitations too. One thing that really needs attention is that these wireless technologies and interoperability have done away with the necessity of people to individually handle the controls that run the water and wastewater systems. In the past, humans were responsible for the personal monitoring of these controls. As a direct consequence of this, interconnected water and wastewater systems are now susceptible to sophisticated attacks that the sector has never before seen. Anyone with nefarious intentions might access the network and perhaps poison it or put an end to the process of treating and distributing water if suitable cybersecurity measures are not in place. Many water and wastewater plants are small or medium-sized, and they lack the security skills necessary to detect and repel any attack directed against them.

- The fact that cybercriminals will only become more talented over time is a fact. As a consequence of this, there is a genuine possibility that an enemy—such as a nation state, hacker, or cyber terrorist—may seize control of a system or network. The aftermath of an advanced persistent threat might lead to the contamination of the water supply with chemicals, or overflowing of streets with untreated sewage, etc. The harm caused would not be restricted to a small area, since these systems are now networked with one another. Instead, an attack might disrupt the supply chain of water throughout the nation, leading to the seizure of the most important resource and putting the lives of the general population in danger.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fighir, D.; Teodosiu, C.; Fiore, S. Environmental and energy assessment of municipal wastewater treatment plants in Italy and Romania: A comparative study. Water 2019, 11, 1611. [Google Scholar] [CrossRef]

- Padilla-Rivera, A.; Güereca, L.P. A proposal metric for sustainability evaluations of wastewater treatment systems (SEWATS). Ecol. Indic. 2019, 103, 22–33. [Google Scholar] [CrossRef]

- Maria, F.D.; Daskal, S.; Ayalon, O. A methodological approach for comparing waste water effluent’s regulatory and management frameworks based on sustainability assessment. Ecol. Indic. 2020, 118, 106805. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer concrete as green building materials: Recent applications, sustainable development and circular economy potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef] [PubMed]

- Neczaj, E.; Grosser, A. Circular economy in wastewater treatment plant–Challenges and barriers. Multidiscip. Digit. Publ. Inst. Proc. 2018, 2, 614. [Google Scholar]

- Ritter, L.; Solomon, K.; Sibley, P.; Hall, K.; Keen, P.; Mattu, G.; Linton, B. Sources, pathways, and relative risks of contaminants in surface water and groundwater: A perspective prepared for the Walkerton inquiry. J. Toxicol. Environ. Health Part A 2002, 65, 1–142. [Google Scholar]

- Rajasekhar, B.; Nambi, I.M.; Govindarajan, S.K. Human health risk assessment of ground water contaminated with petroleum PAHs using monte carlo simulations: A case study of an Indian metropolitan city. J. Environ. Manag. 2018, 205, 183–191. [Google Scholar] [CrossRef]

- Rodriguez-Proteau, R.; Grant, R.L. Toxicity evaluation and human health risk assessment of surface and ground water contaminated by recycled hazardous waste materials. Water Pollut. 2005, 2, 133–189. [Google Scholar]

- Ahmad, H.R.; Aziz, T.; Zia-ur-Rehman, M.; Sabir, M.; Khalid, H. Sources and composition of waste water: Threats to plants and soil health. In Soil Science: Agricultural and Environmental Prospectives; Springer: Cham, Switzerland, 2016; pp. 349–370. [Google Scholar]

- Jassby, D.; Cath, T.Y.; Buisson, H. The role of nanotechnology in industrial water treatment. Nat. Nanotechnol. 2018, 13, 670–672. [Google Scholar] [CrossRef]

- Rout, P.R.; Mohanty, A.; Sharma, A.; Miglani, M.; Liu, D.; Varjani, S. Micro-and nanoplastics removal mechanisms in wastewater treatment plants: A review. J. Hazard. Mater. Adv. 2022, 6, 100070. [Google Scholar] [CrossRef]

- Warwick, C.; Guerreiro, A.; Soares, A. Sensing and analysis of soluble phosphates in environmental samples: A review. Biosens. Bioelectron. 2013, 41, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Alcamo, J. Water quality and its interlinkages with the sustainable development goals. Curr. Opin. Environ. Sustain. 2019, 36, 126–140. [Google Scholar] [CrossRef]

- Tortajada, C. Contributions of recycled wastewater to clean water and sanitation sustainable development goals. NPJ Clean Water 2020, 3, 22. [Google Scholar] [CrossRef]

- Obaideen, K.; Shehata, N.; Sayed, E.T.; Abdelkareem, M.A.; Mahmoud, M.S.; Olabi, A.G. The role of wastewater treatment in achieving sustainable development goals (SDGs) and sustainability guideline. Energy Nexus 2022, 7, 100112. [Google Scholar] [CrossRef]

- Delanka-Pedige, H.M.K.; Munasinghe-Arachchige, S.P.; Abeysiriwardana-Arachchige, I.S.A.; Nirmalakhandan, N. Evaluating wastewater treatment infrastructure systems based on UN sustainable development goals and targets. J. Clean. Prod. 2021, 298, 126795. [Google Scholar] [CrossRef]

- Palme, U.; Lundin, M.; Tillman, A.M.; Molander, S. Sustainable development indicators for wastewater systems–Researchers and indicator users in a co-operative case study. Resour. Conserv. Recycl. 2005, 43, 293–311. [Google Scholar] [CrossRef]

- Sayed, E.T.; Abdelkareem, M.A.; Obaideen, K.; Elsaid, K.; Wilberforce, T.; Maghrabie, H.M.; Olabi, A.G. Progress in plant-based bioelectrochemical systems and their connection with sustainable development goals. Carbon Resour. Convers. 2021, 4, 169–183. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Dugmore, T.I.; Matharu, A.; Martinez-Hernandez, E.; Aburto, J.; Rahman, P.K.; Lynch, J. Perspectives on “game changer” global challenges for sustainable 21st century: Plant-based diet, unavoidable food waste biorefining, and circular economy. Sustainability 2020, 12, 1976. [Google Scholar] [CrossRef]

- Stahel, W.R. Sustainable development and strategic thinking. Chin. J. Popul. Resour. Environ. 2007, 5, 3–19. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2018, 30, 607–627. [Google Scholar] [CrossRef]

- Zhang, A.; Venkatesh, V.G.; Liu, Y.; Wan, M.; Qu, T.; Huisingh, D. Barriers to smart waste management for a circular economy in China. J. Clean. Prod. 2019, 240, 118198. [Google Scholar] [CrossRef]

- Juste Ruiz, J. The process towards a global pact for the environment at the United Nations: From legal ambition to political dilution. Rev. Eur. Comp. Int. Environ. Law 2020, 29, 479–490. [Google Scholar] [CrossRef]

- Dantas, T.E.; De-Souza, E.D.; Destro, I.R.; Hammes, G.; Rodriguez, C.M.T.; Soares, S.R. How the combination of circular economy and industry 4.0 can contribute towards achieving the sustainable development goals. Sustain. Prod. Consum. 2021, 26, 213–227. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Drath, R.; Horch, A. Industrie 4.0: Hit or hype? [Industry forum]. IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Ramakrishna, S.; Ngowi, A.; Jager, H.D.; Awuzie, B.O. Emerging industrial revolution: Symbiosis of industry 4.0 and circular economy: The role of universities. Sci. Technol. Soc. 2020, 25, 505–525. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Berawi, M.A. The role of industry 4.0 in achieving sustainable development goals. Int. J. Technol. 2019, 10, 644–647. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.S.; Yang, J.H.; Wang, K.S. Industry 4.0: A way from mass customization to mass personalization production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Raha, D. Exploring artificial neural networks (ANN) modelling for a biological nutrient removal (BNR) sewage treatment plant (STP) to forecast effluent suspended solids. Indian Chem. Eng. 2007, 49, 205. [Google Scholar]

- Soller, J.A.; Eftim, S.E.; Nappier, S.P. Direct potable reuse microbial risk assessment methodology: Sensitivity analysis and application to State log credit allocations. Water Res. 2018, 128, 286–292. [Google Scholar] [CrossRef]

- Kundu, P.; Debsarkar, A.; Mukherjee, S.; Kumar, S. Artificial neural network modelling in biological removal of organic carbon and nitrogen for the treatment of slaughterhouse wastewater in a batch reactor. Environ. Technol. 2014, 35, 1296–1306. [Google Scholar] [CrossRef] [PubMed]

- Bagheri, M.; Mirbagheri, S.A.; Ehteshami, M.; Bagheri, Z. Modeling of a sequencing batch reactor treating municipal wastewater using multi-layer perceptron and radial basis function artificial neural networks. Process Saf. Environ. Prot. 2015, 93, 111–123. [Google Scholar] [CrossRef]

- Farhaoui, M.; Hasnaoui, L.; Derraz, M. Optimization of drinking water treatment process by modeling the aluminumsulfate dose. Br. J. Appl. Sci. Technol. 2016, 17, 1–14. [Google Scholar] [CrossRef]

- Kesari, K.K.; Soni, R.; Jamal, Q.M.S.; Tripathi, P.; Lal, J.A.; Jha, N.K.; Siddiqui, M.H.; Kumar, P.; Tripathi, V.; Ruokolainen, J. Wastewater treatment and reuse: A review of its applications and health implications. Water Air Soil Pollut. 2021, 232, 208. [Google Scholar] [CrossRef]

- Ahmadi, F.; Zinatizadeh, A.A.; Asadi, A.; McKay, T.; Azizi, S. Simultaneous carbon and nutrients removal and PHA production in a novel single air lift bioreactor treating an industrial wastewater. Environ. Technol. Innov. 2020, 18, 100776. [Google Scholar] [CrossRef]

- Deshpande, B.D.; Agrawal, P.S.; Yenkie, M.K.N.; Dhoble, S.J. Prospective of nanotechnology in degradation of wastewater: A new challenges. Nanostruct. Nano-Objects 2020, 22, 100442. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Parveen, T.; Umar, K.; Ibrahim, M.N.M. Role of nanomaterials in the treatment of wastewater: A review. Water 2020, 12, 495. [Google Scholar] [CrossRef]

- Templeton, M.R.; Butler, D. Introduction to Wastewater Treatment; Bookboon: London, UK, 2011. [Google Scholar]

- Kalfa, A.; Shapira, B.; Shopin, A.; Cohen, I.; Avraham, E.; Aurbach, D. Capacitive deionization for wastewater treatment: Opportunities and challenges. Chemosphere 2020, 241, 125003. [Google Scholar] [CrossRef]

- Verlicchi, P.; Aukidy, M.A.; Zambello, E. Occurrence of pharmaceutical compounds in urban wastewater: Removal, mass load and environmental risk after a secondary treatment—A review. Sci. Total Environ. 2012, 429, 123–155. [Google Scholar] [CrossRef]

- Bora, T.; Dutta, J. Applications of nanotechnology in wastewater treatment—A review. J. Nanosci. Nanotechnol. 2014, 14, 613–626. [Google Scholar] [CrossRef]

- Ma, W.; Jiang, Z.; Lu, T.; Xiong, R.; Huang, C. Lightweight, elastic and superhydrophobic multifunctional nanofibrous aerogel for self-cleaning, oil/water separation and pressure sensing. Chem. Eng. J. 2022, 430, 132989. [Google Scholar] [CrossRef]

- Cao, W.; Ma, W.; Lu, T.; Jiang, Z.; Xiong, R.; Huang, C. Multifunctional nanofibrous membranes with sunlight-driven self-cleaning performance for complex oily wastewater remediation. J. Colloid Interface Sci. 2022, 608, 164–174. [Google Scholar] [CrossRef]

- Ma, W.; Ding, Y.; Li, Y.; Gao, S.; Jiang, Z.; Cui, J.; Huang, C.; Fu, G. Durable, self-healing superhydrophobic nanofibrous membrane with self-cleaning ability for highly-efficient oily wastewater purification. J. Membr. Sci. 2021, 634, 119402. [Google Scholar] [CrossRef]

- Pérez-Page, M.; Yu, E.; Li, J.; Rahman, M.; Dryden, D.M.; Vidu, R.; Stroeve, P. Template-based syntheses for shape controlled nanostructures. Adv. Colloid Interface Sci. 2016, 234, 51–79. [Google Scholar] [CrossRef]

- Nasrollahzadeh, M.; Sajjadi, M.; Iravani, S.; Varma, R.S. Carbon-based sustainable nanomaterials for water treatment: State-of-art and future perspectives. Chemosphere 2021, 263, 128005. [Google Scholar] [CrossRef]

- Alalwan, H.A.; Alminshid, A.H.; Mohammed, M.M.; Mohammed, M.F. Reviewing of using nanomaterials for wastewater treatment. Pollution 2022, 8, 995–1013. [Google Scholar]

- Nasrollahzadeh, M.; Sajjadi, M.; Iravani, S.; Varma, R.S. Green-synthesized nanocatalysts and nanomaterials for water treatment: Current challenges and future perspectives. J. Hazard. Mater. 2021, 401, 123401. [Google Scholar] [CrossRef]

- Internet of Things Wikipedia. Available online: https://en.wikipedia.org/wiki/Internet_of_things (accessed on 17 August 2022).

- Su, J.J.; Ding, S.T.; Chung, H.C. Establishing a smart farm-scale piggery wastewater treatment system with the internet of things (IoT) applications. Water 2020, 12, 1654. [Google Scholar] [CrossRef]

- Kshirsagar, P.R.; Tirth, V.; Islam, S.; Qaiyum, S.; Al Duhayyim, M.; Waji, Y.A. IOT based smart wastewater treatment model for industry 4.0 using artificial intelligence. Sci. Program. 2022, 2022, 5134013. [Google Scholar]

- Geetha, S.; Gouthami, S.J.S.W. Internet of things enabled real time water quality monitoring system. Smart Water 2016, 2, 1. [Google Scholar] [CrossRef]

- Malhotra, V. IoT-based smart water quality monitoring system to expand sensors life and battery power. In Sustainable Communication Networks and Application; Springer: Singapore, 2022; pp. 153–162. [Google Scholar]

- Dhruba, A.R.; Alam, K.N.; Khan, M.; Saha, S.; Khan, M.M.; Baz, M.; Masud, M.; AlZain, M.A. IoT-based water quality assessment system for industrial waste waterhealthcare perspective. J. Healthc. Eng. 2022, 2022, 3769965. [Google Scholar] [CrossRef]

- Davia, C.; Gowen, S.; Ghezzo, G.; Harris, R.; Horne, M.; Potter, C.; Pitt, S.P.; Vandenberg, A.; Xiong, N. Cloud computing services and architecture for education. Int. J. Cloud Comput. 1 2013, 2, 213–236. [Google Scholar] [CrossRef]

- Abolfazli, S.; Sanaei, Z.; Ahmed, E.; Gani, A.; Buyya, R. Cloud-based augmentation for mobile devices: Motivation, taxonomies, and open challenges. IEEE Commun. Surv. Tutor. 2013, 16, 337–368. [Google Scholar] [CrossRef]

- Bhardwaj, S.; Jain, L.; Jain, S. Cloud computing: A study of infrastructure as a service (IAAS). Int. J. Eng. Inf. Technol. 2010, 2, 60–63. [Google Scholar]

- Subashini, S.; Kavitha, V. A survey on security issues in service delivery models of cloud computing. J. Netw. Comput. Appl. 2011, 34, 1–11. [Google Scholar] [CrossRef]

- Azeem, M.; Haleem, A.; Bahl, S.; Javaid, M.; Suman, R.; Nandan, D. Big data applications to take up major challenges across manufacturing industries: A brief review. Mater. Today Proc. 2021, 49, 339–348. [Google Scholar] [CrossRef]

- Cooper, J.; Noon, M.; Jones, C.U.; Kahn, E.; Arbuckle, P. Big data in life cycle assessment. J. Ind. Ecol. 2013, 17, 796–799. [Google Scholar] [CrossRef]

- Saha, P.; Vinnarasi, M.R. Smart underwater monitoring system through IoT using big data. Int. J. Pure Appl. Math. 2018, 120, 1893–1901. [Google Scholar]

- O’Donovan, P.; Coburn, D.; Jones, E.; Hannon, L.; Glavin, M.; Mullins, D.; Clifford, E. A cloud-based distributed data collection system for decentralised wastewater treatment plants. Procedia Eng. 2015, 119, 464–469. [Google Scholar] [CrossRef]

- Ly, Q.V.; Truong, V.H.; Ji, B.; Nguyen, X.C.; Cho, K.H.; Ngo, H.H.; Zhang, Z. Exploring potential machine learning application based on big data for prediction of wastewater quality from different full-scale wastewater treatment plants. Sci. Total Environ. 2022, 832, 154930. [Google Scholar] [CrossRef] [PubMed]

- Stankov, S.P. Big data in water supply and sewerage systems. ActaTechnicaCorviniensis-Bull. Eng. 2022, 15, 21–25. [Google Scholar]

- Sundarasekar, R.; Shakeel, P.M.; Baskar, S.; Kadry, S.; Mastorakis, G.; Mavromoustakis, C.X.; Samuel, R.D.J.; Gn, V. Adaptive energy aware quality of service for reliable data transfer in under water acoustic sensor networks. IEEE Access 2019, 7, 80093–80103. [Google Scholar] [CrossRef]

- Matheri, A.N.; Mohamed, B.; Ntuli, F.; Nabadda, E.; Ngila, J.C. Sustainable circularity and intelligent data-driven operations and control of the wastewater treatment plant. Phys. Chem. Earth Parts A/B/C 2022, 126, 103152. [Google Scholar] [CrossRef]

- Verma, A.; Wei, X.; Kusiak, A. Predicting the total suspended solids in wastewater: A data-mining approach. Eng. Appl. Artif. Intell. 2013, 26, 1366–1372. [Google Scholar] [CrossRef]

- Arridha, R. Classification extension based on IoT-big data analytic for smart environment monitoring and analytic in real-time system. Int. J. Space-Based Situated Comput. 2017, 7, 2. [Google Scholar] [CrossRef] [Green Version]

- Martínez, R.; Vela, N.; El Aatik, A.; Murray, E.; Roche, P.; Navarro, J.M. On the Use of an IoT integrated system for water quality monitoring and management in wastewater treatment plants. Water 2020, 12, 1096. [Google Scholar] [CrossRef]

- Edmondson, V.; Cerny, M.; Lim, M.; Gledson, B.; Lockley, S.; Woodward, J. A smart sewer asset information model to enable an ‘Internet of Things’ for operational wastewater management. Autom. Constr. 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Irfan, M.; Waqas, S.; Arshad, U.; Khan, J.A.; Legutko, S.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Rahman, S.; Skrzypczak, A. Response surface methodology and artificial neural network modelling of membrane rotating biological contactors for wastewater treatment. Materials 2022, 15, 1932. [Google Scholar] [CrossRef]

- Ganguly, P.; Das, P. Integral approach for second-generation bio-ethanol production and wastewater treatment using peanut shell waste: Yield, removal, and ANN studies. Biomass-Convers. Biorefinery 2022, 1–11. [Google Scholar] [CrossRef]

- Agatonovic-Kustrin, S.; Beresford, R. Basic concepts of artificial neural network (ANN) modeling and its application in pharmaceutical research. J. Pharm. Biomed. Anal. 2000, 22, 717–727. [Google Scholar] [CrossRef]

- Shokry, A.; Vicente, P.; Escudero, G.; Pérez-Moya, M.; Graells, M.; Espuña, A. Data-driven soft-sensors for online monitoring of batch processes with different initial conditions. Comput. Chem. Eng. 2018, 118, 159–179. [Google Scholar] [CrossRef]

- Jana, D.K.; Bhunia, P.; Adhikary, S.D.; Bej, B. Optimization of effluents using artificial neural network and support vector regression in detergent industrial wastewater treatment. Clean. Chem. Eng. 2022, 3, 100039. [Google Scholar] [CrossRef]

- Zhao, L.; Dai, T.; Qiao, Z.; Sun, P.; Hao, J.; Yang, Y. Application of artificial intelligence to wastewater treatment: A bibliometric analysis and systematic review of technology, economy, management, and wastewater reuse. Process Saf. Environ. Prot. 2020, 133, 169–182. [Google Scholar] [CrossRef]

- Zaghloul, M.S.; Iorhemen, O.T.; Hamza, R.A.; Tay, J.H.; Achari, G. Development of an ensemble of machine learning algorithms to model aerobic granular sludge reactors. Water Res. 2021, 189, 116657. [Google Scholar] [CrossRef]

- Aleboyeh, A.; Kasiri, M.B.; Olya, M.E.; Aleboyeh, H. Prediction of azo dye decolorization by UV/H2O2 using artificial neural networks. Dye. Pigment. 2008, 77, 288–294. [Google Scholar] [CrossRef]

- GholamiShirkoohi, M.; Tyagi, R.D.; Vanrolleghem, P.A.; Drogui, P. Artificial neural networks and genetic algorithms: An efficient modelling and optimization methodology for active chlorine production using the electrolysis process. Can. J. Chem. Eng. 2021, 99, S389–S403. [Google Scholar]

- Farzin, S.; Chianeh, F.N.; Anaraki, M.V.; Mahmoudian, F. Introducing a framework for modeling of drug electrochemical removal from wastewater based on data mining algorithms, scatter interpolation method, and multi criteria decision analysis (DID). J. Clean. Prod. 2020, 266, 122075. [Google Scholar] [CrossRef]

- Ye, Z.; Yang, J.; Zhong, N.; Tu, X.; Jia, J.; Wang, J. Tackling environmental challenges in pollution controls using artificial intelligence: A review. Sci. Total Environ. 2020, 699, 134279. [Google Scholar] [CrossRef] [PubMed]

- Golzar, F.; Nilsson, D.; Martin, V. Forecasting wastewater temperature based on artificial neural network (ANN) technique and montecarlo sensitivity analysis. Sustainability 2020, 12, 6386. [Google Scholar] [CrossRef]

- Khatri, N.; Khatri, K.K.; Sharma, A. Artificial neural network modelling of faecal coliform removal in an intermittent cycle extended aeration system-sequential batch reactor-based wastewater treatment plant. J. Water Process Eng. 2020, 37, 101477. [Google Scholar] [CrossRef]

- Mohammad, A.T.; Al-Obaidi, M.A.; Hameed, E.M.; Basheer, B.N.; Mujtaba, I.M. Modelling the chlorophenol removal from wastewater via reverse osmosis process using a multilayer artificial neural network with genetic algorithm. J. Water Process Eng. 2020, 33, 100993. [Google Scholar] [CrossRef]

- Kiiza, C.; Pan, S.-Q.; Bockelmann-Evans, B.; Babatunde, A. Predicting pollutant removal in constructed wetlands using artificial neural networks (ANNs). Water Sci. Eng. 2020, 13, 14–23. [Google Scholar] [CrossRef]

- Xie, S.; Zheng, Z.; Chen, W.; Wu, J.; Dai, H.-N.; Imran, M. Blockchain for cloud exchange: A survey. Comput. Electr. Eng. 2020, 81, 106526. [Google Scholar] [CrossRef]

- Rathee, G.; Sharma, A.; Kumar, R.; Iqbal, R. A secure communicating things network framework for industrial IoT using blockchain technology. Ad Hoc Networks 2019, 94, 101933. [Google Scholar] [CrossRef]

- Bai, L.; Hu, M.; Liu, M.; Wang, J. BPIIoT: A light-weighted blockchain-based platform for industrial IoT. IEEE Access 2019, 7, 58381–58393. [Google Scholar] [CrossRef]

- Reyna, A.; Martin, C.; Chen, J.; Soler, E.; Diaz, M. Onblockchain and its integration with IoT. Challenges and opportunities. Future Gener. Comput. Syst. 2018, 88, 173–190. [Google Scholar] [CrossRef]

- Khan, M.A.; Salah, K. IoT security: Review. Blockchain solutions. and open challenges. Future Gener. Comput. Syst. 2018, 82, 395–411. [Google Scholar] [CrossRef]

- Moin, S.; Karim, A.; Safdar, Z.; Safdar, K.; Ahmed, E.; Imran, M. Securing IoTs in distributed blockchain: Analysis, requirements and open issues. Future Gener. Comput. Syst. 2019, 100, 325–343. [Google Scholar] [CrossRef]

- Hakak, S.; Khan, W.Z.; Gilkar, G.A.; Haider, N.; Imran, M.; Alkatheiri, M.S. Industrial wastewater management using blockchain technology: Architecture, requirements, and future directions. IEEE Internet Things Mag. 2020, 3, 38–43. [Google Scholar] [CrossRef]

- Emran, B.J.; Tannant, D.D.; Najjaran, H. Low-altitude aerial methane concentration mapping. Remote Sens. 2017, 9, 823. [Google Scholar] [CrossRef]

- Zarra, T.; Naddeo, V.; Belgiorno, V.; Reiser, M.; Kranert, M. Odour monitoring of small wastewater treatment plant located in sensitive environment. Water Sci. Technol. 2008, 58, 89–94. [Google Scholar] [CrossRef]

- Naddeo, V.; Zarra, T.; Giuliani, S.; Belgiorno, V. Odour impact assessment in industrial areas. Chem. Eng. 2012, 30. [Google Scholar]

- Martí, V.; Jubany, I.; Pérez, C.; Rubio, X.; De Pablo, J.; Giménez, J. Human health risk assessment of a landfill based on volatile organic compounds emission, immission and soil gas concentration measurements. Appl. Geochem. 2014, 49, 218–224. [Google Scholar] [CrossRef]

- Byliński, H.; Gębicki, J.; Namieśnik, J. Evaluation of health hazard due to emission of volatile organic compounds from various processing units of wastewater treatment plant. Int. J. Environ. Res. Public Health 2019, 16, 1712. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pandey, S.; Twala, B.; Singh, R.; Gehlot, A.; Singh, A.; Montero, E.C.; Priyadarshi, N. Wastewater Treatment with Technical Intervention Inclination towards Smart Cities. Sustainability 2022, 14, 11563. https://doi.org/10.3390/su141811563

Pandey S, Twala B, Singh R, Gehlot A, Singh A, Montero EC, Priyadarshi N. Wastewater Treatment with Technical Intervention Inclination towards Smart Cities. Sustainability. 2022; 14(18):11563. https://doi.org/10.3390/su141811563

Chicago/Turabian StylePandey, Shivam, Bhekisipho Twala, Rajesh Singh, Anita Gehlot, Aman Singh, Elisabeth Caro Montero, and Neeraj Priyadarshi. 2022. "Wastewater Treatment with Technical Intervention Inclination towards Smart Cities" Sustainability 14, no. 18: 11563. https://doi.org/10.3390/su141811563

APA StylePandey, S., Twala, B., Singh, R., Gehlot, A., Singh, A., Montero, E. C., & Priyadarshi, N. (2022). Wastewater Treatment with Technical Intervention Inclination towards Smart Cities. Sustainability, 14(18), 11563. https://doi.org/10.3390/su141811563